Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Pole Installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Pole Installation Interview

Q 1. Describe your experience with different types of poles (wood, concrete, steel).

My experience spans across the three major pole types: wood, concrete, and steel. Each has its strengths and weaknesses, making them suitable for different applications. Wood poles, traditionally used, are relatively inexpensive and easy to work with, but are susceptible to rot and insect damage, requiring regular maintenance. Their lifespan is shorter compared to other materials. Concrete poles, known for their durability and resistance to rot and insects, are a popular choice for high-stress situations and long spans. However, they are heavier and more challenging to transport and install. Steel poles, often galvanized or coated for corrosion resistance, offer excellent strength and longevity, making them ideal for areas with high winds or heavy loads. They’re also easier to repair than concrete poles. I’ve worked extensively with all three, selecting the appropriate material based on factors like budget, load requirements, environmental conditions, and aesthetic considerations for the project.

- Wood: Used primarily in areas where cost is a major factor and the ground conditions are suitable.

- Concrete: Preferred for high-traffic areas and demanding environmental conditions.

- Steel: Often used in industrial settings or where exceptional strength is required.

Q 2. Explain the process of setting a utility pole.

Setting a utility pole is a multi-step process requiring precision and safety. It begins with thorough site preparation, including surveying the location to identify underground utilities and ensuring the ground is suitable for setting. Next, a hole of the appropriate depth and diameter is excavated – usually with an auger or backhoe. The pole is then carefully lowered into the hole, ensuring it’s plumb (perfectly vertical) using a level and temporary bracing. Once in place, concrete is poured around the base to secure the pole, leaving enough space for backfilling and compaction. Finally, the area is backfilled and compacted, ensuring the pole is stable and won’t shift over time. We use various tools to ensure alignment, including plumb bobs and transit levels, ensuring accuracy during every step. Think of it like building a strong foundation for a house; a perfectly set pole ensures its long-term stability and safety.

- Site Preparation: Locating underground utilities and preparing the ground.

- Excavation: Digging a hole of appropriate size and depth.

- Pole Setting: Carefully lowering the pole and ensuring it’s plumb.

- Concrete Pouring: Filling the hole with concrete to secure the pole.

- Backfilling and Compaction: Ensuring the pole’s stability.

Q 3. What safety measures do you follow during pole installation?

Safety is paramount in pole installation. We strictly adhere to OSHA regulations and company safety protocols. This includes wearing appropriate Personal Protective Equipment (PPE) such as hard hats, safety glasses, gloves, and high-visibility clothing. We use spotters when raising heavy poles and use lockout/tagout procedures on any equipment before performing maintenance. Before excavation begins, we always perform a thorough underground utility locate to avoid hitting buried cables or pipes. Proper training and regular safety meetings reinforce these procedures, ensuring a safe working environment for everyone on the team. One time, a colleague spotted a partially buried rock that we would have easily hit, potentially causing damage to the pole and injury to the team. That highlighted the importance of continuous vigilance and teamwork.

Q 4. How do you ensure the proper grounding of a pole?

Proper grounding is crucial for electrical safety, preventing voltage surges and protecting equipment and personnel. A grounding system typically involves driving a ground rod into the earth near the pole, connecting it to the pole’s grounding wire using a grounding clamp. The ground wire is then connected to the grounding system of the electrical equipment installed on the pole. The resistance of the ground connection is routinely checked using a grounding ohmmeter to ensure it meets safety standards. Think of it as a safety valve – diverting excess electrical energy harmlessly into the earth, ensuring our electrical equipment remains safe. Improper grounding can lead to serious electric shocks and equipment failure.

Q 5. What are the common challenges encountered during pole installation?

Several challenges can be encountered during pole installation. Unforeseen ground conditions, like bedrock or unstable soil, can hinder excavation and require adjustments to the installation method. Weather conditions, especially strong winds or heavy rain, can impact safety and efficiency. Unexpected underground utilities, even with locates, can lead to delays and necessitate careful rerouting. Difficulties in accessing remote locations can also pose logistical challenges. Another common challenge is ensuring proper pole alignment and plumbness, especially with taller and heavier poles. Each challenge requires careful planning, adaptation, and adherence to safety protocols.

