Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fire Protection System Inspection and Testing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fire Protection System Inspection and Testing Interview

Q 1. What are the different types of fire detection systems?

Fire detection systems are crucial for early warning in case of a fire. They come in various types, each with its own strengths and weaknesses. The most common types include:

- Smoke Detectors: These detect the presence of smoke, a common byproduct of combustion. There are two main types: ionization detectors, which are sensitive to fast-flaming fires, and photoelectric detectors, which are more responsive to smoldering fires. Many modern systems use dual-sensor technology, combining both for broader coverage.

- Heat Detectors: These trigger when a certain temperature threshold is reached. They are categorized into fixed-temperature (trigger at a specific temperature) and rate-of-rise (trigger when the temperature increases rapidly) detectors. Heat detectors are often used in areas where smoke detectors might be prone to false alarms, such as kitchens.

- Flame Detectors: These detect the infrared or ultraviolet radiation emitted by flames. They are typically used in high-risk areas or locations where smoke detectors might be ineffective, such as industrial settings or areas with high dust levels.

- Gas Detectors: Used to detect specific combustible gases, these are vital in areas where flammable gases might accumulate, such as fuel storage facilities or laboratories.

The choice of fire detection system depends on several factors, including the type of occupancy, the potential fire hazards present, and environmental conditions.

Q 2. Explain the process of inspecting a sprinkler system.

Inspecting a sprinkler system is a multi-step process that ensures its readiness in case of a fire. This process typically involves:

- Visual Inspection: A thorough visual examination of all sprinkler heads, pipes, valves, and control equipment. We check for corrosion, damage, obstructions, and any signs of tampering. Think of this like a visual health check for the entire system. We’re looking for anything out of the ordinary.

- Valve Inspection: We verify that all valves are in the open position (unless they’re intentionally closed for maintenance). We also inspect the valve seals and ensure there’s no leakage. This is critical; a closed valve renders the system useless.

- Pressure Test (if required): Depending on the system’s type and local codes, a pressure test might be necessary to ensure the system maintains the required pressure. This involves temporarily pressurizing the system and observing for any pressure drop, which indicates a leak.

- Flow Test (if required): In some instances, we conduct a flow test to verify that the water flow is adequate. This might involve activating a few sprinkler heads to check for proper water discharge. We carefully document everything during this process.

- Documentation: All findings, including any deficiencies, are meticulously documented in a comprehensive report. This report provides a record of the system’s condition and serves as a roadmap for needed repairs or maintenance.

Regular sprinkler system inspections are crucial for preventing fire disasters. Imagine a scenario where a sprinkler head is obstructed – a seemingly small issue that could have catastrophic consequences if undetected.

Q 3. Describe the testing procedures for a fire alarm system.

Testing a fire alarm system is vital to ensuring its reliability. This includes:

- System Initialization: Confirming the system is powered up and ready to respond.

- Visual Inspection: Checking for any signs of damage or tampering on all components (detectors, control panel, etc.).

- Testing Individual Detectors: Each smoke detector and heat detector needs to be tested individually using their respective test buttons. This simulates a fire event to verify their functionality.

- Control Panel Testing: Testing the control panel’s functionality. It often includes checking the battery backup, alarm signals, trouble signals and the overall status of the system.

- Alarm and Notification Testing: Activating the alarm system to verify all horns, strobes and other notification appliances operate as designed. This might involve activating the system via pull stations or the control panel.

- System Communication Testing: Checking the communication between the various parts of the fire alarm system. This is particularly important in large, complex systems.

- Documentation: Maintaining detailed records of all tests performed and findings, including any malfunctions or needed repairs.

Regular testing is not merely a formality; it’s a lifeline. Imagine a scenario where a faulty detector doesn’t trigger during an actual fire—the consequences could be devastating. Regular testing helps prevent this.

Q 4. What are the common causes of fire alarm system malfunctions?

Fire alarm system malfunctions can stem from various sources. Some common causes include:

- Low Battery Power: The most common cause. Batteries need regular replacement to maintain optimal functionality.

- Dust Accumulation: Dust and debris can interfere with the sensors’ operation, leading to false alarms or failure to detect a real fire.

- Component Failure: Detectors, control panels, or other components can fail due to wear and tear or manufacturing defects. Age plays a significant role here.

- Improper Wiring: Loose connections or faulty wiring can cause intermittent or complete system failure.

- Software Glitches: Advanced systems relying on software can experience malfunctions due to software bugs or errors.

- Tampering or Vandalism: Intentional damage or disabling of components can render the system ineffective.

- Environmental Factors: Extreme temperatures, humidity, or other environmental factors can affect the performance of certain components.

Regular maintenance and inspections are vital for preventing these malfunctions. Thinking proactively about maintenance is cheaper than reacting to a major failure.

Q 5. How do you identify and address deficiencies during a fire protection system inspection?

Identifying and addressing deficiencies during a fire protection system inspection involves a systematic approach:

- Detailed Documentation: Thoroughly document all observed deficiencies, including their location, severity, and potential impact on system performance. Clear, concise notes are key.

- Prioritization: Prioritize deficiencies based on their severity and potential risk. Immediate safety hazards need to be addressed promptly.

- Root Cause Analysis: Don’t just identify the problem, understand why it occurred. For example, a corroded pipe isn’t just a corroded pipe; it’s a sign of a potential water leak or lack of proper maintenance.

