Are you ready to stand out in your next interview? Understanding and preparing for Wool Production Management interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Wool Production Management Interview

Q 1. Describe the different breeds of sheep suitable for wool production and their respective fiber characteristics.

Choosing the right sheep breed is crucial for successful wool production. Different breeds offer unique fiber characteristics impacting the final product’s quality and value. Let’s explore some key examples:

- Merino: Renowned for its fine, soft, and crimpy wool, Merino sheep produce fibers with high micron counts (finer diameter), leading to luxurious fabrics. Their fleece is also known for its excellent length and evenness, making it highly sought after in the textile industry. Think of the softest cashmere sweater – that often uses Merino wool.

- Rambouillet: A dual-purpose breed, Rambouillet sheep produce a medium-fine wool with good length and strength. They’re known for their hardiness and adaptability, making them suitable for a wider range of climates. This makes them a cost-effective choice for producers.

- Corriedale: This breed offers a coarser wool than Merino or Rambouillet but is still of good quality. Its strength and durability make it ideal for outdoor clothing and carpets. Think of sturdy outdoor jackets; Corriedale wool might be the fabric.

- Dorset: Known for its high fertility and prolificacy, Dorset sheep produce medium wool suitable for a range of applications. They’re often chosen for their ability to lamb out of season.

The choice of breed depends on factors such as climate, market demand, and production goals. For instance, a producer aiming for high-value luxury fabrics might opt for Merino, whereas one focused on producing durable workwear might choose Corriedale.

Q 2. Explain the process of shearing sheep, from preparation to post-shearing care.

Shearing is a crucial step in wool production, requiring skill and care to minimize stress on the sheep and maximize wool yield. The process typically follows these steps:

- Preparation: Sheep are usually held in a pen for a few days prior to shearing to ensure they’re calm and not stressed by sudden movement. This reduces the risk of injury to both sheep and shearers.

- Shearing: Experienced shearers use specialized shears, either hand-powered or electric, to quickly and efficiently remove the fleece in one continuous piece. The process involves careful handling to avoid cutting the sheep’s skin.

- Classing: Immediately after shearing, the fleeces are visually inspected and classified based on factors like fiber length, fineness, and color (we’ll discuss classing in more detail later).

- Packaging: The classified fleeces are then rolled and packaged, typically in burlap bags, for transport to the processing facility.

- Post-Shearing Care: After shearing, sheep need to be checked for any cuts or injuries and treated accordingly. Providing a clean and comfortable environment is vital to help the sheep recover quickly.

Using proper shearing techniques minimizes stress on the sheep and prevents damage to the fleece, ultimately maximizing wool yield and quality. Investing in proper equipment and training shearers are important aspects for a successful shearing operation.

Q 3. Detail the various methods used for wool classing and grading.

Wool classing and grading are essential processes that determine the value and application of wool. It involves sorting the fleece based on various characteristics.

Methods:

- Visual Assessment: This is the primary method, where experienced classers visually assess the fleece’s characteristics, including fiber length, diameter (micron count), strength, color, and cleanliness. This requires trained eyes to identify subtle variations.

- Instrumental Measurement: Advanced technology like optical sorters and fiber diameter measuring instruments provide objective data on fiber properties. These tools can analyze large quantities of wool quickly and accurately, supplementing visual assessment.

- Sampling: Representative samples are taken from each fleece to assess its overall quality. This helps in assigning the fleece to specific grades and categories.

Grading systems: Wool is graded based on several systems, including the Australian Wool Testing Authority (AWTA) system, which is widely recognized internationally. These systems use standardized criteria to define different grades based on factors like fiber diameter, length, strength, and color. For example, a finer micron count (smaller diameter) generally indicates a higher-quality wool.

Accurate classing and grading are crucial for maximizing wool value as it ensures that each fleece is processed and utilized according to its quality.

Q 4. What are the key factors affecting wool quality, and how can these be controlled?

Wool quality is influenced by several factors, and understanding how to control these factors is crucial for successful wool production:

- Breed: Different sheep breeds have inherent genetic differences impacting fiber diameter, length, and strength (as discussed earlier).

- Nutrition: A balanced diet rich in protein and energy is essential for wool growth. Nutritional deficiencies can lead to thinner fibers and reduced fleece weight.

- Health: Parasites and diseases can significantly affect wool quality. Regular health checks and parasite control are crucial.