Q 6. Describe your experience with different types of digging equipment.

My experience includes working with various digging equipment, from small augers for smaller poles to large backhoes for larger projects. Augers are excellent for creating precise holes in various soil types. Backhoes provide more power and versatility, particularly useful in challenging ground conditions or when handling larger poles. We also utilize trenchers for digging long, narrow trenches for underground cables and conduits, often in conjunction with pole setting. The choice of equipment depends on factors like soil type, pole size, and overall project requirements. Each piece of equipment requires proper operator training and adherence to safety guidelines. For example, when working with a backhoe, ensuring stability on uneven terrain is crucial to prevent accidents.

Q 7. How do you handle unexpected underground utilities during excavation?

Handling unexpected underground utilities during excavation requires immediate action and a safety-first approach. Work immediately stops, and the area is secured to prevent further damage or injury. The utility company responsible for the affected line is contacted immediately for assistance. We collaborate closely with the utility company to safely expose, mark, and reroute the utility line as required. Thorough documentation of the incident and the corrective measures taken is essential. In one instance, we discovered a gas line during excavation. Following protocol, we immediately stopped work, contacted the gas company, and collaborated with them to safely reroute the line before continuing the project. This prevented a potentially hazardous situation and ensured the safety of our crew and the public.

Q 8. Explain your experience with different types of pole-setting equipment.

My experience encompasses a wide range of pole-setting equipment, from the most basic hand tools to sophisticated mechanized systems. I’m proficient with augers of various sizes, designed for different soil conditions – from the smaller, hand-held augers for lighter work to the large, truck-mounted augers capable of setting the largest poles. I’m also experienced with derricks, both the smaller, self-contained units and the larger, crane-mounted versions used for heavier poles and more challenging terrains. Furthermore, I’m skilled in operating and maintaining various types of pole-setting equipment, including backhoes and excavators, which are crucial for digging holes and preparing the foundation. I’m familiar with the safety procedures and maintenance requirements for all equipment I use.

For instance, I recall a project where we needed to set several 60-foot poles in rocky soil. Using a standard auger proved too slow and inefficient. We switched to a larger, hydraulic auger mounted on a specialized truck, and significantly reduced the installation time while ensuring accurate placement. This adaptability is key to efficient and safe pole installation.

Q 9. What are the different types of pole attachments and their installation methods?

Pole attachments are crucial for connecting various utilities and equipment to the pole. Common types include:

- Brackets: Used to mount transformers, insulators, and other equipment to the pole. Installation involves carefully measuring and bolting the bracket securely to the pole at the specified height. Proper torque is essential to ensure longevity and safety.

- Clamps: Secure cables and wires to the pole, typically using U-bolts and other fastening mechanisms. Careful installation is vital to prevent damage to the cables and ensure a strong, reliable connection.

- Arms: Extend horizontally from the pole, providing support for larger equipment or additional cable runs. Arm installation requires precise measurements and alignment to prevent strain on the pole and maintain structural integrity.

- Strain Insulators: These handle the stress of cable pull. Installation needs to account for cable tension and proper grounding.

The installation methods vary depending on the specific attachment and pole type, but generally involve proper measuring, drilling (if necessary), bolting, and securing the attachment to prevent swaying or movement. Safety is paramount; using appropriate fall protection and ensuring a secure working platform are critical.

Q 10. Describe your experience with using aerial lifts and bucket trucks.

I possess extensive experience operating both aerial lifts and bucket trucks. I’m fully certified and regularly undergo refresher training to maintain proficiency and adhere to all safety regulations. My experience covers various models and types of these vehicles, from smaller, knuckle-boom lifts ideal for confined spaces to larger, telescopic boom lifts used for higher-reach jobs. I understand the limitations of each machine and can select the appropriate equipment for the task at hand. I’m skilled in pre-operational checks, including hydraulic and electrical system inspections and ensuring proper load limits are adhered to.

For instance, on a recent project involving the installation of high-voltage lines, we used a telescopic boom lift to reach the necessary height while maintaining safe distances from power lines. The precision and control offered by these machines are critical for performing this type of work accurately and safely.

