Preparation is the key to success in any interview. In this post, we’ll explore crucial Baler operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Baler operation Interview

Q 1. Describe your experience operating different types of balers (horizontal, vertical, etc.).

My experience encompasses a wide range of balers, including horizontal balers, vertical balers, and auto-tie balers. Horizontal balers, often used for large volumes of loose materials like cardboard or textiles, compress material horizontally. I’m proficient in operating various models, understanding their specific controls and nuances. Vertical balers, on the other hand, are better suited for smaller items or materials that need more controlled compaction. I’ve worked with both self-feeding and manually fed versions, adjusting techniques based on the material being processed. Auto-tie balers, which automatically tie the bales after compression, offer efficiency advantages, and I’m experienced in their operation and maintenance. Each type requires a different approach, from understanding the optimal feed rate to recognizing signs of potential issues. For instance, I once had to adjust the bale density settings on a horizontal baler processing particularly fluffy paper to achieve the required compaction level and prevent premature bale ejection.

Q 2. Explain the process of preparing materials for baling.

Preparing materials for baling is crucial for efficient and safe operation. This involves several steps. First, a thorough inspection of the material is necessary. Removing contaminants like metal, plastic, or other incompatible materials is vital to prevent damage to the baler and ensure the bale’s integrity. Secondly, materials should be sorted and segregated according to type and size. This optimizes the baling process and prevents mixing incompatible materials. Think of it like organizing your sock drawer – similar materials together for best results. Third, the material needs to be pre-fed appropriately for the type of baler in use. Too much material at once can overload the machine, while too little can lead to inefficient compression. Finally, regular checks for any moisture content should be made; overly wet material can create problems during the compaction process.

Q 3. How do you ensure the safety of yourself and others while operating a baler?

Safety is paramount when operating a baler. I always start with a pre-operation inspection of the machine for any loose parts or potential hazards. Lockout/Tagout procedures are strictly followed whenever any maintenance or repair is undertaken. Personal Protective Equipment (PPE) such as safety glasses, gloves, and sturdy footwear are always worn. Maintaining a clear workspace free of obstructions around the machine is essential. Never reach into the baler while it’s in operation – the pressure inside can cause serious injury. I routinely check the bale ejection mechanism to ensure it’s operating correctly to avoid crushing injuries. Clear communication with coworkers is also vital. For instance, when a bale is ready for removal, I ensure nobody is close to the ejection point before initiating the process.

Q 4. What are the common maintenance tasks for a baler?

Regular maintenance is key to preventing costly breakdowns and ensuring the baler operates efficiently. This includes daily checks of oil levels, hydraulic fluid levels, and belt tension. Regular lubrication of moving parts is vital to reduce wear and tear. I also inspect the bale chamber for any signs of damage or debris buildup. Weekly or monthly maintenance might include more detailed checks of hydraulic systems, checking for leaks, and cleaning the baler’s interior thoroughly. Periodically, the knives or cutting mechanisms, depending on the baler type, require sharpening or replacement. Keeping detailed maintenance logs, noting all inspections and servicing, is crucial for tracking the baler’s health and anticipating potential problems. Ignoring maintenance can lead to significant downtime and costly repairs, so it’s a critical aspect of responsible baler operation.

Q 5. How do you troubleshoot common baler malfunctions?

Troubleshooting baler malfunctions requires a systematic approach. First, identify the problem. Is the baler not compressing properly? Is it failing to eject bales? Is there a power issue? Once the problem is identified, check the most common causes. For instance, a lack of compression could be due to low hydraulic fluid levels, a damaged ram, or a jammed bale chamber. A failure to eject could stem from issues with the ejection mechanism or a problem with the bale tying system. I utilize diagnostic manuals and operational guides for specifics regarding my equipment. For electrical issues, I have checked power supplies and circuit breakers. If the problem persists, consulting a qualified technician is vital. It’s better to seek expert help than to risk further damage by attempting a repair beyond my skillset. Documenting the troubleshooting process, including the problem, the steps taken, and the resolution, is beneficial for future reference.

