Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Using hand tools and power tools interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Using hand tools and power tools Interview

Q 1. Describe your experience using various hand saws (e.g., hand saw, coping saw, hacksaw).

My experience with hand saws spans years of woodworking and construction projects. I’m proficient with various types, each suited for specific tasks. The standard hand saw is excellent for straight cuts in wood, requiring a smooth, controlled push and pull motion. Think of it like sawing a bread loaf – steady, even strokes are key. A coping saw, with its narrow blade, allows for intricate cuts, ideal for curved shapes in thinner materials like wood or plastic. Imagine cutting out a decorative element from a piece of plywood. Lastly, the hacksaw, with its fine-toothed blade, is crucial for cutting metal – a completely different technique requiring firm, controlled pressure and a much slower pace. It’s essential to choose the correct blade type for the metal you’re working with, otherwise you risk breaking the blade or damaging the material.

- Hand Saw: Straight cuts in wood.

- Coping Saw: Intricate curves in thin materials.

- Hacksaw: Cutting various metals. Blade selection is crucial based on the metal type (e.g., high-speed steel for harder metals).

Q 2. Explain the proper techniques for using a drill press.

Using a drill press safely and effectively involves a systematic approach. First, secure the workpiece firmly to the drill press table using clamps. Never attempt to hold the work by hand. Next, select the correct speed for the material and bit; softer woods require lower speeds, while harder materials may need higher speeds. Always start with a low speed and gradually increase if needed. Position the bit precisely, ensuring it’s perpendicular to the workpiece. Then engage the chuck, carefully feed the material into the spinning bit, applying gentle but firm downward pressure. Avoid forcing the bit, as this could lead to binding or breakage. After completing the drilling, disengage the chuck, and always turn off the drill press before removing the workpiece.

For example, when drilling a precise hole for a cabinet hinge, proper clamping and speed selection are crucial to avoid splintering the wood or damaging the hinge’s placement. Failing to do so can lead to a poorly functioning hinge and potentially damage to the cabinet.

Q 3. How do you select the appropriate drill bit for a specific material?

Choosing the right drill bit is paramount for achieving clean, accurate holes and preventing damage to the material or the bit itself. The material’s hardness dictates the bit’s type and material. For wood, I’d use a standard twist drill bit, possibly with a brad-point bit for cleaner entry holes in hardwood. For softer materials like plastic, a less aggressive bit might be suitable. Metals require high-speed steel (HSS) bits, and different grades of HSS exist for varying metal hardness. The bit diameter also needs to match the intended hole size. Consider using a pilot hole for larger diameter bits in harder materials to prevent splitting or chipping.

For instance, when drilling a pilot hole for a screw, a smaller drill bit made of appropriate material for the workpiece is essential to ensure the screw goes in smoothly without causing cracks.

Q 4. What safety precautions do you take when using power tools?

Safety is always my top priority when using power tools. I always wear appropriate safety glasses or a face shield to protect my eyes from flying debris. Hearing protection is essential, especially when using louder tools. Loose clothing or jewelry should be avoided to prevent entanglement. The work area must be well-lit and free from clutter. Before operating any power tool, I inspect it for damage or loose parts and make sure it’s properly grounded. I always use the correct guards and safety features provided by the manufacturer. Finally, I never rush the job, maintaining focus and concentration throughout. Think of it as performing a surgical procedure – precision and safety are paramount.

Q 5. Describe your experience with various types of screwdrivers and their applications.

My experience includes a wide range of screwdrivers, from basic Phillips and flathead to specialized Torx and security bits. Flathead screwdrivers are used for straight-slotted screws, while Phillips heads have a cross-shaped slot, providing better grip and preventing slippage. Torx and other specialized bits are designed for specific screw types often found in electronics or high-torque applications. The size and type of the screwdriver must always match the screw to avoid damaging either. I always select the correct size screwdriver for the screw head; using the wrong size can strip the screw head or damage the screwdriver. Proper technique involves applying steady, even pressure and avoiding excessive force.

For example, assembling delicate electronics would necessitate using smaller precision screwdrivers and appropriate bit types, while a larger screwdriver might be necessary for assembling outdoor furniture.

Q 6. How do you ensure the accuracy of measurements when using measuring tools?

