Are you ready to stand out in your next interview? Understanding and preparing for Experience with electrical design interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Experience with electrical design Interview

Q 1. Explain your experience with different types of electrical drawings (e.g., schematics, wiring diagrams, panel layouts).

Electrical drawings are the language of electrical engineering, conveying complex designs in a clear and concise manner. I’ve extensive experience with several key types. Schematics provide a simplified, symbolic representation of the electrical system, focusing on the functional relationships between components. Think of it as a high-level blueprint showing how everything connects conceptually. Wiring diagrams, on the other hand, are more detailed, showing the physical layout of wires, terminations, and devices. They’re essential for installation and troubleshooting. Finally, panel layouts are dedicated drawings for electrical panels, meticulously detailing the placement of circuit breakers, fuses, and other components within the panel itself. They’re crucial for safe and efficient panel construction and maintenance.

For example, in a recent project designing the electrical system for a new manufacturing plant, I created schematics to illustrate the overall power distribution, wiring diagrams to guide the electricians during installation, and panel layouts for each of the numerous motor control centers. This multi-faceted approach ensured clear communication and efficient project execution.

Q 2. Describe your experience with various electrical design software (e.g., AutoCAD Electrical, EPLAN, Revit).

Proficiency in electrical design software is paramount. I’m adept at using several leading programs, including AutoCAD Electrical, EPLAN, and Revit. AutoCAD Electrical is excellent for creating detailed schematics, wiring diagrams, and panel layouts, leveraging its extensive library of electrical symbols. EPLAN offers a more structured and standardized approach, ideal for complex projects requiring robust data management and version control. Revit, often used in Building Information Modeling (BIM), allows for seamless integration of electrical designs with other building systems, facilitating better collaboration among different disciplines.

For instance, in a previous project involving a large-scale hospital renovation, we utilized Revit to integrate the electrical design with architectural and mechanical systems. This ensured all systems were coordinated, minimizing clashes and delays during construction. The ability to easily link changes across different disciplines proved invaluable.

Q 3. How do you ensure compliance with relevant electrical codes and standards (e.g., NEC, IEC)?

Adherence to electrical codes and standards is non-negotiable. My experience encompasses thorough familiarity with the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) standards. I meticulously review all designs against these codes, ensuring every aspect complies with relevant safety regulations and best practices. This involves checking things like wire sizing, grounding requirements, overcurrent protection, and arc flash hazard analysis. Software tools often incorporate code compliance checks, but manual verification is crucial.

In one instance, I identified a potential violation of NEC Article 210 regarding branch circuit protection during a review of a design. By rectifying this oversight early on, we avoided potential safety hazards and costly rework during construction.

Q 4. Explain your understanding of different grounding techniques and their applications.

Grounding is fundamental to electrical safety, providing a low-impedance path for fault currents to flow back to the source. Different techniques are employed based on the application and environment. Equipment grounding protects personnel from electric shock by ensuring metal enclosures are grounded. System grounding establishes a reference point for the electrical system, minimizing voltage surges and improving stability. Grounding rods are commonly used to provide a connection to the earth. The choice of technique often depends on factors like soil resistivity and the sensitivity of the equipment.

Imagine a scenario where a faulty appliance develops a short circuit. Proper grounding ensures the fault current flows safely to the ground, tripping a circuit breaker, rather than causing a dangerous electric shock.

Q 5. Describe your experience in the design of power distribution systems.

Designing power distribution systems involves carefully planning how electrical power is delivered throughout a facility. My experience involves sizing conductors, selecting transformers, designing switchgear, and coordinating protective devices. I consider factors such as load requirements, voltage drop, fault current levels, and future expansion needs. This requires a comprehensive understanding of power system analysis, including load flow studies and short-circuit calculations. Ensuring the system is reliable, efficient, and safe is always the top priority.

A recent project involved the design of a power distribution system for a data center. This demanded meticulous attention to detail, as even minor discrepancies could lead to significant downtime. The design process incorporated redundancy measures to enhance reliability.

Q 6. How do you perform short-circuit calculations and coordinate protective devices?

Short-circuit calculations are critical for selecting appropriate protective devices and ensuring system safety. I employ software tools and established calculation methods to determine the magnitude and duration of short-circuit currents. This informs the selection of circuit breakers and fuses with appropriate interrupting ratings. Protective device coordination ensures that the correct device trips first in the event of a fault, isolating the faulted section and minimizing disruption to the rest of the system. This involves setting trip curves and ensuring proper selectivity.

