Cracking a skill-specific interview, like one for Burn-in Testing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Burn-in Testing Interview

Q 1. Explain the purpose of burn-in testing.

Burn-in testing is a crucial process in manufacturing, particularly for electronic components and systems. Its primary purpose is to identify and eliminate early failures, often referred to as ‘infant mortality.’ These are defects that manifest themselves shortly after a product is manufactured, before reaching the end-user. By subjecting the components or systems to high stress conditions for an extended period, burn-in testing weeds out these weak units, thereby improving the overall reliability and lifespan of the final product. Think of it like a rigorous ‘boot camp’ for your electronics before they’re deployed in the real world.

Q 2. What are the different types of burn-in tests?

There are several types of burn-in tests, each tailored to specific needs and product characteristics:

- Temperature-Cycling Burn-in: This involves repeatedly cycling the temperature of the unit between high and low extremes, stressing the solder joints and other temperature-sensitive components. This is particularly important for products operating in diverse climates.

- High-Temperature Burn-in: This method subjects the unit to constant elevated temperatures, accelerating the aging process and revealing potential defects related to heat-induced degradation.

- Power Burn-in: This test involves operating the unit at its maximum power rating for an extended period, stressing power components like capacitors and transistors.

- Functional Burn-in: This test combines operational cycling with elevated temperature or voltage to stress the product under real-world usage conditions. This provides a much more comprehensive stress test to unveil any potential failure modes.

- Combined-Stress Burn-in: This is a more rigorous approach combining multiple stress factors simultaneously, such as high temperature and high voltage, to maximally accelerate failure mechanisms.

The choice of burn-in type depends on the specific application and the potential failure modes of the product being tested.

Q 3. Describe the advantages and disadvantages of burn-in testing.

Advantages of Burn-in Testing:

- Improved Reliability: Significantly reduces early failures, leading to a more reliable product with a longer lifespan.

- Enhanced Customer Satisfaction: Minimizes warranty claims and returns, resulting in improved customer satisfaction.

- Reduced Field Failures: Prevents costly field repairs and replacements by identifying and eliminating faulty units before they reach the customer.

- Better Quality Control: Provides valuable data for process improvement and defect reduction efforts.

Disadvantages of Burn-in Testing:

- High Cost: Burn-in testing requires specialized equipment and can be time-consuming and expensive.

- Time-Consuming: The duration of burn-in tests can be lengthy, especially for products with high reliability requirements.

- Space Requirements: Depending on the scale, significant space might be needed for housing the equipment and tested units.

- May Not Detect All Failures: While effective in catching early failures, it may not detect all potential failures, especially those that manifest after a longer time period.

Q 4. How do you determine the optimal duration for a burn-in test?

Determining the optimal duration for a burn-in test is critical. It’s a balance between identifying infant mortality and minimizing cost and time. Several factors influence this decision:

- Product Complexity: More complex products generally require longer burn-in times.

- Reliability Requirements: Higher reliability requirements necessitate longer test durations.

- Historical Data: Past burn-in test data for similar products can provide valuable guidance.

- Failure Rate Data: Analyzing failure rate curves (e.g., Weibull analysis) can help determine an appropriate duration.

- Cost-Benefit Analysis: Balancing the cost of extended burn-in time against the potential savings from reduced field failures is crucial.

A common approach is to use accelerated testing techniques, employing higher stress levels to shorten the test duration while still identifying early failures. The duration is often expressed in terms of operating hours or equivalent stress hours.

Q 5. What are the key parameters monitored during burn-in testing?

The key parameters monitored during burn-in testing depend heavily on the product, but common parameters include:

- Temperature: Monitoring both ambient and component temperatures.

- Voltage: Tracking voltage levels at various points within the unit.

- Current: Measuring current draw to detect abnormal power consumption.

- Frequency: Monitoring signal frequencies for deviations indicating malfunction.

- Performance Metrics: Measuring key performance indicators (KPIs) relevant to the unit’s function.

- Failure Modes: Carefully documenting the nature of any observed failures.

Data logging systems are crucial for effectively monitoring these parameters and ensuring accurate analysis.

Q 6. How do you analyze the results of a burn-in test?