- Corrective Actions: Develop a plan of action to rectify the deficiencies. This might involve repairs, replacements, or adjustments to the system.

- Verification: After corrective actions are implemented, verify that the deficiencies have been successfully resolved. Retesting is crucial here.

- Reporting: Prepare a comprehensive report detailing all deficiencies, corrective actions, and verification results. This report serves as documentation for compliance and future reference.

Imagine discovering a corroded section in a sprinkler pipe. Addressing it promptly prevents a potentially devastating leak during a fire, saving lives and property.

Q 6. What are the relevant fire codes and standards you need to be familiar with?

Familiarity with relevant fire codes and standards is paramount for competent fire protection system inspection and testing. Key standards include:

- NFPA (National Fire Protection Association) Standards: NFPA 10 (Portable Fire Extinguishers), NFPA 13 (Water Sprinkler Systems), NFPA 72 (National Fire Alarm Code) are crucial standards for understanding requirements and best practices.

- International Building Code (IBC): The IBC outlines requirements for fire protection systems in buildings based on occupancy type and building characteristics.

- Local Codes and Ordinances: It’s critical to understand local jurisdictions’ specific regulations, which may add or modify requirements outlined in national standards.

Staying up-to-date with these standards is crucial. Changes occur regularly and reflect advancements in fire safety technology and understanding.

Q 7. Explain the different classes of fire and the appropriate extinguishing agents.

Fires are classified into different classes based on their fuel source, and each class requires a specific type of extinguishing agent for effective suppression. The main classes include:

- Class A: Ordinary combustibles like wood, paper, cloth. Water is typically the most effective extinguishing agent for Class A fires.

- Class B: Flammable liquids like gasoline, oil, grease. Extinguishing agents like carbon dioxide (CO2), dry chemical, or foam are best suited for these fires. Water can be dangerous to use on Class B fires unless it is a special application like a deluge system.

- Class C: Energized electrical equipment. CO2 or dry chemical extinguishers are preferred to avoid electrical shock. Never use water on a Class C fire.

- Class D: Combustible metals like magnesium, titanium, sodium. These require specialized extinguishing agents like dry powder designed for combustible metal fires. Water often reacts violently with these materials.

- Class K: Cooking oils and fats. Wet chemical extinguishing agents are designed to suppress this type of fire and prevent reignition.

Understanding fire classes is vital for selecting the appropriate extinguisher and using it effectively. Using the wrong agent can exacerbate the fire or pose additional risks.

Q 8. How do you document your inspection findings?

Thorough documentation is crucial for ensuring accountability and facilitating future maintenance. My inspection findings are meticulously documented using a standardized reporting format. This typically involves a combination of written reports, photographic evidence, and potentially video recordings.

- Detailed checklists: I use pre-prepared checklists tailored to the specific fire suppression system being inspected, ensuring consistent coverage and minimizing the chance of overlooking critical details. Each item on the checklist is marked as ‘Pass’, ‘Fail’, or ‘Needs Attention’ with a clear description of any observed issues.

- High-quality photographs: Photos clearly showing any damage, corrosion, or deficiencies supplement the written report, providing irrefutable evidence. I carefully label and number the photos, linking them to specific items in my checklist.

- Digital reporting software: For enhanced efficiency and accessibility, I utilize digital reporting software that allows for easy data entry, automated report generation, and secure storage of inspection records. The reports are usually sent directly to the client, including a suggested timeline for repairs and maintenance.

- Corrective actions: The report outlines the necessary corrective actions, specifying the urgency of each issue and suggesting methods for remediation. I’ll also include any recommendations for future preventative maintenance.

For example, if I find a corroded pipe fitting in a sprinkler system, I’ll take a detailed photograph, note it in the checklist, and clearly describe the extent of the corrosion and the potential fire safety risk in the written report. This comprehensive approach ensures clarity and leaves no room for misinterpretation.

Q 9. What is your experience with different types of fire suppression systems (e.g., CO2, FM-200)?

I have extensive experience with various fire suppression systems, including gaseous agents like CO2 and FM-200, as well as water-based systems like sprinklers and deluge systems. Understanding the nuances of each system is key to effective inspection and testing.

- CO2 Systems: I’m proficient in inspecting CO2 systems, verifying the integrity of storage cylinders, piping, and nozzles. Testing involves checking cylinder pressure, system activation mechanisms, and ensuring adequate discharge time. I’m also knowledgeable about the environmental and safety considerations associated with CO2 discharge.

- FM-200 Systems: FM-200 systems require a thorough inspection of the agent cylinders, piping, and discharge nozzles. Testing these systems focuses on pressure checks, agent concentration monitoring, and the functionality of the detection and release mechanisms. The environmental impact of FM-200 is also considered and documented in the inspection report.

- Water-based systems: My experience encompasses the inspection and testing of various sprinkler systems (wet pipe, dry pipe, pre-action, deluge), focusing on water pressure, pipe integrity, valve operation, and sprinkler head functionality. Testing may involve flow tests, pressure tests, and visual inspections for corrosion or damage.

Each system requires specialized knowledge and adherence to relevant codes and standards. For instance, the inspection of a CO2 system demands a focus on the potential asphyxiation hazard, necessitating strict adherence to safety protocols. Conversely, a sprinkler system inspection will prioritize water pressure, pipe integrity, and valve operation to ensure timely and effective water delivery in case of a fire.

