The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Pattern development and customization interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Pattern development and customization Interview

Q 1. Explain the difference between a sloper and a block pattern.

The terms ‘sloper’ and ‘block pattern’ are often used interchangeably, but there’s a subtle difference. A sloper is a basic, foundational pattern that’s highly customized to fit a specific individual’s body measurements. It’s essentially a ‘blank canvas’ for creating various garment styles. Think of it as a personalized template. A block pattern is more of a generic, standardized pattern representing a particular garment style (e.g., a basic bodice or skirt block). While a block pattern can be altered for a better fit, it’s not as precisely tailored to one person as a sloper. In essence, a sloper is a highly refined block pattern tailored to an individual. Consider this analogy: a sloper is like a perfectly fitted dress form, while a block pattern is like a standard-sized mannequin—you might adapt it, but it won’t be perfectly tailored to every body.

Q 2. Describe your experience with various pattern-making software (e.g., Optitex, Gerber, CLO).

I have extensive experience with several industry-standard pattern-making software packages. My proficiency in Optitex includes creating, grading, and manipulating complex patterns for various apparel types, leveraging its advanced features for automating repetitive tasks. With Gerber, I’m adept at utilizing its integrated systems for streamlining the entire design-to-production pipeline, including marker making and nesting. Furthermore, I’m skilled in CLO 3D, particularly in its capabilities for 3D visualization and virtual fitting, which significantly reduces the need for physical prototypes and enables rapid iteration during the design process. For instance, using CLO 3D’s simulation tools, I recently identified and corrected a drape issue in a flowing maxi dress design before even cutting the fabric—saving both time and materials.

Q 3. How do you grade a pattern for different sizes?

Grading a pattern involves systematically scaling it up or down to create different sizes. This isn’t a simple matter of uniform scaling; it requires understanding how different body measurements change proportionally. There are several methods: manual grading (measuring and redrawing each size), which is time-consuming but allows for fine adjustments, and computer-aided grading (using software like Optitex or Gerber), which is much faster and more accurate for larger volume production. The process usually involves identifying key points on the original pattern (e.g., bust point, waistline), defining grading rules based on industry standards or brand specifications (e.g., a 1-inch increase in bust circumference for each size up), and applying these rules to the software or manually to create new patterns. For example, when grading a sleeve, I need to consider not only the overall sleeve length but also the changes in bicep circumference and cap height for a proper fit across different sizes.

Q 4. Explain your process for creating a pattern from a sketch or design.

My process for creating a pattern from a sketch begins with thorough analysis of the design. I start by identifying the garment’s basic structure (e.g., bodice, skirt, sleeve) and choosing an appropriate base block pattern. Then, I translate the design’s key features into technical drawings or draping notes. If I’m working from a flat sketch, I’ll carefully measure key dimensions and use those as reference points for manipulating the base block. Draped designs may require more intuitive manipulation. I then meticulously adjust the base block to match these dimensions and design details. The result is a refined pattern that closely reflects the original concept. For instance, when creating a pattern for a tailored jacket from a sketch, I will meticulously measure the lapel width, shoulder slope, and sleeve length to accurately translate the design onto the base pattern. This involves a series of incremental adjustments and repeated fittings on a toile (a test garment).

Q 5. What are some common challenges in pattern making and how do you overcome them?

Common challenges include achieving a precise fit, especially across various body types and sizes. Dealing with complex fabric draping, particularly with lightweight or flowing fabrics, presents another hurdle. Also, managing time constraints within project deadlines, and collaborating effectively with designers and production teams are frequent difficulties. To overcome these, I use a combination of techniques: meticulous measurements and fittings, using advanced software for grading and virtual prototyping, and maintaining detailed documentation throughout the entire process. For example, if I’m working with a particularly challenging fabric like silk charmeuse, I would use a muslin toile and allow ample time for fitting and adjustments, taking into consideration the inherent drape and stretch of the fabric.

Q 6. How do you ensure the accuracy of your patterns?

Accuracy is paramount. I employ several strategies to ensure pattern accuracy: precise measuring and consistent use of tools, careful checking of all pattern pieces against each other and against the original design, using industry-standard grading techniques, and creating and fitting toiles meticulously before cutting into the final fabric. Software like Gerber and Optitex provide additional checks and validations during the grading and nesting stages. Regular quality checks throughout the process are crucial. For example, if there’s a mismatch between the pattern pieces, I will go back to the original measurements and re-evaluate the cutting instructions. A well-made toile allows the identification of any fit issues before production, significantly reducing costly mistakes.

Q 7. Describe your experience with different fabric types and how they impact pattern making.

Different fabric types significantly influence pattern making. Woven fabrics (like cotton, linen, and wool) have a distinct grain and behave differently than knits (like jersey and rib). Knowing the fabric’s drape, stretch, and weight is vital. For example, a stiff fabric like canvas might require ease adjustments to prevent the garment from being too tight, while a stretchy knit might need negative ease. Lightweight, flowing fabrics like silk charmeuse demand careful consideration of drape and potential slippage. My experience with various fabrics, from delicate silks to heavy wools, allows me to make informed decisions about pattern adjustments, seam allowances, and construction techniques to achieve the desired silhouette and fit for the garment. I always test different fabrics and construction methods on a toile before committing to the final product.

