Are you ready to stand out in your next interview? Understanding and preparing for Fiber and Yarn Analysis interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Fiber and Yarn Analysis Interview

Q 1. Explain the difference between staple and filament fibers.

The fundamental difference between staple and filament fibers lies in their length. Staple fibers are short fibers, typically ranging from a fraction of an inch to a few inches long. Think of cotton or wool – you can easily see the individual short fibers. Filament fibers, on the other hand, are continuous strands of indefinite length. Silk and most synthetic fibers like nylon or polyester are filament fibers. This difference significantly impacts how they are processed into yarns and the final properties of the fabrics they produce. Staple fibers need to be spun together to create yarn, resulting in a more textured and potentially softer fabric. Filament yarns, being continuous, are often smoother and stronger.

Imagine building a rope: using short pieces of string (staple fibers) requires more intricate knotting (spinning) to create a strong rope, whereas using one long, continuous strand (filament fibers) is much simpler.

Q 2. Describe the various methods used for fiber identification.

Fiber identification utilizes several methods, each with its strengths and weaknesses. Microscopic examination is a cornerstone, allowing us to observe the fiber’s shape, surface characteristics (like scales in wool or striations in some synthetics), and cross-sectional profile (circular, triangular, etc.). This provides a visual fingerprint for many fibers. Burning tests analyze the fiber’s behavior when burned – the smell, the ash residue, and the way it melts or burns helps distinguish different fiber types (for example, wool burns with a characteristic odor of burning hair, while polyester melts and forms a bead).

Solubility tests use specific chemical solutions to dissolve certain fibers while leaving others intact. This helps differentiate between natural and synthetic fibers, or between different synthetic types. Finally, advanced techniques like infrared spectroscopy (FTIR) or thermal analysis (TGA) provide detailed chemical composition information for precise identification.

Q 3. What are the key properties of cotton, wool, and polyester fibers?

Cotton, wool, and polyester exhibit significantly different properties:

- Cotton: A natural cellulosic fiber, cotton is known for its softness, breathability, and absorbency. However, it’s prone to wrinkling and can be weaker than some synthetic fibers. It’s also susceptible to shrinkage and mildew.

- Wool: Another natural fiber, wool offers excellent warmth, elasticity, and moisture-wicking properties. Its inherent crimp (wave-like structure) contributes to its resilience and insulation. However, wool can be more expensive, sensitive to moths, and prone to felting (matting together).

- Polyester: A synthetic fiber, polyester boasts high strength, wrinkle resistance, and easy care. It’s durable, resistant to stretching, and can be readily blended with other fibers to enhance their properties. However, it’s less breathable and doesn’t absorb moisture as well as natural fibers.

Q 4. How do you determine the yarn count (e.g., Ne, Tex)?

Yarn count, expressing yarn fineness, is represented using various systems. The most common are Ne (English) and Tex (metric).

Ne (English system): This indicates the number of 840-yard lengths of yarn per pound. A higher Ne number means a finer yarn. For example, a 40 Ne yarn is finer than a 20 Ne yarn.

Tex (metric system): This system specifies the weight in grams of 1000 meters of yarn. A lower Tex number signifies a finer yarn. For example, a 20 Tex yarn is finer than a 40 Tex yarn.

Determining yarn count involves precise measurement of yarn length and weight using specialized instruments like a skein balance and a length measuring device. The measurements are then substituted into the relevant formula to calculate Ne or Tex.

Q 5. Explain the different types of yarn constructions (e.g., single, ply, core-spun).

Yarn construction refers to the way individual fibers or strands are combined to create the yarn. Several types exist:

- Single yarn: This is the simplest form, consisting of a single strand of fibers twisted together. It’s usually less strong and durable than plied yarns.

- Ply yarn: Two or more single yarns are twisted together to create a stronger, more even, and more resistant yarn. The direction of twist can be the same (S-ply) or opposite (Z-ply) to the twist of the single yarns.

- Core-spun yarn: A core fiber (usually filament) is wrapped with staple fibers. This provides a yarn with superior strength and a softer handle than a single yarn. The core adds stability and strength, whereas the outer layer provides the aesthetic feel of the yarn.

Different yarn constructions are chosen depending on the desired fabric properties, the application, and the fiber type used.

Q 6. What are the common yarn defects and how are they identified?

