The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Knowledge of embroidery industry terminology and standards interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Knowledge of embroidery industry terminology and standards Interview

Q 1. What are the different types of embroidery stitches?

Embroidery stitches are the foundation of any embroidered design. They vary widely in appearance and purpose, impacting the final look and feel of the piece. Some popular types include:

- Running Stitch: A simple stitch ideal for outlines, sketching, or creating lines of varying thickness. Think of it as the pencil stroke of embroidery.

- Backstitch: Creates a strong, solid line often used for outlining or text. It’s like sewing a seam, but decorative.

- Satin Stitch: A dense stitch used to fill areas with a smooth, glossy surface. This is your “paintbrush” for solid color blocks.

- Fill Stitch (various types): A category encompassing multiple stitches (e.g., seed stitch, detached chain stitch) used to fill an area with texture and visual interest. This is like using different brushstrokes to add texture.

- Chain Stitch: Creates looped stitches resembling a chain, perfect for creating outlines or decorative elements. It’s a versatile stitch with many variations.

- French Knots: Small, decorative knots often used for adding texture or detail, like tiny dots of color.

- Cross Stitch: Two intersecting stitches creating an “X”, known for its use in counted cross-stitch patterns.

This list is not exhaustive, but it covers many commonly used stitches. The choice of stitch depends heavily on the desired aesthetic and the complexity of the design.

Q 2. Explain the difference between satin stitch and fill stitch.

While both satin stitch and fill stitch are used to cover areas, they differ significantly in their appearance and execution.

Satin stitch aims for a smooth, glossy, solid surface. The stitches are laid close together, completely covering the underlying fabric. Think of it like painting a solid color; the goal is even coverage.

Fill stitches, on the other hand, use various shorter stitches to fill an area, resulting in a textured look. This isn’t about a solid color, but texture and visual interest. Examples include seed stitch (small, closely packed dots), detached chain stitch (small chain loops), and others. This is more akin to using different painting textures, rather than a solid block of color.

In essence, satin stitch provides a clean, even surface, while fill stitches offer variety and texture.

Q 3. What is a jump stitch and how can you minimize its appearance?

A jump stitch is the visible thread that connects two separate embroidery areas. It’s essentially the gap the machine takes to move from one area to another. These are unavoidable in most designs but should be minimized.

Minimizing jump stitch appearance involves several techniques:

- Careful Design Placement: Strategic placement of design elements can reduce the number of jumps needed.

- Utilizing Jump Stitch Functions in Software: Most digitizing software offers tools to control and shorten jump stitches, minimizing their visibility.

- Using a Smaller Needle or Thread: A finer needle and thread can make the jump stitches less noticeable.

- Professional Digitizing: Skilled digitizers plan designs to reduce jump stitch length and occurrence.

- Post-Processing: Manually concealing jump stitches with a similar colored thread after embroidery can improve the finish.

The goal is to make jump stitches as inconspicuous as possible, ultimately maintaining the integrity and aesthetic of the final embroidered product. Consider it like the tiny scaffolding used to construct a masterpiece – the scaffolding should be removed at the end and leave only the masterpiece intact.

Q 4. Describe the process of digitizing an embroidery design.

Digitizing is the process of converting a design (a drawing, logo, or image) into a stitch file that an embroidery machine can read and execute. It’s a crucial step, translating artistic vision into a machine-readable language.

The process generally involves:

- Image Preparation: The source image is cleaned and optimized for digitizing, removing unwanted elements or inconsistencies.

- Stitch Creation: A digitizing software is used to trace the outlines and fill areas of the design, specifying stitch type, density, and color changes. This is where artistic skill and technical knowledge meet.

- Stitch Density and Underlay Control: The digitizer adjusts the stitch density and underlay for stability, preventing puckering and ensuring the quality of the fabric.

- Color Separation: The design is separated into different color sections, each represented by a distinct stitch file.

- Testing and Refinement: The design is tested on a sample fabric and adjustments made to stitch density, underlay, and jump stitch positioning to optimize the final result.

- Output: Finally, the stitch files are exported in a format compatible with the embroidery machine.

Digitizing requires a combination of artistic sense and technical expertise in stitch types and their limitations. A poorly digitized design can result in damaged fabric, thread breakage, or a disappointing final product.

Q 5. What are some common embroidery fabric types and their suitability?

Choosing the right fabric is crucial for successful embroidery. Different fabrics have varying thread counts, weaves, and stability, impacting stitch quality and durability.

- Cotton: A popular choice, readily available in various weights and weaves. Suitable for most embroidery techniques. However, thin cotton can be prone to puckering.

- Linen: Strong, durable fabric with a unique texture. It’s excellent for detailed work but can be more challenging due to its weave.

- Silk: A luxurious fabric ideal for delicate, fine embroidery. Requires a delicate touch and specialized needles and threads due to its delicacy.

- Polyester: A synthetic fabric that’s strong and easy to care for. Suitable for durable items, but may lack the softness of natural fibers.

- Denim: Heavy-duty cotton ideal for robust designs. May require stronger needles and a denser stitch to penetrate the fabric.

- Felt: A non-woven fabric that’s easy to work with. Excellent for simple, bold designs.