For example, in a manufacturing plant, proper coordination of protective devices prevented a cascade of failures following a short circuit. The coordinated system isolated only the faulted section, limiting the downtime and avoiding a major disruption.

Q 7. Describe your experience with motor control circuits and VFDs.

I have substantial experience with motor control circuits and Variable Frequency Drives (VFDs). Designing motor control circuits involves selecting appropriate contactors, overload relays, and other components to safely start, stop, and protect electric motors. VFDs provide precise control over motor speed and torque, improving efficiency and reducing energy consumption. Designing for VFDs requires special considerations, including harmonic filtering to mitigate the effects of non-sinusoidal currents on the power system.

In one project, integrating VFDs into a conveyor system significantly reduced energy costs and improved the system’s responsiveness. Careful attention to harmonic filtering was crucial to prevent issues with other sensitive equipment.

Q 8. Explain your understanding of lighting design principles and calculations.

Lighting design isn’t just about making a space bright; it’s about creating the right atmosphere and ensuring sufficient illumination for various tasks. It involves understanding concepts like illuminance (measured in lux), luminance (brightness of a surface), and color rendering index (CRI, how accurately colors appear under the light source). Calculations center around determining the number and type of luminaires (light fixtures) needed to achieve the desired illuminance level, considering factors such as room size, ceiling height, reflectance of surfaces (walls, ceiling, floor), and the luminaire’s light distribution.

For example, in designing a retail space, we’d need higher illuminance levels in display areas to highlight products compared to walkways. We’d use software like DIALux or Relux to model the space, inputting parameters like luminaire specifications, room dimensions, and surface reflectances. The software then simulates the light distribution, allowing us to optimize the placement and number of fixtures to meet the required illuminance levels while minimizing energy consumption and glare. We also consider the color temperature of the light source, selecting warmer tones for residential spaces and cooler tones for offices to influence the mood and productivity.

Q 9. How do you ensure the safety of electrical systems during design and implementation?

Safety is paramount in electrical design. We adhere strictly to relevant electrical codes (like NEC in the US or IEC internationally) throughout the design and implementation process. This starts with proper grounding and bonding to prevent electrical shocks. We specify appropriate circuit protection devices such as circuit breakers and fuses to prevent overloads and short circuits. Cable selection takes into account current carrying capacity, insulation rating, and mechanical strength, ensuring they are suitable for the environment and application. Furthermore, we incorporate safety measures such as arc flash mitigation techniques and lockout/tagout procedures during maintenance. Proper documentation, including detailed drawings and specifications, is crucial for ensuring all aspects of the system are safe and comply with regulations. Regular inspections and testing are also vital for maintaining safety over the system’s lifetime. For instance, I once designed a system for a food processing plant where we had to incorporate explosion-proof fittings and intrinsically safe circuits to mitigate the risk of fire or explosions.

Q 10. What are your experiences with different types of transformers and their applications?

My experience encompasses various transformer types, including power transformers (used for stepping up or down voltage in power distribution systems), isolation transformers (providing electrical isolation for safety), and instrument transformers (current and potential transformers for measurement and protection). Power transformers are often large and used in substations, while isolation transformers are commonly found in labs and medical facilities. Instrument transformers, on the other hand, are crucial components in protection relays and metering systems. The choice of transformer depends on factors such as voltage levels, power ratings, efficiency requirements, and the specific application. For instance, in a recent project involving a large industrial facility, we utilized a step-down transformer to safely reduce the high-voltage incoming power to a usable level for the plant’s machinery. We carefully selected the transformer based on its capacity, efficiency, and ability to withstand potential voltage surges.

Q 11. Describe your experience with cable sizing and selection.

Cable sizing and selection are critical for ensuring the safe and efficient operation of an electrical system. It involves determining the appropriate cable size based on the current carrying capacity, voltage drop, and ambient temperature. Factors like cable installation method (e.g., buried, in conduit) and the type of insulation also play a significant role. We use tables and software to perform these calculations, considering derating factors to account for the number of cables in a conduit and other environmental conditions. Improper cable sizing can lead to excessive voltage drop, overheating, and potential fire hazards. I’ve used software like ATP Draw to assist in cable sizing calculations, ensuring we select the appropriate cable to meet the requirements of the specific application, while also optimizing the cost by avoiding oversizing.