Analyzing burn-in test results involves several steps:

- Data Collection: Gathering all collected data from the monitored parameters.

- Failure Analysis: Identifying the types and causes of failures observed.

- Statistical Analysis: Applying statistical methods like Weibull analysis to determine failure rates and predict the overall reliability.

- Failure Rate Curves: Plotting failure rate curves to visualize the failure patterns and estimate the useful life of the product.

- Defect Tracking: Tracking identified defects to pinpoint their root causes and implement corrective actions.

- Report Generation: Generating a detailed report summarizing the test results, findings, and recommendations.

Software tools specifically designed for reliability analysis are often used to aid in this process. The analysis should provide insights into the product’s reliability, identify areas for improvement, and guide design and manufacturing adjustments.

Q 7. Explain the difference between infant mortality and early failures.

While both infant mortality and early failures refer to defects appearing early in a product’s life, there’s a subtle difference. Infant mortality typically refers to a high failure rate observed immediately after manufacturing, often within the first few hours or days of operation. This is usually due to manufacturing defects or flaws introduced during the production process. Early failures, on the other hand, encompasses a broader timeframe, including failures that occur during the initial weeks or months of operation. These could be due to infant mortality issues or other factors like component weaknesses that aren’t immediately apparent. In essence, infant mortality is a subset of early failures.

Imagine a batch of lightbulbs. Infant mortality would be the bulbs that burn out within the first few minutes of use, likely due to a manufacturing fault. Early failures would include those failing within the first month, which could involve infant mortality issues or other weaknesses emerging later.

Q 8. What are the common failure mechanisms detected by burn-in testing?

Burn-in testing reveals latent defects that might not surface during normal operation. These failures often stem from manufacturing imperfections or weaknesses in components. Common failure mechanisms include:

- Early Life Failures (ELF): These are failures that occur within the first few hours or days of operation. They are often due to weak solder joints, infant mortality in components (e.g., capacitors), or manufacturing defects.

- Electro-Migration: The movement of metal ions within conductors due to high current density. This can lead to open circuits or shorts, especially in integrated circuits.

- Electromigration: The movement of metal ions within conductors due to high current density. This can lead to open circuits or shorts, especially in integrated circuits.

- Corrosion: Chemical reactions that degrade materials, leading to performance degradation or complete failure. This is often influenced by humidity and temperature.

- Thermal Cycling Failures: Repeated temperature changes can cause materials to expand and contract, leading to cracking or delamination. This is particularly relevant in applications with varying operating temperatures.

- Dielectric Breakdown: Failure of insulating materials due to excessive voltage stress. This can occur in capacitors and other components.

- Mechanical Failures: Problems related to physical stress, such as cracked components, loose connections, or vibrations.

Identifying these failure mechanisms early is crucial for improving product reliability and preventing costly field failures.

Q 9. How do you select appropriate burn-in test conditions (temperature, voltage, etc.)?

Selecting appropriate burn-in test conditions is critical for effective testing and requires careful consideration of the product’s intended use and its sensitivity to environmental stress. The process usually involves:

- Understanding the Product: Thorough knowledge of the device’s design, materials, and operating specifications is paramount. This includes understanding its thermal limits, voltage tolerance, and expected operating environment.

- Accelerated Stress Testing: Burn-in aims to accelerate failure mechanisms. We might increase temperature above the normal operating range to accelerate degradation processes, such as corrosion or electromigration. Similarly, higher-than-normal voltage or current may reveal weaknesses in components.

- Stress Levels and Duration: This is determined through experience, historical data, and sometimes through accelerated life testing studies. The goal is to find a balance between revealing defects and avoiding unnecessary damage.

- Environmental Factors: Humidity and vibration can significantly impact reliability. The burn-in environment should simulate, or even exceed, the anticipated conditions to expose potential sensitivities.

For example, a microcontroller intended for automotive applications would undergo burn-in at high temperatures (e.g., 125°C) and potentially with vibration to simulate engine conditions. Conversely, a consumer electronics device might undergo testing at more moderate elevated temperatures and with a focus on voltage stress.

The specific conditions, including temperature, voltage, and duration, should be documented meticulously, and justified based on the device’s specification and risk assessment. A well-defined test plan should be in place before commencing burn-in.