The suitability of the fabric depends on the design complexity, desired finish, and intended application of the embroidered item. A light design on a heavy fabric may look out of place, just as heavy stitching on delicate fabric would damage the item.

Q 6. How do you determine the correct thread count for a specific design?

Determining the correct thread count is vital for achieving high-quality embroidery. A thread count that’s too low may lead to loose, unstable stitching, while a thread count that’s too high can cause the fabric to pucker and the needle to break.

Several factors influence thread count selection:

- Fabric Type: Different fabrics have different thread counts. Heavier fabrics generally require a higher thread count.

- Design Density: Complex designs with dense stitching require a higher thread count to support the increased needle penetrations.

- Stitch Type: Some stitches, like satin stitch, need denser stitching than others, like running stitch.

- Machine Type: The capabilities of the embroidery machine should also be considered, as some machines may not handle a very high thread count.

- Design Software: Embroidery digitizing software offers recommendations for thread counts based on the design and fabric parameters.

Trial and error, combined with knowledge of fabric and design characteristics, is often used to finalize the thread count. The ideal thread count minimizes distortion and creates clean, even stitching.

Q 7. What are the different types of embroidery machines and their capabilities?

Embroidery machines range from simple, single-needle home machines to sophisticated, multi-needle industrial machines capable of producing highly detailed and complex designs. Here are some common types:

- Single-Needle Home Machines: These machines are affordable and user-friendly, suitable for basic embroidery projects and hobbyists. They often use pre-programmed designs or simple digitizing software.

- Multi-Needle Home Machines: These machines offer greater speed and efficiency compared to single-needle machines and can handle more complex designs.

- Industrial Single-Head Machines: Used in commercial settings, these machines are robust and capable of high-speed, high-volume embroidery. They offer advanced features for precise stitching and increased production efficiency.

- Industrial Multi-Head Machines: These are the most sophisticated machines, featuring multiple heads that can embroider multiple garments simultaneously, drastically increasing production speed. These are reserved for large-scale commercial operations.

The choice of machine depends on the scale of embroidery work, budget, and technical requirements. While home machines are great for smaller projects, industrial machines are essential for large-scale production and specialized designs.

Q 8. Explain the concept of ‘underlay’ in embroidery.

An underlay in embroidery is a layer of stitches applied before the main design. Think of it as a foundation. It’s crucial for several reasons. First, it stabilizes the fabric, preventing puckering or distortion, especially with delicate materials like silks or knits. Second, it provides a better surface for the top stitches to adhere to, resulting in a cleaner, more professional-looking finish. Finally, it can add body or texture to the design itself. For example, a dense satin stitch underlay can create a plush, raised effect for a logo.

Different types of underlays exist, each suited to different needs. A wash-away underlay is temporary, dissolving after washing, ideal for projects requiring a smooth, flat surface without the bulk of a permanent underlay. Conversely, a tear-away underlay is removed manually after embroidery. A cut-away underlay remains on the garment, offering substantial support for heavily embroidered areas.

Imagine building a house; you wouldn’t just start placing bricks on the bare ground, would you? The underlay is like the foundation – essential for a strong, beautiful, and long-lasting finished product.

Q 9. What is color separation in embroidery and why is it important?

Color separation in embroidery refers to the process of digitally separating a design into individual color layers. Each layer corresponds to a specific thread color. This is crucial because embroidery machines can only use one color at a time. Therefore, each color in the design needs to be digitized as a separate file or ‘colorway’ to be sewn effectively.

Without color separation, you’d end up with a tangled mess of threads, impossible to embroider correctly. The process allows the machine to stitch each color layer sequentially, ensuring precise placement and sharp color definition. Think of a coloring book: each color gets its own page before the final picture emerges. Similarly, color separation allows each thread color to be stitched perfectly without overlapping other colors.

Professional embroidery software handles color separation automatically; you simply upload your design, and the software divides it into individual color layers based on the color palette and design parameters. This is a fundamental step in preparing embroidery designs for production.

Q 10. How do you troubleshoot common embroidery machine errors?

Troubleshooting embroidery machine errors requires a systematic approach. First, always consult your machine’s manual. Common problems include:

- Broken needles: Bent or broken needles often cause skipped stitches or thread breakage. Replace immediately.

- Thread tension issues: Incorrect tension results in puckering, loose stitches, or thread breakage. Adjust the tension dials, checking the top and bobbin tension separately.

- Bobbin winding problems: Improperly wound bobbins can lead to inconsistent stitching or bobbin jams. Ensure the bobbin is correctly wound and seated.

- Jams: Thread jams are common, often caused by lint or debris buildup. Clean the machine thoroughly, including the bobbin case and hook area.

- Timing belt issues: A faulty timing belt can lead to erratic stitching. This is a more advanced problem and may require professional repair.

If you can’t identify the problem, try a simple test: embroider a small sample with a single color. This helps isolate the issue – if the sample stitches well, the problem lies within the design, not the machine itself. It’s always wise to have a skilled technician diagnose and address complex issues; attempting repairs without the proper knowledge could cause further damage.

Q 11. What are the standard industry measurements for embroidery hoops?

