Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Experience with electrical installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Experience with electrical installation Interview

Q 1. Explain the National Electrical Code (NEC) and its importance.

The National Electrical Code (NEC) is a widely adopted set of standards for the safe installation and use of electrical systems in the United States. Think of it as the rulebook for electricians. It’s crucial because it ensures safety, preventing electrical fires, shocks, and other hazards. The NEC covers everything from wiring methods and grounding to overcurrent protection and equipment installation. Regular updates reflect advancements in technology and safety practices. For instance, recent updates have addressed the increasing use of renewable energy sources and smart home technology, ensuring these new technologies are integrated safely into existing electrical systems.

Non-compliance with the NEC can lead to serious consequences, including building permit rejection, insurance claims denial, legal liabilities, and ultimately, injury or death. It’s the cornerstone of safe electrical work and is essential for protecting both people and property.

Q 2. Describe your experience with different types of wiring (e.g., Romex, BX, conduit).

My experience encompasses a wide range of wiring methods. Romex, also known as NM cable, is a common choice for residential wiring due to its ease of installation. It’s a non-metallic sheathed cable with conductors encased in a plastic jacket. I’ve extensively used it in numerous residential renovations and new constructions. BX cable, or armored cable, provides superior protection against physical damage as the conductors are enclosed in a flexible metal sheath. It’s often favored in areas where the risk of cable damage is higher, like garages or areas with heavy equipment. Finally, conduit wiring, where wires are run inside rigid metal or plastic pipes, offers the highest level of protection against damage and provides excellent flexibility for routing wires in complex situations. I’ve worked extensively with conduit in commercial settings, where durability and maintainability are paramount. Each type of wiring presents unique advantages and disadvantages that I consider carefully during the planning stages of a project, selecting the most suitable option based on the specific requirements.

Q 3. How do you ensure electrical safety on a job site?

Electrical safety is my top priority on every job site. I consistently follow these key practices: Always de-energize circuits before working on them; this is achieved through proper lockout/tagout procedures. Using appropriate personal protective equipment (PPE) like insulated gloves, safety glasses, and non-conductive footwear is non-negotiable. I ensure all equipment is properly grounded and that all wiring is correctly installed in accordance with the NEC. Regular testing with multimeters and meggers helps identify potential hazards. A significant part of ensuring safety involves proper job site organization— keeping the area clean, free of tripping hazards, and ensuring adequate lighting. Regular safety briefings with the team reinforce safe work practices, addressing potential risks proactively. My philosophy is to anticipate potential hazards and eliminate them before they can become problems. A near-miss or even an incident is a critical learning opportunity, which I use to enhance safety protocols.

Q 4. What are the different types of electrical panels and their applications?

Electrical panels, or breaker boxes, are the central distribution points for electricity in a building. There are various types, each suited for specific applications. Sub-panels, for instance, are used to distribute power from a main panel to different parts of a larger building, helping to manage the load and prevent overloading. Main panels serve as the primary point of entry for power from the utility grid. Load centers are similar to main panels and used widely in residential settings. The choice of panel depends on factors like the overall electrical load, the number of circuits required, and the building’s size and electrical requirements. For example, a large commercial building will require a much larger panel with more breakers than a small residential house. Understanding the different types and their applications is crucial for ensuring a safe and efficient electrical system.

Q 5. Explain the process of troubleshooting electrical faults.

Troubleshooting electrical faults is a systematic process. I typically start by visually inspecting the affected area for obvious problems like loose connections or damaged wiring. Then, using a multimeter, I measure voltage and current to identify where the fault lies. A methodical approach helps me narrow down the possibilities, starting from the source of the power and working my way to the affected device. Testing various components, checking for shorts or open circuits, and carefully examining circuit breakers are all part of the process. Documentation is also crucial; each step is recorded to aid in future troubleshooting. For example, if a circuit breaker keeps tripping, I might need to trace the circuit to identify a fault like an overloaded branch circuit. In more complex situations, I might need to employ specialized testing equipment, like a clamp meter to measure current precisely. The approach is iterative, often leading to the discovery of the root cause after several investigations. A systematic methodology aids in the effective and efficient resolution of electrical faults.

Q 6. How do you interpret electrical blueprints and schematics?

Interpreting electrical blueprints and schematics is fundamental to my work. These documents provide a detailed roadmap of the electrical system. I’m proficient in reading symbols, understanding circuit diagrams, and tracing the pathways of power throughout the building. Symbols such as those representing circuit breakers, switches, outlets, and wiring types are instantly recognizable. The schematics show how these components interconnect, outlining the power flow and providing precise locations. For example, a schematic will show which circuits are protected by which breakers, and how lighting circuits are wired throughout the house. My experience includes working with both hand-drawn and computer-generated drawings, ensuring that I can decipher the system’s layout accurately. Understanding the drawings allows me to plan installations, make repairs, and troubleshoot problems efficiently. These drawings are like a map guiding me through the electrical system, which, when accurately read and interpreted, makes project execution smooth and safe.

Q 7. What experience do you have with various electrical testing equipment (e.g., multimeters, meggers)?

I have extensive experience with various electrical testing equipment. Multimeters are my everyday tools, allowing me to measure voltage, current, and resistance. I use them to test for continuity, identify shorts, and verify proper circuit function. Meggers, on the other hand, are crucial for testing insulation resistance. They apply a high voltage to determine the integrity of insulation and identify potential ground faults. In addition to these, I’m also familiar with clamp meters for precise current measurement without interrupting the circuit, loop impedance testers for ensuring safety in low-voltage systems, and thermal imaging cameras to identify potential hot spots indicating faulty connections or overloaded circuits. Each piece of equipment plays a specific role in identifying electrical hazards and ensuring that systems are properly installed and safe. My proficiency with these tools is essential for troubleshooting problems accurately and efficiently, making the systems reliable, safe and efficient.

Q 8. Describe your experience with grounding and bonding techniques.

Grounding and bonding are crucial safety measures in electrical installations, preventing electric shock and protecting equipment. Grounding connects a conductive element to the earth, providing a low-resistance path for fault currents to flow. Bonding connects multiple conductive elements together to ensure they are at the same electrical potential.

