The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Data Cable Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Data Cable Installation Interview

Q 1. Explain the difference between shielded and unshielded twisted pair (STP/UTP) cables.

The core difference between Shielded Twisted Pair (STP) and Unshielded Twisted Pair (UTP) cables lies in their shielding. UTP cables, the most common type, consist of twisted pairs of wires without any metallic shielding. This twisting helps reduce electromagnetic interference (EMI) from external sources, but it’s less effective than STP. STP cables, on the other hand, have an additional layer of metallic shielding – usually foil or braided metal – wrapped around the twisted pairs, providing significantly better protection against EMI. Think of it like this: UTP is like wearing a t-shirt to protect yourself from a light rain, while STP is like wearing a raincoat in a downpour.

In practice, UTP is generally sufficient for most home and small office networks, while STP is preferred in environments with high levels of EMI, such as industrial settings or areas with significant electrical equipment. The added shielding in STP comes at the cost of slightly higher price and potential signal attenuation (signal weakening) compared to UTP.

Q 2. Describe the process of terminating a Cat5e cable.

Terminating a Cat5e cable involves connecting the wires to an RJ45 connector using a punch-down tool. The process is crucial for ensuring reliable network connections. Improper termination can lead to poor signal quality, slow speeds, and intermittent connectivity. Here’s a step-by-step guide:

- Cut the cable: Cut the cable to the desired length, ensuring a clean, straight cut.

- Strip the outer sheath: Carefully remove the outer protective sheath, exposing the twisted pairs. Avoid nicking the individual wires.

- Untwist and straighten the pairs: Gently untwist the pairs and straighten the individual wires to about ½ inch.

- Arrange the wires according to the 568A or 568B standard: This ensures consistent pinouts. The standard dictates the order in which wires are inserted into the RJ45 connector. The choice between 568A and 568B is usually consistent across a network.

- Insert into the RJ45 connector: Carefully insert the wires into the RJ45 connector, ensuring they’re fully seated.

- Crimp the connector: Use a crimping tool to firmly connect the wires to the connector. A properly crimped connector will have the pins fully seated and aligned.

- Test the connection: After termination, test the cable using a cable tester to verify continuity and proper wiring.

A common mistake is incorrectly arranging the wires, leading to connectivity issues. Always double-check the wiring before crimping.

Q 3. What are the common types of fiber optic cables and their applications?

Fiber optic cables transmit data using light pulses instead of electrical signals, offering significantly higher bandwidth and longer transmission distances compared to copper cables. Different types cater to various needs:

- Single-mode fiber: Uses a very narrow core diameter, allowing for longer transmission distances with minimal signal loss. Ideal for long-haul telecommunications and high-speed data networks.

- Multi-mode fiber: Uses a larger core diameter, allowing for multiple light paths. Suitable for shorter distances, such as within a building or campus network. Common types include OM1, OM2, OM3, and OM4, with increasing bandwidth capabilities.

Choosing the right type depends on the application. For example, a long-distance backbone network would typically use single-mode fiber, while connecting computers within an office might use multi-mode fiber.

Q 4. How do you test data cables for continuity and signal quality?

Testing data cables for continuity and signal quality is essential to ensure reliable network performance. A cable tester is the primary tool for this. These testers typically have LEDs or a digital display that indicates the connectivity of each wire pair and overall signal quality. The tester will show if there are any breaks, shorts, or incorrect wiring in the cable.

For continuity testing, the tester sends a signal through each wire pair and verifies a complete electrical path from one end to the other. Signal quality tests examine the signal’s strength and integrity, identifying potential attenuation or interference. Many modern testers also perform more advanced tests such as near-end crosstalk and far-end crosstalk to ensure reliable performance in high-speed networks. Identifying a problem early can prevent significant network outages and troubleshooting.

Q 5. What are the safety precautions you should take when working with data cables?

Safety is paramount when working with data cables. Here are some key precautions:

- Power down equipment: Always disconnect power to any network equipment before working with cables to prevent electrical shock.

- Use appropriate tools: Use properly insulated tools to avoid short circuits or electrical shocks. A damaged tool is a safety hazard.