- Climate: Harsh weather conditions can damage wool fibers and affect fleece quality. Providing shelter and managing environmental stresses can improve wool quality.

- Shearing Practices: Proper shearing techniques, as discussed previously, are crucial for maintaining fleece integrity and preventing damage.

- Farming Practices: Good pasture management, including appropriate grazing and rotation, helps maintain consistent wool quality. Avoiding practices that may cause staining or damage is equally important.

Controlling these factors involves implementing best practices in sheep husbandry, nutrition management, parasite control, and shearing. Regular monitoring of wool quality through testing and visual inspection also helps identify areas for improvement.

Q 5. Explain the different types of wool processing, including scouring, carding, and spinning.

Wool processing transforms raw fleece into usable fibers for various textile applications. The key stages include:

- Scouring: This process cleans the wool by removing dirt, grease (lanolin), and vegetable matter. Traditional methods use hot water and detergents, while modern methods employ sophisticated machinery for efficient and thorough cleaning.

- Sorting and Grading: After scouring, the wool is sorted and graded again to ensure consistent quality in the subsequent processing steps. This step reinforces quality control.

- Carding: This process aligns the fibers and removes short fibers and impurities to create a continuous web of fibers. This step prepares the wool for spinning.

- Spinning: The carded wool is twisted and drawn out to create a yarn. Different spinning techniques produce yarns with different properties, such as strength, thickness, and texture.

These processing steps must follow strict quality control procedures to maintain the fiber integrity and yield a superior product. Modern machinery enhances efficiency and consistency in these steps. The choice of processing method depends on the intended end-use of the wool (e.g., fine yarns for apparel vs. coarser yarns for carpets).

Q 6. Describe the various ways to store and handle wool to maintain its quality.

Proper storage and handling of wool are essential to maintain its quality and prevent damage. Here’s how:

- Clean and Dry Storage: Wool should be stored in a clean, dry, and well-ventilated area to prevent moisture buildup and mold growth. High humidity can lead to fiber degradation.

- Protection from Pests: Wool is susceptible to pest infestation. Proper pest control measures, including fumigation if necessary, are crucial to protect the wool from damage.

- Appropriate Packaging: Using breathable materials like burlap or appropriate plastic sheeting prevents moisture damage and allows for adequate airflow. Avoiding airtight containers is key.

- Avoid Direct Sunlight: Direct sunlight can fade wool’s color. Storing the wool in a dark and shaded area helps maintain its color and quality.

- Stacking and Handling: Proper stacking techniques, avoiding excessive pressure or crushing, prevent fiber damage. Handling wool gently prevents breakage.

Following these guidelines ensures that the wool maintains its quality and value throughout the storage period. Proper storage extends the lifespan and usability of the wool, resulting in minimized losses and maximized returns.

Q 7. How do you ensure compliance with industry standards and regulations for wool production?

Compliance with industry standards and regulations is paramount in wool production. This involves adherence to several key areas:

- Animal Welfare: Strict adherence to animal welfare guidelines is crucial. This includes proper handling, shearing practices, and health management to ensure the ethical treatment of sheep. Many certifications exist (like Responsible Wool Standard) that producers can obtain to showcase this compliance.

- Traceability: Maintaining accurate records of wool production, from farm to processing, is essential for traceability. This ensures accountability and allows for tracking any potential issues throughout the supply chain.

- Environmental Compliance: Meeting environmental regulations regarding waste management, water usage, and land management is crucial. Sustainable practices are becoming increasingly important in wool production.

- Quality Standards: Adhering to established wool quality standards, such as those set by AWTA, ensures consistent quality and grading across the industry. This builds trust with buyers.

- Labor Standards: Compliance with labor laws and ethical employment practices is crucial. This includes fair wages, safe working conditions, and respect for worker rights.

Regular audits, certifications, and ongoing training programs are vital in maintaining compliance with all relevant standards and regulations. Proactive measures to identify and address potential non-compliance issues are essential for maintaining a strong reputation and ensuring the long-term sustainability of the wool industry.

Q 8. What are the common pests and diseases affecting sheep, and how do you manage them?

Managing sheep health is crucial for optimal wool production. Common pests include blowflies (causing flystrike), lice, and mites, while diseases range from footrot and pneumonia to internal parasites like worms. Effective management requires a multi-pronged approach.