My experience includes various grounding techniques, from using ground rods and grounding electrodes for systems with high fault currents to employing equipotential bonding to connect metallic enclosures and pipes in bathrooms and kitchens. I’ve worked with different grounding systems, including single-point grounding and multi-point grounding, selecting the appropriate method depending on the specific application and safety regulations. For instance, I once had to troubleshoot a system with a ground loop – a condition where multiple grounding paths create a circulating current. Identifying the loop and re-grounding properly resolved the issue and prevented equipment damage. In terms of bonding, I’ve consistently applied the appropriate bonding conductors to ensure safety and compliance with NEC standards, especially in industrial settings where multiple pieces of equipment are interconnected.

- Grounding: Using ground rods to establish a reliable earth connection, ensuring proper depth and contact for optimal performance.

- Bonding: Connecting metal conduit, enclosures, and equipment to ensure electrical continuity and prevent voltage differences.

- Ground Fault Circuit Interrupters (GFCIs): Installing and testing GFCIs to prevent electric shock by quickly disconnecting power in the event of a ground fault.

Q 9. How do you calculate voltage, current, and resistance?

Ohm’s Law is the foundation for calculating voltage, current, and resistance in a DC circuit. It states that voltage (V) is equal to the current (I) multiplied by the resistance (R): V = I * R.

To calculate any of these values, you need to know the other two. For example, if you know the voltage across a resistor and the resistance itself, you can calculate the current flowing through it: I = V / R. Conversely, if you know the current and resistance, you can calculate the voltage: V = I * R. This simple equation forms the basis for many electrical calculations. In AC circuits, the calculations are more complex due to the sinusoidal nature of the voltage and current, often involving concepts like impedance and reactance. However, Ohm’s Law still provides a fundamental understanding.

For example, if a circuit has a 12V battery and a 6-ohm resistor, the current would be: I = 12V / 6Ω = 2A.

Q 10. Explain the difference between AC and DC power.

The main difference between AC (Alternating Current) and DC (Direct Current) power lies in the direction of electron flow. In DC, electrons flow consistently in one direction, like water flowing through a pipe. Batteries and solar panels produce DC power.

AC, on the other hand, changes direction periodically, typically 50 or 60 times per second (Hz). Imagine a seesaw – the electrons are constantly switching directions. Most household power outlets provide AC power. The advantages of AC include easier transmission over long distances and the ability to efficiently step up or step down voltage using transformers (which don’t work with DC).

DC is generally safer because the voltage doesn’t fluctuate, and it’s preferred for applications like charging batteries and powering low-voltage electronics. AC is more prevalent for large-scale power distribution and appliances.

Q 11. What are your experiences with different types of transformers?

My experience encompasses various transformer types, including step-up, step-down, isolation, and autotransformers. Step-up transformers increase voltage, while step-down transformers decrease it. Isolation transformers provide electrical isolation between the primary and secondary circuits, enhancing safety. Autotransformers provide a variable voltage output by using a single winding.

I’ve worked with transformers in various settings, from small power supplies to large industrial applications. One particular project involved replacing a faulty step-down transformer in a manufacturing plant. This required careful analysis of the existing circuit, selection of a suitable replacement transformer with matching voltage and current ratings, and ensuring safe installation and testing procedures were followed. I have experience in diagnosing transformer issues such as overheating, humming sounds (indicative of internal problems), and output voltage discrepancies, using multimeters and other testing equipment to identify the root cause and implement the necessary repairs or replacements.

Q 12. Describe your experience with motor control circuits.

Motor control circuits are essential for safely starting, stopping, and controlling the speed of electric motors. My experience includes designing and troubleshooting various circuits, including those using contactors, relays, and programmable logic controllers (PLCs). I’ve worked with different types of motor starters, such as across-the-line starters, reduced-voltage starters, and soft starters, choosing the best option based on the motor’s size, load characteristics, and application requirements.

Safety is paramount in motor control circuits, and I have extensive knowledge of incorporating safety features like overload protection, short-circuit protection, and emergency stop switches. For instance, I once worked on a project involving a complex motor control system for a conveyor belt in a warehouse. Careful design and implementation of the safety circuits prevented potential accidents and ensured the smooth operation of the system. I am proficient in reading and interpreting motor control schematics, and debugging problems using multimeters, oscilloscopes, and specialized motor testing equipment.

Q 13. What safety precautions do you take when working with high voltage?

Safety is my top priority when working with high voltage. I always follow a strict safety protocol, beginning with a thorough risk assessment of the job. This includes identifying potential hazards and planning appropriate control measures. I never work alone on high-voltage systems; a qualified colleague is always present as a spotter and to provide assistance if needed.

Before starting any work, I ensure the power is completely isolated and locked out/tagged out, verifying the absence of voltage using appropriate testing equipment. I use insulated tools and personal protective equipment (PPE), including insulated gloves, safety glasses, and arc flash protective clothing, appropriate for the voltage level. I always follow the manufacturer’s instructions for any specialized equipment or tools. After completing the work, I carefully inspect the equipment and connections before restoring power, ensuring everything is properly connected and grounded.

Q 14. Explain your experience with various types of lighting systems.

My experience spans various lighting systems, from traditional incandescent and fluorescent lighting to modern LED and smart lighting systems. I understand the principles of lighting design, including lumen output, color temperature, color rendering index (CRI), and power consumption. I’ve worked with different lighting control systems, including dimmers, occupancy sensors, and daylight harvesting systems to optimize energy efficiency and user comfort.

I’ve been involved in projects ranging from simple residential lighting installations to complex commercial lighting retrofits, ensuring compliance with relevant building codes and safety regulations. For example, I recently oversaw a project to replace inefficient fluorescent lighting fixtures in an office building with energy-efficient LED lighting. This involved careful planning to minimize disruption, proper disposal of hazardous materials, and ensuring seamless integration with the existing electrical system. I also have experience troubleshooting lighting issues, identifying faulty ballasts, wiring problems, or other malfunctions, using multimeters and other diagnostic tools. I am familiar with different types of lighting controls and have successfully implemented systems that reduce energy costs and improve lighting quality.