Q 6. What are the signs of a malfunctioning baler?

Several signs indicate a malfunctioning baler. Slow or inconsistent compaction is a common symptom, often pointing towards hydraulic problems or worn-out components. Unusual noises, such as grinding or squealing, may indicate internal damage or mechanical issues. The inability to form properly shaped bales or frequent bale ejection problems are also significant warning signs. Leaks of hydraulic fluid or oil are potential safety hazards and require immediate attention. If the baler overheats regularly, this suggests a problem with the cooling system or an overload situation. Lastly, be aware of any unusual power draw from the equipment; significantly higher electricity usage compared to standard operations can indicate a hidden problem. Regular checks and monitoring are pivotal to catching these early and preventing major issues.

Q 7. How do you handle jammed materials in a baler?

Handling jammed materials requires a careful and systematic approach. First, switch off the baler and ensure it’s completely powered down before attempting any intervention. Never attempt to dislodge jammed materials while the baler is running. Once the machine is safe, assess the nature of the jam. Is it a minor blockage, or is it a significant amount of material? For minor blockages, I sometimes use appropriate tools to carefully loosen and remove the jammed material. For major jams, I often utilize the baler’s built-in features (if available), such as reverse functions, to gently release the blockage. In some cases, it may be necessary to dismantle parts of the machine (after proper lockout/tagout) to remove the obstruction. However, this should only be attempted by individuals with experience and knowledge of the machine’s internal components. Always prioritize safety and never compromise proper procedures. Remember to document the event and the steps taken to resolve the jam for future reference and to identify potential improvements in the operating process.

Q 8. What safety precautions do you take before starting the baler?

Before starting any baler, safety is paramount. My routine begins with a thorough visual inspection of the entire machine. I check for any obvious damage, loose parts, or leaks. This includes examining the feeding mechanism, the chamber, the tying system, and the ejection area. I then ensure that all guards are securely in place. Next, I verify that the area surrounding the baler is clear of obstructions and that no personnel are within the danger zone. Finally, I test all controls to ensure they are functioning correctly before engaging the power. Think of it like pre-flight checks for an airplane – crucial for a safe operation.

- Check for leaks: Hydraulic fluid leaks can be dangerous and need immediate attention.

- Inspect the feeding mechanism: Ensure there are no blockages or foreign objects that could cause damage.

- Verify safety guards: These are designed to prevent accidental contact with moving parts.

- Clear the area: This prevents accidents involving other people or equipment.

Q 9. Describe your experience with different types of baling wire or twine.

My experience encompasses a wide range of baling materials, each requiring a specific type of twine or wire. For example, I’ve extensively used steel wire for high-density bales of heavy materials like scrap metal or tightly packed cardboard. Steel wire offers superior strength and holds the bale together under significant compression. For lighter materials like hay or straw, I’ve worked with both natural twine (sisal or hemp) and synthetic twine (polypropylene). Natural twine is biodegradable, making it a more environmentally friendly option for agricultural applications. Synthetic twine, on the other hand, offers greater tensile strength and resistance to moisture, crucial in certain weather conditions. The selection depends heavily on the material being baled and the desired bale density. I’ve also had experience with biodegradable plastic twine, which offers a balance between strength and environmental responsibility.

- Steel wire: High strength, suitable for heavy materials.

- Natural twine (sisal, hemp): Biodegradable, suitable for lighter materials.

- Synthetic twine (polypropylene): High tensile strength and moisture resistance.

- Biodegradable plastic twine: A compromise between strength and environmental impact.

Q 10. How do you ensure the proper density and size of bales?

Achieving the proper bale density and size is critical for efficient storage, transportation, and handling. This is largely controlled by the baler’s settings. Most modern balers have adjustable parameters like bale chamber size and pre-compression settings. For instance, a higher pre-compression setting will lead to a denser bale. The density is also affected by the material being baled itself – wetter material will naturally result in a denser bale. I regularly monitor the bale formation during the process and adjust settings as needed to achieve the desired density and size. For example, if I’m baling hay, a looser bale might be preferred for better aeration and to prevent mold, whereas denser bales might be needed for transportation efficiency of scrap metal. Consistent monitoring and adjustments are key to optimal bale characteristics.