Q 10. Describe the process of testing a fire suppression system.

Testing a fire suppression system is a multi-step process that ensures its readiness to protect a building or facility. The exact procedures vary depending on the type of system, but a general framework involves these steps:

- Pre-test inspection: This thorough visual inspection checks for any obvious issues, such as damaged components or leaks, before starting any tests. It’s crucial to identify and address minor problems before they escalate.

- System isolation: The system is isolated from the building’s normal operations to ensure safety and prevent unintended consequences during the test.

- Pressure testing (where applicable): For systems like sprinklers, pressure tests verify the system’s ability to withstand pressure and maintain adequate water flow. These tests require careful monitoring of pressure gauges and adherence to safety protocols.

- Flow testing (where applicable): Flow tests for sprinkler systems check the water flow rate and distribution throughout the system to ensure sufficient water supply in case of fire. This may involve activating specific sprinkler heads.

- Agent discharge testing (for gaseous systems): Gaseous systems like CO2 or FM-200 may involve a partial or full discharge test, depending on system size and regulations. This testing requires adherence to strict safety procedures, including evacuation of the area and potentially the use of specialized equipment.

- Post-test inspection: Following testing, a final inspection ensures the system has not sustained any damage and remains functional. Any necessary repairs are noted and documented.

- Documentation: All test results, including pressure readings, flow rates, and observations, are meticulously documented and added to the system’s maintenance records.

For instance, testing a sprinkler system might involve isolating sections of the system, pressurizing the pipes, and then activating a few sprinklers to check water flow and pressure. Each step is carefully documented to create a complete record of the test.

Q 11. How do you handle discrepancies between design plans and actual system installations?

Discrepancies between design plans and actual installations are a common challenge. My approach involves a systematic process to identify, document, and address these discrepancies:

- Careful comparison: I meticulously compare the design plans against the actual system installation, noting any differences in pipe routing, component specifications, or equipment locations.

- Documentation: Any discrepancies are clearly documented with photographs and detailed descriptions, including the location, nature, and potential impact of the discrepancy. This documentation includes references to the design plans and the as-built system.

- Risk assessment: I assess the safety implications of each discrepancy, determining its potential impact on the system’s performance and identifying any immediate hazards.

- Communication: I communicate the findings to the relevant stakeholders, including the building owner, facility manager, and design engineers, providing clear recommendations for remediation.

- Corrective actions: Depending on the severity of the discrepancy, corrective actions may range from minor adjustments to significant system modifications. I will advise on the appropriate course of action, prioritizing safety and code compliance.

For example, if the plans indicate a specific type of sprinkler head but a different type is installed, I would document this discrepancy and assess the impact on fire suppression. This might involve checking if the installed head provides equivalent or better performance. If not, I would recommend replacement with the specified head.

Q 12. Explain the importance of preventative maintenance for fire protection systems.

Preventative maintenance is absolutely paramount for fire protection systems. Regular maintenance ensures the system’s reliability and readiness in the event of a fire. Neglecting maintenance significantly increases the risk of system failure, jeopardizing lives and property.

- Enhanced system reliability: Preventative maintenance minimizes the likelihood of system failure by addressing minor issues before they escalate into major problems. Think of it like regular car maintenance—small fixes prevent major breakdowns.

- Early detection of problems: Routine inspections and testing allow for the early detection of potential problems, enabling timely repairs and preventing costly downtime.

- Compliance with codes and standards: Regular maintenance ensures compliance with relevant fire safety codes and standards, mitigating legal and insurance liabilities.

- Extended system lifespan: Regular maintenance extends the lifespan of the system, reducing the overall cost of ownership by delaying the need for premature replacement.

- Improved safety: Ultimately, preventative maintenance is essential for enhancing the safety and security of a building or facility, giving occupants peace of mind.

Imagine a sprinkler system that hasn’t been inspected in years. Corrosion could weaken pipes, valves might fail, and sprinkler heads might become clogged. Preventative maintenance ensures these problems are identified and addressed before they lead to a catastrophic failure during a fire.

Q 13. What are the safety precautions you take during inspections and testing?

Safety is my top priority during inspections and testing. I adhere to strict safety protocols throughout the process:

- Lockout/Tagout procedures: Before commencing any work, I follow proper lockout/tagout procedures to ensure the system is de-energized and isolated from any power sources. This prevents accidental activation and ensures worker safety.

- Personal protective equipment (PPE): I always wear appropriate PPE, including safety glasses, gloves, and protective clothing, depending on the specific task. For working with gaseous agents, specialized respirators and protective gear are essential.

- Proper ventilation: When working with gaseous agents, adequate ventilation is crucial to prevent exposure to harmful concentrations. This often involves working in well-ventilated areas or using specialized ventilation equipment.

- Emergency procedures: I’m thoroughly familiar with the emergency procedures specific to the facility and the fire suppression system. This includes evacuation plans and access to emergency exits.

- Trained personnel: I ensure that only qualified and trained personnel conduct inspections and tests to minimize risks.

I use caution during water testing of sprinkler systems, for instance, by placing absorbent materials around the test area to prevent water damage. And for gaseous systems, I follow specific guidelines for safe handling, discharge, and containment of the agent.

Q 14. How do you prioritize repairs or replacements based on urgency and risk?

