Unlock your full potential by mastering the most common Outside Plant Cabling interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Outside Plant Cabling Interview

Q 1. Explain the different types of OSP cable.

Outside plant (OSP) cables come in a variety of types, each designed for specific applications and environments. The choice depends on factors like bandwidth requirements, distance, environmental conditions, and cost.

- Copper Cables: These are traditional cables using copper conductors, offering a cost-effective solution for shorter distances and lower bandwidth applications. Examples include twisted-pair cables (used in telephone lines and DSL), coaxial cables (used in cable television), and shielded twisted-pair cables (used in data networks).

- Fiber Optic Cables: These cables use thin strands of glass or plastic to transmit data as light pulses. They offer significantly higher bandwidth and longer transmission distances compared to copper cables. Different fiber types exist, such as single-mode and multi-mode fibers, which we’ll discuss later. Fiber optic cables are further categorized by their construction, including loose tube, tight buffered, and ribbon types.

- Hybrid Cables: These cables combine both copper and fiber optic conductors within a single sheath, providing flexibility for various applications. This is particularly useful in situations where both high-bandwidth data and legacy copper services are required.

For instance, a large-scale telecommunications network might use fiber optic cables for long-haul backbone connections and copper cables for the final drop to individual homes.

Q 2. Describe the process of splicing fiber optic cables.

Splicing fiber optic cables requires precision and specialized tools to ensure a low-loss connection. The process generally involves these steps:

- Preparation: Carefully clean and prepare the fiber ends using a cleaver to create a perfectly perpendicular surface. This is crucial for optimal light transmission.

- Fusion Splicing: This is the most common method, using a fusion splicer to precisely align and melt the fiber ends together. The splicer uses an electric arc to fuse the fibers, creating a strong and transparent joint.

- Mechanical Splicing: This method uses a mechanical splice that physically aligns and holds the fiber ends together. While less precise than fusion splicing, it’s faster and often used in field situations where a fusion splicer isn’t readily available.

- Testing: After splicing, it’s essential to test the connection using an optical time-domain reflectometer (OTDR) to ensure low loss and minimal reflections. This verifies the integrity of the splice and helps identify any potential problems.

A poorly executed splice can result in significant signal loss, affecting the overall performance of the fiber optic network. Experience and proper training are vital for achieving consistently high-quality splices.

Q 3. What are the common causes of OSP cable failures?

OSP cable failures can stem from various sources, broadly categorized as environmental factors, physical damage, and installation issues:

- Environmental Factors: Extreme temperatures, moisture, rodents, and even ground movement can damage cables. UV radiation can degrade the outer jacket of cables over time.

- Physical Damage: Accidental digging, construction activities, and vehicular accidents are common causes of cable damage. Natural disasters like floods and storms can also lead to widespread cable failures.

- Installation Issues: Improper cable handling, inadequate grounding, and poor termination techniques during installation can create weak points prone to failure.

For example, a cable buried too shallowly might be easily damaged by digging equipment, while water ingress due to a poorly sealed splice can cause significant problems over time. Regular inspection and preventative maintenance are essential to minimize these risks.

Q 4. How do you test for cable faults in an OSP environment?

Testing for cable faults in an OSP environment requires specialized equipment and techniques. The specific approach depends on the type of cable (copper or fiber) and the suspected nature of the fault.

- Copper Cables: A time-domain reflectometer (TDR) is commonly used to locate faults like shorts, opens, and impedance mismatches. Also, a cable toner can trace the cable path and identify the affected section.

- Fiber Optic Cables: An optical time-domain reflectometer (OTDR) is the primary tool, capable of identifying breaks, splices, connectors, and other anomalies along the fiber optic cable. An optical power meter measures the signal strength at different points.

In practice, I’d often start with a visual inspection of the cable route, looking for obvious damage. Then, I’d use the appropriate testing equipment to pinpoint the exact location and nature of the fault. This information is crucial for efficient repair.

Q 5. What safety precautions are necessary when working with OSP cables?

Safety is paramount when working with OSP cables. The following precautions are crucial:

- Locate Underground Utilities: Always use a cable locator before digging to prevent accidental damage to buried cables and other utilities. This prevents injury and service disruptions.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and hard hats, to protect against cuts, electrical shock, and other hazards.

- Traffic Control: If working near roads or other traffic areas, implement appropriate traffic control measures to ensure the safety of workers and the public.

- Working at Heights: If working at heights, use appropriate fall protection equipment and follow safety procedures.

- Lockout/Tagout Procedures: Follow proper lockout/tagout procedures when working on energized cables to prevent accidental electrical shock.