- Adjust pre-compression settings: Impacts the density of the bale.

- Monitor bale formation: Observe the density and size while the bale is being formed.

- Adjust other settings as needed: Consider factors like material type, moisture content, and desired application.

Q 11. What are the different types of materials you have baled?

Over the years, I’ve worked with a diverse range of materials. This includes agricultural products like hay, straw, and silage, as well as recycled materials such as cardboard, plastic film, and even scrap metal. The type of material significantly influences the baler settings and the choice of baling twine or wire. For instance, baling hay requires different settings and twine compared to baling scrap metal. Each material has its unique properties impacting bale density and size. Experience with diverse materials allows for efficient operation regardless of the material type.

- Agricultural products: Hay, straw, silage

- Recycled materials: Cardboard, plastic film

- Other materials: Scrap metal, textiles (in some specialized balers)

Q 12. How do you identify and address potential safety hazards related to baler operation?

Identifying and addressing potential hazards is a continuous process. My approach includes regular inspections, as previously discussed, but also encompasses awareness of potential risks during operation. This includes being mindful of pinch points in the machinery, ensuring proper guarding of moving parts, and understanding the potential for entanglement. Addressing these issues involves not only preventative measures like regular maintenance but also safe operating procedures. For example, never reaching into the baling chamber while the machine is running. Furthermore, I regularly review safety protocols and receive updates on best practices to stay informed about potential hazards and mitigation strategies. Safety is an ongoing commitment, not a one-time task.

- Regular inspections: Identify potential problems before they become hazards.

- Safe operating procedures: Strict adherence to guidelines is essential.

- Awareness of pinch points and entanglement hazards: Understanding the potential risks.

- Continuous learning and updates: Stay informed about safety best practices.

Q 13. What is your experience with baler lubrication and maintenance schedules?

Proper lubrication is critical for baler longevity and performance. I follow a strict lubrication schedule, using the manufacturer’s recommended lubricants and applying them to all designated points. This includes hydraulic cylinders, bearings, and other moving parts. Neglecting lubrication can lead to premature wear, increased friction, and ultimately, equipment failure. Beyond the routine lubrication, I also perform regular maintenance checks, looking for signs of wear or damage. This preventative approach saves time and money in the long run. A well-maintained machine is a safe machine. I maintain detailed records of all lubrication and maintenance activities to track the machine’s health effectively.

- Follow manufacturer’s lubrication schedule: Using the appropriate lubricants.

- Regular maintenance checks: Identifying potential problems early.

- Detailed records: Keeping track of maintenance activities for better preventative care.

Q 14. Explain your understanding of the hydraulic system in a baler.

The hydraulic system in a baler is the powerhouse behind its operation. It utilizes hydraulic fluid under pressure to power the various components, such as the ram that compresses the material, the tying mechanism, and even the bale ejection system. Understanding the hydraulic system involves knowledge of its components: the hydraulic pump, the valves, the cylinders, and the lines connecting them all. I know how to identify leaks, check fluid levels, and troubleshoot common hydraulic problems. For example, I understand that low fluid levels can lead to reduced performance, while leaks can cause serious damage if not addressed immediately. Troubleshooting might involve identifying a faulty valve or a leak in the hydraulic lines. Regular maintenance, such as checking fluid levels and filter conditions, is essential for the smooth functioning of the hydraulic system.

- Hydraulic pump: The heart of the system, generating hydraulic pressure.

- Valves: Control the flow of hydraulic fluid.

- Cylinders: Convert hydraulic pressure into mechanical force.

- Hydraulic lines: Connect all the components of the system.

Q 15. How do you maintain accurate records of baling operations?