Q 11. How do you inspect a pole for damage or defects?

Inspecting a pole for damage or defects involves a thorough visual examination and sometimes, more involved checks. I start by checking for cracks, splits, or decay in the wood (for wooden poles). I look for signs of insect infestation, rot, or significant weathering. For metal poles, I check for corrosion, bending, dents, or any signs of structural weakness. I’ll also check the base of the pole for proper setting depth and signs of settling or movement. Sometimes, we use specialized tools like a sounding hammer to assess the condition of the wood. Any signs of significant damage or weakness will necessitate repairs or replacement.

A critical aspect is checking the grounding system, ensuring proper conductivity and contact to prevent hazards. Proper documentation of all findings is essential for record-keeping and liability purposes.

Q 12. What are the regulations and standards you adhere to during pole installation?

Adherence to safety regulations and industry standards is paramount in pole installation. We strictly follow OSHA (Occupational Safety and Health Administration) guidelines for working at heights, confined spaces, and handling heavy equipment. We also adhere to ANSI (American National Standards Institute) and NESC (National Electrical Safety Code) standards, depending on the project. This includes using appropriate personal protective equipment (PPE), such as hard hats, safety glasses, harnesses, and fall arrest systems. All work is performed according to pre-approved safety plans, and regular safety meetings are conducted to reinforce safe work practices.

Documentation is critical: We maintain detailed records of all inspections, testing, and work performed, ensuring complete traceability and compliance with relevant regulations.

Q 13. How do you determine the appropriate depth and placement for a pole?

Determining the appropriate depth and placement for a pole involves considering several factors. The depth is crucial for stability and to withstand the forces exerted by wind, ice, and the weight of the attached equipment. It depends on the pole’s height, diameter, soil type, and local weather conditions. Soil testing is often employed to determine the appropriate depth to ensure sufficient bearing capacity. Pole placement also involves considering utility line clearances, accessibility for maintenance, and minimizing interference with other underground utilities.

Engineering plans typically specify the required depth and placement, considering factors such as the terrain, the presence of underground utilities and the type of pole being installed. I use tools and techniques to accurately mark the location and dig the hole to the specified depth.

Q 14. Explain your experience with working at heights and in confined spaces.

I have extensive experience working at heights and in confined spaces, both of which are inherent parts of pole installation. I’m certified in fall protection and rescue techniques and fully proficient in using various types of harnesses, lanyards, and fall arrest systems. I undergo regular training to refresh my skills and stay updated on the latest safety protocols. Working in confined spaces like manholes requires specific training and awareness of potential hazards, including the risk of asphyxiation and lack of ventilation. I understand the importance of using proper ventilation equipment and following confined space entry procedures.

Safety is always the top priority. I never compromise on safety procedures, even in situations where time is a constraint. Thorough pre-job planning and risk assessments are critical before engaging in any work at heights or in confined spaces.

Q 15. How do you ensure the stability and longevity of a newly installed pole?

Ensuring the stability and longevity of a newly installed pole relies on a multi-faceted approach, starting with proper site preparation and extending to meticulous installation techniques. Think of it like building a strong foundation for a house – if the foundation is weak, the entire structure is at risk.

- Proper Depth and Setting: The pole must be set to the correct depth, as specified in the engineering plans, to provide sufficient anchorage in the ground. This depth is crucial to withstand the forces of wind, ice, and other environmental factors. Insufficient depth can lead to leaning or even pole failure.

- Concrete Quality and Curing: The use of high-quality concrete with the correct water-cement ratio is essential. Poorly mixed concrete is weak and prone to cracking, compromising the pole’s stability. Proper curing, allowing the concrete to harden gradually, prevents premature cracking and ensures maximum strength.

- Backfilling Techniques: The backfill material around the pole must be carefully compacted to eliminate voids. Voids create weak points that can lead to settlement and instability. We use a layered approach, compacting each layer thoroughly to ensure uniform support around the pole.

- Ground Conditions: Understanding the soil type is paramount. Rocky or unstable soil requires different techniques, potentially including the use of augers or specialized equipment. We always conduct a thorough site assessment before installation to tailor our approach to the specific conditions. For example, in sandy soil, we might need to use a larger volume of concrete to ensure sufficient support.