Embroidery hoops come in a wide range of sizes, determined by the diameter of the circular frame. However, there aren’t universally standardized measurements across all manufacturers. Standard sizes are usually described by their diameter, such as 4×4 inches, 5×7 inches, 6×10 inches, and larger formats. These measurements refer to the area of fabric that can be held securely within the hoop and embroidered. It’s important to note that the hoop’s overall dimensions will be slightly larger to account for the frame itself.

Choosing the right hoop size depends entirely on the design’s size and the fabric’s dimensions. Overly large hoops for small designs might cause fabric wrinkles, while too small a hoop for a larger design will lead to significant distortion. Always ensure the hoop securely holds the fabric, preventing movement during the stitching process, crucial for accurate stitching.

Q 12. What is the importance of proper tension in embroidery?

Proper tension is paramount in embroidery. It refers to the balance between the top and bobbin threads. If the tension is off, the result is immediately noticeable. Too much top tension leads to puckering on the top, creating a stretched look on the back. Too much bobbin tension leads to the reverse, with the back looking tight and the top loose. Ideal tension produces a balanced, even stitch where both top and bottom threads are neatly interlocked without pulling.

Maintaining proper tension requires careful adjustment. Many machines have tension dials for both the top and bobbin threads. Experimentation is often required to find the perfect balance for each fabric type and thread weight. You can achieve this using test stitches until you achieve a balanced stitch – a balance that looks the same on both the top and back sides of the fabric.

Think of it as a tug-of-war. The top and bottom threads need to be equally strong, pulling equally to create a neat stitch. Improper tension leads to an uneven outcome, just like an uneven tug-of-war.

Q 13. Explain the concept of density in embroidery design.

Density in embroidery design refers to the closeness of the stitches. It’s measured in stitches per inch (SPI) or stitches per centimeter (SPC). Higher density means more stitches in a given area, resulting in a denser, more filled look. Lower density creates a more open, less filled appearance. The choice of density depends on the design’s style, fabric type, and desired effect.

High density is ideal for designs requiring a solid, even fill, such as satin stitches or lettering. However, excessively high density can lead to fabric distortion or even needle breakage. Lower density is better for designs requiring a more delicate or intricate look, allowing the fabric’s texture to show through. Think of a painting: high density is analogous to densely applied paint for a solid color, while low density is like a watercolor painting with more space between brushstrokes.

Embroidery software typically allows you to adjust the density of individual elements within a design. This control provides flexibility to create various textures and visual effects within a single piece.

Q 14. How do you handle different fabric weights when embroidering?

Handling different fabric weights when embroidering requires adjustments in several areas. The first is stabilization. Lighter fabrics like chiffon or silk need significantly more support to prevent puckering. A cut-away stabilizer or a heavy-weight tear-away stabilizer is usually essential. Heavier fabrics like denim or canvas might only need a lightweight stabilizer or even none at all. The second key adjustment is needle selection. Fine needles are best for lighter fabrics, while heavier needles are suitable for thicker fabrics.

Hooping is another crucial factor. Heavier fabrics might require a more aggressive hooping technique to ensure the fabric is held taut and flat. For lighter fabrics, you want to avoid over-tensioning, which can lead to stretching or even tearing. Stitch density is also important. Heavier fabrics generally can support higher stitch densities, while lighter fabrics might require lower densities to avoid damage.

Finally, the choice of thread can matter; finer threads are better suited to delicate fabrics, and thicker threads may be used with heavier ones, maintaining balance and aesthetics. Understanding these nuances allows you to achieve professional-looking embroidery across a wide range of fabrics.

Q 15. What are some common embroidery design software programs?

Several software programs are used for creating embroidery designs, each offering unique features and capabilities. Popular choices include:

- Wilcom EmbroideryStudio: A professional-grade software known for its advanced features, allowing for intricate designs and precise control over stitch properties.

- Embird: A versatile software package that’s popular for its ease of use and a wide range of editing tools. It’s a good choice for both beginners and experienced embroiderers.

- Tajima DG/ML: Primarily used in the industrial embroidery sector, this software is known for its powerful capabilities and compatibility with high-speed embroidery machines.

- Pulse: A more affordable option that’s still very capable. It’s a good choice for smaller businesses or individual designers.

The best software choice depends on your specific needs and budget. Factors to consider include the complexity of designs you create, your machine’s compatibility, and your technical skill level. For example, a small business might start with Embird before upgrading to Wilcom as their production needs grow.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between a running stitch and a backstitch?

Both running stitch and backstitch are fundamental embroidery stitches, but they differ significantly in their appearance and application:

- Running Stitch: This is a simple stitch created by inserting the needle up and down, making evenly spaced straight lines. It’s quick and easy to execute, often used for outlining or filling large areas with a somewhat loose effect. Think of it like drawing a line with a needle, similar to how you’d sketch a design on paper.

- Backstitch: This stitch creates a stronger, more solid line. Each stitch is made by inserting the needle back into the fabric a short distance from the previous stitch’s exit point. This creates a continuous, firm line that’s ideal for details requiring durability. Backstitching is like sewing a strong seam that locks the thread in place.

The key difference lies in the security of the stitching. Running stitch is faster but less secure, while backstitch is slower but far more durable.

Q 17. What are some common fabric finishes that impact embroidery quality?