- Proper grounding: Ground yourself to prevent static electricity from damaging sensitive electronics.

- Personal Protective Equipment (PPE): Consider wearing safety glasses to protect your eyes from potential debris.

- Follow safety regulations: Adhere to all relevant safety regulations and best practices for working at heights or in confined spaces. Always be aware of your surroundings.

- Know your surroundings: Before beginning any work, carefully examine the workspace for potential hazards. Be careful not to damage other cables or systems.

Ignoring safety precautions can lead to serious injury or equipment damage. A moment of carelessness can have serious consequences.

Q 6. Explain the importance of proper cable management.

Proper cable management is essential for several reasons:

- Improved network performance: Neatly organized cables reduce signal interference, improving network speed and reliability. Tangled cables can cause signal attenuation and crosstalk.

- Enhanced safety: Organized cables reduce tripping hazards and prevent accidental damage to cables.

- Easier troubleshooting: When cables are well-organized, identifying and fixing problems becomes much easier. Imagine searching for a specific cable in a tangled mess versus a neatly labeled rack.

- Scalability and maintainability: Well-managed cabling makes it easier to add or replace cables as the network grows.

- Professional appearance: Neat cabling gives a professional impression, reflecting your attention to detail.

In a large data center, proper cable management is crucial for efficiency and uptime. Without it, troubleshooting and maintenance would be a nightmare.

Q 7. What tools and equipment are commonly used in data cable installation?

A range of tools and equipment is used in data cable installation, depending on the project’s complexity. Here are some common ones:

- Cable tester: Used to test the continuity and signal quality of cables.

- Punch-down tool: Used to terminate cables onto RJ45 connectors.

- Crimping tool: Used to secure the RJ45 connector onto the cable.

- Wire strippers/cutters: Used to strip the outer sheath and cut the cable to length.

- Cable labels and markers: For clear identification of cables and connections.

- Fiber optic tools (for fiber installations): These tools include fiber optic cleavers, fusion splicers, and OTDRs (Optical Time Domain Reflectometers) for testing fiber optic cable continuity and quality.

- Ladder, lifts, and other work positioning equipment (for overhead or elevated runs): This equipment is critical for safety when working above ground level.

- Cable management accessories: These accessories include cable ties, raceways, and patch panels to keep the cable organized.

Choosing the right tools ensures efficiency and quality of work. Using the wrong tools can damage cables or lead to unsafe working conditions.

Q 8. Describe your experience with different cable pulling techniques.

Cable pulling techniques are crucial for safely and efficiently installing data cables. My experience encompasses several methods, each chosen based on the cable type, conduit size, and environment.

- Hand Pulling: This is suitable for shorter runs and smaller cables. It involves attaching a pulling grip to the cable and manually pulling it through the conduit. Lubricant is often essential to reduce friction and prevent damage.

- Power Pulling: For longer runs or larger cable bundles, a power pulling machine is necessary. This equipment provides controlled and consistent pulling force, minimizing the risk of cable damage. It’s crucial to select a machine with appropriate capacity to prevent overloading.

- Pulling Socks: These protective sleeves are used to reduce friction and protect the cable’s outer jacket during pulling. They are particularly useful in tight bends or rough conduits.

- Cable Lubricants: Various lubricants are available, each suited for specific cable types and environmental conditions. Using the right lubricant significantly reduces friction, easing the pulling process and preventing damage.

- Fish Tape: In challenging situations, a fish tape – a flexible metal ribbon – is used to navigate bends and obstacles in the conduit before attaching the cable. This is particularly effective in situations where direct pulling is difficult or impossible.

I’ve successfully employed these techniques in various settings, including office buildings, data centers, and industrial facilities, always prioritizing safety and minimizing downtime.

Q 9. How do you troubleshoot common cabling problems?

Troubleshooting cabling problems requires a systematic approach. I begin with visual inspection for obvious physical damage, loose connections, or mislabeled cables. Then, I move to more advanced techniques.

- Testing Cable Continuity: A cable tester verifies the integrity of the cable, confirming whether signals can pass through without interruption. This helps identify breaks or shorts in the cable.