Q 15. Describe your experience with installing and troubleshooting security systems (e.g., CCTV, alarm systems).

My experience with security systems encompasses both installation and troubleshooting of CCTV and alarm systems. Installation involves careful planning to ensure optimal camera placement for coverage and minimal blind spots. This includes running cabling, often concealed within walls or ceilings, connecting cameras to DVRs or NVRs (Digital Video Recorders or Network Video Recorders), and configuring the system for remote access and recording. Troubleshooting, on the other hand, requires a systematic approach. I start by identifying the problem – a malfunctioning camera, a tripped alarm, or connectivity issues – and then systematically check each component, from cabling and connections to power supplies and network configurations. For example, I recently resolved an issue where a CCTV camera wasn’t recording by identifying a faulty network cable connection. Replacing the cable immediately restored functionality.

I’m proficient with various security system technologies, including IP-based systems, analog systems, and hybrid setups. I understand the importance of adhering to security protocols and best practices during installation and maintenance to ensure system integrity and reliability. Understanding access control and user permissions is also critical for ensuring security systems remain effective.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage time and resources on an electrical installation project?

Managing time and resources on an electrical installation project requires careful planning and execution. I begin with a thorough review of the project blueprints, identifying materials needed and estimating labor hours. This helps create a detailed project schedule, breaking down the work into manageable tasks with assigned deadlines. I use project management software to track progress, identify potential bottlenecks, and ensure adherence to the schedule. Resource management involves sourcing materials efficiently, securing necessary permits, and coordinating with other tradespeople, such as plumbers or drywallers. For example, on a recent large-scale commercial project, I identified a potential delay in receiving specialized conduit fittings. I proactively contacted alternative suppliers, securing the fittings in time to avoid any disruptions to the project timeline.

Effective communication is crucial. Regular meetings with the client and the project team ensure everyone is aligned and any issues are addressed promptly. Contingency planning is also essential – having backup plans for potential delays or material shortages ensures the project remains on track, even when unforeseen challenges arise.

Q 17. What is your experience with different types of conduits and fittings?

My experience encompasses a wide range of conduits and fittings, including rigid metal conduit (RMC), intermediate metal conduit (IMC), flexible metal conduit (FMC), electrical metallic tubing (EMT), and PVC conduit. I’m familiar with the respective applications and limitations of each type. For example, RMC is ideal for high-strength applications, while EMT is more flexible and easier to install. I’m proficient in using various fittings, such as couplings, elbows, connectors, and boxes, ensuring proper installation according to the National Electrical Code (NEC) and local regulations. Proper conduit bending techniques are also crucial for a neat and efficient installation. Improper bending can damage the conduit and compromise safety. I ensure all fittings are correctly secured and grounded to meet safety standards. Choosing the right conduit type for a specific application is important and depends on factors such as environmental conditions, load requirements, and installation location.

Q 18. Describe your experience with electrical system design and calculations.

I have extensive experience in electrical system design and calculations, including load calculations, voltage drop calculations, and short-circuit current calculations. Load calculations determine the required amperage for circuits, ensuring proper sizing of wiring and circuit breakers. Voltage drop calculations ensure sufficient voltage reaches the end points of a circuit, preventing performance issues. Short-circuit calculations are critical for protective device coordination, ensuring appropriate circuit breaker sizing to prevent damage during faults. I utilize specialized software and calculation tools to streamline the design process. For example, I recently designed the electrical system for a new office building, completing detailed load calculations to determine the appropriate size and number of electrical panels required. Thorough planning ensures a safe and effective electrical system that meets the building’s needs. This involves understanding and implementing relevant electrical codes and standards.

Q 19. How do you handle unexpected problems or delays on a project?

Handling unexpected problems or delays requires a calm and systematic approach. My first step is to thoroughly assess the situation, identifying the root cause of the problem and its potential impact on the project schedule and budget. Then, I develop a solution, considering various options and choosing the most efficient and cost-effective approach. This often involves collaborating with the project team and the client to find the best solution. Transparent communication is vital during this process, keeping everyone informed of the situation and the steps being taken to resolve it. For instance, I once encountered a delay due to a supplier failing to deliver materials on time. I immediately contacted alternative suppliers, negotiated expedited shipping, and communicated the revised timeline to the client, mitigating the impact on the overall project.

Q 20. What is your experience with working at heights and in confined spaces?

I have significant experience working at heights and in confined spaces, always prioritizing safety. When working at heights, I adhere strictly to safety regulations, using appropriate fall protection equipment such as harnesses and safety lines. This includes conducting regular inspections of equipment before and during use. In confined spaces, I follow entry procedures, ensuring proper ventilation and using gas detection equipment to prevent exposure to hazardous atmospheres. I am also trained in rescue procedures for both scenarios and ensure that all team members are aware of these procedures. My experience includes working on scaffolding, using aerial lifts, and entering manholes and crawl spaces. Safety is never compromised, and I always prioritize the well-being of myself and my team. Regular training and adherence to safety protocols are critical in such environments.

Q 21. Describe your experience with different types of electrical distribution systems.

My experience includes various electrical distribution systems, including low-voltage systems (typically 120/240V in residential settings), medium-voltage systems (used in commercial and industrial settings), and high-voltage systems (for large-scale power distribution). I understand the differences in safety protocols and installation requirements for each voltage level, including the use of appropriate protective equipment and installation techniques. I am familiar with different grounding and bonding methods to ensure safety and system integrity. I have worked with various system configurations, such as radial systems, loop systems, and parallel systems, understanding the advantages and disadvantages of each. For example, I’ve worked on projects involving both three-phase and single-phase systems, understanding how to select appropriate transformers and protective devices for each. My knowledge extends to different types of transformers, circuit breakers, and switchgear, tailored to the specific distribution system in use.

Q 22. How do you ensure compliance with building codes and regulations?

Ensuring compliance with building codes and regulations is paramount in electrical installations. It’s not just about avoiding penalties; it’s about ensuring safety and preventing potential hazards. My approach involves a multi-step process:

- Thorough Code Review: Before starting any project, I meticulously review all relevant local, state, and national electrical codes (like the National Electrical Code – NEC in the US). I identify specific requirements for the project’s scope, including wiring methods, grounding techniques, and safety standards.