Q 10. Describe your experience with different burn-in test equipment.

My experience encompasses a range of burn-in test equipment, including:

- Temperature-controlled chambers: I’ve extensively used large-scale chambers capable of holding hundreds of units simultaneously, as well as smaller, more focused chambers for specialized testing. These chambers maintain precise temperature control, often with humidity control as well.

- Load boards: These are crucial for applying the correct power and signals to the units under test. I’ve worked with load boards ranging from simple designs for straightforward testing to complex boards with extensive monitoring capabilities.

- Data acquisition systems: These are essential for monitoring critical parameters such as temperature, voltage, current, and output signals during burn-in. I have experience with both automated systems that collect data remotely and manual systems where readings are taken periodically.

- Automated test equipment (ATE): For high-volume production, ATE systems automate the burn-in process, including loading, testing, and data analysis. This significantly improves efficiency and reduces the risk of human error.

Choosing the right equipment depends on factors such as the number of units to be tested, the complexity of the test, and the required level of automation. Each piece of equipment must be calibrated regularly to ensure accurate and reliable results. For instance, a discrepancy in temperature readings can easily skew failure rates, thus impacting conclusions. Maintaining equipment logs is a critical aspect of my process.

Q 11. How do you ensure the accuracy and reliability of burn-in test results?

Ensuring accurate and reliable results involves multiple steps:

- Calibration: Regular calibration of all test equipment is paramount. This includes temperature chambers, power supplies, and measurement instruments. Calibration certificates should be maintained to document the accuracy.

- Test Plan: A well-defined test plan with clear specifications for temperature, voltage, duration, and monitoring parameters is essential. It should clearly outline acceptance criteria and failure definitions. This plan should be created in a collaborative effort, involving engineers from several design and test groups.

- Statistical Analysis: Applying appropriate statistical methods to analyze the data is crucial. This helps determine the failure rate and identify trends. We should ensure the sample size is sufficient for statistically valid conclusions.

- Control Groups: Including control groups (units not subjected to burn-in) can help rule out environmental factors affecting the results. I typically compare the performance of units with burn-in against these control groups.

- Documentation: Meticulous documentation of the entire process, from test plan to final report, is crucial for traceability and auditability. This involves maintaining detailed records of test conditions, results, and analysis.

A robust quality control system is vital throughout the entire process. For example, I would regularly audit the equipment calibration process, spot-check the data collected, and carefully review the statistical analysis before drawing conclusions. This multi-layered approach increases confidence in the results.

Q 12. What are some common challenges encountered in burn-in testing?

Burn-in testing presents several challenges:

- Time-Consuming Nature: Burn-in tests can take days or even weeks, significantly impacting product time-to-market. It’s a time-cost tradeoff that needs to be carefully considered.

- High Costs: The need for specialized equipment, skilled personnel, and significant time investment makes burn-in a relatively expensive process.

- False Failures: Some failures might be caused by the burn-in process itself, rather than inherent defects. Differentiating between these is challenging and requires careful analysis.

- Test Coverage: Burn-in doesn’t cover all potential failure mechanisms. Other testing methodologies, such as environmental stress screening (ESS) and HALT (Highly Accelerated Life Testing), need to be considered for a comprehensive approach.

- Data Interpretation: Analyzing the data generated during burn-in requires expertise in statistical analysis and failure mechanisms. It can require the use of Failure Rate (FR) and Mean Time Between Failures (MTBF) analysis and the use of Weibull analysis in more complex situations.

Addressing these challenges often involves optimizing the burn-in process, using efficient test equipment, and employing advanced data analysis techniques. The key is to find the optimal balance between cost, time, and the level of reliability desired.

Q 13. How do you handle failed units during burn-in testing?

Handling failed units involves a systematic approach:

- Failure Analysis: Failed units undergo thorough failure analysis to determine the root cause of failure. This might involve visual inspection, electrical testing, and even destructive analysis techniques like cross-sectioning and microscopy.

- Data Recording: Detailed records of the failure, including the time of failure, symptoms observed, and test conditions, should be documented. This data is crucial for identifying trends and improving the design or manufacturing process.