Accuracy in measurements is crucial for any project. I use a combination of tools and techniques to ensure precision. For basic measurements, a reliable measuring tape is my go-to tool. However, for more accurate and precise measurements, I use a steel rule or a combination square, especially when working on projects requiring precise angles or dimensions. When measuring, I always make sure the tape measure or rule is held firmly against the surface and read the measurement at eye level to avoid parallax error – that’s the apparent shift in position when viewing an object from different angles. I also double-check my measurements to ensure consistency.

For example, when cutting wood for a frame, inaccurate measurements can lead to a poorly fitting frame. Double-checking measurements is crucial to prevent this.

Q 7. Explain the difference between various types of hammers and their uses.

Different hammers cater to various needs. A claw hammer is the most common, used for driving nails and removing them using the claw. A ball-peen hammer, with its rounded end, is useful for shaping metal or riveting. A sledgehammer, with its heavier head, is ideal for demolition or driving large stakes. A rubber mallet is gentler, preventing damage to delicate surfaces. The choice depends entirely on the task. For example, you wouldn’t use a sledgehammer to hang a picture; that would be inappropriate and potentially dangerous. Similarly, using a claw hammer to shape metal would be inefficient and could damage the hammer.

Choosing the right hammer is all about matching the tool to the job, considering the material being worked on and the force required.

Q 8. What are the safety considerations when working with different types of wood?

Safety when working with wood hinges on understanding the wood’s properties. Different woods have varying hardness, grain patterns, and potential for splintering. For example, hardwoods like oak and maple are dense and can be difficult to work with, potentially causing kickback on power tools if not handled carefully. Softer woods like pine are easier to work with but can still present dangers if not handled correctly. Always wear appropriate safety gear, including safety glasses, a dust mask (especially when working with hardwoods, which produce finer dust), and hearing protection when using power tools.

- Hardwoods: Use sharp tools to minimize splintering and ensure a clean cut. Take extra caution with power tools due to the risk of kickback.

- Softwoods: While generally easier to work with, still wear safety glasses to protect your eyes from flying debris. Pay attention to the grain direction to prevent tear-out.

- Knots: Avoid knots whenever possible as they are weak points in the wood and can cause tools to bind or break.

- Pressure-treated lumber: Be aware of the chemicals used in pressure-treated lumber; wear gloves and a respirator to avoid skin and respiratory irritation.

Always inspect the wood for nails, screws, or other hidden hazards before beginning any work. A thorough understanding of the material and its properties is paramount to safe woodworking.

Q 9. Describe your experience using a planer.

I have extensive experience using planers, both thickness planers and surface planers. I’m comfortable setting up and operating both types to achieve precise surface finishes. I understand how to adjust the cutting depth, feed rate, and outfeed rollers to optimize the planing process for different wood types and desired thicknesses. For example, when planing hardwoods, I use a slower feed rate and a shallower cutting depth to avoid burning the wood and to ensure a smooth finish. Conversely, softer woods can tolerate a higher feed rate. I’m also adept at troubleshooting common issues like snipe (uneven cuts at the ends of the board) by adjusting the infeed and outfeed tables, and using appropriate techniques like planing several passes or using a jointer beforehand.

One time, I had to plane a warped board. To correct the warp, I used the planer in conjunction with a jointer to create a flat surface before running the whole board through the planer to achieve a uniform thickness. This process involves careful attention to detail and careful feed rate adjustments, and is something I feel very comfortable with.

Q 10. How do you troubleshoot a malfunctioning power tool?

Troubleshooting a malfunctioning power tool involves a systematic approach. First, I always ensure the tool is unplugged and the power is off before attempting any repair. Safety is paramount.

- Check the obvious: Inspect the power cord for damage, frayed wires, or loose connections. Check the plug to make sure it’s securely plugged in.

- Examine the tool itself: Look for any obvious damage or loose parts. Check blades, bits, or other consumables for wear or damage.

- Test the power supply: Try the tool in a different outlet to rule out power supply issues.

- Consult the manual: The owner’s manual contains troubleshooting information specific to the model and type of tool.

- Listen carefully: Unusual noises, such as grinding or squealing, often indicate a problem with the tool’s motor or bearings.

- Check the brushes (for motor-driven tools): Worn-out brushes are a common cause of power tool malfunctions. Inspect and replace if necessary (depending on my skill level and ability to source replacement parts).

If the problem persists after these steps, I’ll seek professional repair or consult with an expert depending on the complexity of the issue. It’s always better to err on the side of caution and avoid attempting complex repairs unless properly trained.

Q 11. Explain the importance of maintaining power tools.