- Prevention: This is key. Regular drenching (with appropriate veterinary guidance to avoid resistance) controls internal parasites. Strategic shearing minimizes flystrike risk by improving ventilation and reducing dampness. Good pasture management, including rotational grazing, helps prevent parasite build-up.

- Early Detection: Regular flock inspections are essential. Identifying problems early allows for swift intervention, minimizing losses. Look for signs like lameness, coughing, listlessness, or unusual skin conditions.

- Treatment: Treatment depends on the specific pest or disease. This may involve topical treatments for parasites, antibiotics for bacterial infections, or parasite control measures. Always consult a veterinarian for diagnosis and treatment recommendations. For example, footrot often requires trimming and topical medication; pneumonia necessitates antibiotics and supportive care.

- Biosecurity: Preventing the introduction of new diseases is vital. Quarantine new sheep before integrating them into the flock. Maintain good hygiene practices in handling facilities.

Imagine a scenario where you notice several sheep exhibiting lameness. By promptly identifying this as a potential footrot outbreak, immediate treatment can prevent the spread and minimize production losses. This proactive approach, integrating prevention, early detection, and treatment, is crucial for healthy, productive sheep.

Q 9. How do you manage the nutritional needs of sheep for optimal wool production?

Nutritional management is paramount for maximizing wool yield and quality. Sheep require a balanced diet containing sufficient energy, protein, and essential minerals for fleece growth and overall health. The nutritional requirements vary depending on the breed, age, physiological state (pregnancy, lactation), and season.

- Pasture Management: High-quality pasture provides a significant portion of the sheep’s nutritional needs. Rotational grazing ensures optimal pasture utilization and reduces parasite build-up. Supplementing with appropriate fertilizers ensures nutrient-rich forage.

- Supplements: Depending on pasture quality and sheep requirements, supplements may be necessary. These can include protein supplements (e.g., lupins, soybean meal), energy supplements (e.g., grain), and mineral supplements (e.g., salt licks containing copper, selenium, and zinc). Careful monitoring of supplement intake is vital to avoid overfeeding.

- Monitoring Body Condition: Regularly assessing body condition score (BCS) helps determine nutritional status. A BCS scale (usually 1-5) helps gauge fat reserves. Maintaining a healthy BCS is crucial for wool production and reproduction.

- Water Availability: Access to clean, fresh water is crucial, especially during hot weather. Dehydration negatively impacts wool production and overall health.

For example, during lactation, ewes have increased nutritional demands to support milk production. Providing high-quality pasture supplemented with protein and energy ensures optimal milk production and minimizes negative impact on fleece quality.

Q 10. Explain the importance of sustainable practices in wool production.

Sustainable practices are essential for the long-term viability and environmental responsibility of wool production. This involves minimizing environmental impact while ensuring animal welfare and economic sustainability.

- Reduced Chemical Inputs: Minimizing pesticide and fertilizer use reduces environmental pollution and protects biodiversity. Integrated pest management strategies prioritize prevention and biological control.

- Efficient Water Use: Implementing water-efficient irrigation techniques and rainwater harvesting reduces water consumption.

- Carbon Footprint Reduction: Managing grazing practices effectively and utilizing renewable energy sources can reduce the industry’s carbon footprint.

- Animal Welfare: Prioritizing animal health and welfare, including humane shearing practices and responsible pasture management, improves animal well-being and minimizes stress.

- Soil Health: Maintaining healthy soil through responsible grazing practices ensures long-term pasture productivity and reduces erosion.

Adopting sustainable practices can enhance the reputation of wool producers and increase market demand for ethically and sustainably produced wool. Consumers are increasingly aware of environmental and animal welfare issues, rewarding those committed to sustainability.

Q 11. Discuss the economic factors impacting wool prices and production profitability.

Wool prices are influenced by various economic factors impacting profitability. Global supply and demand play a significant role; increased demand from fashion industries can drive prices up, while oversupply can depress them. Competition from synthetic fibers also impacts wool prices. Other relevant factors include:

- Exchange Rates: Fluctuations in exchange rates can significantly affect profitability for international wool trade.

- Transportation Costs: Changes in fuel prices and logistics affect the cost of transporting wool to markets.

- Input Costs: The cost of feed, veterinary services, and labor all affect production profitability.

- Government Policies: Subsidies, tariffs, and other government policies can influence wool production and pricing.

- Fiber Quality: Higher-quality wool commands higher prices. Factors like fiber diameter, length, and strength significantly impact price.