- Testing Signal Strength: Specialized tools measure signal strength at different points along the cable run, allowing me to pinpoint the location of attenuation or signal loss. This is crucial, especially in longer runs.

- Checking Connections: Loose connections are a common source of problems. I carefully inspect all connectors, ensuring they are securely plugged in and properly terminated.

- Verifying Network Configuration: Problems might stem not from the cable itself, but from network configuration issues. I collaborate with network administrators to check for IP address conflicts, incorrect subnet masks, or other network settings that might affect connectivity.

- Using a Toner and Probe: When dealing with a large bundle of cables, this combination can help precisely locate a particular cable within a conduit or wall. The toner sends a signal through the cable, and the probe pinpoints its location.

For example, in a recent project, we experienced intermittent connectivity issues. By systematically using a cable tester and then checking connections, we discovered a loose RJ45 connector. A simple tightening resolved the problem.

Q 10. What is the difference between a patch panel and a punch down block?

While both patch panels and punch down blocks are used for terminating cables, they serve different purposes and have distinct characteristics.

- Patch Panel: A patch panel provides a centralized point for connecting multiple cables. It typically has labeled ports for easy identification and management. Patch panels are usually found in server rooms or telecommunication closets, connecting cables from various sources to network equipment.

- Punch Down Block: A punch down block is a simpler device used for terminating individual cables. It lacks the organization and labeling features of a patch panel. They are often integrated into wall plates or other termination points within the network infrastructure.

Think of a patch panel as a central telephone exchange, while a punch down block is like a single phone jack on your wall. Both connect phone lines, but the patch panel offers much greater organization and manageability.

Q 11. Explain the concept of TIA/EIA standards for cabling.

TIA/EIA standards (Telecommunications Industry Association/Electronic Industries Alliance) define cabling infrastructure requirements, ensuring interoperability and performance across different vendors’ equipment. These standards cover various aspects, including cable types, connectors, testing procedures, and installation practices.

For example, TIA-568 standards specify the color codes for twisted-pair cabling, ensuring consistent wiring, while TIA-942 focuses on standards for data centers and their cabling infrastructure. Adherence to these standards is crucial for reliable and high-performing networks and simplifies troubleshooting and future upgrades.

Q 12. How do you identify different types of connectors (e.g., RJ45, SC, ST)?

Identifying connectors requires visual inspection and understanding their unique features. Here are some common examples:

- RJ45: This 8-position connector is the most common for twisted-pair Ethernet cables. It’s easily recognizable by its rectangular shape and eight pins.

- SC: A square connector used primarily for fiber optic cables. It’s characterized by its simple push-pull design.

- ST: Another fiber optic connector with a bayonet-style coupling. It’s easily identified by its circular shape and bayonet lock mechanism.

- BNC: A coaxial connector often used for video and high-frequency signals. It features a threaded coupling mechanism.

Practiced professionals can quickly identify connectors by their shape, size, and color coding, which often indicates the type of cable and data transmission capabilities. For example, an RJ45 connector with a specific color-coded wire arrangement might indicate Cat6 compared to Cat5e.

Q 13. Describe your experience with fiber optic splicing.

Fiber optic splicing involves precisely joining two fiber optic cables to maintain signal transmission. My experience includes using various splicing methods, including fusion splicing and mechanical splicing.

- Fusion Splicing: This precise method uses heat and pressure to fuse the ends of two fibers together. It creates a strong, low-loss connection. Specialized fusion splicers are used for this precise procedure, requiring a good understanding of fiber alignment and optimal fusion parameters.

- Mechanical Splicing: Mechanical splices use mechanical components to hold the fiber ends together. This method is typically faster but can potentially result in higher signal loss than fusion splicing. It’s a good option for less demanding applications where speed is prioritized over optimal performance.

Proper cleaning and preparation are essential for both methods. The fibers must be perfectly aligned to minimize signal loss. Post-splice testing ensures the connection meets the required specifications. Fiber optic splicing is critical for maintaining signal integrity in long-haul telecommunications and network infrastructure.

Q 14. What are the key differences between Cat5e, Cat6, and Cat6a cables?

Cat5e, Cat6, and Cat6a cables are all twisted-pair cables used for Ethernet networks, but they differ in their bandwidth and performance capabilities.