Q 12. How do you perform load calculations for electrical systems?

Load calculations are fundamental to electrical system design. They involve determining the total power demand of all equipment and appliances connected to the system. This involves identifying individual loads (e.g., motors, lighting, HVAC), determining their power ratings, and calculating the total demand considering diversity factors (not all loads operate simultaneously). The results inform the selection of appropriate circuit breakers, transformers, and other system components. We often use software and standardized calculation methods to perform these calculations accurately. A common method is to sum up the individual load demands and apply a diversity factor based on the type of loads and their operating patterns. For example, in a commercial building, we’d calculate the total load for lighting, air conditioning, and other equipment, applying appropriate diversity factors to reflect the simultaneous operation of these loads. This would inform the design of the main electrical service and the distribution system.

Q 13. Explain your experience with the design of control panels and switchboards.

Designing control panels and switchboards requires a deep understanding of electrical safety, functionality, and ergonomics. We design these panels to house circuit breakers, switches, relays, and other control devices, ensuring they are properly arranged for easy access and maintenance. Safety is prioritized through the use of proper grounding, labeling, and safety interlocks. We must also consider environmental factors, such as temperature and humidity, and select appropriate enclosure materials and components to ensure reliability. Software tools are often used for panel layout and component selection, ensuring compliance with standards and regulations. In a recent project, I designed a control panel for a water treatment plant, incorporating a PLC (Programmable Logic Controller) to automate various processes. The design ensured easy access for maintenance, clear labeling, and compliance with relevant safety standards.

Q 14. Describe your experience with troubleshooting and resolving electrical system problems.

Troubleshooting electrical system problems requires a systematic approach. It begins with careful observation and data collection, identifying symptoms and potential causes. We use multimeters, clamp meters, and other diagnostic tools to measure voltage, current, and resistance, pinpoint faulty components, and isolate the problem. Understanding circuit diagrams and electrical schematics is crucial. For example, I once encountered a situation where a motor wouldn’t start. By systematically checking voltage, current, and the motor’s control circuit, I identified a faulty relay that was preventing the motor from receiving power. I replaced the relay and the system was restored to operation. Documenting the troubleshooting process and the solution implemented is vital for future reference and preventative maintenance.

Q 15. How do you manage and document your electrical design projects?

Managing and documenting electrical design projects requires a systematic approach ensuring clarity, accuracy, and traceability throughout the project lifecycle. I utilize a combination of digital tools and established best practices. This typically begins with a comprehensive project brief outlining client requirements, specifications, and project scope. This is followed by developing detailed design schematics and drawings using software like AutoCAD Electrical or similar tools, meticulously labeled and cross-referenced.

- Version Control: I religiously use version control systems (like SVN or Git) to track changes, enabling easy rollback to previous revisions if needed and ensuring collaborative teamwork.

- BOM Management: A Bill of Materials (BOM) is crucial, detailing every component used, including part numbers, quantities, and supplier information. This simplifies procurement and reduces errors.

- Documentation Standards: I adhere to industry standards such as IEEE or IEC, providing consistent and clear documentation, including calculations, test results, and as-built drawings. This is vital for future maintenance and modifications.

- Cloud Storage: Utilizing cloud storage for easy access and collaborative work on project documents and designs is a practice I consistently use.

For example, on a recent commercial building project, implementing a rigorous version control system allowed us to quickly revert to a previous design iteration after a client requested a change, saving significant time and resources.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with renewable energy systems integration (solar, wind)?

I have significant experience integrating renewable energy systems, particularly solar and wind, into various projects. This involves a deep understanding of power generation, grid interconnection requirements, and safety protocols. My work encompasses the entire process, from initial feasibility studies and system sizing to detailed design, procurement, and commissioning.

- System Sizing and Design: I use specialized software to model and simulate system performance, accounting for factors like solar irradiance, wind speed, and energy demand. This ensures optimal system sizing and efficiency.

- Grid Interconnection: I’m proficient in designing the necessary interconnection equipment and complying with utility grid codes, ensuring seamless integration with the existing power grid. This includes considerations for protection relays, inverters, and transformers.

- Safety and Compliance: Adhering to all relevant safety standards and regulations (like NEC or equivalent) is paramount. This involves selecting appropriate protective devices and ensuring proper grounding and bonding.

For instance, I led the design of a hybrid solar-wind system for a remote telecommunications tower. This involved careful consideration of battery storage, power conversion, and remote monitoring capabilities to ensure reliable and sustainable power supply.