Q 8. How do you handle fit issues during the pattern-making process?

Addressing fit issues is crucial in pattern making. It’s an iterative process, not a one-time fix. My approach involves a combination of careful measurements, understanding the body’s natural drape, and meticulous adjustments based on the muslin fitting.

- Initial Assessment: I start by analyzing the muslin fit on a body form or a live model. I note areas of tightness, looseness, pulling, or gapping. Detailed notes and sketches are vital.

- Graded Adjustments: Based on the fit issues, I make adjustments to the pattern pieces. These adjustments might include adding or subtracting seam allowance, pivoting darts, or changing the shape of specific areas (e.g., shoulders, bust, waist).

- Systematic Approach: I don’t make random adjustments. I use a systematic approach, understanding how each part of the garment interacts with the others. For example, altering the shoulder slope might necessitate adjustments to the armhole.

- Multiple Muslins: Often, more than one muslin is necessary. Each muslin allows for refined adjustments and confirms that a previous correction didn’t create a new problem.

- Understanding Fabric: The fabric itself greatly influences fit. A stable fabric will behave differently than a drapey fabric, necessitating different pattern adjustments.

For instance, if a bodice is too tight across the bust, I might add width to the pattern piece, but I’ll also assess if I need to readjust the shoulder width or the armhole depth to maintain balance and avoid creating other fit problems.

Q 9. Explain your understanding of ease and its application in pattern making.

Ease is the amount of extra fabric added to a pattern to make the garment comfortable and wearable. It accounts for the difference between the body’s measurements and the finished garment’s measurements. There are several types of ease:

- Ease for Movement: This ease allows for freedom of movement and prevents the garment from feeling restrictive. It’s particularly important for areas like armholes and sleeves.

- Design Ease: This is extra fabric that creates a specific style or drape. For example, a loose, flowing dress would have more design ease than a fitted sheath dress.

- Fitting Ease: This ease accounts for the fact that different body shapes exist and the pattern must be forgiving to create a comfortable garment.

Application of ease varies greatly depending on the garment type and desired fit. A tailored jacket will have minimal ease, while a relaxed tunic will have significant ease. It’s crucial to understand the distinction between the types of ease and to apply them correctly to create the intended silhouette. For example, in a tailored shirt, the ease is carefully calculated to maintain a clean fit. But for a flowy blouse, more ease is needed to create the desired drape and to avoid making it feel tight on the wearer.

Q 10. Describe your experience with different pattern-making methods (e.g., draping, flat pattern making).

I’m proficient in both draping and flat pattern making, understanding that each method has strengths and weaknesses, making them suitable for different design situations.

- Draping: Draping is a three-dimensional method where fabric is manipulated directly on a dress form to create the desired shape. It’s excellent for creating unique, sculptural designs and for achieving a perfect fit on a specific body type. It allows for intuitive shaping, but it can be time-consuming and less reproducible. A recent project involved draping a unique asymmetrical bodice for a wedding dress. The drape gave me precise control over the silhouette and flow of the fabric.

- Flat Pattern Making: This is a two-dimensional method involving manipulating pattern pieces on a flat surface. It’s more precise and easily reproducible, making it ideal for mass production. It allows for precise measurements and calculations, making it easier to adjust patterns for different sizes. Flat pattern making formed the basis of my work on a recent production run for a line of children’s pants.

Often, a combination of both methods is used. For instance, I might drape a prototype to establish the basic design and then use flat pattern making to refine and grade the pattern for multiple sizes.

Q 11. How do you create a pattern for a garment with complex design details?

Creating patterns for complex garments requires a methodical approach that breaks down the design into manageable parts.

- Deconstruction: I start by deconstructing the design. This involves identifying the basic garment components (e.g., bodice, skirt, sleeves) and any additional design elements (e.g., pleats, ruffles, yokes).

- Individual Pattern Pieces: Each component is then developed as an individual pattern piece. Complex details might require multiple pattern pieces to accurately capture the design. For instance, a princess-seam dress requires constructing several pieces to achieve that specific silhouette.

- Testing and Refinement: Multiple muslins are created to test the fit and ensure all components work together harmoniously. Each muslin serves as a step toward refinement.

- Understanding Design Principles: A deep understanding of design principles like balance, proportion, and drape is critical for successful execution. One instance involved a pattern for a jacket with elaborate sleeves that involved multiple notches and seams for a fitted yet comfortable garment.

For example, a garment with a complex draped neckline would initially involve draping the neckline on a dress form, then transferring the shape to paper patterns, and refining them through multiple iterations of muslin testing. The overall process demands precision, patience, and an understanding of fabric behavior.

Q 12. How familiar are you with industrial sewing techniques and their impact on pattern design?

My familiarity with industrial sewing techniques is extensive and directly impacts my pattern design choices. Understanding how a garment will be constructed influences the design and pattern elements.

- Seam Allowances: I carefully consider seam allowances based on the chosen sewing technique. Different seams (e.g., French seams, flat felled seams) require different seam allowances.

- Notions: The pattern must account for notions like zippers, buttons, and interfacing, which affect the fit and construction. The placement of buttonholes and other notions needs to be planned before I start creating the pattern.

- Production Efficiency: I design patterns for efficient production. This might involve minimizing the number of pattern pieces, using simpler seam constructions, or incorporating techniques that minimize fabric waste.