Maintaining power tools is crucial for safety, performance, and longevity. Regular maintenance prevents accidents, ensures the tool works optimally, and extends its lifespan, saving money in the long run. The specific maintenance will vary depending on the tool; however, general principles apply.

- Cleanliness: After each use, clean the tool of sawdust, debris, and any other residue. Compressed air is effective for removing dust from hard-to-reach areas.

- Lubrication: Many power tools require lubrication of moving parts (check the manual). Use the recommended lubricant to maintain smooth operation and prevent wear.

- Blade/Bit Sharpening: Sharpen or replace blades and bits regularly for optimal cutting performance and safety. Dull tools are more dangerous and produce inferior results.

- Inspection: Regularly inspect the tool for any damage or wear. Look for cracks, loose screws, or frayed wires.

- Storage: Store tools in a dry, clean environment to protect them from corrosion and damage.

Neglecting these steps can lead to accidents, reduced performance, and shortened lifespan of the tools, increasing the overall cost of ownership.

Q 12. Describe your experience using a router.

My experience with routers is extensive, encompassing both handheld and router table setups. I’m proficient in using various bits to create a wide range of profiles, dadoes, rabbets, and decorative edges. Understanding the different types of bits and their applications is key—a straight bit is vastly different from a Roman ogee bit in function and result. I’m meticulous about setting up the router for each task, carefully choosing the appropriate speed and feed rate to avoid burning the wood. This is especially crucial when working with hardwoods. For safety, I always use a router table’s fence for consistent cuts and to prevent the workpiece from kicking back. This also protects from potential injury.

I remember one project where I had to create a complex curve on a tabletop using a template guide. The accuracy required a steady hand and a deep understanding of the router’s behavior, ensuring proper bit depth and speed adjustment, and employing the correct template guiding system. This resulted in a perfect, smooth curve, which truly highlighted the precision possible with this tool when used skillfully.

Q 13. What are the different types of sandpaper and their applications?

Sandpaper is categorized by its grit, which refers to the number of abrasive particles per square inch. Lower grit numbers indicate coarser sandpaper, suitable for removing substantial material quickly, while higher grit numbers represent finer sandpaper used for smoothing and polishing.

- Coarse Grit (24-60): Used for shaping, removing significant material, and initial smoothing. Effective for removing large imperfections.

- Medium Grit (80-120): Used for leveling surfaces and removing scratches left by coarser grits. A good transition grit.

- Fine Grit (150-220): Used for refining the surface and reducing finer scratches. Creates a smoother finish.

- Very Fine Grit (240-400): Used for creating a very smooth finish before applying a finish. Removes the finest scratches.

- Extra Fine Grit (above 400): Used for polishing and final smoothing before finishing, creating an exceptionally smooth surface.

The choice of sandpaper depends heavily on the material being worked on and the desired outcome. Always use a progressively finer grit to avoid leaving visible scratches from coarser grits. You always need a smooth transition for a proper finish.

Q 14. How do you handle different types of metal when using hand tools?

Handling different types of metal with hand tools requires an understanding of their properties and the appropriate tools. Some metals are softer and easier to work with than others. Safety precautions are paramount, as many metalworking processes produce sharp edges, flying debris, and potentially hazardous fumes.

- Soft Metals (e.g., Aluminum, Lead): These are easier to shape and cut. However, even these soft metals can cause injuries if you are not wearing appropriate safety gear. Files, hacksaws, and chisels are commonly used. Aluminum can often be bent and shaped with hand tools with care.

- Hard Metals (e.g., Steel, Brass): These require stronger tools and more force. Hacksaws with appropriate blades (depending on the material’s hardness), files, and chisels are used. Proper clamping is crucial for safety and control.

- Precious Metals (e.g., Gold, Silver): Often worked with specialized tools designed for finer work. The techniques often involve more delicate shaping and require higher levels of precision and skill.

Always wear safety glasses to protect your eyes from flying debris and metal chips. Gloves are recommended to protect your hands. When working with metals that produce hazardous fumes, ensure adequate ventilation is available and utilize a respirator if necessary.

Q 15. What are the different types of wrenches and their applications?

Wrenches are fundamental hand tools used to tighten or loosen nuts and bolts. Different types cater to specific needs and access requirements.

- Open-end wrenches: Have an open-ended U-shaped jaw. They’re simple and versatile but only grip on one side of the fastener at a time. Great for quick work but less secure than others.

