Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of Oil and Gas Industry Standards interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of Oil and Gas Industry Standards Interview

Q 1. Explain your understanding of API standards related to well control.

The American Petroleum Institute (API) publishes numerous standards crucial for well control, focusing on preventing blowouts and other well control incidents. These standards cover various aspects, from equipment design and maintenance to operational procedures and training. Key API standards related to well control include:

- API RP 53: This Recommended Practice provides guidelines for designing and operating well control equipment, focusing on the selection and use of blowout preventers (BOPs). It’s essentially a bible for well control engineers. For example, it details the testing and maintenance requirements for BOPs, including hydraulic and mechanical components.

- API RP 54: This Recommended Practice addresses well control procedures during drilling operations. It dictates the steps to be followed during normal drilling operations, as well as the emergency procedures for various well control scenarios, like a kick (influx of formation fluids into the wellbore).

- API RP 16A: This specification covers the design and manufacture of BOP systems, ensuring they meet stringent safety requirements. The specifications include details of the materials used, design pressures, and testing protocols.

Understanding and adhering to these API standards is vital for minimizing risks and ensuring the safety of personnel and the environment during well drilling and operation. Failure to comply can lead to catastrophic incidents, highlighting the importance of continuous training and rigorous adherence to these standards.

Q 2. Describe the importance of OSHA regulations in the oil and gas industry.

The Occupational Safety and Health Administration (OSHA) plays a critical role in ensuring worker safety in the oil and gas industry. OSHA regulations establish minimum safety and health standards for workplaces, including those in the often hazardous environment of oil and gas operations. These regulations cover a wide range of aspects, including:

- Personal Protective Equipment (PPE): OSHA mandates the use of appropriate PPE, such as hard hats, safety glasses, gloves, and flame-resistant clothing, to protect workers from various hazards.

- Hazardous Materials Handling: Strict guidelines are in place for the safe handling, storage, and transportation of hazardous materials common in oil and gas operations, like crude oil, natural gas, and drilling fluids.

- Emergency Response Planning: OSHA requires employers to develop and implement comprehensive emergency response plans to address potential incidents such as fires, explosions, or spills.

- Confined Space Entry: Strict protocols are defined for entering confined spaces, like tanks or vessels, to prevent incidents related to asphyxiation or exposure to hazardous atmospheres.

Non-compliance with OSHA regulations can result in substantial fines and legal consequences for companies. More importantly, it can lead to serious injuries or fatalities among workers. Thus, rigorous adherence to OSHA standards is paramount for responsible oil and gas operations.

Q 3. What are the key components of a wellhead and how do they ensure well integrity?

The wellhead is the crucial interface between the wellbore and the surface equipment. Its primary function is to ensure well integrity, preventing uncontrolled flow of fluids and maintaining pressure control. Key components include:

- Casing Head: This is the uppermost component, sealing the top of the casing string and providing a mounting point for other wellhead components. It’s designed to withstand high pressures.

- BOP (Blowout Preventer): This is a critical safety device placed on top of the wellhead. It’s designed to prevent uncontrolled flow of fluids from the wellbore in case of a well kick or blowout. Various types exist, such as annular BOPs and ram-type BOPs.

- Christmas Tree: This assembly of valves and fittings controls the flow of hydrocarbons from the well. It allows for regulated production and also facilitates well shut-in during emergencies.

- Tubing Head: This component connects the production tubing to the wellhead. It’s designed to withstand the pressure of the hydrocarbons being produced.

These components, working together, prevent uncontrolled fluid flow, contain pressure, and allow for safe and efficient well operations. Regular inspections, testing, and maintenance of the wellhead components are crucial for ensuring ongoing well integrity.

Q 4. Discuss the significance of pressure testing in pipeline safety.

Pressure testing is a fundamental aspect of pipeline safety, ensuring the integrity of the pipeline system and preventing leaks or ruptures. It involves pressurizing the pipeline with a test medium (usually water or air) to a specified pressure to check for weakness or defects. The significance of pressure testing lies in its ability to:

- Identify Leaks and Weak Points: Pressure testing helps detect even small leaks or weak points in the pipeline before it enters service, preventing potential failures during operation.

- Verify Weld Integrity: It ensures the integrity of welds, a crucial aspect of pipeline construction, by highlighting any defects that might compromise the pipeline’s strength.

- Confirm Design Specifications: Pressure testing verifies that the pipeline meets the design specifications for pressure resistance and structural integrity.

- Minimize Environmental Risks: By identifying and rectifying defects early, pressure testing helps to minimize the risk of environmental damage from potential leaks or ruptures.

Different types of pressure tests exist, including hydrostatic testing (using water) and pneumatic testing (using air), each with its own advantages and limitations. The specific testing procedures are usually dictated by relevant industry standards and regulations.

Q 5. Explain the different types of drilling fluids and their functions.

Drilling fluids, also known as mud, are essential in drilling operations. They serve multiple crucial functions. Different types exist, each optimized for specific drilling conditions:

- Water-Based Muds: These are the most common, utilizing water as the base fluid. Various additives, such as clays, polymers, and weighting agents (like barite), are added to control rheology (flow properties), density, and filtration. They are cost-effective but may not be suitable for all formations.

- Oil-Based Muds: These use oil as the base fluid, offering better lubricity, shale inhibition, and stability in challenging formations. They are more expensive and present greater environmental concerns requiring careful waste management.

- Synthetic-Based Muds: These utilize synthetic oils as the base fluid, combining the benefits of oil-based muds with reduced environmental impact. They are generally more expensive than water-based muds but offer superior performance in certain formations.

The functions of drilling fluids include:

- Hole Cleaning: Removing cuttings from the wellbore.

- Pressure Control: Maintaining pressure balance to prevent influx of formation fluids.

- Lubrication: Reducing friction on the drill string.

- Shale Inhibition: Preventing swelling and sloughing of shale formations.