- Corrective Actions: Based on the failure analysis, corrective actions are implemented. This might involve changes to the design, manufacturing process, or component selection.

- Disposition of Failed Units: Failed units are disposed of according to company procedures. This may involve recycling, proper disposal, or further analysis by specialized teams.

Failure analysis is not merely about identifying the failed unit; it’s about understanding *why* it failed, allowing for improvements to prevent similar failures in the future. This iterative process, incorporating lessons from failed units, is key to improving product reliability.

Q 14. Describe your experience with burn-in test data analysis software.

My experience includes using various burn-in data analysis software packages. These tools provide advanced capabilities to analyze large datasets, identify failure trends, and generate reports. Key features of these tools include:

- Data Import and Management: The ability to import data from different sources and manage large datasets efficiently. This reduces human error and speeds up the analysis.

- Statistical Analysis: Tools for performing various statistical analyses, such as Weibull analysis, to determine failure rates and predict product life.

- Graphical Representation: Tools to generate various graphs and charts, such as failure rate plots, bathtub curves, and histograms, for visualizing the data and identifying trends.

- Report Generation: The ability to automatically generate comprehensive reports summarizing the burn-in results.

For example, I’ve used software that allowed automated creation of reports detailing failure rates, MTBF (Mean Time Between Failures), and other key metrics, saving considerable time and reducing the potential for human error. The ability to visualize data through various charts and graphs allows for better understanding and interpretation of the results, ultimately leading to more informed decision-making.

Q 15. How do you develop a burn-in test plan?

Developing a burn-in test plan involves a systematic approach to ensure the reliability and longevity of a product. It starts with clearly defining the objectives, such as identifying early failures, assessing product robustness, and determining optimal operating conditions. This involves understanding the product’s intended use and the environmental stresses it might face.

- Define Test Objectives: Specify the goals – what are you hoping to achieve with this burn-in test? Are you targeting infant mortality failures, assessing long-term reliability under specific stress conditions, or validating a design change?

- Select Test Samples: Choose a representative sample of units from production reflecting variations in manufacturing processes. The sample size needs to be statistically significant to draw meaningful conclusions.

- Determine Test Conditions: This is crucial. You’ll define the environmental stresses (temperature, humidity, voltage, vibration, etc.), the duration of the test, and the monitoring parameters (e.g., power consumption, temperature, performance metrics). The conditions should simulate real-world or even extreme usage conditions to accelerate potential failure modes.

- Establish Acceptance Criteria: Define acceptable failure rates or performance degradation levels. This helps determine if the product meets the pre-defined reliability targets.

- Develop a Monitoring and Data Collection Plan: Detail how you will monitor the units during the test and how the data will be collected and analyzed. This could include automated data logging systems and monitoring dashboards.

- Define Failure Modes and Reporting: Specify how failures will be categorized and documented. This forms the basis for failure analysis and corrective actions.

- Establish a Test Schedule and Resources: Outline the timeline, resources needed (equipment, personnel, etc.), and budget for the burn-in test.

For example, let’s say we’re testing a new smartphone. Our objectives might be to identify early failures in the battery, screen, and processor within the first 72 hours of continuous use at high ambient temperatures. We’d define specific temperature thresholds, monitor power consumption, and document any failures, meticulously categorizing their root cause.

Career Expert Tips:

