Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Wool Pressing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Wool Pressing Interview

Q 1. Describe the different types of wool pressing machines and their applications.

Wool pressing machines come in various types, each suited for different applications. The choice depends on factors like production scale, wool type, and desired finish.

- Hand Presses: These are smaller, manually operated machines ideal for smaller workshops or individual use, perfect for delicate fabrics or small-batch production. They’re simple to operate and require minimal maintenance.

- Pneumatic Presses: Utilizing compressed air, pneumatic presses offer a balance between power and control. They’re faster than hand presses and suitable for medium-scale operations. The pressure is easily adjustable, allowing for tailoring to different wool weights and thicknesses.

- Hydraulic Presses: These are the workhorses of large-scale wool processing. Hydraulic presses provide immense pressing power, crucial for efficiently processing large quantities of wool or heavy fabrics. They are often automated for higher throughput and consistency.

- Steam Presses: Incorporating steam alongside pressure, steam presses deliver superior wrinkle removal and create a smoother, more polished finish. They are especially important when working with more stubborn creases or thicker wool fabrics.

For instance, a high-end tailor might use a hand press for delicate cashmere, while a large textile mill relies on hydraulic presses for heavy woolen blankets. Steam presses are commonly seen in garment finishing factories.

Q 2. Explain the process of setting up a wool pressing machine for optimal performance.

Setting up a wool pressing machine for optimal performance involves several crucial steps. Proper setup ensures both efficient operation and prevents damage to the machine and the wool itself.

- Machine Inspection: Begin by thoroughly inspecting the machine for any damage, loose parts, or leaks (especially critical for hydraulic and pneumatic systems).

- Surface Preparation: Ensure the pressing surface is clean and free from debris. For steam presses, check the steam generation and distribution system.

- Pressure Adjustment: The pressure needs to be calibrated based on the wool type and thickness. Too little pressure results in inadequate pressing, while too much can damage the fabric. Start with lower pressure and gradually increase until you achieve the desired result. Consult the manufacturer’s guidelines for pressure recommendations.

- Temperature Control (Steam Presses): For steam presses, carefully regulate the temperature. Too high a temperature can scorch the wool, while too low a temperature is ineffective. Experimentation, guided by wool type, is often necessary.

- Test Pressing: Always conduct a test press on a scrap piece of fabric to ensure the settings are correct before pressing valuable materials. This helps avoid any accidental damage.

Imagine setting up a hydraulic press without checking for leaks; a burst hose could cause serious damage and injury. Always prioritize safety and careful calibration.

Q 3. How do you identify and address common problems encountered during wool pressing?

Troubleshooting wool pressing often involves identifying the cause of the problem and addressing it systematically. Common issues and their solutions include:

- Uneven Pressing: This could be due to uneven pressure distribution, a problem with the press plate, or inconsistent wool thickness. Solution: Check pressure settings, inspect the press plate for damage, and ensure even fabric placement.

- Wrinkles/Creases Remaining: Insufficient pressure, inadequate steam (in steam presses), or incorrect pressing temperature might be the culprit. Solution: Adjust pressure, temperature, and steam settings accordingly. Multiple passes might be required.

- Fabric Damage (Scorching/Marks): Excessive pressure, temperature, or prolonged pressing time can cause damage. Solution: Reduce pressure and temperature; shorten pressing time. Use a press cloth for added protection.

- Machine Malfunctions: Mechanical issues (e.g., leaks, faulty valves) require professional attention. Solution: Contact a qualified technician for repair or maintenance.

For example, if I notice scorching after pressing, I immediately reduce the temperature and check for possible malfunctions in the steam system before continuing.

Q 4. What are the key quality control checkpoints during the wool pressing process?

Quality control checkpoints are crucial to ensure consistently high-quality pressed wool. These checkpoints involve both the process and the final product.

- Fabric Inspection Before Pressing: Check for pre-existing damage or irregularities to prevent further damage during pressing.

- Pressure and Temperature Monitoring: Regularly check and adjust pressure and temperature settings to maintain consistency.

- Visual Inspection After Pressing: Inspect the pressed wool for wrinkles, creases, scorch marks, or other imperfections.

- Texture and Drape Assessment: Evaluate the final texture and drape of the pressed wool; it should be smooth, even, and drape well.

- Dimension Checking: In some applications, the dimensions of the pressed wool must be checked for shrinkage or distortion.

Imagine delivering a batch of pressed wool with scorch marks; it’s a significant quality issue. Rigorous quality control ensures this doesn’t happen.