Fabric finishes greatly influence embroidery quality. A poorly finished fabric can lead to puckering, distortion, or thread breakage. Common finishes that impact embroidery are:

- Preshrinking: Fabric should always be pre-shrunk before embroidery to prevent the finished piece from shrinking after washing.

- Weave type: Tightly woven fabrics generally hold embroidery well, while loose weaves might require additional stabilizer. A loosely woven fabric will be more prone to puckering.

- Fabric weight: Heavier fabrics can handle denser embroidery, while lighter fabrics might require careful stabilizer selection to prevent distortion.

- Fiber content: Natural fibers (cotton, linen) often behave differently than synthetics (polyester). Natural fibers can be more prone to puckering or distortion and might require more thoughtful stabilizer selection.

- Finishing treatments: Coatings or treatments on fabrics can affect needle penetration and thread flow, necessitating adjustments in the embroidery process.

For instance, a delicate silk garment requires careful consideration of both the stabilizer used and the stitch density to avoid damaging the base fabric.

Q 18. Explain the importance of proper stabilizer selection for embroidery.

Proper stabilizer selection is crucial for achieving high-quality embroidery. The stabilizer acts as a support layer during the stitching process, preventing puckering, distortion, and thread breakage. Choosing the wrong stabilizer can ruin a project.

Different stabilizers are designed for various fabrics and embroidery types. For instance:

- Cut-away stabilizer: Used for most projects, this is removed after stitching. Its stiffness prevents puckering and it is ideal for a wide range of fabrics.

- Tear-away stabilizer: Tears away from the finished project once the stitching is complete; often preferred for delicate fabrics because it minimizes damage.

- Wash-away stabilizer: Dissolves in water after stitching, suitable for projects where absolutely no stabilizer residue is desired.

- Fusible stabilizer: Ironed onto the back of the fabric, providing extra support.

Imagine trying to embroider on a thin, lightweight fabric without a stabilizer – the fabric would likely wrinkle and distort terribly. The stabilizer acts like a strong foundation on which to create the design, allowing for clean stitches and a professional finish.

Q 19. What is the difference between applique and embroidery?

While both appliqué and embroidery embellish fabrics, they are distinct techniques:

- Appliqué: Involves sewing a decorative piece of fabric onto a larger piece of fabric, creating a layered effect. The appliquéd shape is usually cut out and then stitched onto the backing.

- Embroidery: Uses a needle and thread to create designs directly onto the fabric, employing a wide variety of stitches and techniques.

Think of it this way: appliqué is like adding a patch, while embroidery is like drawing or painting with thread. However, they can be combined! An embroidered design can enhance an appliquéd shape, making it even more eye-catching.

Q 20. What are some quality control checks you perform during embroidery production?

Rigorous quality control is essential in embroidery production. My checks typically include:

- Design accuracy: Checking that the embroidered design precisely matches the digital design.

- Stitch consistency: Examining stitch density, tension, and overall uniformity.

- Fabric integrity: Inspecting for puckering, distortion, or damage to the base fabric.

- Color accuracy: Ensuring colors match the design specifications.

- Thread breakage: Checking for any broken threads or skipped stitches.

- Stabilizer residue: Removing excess stabilizer and checking for any leftover pieces.

- Overall finish: Evaluating the final aesthetic quality, ensuring it meets the set standards.

For instance, if I notice inconsistent stitching, I’ll investigate the machine’s settings or the quality of the thread. Each step is vital for delivering a high-quality final product.

Q 21. How do you handle a design that is too large for the available hoop size?

When a design exceeds the hoop’s size, a technique called “stitching in sections” or “hoop jumping” is used.

This involves dividing the design into smaller sections that fit within the hoop. Each section is embroidered individually, then the hoop is repositioned to stitch the next section, ensuring the sections seamlessly join.

The process involves:

- Design Segmentation: Using the embroidery software, the design is carefully divided into manageable sections that fit within the hoop.

- Marking: The software often allows marking or numbering of sections for easy tracking. The sections should slightly overlap to ensure flawless joining.

- Sequential Stitching: Each section is embroidered, with careful repositioning of the fabric in the hoop after each section.

- Securing Overlaps: The overlapping parts help the final piece of fabric lie flat without visible seams.

Careful planning and precise execution are vital for a seamless final result. The overlaps help to cover the points where the different sections of the design meet.

Q 22. What are the different types of embroidery threads available?

Embroidery threads come in a wide variety of materials, each with its own unique properties affecting the final look and durability of the embroidery. The choice of thread depends heavily on the project, the desired effect, and the fabric being embroidered.

- Rayon: A lustrous, smooth thread often used for high-quality embroidery. It produces a beautiful sheen and is available in a vast array of colors. However, it can be slightly weaker than other options.

- Polyester: A strong, durable, and vibrant thread commonly used in industrial embroidery due to its resilience and resistance to fading. It’s a popular choice for items that need to withstand frequent washing or wear.

- Cotton: A softer, more natural-feeling thread, ideal for projects where a softer hand is desired. It’s absorbent and can be more susceptible to fading or damage with repeated washing.

- Metallic Threads: These threads add a touch of sparkle and luxury, available in various finishes like gold, silver, or other metallic shades. They require special needles and often need slower stitching speeds to avoid breakage.