Prioritizing repairs or replacements involves a careful assessment of urgency and risk:

- Risk assessment: I assess the potential risk associated with each issue, considering the severity of the problem, the likelihood of failure, and the potential consequences of failure (e.g., life safety, property damage).

- Urgency rating: Based on the risk assessment, I assign an urgency rating to each issue, categorizing them as critical, high, medium, or low priority. Critical issues demand immediate attention.

- Cost-benefit analysis: I consider the cost of repairs or replacements relative to the potential cost of inaction (e.g., potential fire damage). A cost-benefit analysis guides decisions about which repairs should be addressed first.

- Communication: I clearly communicate the prioritization to the stakeholders, explaining the rationale behind the decisions and providing a timeline for repairs.

- Documentation: I maintain detailed records of the prioritization, including the risk assessment, urgency ratings, and planned corrective actions. This documentation helps track progress and ensures accountability.

For example, a corroded pipe with a high risk of leakage would be classified as high priority, requiring immediate attention to prevent water damage or system failure. Minor cosmetic issues, however, might be deemed low priority and addressed during scheduled maintenance.

Q 15. What is your experience with fire pump testing?

Fire pump testing is crucial for ensuring the life safety systems within a building are functioning correctly during an emergency. My experience encompasses the full spectrum of testing, from routine weekly flow tests to comprehensive annual performance tests, including the detailed documentation required for compliance. This includes testing various types of fire pumps, such as electric, diesel, and jockey pumps. I’m proficient in interpreting test results, identifying potential issues such as pressure discrepancies or inadequate flow rates, and recommending necessary repairs or maintenance. For example, I recently worked on a project where a diesel fire pump failed its annual test due to a faulty fuel injector. By identifying this issue early, we prevented a potential failure during a real emergency.

A typical fire pump test involves verifying the pump’s ability to achieve its designed flow rate and pressure at a specific time. This usually requires specialized equipment like flow meters and pressure gauges. Beyond the flow testing, I also check the pump’s starting mechanism, lubrication, and overall condition. The entire process is meticulously documented and reported, ensuring adherence to relevant codes and standards, like NFPA 20.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the function of a fire command center.

A fire command center serves as the central hub for monitoring and controlling a building’s fire protection systems. Think of it as the brain of the operation. It provides a centralized location for receiving fire alarms, monitoring fire suppression systems (like sprinklers and fire pumps), and coordinating emergency responses. The center typically includes a sophisticated alarm system with visual and audible indicators displaying the location and type of alarm, along with information from various sensors throughout the building. This allows personnel to quickly assess the situation and take appropriate actions, such as dispatching fire crews and initiating evacuation procedures.

In addition to alarm monitoring, a modern fire command center may integrate with other building management systems, allowing for control of lighting, ventilation, and access control systems. This integrated approach improves efficiency during emergencies, allowing for quicker and more coordinated responses. For instance, a fire command center can automatically shut down elevators and direct ventilation systems to contain smoke spread.

Q 17. How familiar are you with NFPA standards?

I am very familiar with NFPA standards, particularly those related to fire protection systems. My work consistently relies on NFPA 13 (Standard for the Installation of Sprinkler Systems), NFPA 20 (Standard for the Installation of Stationary Pumps for Fire Protection), NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems), and NFPA 72 (National Fire Alarm and Signaling Code). I understand the requirements for inspections, testing, and maintenance outlined in these standards and apply them rigorously in my work. My experience ensures compliance, not only to satisfy regulations but to prioritize the safety and reliability of the systems I inspect.

I use NFPA standards as the foundation for my inspection and testing procedures. For example, when testing a fire sprinkler system, I follow the specific guidelines outlined in NFPA 25 to ensure the system is functioning as designed and ready to protect lives and property. I regularly update my knowledge of these standards to keep pace with the latest revisions and advancements in fire protection technology.

Q 18. What are the different types of fire extinguishers and their applications?

Fire extinguishers are classified based on the type of fire they are designed to combat. The most common classes are A, B, C, D, and K.

- Class A: Used for ordinary combustible materials like wood, paper, and cloth. They typically contain water or water-based agents.

- Class B: Used for flammable liquids like grease, gasoline, and oil. They usually employ carbon dioxide, dry chemical, or foam.

- Class C: Used for energized electrical equipment. These extinguishers use agents that don’t conduct electricity, such as carbon dioxide or dry chemical.

- Class D: Used for combustible metals, requiring specialized agents to prevent explosive reactions.

- Class K: Used for cooking oils and greases in commercial kitchens. They employ wet chemical agents that saponify the grease, creating a stable soap-like substance.

The selection of an extinguisher depends on the potential fire hazards present in a given location. For example, a kitchen would require Class K extinguishers, while an office building might necessitate Class A, B, and C extinguishers. Proper training in extinguisher use is essential for effective fire suppression and safety.

Q 19. Describe your experience with backflow preventer testing.

Backflow preventers are critical devices that protect potable water supplies from contamination. My experience with backflow preventer testing involves conducting regular inspections and tests according to local regulations and plumbing codes. This typically includes visual inspections for any signs of damage or leakage, as well as functional testing to verify the device’s ability to prevent backflow. The testing methods vary depending on the type of backflow preventer, but generally involve pressure testing and observing the device’s operation. I am proficient in using various testing equipment and documenting the results meticulously.