Maintaining accurate records in baling operations is crucial for efficiency, tracking productivity, and troubleshooting. I typically use a combination of digital and physical methods. Digitally, I rely on dedicated baler software or integrated systems that automatically record bale count, weight, dimensions, and timestamps. This data is often linked to other aspects of the operation, such as material source and destination. For example, I might use a system that tracks bales from the field, through processing, to shipment, linking them to specific orders or contracts.

Physically, I maintain detailed logbooks. These include manual entries of daily bale counts, any maintenance performed, and notes on any irregularities encountered during the day. This creates a backup system and allows for detailed analysis even when digital systems malfunction. The logbooks are systematically organized and clearly labeled, making it easy to reference past performance and identify trends. This two-pronged approach ensures comprehensive and reliable record-keeping, crucial for evaluating overall operational success and for regulatory compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different bale sizes and configurations.

My experience encompasses a wide range of bale sizes and configurations, from small, square bales commonly used for hay to large, rectangular bales used in the recycling and waste management industries. I’m proficient in operating balers that produce variable bale sizes, adjusting settings based on material type and customer requirements. For instance, I’ve worked with balers producing bales ranging from 4x4x8 feet for cardboard to much smaller bales of 2x2x3 feet for textiles. This includes experience with different bale densities, achieved through varying pressure settings on the baler. Understanding how different bale sizes and configurations affect storage, transport, and downstream processing is key. For example, optimizing bale density improves transport efficiency by minimizing wasted space, reducing fuel costs and transportation emissions. Conversely, too high a density can compromise bale integrity and make handling more difficult.

Q 17. How do you handle unexpected downtime or equipment failure?

Unexpected downtime is a significant concern in any baling operation, so I approach it systematically. My first step is always safety: ensuring the area is secure and the equipment is properly shut down to prevent accidents. Then, I perform a quick visual inspection to identify the potential cause of the failure. Is it a simple blockage? A hydraulic leak? Electrical issue? Based on my assessment, I’ll either attempt a minor repair or contact maintenance personnel. If it’s a major issue requiring specialized tools or parts, I follow established procedures for reporting equipment malfunctions and coordinating repairs. During downtime, I’ll often utilize the time to conduct routine maintenance tasks on other aspects of the system or address any backlog of paperwork. Prioritizing safety and employing a structured troubleshooting approach minimizes downtime and keeps the operation running smoothly. Regular preventative maintenance significantly reduces the likelihood of unexpected failures.

Q 18. Explain your understanding of the different types of baler controls.

Baler controls vary widely, from simple manual levers and switches to sophisticated computer-controlled systems. I’m experienced with both. Simple mechanical controls allow for direct manipulation of the baling process, offering a good understanding of the machine’s mechanics. However, these lack the data logging and automated functions of more advanced systems. Modern balers frequently employ PLC (Programmable Logic Controller) based controls. These allow for precise control over parameters like bale density, size, and tying cycle. They offer diagnostic capabilities, providing real-time feedback on the baler’s performance and potential issues. Some advanced systems even incorporate sensors for automated adjustments to the baling process based on material characteristics. Understanding the nuances of each control system, whether mechanical or computerized, is essential for efficient and safe operation. It’s important to understand safety protocols associated with each type of control to prevent accidents.

Q 19. What is your experience with preventative maintenance on a baler?

Preventative maintenance is paramount to ensure reliable baler operation and prevent costly breakdowns. My approach follows a scheduled maintenance plan, incorporating daily, weekly, and monthly checks. Daily checks include visual inspections for leaks, loose connections, and debris buildup. Weekly checks involve more in-depth lubrication of moving parts and cleaning of key components. Monthly maintenance includes thorough inspections of hydraulic systems, belts, and electrical connections, often involving testing and adjustments. I meticulously document all maintenance activities in the logbooks, recording dates, procedures, and any identified issues. This systematic approach minimizes downtime and extends the lifespan of the baler. A well-maintained baler operates more efficiently, produces higher-quality bales, and is far safer to use. Remember, neglecting preventative maintenance can lead to significant and expensive repairs down the line.