For example, a surge in demand for Merino wool for high-end apparel could lead to increased prices, boosting profitability for farmers producing this type of wool. Conversely, a global economic downturn could reduce demand, leading to lower prices and reduced profitability.

Q 12. How do you monitor and track key performance indicators (KPIs) in wool production?

Effective monitoring of key performance indicators (KPIs) is crucial for optimizing wool production. KPIs should be relevant to various aspects of the operation, including animal health, pasture management, and wool quality.

- Wool Yield per Ewe: This measures the kilograms of wool produced per ewe per shearing.

- Fiber Diameter and Length: These indicators reflect wool quality and influence price.

- Fleece Cleanliness: This impacts the value of the wool.

- Lambing Percentage: This indicates reproductive efficiency.

- Mortality Rate: This reflects animal health management.

- Pasture Utilization: This shows the efficiency of pasture management.

- Production Costs: Tracking costs helps assess profitability.

Regular data collection and analysis of these KPIs, perhaps using spreadsheets or dedicated farm management software, allow for informed decision-making and adjustments to improve productivity and profitability. For instance, consistently low wool yield might prompt investigation into nutritional management or animal health issues.

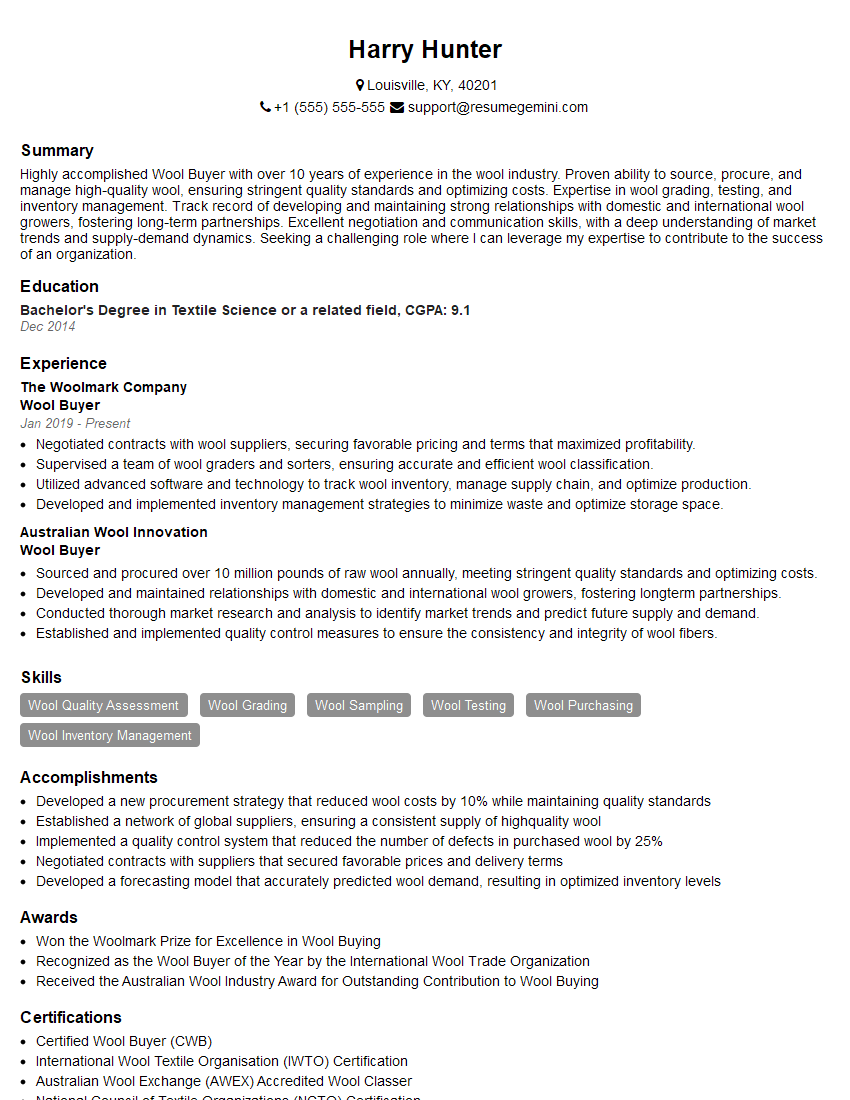

Q 13. Describe your experience with wool inventory management and control.

Effective wool inventory management is crucial for maximizing value and minimizing losses. This involves tracking wool from shearing to sale, ensuring proper storage conditions and minimizing shrinkage.