Q 5. Describe your experience with different types of wool fabrics and their pressing requirements.

My experience encompasses various wool fabrics, each with unique pressing needs. Understanding these differences is crucial for achieving optimal results.

- Cashmere: Delicate and prone to damage, cashmere requires low pressure and temperature, often with a press cloth to prevent sheen.

- Merino Wool: A versatile fiber, merino wool can handle moderate pressure and temperature. Steam pressing works well for wrinkle removal.

- Heavy Woolens (e.g., Tweed): These require higher pressure and temperature for effective pressing; steam is often beneficial.

- Wool Blends: The pressing requirements depend on the blend composition. Consider the properties of each fiber involved.

For example, a heavy tweed jacket requires a different approach than a delicate cashmere sweater; high pressure on cashmere would ruin it.

Q 6. How do you maintain the cleanliness and optimal functioning of wool pressing equipment?

Maintaining the cleanliness and optimal functioning of wool pressing equipment is essential for both safety and efficiency. Regular maintenance ensures the equipment operates at peak performance.

- Regular Cleaning: Clean the pressing surfaces after each use, removing any residual wool fibers or debris. For steam presses, regularly flush the steam system to remove mineral deposits.

- Lubrication: Lubricate moving parts as recommended by the manufacturer to prevent wear and tear.

- Pressure Gauge Calibration: Regularly check and calibrate the pressure gauge to ensure accurate readings.

- Professional Inspections: Schedule regular professional inspections to identify potential issues before they become major problems.

Think of it like maintaining your car – regular maintenance prevents major breakdowns and extends the machine’s lifespan.

Q 7. What safety precautions do you follow while operating wool pressing machinery?

Safety is paramount when operating wool pressing machinery. The following precautions are essential:

- Proper Training: Ensure all operators receive thorough training before operating any machine. This includes understanding the controls, safety mechanisms, and emergency procedures.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including heat-resistant gloves, safety glasses, and closed-toe shoes.

- Machine Guards: Ensure all machine guards are in place and functioning correctly before starting operation.

- Emergency Shut-off: Know the location and operation of the emergency shut-off switch.

- Avoid Loose Clothing: Avoid wearing loose clothing or jewelry that could get caught in moving parts.

- Hot Surface Awareness: Always be aware of hot surfaces, especially on steam presses, and avoid touching them.

Ignoring safety precautions can lead to serious injury; safe practices are never optional.

Q 8. Explain your experience with troubleshooting mechanical issues in wool pressing machines.

Troubleshooting mechanical issues in wool pressing machines requires a systematic approach. My experience involves diagnosing problems ranging from simple malfunctions like jammed rollers or faulty heating elements to more complex issues like hydraulic leaks or electrical shorts. I begin by carefully inspecting the machine, listening for unusual sounds, and checking all safety mechanisms. For instance, a persistent grinding noise might indicate worn bearings requiring replacement. A lack of heat could be due to a malfunctioning thermostat or a problem with the power supply.

I always prioritize safety – ensuring the machine is completely powered down before any repairs. My diagnostic process includes using multimeters to test electrical components, pressure gauges to check hydraulic systems, and visual inspections to identify mechanical wear. I’m adept at repairing or replacing parts as needed, and I maintain detailed records of all repairs, including parts used and labor hours, for preventative maintenance and future reference. I also understand the importance of regular scheduled maintenance to prevent more serious breakdowns.

For example, I once encountered a situation where a pressing machine suddenly stopped working mid-cycle. By systematically checking the power supply, the control panel, and the heating elements, I quickly discovered a blown fuse. Replacing the fuse restored the machine to full functionality, preventing production delays.

Q 9. How do you ensure consistent pressing results across different batches of wool fabric?

Consistent pressing results across different batches of wool fabric are crucial for maintaining quality and brand consistency. This is achieved through meticulous control of several key factors. First, the machine settings – temperature, pressure, and pressing time – must be precisely calibrated and remain consistent. I use digital gauges and timers to ensure accuracy. Second, the type of pressing board and its condition are vital. A warped or damaged board will create inconsistent results. Regular maintenance and replacement of pressing boards are therefore essential. Third, the preparation of the wool fabric itself is critical. Consistent pre-treatment, such as pre-shrinking and cleaning, minimizes variations in the final product.