- Silk: A luxurious and high-end thread known for its beautiful sheen and drape. It’s often used in fine embroidery projects but is more delicate and expensive than other options.

For example, I recently worked on a project embroidering a company logo onto corporate polos. Given the need for durability and washability, we opted for a high-quality polyester thread. For a delicate wedding invitation, however, we chose a fine rayon thread to achieve the desired elegant look.

Q 23. What are the industry standard file formats used for embroidery designs?

The embroidery industry utilizes several standard file formats, each with its own strengths and weaknesses. The most common are:

- .DST (Tajima): A widely used format compatible with most embroidery machines. It’s known for its reliability and simplicity.

- .EXP (Barudan): Another popular format specifically designed for Barudan embroidery machines. Like .DST, it’s known for its stability and ease of use.

- .PES (Brother): The native format for Brother embroidery machines, it offers good compatibility and features.

- .XXX (Wilcom): A versatile format that’s highly compatible with a wide array of embroidery machines. Its flexibility makes it a common choice for design sharing and conversion.

- .CSD (Singer): Primarily used for Singer embroidery machines, this format is less widely used than the others.

It’s important to note that file conversion between formats is often possible, although some detail loss may occur. I routinely work with multiple formats and often use specialized software for converting designs to ensure compatibility with our client’s machines.

Q 24. How do you calculate the cost of an embroidery project?

Calculating the cost of an embroidery project involves a multifaceted approach encompassing several key factors. It’s not simply a matter of thread and labor; many hidden costs are involved.

- Thread Cost: This is determined by the type, quantity, and color of threads used.

- Labor Cost: This includes the time spent on digitizing the design (if necessary), setting up the machine, and actual embroidery time. Hourly rates vary based on experience and skill.

- Material Cost: This accounts for the cost of the backing material (such as stabilizer), and any additional embellishments like beads or sequins.

- Machine Wear and Tear: The ongoing maintenance and eventual replacement of needles, bobbins, and other machine parts also impact the cost.

- Overhead Costs: Rent, utilities, software licenses, and other operational expenses add to the overall project cost.

- Profit Margin: A crucial aspect to ensure business viability; a reasonable profit margin needs to be factored in.

For example, a simple logo embroidery might cost less than $5, while a complex, multi-colored design on a large item might cost upwards of $50 or more. Each project needs a detailed cost breakdown to avoid financial losses.

Q 25. What are some common challenges in industrial embroidery production?

Industrial embroidery production faces several unique challenges. These can be broadly categorized into design, production, and maintenance issues.

- Design Complexity: Intricate designs, especially those with small details, may lead to problems like thread breakage or distortion. Proper digitizing and careful attention to stitch density are essential.

- Production Efficiency: Balancing speed and quality is a constant challenge. Production bottlenecks from machine malfunctions or operator errors need to be minimized for on-time delivery.

- Thread Consistency: Ensuring a consistent thread supply is critical; variations in thread quality can lead to uneven stitching and affect the finished product’s appearance.

- Machine Maintenance: Regular maintenance is crucial to prevent downtime and ensure high-quality output. Ignoring this can lead to costly repairs or replacements.

- Fabric Handling: Different fabrics require specific hooping and tension adjustments to avoid puckering or damage during the embroidery process.

For example, we once faced a production delay due to a faulty bobbin winder, highlighting the importance of proactive maintenance. Effective planning, careful operator training, and proactive maintenance strategies are crucial to mitigate such challenges.

Q 26. Describe your experience with different types of embroidery needles.

Embroidery needles are highly specialized tools, and the selection of the correct needle is crucial for successful embroidery. Different needles are designed for different thread types and fabric weights.

- Sharp Needles: These are the most common type, ideal for most fabrics and threads. Their sharp point allows for easy penetration.

- Ballpoint Needles: Designed for knit fabrics, these needles have a rounded tip to prevent snagging or damaging the fabric’s loops.

- Embroidery Needles: Specifically designed for embroidery, these needles often have a slightly larger eye to accommodate thicker threads or metallic threads.

- Metallic Needles: These needles have a reinforced eye to prevent damage when using metallic threads, which tend to be more abrasive than other types.

- Stretch Needles: Similar to ballpoint needles but designed for highly elastic fabrics. They offer superior performance in stretch knits.

I have extensive experience with all of these needle types and regularly adapt my needle choices based on the specifics of each project. For instance, using a sharp needle on a knit fabric would result in runs, whereas a ballpoint needle is ideal for that situation.

Q 27. Explain your experience with various types of embroidery hoops and their applications.

Embroidery hoops serve a critical function in holding the fabric taut during the embroidery process, ensuring even stitching and preventing puckering. Various types are available, each suitable for different needs.

- Plastic Hoops: Commonly used for smaller embroidery projects due to their affordability and ease of use. They are relatively lightweight.

- Metal Hoops: Provide a more secure and consistent tension, making them suitable for larger projects or those requiring high precision. They’re generally more durable.

- Magnetic Hoops: These hoops use magnets to hold the fabric in place, which is faster than traditional screw hoops, but the fabric can sometimes shift slightly.

- Frame Hoops: Larger hoops used for industrial embroidery machines for supporting larger garments or fabrics.