- Cooling and Lubricating Drill Bits: Extending the life of the drill bit.

Selecting the appropriate type of drilling fluid is critical for efficient and safe drilling operations, considering factors such as formation characteristics, environmental regulations, and cost.

Q 6. What are the key elements of a well completion design?

Well completion design is a crucial phase, determining how a well will be produced after drilling. A poorly designed completion can significantly impact production efficiency and longevity. Key elements include:

- Casing and Tubing Design: Selection of appropriate casing and tubing sizes, grades, and lengths to withstand anticipated pressures and temperatures. This choice depends on reservoir properties and well depth.

- Perforation Design: Strategic placement of perforations in the casing to create pathways for hydrocarbons to flow into the wellbore. The location and density of perforations significantly affect production rates.

- Completion Method: Choosing between different completion methods like openhole completion (no casing in the producing zone), gravel pack completion (gravel around perforations for proppant support), or sand control completion (using specialized screens or packers to prevent sand production).

- Artificial Lift Systems: Selection of appropriate artificial lift methods, such as ESPs (electric submersible pumps) or gas lift, to enhance production in low-pressure reservoirs.

- Downhole Equipment: This includes packers, valves, and other downhole tools to control flow, isolate zones, and enhance production.

Well completion design requires a thorough understanding of reservoir characteristics, drilling data, and production goals. Detailed reservoir simulations and engineering analysis are crucial for optimizing completion design and maximizing production potential. A well-designed completion ensures efficient and safe production throughout the well’s life.

Q 7. How do you ensure compliance with environmental regulations during drilling operations?

Ensuring compliance with environmental regulations during drilling operations is paramount, requiring careful planning and execution. This involves several key aspects:

- Permitting and Approvals: Obtaining all necessary permits and approvals from relevant environmental agencies before commencing drilling operations. This often involves submitting detailed environmental impact assessments.

- Waste Management: Implementing a robust waste management plan to handle drilling fluids, cuttings, and other wastes responsibly. This often includes recycling and disposing of wastes according to regulatory standards.

- Spill Prevention and Control: Implementing procedures to prevent spills of drilling fluids, fuel, or other hazardous materials. This includes regular equipment inspections and leak detection systems.

- Air Emissions Monitoring: Monitoring and controlling air emissions from drilling operations, especially methane emissions. This often involves the use of specialized monitoring equipment and implementing emission reduction technologies.

- Water Management: Proper management of produced water and drilling wastewater, ensuring proper treatment and disposal according to relevant regulations.

- Environmental Monitoring: Regular environmental monitoring of soil, water, and air quality to ensure that drilling operations are not impacting the surrounding environment.

Compliance with environmental regulations requires a multidisciplinary approach, involving geologists, engineers, environmental specialists, and regulatory compliance officers. A proactive and integrated approach helps to protect the environment and minimize the environmental footprint of drilling operations. Failure to comply can result in significant penalties and reputational damage.

Q 8. Describe your experience with reservoir simulation software and its application in production optimization.

Reservoir simulation software is crucial for predicting and optimizing oil and gas production. These sophisticated programs use complex mathematical models to represent the subsurface reservoir, including its geology, fluid properties, and the flow of hydrocarbons. My experience involves using industry-leading software like CMG GEM and Eclipse to build dynamic reservoir models. This involves inputting geological data (porosity, permeability, saturation), fluid properties (oil viscosity, gas compressibility), and production history. The software then simulates the reservoir’s behavior under different operating conditions, allowing us to predict future production rates, optimize well placement, and evaluate enhanced oil recovery (EOR) techniques. For instance, in one project, we used simulation to evaluate the effectiveness of waterflooding in a mature field. By adjusting injection rates and well configurations in the simulation, we identified an optimal strategy that significantly increased production and extended the field’s lifespan. This not only saved the company considerable costs but also proved the value of predictive modelling in production decisions.

In production optimization, reservoir simulation helps us answer critical questions such as: What is the optimal well spacing? What is the best production strategy for maximizing recovery? What is the impact of different EOR techniques? The results from simulations are crucial inputs in the decision-making process, providing quantitative evidence for selecting the most profitable and sustainable approach.

Q 9. What are the different types of oil and gas production facilities?

Oil and gas production facilities are diverse, ranging from simple wellhead setups to large, complex processing plants. They can be broadly categorized as follows:

- Wellhead facilities: These are the initial processing points, located directly at the wellbore. They typically include safety valves, flow meters, and pressure gauges to monitor and control production. Simple facilities may only separate gas and oil, while more complex ones may also remove water and other impurities.

- Gathering systems: These pipelines and flowlines transport hydrocarbons from multiple wells to central processing facilities. They often include compressor stations to maintain pressure and ensure efficient flow.

- Processing plants: These plants separate oil and gas, remove impurities, and prepare the hydrocarbons for transportation or sale. They may include dehydration units, gas treating facilities, and stabilization units.

- Terminals: These facilities handle the storage, transfer, and export of processed hydrocarbons. They may include tanks, pipelines, and loading docks for ships or trucks.

The complexity of a production facility depends on several factors, including the reservoir type (conventional or unconventional), the characteristics of the produced fluids, and the proximity to transportation infrastructure. For example, a facility producing only light crude oil might be relatively simple compared to one producing heavy oil with a significant amount of associated gas, which would require more extensive processing.

Q 10. Explain the concept of artificial lift and its various methods.

Artificial lift is any method used to enhance the production rate of a well when natural reservoir pressure is insufficient. Think of it as giving the oil and gas a helping hand to reach the surface. Several methods exist, each suited to specific well conditions:

- Rod lift: A surface-driven pump is connected to a subsurface pump via a series of rods. It’s a reliable and widely used method, particularly suitable for medium-depth wells with moderate production rates.