- Detailed Record Keeping: Maintain accurate records of wool quantity, grade, and storage location. This includes details on shearing date, bale identification, and storage conditions.

- Proper Storage: Store wool in a dry, clean, and well-ventilated environment to prevent damage and maintain quality. Protect bales from moisture, pests, and contamination.

- Regular Inspection: Regularly inspect stored wool for signs of damage or deterioration. Address any issues promptly.

- Efficient Sales Management: Utilize market information to determine optimal selling times and prices. Negotiate with buyers effectively to secure the best deals.

- Inventory Software: Utilize inventory management software to track wool quantities, quality, and sales, providing a real-time overview of inventory levels and sales performance.

Imagine a scenario where a significant portion of stored wool is affected by moisture damage. Effective inventory management, through regular inspections and appropriate storage, could minimize or prevent such losses.

Q 14. Explain your approach to managing a team in a wool production environment.

Managing a team in a wool production environment requires strong leadership, clear communication, and a focus on teamwork. It is crucial to foster a supportive and productive work environment.

- Clear Communication: Regularly communicate expectations, goals, and feedback to team members. Encourage open dialogue and address concerns promptly.

- Delegation and Empowerment: Delegate tasks effectively and empower team members to take ownership of their work. Provide them with the necessary training and resources.

- Team Building: Foster teamwork by organizing regular team meetings, social events, and training sessions. This helps build relationships and strengthen team cohesion.

- Motivation and Recognition: Recognize and reward hard work and achievements. Celebrate successes and foster a positive and motivating work environment.

- Safety First: Prioritize worker safety by providing adequate training, safety equipment, and a safe working environment. Adhere to all relevant health and safety regulations.

For example, a well-trained and motivated shearing team is essential for efficient and humane shearing. This involves providing training on safe shearing practices, encouraging teamwork, and acknowledging individual skill.

Q 15. How do you handle conflicts or disagreements within the team?

Conflict resolution is crucial in any team, especially in the demanding environment of wool production. My approach is proactive and focuses on open communication and understanding. I believe in creating a safe space where team members feel comfortable voicing their concerns.

Firstly, I encourage open dialogue to identify the root cause of the disagreement. I actively listen to each individual’s perspective without interrupting or judging, ensuring everyone feels heard. Then, we collaboratively brainstorm solutions, focusing on the common goal of improving wool production efficiency and quality. Sometimes, this involves compromising; other times, it means finding creative solutions that address everyone’s needs. For instance, in a past disagreement about shearing techniques, we held a workshop demonstrating different approaches, ultimately leading to the adoption of a method that boosted both speed and fleece quality. Finally, I ensure that the agreed-upon solution is documented and clearly communicated to the entire team. This prevents future misunderstandings and reinforces the importance of collaborative problem-solving.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with wool marketing and sales?

My experience in wool marketing and sales spans over a decade, encompassing various aspects from direct sales to managing online platforms. I understand the importance of understanding market trends and customer needs, which is essential for successful wool sales. For instance, I successfully navigated a period of fluctuating global wool prices by diversifying our sales channels, securing contracts with both established textile mills and emerging sustainable fashion brands. This involved not only understanding the different quality demands and price points of each market segment but also building strong, reliable relationships with buyers. I also have extensive experience in pricing strategies, quality grading, and negotiating contracts, understanding the crucial interplay between these factors and the overall profitability of the wool production enterprise.

Moreover, I’m adept at utilizing marketing strategies, including digital marketing to reach broader audiences and promotional campaigns that highlight the unique qualities and sustainability of our wool. I’ve seen firsthand how targeted marketing can significantly increase brand recognition and ultimately, boost sales.

Q 17. How do you identify and address potential risks and challenges in wool production?

Risk management is paramount in wool production. I employ a multi-faceted approach that identifies and mitigates potential challenges proactively. My strategy begins with a thorough risk assessment, considering factors like weather patterns, disease outbreaks, market fluctuations, and changes in government regulations. For example, we regularly review weather forecasts to anticipate potential droughts or extreme weather events that could harm the sheep or reduce pasture quality. This allows us to implement preventive measures such as supplemental feeding or implementing alternative grazing strategies.

- Disease outbreaks: We implement stringent biosecurity protocols to minimize the risk of disease spread, including regular veterinary checkups and vaccination programs.