My experience includes using all these hoop types. For instance, I use plastic hoops for quick, small projects, and metal hoops for larger, more intricate designs requiring a consistent tension. Choosing the right hoop depends heavily on both the project and the machine being used.

Q 28. How do you maintain and clean embroidery machines to ensure optimal performance?

Proper maintenance and cleaning of embroidery machines are essential for ensuring their longevity and optimal performance. Regular cleaning and lubrication prevent damage and ensure accurate stitching.

- Daily Cleaning: Remove lint, threads, and dust from the machine after each use. Pay particular attention to the bobbin area, needle plate, and feed dogs.

- Regular Lubrication: Using the recommended lubricant, lubricate moving parts as per the machine’s manual. This helps to reduce friction and wear.

- Needle Replacement: Regularly replace needles, as a bent or dull needle can damage both the machine and the fabric.

- Bobbin Case Cleaning: Clean the bobbin case and ensure it is properly aligned. Lint and debris in the bobbin case can cause stitching problems.

- Periodic Professional Servicing: Schedule regular professional servicing for a thorough inspection, cleaning, and any necessary adjustments or repairs.

Ignoring these simple maintenance steps can lead to costly repairs, production delays, and poor stitch quality. I routinely incorporate these practices into my workflow, ensuring our machines operate at peak efficiency.

Key Topics to Learn for Knowledge of embroidery industry terminology and standards Interview

- Stitch Types and Techniques: Understanding various embroidery stitches (e.g., satin stitch, running stitch, chain stitch), their applications, and limitations. Knowing when to use each stitch for optimal results.

- Thread Types and Properties: Familiarity with different thread materials (e.g., rayon, polyester, cotton), their suitability for various fabrics and designs, and their impact on stitch quality and durability. Understanding thread count and tension.

- Embroidery Machine Operation and Maintenance: Knowledge of different embroidery machine types (e.g., single-head, multi-head), their functionalities, and basic troubleshooting. Understanding bobbin winding, needle selection, and hooping techniques.

- Design Software and Digitizing: Familiarity with embroidery design software (e.g., Wilcom, Pulse) and the digitizing process. Understanding stitch density, underlay, and color separation.

- Fabric Types and Suitability: Understanding various fabrics (e.g., cotton, polyester, denim) and their suitability for different embroidery techniques. Recognizing potential issues like fabric puckering or thread breakage.

- Quality Control and Standards: Knowledge of industry standards for embroidery quality (e.g., stitch consistency, color accuracy, and durability). Understanding quality control procedures and identifying potential defects.

- Production Processes and Workflow: Familiarity with the overall embroidery production process, from design creation to finishing. Understanding efficiency, scheduling, and potential bottlenecks.

- Troubleshooting Common Embroidery Problems: Ability to diagnose and solve common problems like thread breaks, needle jams, and poor stitch quality. Understanding preventative maintenance techniques.