- Cat5e: Supports Gigabit Ethernet speeds (1 Gbps) and is suitable for most home and small office networks. Its bandwidth is limited to approximately 100 MHz.

- Cat6: Offers improved bandwidth up to 250 MHz, supporting 10 Gigabit Ethernet (10 Gbps) over shorter distances. It’s suitable for higher-bandwidth applications.

- Cat6a: The most advanced of these three, Cat6a supports 10 Gigabit Ethernet over longer distances with a bandwidth of 500 MHz. Its enhanced performance makes it ideal for demanding network environments like data centers and high-speed network applications.

The key differences lie in their construction and shielding, which affect their ability to handle higher frequencies and reduce signal interference. Cat6 and Cat6a use more advanced twisting techniques and often include additional shielding to prevent crosstalk and signal degradation. Choosing the right cable type depends on network requirements and budget constraints.

Q 15. How do you ensure proper grounding and bonding in a cabling system?

Proper grounding and bonding are crucial for safety and signal integrity in a cabling system. Grounding connects the metallic parts of the cabling infrastructure to earth, preventing dangerous voltage buildup. Bonding connects different metallic parts within the system to each other, ensuring they are at the same electrical potential, preventing voltage differences that could cause signal interference or damage equipment.

To achieve this, we use grounding conductors connected to a central grounding point (like a grounding rod) and bond the various metal components (conduit, racks, equipment chassis) using bonding straps or jumpers. This creates a low-impedance path for fault currents to flow to earth, protecting personnel and equipment. Regular inspections and testing of grounding and bonding systems are vital to ensure effectiveness. We utilize a ground continuity tester to verify that the path is functioning correctly and to identify potential issues before they lead to problems.

For example, in a data center installation, we’d ensure each rack is bonded to the building’s grounding system, and all metallic conduits are properly grounded and bonded together. Any exposed metal parts are also carefully grounded. Failure to do so could result in electrical shock or even fire.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the best practices for labeling and documenting cables?

Clear, consistent labeling and documentation are essential for maintainability and troubleshooting. We use a standardized labeling system that includes cable type, destination, source, and date installed. Labels are applied securely and in a visible location, ideally at both ends of the cable and at any intermediate points. We utilize heat-shrink labels or industrial-grade label printers for durability.

Documentation is equally crucial and should include comprehensive cable diagrams, showing the cable pathway, connections, and equipment details. Software applications like AutoCAD or specialized cable management software are invaluable in creating these diagrams. A well-maintained database linked to the diagrams allows quick identification of cable runs and assists in future maintenance or upgrades. For instance, if a cable needs to be replaced, clear labeling and diagrams expedite the process minimizing downtime and avoiding errors. Imagine trying to trace a cable in a complex network without proper labeling – it would be a nightmare.

Q 17. Explain your experience working with different cable pathways (e.g., conduit, raceway).

I have extensive experience working with various cable pathways, including conduit, raceway, and cable trays. Conduits provide excellent protection from environmental hazards and offer superior strength for cables running through walls or underground. Raceways offer more flexibility for routing and branching, often utilized for surface-mounted cable runs. Cable trays provide an accessible way to organize and manage multiple cables, typically found in data centers or server rooms.

Choosing the right pathway depends on factors like cable type, environmental conditions, and the overall network design. For example, I’ve used rigid metallic conduit for underground runs to protect against rodent damage and water ingress, and used PVC-coated flexible conduit for internal runs where flexibility and ease of installation were critical. For high-density cabling environments like data centers, I frequently utilize cable trays to optimize space and improve cable management. My experience spans the installation of various pathway types, ensuring I can select the most appropriate solution for any given project.

Q 18. How do you handle cable slack and prevent future issues?

Proper cable slack management is vital for preventing future problems such as cable strain, damage, and signal degradation. Insufficient slack can lead to cable breakage or damage during building expansion or equipment relocation. Excess slack, however, can lead to cable tangles, causing difficult tracing and potential fire hazards.