Ignoring these precautions can lead to serious injuries or fatalities. Safety should always be the top priority in any OSP cable work.

Q 6. Explain the difference between single-mode and multi-mode fiber.

The key difference between single-mode and multi-mode fiber lies in the size of the core and how light propagates through it:

- Single-Mode Fiber: Has a smaller core diameter (around 9 µm), allowing only one mode of light to propagate. This results in lower signal attenuation and allows for much longer transmission distances (tens to hundreds of kilometers) with higher bandwidths. It’s ideal for long-haul communication and high-speed data transmission.

- Multi-Mode Fiber: Has a larger core diameter (50 µm or 62.5 µm), allowing multiple modes of light to propagate. This leads to higher signal attenuation and shorter transmission distances (hundreds of meters to a few kilometers) compared to single-mode fiber. However, it’s typically cheaper and easier to work with, making it suitable for shorter-distance applications such as local area networks (LANs).

Imagine a water pipe; single-mode fiber is like a thin straw, allowing only a single stream of water to flow through it cleanly, while multi-mode fiber is like a wider pipe, allowing multiple streams of water to flow, leading to some mixing and turbulence.

Q 7. Describe your experience with various cable termination techniques.

My experience encompasses a wide range of cable termination techniques for both copper and fiber optic cables. For copper cables, I’m proficient in various connector types like RJ45 (for Ethernet), BNC (for coaxial), and various other connector types based on the specific application. This includes crimping, punch-down, and soldering techniques ensuring reliable connections.

In fiber optic cable termination, I have extensive experience with fusion splicing, mechanical splicing, and various connector types like SC, ST, FC, LC, and MTP/MPO connectors. I’m adept at using polishing machines and testing equipment to ensure low-loss and high-quality terminations. I have also worked with different cable types including loose tube, tight buffered, and ribbon cables. In each case, proper preparation and careful attention to detail are essential for optimal performance. I’ve always prioritized using the correct tools and following manufacturers’ specifications, leading to successful and reliable terminations in various field conditions.

Q 8. What are the key considerations for OSP cable routing and placement?

OSP cable routing and placement are crucial for network reliability, maintainability, and longevity. Key considerations involve minimizing environmental impact, ensuring sufficient cable slack, protecting cables from damage, and optimizing signal integrity. This includes understanding the specific environment—considering factors such as soil conditions, potential for flooding, proximity to utilities (power lines, gas pipes), and the presence of potential hazards like tree roots or construction activity.

- Safety: Maintaining a safe distance from power lines and other utilities is paramount. This often involves calling ‘one-call centers’ to locate underground utilities before excavation begins.

- Accessibility: Cables should be easily accessible for maintenance and repair. This might involve using manholes, handholes, or easily accessible aerial pathways.

- Environmental Considerations: Minimizing disruption to the environment is vital. This involves careful route planning, selecting appropriate trenching methods, and adhering to environmental regulations.

- Future Scalability: The route should allow for future expansion. Leaving extra space in conduits or ducts is crucial for handling increased capacity in the future.

- Signal Integrity: Sharp bends and excessive twists can degrade signal quality. Maintaining gentle curves and avoiding excessive stress on the cables is key.

For example, in a recent project, we opted for aerial cable placement in a rural area due to the challenging terrain and cost-effectiveness compared to trenching. In a densely populated urban area, however, underground placement was necessary to avoid visual clutter and potential damage.

Q 9. How do you handle cable slack in OSP deployments?

Proper cable slack management is essential to prevent cable damage due to thermal expansion, ground movement, or other stresses. Insufficient slack can lead to cable breaks, while excessive slack creates clutter and can pose tripping hazards. A good rule of thumb is to allow a minimum of 1-2% slack for aerial installations and 5-7% for underground deployments, but this can vary greatly depending on environmental factors.

We typically address cable slack by using slack loops in manholes or handholes for underground installations. These loops are carefully secured to prevent unwanted movement. For aerial installations, we use messenger wire or properly sized and tensioned support structures to manage cable sag and allow for thermal expansion.

Consider this: imagine a guitar string—too tight and it snaps, too loose and it’s unplayable. Cable slack needs to be ‘just right’ to accommodate movement without causing damage.

Q 10. Explain your experience with various types of OSP cable connectors.

My experience encompasses a wide range of OSP cable connectors, including splice closures, mechanical connectors, and fusion splices. The choice of connector depends on the cable type, environment, and required performance.

- Splice Closures: These protect fiber optic or copper cable splices from environmental factors. They come in various designs to accommodate different cable counts and installation conditions, often including features like sealing compounds and grounding terminals. I’ve used many types, including those rated for direct burial or aerial applications.