- ESP (Electrical Submersible Pump): An electric motor drives a submersible pump located downhole. ESP is efficient for high production rates and high water cut wells but requires significant power and can be more susceptible to damage from sand production.

- Gas lift: High-pressure gas is injected into the wellbore, reducing fluid density and helping it flow to the surface. It’s a versatile method, commonly used in offshore applications or for wells with high gas-oil ratios.

- Hydraulic lift: Uses a hydraulic piston to lift fluids from the well. It’s often used in high-production wells or challenging conditions.

The choice of artificial lift method depends on several factors including: well depth, production rate, fluid properties, cost, and available infrastructure. For instance, in a deep, high-production well with high water cut, ESP might be the preferred choice due to its high efficiency and capacity. However, in a shallower well with low production rates, rod lift might be a more cost-effective solution.

Q 11. Describe the role of hydraulic fracturing in unconventional oil and gas production.

Hydraulic fracturing, or fracking, is a crucial technique for extracting hydrocarbons from unconventional reservoirs like shale and tight gas formations. These reservoirs have low permeability, meaning the natural flow of hydrocarbons is restricted. Fracking overcomes this by creating artificial fractures in the rock formation, enhancing permeability and allowing hydrocarbons to flow more easily to the wellbore.

The process involves injecting a high-pressure mixture of water, sand, and chemicals into the wellbore. The pressure creates fractures in the surrounding rock, and the sand (proppant) keeps the fractures open, creating pathways for hydrocarbon flow. This significantly increases the well’s productivity and allows for the economic extraction of hydrocarbons that would otherwise be inaccessible. Fracking has revolutionized the oil and gas industry, enabling the development of vast reserves of unconventional resources, but environmental concerns related to water usage and potential groundwater contamination require careful management and mitigation strategies.

In practical terms, the effectiveness of fracking depends on many factors including the geology of the formation, the design of the fracture network, and the choice of proppant. Careful planning and optimization are essential to maximize production and minimize environmental impact.

Q 12. How do you manage risks associated with hazardous materials in oil and gas operations?

Managing risks associated with hazardous materials in oil and gas operations is paramount. This requires a comprehensive approach involving several key elements:

- Hazard identification and risk assessment: A thorough assessment identifies all potential hazards (e.g., flammable liquids, toxic gases, corrosive chemicals) and assesses the likelihood and severity of associated risks.

- Safety procedures and training: Establishing and implementing detailed safety procedures, along with regular training for personnel, ensures a safe working environment. This includes emergency response plans for various scenarios.

- Engineering controls: Implementing engineering controls like leak detection systems, pressure relief valves, and containment barriers minimizes the risk of spills and releases.

- Personal protective equipment (PPE): Providing and enforcing the use of appropriate PPE (e.g., respirators, protective clothing) is crucial for protecting workers from exposure to hazardous materials.

- Regulatory compliance: Adherence to all relevant safety regulations and industry best practices is crucial. Regular inspections and audits ensure compliance.

- Emergency response planning: Developing detailed emergency response plans to deal with spills or releases, including procedures for evacuation, containment, and cleanup, is paramount.

A robust safety management system is essential. This includes regular monitoring, incident investigation, and continual improvement based on lessons learned. For example, a regular review of safety procedures and emergency response drills can help to identify potential weaknesses and improve the overall safety performance.

Q 13. What are the key performance indicators (KPIs) used to monitor well performance?

Several key performance indicators (KPIs) are used to monitor well performance, providing insights into production efficiency and identifying areas for improvement. These include:

- Production rate (oil, gas, water): The volume of each fluid produced per unit of time (e.g., barrels of oil per day, cubic meters of gas per day).

- Wellhead pressure and temperature: These parameters provide information about reservoir pressure and the condition of the wellbore.

- Water cut: The percentage of water in the total fluid production, which can indicate reservoir depletion or water influx.

- Gas-oil ratio (GOR): The ratio of gas production to oil production, indicating changes in reservoir pressure and fluid composition.

- Cumulative production: The total volume of hydrocarbons produced since the well was put into service.

- Operating costs: The expenses associated with operating the well (e.g., artificial lift costs, maintenance, chemicals).

Regular monitoring of these KPIs enables operators to identify trends, predict potential problems, and make informed decisions regarding well management and maintenance. For example, a sudden increase in water cut might indicate a need for remedial work or a change in production strategy.

Q 14. Explain your understanding of production logging tools and their applications.

Production logging tools are specialized instruments deployed downhole to measure various parameters during production. They provide real-time data on fluid flow, pressure, and other properties within the wellbore, giving valuable insight into the well’s performance and identifying potential production problems.

These tools are deployed either through wireline or tubing conveyance. Examples include:

- Flow meters: Measure the flow rate of oil, gas, and water at various points in the wellbore.

- Pressure gauges: Measure pressure at different depths to identify pressure drops and flow restrictions.

- Temperature sensors: Measure temperature profiles, which can indicate fluid flow patterns and heat transfer.

- Fluid samplers: Collect fluid samples for laboratory analysis to determine fluid properties.

The data collected from production logging tools are used for various applications, including:

- Identifying zones of high or low productivity: Helps optimize completion strategies and identify areas for stimulation.

- Diagnosing production problems: Detects issues like water coning, gas channeling, or flow restrictions.

- Evaluating the effectiveness of artificial lift: Assesses the performance of pumps or other lift systems.

- Optimizing production strategies: Provides data for designing efficient production schemes.

For example, a production log might reveal that a particular zone within the wellbore is producing more water than expected, indicating a need to adjust the production strategy or implement a water management solution.

Q 15. How do you handle emergency situations related to well control?

Well control emergencies demand immediate, decisive action based on established protocols. My approach follows a structured framework: Identify, Assess, Respond, Recover.

- Identify: Quickly determine the nature of the emergency (e.g., kick, blowout, fire). This involves checking pressure gauges, flow rates, and observing any visible signs.