To manage cable slack effectively, we typically use cable ties, straps, and rings to secure cables in the pathway, allowing for controlled slack at strategic points. We avoid over-tightening to prevent damage. We also install slack loops at termination points to absorb movement or expansion. For example, at a rack, we’d leave approximately 6-12 inches of slack depending on the cable type and pathway characteristics. We meticulously document the slack management strategy as part of our overall cabling documentation to ensure easy future access and prevent problems.

Q 19. What is your experience with cable testing equipment (e.g., OTDR, cable testers)?

I’m proficient in using various cable testing equipment including OTDRs (Optical Time Domain Reflectometers) and cable testers (both copper and fiber). OTDRs are essential for fiber optic cable testing. They measure signal attenuation and identify faults along a fiber optic cable by sending pulses of light and analyzing the reflections. Cable testers for copper cables measure parameters such as wiremap, continuity, length, and signal attenuation. This helps identify shorts, opens, and other faults within the copper cabling system.

I use these tools routinely to verify cable integrity, troubleshoot problems, and ensure that the installed cabling meets industry standards before the system is put into operation. For example, an OTDR can pinpoint a fiber break precisely within a kilometer of cable. A copper tester can quickly identify a twisted-pair cable that’s been incorrectly wired. My experience allows me to interpret the results accurately and efficiently, guiding me towards rapid problem resolution.

Q 20. Describe a situation where you had to troubleshoot a complex cabling problem.

In one project, we experienced intermittent network connectivity issues in a newly installed network. After thoroughly checking the network devices, we used an OTDR to trace a fiber optic cable and discovered a micro-bend in the fiber within a conduit section. The bend was caused by excessive strain during installation. We had initially overlooked this during the initial testing because the fault was intermittent. By using an OTDR, we precisely located the problem area, excavated the section of conduit, and corrected the micro-bend, resolving the connectivity issues.

This incident highlighted the importance of thorough testing, particularly using appropriate equipment like OTDRs, and meticulous attention to detail during cable installation. It also underlined the need for thorough documentation, allowing us to readily revisit the impacted cable section. Without our familiarity with specialized testing equipment and its interpretation, the troubleshooting process would have been significantly extended, resulting in increased project costs and downtime.

Q 21. What is your understanding of network topologies (e.g., star, ring, mesh)?

Network topologies describe the physical or logical layout of a network. A star topology has all devices connected to a central hub or switch. This is the most common topology for Ethernet networks, offering scalability and ease of management. A ring topology connects devices in a closed loop, with data flowing in one direction. This topology was once popular but is less common now. Mesh topologies have multiple pathways between devices, offering redundancy and fault tolerance, often used in large, complex networks.

Understanding these topologies is essential for planning and installing data cabling systems. The choice of topology directly impacts cabling requirements, the type of network devices needed, and overall network performance. For example, a star topology simplifies troubleshooting as any issues generally stem from a central point. However, a failure at that central point can bring down the entire network. A mesh topology is more resilient but requires more cabling and more complex management.

Q 22. Explain your experience with different cable installation methods (e.g., aerial, underground).

My experience encompasses a wide range of data cable installation methods, both aerial and underground. Aerial installations, often involving the use of poles and existing infrastructure, require a keen understanding of safety protocols and proper cable support mechanisms to prevent damage and ensure longevity. I’m proficient in techniques like using lashing wire to secure cables to aerial supports and selecting appropriate cable types suitable for exposure to weather elements. For example, I’ve worked on projects involving the installation of fiber optic cables strung between buildings, requiring meticulous attention to detail and adherence to stringent safety regulations.

Underground installations, conversely, involve trenching, cable laying, and backfilling. This requires knowledge of local regulations concerning trench depth, cable protection (conduits, duct banks), and ground conditions. I have extensive experience using directional drills to minimize disruption to landscaping and avoid damage to existing underground utilities. One particular project involved running high-capacity fiber optic cables beneath a busy highway, which demanded precise planning and execution to ensure the safety of the workers and the public while avoiding potential damage to existing infrastructure.

In both cases, careful planning and adherence to best practices are crucial, encompassing factors like cable routing optimization, efficient resource utilization, and strict adherence to safety regulations.

Q 23. How do you handle unexpected issues or challenges during installation?