- Box-end wrenches: Completely enclose the fastener, providing superior grip and torque. However, they’re less versatile for accessing fasteners in tight spaces.

- Combination wrenches: Combine both open-end and box-end configurations on opposite ends of the same wrench, providing flexibility.

- Adjustable wrenches (Crescent wrenches): Allow for adjusting the jaw width to fit various sizes of fasteners. Useful but offer less grip than fixed wrenches, therefore potentially less precise.

- Socket wrenches: Utilize sockets of different sizes that fit onto a ratchet handle or wrench. Offer excellent grip and high torque, perfect for repetitive tasks or working with multiple sizes. Ratchets improve efficiency.

- Torque wrenches: Precisely control the amount of torque applied to a fastener, preventing over-tightening that could damage the bolt or its surroundings. Crucial for critical applications.

For example, on a car engine, I’d likely use a combination wrench for most fasteners, a socket wrench set for bolt patterns requiring multiple sizes, and a torque wrench to ensure proper tightening of critical components like the cylinder head bolts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the use of chisels and other woodworking hand tools.

Chisels and other woodworking hand tools are essential for shaping, carving, and joining wood. Precision and control are key when using these tools.

- Chisels: Used for chopping, paring, and shaping wood. Different types include firmer chisels (for heavy-duty work), mortise chisels (for creating holes), and bevel-edged chisels (for smoother cuts). Sharpness is crucial for efficient and clean cuts. I always sharpen mine regularly.

- Planes: Smooth wood surfaces and remove material evenly. Jack planes are used for general smoothing while smoothing planes handle finer details. Proper blade adjustment is essential for a smooth cut.

- Hand saws: Cut wood to specific shapes and sizes. Types vary based on tooth size and configuration (rip saws for cutting with the grain and crosscut saws for cutting across the grain).

- Mallet: Used to strike chisels and other tools without damaging them. Wooden mallets are better for preventing damage to tools.

- Files and rasps: Shape and smooth wood after initial cuts. Files are finer than rasps.

In a recent project, I used a mortise chisel to create precisely sized holes for installing wooden dowels in a cabinet, followed by smoothing the surfaces with a hand plane and files. Maintaining sharp tools was key to achieving a perfect fit and finish.

Q 17. Describe your experience with various types of pliers and their applications.

Pliers are versatile hand tools used for gripping, bending, cutting, and holding various objects. The choice of pliers depends on the specific task.

- Slip-joint pliers: Adjustable jaws, offering versatility in gripping different sizes of objects.

- Lineman’s pliers: Heavy-duty pliers with a cutting edge, ideal for gripping and cutting wire.

- Needle-nose pliers: Long, slender jaws, suitable for reaching tight spaces and manipulating small components.

- Locking pliers (e.g., Vise-Grips): Self-locking jaws, providing a strong grip without constant pressure. Excellent for holding parts in place.

- Diagonal cutting pliers (dikes): Used for cutting wire cleanly.

For instance, I recently used needle-nose pliers to install tiny electronic components on a circuit board, and locking pliers to hold a stubborn nut while tightening a bolt on a bicycle. The choice of pliers was crucial for completing these tasks effectively and without damage.

Q 18. How do you ensure the safety of yourself and others when using power tools in a team environment?

Safety is paramount when using power tools, especially in a team environment. A comprehensive safety protocol is essential.

- Pre-task planning: Carefully plan the task, identifying potential hazards and developing a safe work procedure. This involves risk assessment and using proper personal protective equipment (PPE).

- Tool maintenance: Ensure all power tools are properly maintained, with sharp blades and correctly functioning safety guards. Regular inspections are crucial.

- PPE usage: Mandatory PPE includes safety glasses, hearing protection, dust masks (depending on the material), and appropriate work gloves. I always insist on this for my team.

- Clear communication: Maintain open communication within the team. Announce when power tools are in use, warning others to stay clear of the working area. Designated safety officers can significantly improve safety.

- Emergency procedures: Establish clear emergency procedures, including how to respond to injuries and how to shut down equipment in case of an emergency. First Aid training is helpful.

- Safe work practices: Never rush. Maintain a safe working distance between tools and other personnel. Never operate a tool if you are tired or feeling unwell.

In my experience, a proactive approach to safety fosters a culture of responsibility, leading to a significantly reduced risk of accidents and injuries.

Q 19. What are the different types of fasteners and their applications?

Fasteners are essential for joining materials together. Selecting the appropriate fastener is crucial for strength, durability, and ease of assembly.