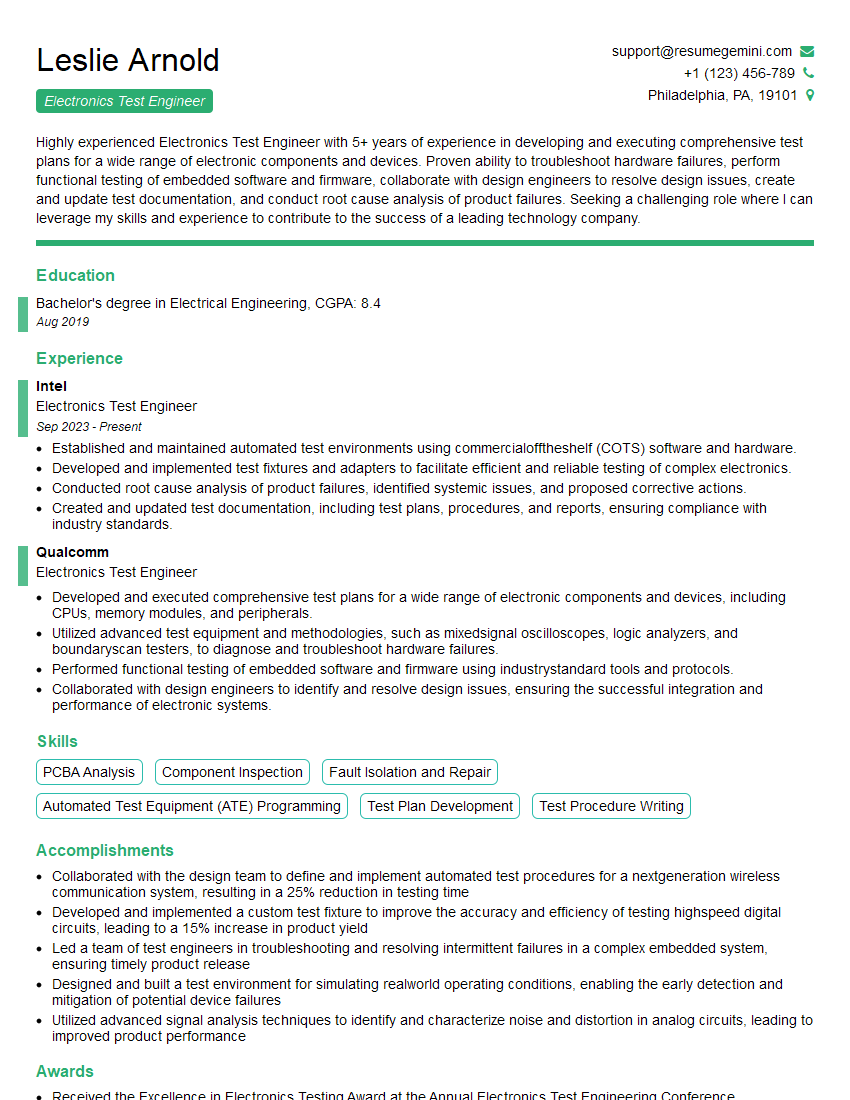

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of statistical process control (SPC) in burn-in testing.

Statistical Process Control (SPC) in burn-in testing involves using statistical methods to monitor the process and identify potential issues throughout the testing phase. This helps ensure consistency and reliability. It’s all about preventing problems rather than just reacting to failures. We use control charts, such as X-bar and R charts or p-charts to track key metrics and identify trends.

X-bar and R charts monitor the average (X-bar) and range (R) of a specific parameter (e.g., temperature, power consumption) across different units. If the data points fall outside the control limits, it indicates a potential problem in the process. p-charts track the proportion of failed units over time. A sudden increase in the failure rate outside the control limits might indicate a manufacturing defect or a design flaw.

In practice, this means regularly analyzing burn-in data. If we observe a sudden increase in failures or a shift in the average power consumption, it suggests an investigation into the production process or the product design is necessary. SPC provides the objective data-driven insights needed to quickly identify and resolve issues, improving product reliability and minimizing costs.

Q 17. How do you improve the efficiency of burn-in testing?

Improving burn-in testing efficiency involves optimizing the process to reduce time and cost while maintaining the effectiveness of the test. This can be achieved through several strategies.

- Accelerated Stress Testing: Instead of running tests under normal operating conditions for an extended period, we can apply increased stress levels (higher temperatures, voltages, etc.) to accelerate failure mechanisms. This reduces the overall burn-in time. However, it’s crucial to ensure the acceleration factors are properly validated.

- Automated Test Systems: Implementing automated monitoring and data collection systems can significantly reduce manual labor and improve data accuracy. Automated systems can continuously monitor multiple units simultaneously, collecting large amounts of data quickly.

- Improved Test Chamber Design: Optimizing burn-in chamber designs for better thermal uniformity and efficiency can lead to reduced test times and energy consumption.

- Data Analytics: Employing sophisticated data analytics techniques can help to identify patterns and predict failures more accurately, leading to better decision-making and reduced test duration.