I also utilize a system of regularly testing and adjusting machine settings to ensure that they are functioning optimally and maintaining consistent results. We regularly use test swatches of fabric to verify the press’s performance against pre-set quality controls. Through this rigorous process, we aim to minimize inconsistencies arising from factors such as material variations. This continuous monitoring, combined with detailed record-keeping of machine settings and fabric characteristics for each batch, ensures consistent outcomes and helps identify any deviations from established standards.

Q 10. Describe your experience with different pressing techniques, such as steam pressing and dry pressing.

My experience encompasses both steam pressing and dry pressing, each suited to different wool fabrics and desired finishes. Steam pressing, using pressurized steam to moisten and relax the fibers, is excellent for delicate wools or fabrics requiring a smoother, softer finish. It helps to remove wrinkles and creases effectively while minimizing the risk of damage. Dry pressing, on the other hand, uses heat and pressure alone. It’s ideal for heavier wool fabrics or when a crisper finish is desired. It’s faster but needs careful monitoring to prevent scorching.

Choosing the appropriate technique is paramount. For example, a fine cashmere sweater would benefit from the gentler approach of steam pressing, whereas a heavy wool coat might require the efficiency of dry pressing. My expertise lies in selecting the correct technique and adjusting parameters (such as steam pressure and temperature) based on the specific fabric type and desired outcome. I’m proficient in using various steam pressing equipment such as industrial steam presses and smaller hand-held steamers, as well as different types of dry pressing equipment.

Q 11. How do you handle fabric defects or inconsistencies during the pressing process?

Handling fabric defects or inconsistencies during the pressing process requires careful attention and a nuanced approach. The first step is to identify the nature of the defect—is it a stain, a tear, a discoloration, or a weave irregularity? The method of handling it varies accordingly. For minor flaws, I might adjust the pressing technique to minimize their appearance; for example, using lower pressure or temperature in areas with defects. For more significant problems, I might need to manually correct the defect before pressing, perhaps by using specialized tools for mending tears or removing stains. In some cases, a heavily damaged section might require cutting and re-sewing.

Documentation is key. I meticulously record the nature of the defect, the method used to address it, and the results. This helps to identify recurring problems or patterns and to track the efficiency of different corrective actions. Furthermore, it also provides a valuable record for quality control and helps to improve future processes. Preventing defects altogether is prioritized through careful inspection of the fabric *before* it enters the pressing stage.

Q 12. What is your experience with different types of pressing boards and their applications?

Different pressing boards serve distinct purposes in wool pressing. The most common type is the padded board, offering a soft, yielding surface that conforms to the fabric’s contours, ideal for delicate materials like cashmere. Harder boards, often made of wood or metal, provide a firm, flat surface for crisp finishes and are suited to thicker fabrics or items requiring a sharp crease. Some boards have specialized features, such as built-in sleeve boards for pressing sleeves or shaped blocks for pressing collars and lapels. My experience includes working with a variety of board materials and designs, adapting my techniques to optimize results for each type.

The choice of pressing board is dictated by the type of wool fabric being pressed and the desired final look. For instance, a padded board is ideal for delicate wool sweaters to prevent shiny marks, whereas a wooden or metal board might be more suitable for a wool suit jacket to maintain a sharper, more structured look. I select the appropriate board to achieve the desired outcome, and I also take into account the condition of the board; replacing damaged or worn boards to prevent inconsistent results.

Q 13. Explain your understanding of the importance of temperature and pressure control in wool pressing.

Temperature and pressure control are absolutely vital in wool pressing. Excessive heat can scorch or damage the fabric, leading to irreversible damage. Insufficient heat might leave the fabric wrinkled or improperly pressed. Similarly, excessive pressure can flatten the fabric too much, losing its natural drape, while insufficient pressure might leave wrinkles unaddressed. The right combination of temperature and pressure depends on the type of wool, its thickness, and the desired finish.

Careful monitoring is paramount. I use calibrated temperature gauges and pressure indicators to ensure accurate control throughout the pressing process. Understanding the characteristics of various wool types and their responses to heat and pressure is crucial for avoiding damage and achieving consistent results. Experience teaches the subtle nuances – for instance, knowing that a finer wool requires lower temperatures and pressures than a heavier, coarser one. This understanding, combined with effective control mechanisms, prevents damage and ensures a quality product.

Q 14. How do you calculate the appropriate pressing time and temperature for various wool fabrics?