- Screws: Various types (wood screws, machine screws, self-tapping screws) exist, each designed for different materials and applications. They’re often used in woodworking and mechanical assemblies.

- Bolts: Usually paired with nuts, providing a strong and reusable fastening solution. Suitable for heavier applications.

- Nuts: Used with bolts to create a secure connection.

- Rivets: Permanent fasteners, used when disassembly isn’t necessary. Common in sheet metal applications.

- Nails: Simple and quick fastening solution, often used in woodworking and construction.

For example, I’d use wood screws to assemble a wooden shelf, machine screws and nuts to secure a metal bracket, and rivets to join two sheets of metal. The choice always depends on material strength and the need for reusability.

Q 20. Describe your experience with different types of adhesives and their applications.

Adhesives play a crucial role in joining various materials. Understanding their properties is crucial for successful bonding.

- Epoxies: Two-part adhesives offering strong bonds, suitable for a wide variety of materials.

- Cyanoacrylates (super glues): Fast-setting adhesives, ideal for small bonding tasks. Caution: skin contact needs to be avoided.

- Polyurethane adhesives: Strong and versatile, often used in construction and woodworking.

- Hot melt adhesives: Applied using a hot glue gun. Quick setting but the bond strength is generally lower.

- Contact cement: Used for bonding larger surfaces, particularly in woodworking applications.

I’ve used epoxies for repairing cracked metal parts and cyanoacrylates for quick fixes in electronics. Selecting the appropriate adhesive depends heavily on material compatibility, environmental conditions, and the required bond strength. Following the manufacturer’s instructions is crucial for a good result.

Q 21. How do you select the appropriate cutting tool for a specific material?

Choosing the right cutting tool depends on factors like the material being cut, the desired cut quality, and the thickness of the material. This involves a careful consideration of both material properties and tool capabilities.

- Wood: Hand saws, circular saws, jigsaw for various cuts. Chisels for intricate shaping.

- Metal: Hacksaw for most metals, band saw for curved cuts, angle grinder for faster cutting.

- Plastic: Utility knife, jigsaw for thicker plastics, specialized plastic cutting tools for cleaner cuts.

- Concrete/Masonry: Masonry saw, angle grinder with masonry blade.

For instance, if I needed a clean, precise cut in a piece of hardwood, I might use a fine-tooth hand saw. For a thicker piece of wood, a circular saw would be more efficient. When cutting metal, the appropriate blade type for the specific metal is crucial to avoid damage to the tool and ensure a clean cut. Always choose a tool designed for the material and thickness to avoid accidents.

Q 22. Explain the importance of using personal protective equipment (PPE) when using power tools.

Personal Protective Equipment (PPE) is paramount when using power tools. It’s not just about following safety regulations; it’s about protecting your most valuable asset – yourself. Failing to wear appropriate PPE can lead to serious, even life-altering injuries.

- Eye Protection: Safety glasses or a face shield are essential to prevent flying debris from causing eye damage. I’ve seen firsthand the devastating consequences of a small piece of wood embedding itself in someone’s eye.

- Hearing Protection: Power tools are often incredibly loud. Prolonged exposure to loud noises can lead to permanent hearing loss. Earmuffs or earplugs are a must.

- Respiratory Protection: Depending on the material being worked with (e.g., certain types of wood, dust from concrete or drywall), a dust mask or respirator might be necessary to prevent inhaling harmful particles. This is especially crucial when working with asbestos or lead-based paint.

- Hand Protection: Gloves protect your hands from cuts, splinters, and abrasions. The type of glove will depend on the task – some materials require more robust protection than others.

- Foot Protection: Sturdy work boots with steel toes protect your feet from falling objects or accidental impacts.

In short, PPE isn’t optional; it’s a fundamental aspect of safe and responsible power tool use. It’s a habit I’ve ingrained from years of experience, and it’s a habit I expect from anyone working alongside me.

Q 23. Describe your experience with using a miter saw.

I have extensive experience with miter saws, from basic crosscuts to complex compound miters. I’m comfortable using both sliding and non-sliding models. I understand the importance of proper blade selection and adjustment based on material type and cut angle.

For instance, when working with hardwoods, I ensure that I have a sharp blade appropriate for the material’s density, to avoid binding and kickback. I always double-check the fence and miter settings to guarantee accuracy and avoid accidental cuts. Before each cut, I carefully secure the workpiece and make sure that it’s clear of any obstructions. My experience extends beyond simply making the cut; it encompasses proper maintenance, including blade cleaning and lubrication to ensure its continued precision and longevity.