- Assess: Evaluate the severity of the situation, considering the type of well, the volume and pressure of the fluids, and potential environmental impacts. This might involve consulting well logs and previous well testing data.

- Respond: Implement pre-planned emergency procedures. This could involve closing valves, activating emergency shut-down systems, deploying kill mud, or contacting emergency services. Communication is key – ensuring everyone involved knows their role and responsibilities.

- Recover: Once the immediate danger is mitigated, we transition to damage control, well repair, and investigation. This includes documenting the incident, conducting a root cause analysis, and implementing corrective actions to prevent future occurrences. We also collaborate with regulatory bodies to report the incident and comply with all regulations.

For instance, during a kick situation, I would immediately initiate the well kill procedure, using weighted mud to overcome the formation pressure and prevent further uncontrolled flow. If the situation escalated to a blowout, the emergency response plan would be activated, involving the use of specialized equipment and personnel.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the various types of pipelines and their respective applications?

Pipelines are categorized by several factors, including diameter, material, pressure rating, and the fluid transported. Some key types include:

- Gathering Pipelines: These relatively small-diameter pipelines transport crude oil or natural gas from wellheads to processing facilities. They often operate at lower pressures compared to transmission lines.

- Transmission Pipelines: These large-diameter pipelines transport hydrocarbons over long distances, from processing facilities to refineries or storage terminals. They are designed for high pressures and volumes.

- Distribution Pipelines: These pipelines distribute refined products (gasoline, diesel, etc.) from refineries to terminals and eventually to end users. They typically operate at lower pressures than transmission lines.

- Product Pipelines: Transport refined petroleum products (gasoline, diesel, jet fuel) from refineries to distribution points.

Material selection depends on the transported fluid and environmental conditions. Steel is common for high-pressure transmission lines, while other materials like polyethylene (PE) might be used for lower-pressure gathering lines or distribution lines.

Application Example: A large oil field would use gathering lines to collect crude oil from numerous wells, then a transmission line to ship it to a refinery hundreds of miles away. From the refinery, product pipelines distribute the refined products to various locations.

Q 17. Explain your experience with pipeline integrity management programs.

Pipeline Integrity Management (PIM) programs are crucial for ensuring pipeline safety and preventing incidents. My experience involves developing and implementing these programs, which typically include:

- Risk Assessment: Identifying potential threats such as corrosion, third-party damage, and material degradation.

- In-Line Inspection (ILI): Utilizing advanced tools to detect internal pipeline defects. ILI technologies such as magnetic flux leakage (MFL) or ultrasonic testing (UT) are used for pipeline integrity assessment.

- External Corrosion Direct Assessment (ECDA): Assessing the external corrosion risk based on environmental factors and soil conditions.

- Data Management: Efficiently managing and analyzing pipeline inspection data to prioritize repairs and maintenance.

- Repair and Remediation: Implementing strategies to address identified defects, ranging from simple repairs to more extensive replacements.

- Compliance Monitoring: Meeting all relevant regulatory requirements and internal safety standards.

In a previous role, I managed a PIM program for a 500-mile pipeline. We utilized advanced ILI techniques to pinpoint critical defects, prioritizing repairs based on a risk-based model. This resulted in a significant reduction in pipeline-related incidents and improved overall safety.

Q 18. Discuss the importance of corrosion control in pipelines and facilities.

Corrosion control is paramount in the oil and gas industry. Corrosion can lead to leaks, spills, environmental damage, and significant financial losses. My experience involves several methods:

- Coating: Applying protective coatings to pipelines and equipment to create a barrier between the metal and the corrosive environment.

- Cathodic Protection: Using an impressed current or sacrificial anodes to suppress corrosion by making the metal surface negatively charged.

- Corrosion Inhibitors: Adding chemicals to fluids to reduce their corrosiveness.

- Material Selection: Choosing corrosion-resistant materials (e.g., stainless steel, duplex steel) for equipment and pipelines.

- Regular Inspection: Conducting routine inspections to detect early signs of corrosion and prevent escalation.

A specific example: In a high-sulfur environment, we implemented a combination of internal corrosion inhibitors and external cathodic protection on our pipelines to effectively mitigate corrosion.

Q 19. How do you ensure the safe handling and disposal of produced water?

Produced water management requires careful attention to environmental regulations and safety. Safe handling and disposal involve:

- Treatment: Reducing the concentration of contaminants such as oil, salts, and heavy metals. This may involve various techniques such as chemical treatment, filtration, and biological treatment.

- Disposal: This can include reinjection into producing formations, discharge to surface water (with appropriate permits and treatment), or disposal in permitted disposal wells.

- Recycling and Reuse: Exploring options for recycling or reusing the treated water in other aspects of operations, reducing freshwater consumption.

- Monitoring and Reporting: Regularly monitoring water quality and reporting findings to regulatory agencies.

For example, in a previous project, we implemented a produced water treatment facility that utilized advanced filtration and reverse osmosis to meet stringent discharge standards before releasing the treated water into a nearby river, under proper permitting.

Q 20. Describe your understanding of flow assurance and its challenges.

Flow assurance is the process of ensuring the continuous and efficient flow of hydrocarbons through a production system. Challenges include:

- Wax Deposition: Wax crystals can precipitate out of solution at lower temperatures, clogging pipelines and restricting flow.

- Hydrate Formation: Under specific conditions of pressure and temperature, water and hydrocarbons can form ice-like hydrates that block pipelines.

- Scale Deposition: Inorganic salts can precipitate out of solution, forming scale deposits that can restrict flow.

- Emulsions: Water and oil can form stable emulsions that are difficult to separate, affecting flow rates.

Addressing these challenges often involves using techniques such as chemical injection (to inhibit hydrate or wax formation), heating the fluids, installing pigging systems to remove deposits, or optimizing production strategies.