- Market volatility: We use hedging strategies to protect against price fluctuations and diversify our sales channels to minimize dependence on a single buyer.

- Regulatory changes: We stay abreast of any changes in environmental regulations or animal welfare standards to ensure our practices remain compliant and sustainable.

Beyond preventive measures, I focus on developing contingency plans to address potential disruptions. This includes having alternative sources for feed and veterinary care, and establishing strong relationships with multiple buyers to ensure market access even during unforeseen events.

Q 18. Describe your experience with using technology in wool production (e.g., farm management software).

Technology plays a vital role in modern wool production. I have extensive experience using farm management software for tracking animal health, feed consumption, and production metrics. For example, we utilize a software system that integrates GPS tracking of our sheep, allowing us to monitor their grazing patterns and identify potential problems early. This system provides valuable data for optimizing pasture management and maximizing sheep health. This data allows for evidence-based decision-making, improving efficiency and reducing waste.

Furthermore, we use specialized software for managing wool processing and quality control, automating tasks like fiber testing and grading, which ensures consistency and traceability throughout the production chain. These technologies not only enhance efficiency but also provide valuable insights into areas for improvement. For instance, through data analysis, we were able to identify a correlation between a specific pasture and higher fleece micron count, leading to targeted pasture management practices to enhance wool quality.

Q 19. What are the environmental considerations in wool production, and how can they be minimized?

Environmental sustainability is a core value in our wool production. We focus on minimizing our environmental footprint through several key strategies. Our methods prioritize responsible land management, ensuring sustainable grazing practices to prevent overgrazing and soil erosion. We also implement rotational grazing, allowing pastures to recover and maintain their biodiversity.

- Water management: We use efficient irrigation techniques to minimize water waste and protect water resources.

- Waste management: We manage animal waste responsibly, utilizing methods such as composting to enrich the soil and reduce greenhouse gas emissions.

- Carbon sequestration: Our grazing practices support carbon sequestration in the soil, contributing to mitigating climate change.

- Biodiversity conservation: We work to protect biodiversity on our land by implementing practices that support native plants and wildlife.

We continually seek ways to improve our environmental performance and comply with all relevant regulations. Regular environmental audits and ongoing education for our team ensure that sustainability remains a top priority.

Q 20. Explain your understanding of supply chain management in the wool industry.

Supply chain management in the wool industry is complex, involving multiple stakeholders from sheep farmers to textile manufacturers. My understanding encompasses the entire process, from fleece shearing and handling to final product distribution. I recognize the importance of traceability and transparency throughout the supply chain, ensuring that wool can be tracked from farm to finished product. This not only builds consumer trust but also helps manage quality and meet specific market demands.

I have experience in optimizing each stage of the supply chain, focusing on efficiency and collaboration. This involves developing strong relationships with key stakeholders, including wool brokers, processors, and manufacturers, to ensure smooth flow of goods and information. I’ve also implemented strategies such as just-in-time inventory management to minimize storage costs and reduce waste. Additionally, I’m familiar with using technology to track inventory, monitor shipments, and manage logistics. Efficient supply chain management translates directly to lower costs, increased profitability, and a more responsive business model.

Q 21. Describe your experience with quality control procedures in wool processing.

Quality control is essential for ensuring the value and marketability of wool. My experience involves implementing rigorous procedures at every stage of the processing, from shearing to final product. These procedures include regular checks for cleanliness, fiber length, micron count, and strength.

We use advanced testing equipment to objectively assess wool quality, and our team is trained to identify and classify wool according to industry standards. Any irregularities or defects are meticulously documented and addressed. This process ensures consistency and meets the specific requirements of our customers. For example, we use optical sorters to separate wool fibers based on color and length, improving the overall quality and value of the final product. Additionally, we meticulously maintain records of each batch of wool, ensuring traceability and accountability. This systematic approach not only enhances product quality but also protects our brand reputation and builds customer trust.

Q 22. How do you manage waste and by-products in wool production?

Waste management in wool production is crucial for environmental sustainability and economic efficiency. It involves minimizing waste at every stage, from shearing to processing.

Shearing Waste: This includes soiled fleece pieces, tags (small pieces of fleece), and vegetable matter (burrs, seeds). We utilize advanced shearing techniques to minimize these, and the collected waste is often composted or used as fertilizer, closing the loop on waste and reducing landfill burden. We also explore partnerships with companies that can utilize these materials for other applications like insulation or felt manufacturing.