Q 17. What is your experience with PLC programming and control systems design?

My experience with PLC programming and control systems design spans several industrial automation projects. I’m proficient in programming PLCs using various languages like Ladder Logic (LD), Function Block Diagram (FBD), and Structured Text (ST), depending on the specific application and PLC brand (Siemens, Allen-Bradley, etc.).

- Control System Design: I design control systems, from defining input/output (I/O) requirements to developing the control logic and HMI (Human-Machine Interface) for efficient monitoring and operation.

- SCADA Integration: I integrate PLCs with Supervisory Control and Data Acquisition (SCADA) systems, enabling remote monitoring and control of industrial processes.

- Troubleshooting and Debugging: I have extensive experience in troubleshooting and debugging PLC programs and control systems, utilizing diagnostic tools and techniques to identify and resolve issues quickly and effectively.

In a recent project involving a manufacturing plant, I developed a PLC-based control system for a production line. This involved programming the PLC to manage motor control, sensor data acquisition, and production tracking, resulting in improved efficiency and reduced downtime.

Q 18. Describe your experience with the design of fire alarm systems.

Designing fire alarm systems requires a deep understanding of building codes, safety regulations, and system components. My experience includes designing systems for various building types, from small offices to large industrial facilities. This involves selecting appropriate detectors, notification appliances, and control panels based on the specific hazards and occupancy levels.

- System Design: I create detailed design drawings specifying the location of detectors, notification appliances, and control panels, ensuring adequate coverage and compliance with relevant codes (NFPA 72, etc.).

- Component Selection: Choosing reliable and appropriate components is crucial. This includes selecting detectors suitable for different environments (smoke, heat, etc.) and notification appliances that meet audibility and visibility requirements.

- System Testing and Commissioning: Rigorous testing and commissioning are vital to ensure the system’s functionality and compliance. This includes functional testing of all components and system integration.

For example, in a recent hospital project, I designed a sophisticated fire alarm system with features such as voice evacuation, fire zone mapping, and integration with the building management system. This ensured a safe and efficient response in case of fire.

Q 19. How do you incorporate energy efficiency measures in your electrical designs?

Incorporating energy efficiency measures is a core principle in my electrical designs. This begins during the initial design phase and involves a holistic approach considering various aspects of the project. It goes beyond simply selecting energy-efficient equipment.

- Lighting Design: Utilizing energy-efficient lighting technologies like LEDs with appropriate controls (dimmable ballasts, occupancy sensors) significantly reduces energy consumption.

- Motor Selection: Selecting high-efficiency motors (premium efficiency motors) reduces energy wasted by motors. Variable frequency drives (VFDs) further optimize motor operation for additional savings.

- Power Factor Correction: Installing power factor correction capacitors improves the power factor of the electrical system, reducing energy losses and improving overall efficiency.

- Building Management Systems (BMS): Integrating BMS allows for real-time monitoring and control of energy consumption, enabling optimized energy usage based on occupancy and environmental conditions.

For example, in a recent office building design, I implemented a smart lighting control system with occupancy sensors and daylight harvesting, which resulted in a significant reduction in energy consumption compared to traditional lighting systems.

Q 20. Explain your knowledge of different types of circuit breakers and their functions.

Circuit breakers are essential safety devices designed to protect electrical circuits from overcurrent conditions. Different types exist, each with specific functions and applications.

- Molded Case Circuit Breakers (MCCBs): These are commonly used in industrial and commercial settings for branch circuit protection and offer high interrupting capacity.

- Miniature Circuit Breakers (MCBs): These are smaller and mainly used in residential and small commercial applications for branch circuit protection.

- Air Circuit Breakers (ACBs): ACBs are used in higher voltage systems and offer higher interrupting capacity than MCCBs or MCBs, and are typically used for feeder protection.

- Vacuum Circuit Breakers (VCBs): VCBs are frequently used in high-voltage applications, offering excellent interrupting capacity in a compact design.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs protect against electrical shocks by detecting small currents leaking to the ground.

The selection of the appropriate circuit breaker depends on factors such as voltage level, current rating, fault current, and the application’s specific requirements. Understanding the nuances of each type is critical for designing safe and reliable electrical systems.

Q 21. Describe your experience with the design of low voltage and high voltage systems.