- Permitting and Inspections: I always obtain the necessary permits from the relevant authorities before commencing work. This involves submitting detailed plans and specifications that demonstrate compliance with the codes. Regular inspections during the installation process allow for timely identification and correction of any non-compliances.

- Documentation and Record Keeping: Comprehensive documentation is crucial. I maintain meticulous records, including the permit applications, inspection reports, material specifications, and installation diagrams. This documentation serves as a valuable reference and aids in ensuring traceability during future maintenance or upgrades.

- Continuous Learning: Electrical codes and regulations are constantly evolving. I stay updated through professional development courses, code updates, and industry publications to maintain my knowledge and adapt to the latest requirements.

For example, in a recent commercial project, we were installing a new electrical system in a historic building. The building’s unique construction required us to work closely with the building inspector to ensure we met both current code and the historical preservation requirements. Through careful planning and consistent communication, we successfully completed the project and received final approval, illustrating the importance of comprehensive compliance procedures.

Q 23. What is your experience with using specialized software for electrical design or calculations?

I’m proficient in several specialized software packages used for electrical design and calculations. My experience includes using:

- AutoCAD Electrical: For creating detailed electrical schematics, panel layouts, and wiring diagrams. I’m skilled in using its libraries of symbols and components to create accurate and easily understandable drawings. For instance, I recently used AutoCAD Electrical to design the electrical system for a large-scale manufacturing facility, ensuring accurate placement of equipment and proper wiring routing.

- ETAP (Electrical Transient Analyzer Program): This software allows for advanced power system studies, including short-circuit calculations, load flow analysis, and arc flash hazard analysis. It helps in ensuring the system’s stability and safety. I used ETAP to analyze the power distribution system for a hospital, identifying potential vulnerabilities and recommending necessary upgrades to ensure reliable power delivery.

- SKM PowerTools: This suite offers similar capabilities to ETAP and aids in designing robust and safe electrical systems, performing critical calculations to mitigate risks.

These programs are not merely tools; they are integral to my process, allowing for precise calculations, efficient design, and enhanced safety measures, resulting in more robust and reliable electrical systems.

Q 24. Describe a challenging electrical installation project and how you overcame it.

One challenging project involved installing a new electrical system in an active data center with minimal downtime. The existing system was outdated, and the client required a seamless transition with no interruption to their operations. This presented several hurdles:

- Tight Deadlines: The client had a narrow window for the upgrade, demanding precise scheduling and efficient execution.

- Complex Infrastructure: The data center housed numerous sensitive servers and network equipment, necessitating careful planning to avoid any damage or disruption.

- Safety Concerns: Working with live electrical systems required strict adherence to safety protocols to prevent accidents.

To overcome these challenges, we implemented a phased approach. We worked closely with the data center management team to create a detailed shutdown plan that minimized downtime and ensured a smooth transition. We used temporary power solutions to maintain operations during the phases, followed by testing and commissioning each phase before moving to the next. This methodical approach, combined with precise planning and diligent execution, resulted in a successful project completion within the specified deadline, without any disruption to the data center’s operations. This project highlighted the importance of meticulous planning, clear communication, and proactive problem-solving in managing complex electrical installations.

Q 25. How do you maintain accurate records and documentation for electrical installations?

Maintaining accurate records and documentation is crucial for several reasons, including safety, compliance, and future maintenance. My approach to documentation involves:

- Digital Record Keeping: I use cloud-based systems for storing all project-related documentation, including drawings, permits, inspection reports, and material specifications. This ensures easy access, version control, and seamless collaboration with the team.

- As-Built Drawings: I maintain updated as-built drawings that reflect the actual installed system. Any deviations from the original plans are accurately recorded. This is vital for future maintenance and repairs.

- Material Tracking: I meticulously track all materials used, including their specifications, serial numbers (if applicable), and installation locations. This information helps in troubleshooting and warranty claims.

- Inspection Reports: All inspection reports are stored and readily accessible, providing a clear record of compliance with building codes and regulations.

For instance, in a recent residential project, meticulous record-keeping facilitated a quick resolution when a minor issue arose with a circuit breaker. Having all the specifications on file allowed us to promptly replace it with the correct model, preventing any further disruption.

Q 26. What is your experience with troubleshooting and repairing electrical equipment?

Troubleshooting and repairing electrical equipment requires a systematic and methodical approach. My process involves:

- Safety First: Always de-energize the circuit before starting any troubleshooting or repair work. Safety is my top priority.

- Visual Inspection: I begin with a thorough visual inspection to identify any obvious issues like loose connections, damaged wires, or faulty components.

- Testing and Measurement: I use specialized tools like multimeters, clamp meters, and insulation testers to diagnose the problem accurately. I measure voltage, current, and resistance to pinpoint the fault.

- Systematic Approach: I follow a structured approach, starting from the most likely cause and systematically eliminating possibilities until the root cause is identified.

- Documentation: I document all troubleshooting steps, test results, and repairs performed for future reference.

For example, I recently resolved a recurring tripping circuit breaker issue in a commercial building. Through systematic testing, I identified a high load on the circuit that exceeded its capacity. The solution involved rerouting some loads to balance the circuit, preventing further issues.

Q 27. Describe your familiarity with various types of electrical connectors and terminations.

My experience encompasses a wide range of electrical connectors and terminations, including:

- Wire Nuts: For connecting wires of the same size and material within junction boxes.

- Screw-Type Connectors: For connecting wires of different sizes and materials, often used in lighting fixtures and appliances.

- Push-In Connectors: Quick and easy to use, ideal for low-voltage applications.

- Terminal Blocks: Used in control panels and other applications for neat and organized wire connections.

- Compression Connectors: Used for high-current applications, creating a secure and reliable connection.

- Crimp Connectors: Used with specialized tools to create secure and reliable connections. Especially useful in wiring harnesses.

- Solderless Connectors: Provide mechanical connection without needing soldering.

Choosing the appropriate connector is crucial to ensuring a safe and reliable electrical connection. The choice depends on factors like the wire size, material, current carrying capacity, and the specific application. Improper selection can lead to overheating, fire hazards, or equipment malfunction. I always adhere to best practices and manufacturer recommendations when selecting and installing connectors.