Numerous yarn defects can arise during manufacturing. Some common ones include:

- Slubs: Thick, irregular places in the yarn caused by variations in fiber distribution during spinning.

- Neps: Small knots or entangled fibers that create a fuzzy appearance.

- Thin places: Weak points in the yarn with reduced fiber density, leading to potential breakage.

- Hairiness: Loose fibers protruding from the yarn surface, affecting the yarn’s appearance and strength.

- Broken ends: Actual breaks in the yarn strand.

These defects are typically identified through visual inspection, often aided by magnifying glasses or specialized instruments. Automated systems using image analysis can also detect defects with high efficiency in modern mills.

Q 7. Describe the different methods for measuring yarn strength and elongation.

Yarn strength and elongation are crucial properties determining fabric performance. Measurement is typically done using a tensile tester.

Strength: This indicates the yarn’s resistance to breaking under tension. The tensile tester applies a force to the yarn until it breaks; the maximum force recorded represents the yarn’s strength. The result is often expressed in units of centiNewtons (cN) or grams force (gf).

Elongation: This refers to the yarn’s ability to stretch before breaking. The tensile tester measures the extent to which the yarn elongates (stretches) under tension, usually expressed as a percentage of the original length. High elongation implies greater elasticity and flexibility, while higher strength implies greater resistance to breakage.

Modern tensile testers often provide additional parameters like modulus (stiffness) and toughness, offering a more comprehensive picture of yarn quality.

Q 8. Explain the concept of yarn hairiness and its impact on fabric quality.

Yarn hairiness refers to the protruding fibers from the yarn surface. Imagine a well-groomed head of hair versus one with lots of flyaways – that’s analogous to yarn hairiness. Low hairiness indicates a smooth, even yarn, while high hairiness suggests a rougher, less consistent yarn.

Hairiness significantly impacts fabric quality. High hairiness can lead to:

- Reduced fabric smoothness: A hairy fabric feels rougher and may be less comfortable against the skin.

- Increased pilling: Protruding fibers are more prone to catching and forming pills, detracting from the fabric’s appearance.

- Weakening of the fabric: Excessive hairiness can weaken the yarn, leading to premature fabric wear and tear.

- Problems in dyeing and finishing: Uneven dye uptake and difficulties in achieving consistent finishes.

Conversely, low hairiness results in smoother, more durable fabrics with better drape and handle, making it desirable for high-quality apparel and textiles.

Q 9. How do you determine the fiber content of a fabric using microscopy?

Microscopy is a crucial technique for fiber identification in fabric analysis. It allows us to visualize the microscopic structure of fibers, enabling us to distinguish between different fiber types based on their characteristic morphology.

The process typically involves these steps:

- Sample Preparation: A small sample of the fabric is carefully dissected to separate individual fibers. These fibers are then mounted on a glass slide using a suitable mounting medium.

- Microscopic Examination: The slide is examined under a light microscope, preferably a polarized light microscope, which enhances the visibility of fiber details. Different magnifications may be necessary to observe specific features.

- Fiber Identification: Based on observations like fiber shape (round, flat, triangular), cross-sectional shape (circular, kidney-shaped, trilobal), surface characteristics (smooth, serrated, striated), and the presence of specific structural features (e.g., nodes in cotton), the fiber type is identified using reference images and databases.

For example, cotton fibers are characterized by their twisted ribbon-like shape with characteristic convolutions, while wool fibers show a scale structure under magnification. Synthetic fibers such as polyester or nylon show distinct cross-sectional shapes (round or trilobal).

Q 10. Describe the different types of fiber testing instruments and their applications.

Various instruments are employed in fiber testing, each serving a specific purpose. Here are a few examples:

- Fiber Diameter/Fineness Measurement Instruments: These include instruments like the AFIS (Advanced Fiber Information System) for measuring cotton fiber diameter and length, and the Uster® Tester for yarn uniformity.

- Tensile Strength Testers: These machines measure the strength and elongation properties of fibers and yarns, providing vital information about their durability. Examples include Instron machines.

- Microscope: As discussed earlier, essential for visualizing fiber morphology and identifying fiber types.

- Moisture Regain Apparatus: Used to determine the moisture content in fibers and fabrics which affects their physical properties.

- Colorimetry Equipment: These instruments measure the color of fibers and fabrics for quality control and consistency purposes.