Calculating the appropriate pressing time and temperature for various wool fabrics is a combination of science and experience. There’s no single formula; instead, it involves considering several factors. The fiber content of the wool (e.g., 100% wool, wool blends) plays a significant role – pure wool often requires lower temperatures than wool blends. The weight of the fabric influences the duration; heavier fabrics naturally require longer pressing times. The desired finish also plays a part – a crisp finish might necessitate higher temperatures and pressures than a softer, more fluid drape.

My approach involves referencing industry standards and guidelines while also relying on practical experience. I start with recommended settings for a specific fabric type and then adjust based on visual inspection during the pressing process. Test swatches can be extremely useful – pressing small samples of the fabric at different temperatures and pressures to determine the ideal settings before pressing the entire garment. This iterative process, refined over years of experience, minimizes risks and ensures optimal results. Thorough record-keeping of successful settings for various fabric types is also crucial for future reference and consistency.

Q 15. Describe your experience with using different pressing aids, such as pressing cloths and interfacings.

My experience with pressing aids is extensive, encompassing various fabrics and pressing techniques. Pressing cloths are crucial for preventing shine and marking on delicate wool. I’ve used a range of materials, including cotton muslin, silk organza, and even specialized Teflon-coated cloths, selecting the appropriate cloth based on the wool’s weight, color, and finish. For instance, a lightweight silk organza is perfect for pressing fine merino wool, preventing any impression from the press, while a heavier cotton muslin is ideal for thicker, more robust wool blends. Interfacings, on the other hand, add support and structure during pressing, particularly helpful when working with complex garments or shaping specific areas. I’m experienced with different interfacing types – fusible, sew-in, and woven – each suited for different applications. For example, fusible interfacing is great for collars and cuffs, providing a crisp finish, while a woven interfacing might be used for adding body to a wool jacket lining. Choosing the right interfacing and pressing cloth is essential for a professional finish.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you minimize the risk of fabric damage or shrinkage during wool pressing?

Minimizing fabric damage and shrinkage during wool pressing involves a multi-pronged approach. Firstly, understanding the wool’s fiber content and its reaction to heat and moisture is critical. Different wool types – merino, cashmere, Shetland – have varying sensitivities. I always pre-test any pressing technique on a hidden seam allowance to ensure it doesn’t cause any damage or unwanted shrinkage. Secondly, using the correct temperature setting on the press is paramount. I always start at a lower temperature and gradually increase it as needed, avoiding excessive heat that could scorch or felt the wool. Thirdly, pressing cloths act as a buffer, preventing direct contact between the hot press and the fabric. Finally, appropriate pressure and time are vital. Over-pressing can flatten the fabric or cause unwanted creases. I’ve learned to develop a light touch and adjust pressure according to the fabric’s weight. For instance, pressing a delicate cashmere sweater requires significantly less pressure than pressing a heavy wool coat.

Q 17. How do you maintain accurate records of production and quality control during wool pressing?

Maintaining accurate records is vital for quality control and production tracking. I typically use a combination of digital and physical record-keeping. Each pressing job receives a unique identifier, linked to a detailed record including the fabric type, quantity, pressing method used (e.g., steam pressing, dry pressing, blocking), and any special instructions. This data is logged digitally on a production management system, providing real-time tracking of output and helping identify bottlenecks. I also maintain physical logs detailing inspection results, noting any defects or inconsistencies. This combined approach ensures traceability throughout the process, facilitates quality assessment, and allows for continuous improvement.

Q 18. Describe your experience with working in a fast-paced production environment.

I thrive in fast-paced production environments. My previous roles required meeting tight deadlines and handling high-volume workloads. I’m adept at prioritizing tasks, managing my time effectively, and maintaining accuracy under pressure. For example, in one role, we faced a significant order increase during peak season. By effectively delegating tasks where possible, implementing efficient workflow strategies, and maintaining clear communication with my team, we successfully met the deadline without compromising quality. I’m confident in my ability to multitask and adapt to rapidly changing demands.

Q 19. Explain your ability to adapt to changing production schedules and priorities.

Adaptability is key in this industry. I regularly adjust to changing schedules and priorities. When faced with a sudden shift in production plans, I prioritize tasks based on urgency and impact. Clear communication with management and team members ensures everyone is informed and working towards the revised goals. I’m proficient at re-prioritizing my workload, reassessing timelines, and allocating resources effectively. For instance, during a recent project, a critical client order required immediate attention. By shifting my focus and leveraging my team’s expertise, we completed the pressing of the order ahead of the revised deadline without disrupting other ongoing production lines.

Q 20. How do you handle situations where pressing machine malfunctions occur?