I have extensive experience in designing both low-voltage and high-voltage systems, understanding the distinct challenges and safety considerations associated with each.

- Low-Voltage Systems (up to 1000V): These are commonly found in residential, commercial, and industrial settings. Design involves careful consideration of wiring methods, protection devices, and load calculations. I use software like AutoCAD Electrical for detailed schematics and calculations.

- High-Voltage Systems (above 1000V): These require specialized knowledge and adherence to stringent safety standards. Design involves detailed calculations, specialized equipment selection (transformers, switchgear, protective relays), and compliance with relevant regulations. Safety procedures are paramount, including proper lockout/tagout practices and personal protective equipment (PPE) use.

For instance, I worked on a project involving a high-voltage substation upgrade, requiring detailed knowledge of protective relay coordination, fault current calculations, and grounding design to ensure system stability and safety. In contrast, a recent residential project involved designing a low-voltage system, focusing on efficient wiring methods and compliant protection devices.

Q 22. Explain your understanding of harmonics and their impact on electrical systems.

Harmonics are non-sinusoidal waveforms that are multiples of the fundamental frequency in an AC electrical system. Think of it like this: a pure sine wave (our fundamental frequency, like 60Hz in North America) is a smooth, single tone. Harmonics are like adding extra, higher-pitched tones that distort the smooth sound. These distortions are caused by non-linear loads like rectifiers in power supplies, variable-speed drives (VSDs), and large switching power converters.

Their impact can be significant. Higher-order harmonics can cause overheating in transformers and motors due to increased eddy currents and losses. They can also create voltage and current distortions, leading to inaccurate metering, premature equipment failure, and resonance problems that can amplify the harmonic distortion even further. For instance, a motor that is significantly oversized for the load might generate excessive harmonic currents. In sensitive equipment, such as medical devices, harmonics can cause malfunctions and inaccurate readings. Mitigation strategies often include harmonic filters, power factor correction capacitors, and careful load balancing.

Q 23. How do you ensure the electromagnetic compatibility (EMC) of your electrical designs?

Ensuring electromagnetic compatibility (EMC) is crucial for preventing unwanted interference between electrical devices and systems. My approach involves a multi-faceted strategy. Firstly, I utilize proper grounding and shielding techniques from the design stage itself. This minimizes the radiated and conducted emissions that can disrupt other systems. Secondly, I incorporate components known for their low emission profiles, and I conduct thorough simulations using software tools like ANSYS Maxwell or similar software to identify potential electromagnetic interference (EMI) hotspots. These simulations help predict the performance before the physical build, saving time and resources. Thirdly, testing plays a critical role, including pre-compliance testing and finally, accredited EMC testing to verify compliance with relevant international standards such as IEC 61000. During testing, I am meticulous in addressing any issues identified through iterative design improvements.

Q 24. What experience do you have with electrical system testing and commissioning?

My experience with electrical system testing and commissioning is extensive. I’ve been involved in various projects from small-scale installations to large industrial facilities. My typical process involves developing a comprehensive test plan that covers all aspects of the system. This plan outlines the specific tests to be performed, the test equipment needed, and the acceptance criteria. Then, the actual testing would commence, involving measurements of voltage, current, insulation resistance, earth ground continuity, and protection system operation. For complex systems, I utilize automated testing equipment for efficient data acquisition and analysis. Once testing is complete, a detailed report is compiled, highlighting any deviations from specifications and recommendations for rectifying issues. Commissioning involves verifying that the installed system meets functional and performance requirements and that it’s safely operational. I have hands-on experience with protective relay testing using dedicated test sets and using commissioning software for documenting and managing the entire process. A recent example includes commissioning a new substation for a large data center, where we successfully ensured the stability and reliability of the power distribution system.

Q 25. Describe your experience in working with multidisciplinary engineering teams.

Collaboration is key in electrical design. I thrive in multidisciplinary environments. On past projects, I’ve worked closely with mechanical, civil, and process engineers, as well as architects and project managers. One successful project involved designing the electrical system for a new manufacturing facility. Effective communication was paramount. We used collaborative software platforms to share drawings, specifications, and manage revisions. Regular meetings, transparent communication, and a focus on mutual respect were crucial in resolving any conflicts or disagreements that arose. My ability to translate technical information into easily understandable language has enabled me to bridge the communication gap between different disciplines, facilitating smooth project execution.

Q 26. Explain your familiarity with project management methodologies relevant to electrical design.