- Hairiness Testers: Specifically designed to quantify yarn hairiness, providing numerical data to assess surface smoothness.

The choice of instrument depends on the specific fiber properties being evaluated and the overall quality control requirements.

Q 11. What are the standard test methods for determining fiber fineness?

Standard test methods for determining fiber fineness vary depending on the fiber type. However, some common methods include:

- Airflow Methods: For fibers like cotton, airflow methods measure the resistance to airflow through a fiber sample, relating the resistance to fiber diameter. The AFIS (Advanced Fiber Information System) is a prime example.

- Optical Methods: Microscopic image analysis measures fiber diameter directly. This method is often used for fibers with irregular shapes, where airflow methods might be less accurate.

- Gravimetric Methods: For wool and other animal fibers, fineness can be determined by measuring the weight per unit length. This often involves precise weighing and length measurement of a fiber bundle.

Each method has its advantages and disadvantages; the best choice depends on factors such as fiber type, the accuracy required, and available equipment.

Q 12. Explain the concept of fiber maturity and its influence on fiber properties.

Fiber maturity refers to the degree of cell wall development in a fiber. Think of it like a fruit ripening – an immature fiber has a thinner cell wall and is less developed, while a mature fiber has a thicker, more robust cell wall.

Fiber maturity significantly impacts various fiber properties:

- Strength: Mature fibers with thicker cell walls tend to be stronger and more resistant to breakage.

- Luster: Mature fibers often exhibit a higher luster due to their smoother surface and more complete cell wall development.

- Dye Affinity: Maturity can influence dye uptake, impacting the final color of the fabric.

- Elasticity: Mature fibers may show different elasticity characteristics compared to immature ones.

The level of maturity is crucial for determining the quality and overall performance characteristics of a fiber. For instance, in cotton, high maturity is associated with superior strength and spinning properties, while immature fibers are weaker and less desirable.

Q 13. How do you assess the uniformity of a yarn sample?

Yarn uniformity assessment refers to evaluating how consistent the yarn’s properties are throughout its length. Think of it like a perfectly straight, even road versus a bumpy, uneven one.

Yarn uniformity is assessed using instruments like the Uster® Tester which measures parameters such as:

- Yarn count (thickness): Uniform yarn should have a consistent thickness along its length. Variations in thickness are undesirable.

- Strength: Consistency in strength across the yarn is crucial for overall quality.

- Hairiness: As discussed earlier, uniform hairiness distribution contributes to fabric quality.

The Uster® Tester provides detailed reports including the CV (Coefficient of Variation) which quantifies the variability in yarn properties, with lower CV values indicating greater uniformity. Other methods may involve visual inspection or simple measurements of yarn diameter at different points.

Q 14. What are the common causes of yarn breakage during processing?

Yarn breakage during processing can stem from numerous factors. Here are some common causes:

- Low fiber strength: Weak fibers or fibers damaged during processing are more prone to breaking.

- Poor fiber maturity: Immature fibers lack the strength to withstand processing stresses.

- High hairiness: Excessive hairiness increases friction and can contribute to breakage.

- High yarn imperfections: Nepps (small entangled fiber clusters), slubs (thick places in the yarn), and other imperfections weaken the yarn and increase the likelihood of breakage.

- Incorrect processing parameters: Excessive tension, inappropriate speed, or inadequate lubrication during spinning can cause breakage.

- Fiber contamination: Foreign materials like leaf fragments in cotton can damage fibers.

- Static electricity: Buildup of static electricity can lead to increased yarn breakage, especially with synthetic fibers.

Addressing these causes through careful selection of raw materials, proper processing techniques, and appropriate machine settings can significantly reduce yarn breakage.

Q 15. Describe the different methods for measuring yarn twist.

Measuring yarn twist, also known as turns per inch (TPI) or turns per centimeter (TPC), is crucial for determining yarn strength and structure. Several methods exist, each with its strengths and weaknesses:

Direct Measurement: This involves unwinding a known length of yarn and counting the number of turns. It’s simple but prone to error, especially with tightly twisted yarns. Think of it like carefully untwisting a rope to count the individual strands’ rotations.

Twist Tester (Direct Method): Automated twist testers grip the yarn, unwind a predetermined length, and electronically count the number of turns. This is more accurate and faster than manual methods.

Indirect Measurement (Using a Micrometer): This involves measuring the yarn diameter and then using a formula to calculate the twist. This is quicker but less accurate than direct methods, as the formula relies on assumptions about yarn structure.