- Equipment Limitations: I consider the limitations of industrial sewing equipment. For example, complex curves might need to be simplified to make them workable on industrial machines.

For instance, if a garment uses a coverstitch machine for a clean finish, the seam allowance needs to be adjusted accordingly to accommodate the stitch width. Understanding these intricacies leads to a pattern that is not only aesthetically pleasing but also practical and efficient for industrial production.

Q 13. What is your experience with creating patterns for different garment styles (e.g., dresses, jackets, trousers)?

My experience encompasses a wide range of garment styles. I have created patterns for dresses, jackets, trousers, skirts, and numerous other items. The approach varies depending on the garment’s style and fit requirements.

- Dresses: Dress patterns can range from simple A-line shapes to complex designs incorporating multiple seams, darts, and embellishments. The fit considerations include bust, waist, and hip measurements.

- Jackets: Jacket patterns require precise measurements and attention to detail to create a well-fitting, structured garment. Understanding shoulder construction and lining techniques is crucial.

- Trousers: Trouser patterns necessitate careful consideration of the rise, inseam, and leg width to ensure a comfortable and well-proportioned fit. Different styles like skinny, straight, or wide-leg pants require specific pattern adjustments.

Each garment type requires different considerations. For example, a tailored jacket would need a different approach, focusing on precise fitting and structured design elements, compared to a flowing maxi dress, which would emphasize draping and ease.

Q 14. Explain your process for creating a muslin.

Creating a muslin is a critical step in pattern making, allowing for testing of the fit and design before cutting into the final fabric. It’s essentially a test garment made from a cheap, easily-manipulated fabric.

- Choosing the Fabric: Muslin is the traditional choice due to its inexpensive nature and ability to mimic the drape of various fabrics to some extent, providing an idea of the final look. However, other lightweight and inexpensive fabrics can be used.

- Cutting the Pattern: The pattern pieces are cut from the chosen fabric, adding seam allowances. It’s essential to mark all notches, grainlines, and other important markings from the pattern pieces.

- Constructing the Muslin: The muslin is then sewn together, using simple basting stitches. I tend to avoid using a sewing machine unless absolutely necessary, as hand stitching allows for easier adjustment and modification.

- Fitting and Adjustments: The muslin is then fitted on a dress form or a live model. Any needed adjustments are noted, and the muslin is taken apart.

- Refining the Pattern: The pattern pieces are adjusted based on the muslin fitting. A new muslin might be created to check if the adjustments were successful. This process repeats until a satisfactory fit is achieved.

The muslin is not merely a prototype; it acts as a communication tool, allowing for feedback and refinement of the design. It’s where fit issues are addressed systematically, before committing to the final fabric.

Q 15. How do you use a muslin to make adjustments to a pattern?

A muslin is a crucial tool in patternmaking. It’s a test garment made from inexpensive fabric, like muslin or calico, sewn using your pattern. It allows you to check the fit and make adjustments *before* cutting into your expensive final fabric. Think of it as a ‘dress rehearsal’ for your garment.

To use a muslin effectively, first, cut and sew the muslin following your pattern instructions precisely. Then, try it on. Note any areas that are too tight, too loose, need more or less length, or have poor drape. These areas might include the bust, waist, hips, shoulders, sleeves, or overall length.

Making adjustments involves several steps:

- Pinning: Pin directly onto the muslin to mark the areas needing alteration. For example, you might pin to take in the side seams if the garment is too loose.

- Marking: Use tailor’s chalk or a fabric marker to clearly indicate the adjustments on the muslin. This helps to visually guide your pattern adjustments.

- Unpicking and Redrafting: Carefully unpick seams and sections of the muslin where adjustments are necessary. Use these markings to redraw the pattern pieces on paper, adding or subtracting seam allowances as required. This process might involve adding or removing darts, changing the seam lines, or shifting pattern pieces.

- Creating a new Muslin (if needed): Sometimes, multiple iterations of muslin fitting are necessary, especially with complex designs. After making your pattern adjustments, cut a new muslin to confirm the changes have solved the fit issue.

For example, if the shoulder seam is too tight, you would unpick the seam, spread it open, add a small wedge of fabric to the pattern piece, and re-sew. Careful attention to detail is crucial to ensuring a well-fitting final garment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you work with a design team to ensure pattern accuracy and design integrity?

Collaboration is key in pattern development. Working effectively with a design team ensures that the final product aligns with the design vision while maintaining technical accuracy. My approach involves:

- Clear Communication: Regular meetings and clear communication channels are essential. We use shared digital platforms to track progress and feedback.

- Shared Goals and Understanding: The entire team needs a shared understanding of the design brief, target market, and technical requirements. This prevents misinterpretations and ensures everyone is working towards the same objective.

- Iterative Reviews: We typically review pattern prototypes multiple times throughout the process – design review, technical review, and fit review. The muslin fitting process is integral to this, allowing for early identification and resolution of issues.

- Constructive Feedback: The design team provides feedback on the aesthetic appeal, while I focus on the technical aspects, such as fit, construction, and grading. This is a continuous feedback loop, ensuring pattern accuracy and maintaining design integrity.

- Documentation: Meticulous documentation of all pattern changes, specifications, and design decisions is maintained. This is vital for production and archiving purposes.