For example, I worked on a project where we used a combination of pipeline heating and chemical injection to prevent wax deposition in a deepwater pipeline, ensuring continuous production.

Q 21. What are the different types of gas processing plants and their functions?

Gas processing plants remove impurities and process natural gas to meet pipeline specifications and market demands. Common types include:

- Sweetening Plants: Remove hydrogen sulfide (H2S) and other sulfur compounds (mercaptans) using processes like amine treating or Claus processing, to meet pipeline specifications and environmental regulations.

- Dehydration Plants: Remove water vapor from natural gas to prevent hydrate formation and corrosion in downstream facilities. Glycol dehydration is a common technique.

- Liquefied Natural Gas (LNG) Plants: Cool natural gas to cryogenic temperatures to convert it into liquid form for easier transportation and storage.

- Natural Gas Liquids (NGL) Recovery Plants: Separate heavier hydrocarbons such as ethane, propane, butane, and pentanes from natural gas, producing valuable NGL products.

Function Example: A typical gas processing plant might combine sweetening and dehydration units to remove H2S and water, followed by an NGL recovery plant to extract valuable hydrocarbons before the remaining gas is sent to a pipeline.

Q 22. Explain the concept of gas sweetening and its importance.

Gas sweetening is the process of removing undesirable sulfur-containing compounds, primarily hydrogen sulfide (H2S) and mercaptans, from natural gas. These compounds are corrosive, toxic, and can poison catalysts in downstream processing, making gas sweetening crucial for pipeline transportation, industrial use, and liquefied natural gas (LNG) production. Think of it like refining raw sugar – you need to remove impurities to get a usable product.

The importance stems from several factors:

- Safety: H2S is extremely toxic, even at low concentrations. Sweetening ensures a safe working environment and prevents potential hazards to personnel and the public.

- Environmental Protection: Sulfur compounds contribute to acid rain and air pollution. Removing them minimizes the environmental impact.

- Equipment Protection: H2S is highly corrosive, damaging pipelines, valves, and other equipment. Sweetening protects valuable infrastructure and extends its lifespan.

- Product Quality: Sweetened gas meets quality standards required by customers and downstream processing facilities. For instance, LNG requires extremely low sulfur content.

Common gas sweetening methods include amine treating (using solvents like MEA or DEA to absorb H2S), Claus process (converting H2S to elemental sulfur), and physical absorption (using solvents like Selexol).

Q 23. How do you manage and mitigate the risks associated with hydrogen sulfide (H2S)?

Managing and mitigating H2S risks requires a multi-layered approach encompassing prevention, detection, and response. Think of it like building a fortress – multiple defenses are needed to withstand an attack.

- Prevention: This involves careful well design and construction to minimize H2S production. Employing proper drilling and completion techniques, including using specialized drilling fluids, is essential. Regular inspections and maintenance of equipment are crucial to detect potential leaks early.

- Detection: Continuous monitoring is key. We use fixed and portable gas detectors at various locations, including wellheads, processing facilities, and even personnel-worn devices. Alarm systems trigger immediate actions upon detection of H2S above permissible limits.

- Response: A well-defined emergency response plan is critical. This includes evacuation procedures, emergency shutdowns, and the use of personal protective equipment (PPE). Training personnel regularly on H2S safety procedures and emergency response is paramount. This ensures everyone knows what to do and how to react in case of a release.

For example, in a previous role, we implemented a sophisticated real-time monitoring system that immediately alerted the control room of any H2S leak. This allowed for rapid response, preventing a potentially serious incident. This system combined with regular safety drills significantly reduced our risk profile.

Q 24. Describe your experience with data acquisition and interpretation in oil and gas operations.

My experience in data acquisition and interpretation spans various aspects of oil and gas operations. I’ve worked with various data sources, from surface measurements to downhole sensors. I’m proficient in using software such as Petrel, Eclipse, and similar reservoir simulation programs.

My expertise includes:

- Production Data Analysis: Analyzing well test data (pressure, rate, temperature) to understand reservoir behavior and estimate reserves. This involves applying material balance principles and decline curve analysis.

- Seismic Data Interpretation: Integrating seismic data with well logs and other geological information to create accurate reservoir models. I’ve worked on projects involving 3D seismic surveys and their interpretation for identifying potential drilling locations.

- Well Log Analysis: Interpreting data from various well logging tools (e.g., gamma ray, resistivity, density) to determine lithology, porosity, and permeability. This helps characterize the reservoir and optimize completion strategies.

- Data Integration and Visualization: Combining data from various sources to develop comprehensive reservoir models and visualizations. This involves using advanced analytical techniques to gain insights into reservoir performance.

For example, in one project, we were able to improve oil production by 15% by using advanced data analytics to identify areas of the reservoir that were not being fully exploited. This involved detailed interpretation of pressure and flow rate data, combined with geological modelling, to optimize well placement and completion strategies.

Q 25. What are the different types of drilling rigs and their applications?

Drilling rigs are broadly categorized into land-based and offshore rigs. Each type further has sub-categories based on their mobility and capacity.

- Land Rigs:

- Mast Rigs: Smaller, less powerful, typically used for shallow wells. They are relatively simple to move and set up.

- Truck-mounted Rigs: Highly mobile and versatile, used for exploration in remote or difficult-to-access areas.

- Modular Rigs: Constructed in sections and assembled on-site. This allows for better customization to specific needs.

- Offshore Rigs:

- Jack-up Rigs: Raised on legs above the water surface, suitable for shallow waters.

- Semi-submersible Rigs: Float on pontoons, stable in moderate water depths.

- Drillships: Floating vessels with dynamic positioning systems, allowing for operation in deep waters.

- Platform Rigs: Fixed structures, offering stability for long-term drilling and production.

The choice of rig depends on several factors, including water depth, well depth, location accessibility, and budget. For instance, a jack-up rig would be suitable for a shallow-water project near the coast, whereas a drillship would be required for deepwater exploration.