For example, I recently tested a double check valve backflow preventer in a commercial building. The test involved isolating the preventer, pressurizing the downstream side, and verifying that no water flowed back into the potable water supply. This ensures the safety of the water supply and protects against potential health hazards.

Q 20. How do you communicate effectively with clients and stakeholders about inspection results?

Effective communication is crucial in this field. I prioritize clear and concise reporting, avoiding technical jargon whenever possible. I explain findings in layman’s terms, ensuring clients and stakeholders understand the inspection results and any necessary actions. I use a combination of written reports, visual aids (like photos or diagrams), and face-to-face discussions to convey information effectively. I also answer questions patiently and thoroughly, making sure everyone feels comfortable and informed.

For example, if a system requires repair, I clearly explain the issue, its potential consequences, and the recommended solution. I then provide a detailed cost breakdown and timeline for the necessary repairs, empowering clients to make informed decisions. I believe in fostering a collaborative relationship with clients, prioritizing transparency and mutual understanding throughout the process.

Q 21. What software or tools do you use for reporting and documentation?

I utilize a variety of software and tools for reporting and documentation, including specialized fire protection inspection software that streamlines the data collection and reporting process. This software allows me to create professional, detailed reports, including images and system diagrams, which are easily shared with clients. I also use cloud-based storage to ensure secure data backup and easy access to inspection records. My choice of tools prioritizes efficiency, accuracy, and regulatory compliance.

In addition to specialized software, I also use standard productivity tools like Microsoft Office Suite for creating reports and presentations. Using a combination of these technologies allows me to maintain a high level of organization and ensure all documentation meets industry standards and client expectations.

Q 22. Describe a challenging inspection you faced and how you resolved it.

One particularly challenging inspection involved a high-rise building with a complex sprinkler system integrated with a fire alarm system. The system showed numerous false alarms originating from a specific zone, yet visual inspection revealed no apparent issues. This initially pointed to a faulty alarm panel or sensor. However, after meticulously checking every sprinkler head in that zone, I discovered a minor leak in a concealed sprinkler pipe causing a consistent drip that eventually triggered the alarm. This drip, though seemingly insignificant, was sufficient enough to activate the system. The resolution involved carefully locating the leak, repairing the pipe, and performing a complete system test to confirm functionality. This case highlighted the importance of thoroughness – sometimes the smallest detail can be the root of a major problem. It reinforced the need for systematic checks rather than just relying on automated system readings.

Q 23. How do you stay updated on the latest fire protection codes and technologies?

Staying current in fire protection is paramount. I achieve this through a multi-pronged approach. Firstly, I actively participate in professional development courses and seminars offered by organizations like NFPA (National Fire Protection Association) and local fire marshal offices. These courses provide updated knowledge on codes and regulations, and introduce the latest technologies. Secondly, I subscribe to industry publications and journals like Fire Protection Engineering and online resources that regularly publish articles on new developments and best practices. Thirdly, I network with other professionals in the field; exchanging experiences and insights through conferences and online forums. This combined approach keeps my knowledge fresh and relevant.

Q 24. Explain the concept of a ‘false alarm’ and how to minimize them.

A ‘false alarm’ is an unwanted activation of a fire detection system that doesn’t involve an actual fire. These alarms disrupt operations, waste resources, and can lead to complacency. Minimizing false alarms requires a multi-faceted strategy. Regular inspection and testing of all system components (smoke detectors, heat detectors, sprinkler system, etc.) are crucial. Ensuring proper maintenance of these components is equally important, which includes cleaning smoke detectors and checking for any damage or malfunction. Understanding the system’s sensitivity is key – adjusting sensitivity levels based on the environment can help reduce unnecessary activations. Additionally, employee training on the proper use of the system and procedures for reporting real emergencies is essential. Identifying potential sources of false alarms, such as dust accumulation on detectors or cooking fumes in kitchens, and addressing them proactively, are crucial preventative measures.

Q 25. How do you handle emergency situations during an inspection?

My priority during an inspection emergency is the safety of myself and everyone around. This involves immediate evacuation of the area if necessary, contacting emergency services (fire department and building management), and securing the scene to prevent further hazards. I document all events thoroughly, detailing the time, location, cause of the emergency, and steps taken for mitigation and reporting. I follow up by compiling a detailed report to determine the cause and recommending remedial actions to prevent similar incidents. The key is swift, decisive action and detailed documentation for post-incident analysis.

Q 26. What is your experience with various types of fire doors and their inspection?

My experience encompasses various fire door types, including swing doors, sliding doors, rolling steel doors, and fire-rated windows. Inspection involves verifying the door’s rating (e.g., 20-minute, 1-hour rating), checking for proper clearance, ensuring the self-closing mechanism functions correctly, inspecting the frame for damage or gaps, and verifying that the door is properly sealed. I also check hinges, latches, and thresholds for wear and tear. Specific requirements vary depending on the door type and location. For instance, rolling steel doors require testing of the motor and emergency release mechanisms. For example, I once found a fire door that failed its inspection because of a significant gap at the frame which was allowing smoke penetration. Repair of the frame was required.

Q 27. What are the limitations of different types of fire detection systems?

