The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Aerial Bucket Truck Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Aerial Bucket Truck Operation Interview

Q 1. Describe your experience operating different types of aerial bucket trucks.

My experience encompasses operating a variety of aerial bucket trucks, ranging from smaller, articulating boom lifts used for residential work to larger, heavier-duty telescopic boom trucks employed in high-voltage power line maintenance. I’m proficient with both electric and diesel-powered models, and I’ve worked with units from different manufacturers, each with its unique operational characteristics and safety features. For instance, I’ve extensively used a Terex Utilities bucket truck with a 65-foot boom for tree trimming and a smaller Genie Z-45/25 articulating boom for telecom work. The differences involve not just boom reach and articulation, but also control systems and safety interlocks, which I’ve adapted to seamlessly.

Q 2. Explain the pre-operational inspection procedure for an aerial bucket truck.

A pre-operational inspection is crucial for safety and is a non-negotiable part of my routine. It’s a methodical process starting with a visual check of the entire truck, including tires, lights, fluid levels (hydraulic fluid, engine oil), and the condition of the boom and bucket. I meticulously inspect for any leaks, damage, or signs of wear and tear. Then, I carefully examine the hydraulic system for proper functioning and the presence of any leaks. Next, I check all safety devices, including the emergency shut-off, outriggers, and safety harnesses, ensuring they’re in perfect working order. The bucket’s controls, including the rotation and extension mechanisms, are thoroughly tested, and I always perform a ‘pre-climb’ function check, carefully raising and lowering the bucket to verify all functions. Only after this comprehensive check, if everything is satisfactory, do I proceed with my work.

Q 3. What are the different safety regulations and procedures you follow while operating an aerial bucket truck?

Safety is paramount. I strictly adhere to OSHA regulations and company safety protocols, which encompass various aspects of aerial bucket truck operation. These include wearing appropriate personal protective equipment (PPE) like hard hats, safety harnesses, and gloves. I always ensure that the outriggers are properly deployed and properly positioned on stable ground before elevating the boom. Before working at heights, I check that a spotter is in position and maintain constant radio communication with them. Furthermore, I’m trained in safe load limits, understanding the truck’s limitations and never exceeding the rated capacity. I am also trained and certified in lockout/tagout procedures for equipment maintenance or repairs. I always conduct regular risk assessments of the work site before starting, identifying potential hazards and implementing the necessary safety precautions. Furthermore, I maintain a logbook to record every operation, including pre-operational checks and any incidents or near misses.

Q 4. How do you ensure the stability of the bucket truck while working at height?

Maintaining stability is critical. It begins with a thorough assessment of the ground conditions before deploying the outriggers. Uneven terrain requires careful leveling using the outriggers and shims if necessary. I always refer to the truck’s load charts to ensure that the weight of the equipment and personnel does not exceed the rated capacity of the machine. I ensure the outriggers are fully extended and firmly planted on the ground, creating a stable base. During operation, I avoid any sudden movements or jerky actions that might destabilize the truck. The operator’s awareness of boom reach, load capacity, and wind conditions contributes significantly to maintaining stability. For example, high winds require extra caution, and work might need to be suspended if conditions become too hazardous.

Q 5. What are the limitations and safe working load limits of an aerial bucket truck?

Aerial bucket trucks have limitations governed by their manufacturer’s specifications, which are clearly documented. These limitations include maximum working height, outreach, and load capacity, all expressed in weight and force. Exceeding these limits compromises safety and can lead to catastrophic accidents. I always consult these specifications before any operation and ensure my actions remain within the safe working load limits. For example, I’m aware of the impact of uneven load distribution within the bucket on stability and ensure balanced weight allocation. Furthermore, I’m fully aware of factors that can affect stability and safe working loads such as ground conditions, wind speed and the effect of temperature changes on hydraulic systems. These are critical aspects for the operator to understand to ensure safe operations.

Q 6. Describe your experience working with different types of aerial lift controls.

I have experience with various aerial lift controls, including both mechanical and electronic systems. Some trucks utilize traditional lever and joystick controls, while others employ more sophisticated electronic systems with digital displays showing boom position, height, and other vital data. The controls may differ between manufacturers, but understanding the principles of operation remains the same. This involves being proficient in operating the functions such as boom extension/retraction, articulation, rotation, and movement of the bucket. Furthermore, I have experience with using different types of controls like proportional controls which allow for fine adjustments in the movement and position of the bucket which are extremely useful for delicate work. Understanding the system’s responsiveness and nuances is critical to working efficiently and safely.