- Regular Inspection and Maintenance: Even with perfect installation, regular inspections are vital. We check for any signs of settlement, cracking, or damage, addressing any issues promptly to prevent further problems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with trenching and backfilling techniques.

My experience with trenching and backfilling encompasses a wide range of techniques, adapted to various soil types and project requirements. I’m proficient in both hand-trenching for smaller projects and the use of excavators for larger-scale installations. Safety is always my top priority.

- Trenching: I utilize appropriate safety measures like shoring or trench boxes when necessary, especially in deeper trenches to prevent cave-ins. The trench width and depth are carefully determined based on the pole size and the planned concrete placement. For example, when working with a large utility pole, a wider and deeper trench is required compared to a smaller lighting pole.

- Backfilling: Once the pole is set and the concrete has partially cured, we begin backfilling. We use a layered approach, compacting each layer thoroughly. Compaction ensures the ground firmly supports the pole, preventing settling. The type of backfill material is also considered; we often avoid using rocks or materials that could damage the pole or concrete.

- Equipment: I’m experienced in using both hand tools like shovels and tampers for smaller trenches and heavy equipment like excavators and compactors for larger-scale projects. My proficiency extends to understanding the limitations and capabilities of each tool for optimal efficiency and safety.

Q 17. What are the different types of concrete used in pole setting, and their applications?

Several types of concrete are suitable for pole setting, each with specific properties and applications. The choice depends on factors like the pole size, soil conditions, and environmental factors. The wrong concrete can lead to premature failure.

- Standard Portland Cement Concrete: This is the most common type, offering a good balance of strength and workability. It’s suitable for most pole installations.

- High-Early Strength Concrete: This type sets and gains strength much faster than standard concrete, reducing project time. It’s beneficial in areas with unpredictable weather or tight deadlines.

- Rapid-Setting Concrete: Similar to high-early strength, but even faster setting, ideal for emergency repairs or situations requiring immediate stabilization. This is rarely preferred for new installations due to limited workability.

- Fiber-Reinforced Concrete: The addition of fibers enhances the concrete’s resistance to cracking. It is particularly advantageous in areas prone to freeze-thaw cycles or where there’s a higher risk of vibration or impact. Think about a pole location along a busy road or in an area with extreme temperature fluctuations.

We always ensure the concrete mix design meets the specific requirements of the project and adheres to local building codes.

Q 18. How do you handle adverse weather conditions during pole installation?

Adverse weather conditions can significantly impact pole installation. Safety is paramount, and we always prioritize postponing work if conditions are too hazardous. However, we often have to work in challenging weather.

- High Winds: We postpone work if wind speeds exceed the safe limits for crane operation or if the wind poses a risk of the pole tipping during installation. Safety protocols include halting all operations until conditions improve.

- Rain and Snow: Rain or snow can make the ground unstable and affect concrete curing. We monitor conditions closely and may modify our procedures, such as using covered areas to protect the concrete during curing. We will also adjust the timeline for completing the project to account for weather-related delays.

- Extreme Temperatures: Freezing temperatures can damage the concrete and make the ground hard to work with. Extreme heat can lead to rapid water loss from the concrete, reducing its strength. We adapt our methods accordingly, using measures like insulated forms or concrete additives to mitigate these effects. We may need to add admixtures or change the concrete mix design to compensate for heat or cold.

- Safety First: Regardless of the weather, stringent safety procedures are always followed, including the use of appropriate personal protective equipment (PPE) and adherence to established safety protocols.

Q 19. What is your experience with using hand tools and power tools for pole installation?

Proficiency with both hand tools and power tools is essential for efficient and safe pole installation. I’m highly skilled in using a variety of equipment.

- Hand Tools: I’m adept at using shovels, tampers, post-hole diggers, levels, measuring tapes, and other hand tools for tasks like digging, compacting, and aligning the pole. Hand tools are crucial for fine adjustments and precision work, especially in tight spaces.

- Power Tools: I’m experienced with operating augers, excavators, compactors, concrete mixers, and other power equipment. These tools dramatically improve efficiency, especially in large-scale projects. Safety training and certification are a must for operating heavy equipment and power tools.