Different fire detection systems have inherent limitations. For instance, smoke detectors can be affected by dust, humidity, and even insects. They might miss slow-burning fires that produce little smoke. Heat detectors, while less susceptible to environmental factors, may be slower to respond compared to smoke detectors in the case of fast-spreading, high-temperature fires. Sprinkler systems are generally effective but can be affected by low water pressure or obstructions. Each system has its own strengths and weaknesses, and understanding these limitations is crucial for proper system design and implementation. For example, in a kitchen environment, heat detectors alone may be inadequate due to cooking fumes, so the use of a combination of detection systems is often better. Proper system design should always consider the type of occupancy and potential fire hazards.

Q 28. Describe your experience with the inspection and testing of standpipe systems.

Standpipe system inspections involve a thorough examination of the entire system, from the water supply source to the hose connections. This includes checking water pressure, flow rates, and the condition of the pipes, valves, and hose reels. I verify the functionality of the fire hose nozzles and their pressure capabilities. I look for signs of corrosion, leaks, or obstructions within the system. Testing typically involves flow testing to ensure adequate water pressure and flow rate at each hose connection point. Documentation of the entire process, including testing results and any identified deficiencies, is crucial. It’s imperative to ensure the system is regularly flushed to prevent sediment buildup, and that all components are functioning optimally. For example, during an inspection, a partially closed valve was discovered significantly reducing water pressure which could have had catastrophic consequences in a fire situation.

Key Topics to Learn for Fire Protection System Inspection and Testing Interview

- NFPA Codes and Standards: Understanding and applying relevant NFPA codes (e.g., NFPA 10, NFPA 25, NFPA 72) to inspection and testing procedures. This includes knowing the requirements for different system types and frequencies of testing.

- Fire Alarm Systems: Inspecting and testing various fire alarm system components (e.g., initiating devices, control panels, notification appliances) and troubleshooting malfunctions. Practical application includes documenting test results and identifying areas needing repair or replacement.

- Sprinkler Systems: Understanding sprinkler system design, hydraulic calculations, and inspection methods (e.g., pressure testing, flow testing). Practical application involves identifying potential hazards like obstructions and corrosion.

- Standpipe and Hose Systems: Inspecting and testing standpipe and hose systems for proper water pressure, flow rate, and hose condition. Practical application includes ensuring accessibility and proper operation of fire hoses.

- Clean Agent Systems: Understanding the principles of clean agent fire suppression systems (e.g., Halon, FM-200) and their inspection and testing procedures. This includes understanding safety precautions and environmental considerations.

- Inspection Documentation and Reporting: Mastering the proper documentation and reporting techniques, including creating detailed reports with photographic evidence, highlighting findings, and making recommendations for corrective action. This includes understanding the importance of clear and concise communication of findings.

- Safety Procedures and Regulations: Demonstrating a thorough understanding of relevant safety regulations and procedures for working on fire protection systems. This includes lockout/tagout procedures and personal protective equipment (PPE) requirements.

- Troubleshooting and Problem-Solving: Developing strong troubleshooting skills to diagnose and solve common problems encountered during inspections and testing. This includes using systematic approaches to identify root causes.