Q 7. How do you handle emergency situations such as equipment malfunction or power outages while in the bucket?

Emergency procedures are crucial. If equipment malfunction occurs, my first action is to immediately shut down all power using the emergency shut-off switch. I then radio my spotter to alert them of the situation and follow established emergency protocols. In case of a power outage while in the bucket, I remain calm and follow safety procedures. I would assess if the bucket is stable, and if not I will slowly lower the bucket to the ground and carry out the appropriate procedures. I would then assess the situation and if necessary, call for assistance. The main focus in any emergency is to ensure the safety of myself and others around me. Regular training keeps these procedures fresh in my mind, and allows me to react swiftly and safely in unexpected situations.

Q 8. Explain your understanding of load charts and weight distribution in aerial bucket truck operation.

Load charts are crucial for safe aerial bucket truck operation. They detail the maximum weight the truck can carry at various boom positions and extensions. Understanding weight distribution is equally vital; you must ensure the weight in the bucket is balanced and doesn’t exceed the truck’s capacity at its current configuration. Imagine a seesaw: if you overload one side, the whole thing tips. Similarly, improper weight distribution in the bucket can cause instability, potentially leading to tipping or structural damage to the truck. I always meticulously check the load chart before each lift, calculating the total weight, including equipment and personnel, and verifying that the boom’s position and extension align with the chart’s limits. For example, if I’m working on a power line repair with a heavy toolbox and two technicians, I’ll ensure the combined weight is within the specified limits for the boom angle and extension used and distribute weight evenly within the bucket.

Q 9. Describe your experience working at various heights and in different weather conditions.

My experience spans diverse heights and weather conditions. I’ve worked on projects requiring lifts exceeding 100 feet, demanding a high degree of precision and awareness of wind effects. Working in harsh weather, like heavy rain or strong winds, necessitates extra caution and adherence to safety protocols. For instance, during a windstorm, I would carefully assess wind speed and direction, potentially postponing the operation if conditions exceed safe limits. I also adjust my technique in high winds by making smoother movements and having ground personnel pay close attention to the bucket’s movement and stability. Extreme temperatures, both hot and cold, also affect the materials and the operator’s physical capabilities, necessitating appropriate clothing and breaks.

Q 10. How do you communicate effectively with ground personnel during aerial bucket truck operations?

Clear and concise communication is paramount. We use a combination of hand signals, radio communication, and pre-planned instructions to ensure everyone is on the same page. Before starting any lift, we conduct thorough briefings, outlining the tasks, potential hazards, and emergency procedures. While operating, I use hand signals to acknowledge ground personnel’s directions, confirm the bucket’s position, and indicate any issues. Our radio communication is precise and focused, avoiding jargon and ensuring everyone understands the instructions. For example, instead of saying ‘Move it a bit,’ I’d say ‘Please move the bucket two feet to the right.’ This precision prevents miscommunication that could lead to accidents.

Q 11. What are the common causes of aerial bucket truck accidents and how can they be prevented?

Common causes of aerial bucket truck accidents include exceeding weight limits, improper boom operation, inadequate training, failure to inspect equipment, and environmental factors like strong winds or slippery surfaces. Prevention involves meticulous adherence to safety regulations, comprehensive operator training, regular equipment maintenance and inspection (including pre-operational checks), and careful site assessments to identify potential hazards. For example, ensuring the boom is properly secured and retracted before driving the truck, as well as performing detailed pre-shift checks, is vital. We conduct safety training regularly, emphasizing risk assessment and hazard recognition to prevent these accidents.

Q 12. Describe your experience with using fall protection equipment and safety harnesses.

I’m proficient in using various fall protection equipment, including full-body harnesses, lanyards, and shock absorbers. Before each lift, I carefully inspect the harness and other equipment, ensuring they’re in excellent condition and properly secured. The harness is always double-checked by a spotter before any ascent. I understand the critical role fall protection plays in mitigating risks associated with working at heights. The process is similar to a pilot performing pre-flight checks; it’s non-negotiable and critical for everyone’s safety. Regular training and practical demonstrations keep my skills and knowledge sharp in this area.

Q 13. Explain the proper techniques for maneuvering an aerial bucket truck in tight spaces.