I’ve used miter saws in various applications, from simple framing projects to intricate trim work, and I consistently strive for precision and safety in every operation.

Q 24. How do you interpret technical drawings and specifications for tooling?

Interpreting technical drawings and specifications is critical for efficient and accurate tooling. I begin by carefully examining the overall dimensions and scale of the drawing. Then, I thoroughly analyze the details, including angles, tolerances, and material specifications. I ensure I understand the required tools and processes before beginning any work.

For example, if a drawing specifies a 45-degree bevel cut on a specific dimension of a hardwood component, I understand that I need a miter saw capable of making such an angled cut. If the drawing notes a tolerance of +/- 0.1mm, I understand that I must ensure my cuts fall within that tolerance range. Understanding the material, like oak or pine, will help me adjust the cutting parameters and prevent material tear-out.

I frequently use calipers and measuring tools to double-check the dimensions and verify accuracy throughout the process. I always prioritize precision and adhere strictly to the provided specifications to ensure the final product meets the design requirements.

Q 25. Explain the proper techniques for using a table saw.

Using a table saw correctly is crucial for safety and precision. The most important aspects are:

- Proper Blade Height and Tilt: Adjust the blade height just slightly above the material to minimize tear-out and maximize safety. The blade angle should be set according to the cut needed.

- Secure Workpiece: Always use push sticks and featherboards to keep your hands away from the blade. Never use your hands to guide the workpiece. A miter gauge is crucial for cross cuts.

- Consistent Feed Rate: A steady and smooth feed rate prevents kickback and ensures a clean cut. Forceful or jerky movements are dangerous.

- Blade Guard and Riving Knife: Always ensure the blade guard and riving knife are in place. These safety devices are essential to prevent kickback and pinch points.

- Clear the Area: Keep the table saw area clear of clutter and debris to prevent accidents.

A real-world example: Recently, I needed to rip a large sheet of plywood into several strips. I carefully adjusted the blade height and ensured the fence was properly aligned. Then, using a push stick, I fed the plywood slowly and steadily into the blade. By following these steps, I was able to produce accurate cuts safely and efficiently.

Q 26. Describe your experience with different types of clamps and their applications.

My experience encompasses various clamp types and their applications. The choice of clamp depends heavily on the project’s specifics.

- Bar Clamps: These are versatile and ideal for clamping large workpieces. They are adjustable to various lengths and offer substantial clamping force.

- Spring Clamps: Quick and easy to use, spring clamps are perfect for smaller projects that require less clamping force, like gluing up picture frames.

- C-Clamps: Excellent for holding down workpieces or applying pressure in specific areas, C-clamps are sturdy and offer strong clamping power. They are particularly useful when dealing with irregular shaped materials.

- Pipe Clamps: These heavy-duty clamps excel in situations requiring significant clamping force. I’ve used them for very large gluing jobs and woodworking applications needing strong and robust clamping pressure.

- Quick Release Clamps: Very handy for repeated clamping in assembly work because of their fast clamping and releasing mechanisms.

For example, when assembling a large cabinet, I would use bar clamps to hold the sides together while the glue sets. For smaller tasks, such as gluing together small pieces of wood, I would opt for spring clamps for their ease of use. Selecting the correct clamp for the job significantly affects the quality and safety of the final product.

Q 27. How do you resolve common problems encountered while using hand tools and power tools?

Troubleshooting hand and power tools is a crucial skill. My approach involves a systematic process:

- Identify the Problem: Carefully observe the issue. Is the tool not powering on? Is it producing inaccurate cuts? Is there an unusual noise or vibration?

- Check the Obvious: For power tools, ensure the power cord is properly plugged in and that the circuit breaker isn’t tripped. For hand tools, check for damaged or loose parts.

- Inspect for Damage: Examine the tool for any visible damage – broken parts, worn blades, loose screws, or frayed cords.

- Test Functionality: If possible, test the tool with a known good material to isolate the issue.

- Consult Manuals: If the issue persists, refer to the manufacturer’s instructions or online resources for troubleshooting tips.

- Seek Expert Help: If you can’t find a solution, it’s best to consult a qualified repair technician.

For instance, if a drill is not working, I’d first check the power source, then examine the chuck to see if the bit is properly secured. If still no power, a multimeter would assist in isolating the faulty electrical component. Experience helps me diagnose many problems quickly and effectively, ensuring minimal downtime.