Unexpected issues are inevitable in cable installation. My approach involves a structured problem-solving process. First, I assess the situation – identifying the problem, its potential impact, and available resources. Then, I develop a solution, considering safety as the top priority. This might involve consulting technical documentation, collaborating with colleagues, or seeking advice from senior engineers. Documentation of the issue, the solution implemented, and the outcome is crucial for future reference and continuous improvement.

For instance, during an underground installation, we encountered unexpected bedrock that prevented trenching at the planned depth. Instead of forcing the issue, we adjusted the plan by using a smaller diameter conduit, rerouting the cable slightly, and implementing additional protective measures. This averted potential damage to the cable and ensured project completion without compromising safety or quality.

Effective communication is key; I always keep stakeholders informed of any issues and proposed solutions, ensuring transparency and collaboration.

Q 24. What is your proficiency with various cable connectors and terminations?

I’m proficient in the use of a wide range of cable connectors and terminations, including those for fiber optic, coaxial, and twisted-pair cables. My expertise extends to various connector types such as RJ45 (Ethernet), SC/FC/LC (fiber optic), BNC (coaxial), and various types of splice closures. I understand the importance of proper termination techniques to ensure optimal signal integrity and prevent signal loss or degradation. I’ve been trained and certified in the use of fusion splicing for fiber optic cables, a precise technique ensuring high-quality connections for maximum bandwidth and minimal signal attenuation.

For example, I have experience using different crimping tools and testing equipment to ensure proper termination of RJ45 connectors for Ethernet networks. Similarly, I routinely use fiber optic cleaning tools and inspection equipment to guarantee the quality of fiber optic connections, preventing signal attenuation that could severely hamper performance.

I always adhere to manufacturer specifications for connector installation and regularly utilize testing equipment to verify connectivity and signal quality after completion.

Q 25. Describe your understanding of bandwidth and its relevance to cable selection.

Bandwidth, measured in bits per second (bps), represents the amount of data that can be transmitted over a cable in a given time. This is crucial in cable selection because different applications require different bandwidths. For example, a high-definition video stream demands significantly more bandwidth than simple data transfer. Understanding this allows me to choose the appropriate cable type (fiber optic for high bandwidth, twisted-pair for lower bandwidth) and design a network that meets specific requirements.

Choosing the wrong cable can lead to performance bottlenecks. For instance, using a twisted-pair cable for long-distance high-speed data transmission would result in significant signal attenuation and performance issues. Conversely, using an expensive, high-bandwidth fiber optic cable for a low-bandwidth application would be wasteful. Therefore, a thorough understanding of bandwidth requirements is crucial for efficient network design and cost optimization.

My experience includes projects where careful bandwidth consideration led to the successful implementation of high-speed networks, capable of handling demanding applications without compromise. I always analyze network traffic patterns and future scalability needs to recommend the most appropriate cable solution.

Q 26. What are your experiences with working at height or confined spaces?

I have significant experience working at height and in confined spaces, both of which are common in data cable installations. I’m certified in relevant safety procedures and always prioritize safety above all else. This includes using appropriate safety equipment like harnesses, fall protection systems, and confined space entry permits. Regular safety training keeps my skills sharp and ensures that I am always aware of the potential hazards.

Working at height might involve installing cables on poles or towers, while confined spaces could include cable ducts or manholes. In both cases, meticulous planning, risk assessment, and adherence to strict safety protocols are paramount. For example, I have worked on projects where we used specialized equipment like aerial lifts and confined space ventilation systems to ensure the safety of the crew. My experience working in these challenging environments guarantees that I can approach each task efficiently and safely.

I always ensure that my team is properly trained and equipped to handle these challenging situations, and I always conduct thorough risk assessments before commencing any work.

Q 27. How do you stay current with the latest advancements in data cable technology?

Staying current with advancements in data cable technology is crucial in this rapidly evolving field. I achieve this through several methods: I actively participate in industry conferences and workshops, which provide exposure to the latest innovations and best practices. I also regularly read industry publications, journals, and online resources to keep abreast of new developments and technologies. Furthermore, I maintain professional certifications and actively engage in continuing education programs offered by industry leaders. This ensures I’m familiar with emerging standards and technologies, such as new fiber optic types and advancements in network protocols.