Q 26. Explain your understanding of directional drilling techniques.

Directional drilling involves deviating from a vertical wellbore to reach a target reservoir that is not directly beneath the surface location. Imagine it as aiming a guided missile underground to precisely hit a target layer. This technique is essential for accessing reservoirs that are offset from the surface location, maximizing recovery from a single wellbore, and mitigating environmental impact by reducing the number of surface locations required.

Key techniques include:

- Rotary Steerable Systems (RSS): These use downhole motors to control the direction and inclination of the wellbore. Think of it as a sophisticated steering mechanism inside the drill string.

- Measurement While Drilling (MWD): This technology provides real-time data on the wellbore trajectory and formation properties, allowing for accurate steering and adjustments.

- Mud Motors: These motors are used to provide directional control and are particularly useful in scenarios where high torque is required.

Applications include reaching multiple reservoirs from a single surface location, horizontal drilling (creating long horizontal sections within the reservoir), and underbalanced drilling (reducing wellbore pressure to improve drilling efficiency and reduce formation damage).

My experience includes working on projects where directional drilling played a critical role in maximizing recovery from challenging reservoirs and minimizing environmental impact.

Q 27. Discuss the role of well testing in reservoir characterization.

Well testing is crucial for reservoir characterization as it provides valuable data about the reservoir’s properties, such as permeability, porosity, and fluid saturations. It’s like performing a comprehensive medical test on the reservoir to understand its health and potential.

Different types of well tests provide different information:

- Pressure Buildup Tests: Analyzing pressure changes after shutting in a well to determine reservoir permeability and pressure.

- Pressure Drawdown Tests: Analyzing pressure changes during production to evaluate well productivity and reservoir properties.

- Interference Tests: Monitoring pressure changes in one well as a result of production or injection in a nearby well, helping assess reservoir connectivity.

- Production Logging: Measuring flow rates and fluid properties within the wellbore to characterize flow distribution and identify zones with varying productivity.

The data obtained from well testing is used to calibrate reservoir models, refine estimates of hydrocarbon reserves, and optimize production strategies. In essence, it provides crucial input for making informed decisions related to reservoir management and development.

Q 28. Describe your experience with well integrity management programs.

Well integrity management programs focus on maintaining the physical and operational integrity of wellbores throughout their lifecycle. This involves proactive measures to prevent wellbore failures, such as leaks, blowouts, and environmental damage. Think of it as ensuring the well is properly sealed and protected throughout its lifespan.

Key elements include:

- Pre-Drilling Risk Assessment: Identifying potential well integrity challenges early in the planning stage.

- Well Design and Construction: Implementing designs and construction practices that minimize risks associated with the well’s geological setting and drilling operations.

- Regular Inspection and Monitoring: Employing technologies like pressure testing and downhole monitoring to detect potential problems early.

- Data Analysis and Reporting: Analyzing data to identify trends and potential issues, allowing for timely intervention.

- Corrective Actions: Developing and implementing procedures to address identified integrity issues.

In my experience, I’ve worked on several projects where implementation of robust well integrity management programs significantly improved the safety and operational efficiency of wells. This involved developing a comprehensive program encompassing well design, construction, inspection, and maintenance – a holistic approach that minimized risks and maximized efficiency.

Key Topics to Learn for Knowledge of Oil and Gas Industry Standards Interview

- Health, Safety, and Environmental (HSE) Regulations: Understand key international and regional HSE standards (e.g., API, ISO, OSHA) and their practical application in preventing accidents and protecting the environment. Consider case studies demonstrating your understanding of risk assessment and mitigation.

- Well Control and Drilling Operations: Familiarize yourself with well control procedures, blowout prevention equipment, and drilling fluid properties. Be prepared to discuss practical scenarios and problem-solving related to well integrity and safety.

- Production Operations and Optimization: Gain a solid understanding of reservoir engineering principles, production optimization techniques, and artificial lift methods. Be ready to discuss practical challenges and solutions related to maximizing production efficiency and minimizing downtime.

- Pipeline and Transportation Standards: Learn about pipeline design, construction, and operation standards, including safety protocols and leak detection systems. Consider the practical implications of pipeline integrity management and regulatory compliance.

- Materials and Corrosion Control: Understand the selection of materials suitable for oil and gas applications, considering factors like corrosion resistance and environmental impact. Be able to discuss practical case studies involving material failure analysis and corrosion mitigation strategies.

- Measurement and Data Management: Familiarize yourself with industry-standard measurement practices and data acquisition systems. Demonstrate your ability to analyze production data, identify trends, and make informed decisions based on data analysis.