Q 28. What are your professional development goals in the field of electrical installation?

My professional development goals center on enhancing my expertise and staying at the forefront of the electrical installation field. These include:

- Advanced Training: I plan to pursue certifications in specialized areas like industrial electrical systems or renewable energy technologies, broadening my skillset and enhancing my marketability.

- Software Proficiency: I aim to deepen my proficiency in advanced electrical design software, mastering more complex features and expanding my capabilities in creating efficient and robust systems.

- Staying Updated: I will continue to actively participate in industry conferences and workshops, keeping my knowledge current with the latest codes, technologies, and best practices.

- Leadership Development: I also aspire to develop my leadership skills, mentoring junior technicians and contributing to a safe and productive work environment.

Continuously improving my skills and knowledge is essential to remain competitive and provide high-quality services. The electrical installation field is constantly evolving with new technologies and standards, and I’m committed to lifelong learning and professional growth.

Key Topics to Learn for Electrical Installation Interviews

- Electrical Codes and Regulations: Understanding and applying relevant national and local electrical codes (e.g., NEC) to ensure safe and compliant installations. This includes familiarity with different code versions and amendments.

- Wiring Techniques and Methods: Practical experience with various wiring methods (e.g., conduit bending, cable termination, splicing techniques) and their appropriate applications in different settings (residential, commercial, industrial).

- Electrical Diagrams and Schematics: Ability to read, interpret, and create electrical schematics, blueprints, and wiring diagrams. This includes understanding symbols, notations, and conventions used in the industry.

- Troubleshooting and Diagnostics: Experience identifying and resolving electrical faults using appropriate testing equipment (multimeters, voltage testers) and systematic troubleshooting approaches. This includes understanding common electrical problems and their solutions.

- Safety Procedures and Practices: Demonstrating a strong understanding of electrical safety regulations, lockout/tagout procedures, and personal protective equipment (PPE) usage to prevent accidents and injuries.

- Electrical Components and Systems: In-depth knowledge of common electrical components (switches, outlets, circuit breakers, transformers, motors) and their function within larger electrical systems. Understanding of different types of power distribution and control systems.

- Installation Practices for Various Systems: Experience installing and maintaining various electrical systems, including lighting systems, power distribution systems, grounding systems, and potentially specialized systems (e.g., fire alarm, security systems).

- Project Management and Documentation: Understanding of project planning, execution, and documentation including keeping accurate records of materials, labor, and progress. This also includes working effectively as part of a team.