For example, I recently completed a training program on the installation and testing of 400G fiber optic systems, which are becoming increasingly prevalent in high-bandwidth networks. I also actively follow research on advancements in cable materials and manufacturing techniques, enabling me to make informed decisions regarding the selection of cables for different applications.

Staying updated ensures that I can offer the most effective and efficient solutions to my clients while remaining at the forefront of the industry.

Key Topics to Learn for Data Cable Installation Interview

- Cable Types and Properties: Understanding different cable types (fiber optic, coaxial, twisted-pair), their characteristics, and applications in various network environments. This includes knowledge of cable gauges, shielding, and attenuation.

- Installation Techniques: Mastering proper techniques for pulling, terminating, splicing, and testing data cables. This involves practical knowledge of tools and equipment used in the process, such as cable testers, crimpers, and pullers.

- Network Topologies: Familiarity with different network topologies (star, bus, ring, mesh) and their impact on cable installation design and implementation. Understanding the advantages and disadvantages of each topology is crucial.

- Troubleshooting and Repair: Developing skills in identifying and resolving common cable installation issues, such as signal loss, connectivity problems, and cable faults. This includes using diagnostic tools and interpreting test results.

- Safety Regulations and Best Practices: Adhering to safety regulations and best practices for working with data cables, including proper handling, grounding, and working at heights.

- Documentation and Reporting: Understanding the importance of accurate documentation, including cable labeling, schematics, and test results. This ensures maintainability and simplifies troubleshooting.

- Project Management Basics: Demonstrating a basic understanding of project management principles relevant to cable installation projects, such as planning, scheduling, and resource allocation.