- Mechanical Connectors: These connectors are designed for quick and easy field termination of copper cables. They offer a reliable solution for temporary or permanent connections and are commonly used in various OSP applications.

- Fusion Splices: Used exclusively for fiber optics, these create permanent, high-performance connections through the fusion of optical fibers. Precision is paramount, and I have extensive experience using fusion splicing machines and ensuring proper cleanliness and alignment of fibers.

For instance, in a recent project involving a high-bandwidth fiber optic link, we used fusion splicing to ensure minimal signal loss and long-term stability. In another project, requiring rapid connection of copper pairs for a temporary event, we employed mechanical connectors.

Q 11. Describe your experience with underground cable installation.

Underground cable installation requires careful planning and execution to avoid damage to the cables and surrounding infrastructure. The process typically involves trenching, cable placement, backfilling, and testing.

- Trenching: This involves excavating a trench to the appropriate depth and width to accommodate the cables and provide sufficient cover. The trench should be free of rocks and debris that could damage the cables.

- Cable Placement: Once the trench is ready, the cables are carefully placed within the trench, often using pulling ropes and winches to avoid stress on the cables. We often use conduit or duct for additional protection.

- Backfilling: After cable placement, the trench is backfilled with appropriate material, ensuring proper compaction to prevent settlement and cable damage.

- Testing: After installation, thorough testing is carried out to ensure continuity and signal integrity. This includes testing for shorts, opens, and signal attenuation.

One memorable project involved installing a large-capacity fiber optic cable under a busy city street. This required coordination with multiple utility companies and the use of sophisticated trenching and pulling techniques to minimize disruption to traffic and other underground utilities. Safety protocols and the permit acquisition process were also critical.

Q 12. What are the different types of grounding techniques used in OSP?

Grounding in OSP is critical for protecting equipment and personnel from lightning strikes, surges, and other electrical hazards. Several grounding techniques are employed:

- Ground Rods: Driving copper-clad steel rods into the ground provides a low-impedance path to earth. Multiple rods, interconnected with grounding wire, are often used to improve grounding effectiveness. The depth and spacing of rods depend on soil conductivity.

- Ground Mats: These are interconnected grids of grounding wire laid in trenches near equipment or cable pathways. They provide a large surface area for contact with the earth, enhancing grounding performance.

- Building Grounding: Connecting OSP grounding systems to the building’s grounding system ensures a common ground potential, preventing potential differences that could damage equipment.

- Conduit Grounding: Metal conduits are bonded together and grounded at multiple points, providing a low-impedance path for current flow in case of a fault.

The specific technique chosen depends on the environment, infrastructure, and the sensitivity of the equipment being protected. It’s important to follow relevant standards and regulations for proper grounding design and installation.

Q 13. How do you manage cable documentation and records in an OSP project?

Comprehensive cable documentation is essential for efficient maintenance and future upgrades. We use a combination of physical and digital records:

- As-Built Drawings: These show the exact location of cables, conduits, and other OSP infrastructure. They are essential for future maintenance and upgrades.

- Cable Records: Detailed information on each cable, including type, length, manufacturer, date of installation, and connection points, is meticulously maintained in a database.

- GIS Mapping: Geographic Information System (GIS) mapping provides a visual representation of the cable network, allowing for easy identification of cable locations and potential conflicts.

- Database Management: A robust database system helps manage and track all cable records, ensuring easy access to information when needed.

In my experience, using a well-structured database coupled with up-to-date GIS mapping is vital. This allows for quick identification of a cable’s location, specifications, and other related information. This is particularly crucial during emergency repairs.

Q 14. Explain your experience with trenching and boring techniques.

Trenching and boring are two common methods for underground cable installation. The choice depends on factors such as soil conditions, environmental regulations, and the proximity of other utilities.

- Trenching: This involves excavating a continuous trench to the desired depth and width. It’s cost-effective for relatively short distances and straightforward installations but may cause significant disruption to the surrounding area. Different trenching equipment (e.g., backhoes, mini excavators) can be used depending on the soil type and project scale.

- Boring: This method involves creating a narrow hole underground using specialized equipment like horizontal directional drills (HDDs). It minimizes surface disruption, making it ideal for densely populated areas or areas with sensitive vegetation. HDDs allow for precise placement of cables, avoiding existing utilities.

I’ve utilized both methods extensively. In a recent project where minimizing surface disturbance was paramount, we opted for HDD boring to install cables under a busy highway. However, for a less-sensitive area, open trenching was a more cost-effective solution.

Q 15. How do you ensure compliance with industry standards and regulations in OSP work?