Q 20. How do you ensure the efficiency of baling operations?

Ensuring efficient baling operations involves several key strategies. First, optimizing material flow is critical. This includes minimizing bottlenecks in the feed system and ensuring a consistent supply of material to the baler. Secondly, proper baler settings are essential. These settings should be adjusted based on the material type and desired bale characteristics to maximize bale density while maintaining bale integrity. Regular calibration and maintenance of the baler itself, as discussed earlier, are also crucial. Thirdly, operator skill and training play a vital role. A skilled operator can anticipate potential problems and adjust settings proactively, maximizing efficiency and minimizing waste. Effective communication with other teams involved in the process – from material handling to transportation – also contributes to efficiency. Finally, data analysis using the records discussed earlier allows for the identification of areas for improvement, leading to ongoing optimization of the baling operation.

Q 21. Describe your experience working with various bale tying systems.

I’m experienced with a variety of bale tying systems, including twine, wire, and plastic film. Twine tying is commonly used for hay and other agricultural products, offering a biodegradable and relatively inexpensive option. Wire tying provides exceptional strength and is often preferred for heavier materials, but it’s less environmentally friendly and can be more expensive. Plastic film wrapping, often used in conjunction with twine or wire, enhances bale stability and protects the contents from the elements. The choice of tying system depends on several factors, including the type of material being baled, the desired bale density, and environmental considerations. For example, using biodegradable twine is more environmentally responsible than using wire. My experience includes the ability to maintain and troubleshoot various tying mechanisms, ensuring reliable and efficient bale formation. Understanding the limitations and advantages of each system is essential to selecting the best option for a given application.

Q 22. How do you monitor the performance of the baler and make adjustments?

Monitoring baler performance involves a multi-faceted approach combining real-time observation with regular data analysis. I start by visually inspecting the bale size and density – a consistently smaller or less dense bale suggests potential issues with the compression system or material feed. I then check the machine’s control panel for any error codes or warnings; these provide direct clues to malfunctioning components. Key performance indicators (KPIs) like bales produced per hour and downtime are tracked using the baler’s built-in monitoring system or external data loggers. For example, a significant drop in bales per hour could indicate a problem with the knotter, ram, or even insufficient material supply. Based on these observations and data, adjustments are made; this could involve tightening belts, clearing blockages, adjusting the bale density settings, or even scheduling preventative maintenance.

If the problem persists despite adjustments, troubleshooting steps are taken involving more in-depth diagnostics – checking hydraulic pressure levels, inspecting drive chains, or examining the electrical systems. Regular calibration of sensors is also crucial to maintain accuracy in bale density and size measurements. This data-driven, proactive approach ensures optimal baler performance and minimizes downtime.

Q 23. What are your skills in identifying and resolving mechanical issues?

My mechanical skills are extensive, covering hydraulics, pneumatics, and electrical systems common in balers. I can diagnose and repair a wide range of issues. For example, I’ve successfully diagnosed and fixed issues such as a faulty hydraulic ram by checking for leaks and verifying fluid levels, troubleshooted electrical faults using multimeters and schematics, and repaired damaged conveyor belts and chains through proper replacement and tensioning procedures. I am proficient in using diagnostic tools and interpreting error codes displayed by the baler’s control panel. One instance involved a baler experiencing repeated stoppages. By systematically checking the hydraulic system, I identified a failing pressure relief valve as the culprit, preventing further downtime and potential damage. My experience also includes working with different types of baler mechanisms, from horizontal to vertical balers, allowing for adaptability to a wide range of equipment.

Q 24. How do you comply with all safety regulations and procedures?

Safety is paramount in baler operations. I strictly adhere to all company safety regulations and procedures, including wearing appropriate Personal Protective Equipment (PPE) like safety glasses, gloves, and hearing protection at all times. Before commencing any task, I conduct a thorough machine inspection, checking for any potential hazards like exposed wires, loose parts, or hydraulic leaks. Lockout/Tagout procedures are meticulously followed before performing any maintenance or repair work to prevent accidental starts. I ensure the area surrounding the baler is kept clear of obstructions to avoid tripping hazards. Furthermore, I am trained and certified in relevant safety standards and participate in regular safety training to stay updated on best practices. I actively participate in safety meetings and immediately report any unsafe conditions or near misses. Safety is not just a procedure, but an integral part of my work ethic.