For instance, if the designer requests a specific drape on a sleeve, we work together to explore different pattern manipulation techniques to achieve that specific look without compromising the structural integrity or fit of the garment.

Q 17. Explain your experience with pattern manipulation techniques.

My experience with pattern manipulation techniques is extensive. I’m proficient in a range of techniques, including:

- Draping: This involves creating a pattern directly on a dress form, allowing for highly customized shapes and designs.

- Grading: Scaling patterns to different sizes consistently and accurately.

- Slash and Spread: A technique used to add or remove fullness in specific areas, such as widening or narrowing a sleeve.

- Pivot and Shift: Altering the position and shape of pattern pieces to achieve desired design features.

- Adding and Removing Darts: Manipulating darts allows for adjustments to fit and shaping.

- Ease Adjustment: Adding or subtracting ease (the extra fabric allowance for comfort and movement) is critical for a comfortable and well-fitting garment.

I have used these techniques on numerous projects, from simple alterations to highly complex designs. For example, I recently used the slash and spread technique to add fullness to a skirt while maintaining the original waistline. The result was a beautifully flared skirt with a clean, professional finish.

Q 18. How familiar are you with different types of pattern markings and their importance?

I am very familiar with various pattern markings and their importance. These markings are essential for accurate garment construction and ensure consistency during production. Examples include:

- Seam Allowances: The extra fabric added to seam lines for stitching, providing a finished seam.

- Notch Marks: Small markings indicating matching points on different pattern pieces, ensuring accurate alignment during assembly.

- Grainline Markings: Indicate the direction of fabric grain which affects the drape and stability of the garment.

- Darts: Triangular shaped folds of fabric used to shape the garment, such as darts at the bust, waist, or shoulder.

- Button and Buttonhole Markings: These are crucial for precise button placement.

- Hemline Markings: Clearly indicate the desired hemline on the garment.

The correct interpretation and execution of these markings are fundamental for creating a professional-looking and well-fitting garment. Ignoring them can lead to poorly constructed, ill-fitting garments.

Q 19. How do you manage your time effectively when working on multiple pattern projects?

Managing multiple pattern projects effectively requires a structured approach. I utilize a project management system combining several key strategies:

- Prioritization: I prioritize projects based on deadlines, importance, and complexity. This allows me to focus on the most pressing tasks first.

- Task Breakdown: I break down large projects into smaller, manageable tasks. This makes it easier to track progress and delegate if needed.

- Time Blocking: I allocate specific time blocks for each project, minimizing context switching and maximizing productivity. This helps prevent feeling overwhelmed.

- Project Management Software: I use project management software (like Asana or Trello) to track tasks, deadlines, and progress across all projects. This provides a visual overview of my workload.

- Regular Reviews: I schedule regular reviews to assess progress, identify potential roadblocks, and make adjustments to my schedule as needed.

By implementing this system, I can efficiently manage several projects simultaneously while ensuring timely delivery and maintaining a high standard of quality.

Q 20. Describe your process for documenting pattern adjustments and changes.

Documenting pattern adjustments and changes is critical for accuracy and reproducibility. My process involves:

- Detailed Notes: I maintain detailed notes on all pattern alterations. This includes specifying the location, type, and amount of adjustment. For example, “Reduced side seam by 1 cm at hip.”

- Pattern Marking: I use a consistent system of markings directly on the paper patterns. This is often color-coded to indicate the type of adjustment.

- Digital Documentation: I scan and save all adjusted patterns digitally, along with the accompanying notes. This allows easy access and version control.

- Spreadsheet Tracking: For larger projects or production runs, I use a spreadsheet to track all pattern revisions and their corresponding changes.

- Grading Sheets: I keep precise grading sheets which detail how adjustments are applied across different sizes.

This systematic approach minimizes errors, ensures consistency across multiple sizes, and simplifies the process of recreating the pattern in the future.

Q 21. How do you maintain accuracy and consistency when grading patterns?

Grading patterns involves accurately scaling them to different sizes while maintaining proportions and design integrity. Accuracy and consistency are paramount. My approach includes:

- Using Grading Software: I utilize specialized grading software which automates much of the process and helps maintain consistency.

- Understanding Garment Construction: A thorough understanding of how the garment is constructed is essential for accurate grading. Some areas require more adjustment than others.

- Reference Charts: I use reference charts that specify the amount of increase or decrease for each measurement across sizes. These charts are customized to specific body shapes and garment styles.

- Test Grading: I always test grade a small number of sizes to verify accuracy before mass production.

- Regular Checks: I regularly check the graded patterns to ensure that the proportions are correct across all sizes, verifying the consistency of critical design details such as darts and seam lines.

By following these steps, I ensure the final graded patterns maintain accuracy and consistency, resulting in well-fitting garments across the entire size range.

Q 22. How do you handle feedback from fit sessions?

Handling feedback from fit sessions is crucial for refining patterns and achieving the desired garment fit. It’s not just about fixing mistakes; it’s about understanding the why behind the issues. My approach involves a systematic process:

- Careful Documentation: I meticulously record all feedback, including specific measurements, photographs, and sketches of areas needing adjustment. This ensures no detail is overlooked.

- Identifying Patterns: I analyze the feedback to identify recurring issues. Are there consistent problems in the shoulder area across multiple fit models? This helps to pinpoint systematic pattern errors rather than just individual anomalies.