- Smart Sampling Techniques: Careful selection of the units to be tested based on risk assessment can minimize the number of units needed for testing while still achieving statistically significant results.

For instance, using advanced thermal profiling techniques in the burn-in chamber allows for more precise temperature control, potentially reducing testing time by optimizing the stress level applied.

Q 18. What are the cost implications of burn-in testing?

The cost implications of burn-in testing can be significant and involve several factors:

- Equipment Costs: This includes the cost of purchasing and maintaining burn-in chambers, data acquisition systems, and other test equipment.

- Labor Costs: Setting up the test, monitoring the units, and analyzing the results requires personnel. Automation can reduce labor costs but increases initial capital expenditure.

- Material Costs: The cost of the units undergoing burn-in testing can be substantial, especially for expensive products.

- Energy Costs: Burn-in chambers consume significant amounts of energy, especially during prolonged tests.

- Downtime Costs: The time taken for burn-in testing can lead to delays in product launches and increased inventory holding costs.

- Failure Analysis Costs: Investigating failed units to determine the root cause can be time-consuming and expensive.

It’s important to note that the cost of burn-in testing should be considered relative to the potential costs of field failures. The cost of fixing a product in the field is typically much higher than detecting and addressing the issue during burn-in.

Q 19. How do you balance the cost and effectiveness of burn-in testing?

Balancing the cost and effectiveness of burn-in testing requires a careful risk assessment and optimization of the test strategy.

- Risk Assessment: Evaluate the potential costs of field failures and compare them to the cost of burn-in testing. This helps determine the acceptable level of risk and the necessary level of testing.

- Test Duration Optimization: Determine the optimal duration of the test to detect the most critical failure modes without unnecessarily extending the test time and cost. Accelerated testing techniques can be employed here.

- Sample Size Optimization: Use statistical methods to determine the appropriate sample size to achieve the desired level of confidence without excessive testing.

- Automation: Consider automation to reduce labor costs and increase efficiency, while acknowledging the upfront investment.

- Design for Reliability: Investing in robust design practices can reduce the likelihood of early failures, minimizing the need for extensive burn-in testing.

For instance, a detailed Failure Modes and Effects Analysis (FMEA) can help identify the most critical failure modes and prioritize the testing efforts accordingly. This targeted approach can help reduce the overall cost of burn-in while ensuring the critical failure mechanisms are adequately addressed.

Q 20. What are the ethical considerations related to burn-in testing?

Ethical considerations in burn-in testing primarily revolve around responsible resource management and the avoidance of unnecessary waste.

- Minimizing Waste: Efficient test planning and execution are crucial to avoid wasting resources – energy, materials, and time. Optimizing testing strategies reduces environmental impact and economic waste.

- Data Integrity: Maintaining accurate and reliable data is essential for making informed decisions. Manipulating data to achieve a desired outcome is unethical and can have serious consequences.

- Transparency: The results of burn-in testing should be presented transparently and honestly, avoiding any misrepresentation of the product’s reliability.

- Environmental Impact: The energy consumption of burn-in chambers should be considered, and strategies for energy efficiency should be implemented.

For example, it’s crucial to ensure that the test parameters are not unnecessarily harsh, leading to higher failure rates than those seen under normal operating conditions. Excessively stressing the product without a justifiable reason would be unethical, as it leads to resource wastage.

Q 21. Describe your experience with different burn-in chamber types.

My experience encompasses various burn-in chamber types, each with its strengths and weaknesses:

- Standard Environmental Chambers: These are versatile chambers capable of controlling temperature, humidity, and often pressure. They’re suitable for a wide range of products but can be less efficient for specific applications.

- Temperature Cycling Chambers: These chambers are designed for rapid temperature changes, simulating real-world conditions like those experienced in automotive or aerospace applications. They’re highly effective for stress testing components susceptible to thermal shock.

- High-Temperature Burn-in Ovens: These ovens are specialized for high-temperature testing, particularly suitable for evaluating the reliability of components such as integrated circuits and semiconductors. They are very energy efficient for their specific purpose.