Using a Twist Counter: Specialized instruments that can measure twist directly on yarn packages.

The choice of method depends on factors such as yarn type, required accuracy, and available resources. For high-precision requirements, a direct method using an automated twist tester is preferred. For quick assessments, indirect methods might suffice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the relationship between yarn structure and fabric properties.

The relationship between yarn structure and fabric properties is fundamental in textile science. Yarn structure, encompassing factors like twist, fiber type, and fiber arrangement, directly impacts the final fabric’s characteristics:

Twist: Higher twist results in stronger, more compact yarns, leading to fabrics with better abrasion resistance and durability but potentially less softness and drape. Imagine a tightly twisted rope—much stronger than a loosely twisted one. Conversely, lower twist can yield softer, more draping fabrics.

Fiber Type: Natural fibers like cotton, wool, and silk have different properties that affect fabric hand feel, strength, and moisture absorption. Synthetic fibers like polyester and nylon offer distinct characteristics such as durability and wrinkle resistance.

Fiber Arrangement: How fibers are aligned within the yarn influences fabric properties. Parallel arrangement leads to stronger, smoother yarns, whereas random arrangement results in softer, more textured yarns. Think of the difference between neatly combed wool and a more roughly spun version.

Understanding this relationship allows textile engineers to design yarns that create fabrics with specific properties. For instance, a tightly twisted yarn made from strong fibers would be ideal for durable outerwear, while a loosely twisted yarn made from soft fibers would be more suitable for comfortable clothing.

Q 17. How do you interpret a yarn tensile test report?

A yarn tensile test report provides crucial information on a yarn’s strength and elasticity. Key parameters include:

Tensile Strength: The maximum force a yarn can withstand before breaking. Expressed in units like cN/tex or grams per denier. This is a measure of the yarn’s overall strength and resistance to breakage.

Elongation at Break: The percentage increase in length a yarn undergoes before breaking. This indicates the yarn’s elasticity or extensibility. High elongation means more stretch before breaking.

Initial Modulus: This represents the yarn’s stiffness or resistance to stretching. It is the slope of the stress-strain curve at the beginning of the test.

Work of Rupture: The total energy absorbed by the yarn up to the point of breaking. This is a measure of the yarn’s toughness and resilience.

By analyzing these parameters, you can assess yarn quality and predict the fabric’s performance. A high tensile strength indicates a strong yarn, whereas a high elongation suggests a more elastic fabric. A low work of rupture might indicate a brittle yarn prone to breakage.

Q 18. What are the key factors influencing the dyeing properties of fibers?

The dyeing properties of fibers are greatly influenced by their chemical structure and physical characteristics. Key factors include:

Fiber Chemistry: Natural fibers (cotton, wool, silk) have different affinities for dyes compared to synthetic fibers (polyester, nylon). This determines the type of dye and dyeing process that will be most effective.

Fiber Morphology: The surface area and porosity of fibers influence dye uptake. Fibers with a larger surface area or more porous structure generally absorb more dye.

Fiber Crystallinity: Highly crystalline fibers tend to have lower dye affinity than amorphous fibers. Crystallinity affects the ability of the dye to penetrate the fiber.

Fiber Maturity: For natural fibers like cotton, maturity impacts dye uptake. More mature fibers often have better dye affinity and uniformity.

Fiber Treatment: Pretreatments like scouring and bleaching can significantly affect dyeing properties by removing impurities and improving dye uptake.

Understanding these factors is crucial for selecting the appropriate dyes and dyeing processes to achieve consistent and high-quality results. For example, dyeing cotton requires different techniques and dyes than dyeing polyester.

Q 19. Describe the different types of yarn finishing treatments.

Yarn finishing treatments enhance the yarn’s properties and improve its performance in the final fabric. Common treatments include:

Sizing: Applying a protective coating (starch, PVA) to improve yarn strength and reduce breakage during weaving or knitting. This is particularly important for yarns with low tenacity.

Softening: Treatments to improve yarn hand feel and make it softer. This often involves applying lubricants or resins.

Anti-Static Treatments: Reducing the buildup of static electricity, which can be a problem with synthetic fibers, thereby improving processing and reducing the risk of yarn breakage during manufacturing.

Water Repellent Treatments: Creating a hydrophobic layer on the yarn to improve water resistance.