- Prioritize Adjustments: I prioritize adjustments based on their impact on the overall fit and aesthetic. Sometimes a small adjustment in one area can dramatically improve the overall look.

- Iterative Process: I rarely make large, drastic changes. Instead, I make small, incremental adjustments, testing each one before moving on. This allows for greater control and reduces the risk of introducing new problems.

- Communication: Open communication with the fit model and design team is key. I explain my proposed adjustments, the rationale behind them, and any potential implications.

For example, if feedback consistently points to tightness across the bust, I might add a small amount of ease in the pattern’s bust area, perhaps by adjusting the front bodice piece. I’d then check the fit again, making small adjustments until the bust area fits properly without affecting other areas of the garment.

Q 23. What are some common mistakes to avoid when making patterns?

Common mistakes in pattern making often stem from a lack of attention to detail or fundamental understanding. Some critical errors to avoid include:

- Inaccurate Measurements: Using inaccurate measurements from the sloper or base pattern is a foundational error leading to significant fitting problems. Always double-check your measurements.

- Ignoring Grainlines: Neglecting the grainlines can cause distortion in the finished garment, affecting drape and shape. Fabric grain should align properly with body parts to maintain even stretch.

- Insufficient Ease: Not adding enough ease (extra fabric for comfort and movement) can result in a garment that’s too tight and uncomfortable. Ease values vary based on garment style and fabric.

- Incorrect Grading: Errors in grading patterns for different sizes are common. Inconsistent grading will cause size variations that affect fit. A proper understanding of grading rules and methods is crucial.

- Neglecting Seam Allowances: Forgetting to add seam allowances can lead to a garment that’s too small.

- Not Testing on a Muslin: Skipping the muslin stage prevents early detection of pattern flaws and makes costly corrections on the final fabric much more likely.

Consider this example: Forgetting to add seam allowances means the final garment will be several centimeters smaller than intended, rendering it unwearable. A careful check of all measurements and allowances is always a necessary part of my workflow.

Q 24. How do you stay up-to-date with the latest trends and techniques in pattern making?

Staying current in pattern making requires a multifaceted approach:

- Industry Publications: I regularly read trade journals and magazines focused on fashion design and garment construction. These publications often feature articles on new techniques, software, and design trends.

- Workshops and Seminars: Attending workshops and seminars offered by experienced pattern makers provides hands-on learning and networking opportunities.

- Online Courses and Tutorials: Many online platforms offer comprehensive courses and tutorials on advanced pattern-making techniques and software applications.

- Networking: Connecting with other pattern makers through online communities and industry events facilitates knowledge sharing and exposes me to diverse perspectives.

- Following Influencers: Following influential designers and pattern makers on social media provides insights into current trends and innovative techniques.

For instance, I recently attended a workshop on advanced draping techniques which significantly enhanced my ability to create innovative and complex designs.

Q 25. Explain your experience with 3D pattern making software and its advantages.

I have extensive experience with 3D pattern making software such as CLO3D and Optitex. These tools offer significant advantages over traditional methods:

- Speed and Efficiency: 3D software dramatically accelerates the pattern-making process, allowing for quicker prototyping and iteration.

- Visualization: The ability to visualize the garment in 3D before cutting fabric helps identify potential fit issues early on.

- Customization: 3D software enables precise customization of patterns based on individual body measurements and design specifications.

- Grading: Automated grading features streamline the process of creating patterns for multiple sizes.

- Simulation: Some software offers fabric simulation, allowing you to see how different fabrics will drape on the 3D model.

For example, when working on a complex design with multiple layers and intricate details, using 3D software allows me to address potential fit and construction problems that would be difficult, if not impossible, to identify using traditional methods. This significantly reduces waste and ensures a higher-quality final product.

Q 26. Describe your experience with digital pattern making workflow.

My digital pattern making workflow integrates both traditional techniques and digital tools for optimal efficiency and precision. It typically follows these steps:

- Digital Design: I start by sketching the design digitally, often using Adobe Illustrator or similar software. This ensures consistency and accuracy throughout the process.

- Base Pattern Development: This could be either using existing base patterns modified and manipulated digitally, or creating them using a 3D pattern making software.

- 3D Modeling and Simulation: The 2D patterns are then imported into 3D software (CLO3D, Optitex, etc.) for 3D modeling. I use this to visualize the fit and make adjustments before cutting the fabric.

- Pattern Adjustments and Refinements: Based on the 3D simulation, I make necessary pattern adjustments digitally, ensuring accuracy.

- Output and Plotting: Once the pattern is finalized in the 3D software, I use the software to output the finalized, graded patterns to be printed and cut.

- Muslin Fitting: This stage remains vital, even in digital workflow, to ensure the pattern fits the specific requirements of the target customer or model.

This digital workflow allows for rapid iterations and minimizes material waste. The integration of digital tools and traditional techniques offers the best of both worlds: the precision of digital tools combined with the tactile feel of working with physical fabric.

Q 27. How do you handle unexpected challenges during pattern making?

Unexpected challenges are a given in pattern making. My approach to handling them focuses on systematic problem-solving:

- Identify the Root Cause: The first step is to carefully analyze the problem, identify its root cause, and determine its impact on the overall garment.

- Research and Explore Solutions: I research potential solutions, consulting resources such as textbooks, online forums, and experienced colleagues.