- Combined Stress Chambers: These advanced chambers allow for simultaneous application of multiple stress factors, such as temperature, humidity, vibration, and pressure, to accelerate failure modes in a more realistic manner.

In a previous role, I extensively used high-temperature burn-in ovens for testing semiconductor devices. We monitored the devices’ power consumption and other parameters to identify any anomalies and evaluate their stability under extreme temperatures. For automotive components, I’ve utilized temperature cycling chambers to simulate the harsh thermal conditions encountered during operation.

The selection of the appropriate chamber depends greatly on the product’s requirements and the types of stresses it might encounter during its operational life. This decision directly impacts the efficiency and reliability of the burn-in testing process.

Q 22. Explain the relationship between burn-in testing and other reliability tests.

Burn-in testing is a crucial part of a larger reliability testing strategy. It’s not a standalone test but rather a vital step that complements other methods. Think of it as a rigorous initial screening process that weeds out early failures before more sophisticated and time-consuming tests are performed. It sits alongside other reliability tests like Highly Accelerated Life Testing (HALT), Accelerated Life Testing (ALT), and Environmental Stress Screening (ESS).

For example, after a product undergoes burn-in, it might then undergo HALT to push it to its limits and identify failure modes under extreme conditions. Burn-in helps identify infant mortality failures – defects that show up early in a product’s life – thereby preventing these failures from skewing the results of subsequent, more precise, and expensive reliability assessments like ALT. By removing these early failures, you get a more accurate picture of the product’s true long-term reliability.

- Burn-in: Identifies early failures, ‘infant mortality’.

- HALT: Stresses the product to find failure modes under extreme conditions.

- ALT: Accelerates failure mechanisms to predict long-term reliability.

- ESS: Combines various stresses to identify and eliminate weak components.

Q 23. How do you manage burn-in test data and reporting?

Managing burn-in test data and reporting efficiently is critical. We utilize a combination of automated data acquisition systems and specialized software to track test parameters, such as temperature, voltage, and current, for each unit under test. This data is logged continuously, allowing for real-time monitoring and immediate detection of failures. A well-structured database is essential, designed to handle large volumes of data efficiently and allow for easy retrieval and analysis.

Reporting is equally important. We generate comprehensive reports that include:

- Summary of failures: Number of failures, failure rates, and types of failures.

- Statistical analysis: Mean time to failure (MTTF), failure distributions (e.g., Weibull analysis), and confidence intervals.

- Graphical representations: Failure rate curves, histograms, and scatter plots to visualize the data.

- Detailed individual unit data: Complete history of each unit’s test parameters and any observed failures.

We use customized dashboards to visualize key metrics, facilitating quick identification of trends and areas for improvement. These reports are crucial for making data-driven decisions regarding product design and manufacturing processes.

Q 24. What are some best practices for designing effective burn-in tests?

Designing effective burn-in tests requires a careful consideration of several factors. It’s not just about subjecting the units to high temperatures for a long period; it’s about strategically simulating real-world operating conditions to accelerate potential failure mechanisms.

- Define test objectives: What are you trying to identify? Infant mortality? Specific failure modes?

- Select appropriate stress levels: Stress levels should be high enough to accelerate failures but not so high that they cause unrealistic failures. This often involves understanding the product’s failure modes and mechanisms.

- Determine test duration: The duration depends on the product’s complexity and intended lifespan. Common burn-in durations range from 168 to 1000 hours.

- Environmental conditions: Consider temperature, humidity, vibration, and other environmental factors that might influence reliability.

- Monitoring and data acquisition: Implement automated systems to continuously monitor key parameters and detect failures.

- Statistical analysis: Plan the statistical analysis to be performed on the collected data.

For example, for a smartphone, we might apply high temperatures and a cyclical charge/discharge cycle to accelerate battery degradation and identify potential component failures under stress. For a server, we might run it under heavy load, simulating peak performance conditions.

Q 25. How do you troubleshoot problems encountered during burn-in testing?

Troubleshooting during burn-in involves a systematic approach. When a failure occurs, we don’t just replace the unit; we investigate to understand the root cause. This process typically includes:

- Data analysis: Reviewing the collected data to identify trends or patterns leading to the failure. Was it a sudden failure or a gradual degradation?