Ensuring compliance in OSP work is paramount for safety and operational efficiency. It involves a multi-faceted approach, starting with a thorough understanding of relevant codes and standards, such as those from ANSI/TIA, IEC, and local municipality regulations. This understanding dictates everything from the type of cable used and its installation method to the required safety protocols for working at heights or near power lines.

My approach involves:

- Pre-planning and design review: Before any work commences, I carefully review project plans to ensure they adhere to all applicable standards. This includes checking for proper cable routing, grounding requirements, and appropriate safety clearances.

- Material selection and verification: I meticulously verify that all materials used—cables, conduits, hardware—meet the specified standards and possess the necessary certifications. This involves checking for manufacturer’s documentation and conducting quality checks on-site.

- Rigorous adherence to safety procedures: Safety is non-negotiable. I ensure that all team members are trained and follow established safety protocols, using proper personal protective equipment (PPE) and adhering to lockout/tagout procedures when working near energized equipment.

- Detailed documentation and record-keeping: Thorough documentation, including as-built drawings, material specifications, and inspection reports, provides an auditable trail and helps ensure long-term compliance.

- Regular inspections and audits: Post-installation inspections are crucial for verifying that the work meets standards. This includes testing cable continuity, verifying grounding, and checking for any potential hazards.

For example, in a recent project involving fiber optic cable installation near a high-voltage power line, we meticulously followed all applicable safety standards, including maintaining a specific minimum distance and using specialized equipment for grounding to prevent electrical hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with aerial cable installation.

I have extensive experience in aerial cable installation, having worked on numerous projects ranging from small deployments to large-scale network expansions. This work requires a comprehensive understanding of various techniques, safety protocols, and the challenges posed by varying weather conditions and terrain.

My experience includes:

- Cable pulling and stringing: I am proficient in using various techniques for pulling cables through aerial pathways, including the use of rope grips, pulling heads, and tension meters. This involves careful planning to avoid cable damage and ensure proper tension.

- Attachment hardware and support structures: I have experience installing and maintaining different types of aerial cable hardware, including clamps, lashing wire, and various support structures like messenger wires and poles. Knowing the strengths and weaknesses of each is vital for system longevity.

- Safety protocols for working at heights: Safety is paramount when working at heights. I am experienced in using proper fall protection equipment, such as harnesses and safety lines, and adhering to strict safety procedures to mitigate risks.

- Dealing with challenging weather conditions: Aerial installations are often affected by weather. I know how to adapt to varying conditions, including strong winds, rain, and extreme temperatures, ensuring both worker safety and cable integrity.

For instance, on one project, we had to install fiber optic cable across a river using a specialized aerial technique with helicopters. Careful planning and coordination with the helicopter crew were vital for success and worker safety.

Q 17. What are the challenges you faced during a complex OSP project and how did you overcome them?

One challenging project involved installing a high-capacity fiber optic cable system through a densely populated urban area with limited access to underground conduits. The main challenges included navigating existing underground utilities, obtaining necessary permits, and minimizing disruption to traffic and residents.

To overcome these challenges, we employed a multi-pronged approach:

- Thorough site survey and utility locates: We conducted a comprehensive site survey using advanced utility locating equipment to identify the location of existing underground utilities, preventing accidental damage during excavation.

- Close collaboration with city authorities: We worked closely with city authorities to obtain the necessary permits and coordinate construction activities to minimize disruption to traffic and residents.

- Innovative installation techniques: Due to limited access to underground conduits, we adopted trenchless installation techniques, such as horizontal directional drilling (HDD), to minimize excavation work and road closures.

- Detailed project management and communication: Effective communication and coordination among the team, city officials, and residents were key to keeping the project on schedule and mitigating potential conflicts.

- Rigorous quality control: Throughout the project, rigorous quality control measures were implemented to ensure the cable installation met industry standards and specifications. This included regular testing and inspections.

By proactively addressing the challenges and implementing effective solutions, we successfully completed the project on time and within budget, meeting all quality and safety standards.

Q 18. What is your experience with different types of OSP cable pulling equipment?

My experience with OSP cable pulling equipment is extensive and encompasses a wide range of tools and techniques. The selection of the appropriate equipment depends heavily on factors such as cable type, conduit size, distance, and environmental conditions.

Here are some examples of equipment I’m proficient with:

- Capstans and winches: These are essential for pulling heavier cables over longer distances, and I understand how to manage tension and prevent damage.

- Cable pulling lubricants: Knowing the appropriate lubricant for different cable types and conduit materials is critical for smooth pulling and preventing cable damage.

- Pulling grips and heads: Selecting the correct pulling grip or head is vital for a secure pull without damaging the cable. I understand the specific application for each type.