Next Steps

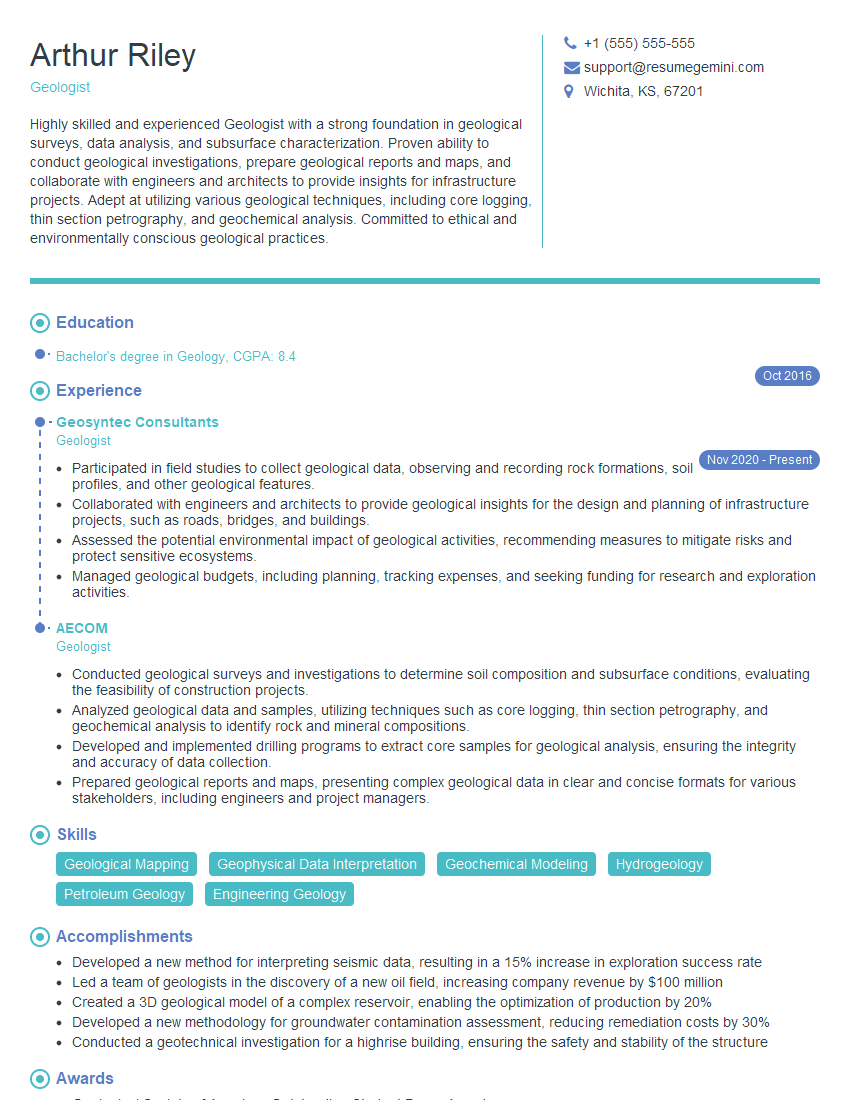

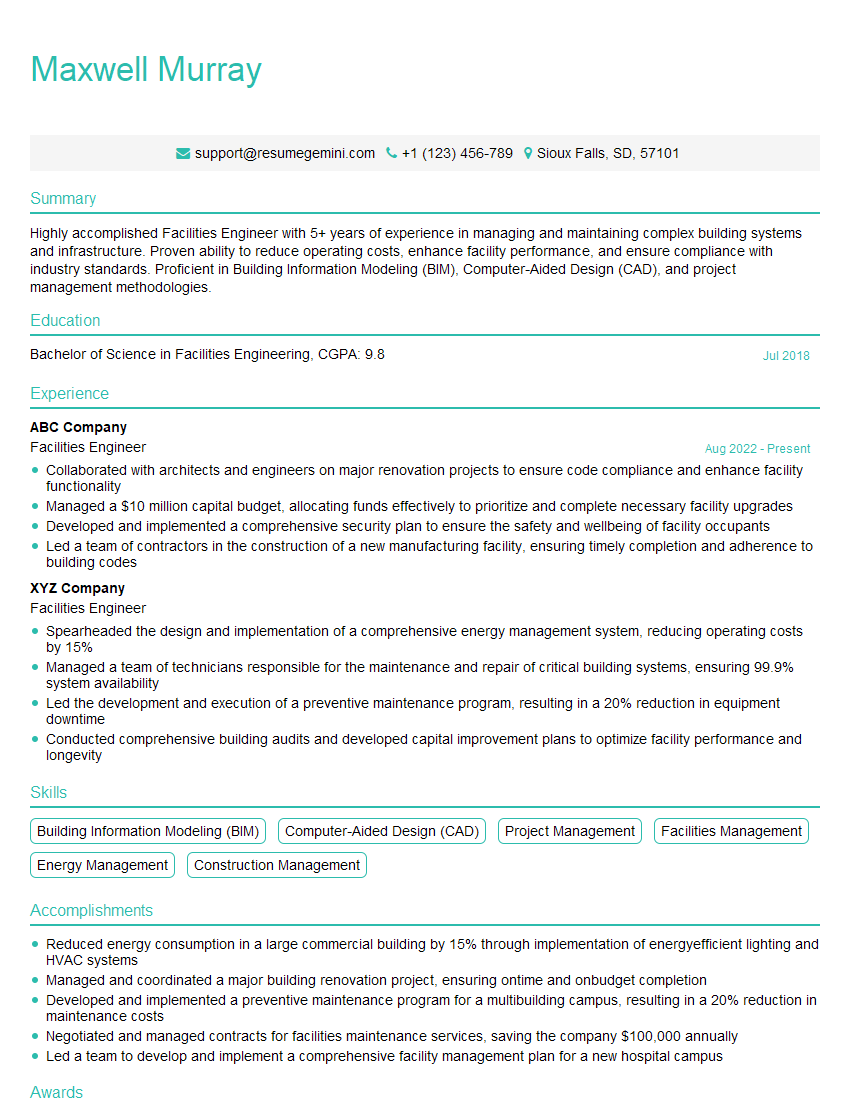

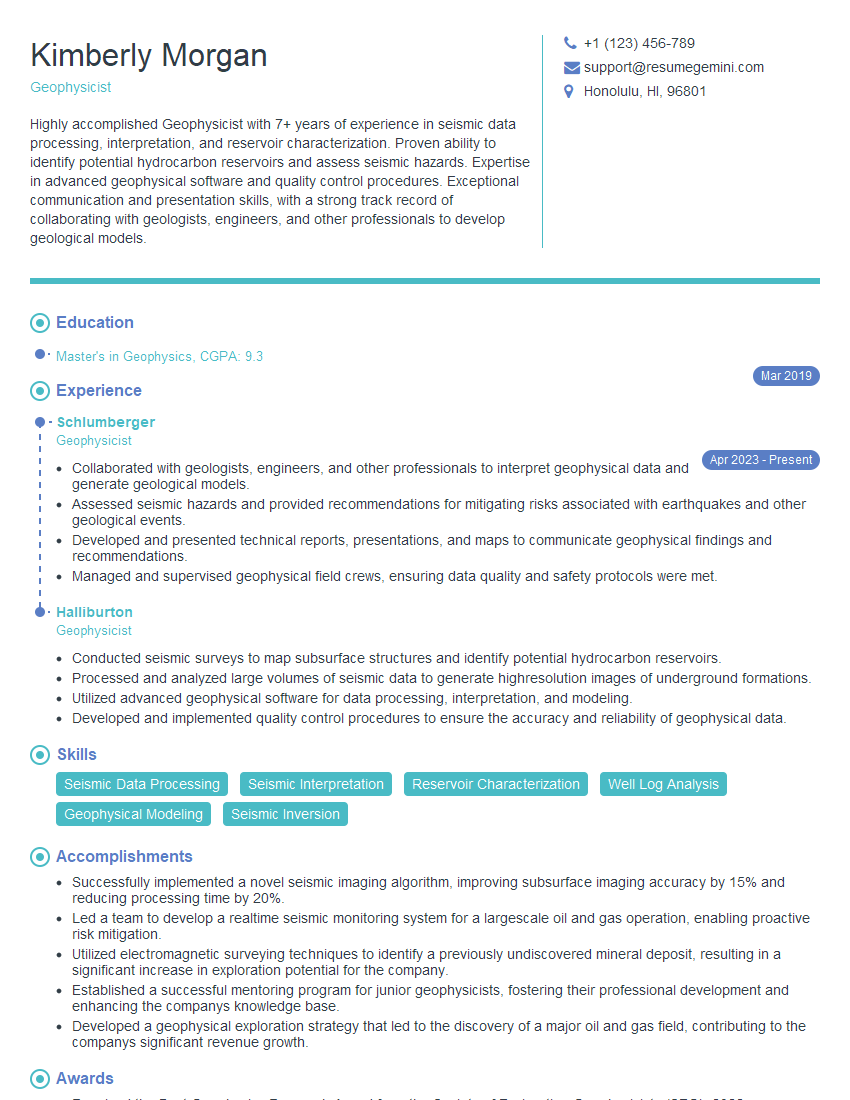

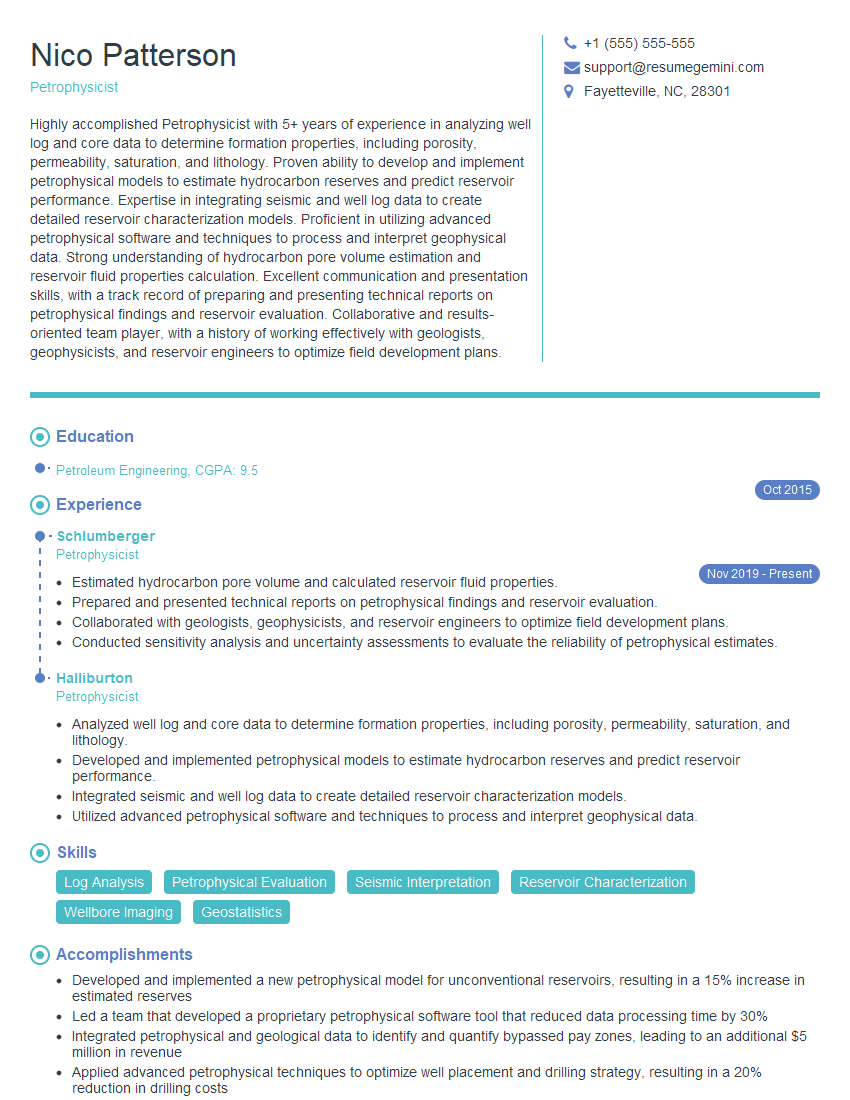

Mastering Oil and Gas Industry Standards is crucial for career advancement in this dynamic sector. A deep understanding of these standards demonstrates your commitment to safety, efficiency, and regulatory compliance – highly sought-after qualities by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your knowledge and experience effectively. ResumeGemini can significantly enhance your resume-building process, providing tools and resources to craft a professional and impactful document that catches the eye of recruiters. Examples of resumes tailored to showcase expertise in Oil and Gas Industry Standards are available through ResumeGemini, helping you present your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good