Next Steps

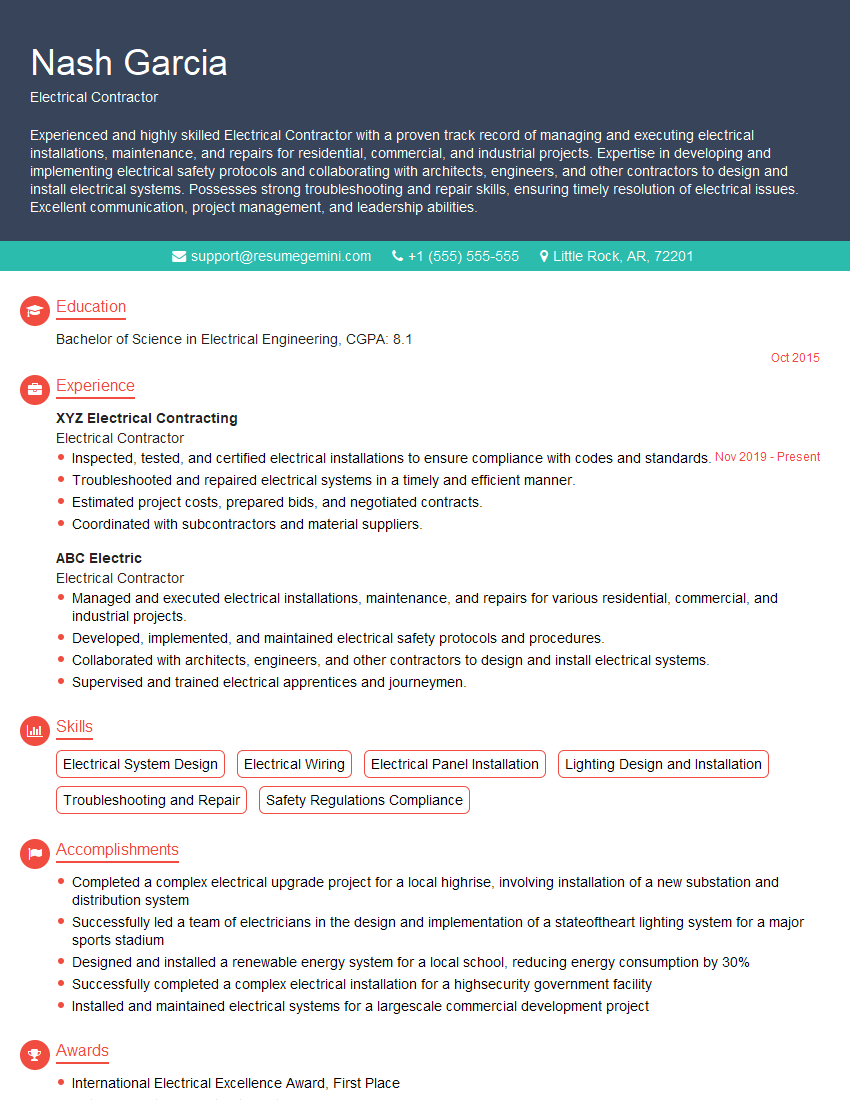

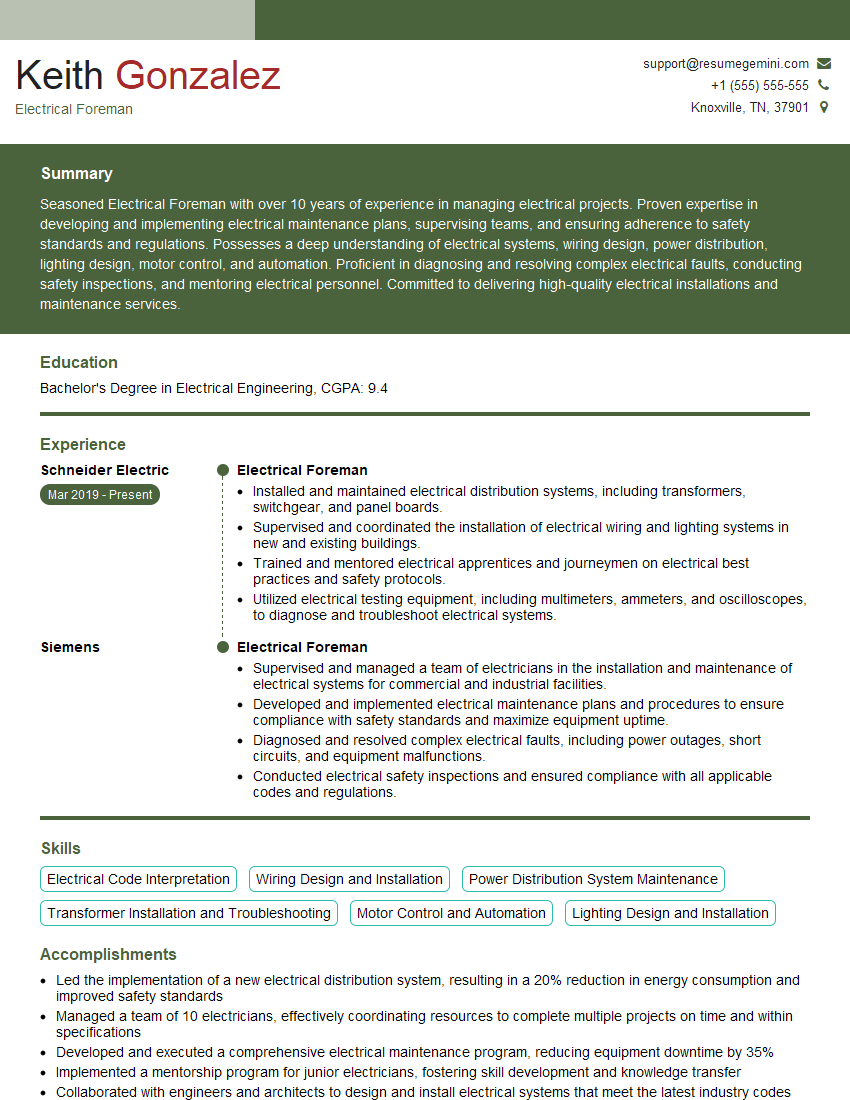

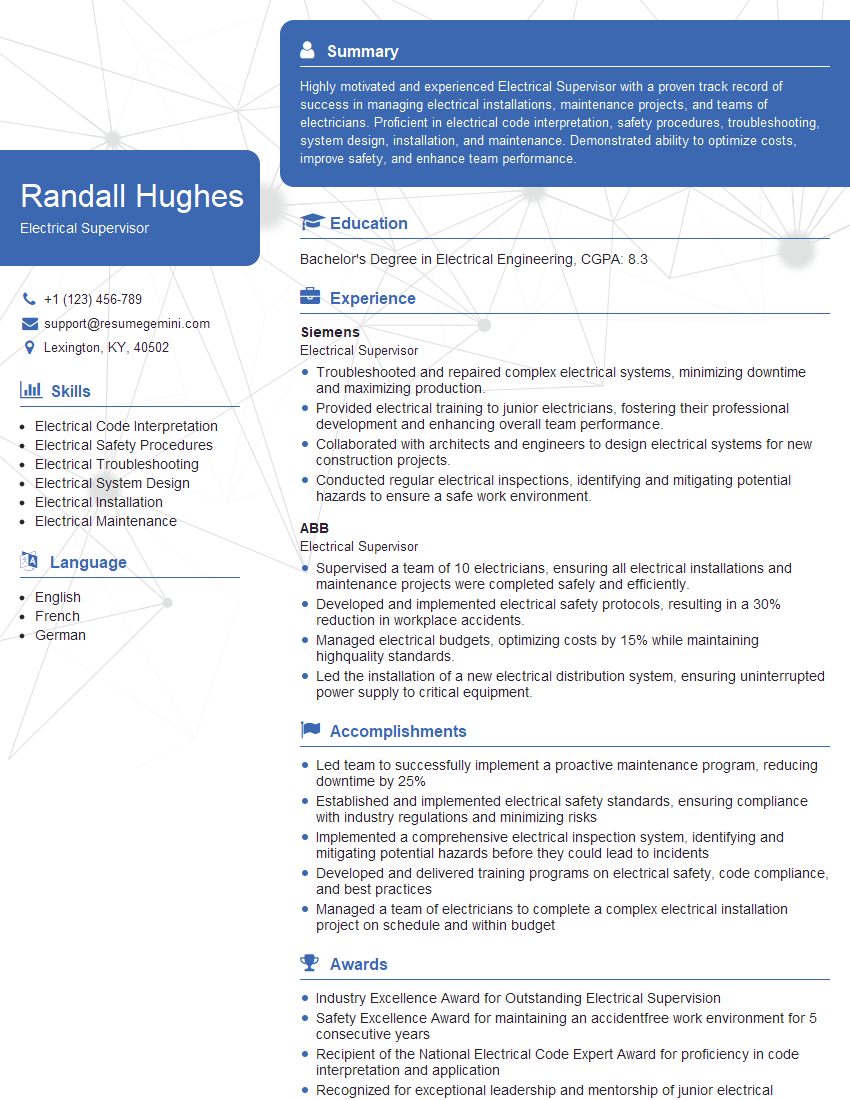

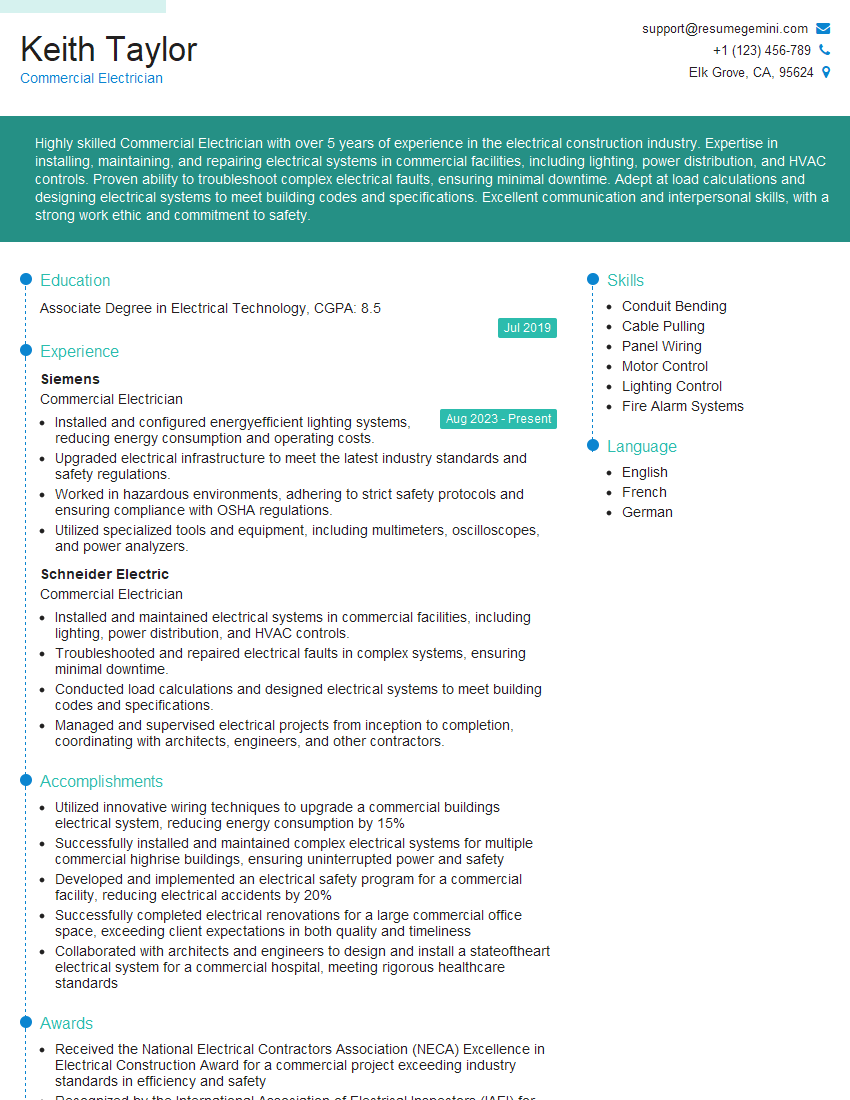

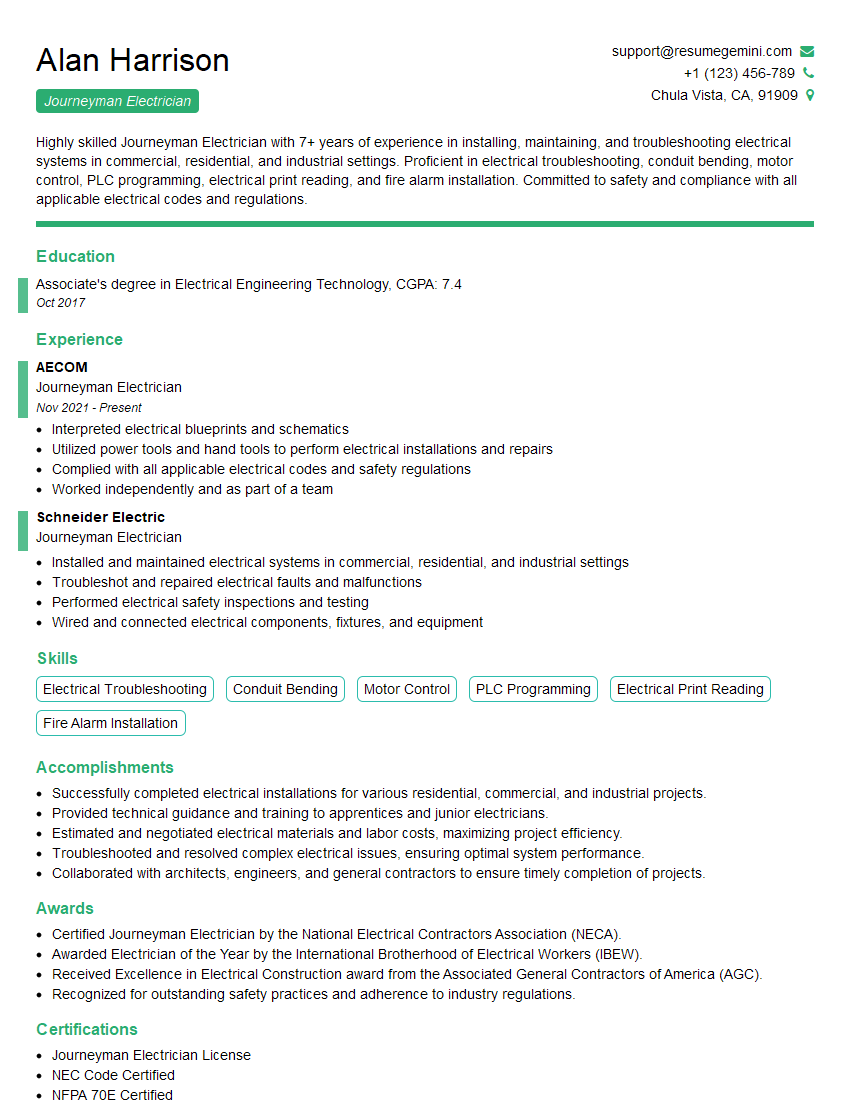

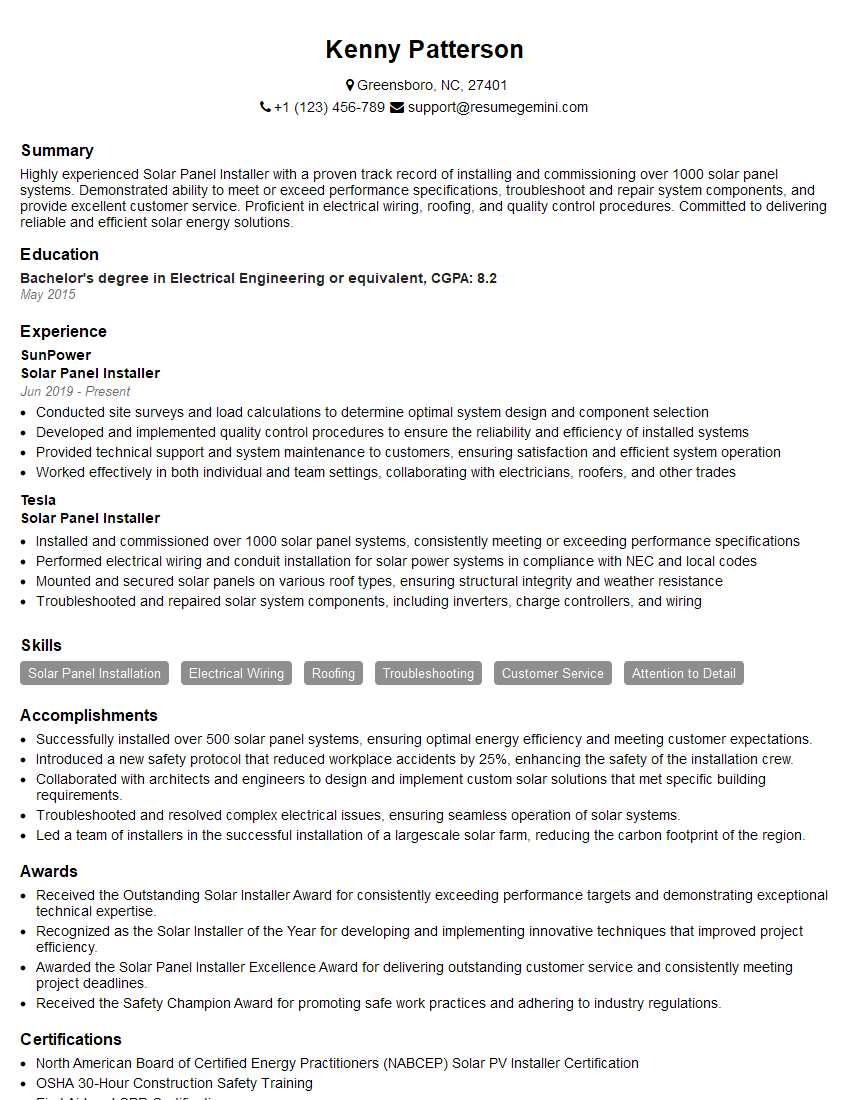