- Tension meters: Precise tension control is crucial; I’m experienced with using tension meters to monitor and maintain optimal tension during the pulling process.

- Hydraulic cable pullers: For particularly challenging pulls or very heavy cables, hydraulic pullers provide the necessary power and control.

I also have experience with specialized equipment for aerial installations such as cable reels, and stringing equipment. The choice of equipment is always guided by safety protocols and the specific requirements of the project. For example, in a recent project involving micro-duct installation, we used a smaller, more maneuverable winch to avoid damage to the delicate infrastructure.

Q 19. How do you identify and resolve common problems with OSP cable connectivity?

Identifying and resolving OSP cable connectivity problems requires a systematic approach. It starts with accurate fault isolation, which often involves a combination of visual inspection, testing, and troubleshooting.

My process typically includes:

- Visual inspection: I begin with a visual inspection of the cable, connectors, and splice points to identify any obvious physical damage, such as cuts, kinks, or loose connections.

- Continuity testing: Using a cable tester, I check for continuity to verify that the cable is electrically sound and there are no breaks in the conductor.

- Signal tracing: In the case of signal problems, I use specialized equipment to trace the signal path to identify the point of failure.

- Optical time-domain reflectometry (OTDR) testing (for fiber optics): For fiber optic cables, OTDR testing helps pinpoint the location and nature of faults such as breaks or excessive attenuation.

- Troubleshooting techniques: Based on the test results, I apply appropriate troubleshooting techniques, which may include replacing damaged cables, repairing connectors, or rectifying splice issues.

For example, I once encountered a connectivity problem on a fiber optic cable that was initially difficult to diagnose. Using OTDR, we were able to pinpoint a micro-bend in the cable, causing significant signal loss. Replacing that section of the cable resolved the problem.

Q 20. Explain your knowledge of different types of OSP cable protection systems.

OSP cable protection is crucial for ensuring the longevity and reliability of the network infrastructure. The choice of protection system depends on various factors such as cable type, environmental conditions, and the level of protection required.

I have experience with several types of OSP cable protection systems:

- Conduits: These are commonly used for underground installations, providing protection from physical damage and environmental factors. Different conduit materials exist (PVC, HDPE, steel) each suited to different applications.

- Duct banks: Duct banks offer a more organized and efficient way to route multiple cables underground, often with individual ducts for better cable management and protection.

- Direct burial: Some cables are designed for direct burial, incorporating robust outer sheathing for protection against soil moisture and rodents. However, it usually requires more robust cable design.

- Aerial cable protection: Aerial cables often use messenger wires for support and protection against abrasion. Various clamps and lashing systems are also employed.

- Micro-ducts: These smaller conduits are increasingly used for blown-fiber installations, offering a cost-effective and efficient way to install high-capacity fiber optic cables.

The selection of the appropriate protection system requires considering factors like the cable’s lifespan, the environment’s harshness, and the overall network design. For example, in areas prone to flooding, we might use specialized conduits with high water resistance capabilities.

Q 21. Describe your experience with fiber optic testing equipment.

My experience with fiber optic testing equipment is extensive. Proper testing is vital for ensuring the quality and performance of fiber optic networks.

I am proficient in using various types of equipment:

- Optical Power Meters (OPMs): These measure the optical power level at various points in the fiber optic link, helping to identify signal loss.

- Optical Time-Domain Reflectometers (OTDRs): OTDRs are essential for locating faults and measuring fiber characteristics such as attenuation and dispersion. I understand how to interpret OTDR traces to pinpoint issues such as fiber breaks or macrobends.

- Optical Light Sources (OLS): These generate optical signals for testing fiber optic connectivity.

- Fiber Optic Splice Loss Testers: Specialized equipment for accurately measuring losses at fiber optic splice points to ensure proper connection quality.

- Visual Fault Locators (VFLs): These handheld devices help quickly identify physical faults in fiber optic cables.

Understanding the nuances of these instruments and interpreting their output accurately is crucial for effective troubleshooting and maintenance. For instance, I recently used an OTDR to troubleshoot a fiber optic link experiencing intermittent outages. The OTDR trace revealed a recurring problem near a specific splice point, leading to the discovery and repair of a loose connection.

Q 22. How do you ensure the proper labeling and identification of OSP cables?

Proper labeling and identification of Outside Plant (OSP) cables are crucial for efficient maintenance, troubleshooting, and future expansion. Think of it like addressing a package – without clear labeling, finding the right cable becomes a logistical nightmare.