Next Steps

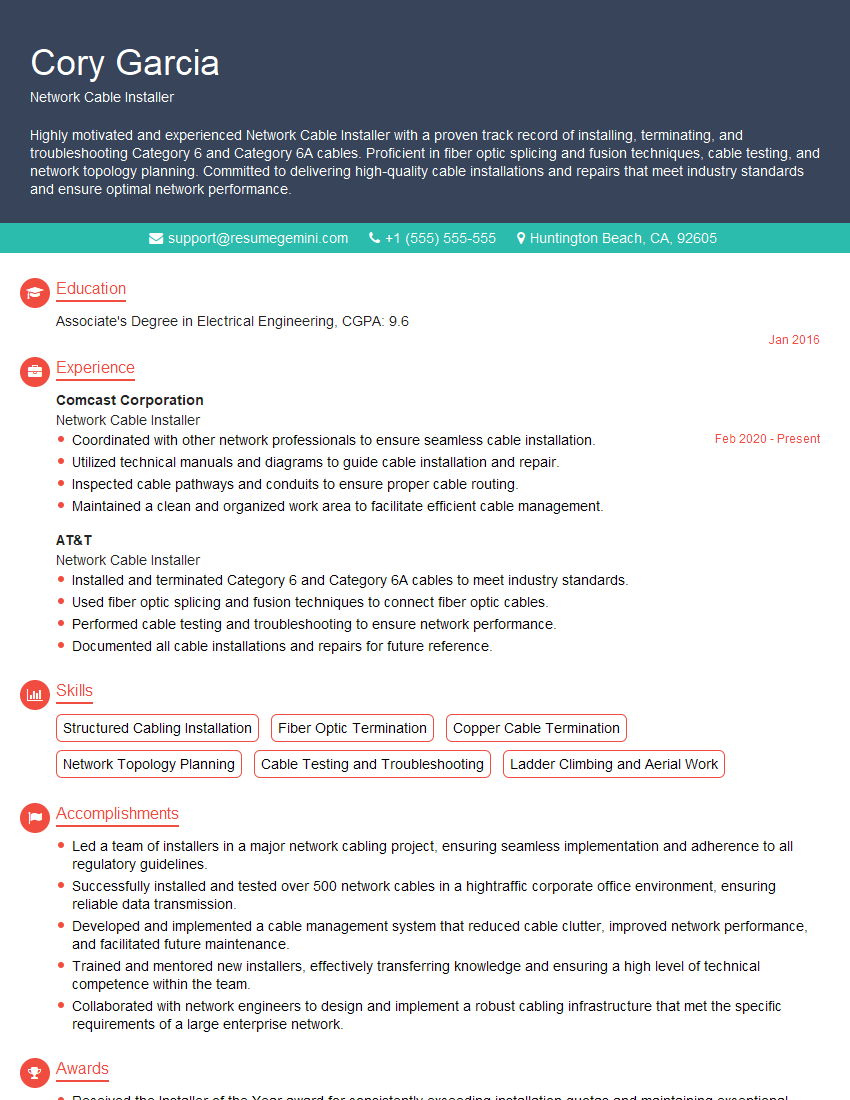

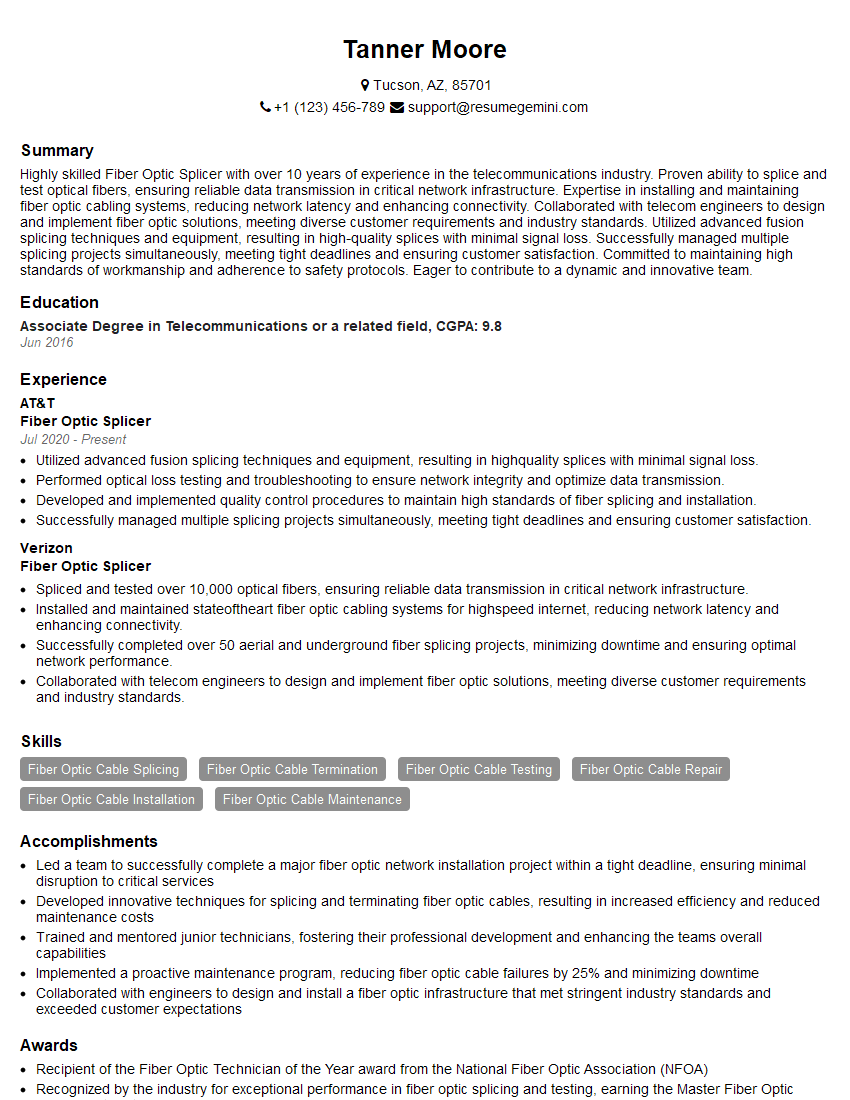

Mastering data cable installation opens doors to a rewarding career with excellent growth potential in the ever-expanding field of telecommunications and networking. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes tailored specifically to Data Cable Installation are available to guide you. Invest the time to craft a compelling resume; it’s your first impression and a key to unlocking exciting career opportunities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good