Flame Retardant Treatments: Imparting flame-retardant properties to the yarn to enhance safety.

The choice of finishing treatment depends on the yarn type, intended application, and desired properties of the final fabric. For example, sizing is commonly used for weaving yarns, while softening might be applied to yarns for knitwear.

Q 20. How do you assess the colorfastness of dyed yarn?

Assessing the colorfastness of dyed yarn involves evaluating its resistance to fading or color change under various conditions. Standardized test methods, often specified by international standards organizations (like ISO), are used. These methods typically expose dyed yarn samples to different stressing agents:

Washing Fastness: Determines color change and bleeding during washing using different water temperatures and detergents.

Light Fastness: Measures color change due to exposure to light using a Xenon arc lamp or sunlight.

Perspiration Fastness: Evaluates color change caused by exposure to artificial sweat.

Rubbing Fastness: Tests the resistance of the dye to abrasion during rubbing.

Crocking Fastness: Assesses color transfer to another surface through rubbing.

Colorfastness is typically graded using a numerical scale, with higher grades indicating better resistance to fading or color change. These tests ensure that the dyed yarn maintains its color over time and under various conditions of use and cleaning.

Q 21. What are the common causes of fabric defects related to yarn quality?

Yarn quality plays a significant role in fabric defect formation. Several issues stemming from poor yarn quality can lead to fabric defects:

Broken Ends: Weak or damaged yarns break during weaving or knitting, resulting in missed stitches or breaks in the fabric.

Slubs: Thick places in the yarn cause unevenness and texture imperfections in the fabric.

Nepping: Small knots or entangled fibers in the yarn create unsightly lumps or bumps in the fabric.

Thin Places: Weakened or thinned areas in the yarn result in weak points in the fabric that are prone to tearing.

Hairiness: Loose fibers protruding from the yarn can create a fuzzy or pilled appearance in the fabric.

Uneven Dyeing: Inconsistent dye uptake due to variations in yarn properties leads to uneven coloration in the fabric.

Careful yarn selection and quality control during manufacturing are essential for preventing these defects and producing high-quality fabrics. Techniques like yarn testing and visual inspection are used to identify and remove substandard yarns before they are processed into fabric.

Q 22. How do you determine the shrinkage properties of a fabric?

Determining fabric shrinkage involves measuring the dimensional change after exposure to specific conditions, typically washing and drying. We use standardized test methods, like those outlined in AATCC (American Association of Textile Chemists and Colorists) test methods. The process usually involves taking precise measurements of a fabric sample before and after treatment. The percentage shrinkage is then calculated using a simple formula: [(Original dimension – Final dimension) / Original dimension] x 100%. For example, if a fabric sample is 10 cm long initially and shrinks to 9.5 cm after washing, the percentage shrinkage is [(10 – 9.5) / 10] x 100% = 5%.

Different factors influence shrinkage, including fiber type (wool shrinks more than cotton), fabric construction (tightly woven fabrics shrink less), and finishing treatments (some treatments can reduce shrinkage). Understanding these factors is crucial for predicting and managing shrinkage in the final garment.

In my experience, we’ve used both laboratory-scale washing machines and industrial-scale machines, depending on the client’s needs. The choice of washing parameters (temperature, agitation, detergent type) is critical and dictated by the specific fabric and intended end use.

Q 23. Explain the importance of quality control in the textile industry.

Quality control (QC) in the textile industry is paramount to maintaining consistent product quality, meeting customer expectations, and ensuring brand reputation. It encompasses all activities that ensure the product conforms to specified requirements and standards. This includes raw material inspection (fiber quality, yarn strength), in-process checks (fabric defects, weaving irregularities), and final product testing (colorfastness, dimensional stability). Without rigorous QC, textile manufacturers risk producing defective products, leading to customer dissatisfaction, returns, and significant financial losses.

For instance, a small defect in yarn could lead to a tear in the finished garment. Consistent QC helps prevent such scenarios. The methods employed range from visual inspections to sophisticated instrument testing. Effective QC involves proactive measures to prevent defects rather than just reacting to them, saving both time and resources.

Q 24. Describe your experience with statistical process control (SPC) in textile testing.