My approach involves a multi-layered system. First, I utilize a standardized labeling system, often adhering to industry best practices (like TIA standards), employing unique identifiers including cable type, route, and termination points. These identifiers are clearly marked using durable, weatherproof labels directly on the cable and at each splice point and termination.

- Cable Markers: Heat-shrink sleeves, adhesive labels, or even engraved metal tags are used, depending on the environment and cable type.

- As-Built Drawings: Detailed, accurate as-built drawings are maintained, cross-referenced with the physical labels. These drawings act as a digital map of the OSP network. These are usually stored in GIS systems.

- Database Management: All label information is input into a centralized database for easy retrieval and management. This database often integrates with the GIS system.

For example, a fiber optic cable might be labeled ‘F-MAIN-1-A-20231027’ indicating Fiber, Main Route, Segment 1, Cable A, and Installation Date. This level of detail ensures quick identification and reduces downtime in case of repairs or upgrades.

Q 23. What is your experience with different types of OSP cable management systems?

My experience encompasses a wide range of OSP cable management systems, from simple aerial deployments to complex underground networks. I’ve worked with various methods to effectively manage cable congestion and ensure easy access for maintenance and future upgrades.

- Aerial Cable Systems: I’m proficient in utilizing various aerial support structures like poles, arms, and messenger wires, ensuring proper spacing and strain relief to prevent damage from wind or other environmental factors. Understanding proper sag calculations and ensuring appropriate clearances is critical here.

- Underground Cable Systems: This includes experience with various duct and conduit systems, including HDPE (High-Density Polyethylene) conduits, micro-ducts, and traditional concrete ducts. I’m adept at planning the route, selecting the right conduit type based on environmental conditions and cable type and ensuring proper pulling techniques to avoid cable damage.

- Cable Trays and Ladders: In areas where cables are bundled together, I utilize cable trays and ladders for organized and safe management, ensuring proper ventilation and preventing overheating.

In one project, we utilized a hybrid system combining aerial and underground cable runs to optimize cost and minimize disruption. The aerial portion spanned a sparsely populated area, while the underground section was employed in densely populated regions, showcasing flexibility in choosing the right system for the job.

Q 24. Explain your experience with GPS and GIS tools for OSP projects.

GPS and GIS tools are invaluable assets in OSP project planning and execution. They facilitate accurate cable mapping, efficient route planning, and streamlined maintenance processes. Imagine trying to navigate a complex network of cables without a map – it would be incredibly challenging and time-consuming.

My experience includes utilizing GIS software (such as ArcGIS) to create and update digital maps of the OSP infrastructure. GPS-enabled devices are used for field surveys, to accurately record cable locations, identify existing infrastructure and plan optimal cable routes, minimizing excavation and environmental impact. Real-time data allows for easier tracking of crews and equipment during installations. The GIS system stores this data for easy access and reporting, simplifying future maintenance and expansions.

For example, during a recent project, we used GIS to identify the optimal route for a new fiber optic cable, avoiding underground utilities and minimizing disruption to existing services. This avoided costly delays and potential damage to other infrastructure.

Q 25. How do you plan for and manage OSP cable maintenance?

OSP cable maintenance is essential to ensure the long-term reliability and performance of the network. A proactive approach is key to avoiding costly outages and service disruptions. My maintenance planning involves:

- Regular Inspections: Conducting routine inspections of the entire OSP network, both aerial and underground, checking for damage, corrosion, and other issues. Utilizing drones for aerial inspections can greatly improve efficiency and safety.

- Preventive Maintenance: Implementing preventative measures such as cleaning cable ducts, applying corrosion inhibitors, and performing regular testing of cable integrity. This reduces the likelihood of future failures.

- Reactive Maintenance: Having procedures in place to address issues that arise, from responding to customer reported outages to repairing damaged cables quickly and efficiently.

- Documentation: Maintaining meticulous records of all maintenance activities, including inspections, repairs, and upgrades. This documentation is crucial for future planning and troubleshooting.

A well-defined preventative maintenance schedule, along with quick response to reported issues, significantly extends the lifespan of the OSP infrastructure and reduces the total cost of ownership.

Q 26. Describe your experience with various types of OSP cable enclosures.

I’ve worked with a variety of OSP cable enclosures, each suited for different applications and environments. The choice depends on factors like cable type, capacity, environmental conditions, and security requirements.

- Handholes: Commonly used in underground systems, handholes provide access points for splicing, testing, and maintenance of underground cables.

- Manholes: Larger underground structures providing more space for complex cable terminations and splicing.

- Pedestals: Above-ground enclosures, often used in urban areas for housing cable terminations and equipment. These are usually weatherproof and secure.