Processing Waste: During scouring (cleaning) and carding (aligning fibers), various by-products are generated, including lanolin (wool grease) and processing water. Lanolin is a valuable byproduct, widely used in cosmetics and other industries. We partner with lanolin recovery specialists to ensure efficient extraction and sale. We employ advanced water treatment systems to reduce water pollution and ensure safe discharge, recycling and reusing as much water as possible.

End-of-Life Waste: At the end of a garment’s life, wool can be recycled. We promote initiatives that encourage wool recycling, including partnerships with textile recycling companies that can process and repurpose the fibers. This extends the life cycle of the wool and minimizes its environmental footprint.

Q 23. What are your strategies for improving wool production efficiency and yield?

Improving wool production efficiency and yield involves a multi-faceted approach focusing on sheep genetics, farming practices, and processing techniques.

- Genetic Selection: Breeding programs focusing on higher fleece weight, improved fiber quality (fineness, length, strength), and disease resistance are paramount. We use genetic testing and data analysis to identify superior breeding rams and ewes, leading to a larger and more consistent yield of high-quality wool.

- Pasture Management: Optimizing pasture conditions with suitable fertilization, grazing rotation, and weed control directly impacts sheep health and wool production. Healthy sheep produce healthier wool.

- Shearing Techniques: Well-trained shearers are essential for minimizing fleece damage, increasing yield, and improving the quality of the wool. We invest in training and provide the latest shearing tools to achieve optimal results.

- Improved Processing: Optimizing scouring and carding processes reduces waste and improves fiber alignment, leading to higher yields of usable wool. Advanced technology can help to sort and grade wool more efficiently.

For instance, we implemented a rotational grazing system on our farm which improved pasture quality and resulted in a 15% increase in fleece weight within two years. This was coupled with a targeted breeding program focusing on increased fiber diameter and staple length, further improving the quality and value of our wool production.

Q 24. How do you ensure the traceability of wool from farm to final product?

Wool traceability, from farm to final product, is crucial for building consumer trust and ensuring product authenticity. This requires a robust system integrating farm records, processing records, and supply chain management.

We utilize a combination of methods:

- Farm-Level Tracking: Each flock is assigned a unique identification number, linked to detailed records including breeding history, health records, and shearing data. Each bale of wool is tagged with a unique ID matching the flock and shearing date.

- Processing Tracking: All processing steps are recorded, from scouring and carding to spinning and dyeing. Each batch of processed wool retains its unique ID, allowing for complete tracking throughout the supply chain.

- Blockchain Technology: We are exploring the use of blockchain technology to create a secure, transparent, and tamper-proof record of the wool’s journey. This provides unparalleled traceability and enhances supply chain integrity.

- RFID Tags: Radio-Frequency Identification (RFID) tags can be attached to bales of wool and scanned at various points in the supply chain, providing real-time tracking capabilities.

This comprehensive traceability system allows consumers to verify the origin, processing methods, and sustainability credentials of their wool products, building confidence and creating a premium market advantage.

Q 25. Describe your understanding of animal welfare standards in sheep farming.

Animal welfare is paramount in our sheep farming operation. We adhere to strict standards ensuring the sheep’s health, comfort, and well-being are prioritized throughout their life cycle.

- Access to Pasture and Water: Sheep have ample access to clean water and high-quality pasture throughout the year.

- Shelter: Adequate shelter is provided during inclement weather.

- Health Management: We follow a preventative healthcare program, including regular veterinary checks, vaccinations, and parasite control.

- Shearing Practices: Shearing is conducted by trained and experienced shearers using humane techniques that minimize stress and injury to the sheep.

- Handling: Sheep are handled with care and respect to minimize stress.

- Compliance with Regulations: We comply with all relevant animal welfare regulations and industry best practices.

We have implemented a comprehensive training program for all our staff on animal welfare best practices, emphasizing respectful handling and early detection of any potential health issues. We also regularly review our practices and procedures to ensure continuous improvement.

Q 26. What are the current trends and innovations in wool production technology?

Wool production technology is constantly evolving to improve efficiency, sustainability, and product quality.

- Precision Shearing: Advanced shearing equipment uses lasers and sensors to improve shearing speed and reduce fleece damage.

- Automated Sorting and Grading: Automated systems use optical sensors to sort and grade wool based on fiber diameter, length, and color, significantly increasing efficiency and accuracy.