Machine malfunctions are inevitable. My approach involves a methodical troubleshooting process. First, I assess the problem’s severity – is it a minor issue or a major breakdown? For minor issues, such as a jammed feed mechanism, I have the skills to perform basic repairs and maintenance. I’m familiar with the operating manuals and have received adequate training in preventative maintenance. For more serious issues, I immediately report the problem to the maintenance team, providing them with all the necessary details to facilitate a quick repair. In the meantime, I prioritize other tasks or, if necessary, seek alternative pressing methods to minimize production downtime. For example, if the steam press malfunctions, I might temporarily use a dry press for less demanding fabrics while the issue is resolved.

Q 21. What are your strategies for improving efficiency and productivity in wool pressing operations?

Improving efficiency and productivity involves continuous optimization. I focus on several key areas: Firstly, process streamlining – identifying and eliminating bottlenecks in the workflow. Secondly, preventative maintenance – regularly servicing equipment to minimize downtime and maximize its lifespan. Thirdly, proper training and teamwork – ensuring the team has the necessary skills and works collaboratively. Fourthly, implementing quality control measures throughout the process, proactively identifying and addressing potential issues. Finally, I actively seek opportunities for technological advancements. For example, exploring the use of advanced pressing equipment or implementing software solutions to optimize resource allocation. By addressing these areas systematically, I can continuously improve efficiency and productivity in wool pressing operations.

Q 22. Describe your experience with training other employees in wool pressing techniques.

Training others in wool pressing is a rewarding aspect of my role. I believe in a hands-on, layered approach. It begins with a thorough overview of the different wool types and their unique pressing requirements – from delicate cashmere to robust merino. I explain the importance of understanding fiber structure and how it impacts the pressing process. For instance, the delicate nature of cashmere necessitates lower temperatures and gentler pressure compared to heavier wools.

Following the theoretical overview, we move to practical demonstrations. I guide trainees through the entire pressing process, from preparing the garment (checking for stains, pre-treating if necessary) to selecting the appropriate press, temperature, and pressure settings. I emphasize the importance of proper steam application and the techniques for removing wrinkles without damaging the fabric. We then proceed to supervised practice sessions where I provide immediate feedback and address individual challenges. For example, I might teach a trainee how to effectively press a difficult-to-manage area like a sharply tailored shoulder seam. Regular quizzes and practical assessments ensure knowledge retention and the development of proficient pressing skills.

Finally, I encourage continuous learning by providing access to industry resources and encouraging experimentation under supervision. This approach ensures that each trainee develops a deep understanding and confidence in their pressing skills.

Q 23. How do you prioritize tasks and manage your time effectively in a busy pressing area?

Prioritizing tasks in a busy pressing area requires a structured approach. I utilize a combination of techniques, including a prioritized task list and a visual workflow system. This enables me to quickly assess the urgency and complexity of each task. For example, rush orders for high-profile clients always take precedence. Similarly, items requiring specialized pressing techniques are tackled with appropriate time allocation.

Time management is crucial. I regularly review my workload, estimating the time needed for each task. I also incorporate time-saving strategies, like batching similar tasks together (e.g., pressing all the trousers at once) to enhance efficiency. Moreover, I proactively communicate with colleagues about potential delays or bottlenecks, ensuring smooth workflow and collaborative problem-solving. Unexpected urgent requests are integrated into the workflow by temporarily shifting less-critical tasks, always maintaining clear communication with all parties involved.

Q 24. What methods do you use to ensure consistent quality across all wool pressing operations?

Maintaining consistent quality across all wool pressing operations involves a multifaceted approach. First, meticulous adherence to standardized operating procedures (SOPs) is crucial. These SOPs detail every step of the process, from garment preparation to final inspection, ensuring consistency regardless of who performs the task. For example, our SOPs specify exact temperature and steam settings for different wool types.

Regular calibration and maintenance of pressing equipment are non-negotiable. We have a schedule for checking the temperature accuracy and steam pressure of each machine. This prevents inconsistencies caused by faulty equipment. We also conduct regular quality checks throughout the process – both during and after pressing – to promptly identify and address any deviations from standards. This includes inspecting for wrinkles, creases, or any signs of damage. Finally, ongoing training and competency assessments for all staff guarantee that everyone maintains the required skill level to meet our quality standards. By combining these approaches, we ensure that every item leaves our department in perfect condition.

Q 25. Explain your experience with different types of fabric finishes and their impact on pressing.