I am proficient in several project management methodologies. I often utilize Agile methodologies, breaking down complex projects into smaller, manageable tasks, focusing on iterative development and regular feedback loops. This allows for flexibility and adaptability, which is crucial given the evolving nature of many projects. I’ve also used Waterfall methodologies for projects with well-defined scopes and strict requirements. The choice of methodology depends on the project’s specifics, but regardless, I prioritize meticulous planning, robust risk management, and effective progress tracking. Tools like MS Project and Jira are regularly utilized for scheduling, resource allocation, and task management. My experience with these frameworks allows for efficient and timely project completion.

Q 27. How do you handle changes and unexpected challenges during an electrical design project?

Handling changes and unexpected challenges is an inevitable part of electrical design. My approach involves a proactive risk assessment process at the beginning of a project. I identify potential challenges and develop contingency plans to mitigate them. When unexpected issues do arise, I initiate a structured problem-solving process. This involves clearly defining the issue, analyzing its root cause, and evaluating the available solutions. Open communication with the project team and stakeholders is critical. I ensure everyone is informed of the situation, potential impacts, and the steps being taken to resolve it. Involving all stakeholders in the decision-making process helps ensure buy-in and facilitates a collaborative approach to problem-solving. My experience has taught me that a calm and methodical response is crucial in successfully navigating unexpected challenges.

Q 28. Describe your experience with cost estimation and budgeting for electrical projects.

Cost estimation and budgeting are essential for successful project delivery. My experience encompasses preparing detailed cost estimates using various methods, including bottom-up, top-down, and parametric estimations. I use specialized software and established databases for pricing equipment and materials. I consider factors such as labor costs, material costs, permitting fees, and contingency allowances. I also develop detailed budgets that align with the project timeline and track expenses throughout the project lifecycle. Regular cost monitoring and reporting enable early identification of potential cost overruns, allowing me to take timely corrective actions. A critical aspect of my approach involves collaborating closely with procurement teams to negotiate favorable pricing and secure timely delivery of materials. Accuracy in cost estimation and budget management is critical for preventing project delays and financial setbacks.

Key Topics to Learn for Electrical Design Interviews

- Electrical Codes and Standards: Understanding NEC, IEC, or other relevant codes is crucial. Be prepared to discuss practical application of these standards in your projects.

- Power Systems Design: Demonstrate your knowledge of power distribution systems, including transformers, circuit breakers, and protective devices. Discuss your experience with load calculations and system sizing.

- Lighting Design: Showcase your expertise in lighting calculations, fixture selection, and energy-efficient lighting strategies. Be ready to discuss different lighting technologies and their applications.

- CAD Software Proficiency: Highlight your skills in AutoCAD, Revit, or other relevant software used for electrical design. Be prepared to discuss specific projects where you utilized these tools.

- Control Systems: Discuss your experience designing or working with control systems, including PLC programming, motor controls, and instrumentation.

- Electrical Calculations and Analysis: Be ready to discuss your understanding of circuit analysis, power factor correction, and other relevant calculations. Be prepared to explain your problem-solving approach.

- Project Management and Teamwork: Interviewers often assess your ability to manage projects, collaborate effectively, and meet deadlines. Prepare examples showcasing these skills.

- Troubleshooting and Problem-Solving: Demonstrate your ability to identify and solve electrical problems, highlighting your systematic approach to troubleshooting.