- Maintenance and Safety: Regular maintenance of both hand and power tools is critical to ensure safety and efficiency. I always inspect tools before use and report any damage or malfunctions immediately.

Q 20. Explain your knowledge of different types of guy wires and their installation.

Guy wires are crucial for stabilizing poles, particularly tall ones or those in areas prone to high winds. Understanding different types and their installation is key.

- Types of Guy Wires: There are several types, including galvanized steel, stainless steel, and high-strength synthetic materials like Kevlar or Dyneema. The choice depends on factors like the pole’s height, the environmental conditions (e.g., corrosion resistance), and the anticipated load. For example, coastal areas might necessitate stainless steel due to corrosion resistance.

- Installation: Proper installation involves several steps: attaching the guy wire to the pole using a properly sized and rated clamp or anchor, setting anchor points in the ground (usually concrete anchors), ensuring proper tension using a tensioning tool, and protecting the wire from abrasion or damage. We use specialized tools for accurate tensioning to avoid over-tensioning which could damage the pole or under-tensioning which would reduce its effectiveness.

- Anchor Points: These are critical for guy wire stability. We use concrete anchors set deep enough to provide sufficient resistance to pulling forces. The anchor placement and depth are calculated based on the pole’s height, the expected wind loads, and the soil conditions. Careful consideration must be given to potential underground utilities.

Q 21. Describe your experience with working as part of a team in a fast-paced environment.

I thrive in fast-paced team environments and have extensive experience collaborating effectively with diverse teams to achieve project goals on time and within budget. Successful pole installation requires coordination and communication among multiple crew members, so teamwork is essential.

- Communication: Clear and concise communication is essential to ensure everyone understands their roles and responsibilities. I effectively communicate with team members, supervisors, and clients. We use briefings at the start of the day to set tasks, assign roles, and highlight safety measures.

- Coordination: In a fast-paced environment, coordinating the different stages of the installation process – from trenching and concrete placement to pole erection and guy wire installation – is vital. I contribute to the planning and scheduling aspects as well as to the execution itself.

- Problem-Solving: Inevitably, unforeseen issues arise during installation. My ability to quickly identify and solve problems, while maintaining safety standards, is crucial to keeping the project moving efficiently. For example, encountering unexpected underground utilities requires immediate problem-solving to adjust the plan safely.

- Mentoring: I’ve also had opportunities to mentor less experienced team members, sharing my knowledge and helping them develop their skills.

Q 22. How do you manage your time effectively to complete pole installation projects on schedule?

Effective time management in pole installation is crucial for meeting deadlines and staying within budget. My approach involves a multi-pronged strategy. First, I meticulously review project plans and specifications, identifying potential bottlenecks early on. This often involves collaborating with engineers and site supervisors to refine timelines and resource allocation. Then, I create a detailed schedule, breaking down the project into manageable tasks with assigned deadlines. This isn’t just a static document; I use project management software to track progress, identify delays, and adjust the schedule dynamically. I also factor in unexpected delays – weather, equipment malfunction, or unforeseen site conditions – by building in buffer time. Finally, proactive communication is key. I regularly update stakeholders on progress, and if issues arise, I address them immediately to avoid cascading delays. For example, on a recent project involving 100 poles, I identified a potential delay in acquiring permits. By proactively contacting the relevant authorities and providing all necessary documentation, I managed to secure the permits ahead of schedule, keeping the project on track.

Q 23. How do you troubleshoot common problems that occur during pole installation?

Troubleshooting in pole installation involves a systematic approach. I start by identifying the nature of the problem: Is it a foundation issue, a pole alignment problem, a problem with the hardware or with the grounding system? Then, I use a combination of visual inspection, testing equipment (such as a level, tension meter, and ground resistance tester), and my understanding of structural mechanics to diagnose the root cause. For instance, if a pole is leaning, I’ll check the foundation for settling or uneven load distribution. If there’s a grounding problem, I’ll use a megohmmeter to test the resistance and identify any breaks in the grounding wire. Addressing these issues often requires a combination of corrective actions. This might involve adjusting the foundation, re-aligning the pole, replacing faulty hardware, or redoing the grounding system. Documentation is critical at every step – photos, measurements, and notes on the problem and solution ensure that lessons learned are documented, aiding future projects. One example involved a pole that was slightly misaligned. Through careful measurement, we discovered that the foundation had settled slightly after the concrete curing process. Instead of re-pouring the foundation, we used specialized shims to correct the alignment, saving time and resources.