- Splice Cases: Smaller enclosures designed for connecting individual cables or fibers. They protect the splices from environmental elements.

For example, in a high-traffic urban area, we utilized hardened pedestals with access control features to protect the fiber optic terminations from vandalism and theft. In less populated areas, simpler handholes were sufficient for the task.

Q 27. What is your familiarity with relevant industry standards like TIA-568 and ANSI/ICEA?

I’m very familiar with relevant industry standards, including TIA-568 (for structured cabling systems) and ANSI/ICEA (for outside plant cable specifications). Adherence to these standards is paramount for ensuring the safety, reliability, and interoperability of OSP networks. These standards provide guidelines for everything from cable types and installation practices to testing procedures.

TIA-568 defines the cabling standards for commercial buildings, which, while not directly for OSP, frequently inform the standards at the building’s edge. ANSI/ICEA provides specific guidelines for outdoor cable design and construction, including requirements for cable shielding, dielectric strength, and environmental resistance. Understanding these standards allows me to select appropriate cable types, design suitable infrastructure and ensure compliance with regulations.

For example, using a cable that doesn’t meet ANSI/ICEA standards for burial depth in a specific soil type could lead to cable damage and service interruptions. Similarly, failure to adhere to TIA-568 principles at the building’s edge could compromise the integrity of the network connection. My expertise allows me to avoid such pitfalls.

Key Topics to Learn for Outside Plant Cabling Interview

- Fiber Optics: Understanding different fiber types (single-mode, multi-mode), splicing techniques, testing methodologies (OTDR), and troubleshooting common fiber optic issues.

- Copper Cabling: Familiarity with various copper cable types (e.g., twisted pair, coaxial), installation practices, grounding and bonding techniques, and troubleshooting techniques for signal degradation.

- Network Topologies: Knowledge of common outside plant network topologies (e.g., star, ring, bus), their advantages and disadvantages, and how they impact cabling design and implementation.

- Cable Routing and Infrastructure: Understanding best practices for cable routing, including considerations for aerial, underground, and duct installations. This includes knowledge of conduit systems, manholes, and splice closures.

- Safety Regulations and Practices: Thorough understanding of relevant safety regulations (OSHA, local codes) and best practices for working with high-voltage lines, underground utilities, and hazardous materials.

- Documentation and As-Built Drawings: Ability to interpret and create accurate as-built drawings and documentation for installed cabling infrastructure.

- Testing and Troubleshooting: Hands-on experience with various testing equipment (e.g., TDR, VFL) and ability to effectively troubleshoot connectivity issues in the field.

- Project Management Aspects: Understanding of project planning, scheduling, budgeting, and resource allocation within the context of outside plant cabling projects.