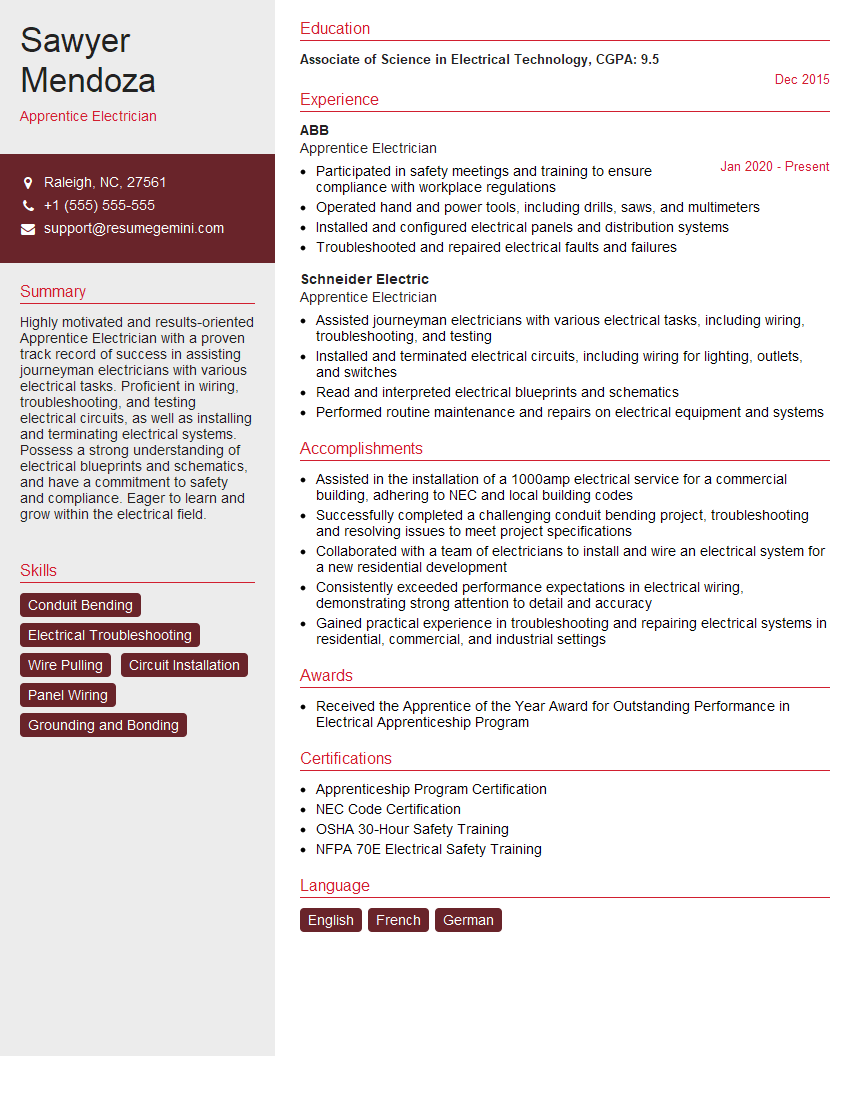

Mastering the fundamentals of electrical installation is crucial for career advancement in this dynamic field. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To increase your chances of landing your dream job, creating an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and effective resume that stands out from the competition. They even provide examples of resumes tailored to electrical installation experience, giving you a head start in crafting your perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good