- Experiment and Iterate: I experiment with different solutions, testing each one before proceeding to the next. This iterative approach allows me to find the most effective solution with minimal impact on the project timeline.

- Seek Assistance When Needed: If I encounter a problem beyond my expertise, I don’t hesitate to seek help from experienced pattern makers or colleagues.

- Document the Solution: Once a solution is found, I document it for future reference, learning from mistakes and avoiding repeating them.

For example, I once encountered an unexpected issue with fabric shrinkage during the first muslin fitting. By carefully analyzing the issue, I was able to determine the cause and adjust the pattern accordingly, preventing potential problems during production.

Q 28. What are your strategies for ensuring patterns are production-ready?

Ensuring production-ready patterns requires meticulous attention to detail and a thorough understanding of manufacturing processes:

- Clear and Concise Pattern Markings: All pattern pieces must be clearly marked with grainlines, notches, and seam allowances. Any special instructions should be clearly noted.

- Accurate Grading: Patterns must be accurately graded to ensure consistent sizing across the size range. Inconsistencies during production lead to waste and rework.

- Comprehensive Technical Specifications: Detailed technical specifications should be included, indicating fabric type, quantity, and construction details. This ensures that the garment can be consistently reproduced.

- Testing and Quality Control: Conducting thorough testing on the production samples is crucial to identify and address potential issues before mass production.

- Pattern Reviews and Approvals: Multiple reviews and approvals from pattern makers, designers, and production personnel ensure that everyone is on the same page and the patterns are ready for production.

For instance, I always create a detailed technical specification sheet which includes the exact measurements of each pattern piece, grainline direction, and any special instructions for construction. This ensures that the production team is able to understand and replicate the pattern accurately and efficiently.

Key Topics to Learn for Pattern Development and Customization Interview

- Pattern Construction Techniques: Understanding various methods for creating base patterns (e.g., sloper, drafting, draping), their strengths and weaknesses, and selecting the appropriate method for a given design.

- Pattern Alteration and Grading: Mastering techniques for adjusting patterns to fit different body types and sizes, including grading for production runs. Practical application includes using both manual and digital grading methods.

- Software Proficiency: Demonstrating familiarity with industry-standard pattern design software (e.g., Adobe Illustrator, CLO3D, Optitex). This includes showcasing skills in digital pattern making, manipulation, and output.

- Fabric Selection and its Impact: Understanding how fabric properties (drape, stretch, weight) influence pattern design and construction. Practical application includes knowing how to adjust patterns to accommodate different fabrics.

- Pattern Testing and Refinement: Understanding the iterative process of creating and testing prototypes, making adjustments based on fit and drape, and documenting the process.

- Customization Techniques: Exploring different approaches to customizing base patterns to create unique designs, including adding design details, manipulating seams, and incorporating different construction methods.

- Understanding Design Principles: Applying fundamental design principles (e.g., balance, proportion, silhouette) to create well-proportioned and aesthetically pleasing patterns.

- Problem-Solving and Troubleshooting: Demonstrating the ability to identify and resolve common pattern-making challenges (e.g., fit issues, construction difficulties), using both creative and technical problem-solving approaches.