- Improved Scouring and Processing: New techniques and equipment reduce water consumption and waste generation in the scouring process, while improving fiber cleanliness and aligning.

- Fiber Technology: Research into new fiber treatments and modifications enhance wool’s performance properties, such as water resistance and wrinkle resistance.

- Robotics and Automation: The increasing use of robotics and automation improves the efficiency and reduces the labor costs in several stages of wool production.

For example, we have recently implemented a laser-guided shearing system which has resulted in a 10% reduction in shearing time and a noticeable improvement in fleece quality.

Q 27. How do you adapt to changes in market demands and consumer preferences for wool products?

Adapting to changing market demands and consumer preferences requires continuous monitoring of trends and proactive adjustments to our production and marketing strategies.

- Market Research: We closely monitor market trends, including consumer preferences for specific wool types (e.g., fine merino, coarser yarns), colors, and sustainability credentials.

- Product Diversification: We offer a range of wool products to cater to diverse market segments. This may include different fiber types, colors, and levels of processing.

- Sustainable Practices: Consumers are increasingly demanding sustainable and ethically produced products. We showcase our commitment to animal welfare, environmental sustainability, and fair labor practices to meet this demand.

- Traceability and Transparency: Providing clear and transparent information about the origin and processing of our wool builds trust and enhances consumer confidence.

- Collaboration and Partnerships: We actively seek collaborations with designers, manufacturers, and retailers to understand current trends and develop innovative products.

For instance, in response to growing demand for sustainable wool, we’ve partnered with a certified organic farm and implemented stricter environmental management strategies on our farm. We also participate in eco-friendly product showcases to directly engage with conscious consumers.

Q 28. Describe your experience with implementing and managing a wool production budget.

Managing a wool production budget requires careful planning, monitoring, and control. This involves projecting income, estimating expenses, and tracking performance against the budget throughout the production cycle.

Budgeting Process:

- Income Projection: Based on market prices, wool yield projections, and anticipated sales volume.

- Expense Estimation: Includes costs for sheep feed, veterinary care, shearing, processing, transportation, labor, and other operational expenses.

- Contingency Planning: A buffer should be included to account for unforeseen events, like disease outbreaks or market fluctuations.

- Regular Monitoring: We regularly track actual income and expenses against the budget, identifying variances and making necessary adjustments.

- Performance Analysis: Regular analysis of budget performance helps to identify areas for cost reduction and efficiency improvements.

For example, we use a spreadsheet software to create a detailed budget, tracking each expense category and comparing it to actual spending on a monthly basis. This allows us to promptly address any overspending or revenue shortfalls and maintain profitability.

Key Topics to Learn for Wool Production Management Interview

- Sheep Husbandry and Breeding: Understanding sheep breeds, their wool characteristics, and optimal breeding strategies for maximizing fleece quality and yield. Practical application: Analyzing breed performance data to inform breeding decisions and improve flock management.

- Wool Harvesting and Handling: Mastering shearing techniques, fleece classification, and minimizing fiber damage during the harvesting and processing stages. Practical application: Implementing quality control measures to ensure consistent fiber quality and maximize value.

- Wool Processing and Technology: Familiarizing yourself with the various stages of wool processing, from scouring and carding to spinning and finishing. Practical application: Troubleshooting issues in the production line and optimizing processing parameters for improved efficiency and product quality.

- Quality Control and Assurance: Understanding the critical quality parameters of wool and implementing effective quality control measures throughout the production process. Practical application: Developing and implementing protocols for testing and grading wool to meet specific market demands.

- Supply Chain Management: Understanding the flow of wool from farm to final product, including logistics, storage, and inventory management. Practical application: Optimizing the supply chain for cost-effectiveness and timely delivery.

- Sustainability and Ethical Practices: Understanding the environmental and ethical considerations related to wool production, including animal welfare and sustainable farming practices. Practical application: Implementing sustainable practices to reduce the environmental impact of wool production.

- Financial Management and Cost Control: Understanding the financial aspects of wool production, including budgeting, cost analysis, and profitability. Practical application: Developing strategies for maximizing profitability while maintaining high quality standards.

Next Steps

Mastering Wool Production Management opens doors to exciting career opportunities with significant growth potential. A strong understanding of these key areas will set you apart in a competitive job market. To maximize your chances of landing your dream role, creating a well-structured, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a compelling resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Wool Production Management to help you showcase your qualifications in the best possible light. Take the next step towards your career success today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good