Q 28. What is your experience with diagnosing and repairing faulty power tools?

Diagnosing and repairing faulty power tools requires a combination of practical experience and technical knowledge. I approach it systematically:

- Safety First: Always disconnect the tool from the power source before attempting any repairs.

- Visual Inspection: Look for any obvious damage, such as broken wires, frayed cords, or loose connections.

- Testing Components: I use a multimeter to check for continuity in circuits, voltage in power cords, and the functionality of various components.

- Component Replacement: Based on my diagnosis, I replace faulty parts (e.g., brushes in a motor, switches, or capacitors). I source high-quality replacement parts.

- Calibration and Testing: After repairs, I recalibrate and rigorously test the tool to confirm its proper function and safety.

I’ve successfully repaired a number of power tools over the years, ranging from simple issues like replacing worn brushes in a circular saw to more complex repairs involving motor rewinding. My experience ensures that repairs are done correctly, safely, and extend the lifespan of the tools.

Key Topics to Learn for Using Hand Tools and Power Tools Interview

- Safety Procedures: Understanding and applying safety regulations for both hand and power tools, including proper PPE (Personal Protective Equipment) usage and emergency procedures.

- Hand Tool Proficiency: Demonstrating practical knowledge of various hand tools like hammers, screwdrivers, saws, wrenches, levels, and measuring tapes; including their proper use, maintenance, and limitations.

- Power Tool Operation: Safe and efficient operation of common power tools such as drills, saws (circular, reciprocating, jigsaw), sanders, and impact drivers; understanding their functionalities and potential hazards.

- Material Selection and Application: Knowledge of different materials (wood, metal, plastic) and selecting the appropriate tools and techniques for each material’s unique properties.

- Project Planning and Execution: Demonstrating the ability to read blueprints or schematics, plan a project, and execute it efficiently and accurately using hand and power tools.

- Troubleshooting and Repair: Identifying common problems encountered while using tools, performing basic maintenance and repairs, and knowing when to seek professional assistance.

- Tool Maintenance and Storage: Proper cleaning, lubrication, storage, and care of both hand and power tools to ensure their longevity and safe operation.

- Understanding Tool Specifications: Interpreting tool specifications (voltage, amperage, RPM) and selecting the appropriate tool for the job based on these specifications.