Next Steps

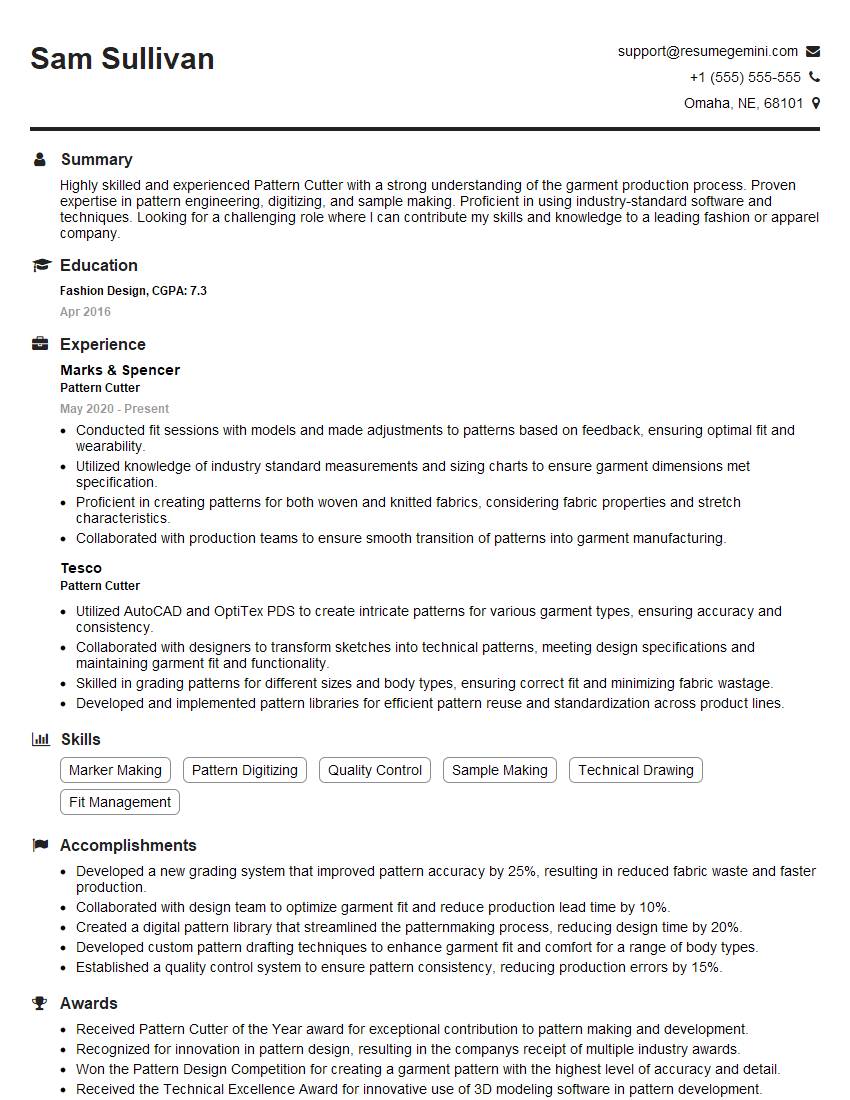

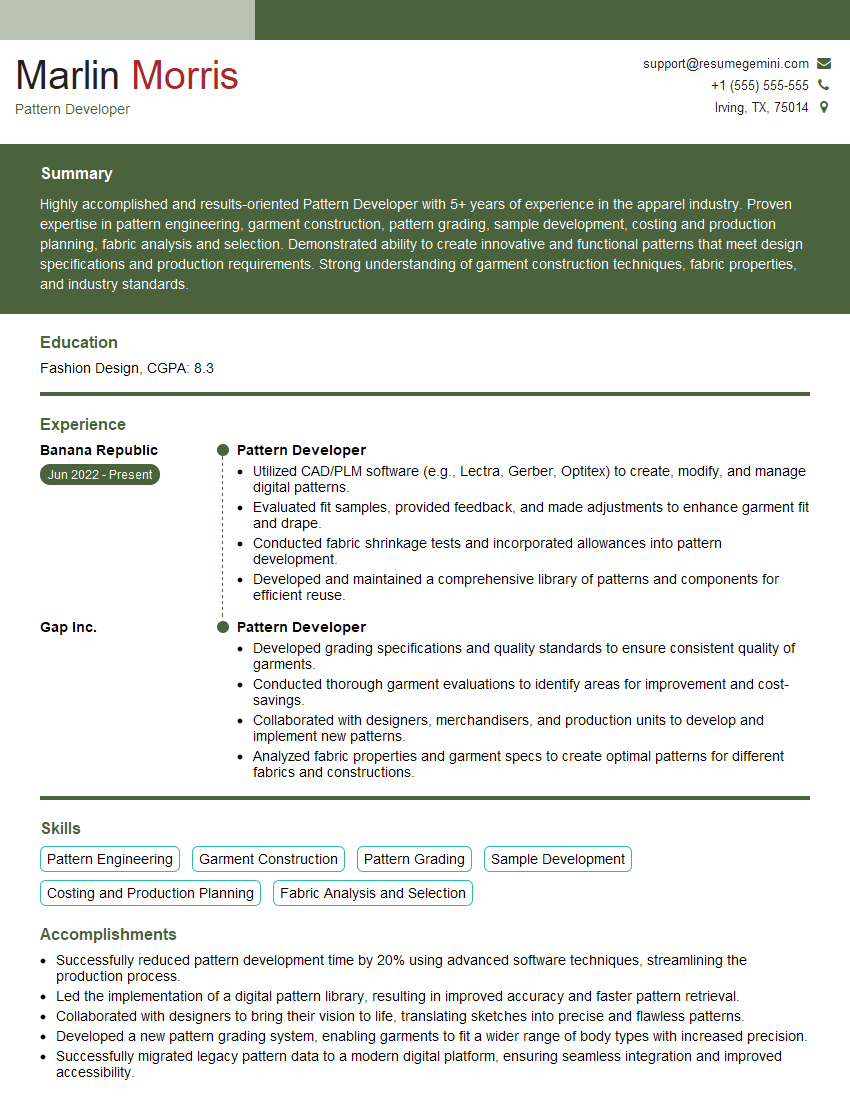

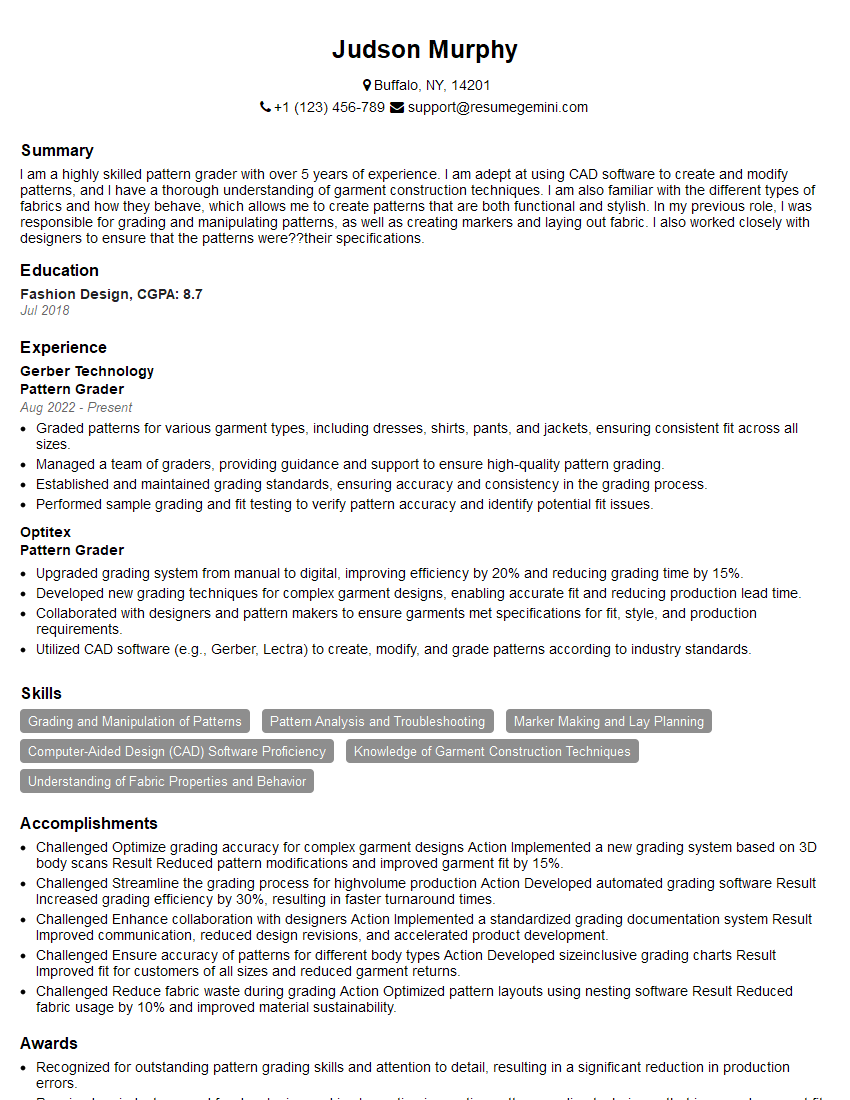

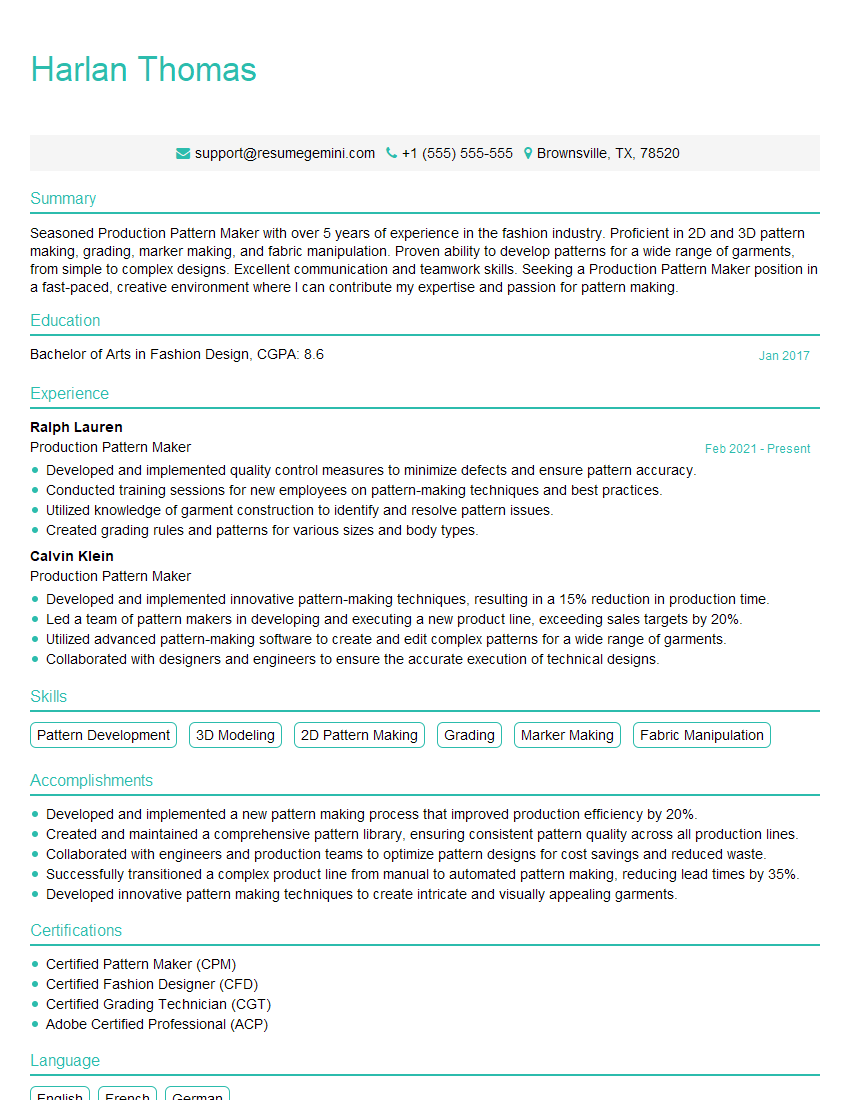

Mastering pattern development and customization is crucial for advancing your career in fashion design, apparel manufacturing, or related fields. A strong understanding of these skills will open doors to exciting opportunities and higher earning potential. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to pattern development and customization are available within ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good