Different fabric finishes significantly influence the pressing process. Understanding these finishes is paramount to achieving optimal results. For instance, a superfine wool with a crisp finish might require a higher temperature and more pressure to achieve a sharp crease, while a softer, brushed wool would need a lower temperature and gentler approach to avoid damaging the delicate fibers.

Water-repellent finishes, common in outdoor wear, require careful handling. Excessive heat can damage the coating, potentially causing discoloration or altering the fabric’s texture. Similarly, delicate finishes like silk charmeuse or delicate lace require very low temperatures and minimal pressure to preserve their delicate drape. I am experienced with identifying these varied finishes through touch and visual inspection and adapting my pressing techniques accordingly, consulting resources as needed for unfamiliar finishes.

Q 26. How do you identify and address potential environmental hazards associated with wool pressing?

Environmental hazards in wool pressing are primarily related to the use of steam and cleaning chemicals. We minimize these hazards through various safety measures. Firstly, our pressing equipment is regularly inspected and maintained to prevent steam leaks. Proper ventilation is crucial in the pressing area to dissipate steam and reduce humidity, creating a safer working environment. The area is also well-lit to minimize the risks associated with poor visibility.

For cleaning agents, we use only environmentally-friendly, biodegradable products, following the manufacturer’s instructions meticulously. All staff receive comprehensive training on the safe handling and disposal of these chemicals, including the proper use of personal protective equipment (PPE) such as gloves and eye protection. We maintain detailed records of all chemical usage and disposal, complying with all relevant environmental regulations. Regular safety inspections and employee feedback sessions further reinforce our commitment to a safe and environmentally responsible workspace.

Q 27. Describe your experience with implementing and maintaining quality control procedures.

Implementing and maintaining quality control procedures is a crucial part of my role. We have a robust system that begins with the initial inspection of incoming wool garments. This includes checking for defects and pre-existing damage, ensuring that any issues are addressed before the pressing stage. Then, during the pressing process, regular in-process checks are performed to identify and correct any irregularities. This ensures that any problems are caught early, preventing costly rework or rejects.

Post-pressing inspection is rigorous, involving a detailed examination of each garment for wrinkles, creases, and any signs of damage. We utilize digital image capture for precise documentation of any defects for further analysis and improvement. Statistical process control (SPC) charts help us track key metrics, including the number of rejects and the causes of defects, providing valuable data to identify trends and areas for improvement. Finally, we have a system for feedback collection from both employees and clients, which enables continuous improvement and helps us adapt our procedures to maintain the highest level of quality. The regular review of this data helps refine our procedures and maintain our consistently high standards.

Key Topics to Learn for Wool Pressing Interview

- Wool Fiber Properties: Understanding different wool types (e.g., merino, cashmere), their inherent characteristics (strength, elasticity, crimp), and how these influence pressing techniques.

- Pressing Equipment & Techniques: Familiarity with various pressing machines (steam presses, hand presses), their operation, maintenance, and the appropriate techniques for different wool fabrics (e.g., delicate silks vs. heavy coats).

- Pressing Processes: Mastering the steps involved in the pressing process, from pre-pressing preparation to final finishing, including techniques for removing wrinkles, creases, and setting the fabric.

- Quality Control & Inspection: Understanding the importance of quality control in wool pressing, identifying common pressing defects (e.g., scorching, shine marks, wrinkles), and implementing corrective actions.

- Safety Procedures: Knowledge of safety protocols and best practices related to operating pressing machinery and handling hot surfaces.

- Problem-Solving & Troubleshooting: Ability to identify and resolve common pressing issues, such as uneven pressing, fabric damage, or machine malfunctions.

- Sustainability & Environmental Considerations: Understanding environmentally friendly pressing practices, including water and energy conservation.

- Industry Best Practices: Staying current with industry trends and advancements in wool pressing techniques and technologies.