Q 24. What is your experience with pre-installation site surveys and planning?

Pre-installation site surveys and planning are paramount to a successful pole installation. My experience includes conducting thorough site surveys to assess various factors, including soil conditions, accessibility, overhead and underground utilities, and environmental considerations. I use surveying equipment, such as total stations and GPS, to accurately map the site and determine optimal pole locations. I also analyze existing site plans, blueprints, and utility maps to avoid conflicts and ensure compliance with regulations. This data informs detailed plans, including logistics like equipment access, material delivery schedules, and crew deployment. For instance, on a recent project in a dense urban area, the pre-installation survey revealed the presence of underground gas lines very close to the planned pole locations. This led us to adjust the pole placements and develop a detailed safety plan, ensuring a smooth and safe installation. The planning stage also includes risk assessments to identify potential hazards and develop mitigation strategies.

Q 25. Describe your experience with maintaining accurate records and documentation.

Maintaining accurate records and documentation is a fundamental part of my workflow. This includes detailed daily reports that document progress, challenges encountered, materials used, and any safety incidents. These reports are often accompanied by photographic and video evidence. I also maintain comprehensive as-built drawings reflecting the final pole placements and any deviations from the original plan. These drawings include key information such as pole types, coordinates, grounding details, and connection points. All this documentation is stored in a centralized, easily accessible system, ensuring seamless continuity throughout the project lifecycle. Furthermore, I use specialized software to record material quantities, labor hours, and equipment utilization, which aids in accurate cost accounting and project reporting. For example, a detailed record of the materials used on each pole is essential for warranty claims and future maintenance.

Q 26. How do you prioritize safety concerns while meeting project deadlines?

Safety is my top priority, and it’s intrinsically linked to meeting project deadlines, not a trade-off. My approach involves proactively identifying and mitigating potential hazards during the planning phase itself. This involves developing site-specific safety plans that cover everything from proper use of personal protective equipment (PPE) to safe excavation procedures and traffic control measures. Daily safety briefings with the crew are essential, ensuring everyone understands the risks and procedures. Regular safety inspections are conducted to identify and address any potential hazards. We use a system of near-miss reporting to learn from mistakes and improve safety protocols. I firmly believe that a safe work environment is a productive work environment. For example, on a project near a busy highway, we implemented a detailed traffic control plan with flaggers and appropriate signage well in advance, ensuring worker safety and minimizing project disruptions.

Q 27. What are your salary expectations for this role?

My salary expectations for this role are commensurate with my experience and skills, aligning with the industry standard for a seasoned pole installation professional with my qualifications and track record. I am open to discussing a specific range based on the full details of the position and benefits package.

Q 28. Do you have any questions for me?

Yes, I do have a few questions. I’d like to learn more about the specific technologies and methodologies used by your team. Could you also elaborate on the company’s approach to professional development and training opportunities? Finally, I’d be interested in understanding the long-term career growth prospects within the company.

Key Topics to Learn for Pole Installation Interview

- Safety Regulations and Procedures: Understanding and applying relevant safety standards, including OSHA regulations and company-specific safety protocols for working at heights and handling heavy equipment.

- Pole Types and Specifications: Familiarity with various pole types (wood, concrete, metal), their applications, and understanding specifications related to size, strength, and installation requirements.

- Equipment Operation and Maintenance: Proficiency in operating and maintaining relevant equipment, including excavators, cranes, and specialized pole-setting machinery. Understanding preventative maintenance procedures is crucial.

- Ground Preparation and Site Assessment: Knowledge of proper site preparation techniques, including soil analysis, excavation procedures, and ensuring a stable foundation for pole installation. Understanding site surveying and potential challenges.