Next Steps

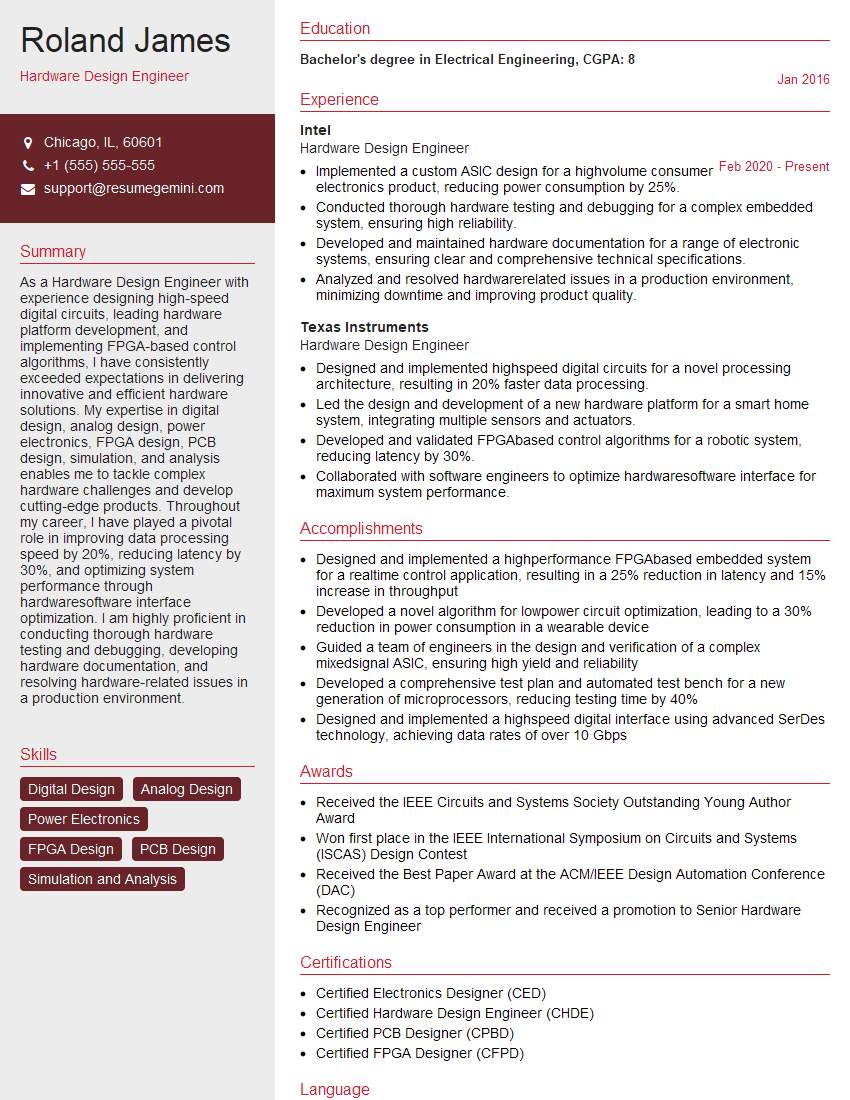

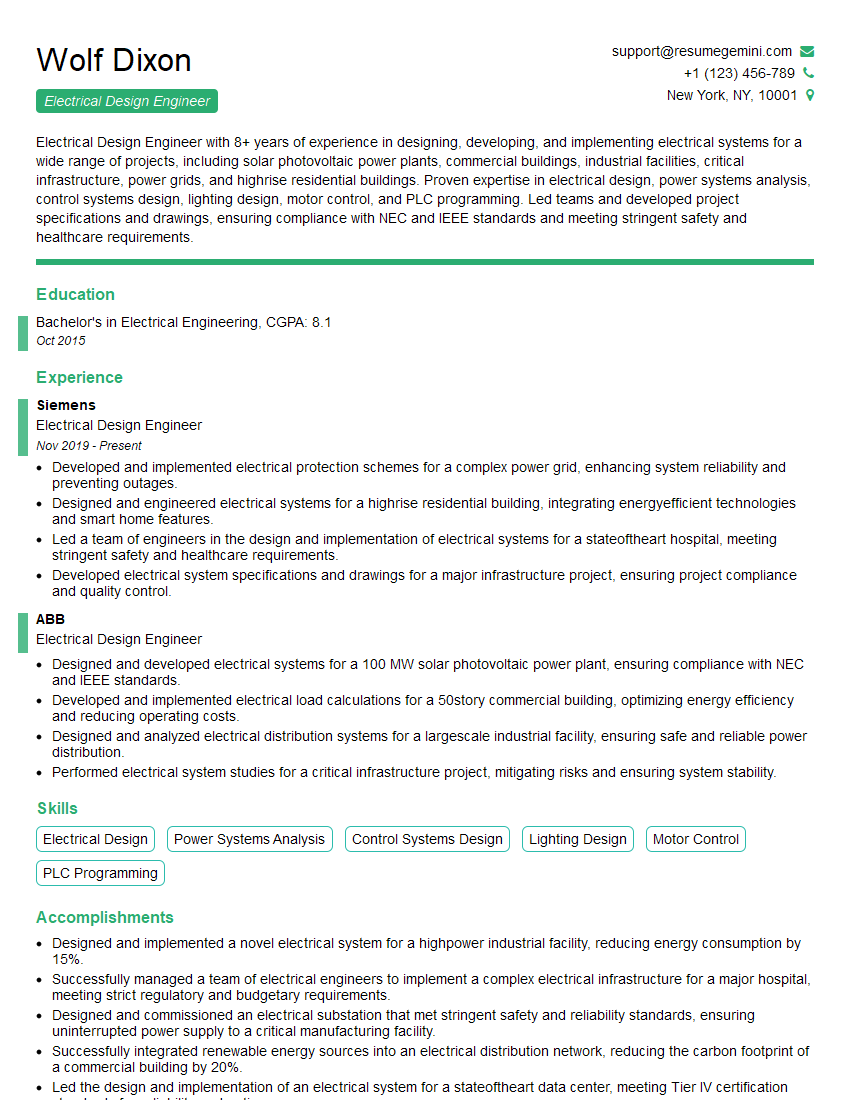

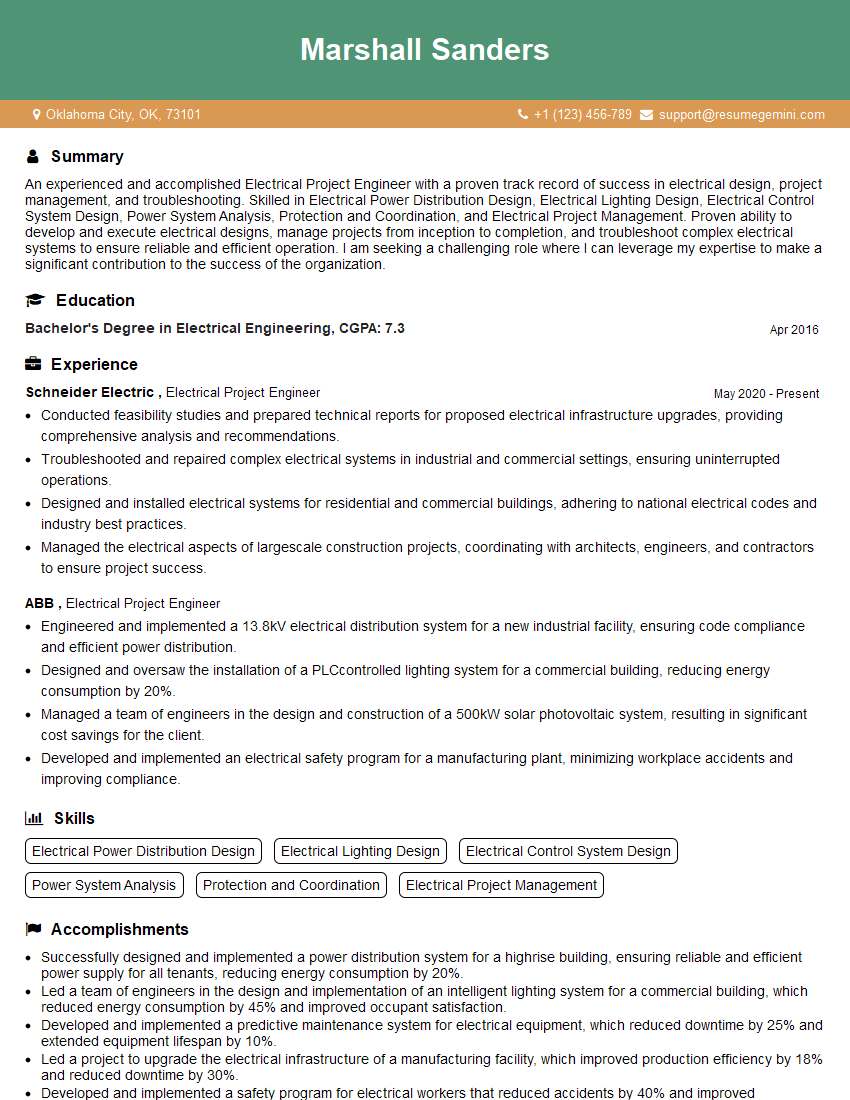

Mastering electrical design principles is essential for career advancement in this dynamic field, opening doors to exciting opportunities and higher earning potential. A strong, ATS-friendly resume is your key to unlocking these prospects. ResumeGemini can help you craft a compelling resume that showcases your skills and experience effectively. We provide examples of resumes tailored to electrical design roles, guiding you toward creating a document that stands out to recruiters. Invest the time to build a professional resume; it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good