Next Steps

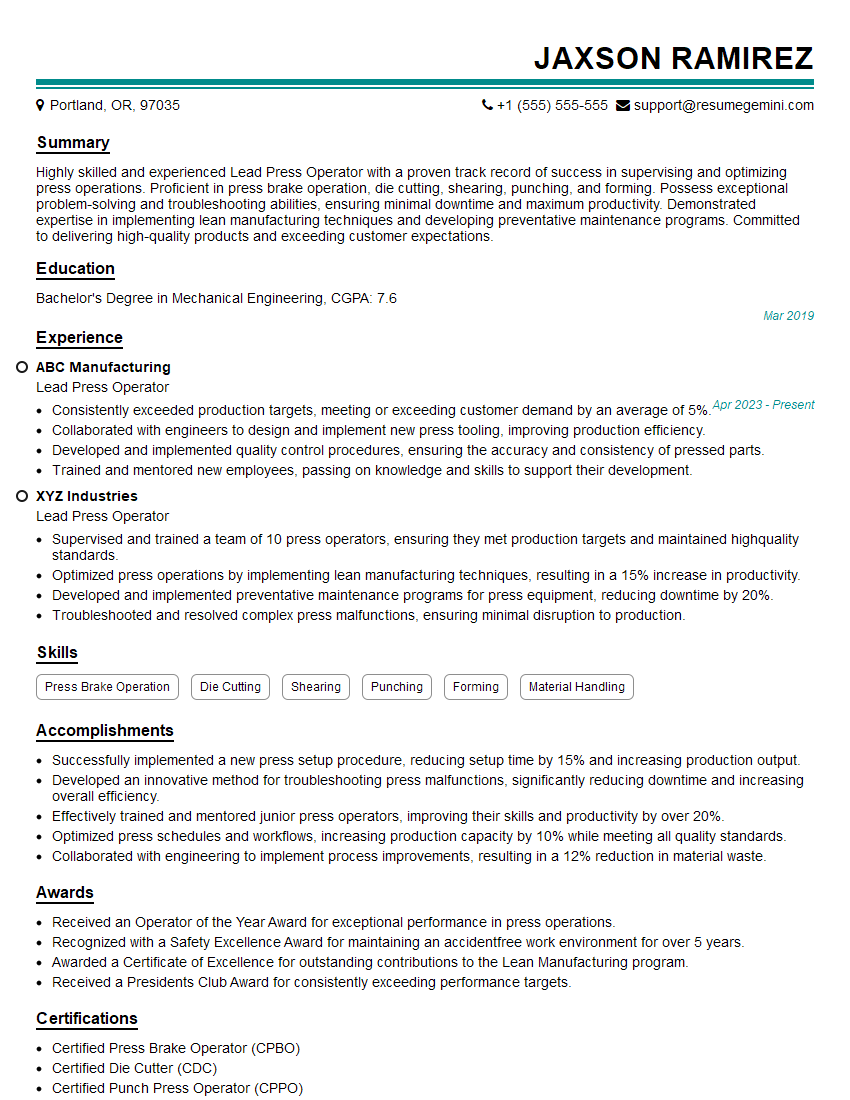

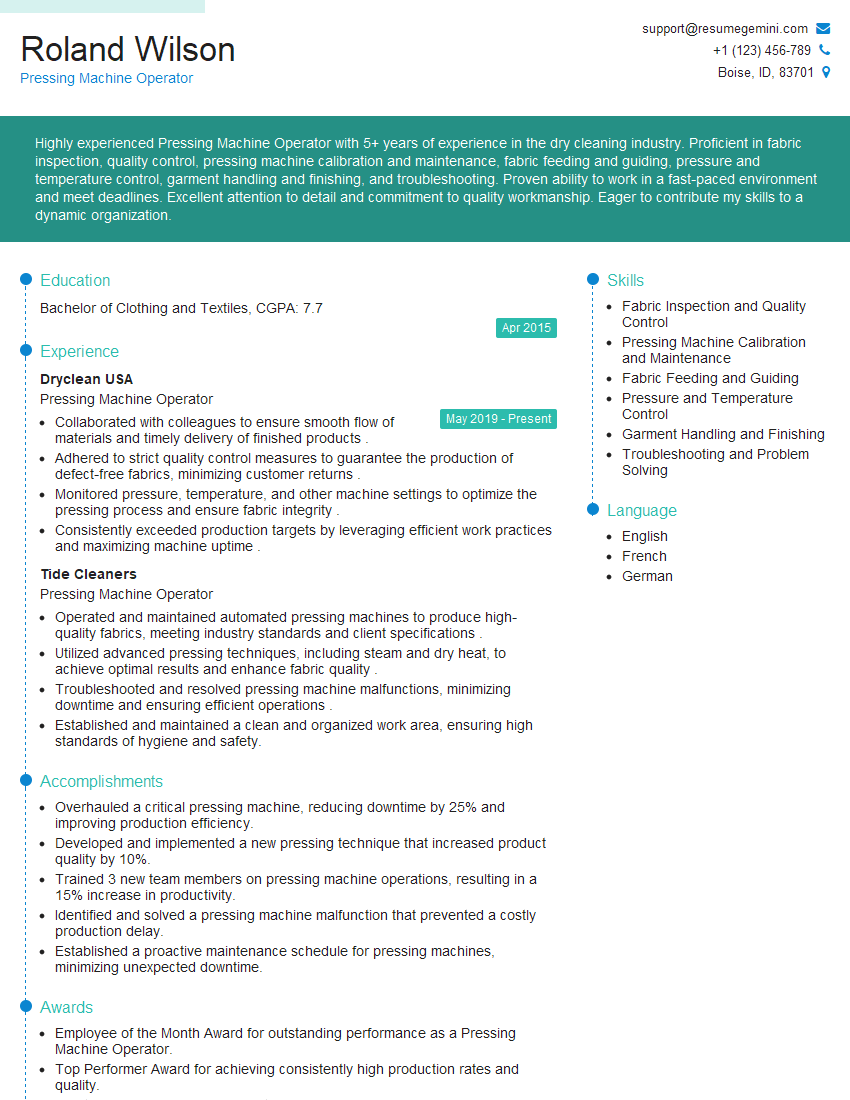

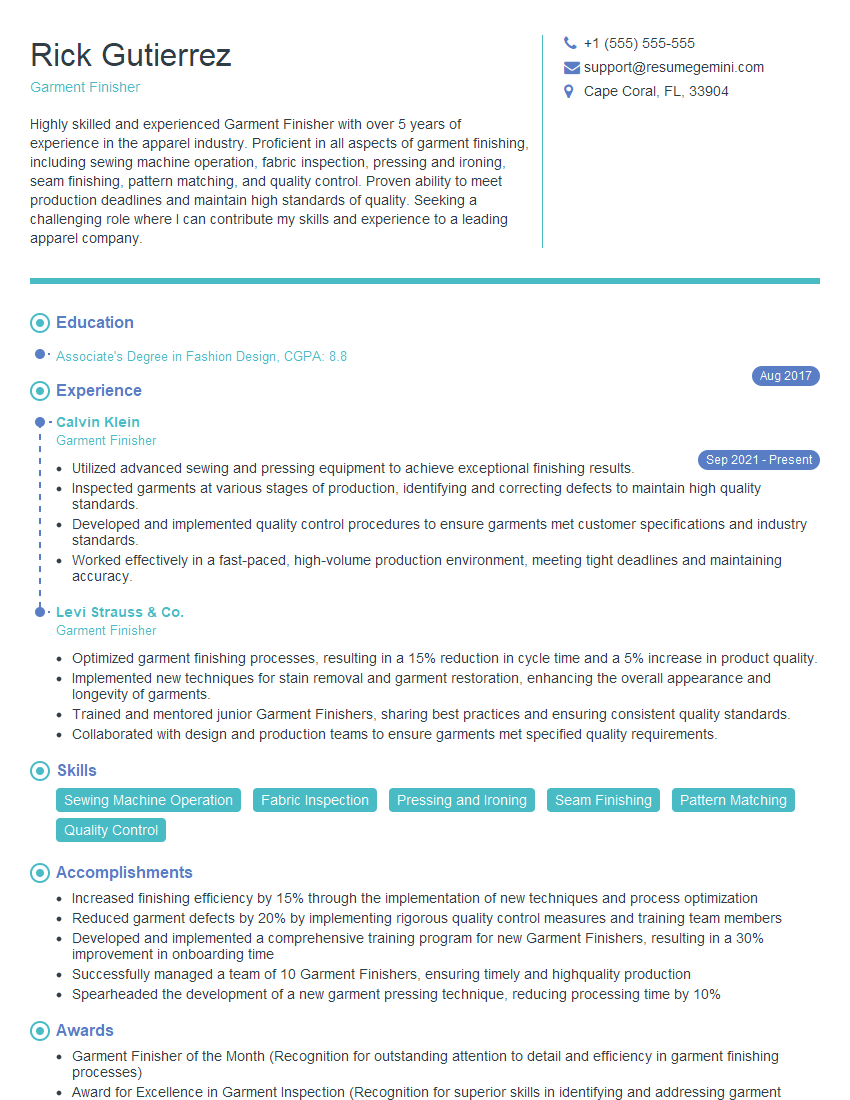

Mastering wool pressing opens doors to exciting career opportunities in the textile and fashion industries, offering diverse roles and excellent growth potential. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to the wool pressing industry are available to guide you. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good