- Visual inspection: Carefully examining the failed unit for any visible damage or defects.

- Component-level testing: If necessary, isolating and testing individual components to pinpoint the point of failure.

- Failure analysis: Employing techniques like microscopy or X-ray inspection to determine the precise cause of failure at a microscopic level.

- Design review: Based on the failure analysis, reviewing the product design for potential improvements.

- Documentation: Meticulously documenting the entire troubleshooting process and the conclusions drawn to prevent recurrence.

For instance, if multiple units fail due to overheating, we’d investigate the thermal design, possibly improving heat sinks or airflow. A systematic approach ensures we learn from every failure and improve future designs and test processes.

Q 26. Describe your experience with automated burn-in testing systems.

I have extensive experience with automated burn-in testing systems. These systems are essential for managing large-scale burn-in tests efficiently and accurately. I’ve worked with systems that automate data acquisition, failure detection, and reporting. These typically involve sophisticated hardware and software integrations. These systems often incorporate:

- Automated test handlers: For loading and unloading units under test.

- Data acquisition systems: To continuously monitor key parameters such as temperature, voltage, and current.

- Real-time monitoring software: To display test status and immediately alert of failures.

- Database management systems: To store and manage large amounts of test data.

- Reporting and analysis tools: To generate comprehensive reports and perform statistical analysis.

The benefits are significant – improved accuracy, reduced human error, increased efficiency, and the ability to handle large volumes of units.

For example, in a previous role, we implemented a system that reduced our testing time by 40% while simultaneously improving the accuracy of failure detection, leading to a significant increase in overall product reliability.

Q 27. How do you contribute to continuous improvement in burn-in testing processes?

Continuous improvement in burn-in testing processes is a priority. This involves a cyclical approach of evaluation, improvement, and re-evaluation.

- Data analysis: Regularly reviewing test data to identify trends, areas for improvement, and potential risks.

- Process optimization: Streamlining processes to increase efficiency and reduce costs while maintaining accuracy.

- Technology upgrades: Exploring and implementing new technologies and tools to enhance the effectiveness of burn-in tests. This could involve upgrading hardware, software, or implementing advanced data analysis techniques.

- Collaboration: Working closely with design and manufacturing teams to identify and address potential reliability issues early in the product development cycle.

- Regular training: Ensuring that all personnel involved in burn-in testing are adequately trained and up-to-date on the latest best practices and technologies.

For example, by analyzing failure data, we might identify a weakness in a specific component, leading to a design change to improve reliability. By automating certain tasks, we can free up personnel to focus on more complex analysis and troubleshooting.

Key Topics to Learn for Burn-in Testing Interview

- Fundamentals of Burn-in Testing: Understanding the purpose, methodologies, and benefits of burn-in testing in ensuring product reliability.

- Test Planning and Design: Defining test objectives, selecting appropriate test conditions (temperature, voltage, etc.), and developing comprehensive test plans.

- Equipment and Instrumentation: Familiarity with burn-in chambers, monitoring equipment, and data acquisition systems used in burn-in testing.

- Data Analysis and Interpretation: Understanding failure rates, identifying failure modes, and analyzing data to draw meaningful conclusions about product reliability.

- Practical Applications: Exploring real-world examples of burn-in testing across various industries (e.g., electronics, automotive, aerospace) and understanding how it impacts product lifecycle.

- Statistical Methods in Burn-in Testing: Applying statistical concepts like Weibull analysis and reliability prediction to interpret test results.

- Troubleshooting and Problem Solving: Identifying and resolving issues during burn-in tests, including equipment malfunctions and unexpected failures.

- Reporting and Documentation: Creating clear and concise reports summarizing test results, findings, and recommendations.

- Advanced Burn-in Techniques: Exploring advanced techniques such as Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS).

Next Steps

Mastering burn-in testing opens doors to exciting career opportunities in quality assurance and reliability engineering, offering higher earning potential and increased responsibility. To maximize your job prospects, it’s crucial to present your skills effectively. An ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your burn-in testing expertise. ResumeGemini offers examples of resumes tailored specifically to burn-in testing roles, helping you craft a compelling document that stands out from the competition. Invest the time to create a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good