Next Steps

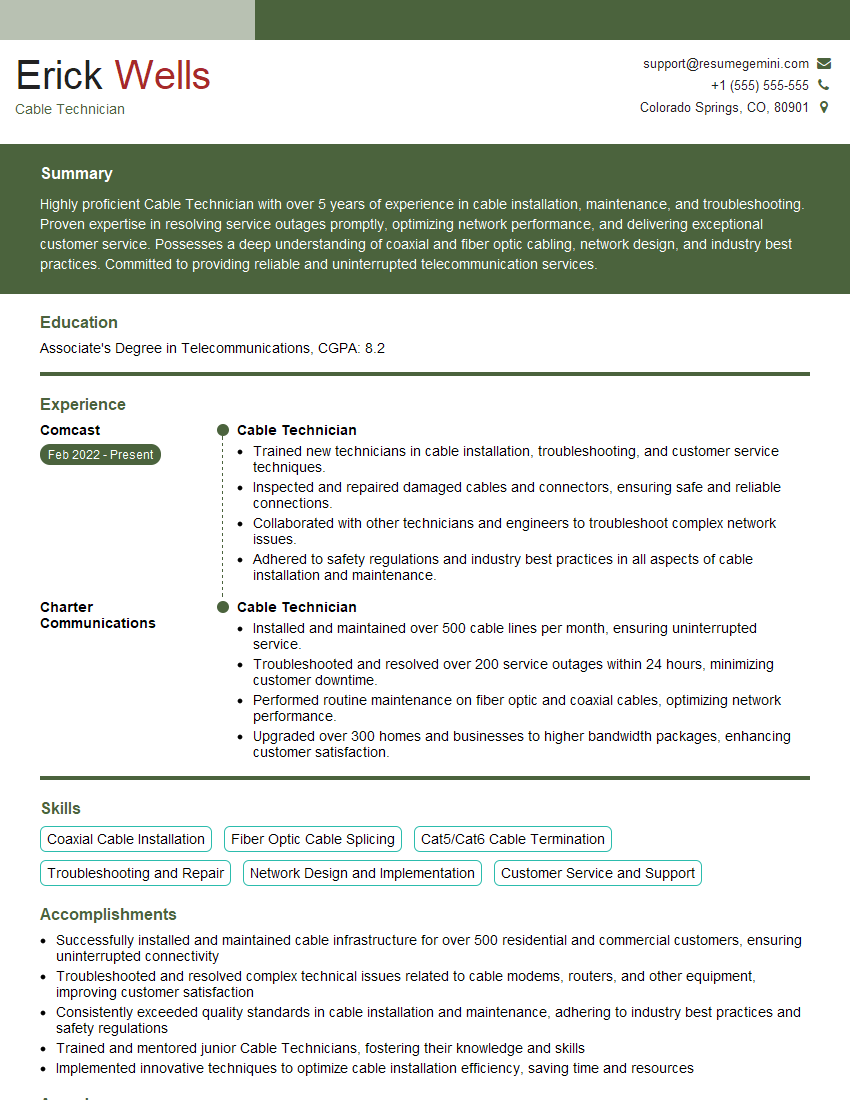

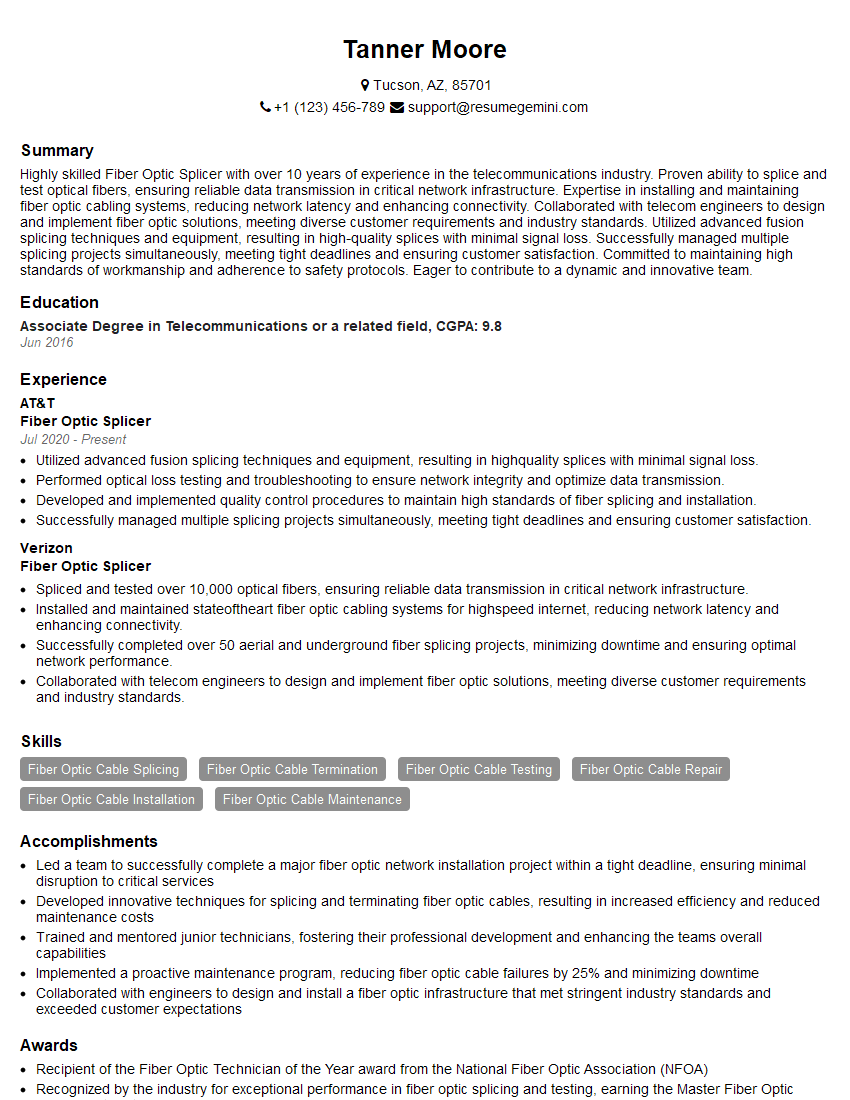

Mastering Outside Plant Cabling opens doors to exciting career opportunities in telecommunications, networking, and infrastructure development. Your expertise in this field is highly valuable, and demonstrating a strong understanding during interviews will significantly boost your chances of landing your dream job. To make a strong impression, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of Outside Plant Cabling roles. Examples of resumes optimized for this field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good