Q 25. What is your experience working with different types of waste materials?

My experience spans a variety of waste materials, including cardboard, paper, plastic, textiles, and even some types of industrial waste (always following specific regulations for handling hazardous materials). Each material presents unique challenges for baling; for example, very wet materials require adjustments to the baler’s settings to avoid excessive moisture buildup, and materials with sharp edges necessitate extra precautions to prevent damage to the baler’s components. I adjust baler settings such as bale density and bale size to optimize the process for each material type. For instance, cardboard generally requires higher compression for efficient storage and transport, whereas softer materials like textiles might need lower compression to avoid damage. Understanding the properties of different materials is crucial for efficient and safe baling.

Q 26. How do you determine when a baler needs to be serviced or repaired?

Determining when a baler needs servicing or repair involves continuous monitoring and proactive maintenance. Regular visual inspections are key—checking for leaks, worn parts, or unusual noises. I also pay close attention to the baler’s performance data; consistent decreases in production rate, irregular bale formation, and frequent error codes all signal potential problems. A preventive maintenance schedule, tailored to the baler’s usage and operational hours, is followed religiously, including lubrication checks, belt adjustments, and sensor calibrations. Any deviation from normal operating parameters triggers a thorough investigation. For example, consistently low bale density might point to worn compression rams or faulty hydraulic components. In such cases, I would consult maintenance manuals and work with qualified technicians to address the issues promptly.

Q 27. Explain your understanding of the environmental impact of baling operations.

Baling operations significantly reduce the environmental impact of waste management. By compacting waste materials, we reduce the volume requiring transport and landfill space. This translates directly to lower greenhouse gas emissions from transportation and a smaller environmental footprint from landfills. The reduced volume also makes waste materials easier to recycle or handle for other disposal methods. For instance, densely packed bales of cardboard are significantly easier to transport than loose cardboard, requiring fewer trucks and reducing fuel consumption. However, we must be mindful of the energy consumption of the baler itself and choose energy-efficient models whenever possible. Furthermore, proper material segregation before baling is crucial to avoid contamination and ensure that recyclable materials are truly processed for reuse.

Q 28. Describe your experience in a team environment related to baler operations.

In team environments, effective communication and collaboration are crucial for efficient baler operations. I’ve worked as part of a team where we regularly shared information about equipment status, upcoming maintenance, and identified any potential issues proactively. For example, I’ve worked alongside maintenance technicians, material handlers, and supervisors to ensure smooth workflow and quick resolution of problems. We rely on a system of clear communication, whether through daily briefings, shift handover reports, or direct communication during urgent situations. Teamwork is critical for addressing unexpected issues; a quick response by the whole team to a jammed baler can prevent major downtime. Open communication and a collaborative spirit foster a safe and efficient work environment, where every member contributes to the overall success of the baling process.

Key Topics to Learn for Baler Operation Interview

- Baler Mechanics: Understanding the internal mechanisms, including the ram, chamber, and tying system. This includes knowledge of different baler types (e.g., horizontal, vertical).

- Operational Procedures: Safe and efficient operation protocols, including pre-operation checks, material feeding techniques, and troubleshooting common malfunctions.

- Maintenance and Troubleshooting: Identifying and resolving common issues, preventative maintenance schedules, and understanding the importance of regular lubrication and part replacement.

- Safety Procedures: Comprehensive knowledge of safety regulations and best practices related to baler operation, including lockout/tagout procedures and personal protective equipment (PPE) usage.

- Material Handling: Efficiently handling various materials suitable for baling, understanding material density and its impact on baler performance, and recognizing potential hazards associated with different materials.