Next Steps

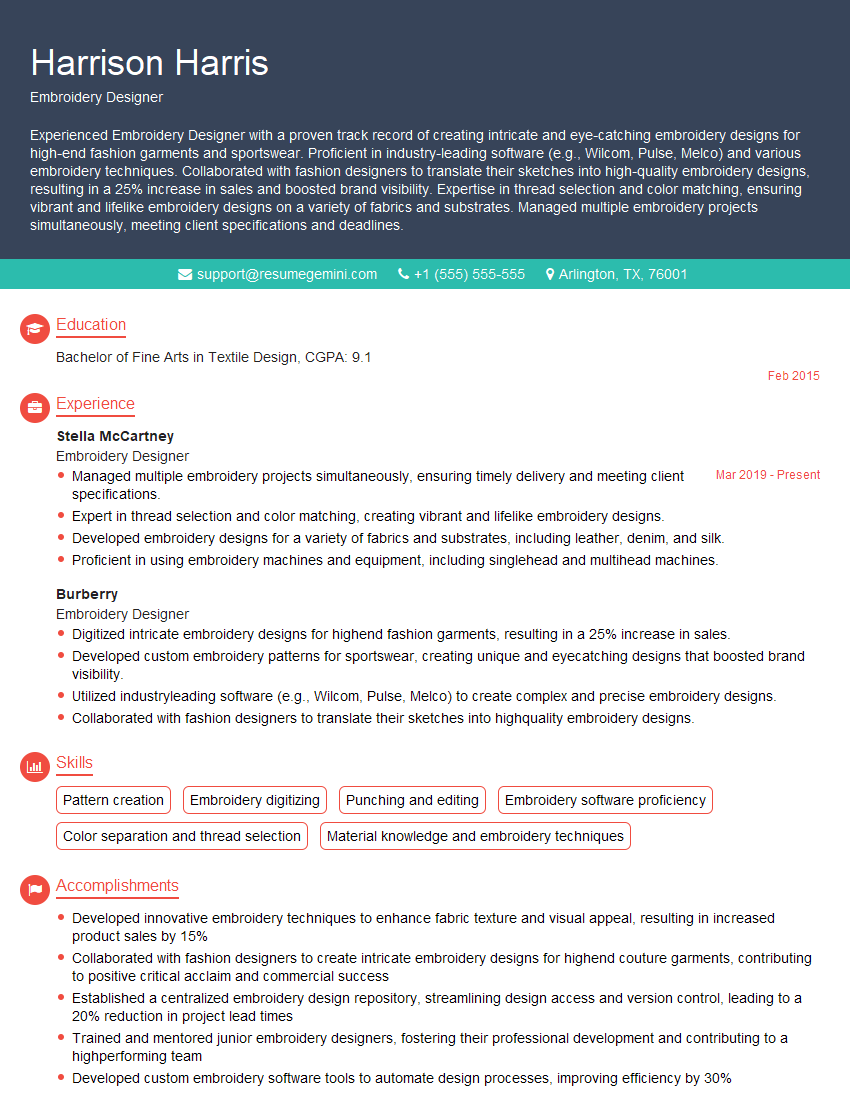

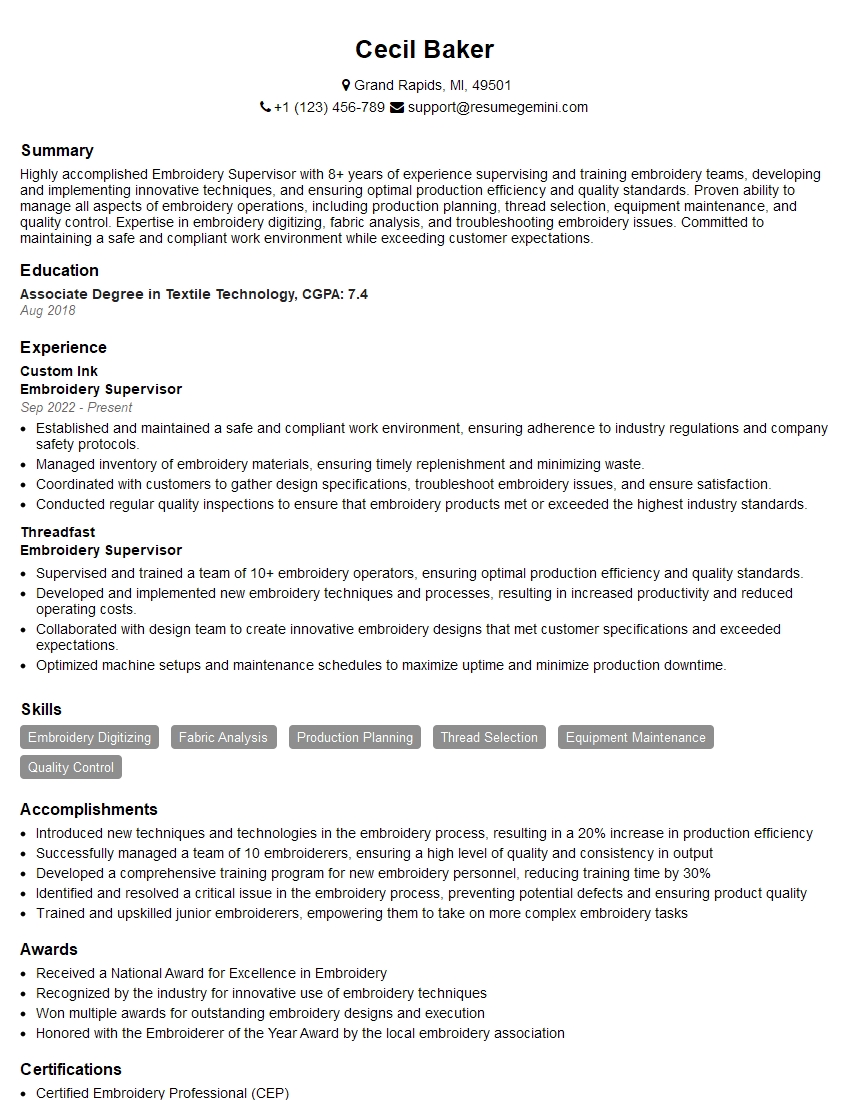

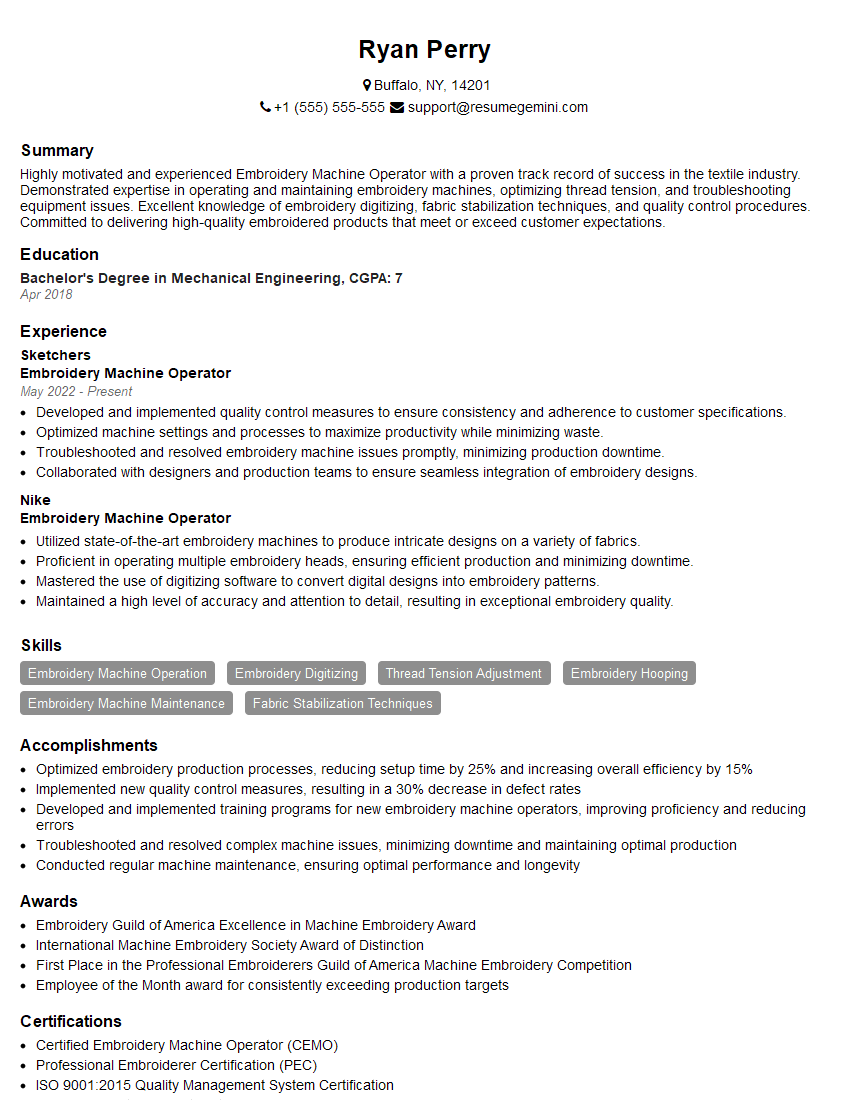

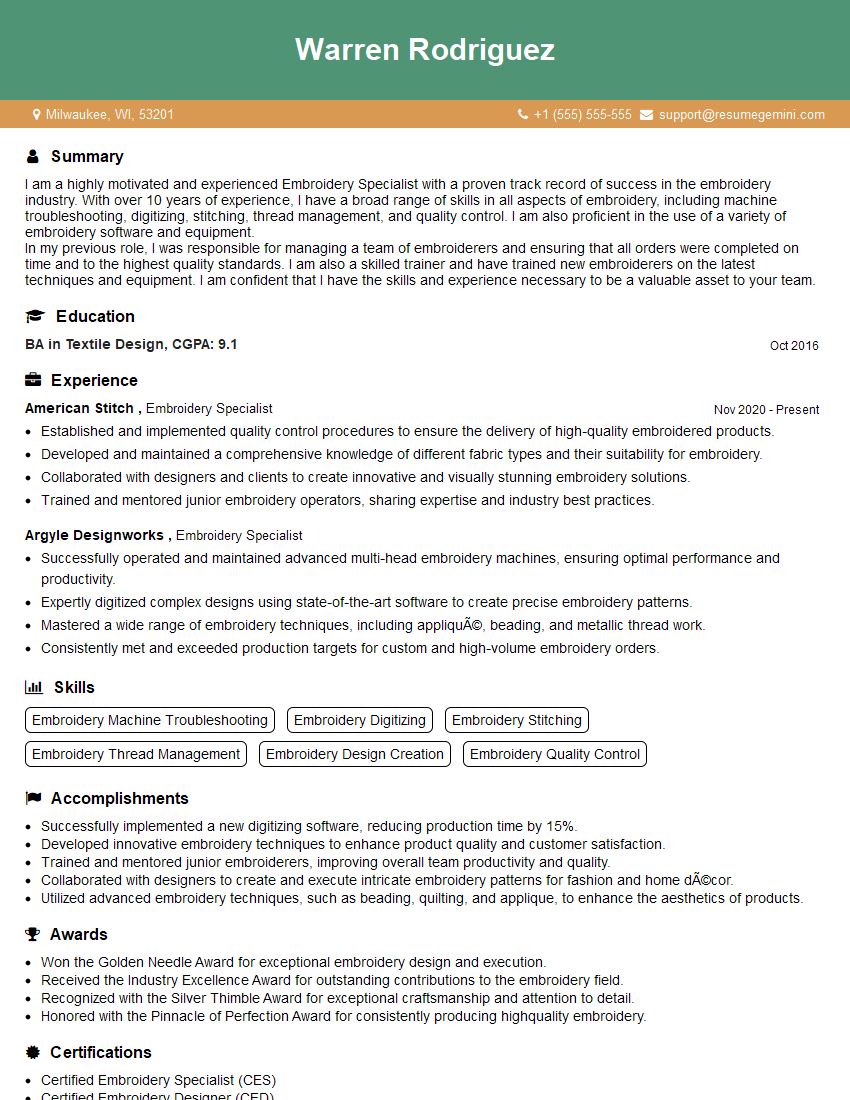

Mastering embroidery industry terminology and standards is crucial for career advancement, opening doors to higher-level roles and increased earning potential. A strong understanding of these concepts demonstrates your expertise and professionalism to potential employers. Creating an ATS-friendly resume is key to getting your application noticed. Focus on using keywords relevant to the industry and highlighting your skills and experience effectively. ResumeGemini can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to showcasing knowledge of embroidery industry terminology and standards are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good