Next Steps

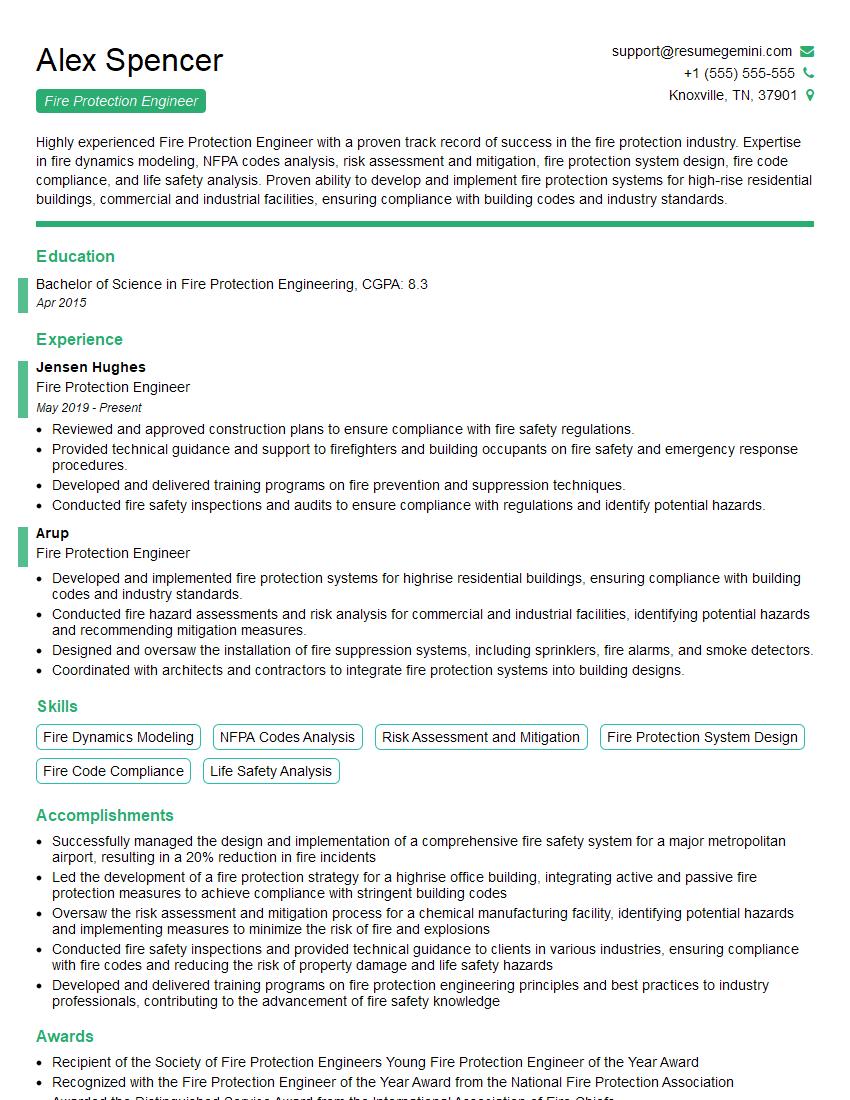

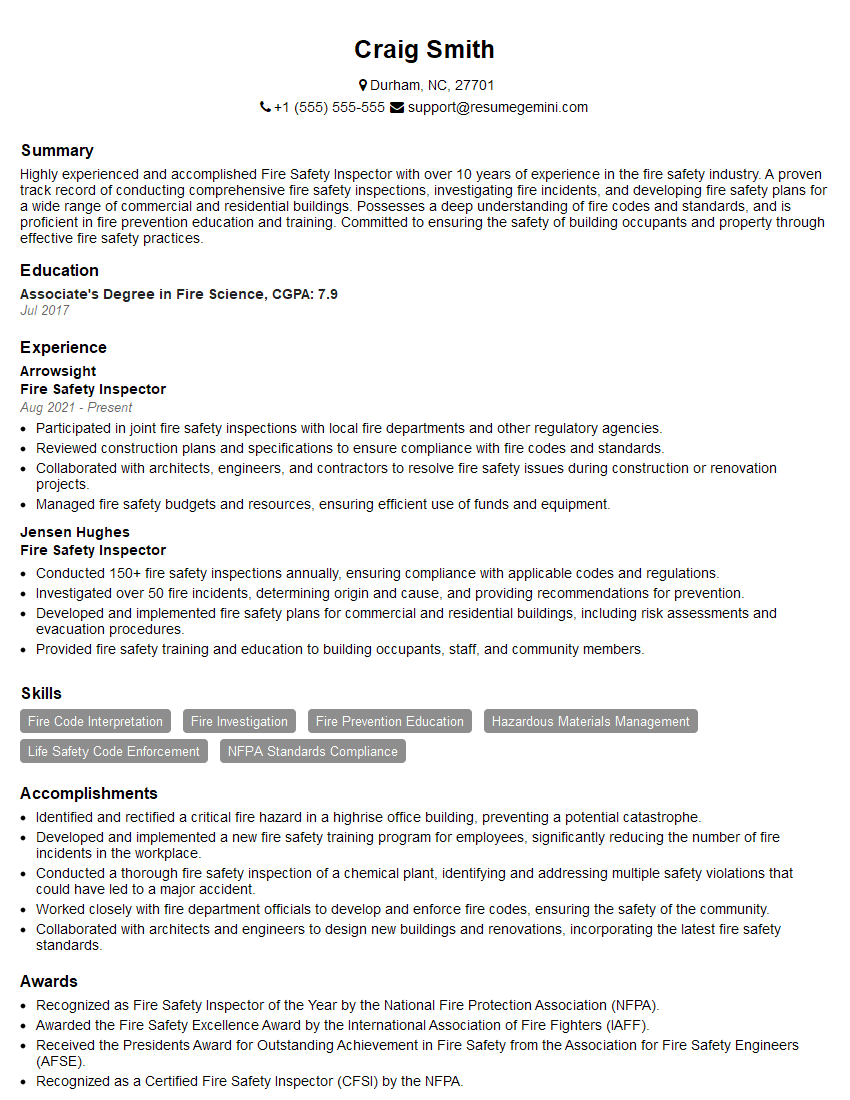

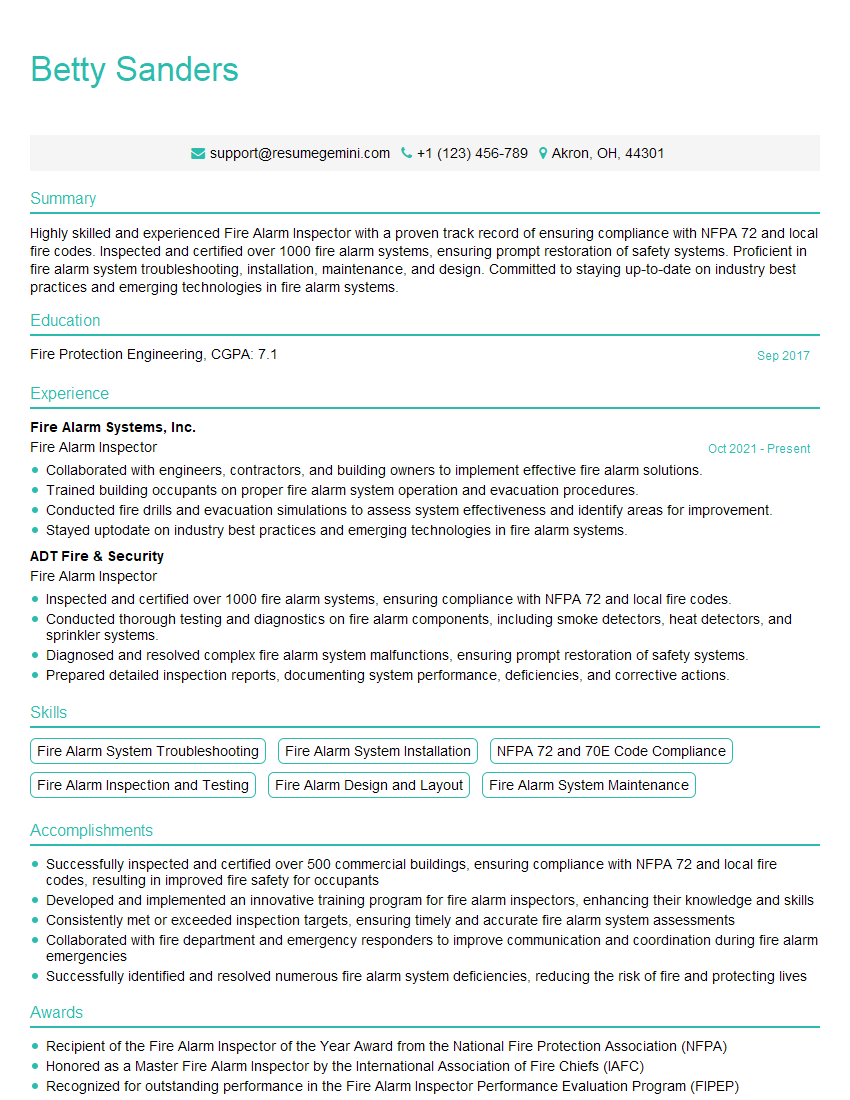

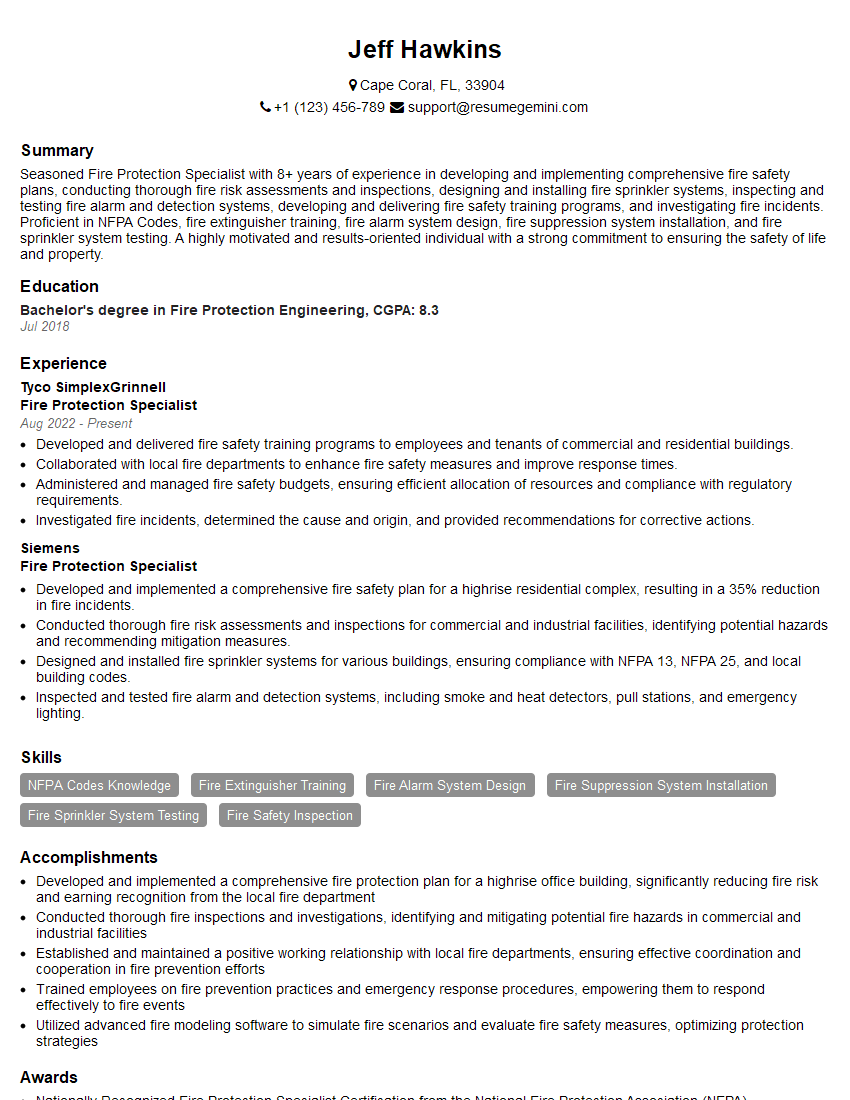

Mastering Fire Protection System Inspection and Testing opens doors to exciting career advancements, leading to increased responsibility, higher earning potential, and greater job security. To maximize your job prospects, crafting an ATS-friendly resume is crucial. This ensures your qualifications are effectively highlighted for applicant tracking systems. We strongly recommend using ResumeGemini to build a powerful, professional resume that showcases your skills and experience. ResumeGemini offers examples of resumes tailored to Fire Protection System Inspection and Testing to help you get started. Invest in your future – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good