- Performance Optimization: Techniques for maximizing bale density, minimizing downtime, and optimizing overall baler efficiency. This includes understanding the impact of different settings and adjustments.

- Quality Control: Inspecting bales for proper size, density, and integrity. Understanding how to adjust baler settings to meet specific quality requirements.

- Data Interpretation: Understanding and interpreting basic performance data, such as bale count, production rates, and downtime metrics.

Next Steps

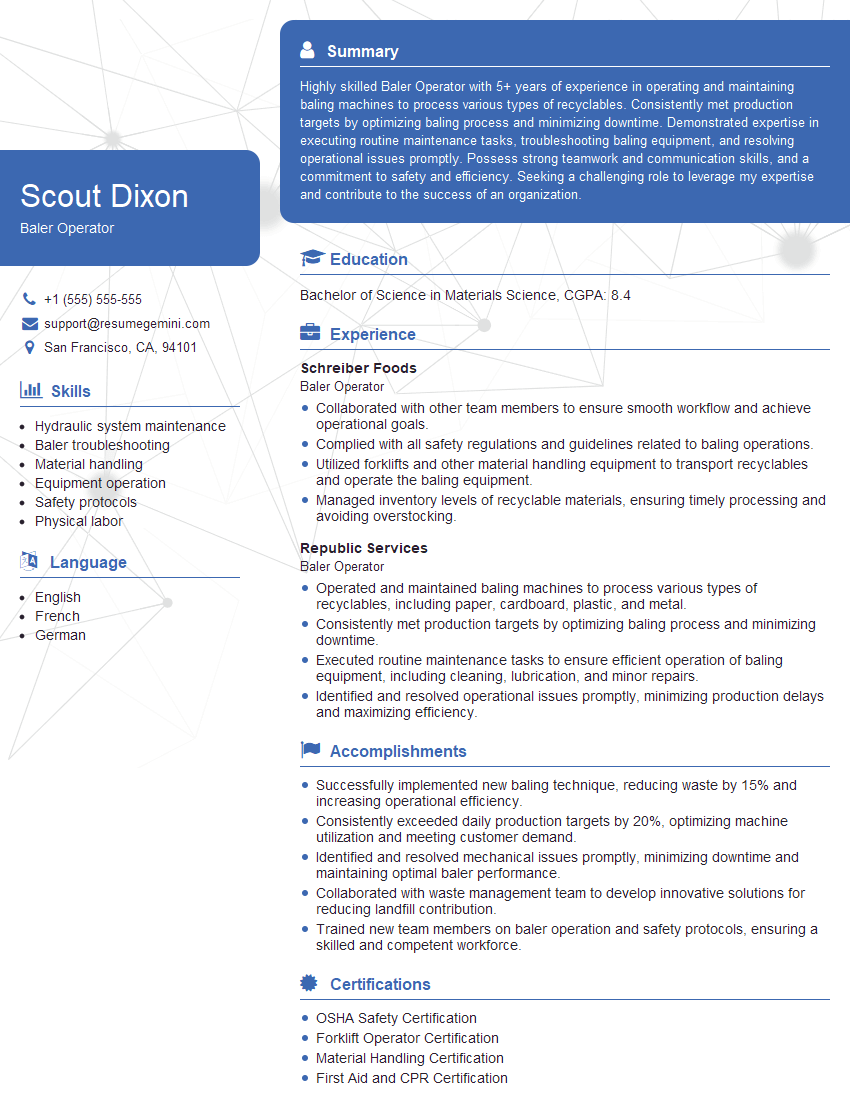

Mastering Baler operation opens doors to rewarding careers in manufacturing, recycling, and waste management. A strong understanding of these principles demonstrates valuable technical skills and commitment to safety, making you a highly desirable candidate. To significantly boost your job prospects, focus on crafting an ATS-friendly resume that highlights your relevant experience and skills. We strongly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to help you create a resume that gets noticed, and we offer examples of resumes tailored to Baler operation to guide you. Take the next step towards your dream job – start building your resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good