Statistical Process Control (SPC) is a powerful tool I’ve extensively used in textile testing to monitor and control process variation. It uses statistical methods to analyze data collected from various stages of production, identify trends, and predict potential issues. In the textile industry, we use SPC to monitor parameters like yarn strength, fabric weight, and color consistency. Control charts, like X-bar and R charts, are essential tools to visualize the process data and detect any deviations from the target values.

For example, if we observe an upward trend in yarn strength variability on a control chart, we investigate the cause—perhaps a machine needs calibration or raw material quality is inconsistent. Early detection through SPC allows for prompt corrective actions, preventing large-scale defects and maintaining process stability.

My experience involves using specialized software for data analysis and generating control charts. We regularly review control charts to identify patterns and make process adjustments based on data-driven insights. This approach ensures efficient and consistent quality throughout the textile manufacturing process.

Q 25. How do you handle discrepancies between test results and quality standards?

Discrepancies between test results and quality standards are investigated thoroughly. The first step involves verifying the accuracy and reliability of the test results. This includes checking the calibration of equipment, the competence of the testing personnel, and the adherence to standard test methods. If the test results are confirmed to be accurate, then we investigate the root cause of the non-conformance to quality standards. This may involve analyzing the entire production process to identify weaknesses and areas for improvement.

For example, if a batch of fabric fails a colorfastness test, we might examine the dyeing process, the quality of the dyes, or the pre-treatment of the fabric. Corrective actions may include retraining personnel, adjusting process parameters, or sourcing alternative materials. We meticulously document the investigation process, corrective actions, and preventative measures taken to prevent future occurrences. The goal is not only to address the immediate problem but also to enhance the overall quality control system.

Q 26. Describe your experience with different types of textile testing equipment.

My experience encompasses a wide range of textile testing equipment. This includes:

- Universal Testing Machines (UTM): Used for determining tensile strength, elongation, and tear strength of fibers, yarns, and fabrics.

- Colorimeters and Spectrophotometers: Used for precise color measurement and colorfastness testing.

- Microscopy: Used for fiber identification and analysis of fabric structure.

- Air Permeability Testers: Used to measure the air permeability of fabrics.

- Abrasion Testers: Used to assess the fabric’s resistance to abrasion.

- Wash Fastness Testers: Used to simulate washing conditions and assess colorfastness and dimensional stability.

I’m proficient in operating and maintaining these instruments, ensuring accurate and reliable results. The choice of instrument depends on the specific properties being tested and the relevant standards being followed.

Q 27. How do you ensure accurate and reliable test results?

Ensuring accurate and reliable test results hinges on several critical factors. First and foremost is the proper calibration and maintenance of testing equipment. Regular calibration against traceable standards is essential to ensure accuracy. Second, following standardized test methods, such as those published by AATCC, ISO, or ASTM, is crucial for consistency and comparability of results. Adhering to established procedures minimizes errors and ensures the reliability of the obtained data.

Third, the competence and training of the testing personnel are vital. Well-trained technicians understand the correct operation of equipment, the nuances of the test methods, and the interpretation of results. Finally, maintaining a clean and well-organized laboratory environment helps minimize contamination and accidental errors. All of these factors contribute to generating reliable data that supports informed decision-making in the textile industry.

Q 28. Explain your experience with data analysis and reporting in a textile testing environment.

Data analysis and reporting are integral parts of my role. I utilize statistical software to analyze large datasets obtained from various textile tests. This involves calculating descriptive statistics (mean, standard deviation), performing statistical tests (t-tests, ANOVA), and creating visualizations (histograms, box plots, scatter plots) to effectively communicate findings. The results are compiled into comprehensive reports, clearly summarizing the findings and conclusions. These reports often include control charts, which effectively communicate process stability or variability.

These reports are crucial for decision-making within the organization, for example, to identify areas needing improvement, track quality trends over time, and support quality control management. Clear, concise, and visually appealing reports facilitate effective communication of complex data, allowing stakeholders to understand the implications of the testing results and make informed decisions. In some cases, I’ve also been involved in presenting these findings to clients, explaining the results and addressing their concerns or questions. This requires strong communication skills and the ability to translate technical information into a readily understandable format.

Key Topics to Learn for Fiber and Yarn Analysis Interview

- Fiber Identification and Classification: Understanding fiber properties (natural vs. synthetic, staple vs. filament), microscopic analysis techniques, and fiber identification tests.

- Yarn Structure and Properties: Analyzing yarn count, twist, hairiness, and strength; relating yarn structure to fabric properties and end-use applications.