- Installation Techniques: Mastering various pole installation methods, including hand-digging, auger drilling, and crane-assisted installation. Understanding the nuances of each method and choosing the appropriate one based on site conditions.

- Guying and Anchoring: Understanding the principles of guying and anchoring to ensure pole stability and longevity. Knowledge of different guying techniques and materials.

- Troubleshooting and Problem Solving: Ability to identify and troubleshoot common problems encountered during pole installation, such as unstable ground conditions, equipment malfunctions, or unforeseen site challenges. Demonstrating problem-solving skills is vital.

- Post-Installation Inspection and Documentation: Understanding the importance of thorough post-installation inspections to ensure compliance with standards and proper functionality. Knowledge of accurate record-keeping and documentation procedures.

Next Steps

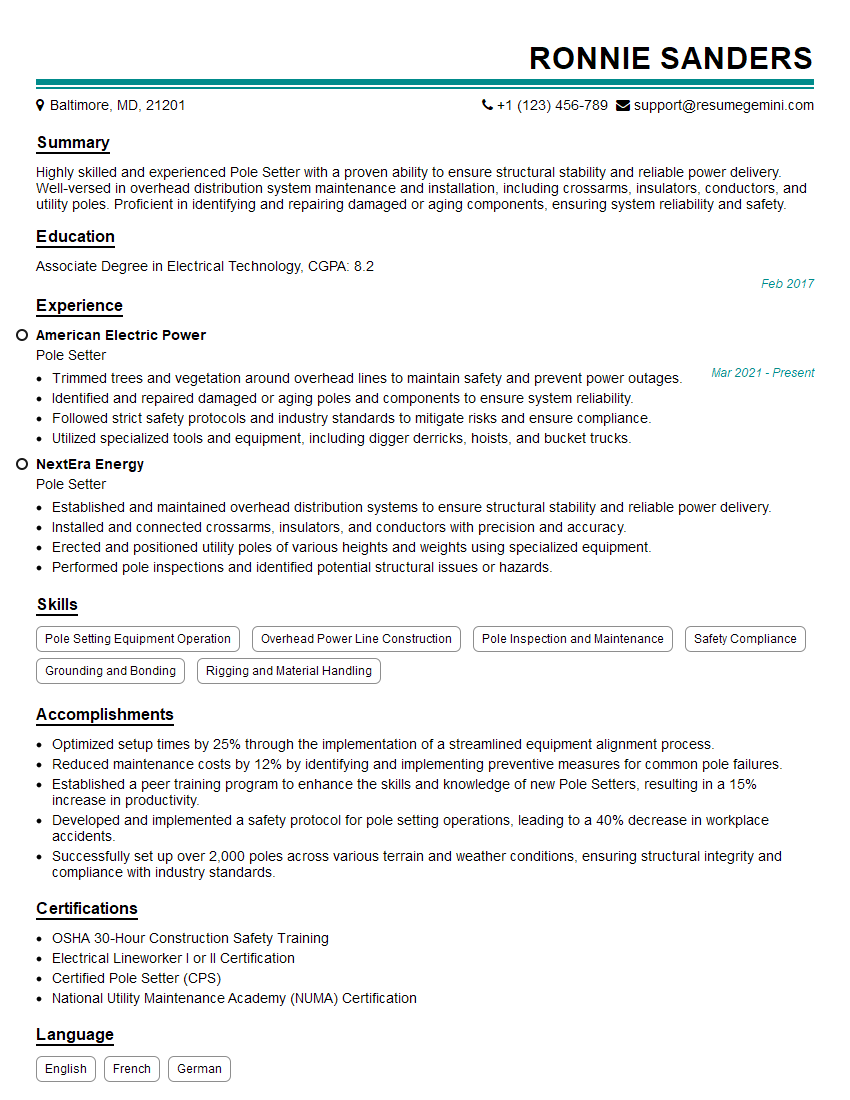

Mastering pole installation opens doors to a rewarding career with excellent growth potential within the utility, telecommunications, and construction industries. To maximize your job prospects, it’s essential to present your skills effectively. Creating an Applicant Tracking System (ATS)-friendly resume is crucial for getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your qualifications. Examples of resumes tailored to Pole Installation are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good