Next Steps

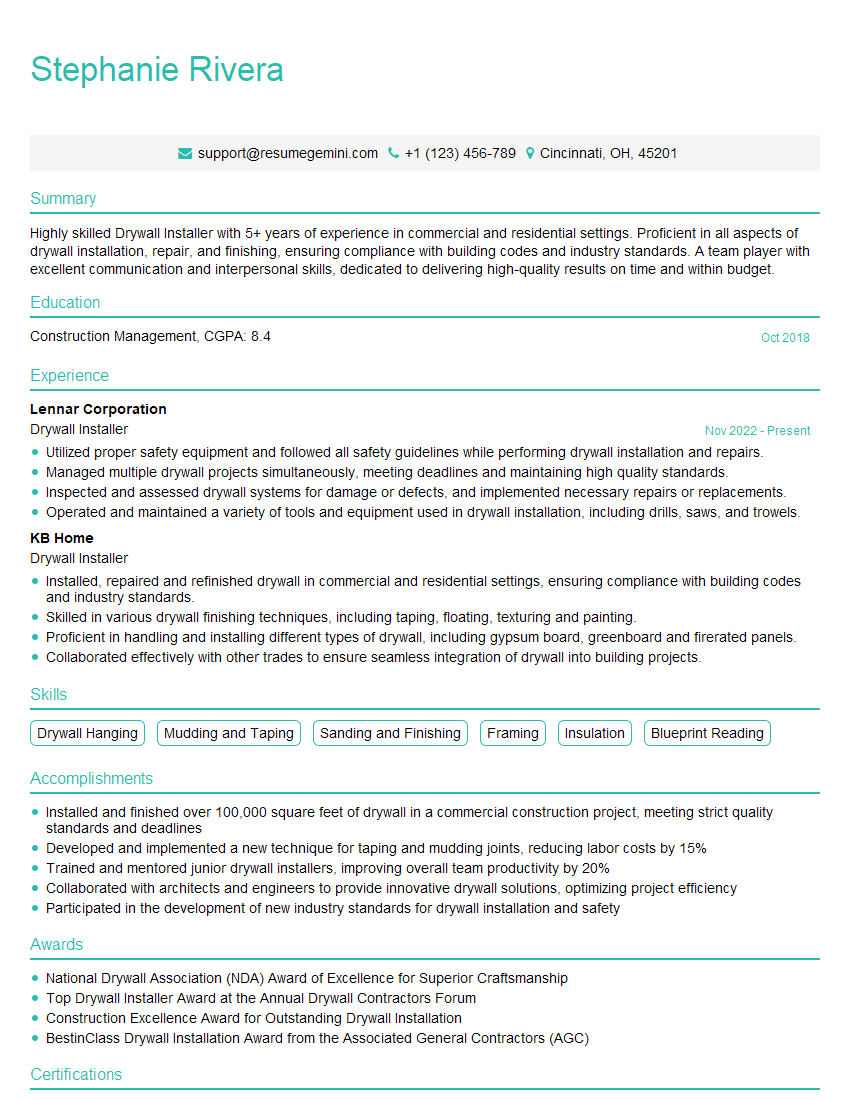

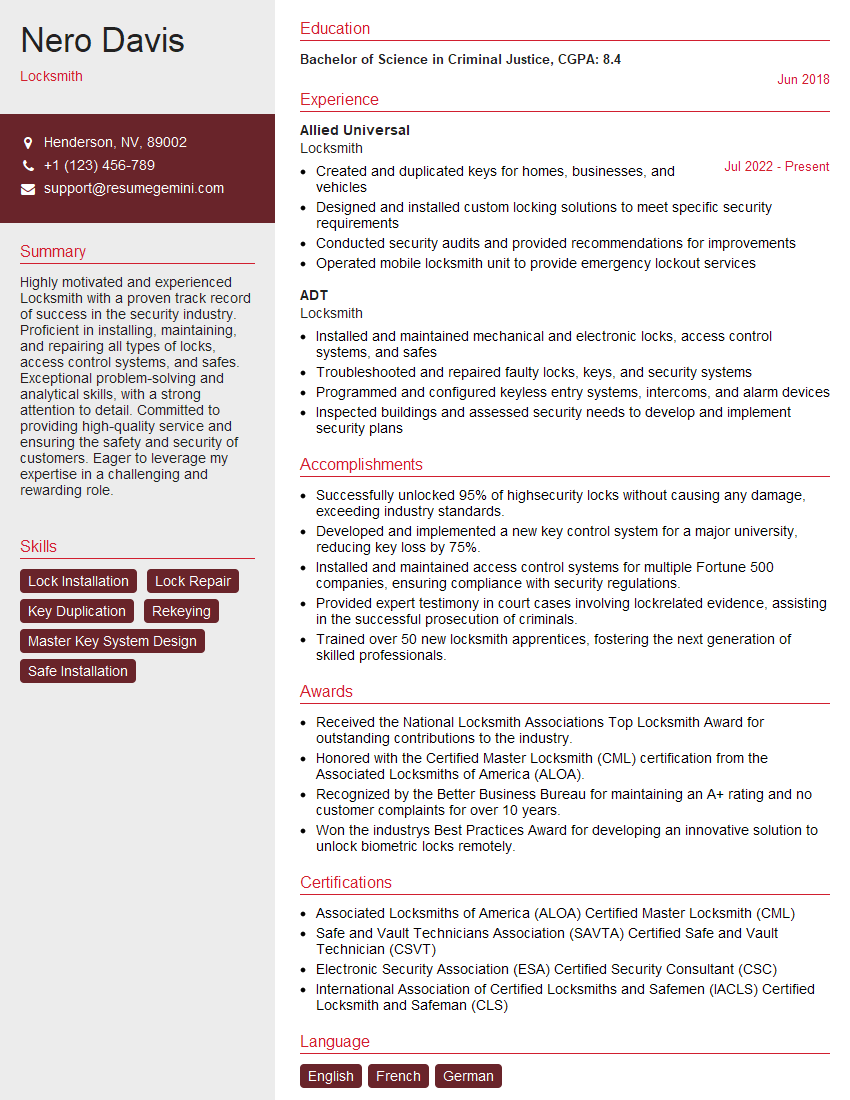

Mastering the use of hand and power tools is crucial for success in many skilled trades and manufacturing roles, opening doors to rewarding careers and significant growth potential. To maximize your job prospects, create a strong, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that showcases your abilities effectively. Examples of resumes tailored to using hand and power tools are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good