- Testing and Quality Control: Familiarizing yourself with standard testing methods (e.g., tensile strength, elongation, abrasion resistance) and understanding quality control procedures in yarn manufacturing.

- Fiber and Yarn Defects: Identifying common defects (e.g., neps, slubs, weak places) and understanding their causes and impact on yarn quality.

- Instrumental Analysis: Understanding the principles and applications of instrumental techniques used in fiber and yarn analysis, such as spectroscopy and chromatography.

- Statistical Analysis of Test Data: Interpreting and presenting test data using statistical methods, understanding variability and quality control charts.

- Raw Material Evaluation: Assessing the quality of raw materials (fibers, blends) and their influence on the final yarn properties.

- Problem-Solving and Troubleshooting: Applying your knowledge to diagnose and solve problems related to yarn quality and manufacturing processes.

Next Steps

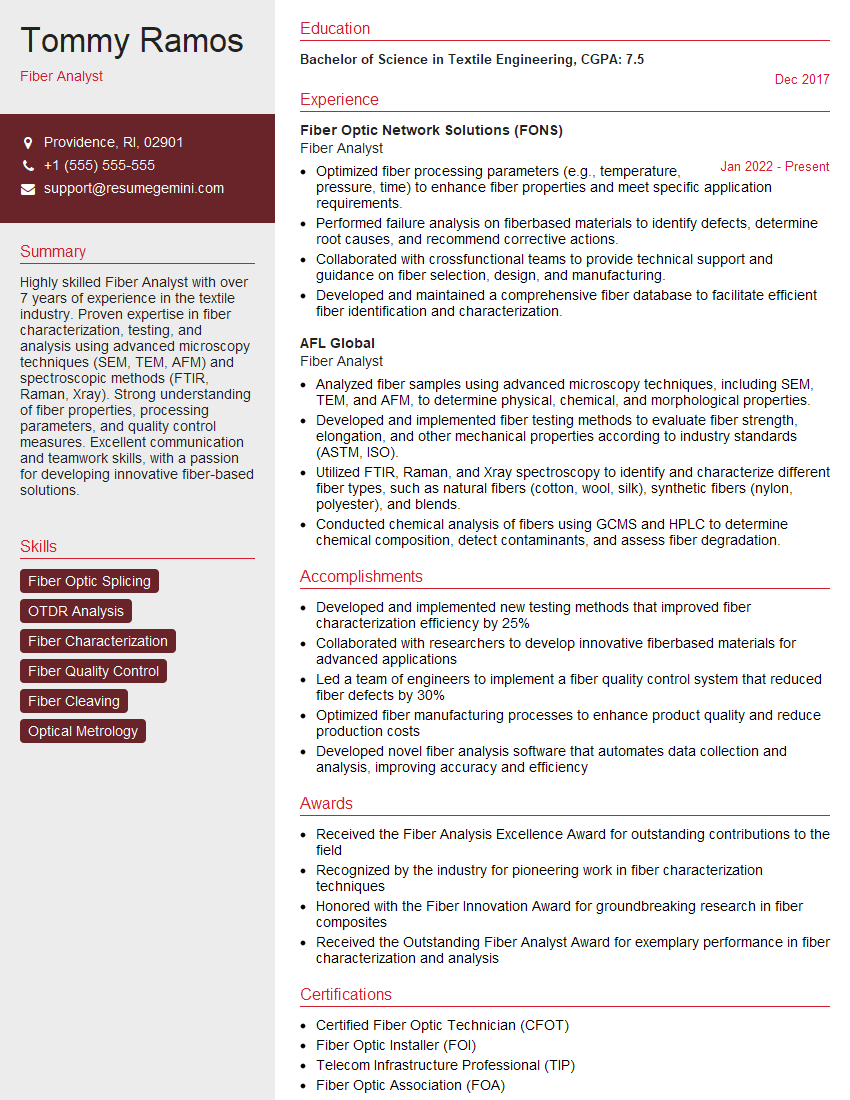

Mastering Fiber and Yarn Analysis opens doors to exciting career opportunities in the textile industry, offering specialization in quality control, research and development, or technical sales. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the textile industry. Examples of resumes specifically designed for Fiber and Yarn Analysis professionals are available, providing you with templates and guidance to build your winning application. Take the next step towards your dream career!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good