Maneuvering in tight spaces requires planning and precision. I use a combination of slow, controlled movements, careful observation of surroundings, and effective communication with ground personnel. Understanding the truck’s turning radius and the limitations of the boom’s articulation are crucial. In confined areas, I avoid sharp turns and sudden movements, preferring gradual adjustments. Prior to entering a tight space, I’ll assess the area, looking for obstacles and calculating the optimal path. We also use spotters to guide the truck and warn of any potential obstructions. The process is like driving a large vehicle in a parking lot – slow and deliberate movements are key to avoiding collisions and damage.

Q 14. How do you perform daily maintenance checks on an aerial bucket truck?

Daily maintenance checks are a cornerstone of safe operation. These checks, conducted before each shift, include inspecting tires, fluids (oil, coolant, hydraulic fluid), brakes, lights, and the boom’s functionality. I also carefully examine the bucket’s condition, ensuring all safety features, such as railings and gates, are secure and working properly. The checklist I follow is comprehensive, covering every critical component. Any unusual wear and tear, leaks, or malfunctions are immediately reported and addressed to prevent potential failures during operation. It’s a thorough process, similar to a mechanic’s pre-flight check on an aircraft; it’s preventative maintenance, and it’s crucial for operational safety and efficiency.

Q 15. What are the signs of a malfunctioning aerial bucket truck, and what actions should be taken?

Recognizing a malfunctioning aerial bucket truck is crucial for safety. Malfunctions can range from subtle issues to outright failures. Signs can include unusual noises (grinding, squealing, or knocking), hydraulic leaks (oil stains or drips), erratic boom movement (jerky or unresponsive), malfunctioning controls (buttons sticking or unresponsive), warning lights illuminating on the dashboard, and problems with the outriggers (uneven deployment or instability).

- Unusual Noises: Grinding noises often indicate worn gears or bearings, while squealing might signal a hydraulic pump issue or brake problems. Knocking sounds could suggest loose components or a more serious structural issue.

- Hydraulic Leaks: Leaking hydraulic fluid is a serious problem as it compromises the stability and function of the boom. Address this immediately.

- Erratic Boom Movement: Jerky or unresponsive movements could indicate problems with hydraulic lines, valves, or the control system itself.

- Malfunctioning Controls: Faulty controls can lead to unexpected movements of the boom and pose a significant safety risk.

- Warning Lights: Always heed warning lights; they are there for a reason! Immediately investigate and address the issue before proceeding.

- Outrigger Problems: Unstable outriggers are a major safety hazard, leading to the risk of tipping.

Actions to Take: If any of these signs are present, immediately shut down the aerial bucket truck, lower the boom completely, secure the vehicle (engage parking brake, chock wheels, etc.), report the issue to the supervisor, and do not attempt any repairs unless you are qualified to do so. A qualified mechanic should inspect the truck before it’s used again. This prevents further damage and avoids accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with different types of aerial bucket truck attachments and their applications?

I’m very familiar with various aerial bucket truck attachments. Their choice depends greatly on the job at hand. Some common attachments include:

- Insulated Buckets: Used for working on energized lines, these buckets are designed to protect the operator from electrical shock. The insulation level is crucial and must match the voltage of the line being worked on.

- Aerial Platforms: Standard platforms provide a stable workspace for various tasks. Some are designed for specific weights and sizes of equipment.

- Material Handling Attachments: Hooks, grapples, and winches allow for efficient handling of materials like cables, wires, and tools. Weight limits are paramount here to prevent overloading the truck.

- Articulating Buckets: Offer greater reach and maneuverability compared to standard buckets, useful in confined spaces or for accessing hard-to-reach areas.

- Specialized Tool Trays: Provide secure storage for frequently used tools, keeping the workspace organized and safe.

The application of each attachment is specific to the task. For instance, when working on high-voltage lines, only an insulated bucket with proper safety protocols is acceptable. When dealing with heavy loads, careful attention must be paid to weight capacities. Selecting the appropriate attachment ensures safety, efficiency, and compliance with safety standards.

Q 17. Describe your experience with troubleshooting common aerial bucket truck problems.

Troubleshooting is a key skill for aerial bucket truck operators. I have extensive experience addressing a range of issues, such as:

- Hydraulic System Problems: Identifying leaks, addressing low hydraulic fluid levels, and checking for blockages in the hydraulic lines and filters.

- Electrical Issues: Troubleshooting malfunctions in the control system, lights, and other electrical components. This often involves using a multimeter to check circuits and identify faulty components.

- Boom Problems: Diagnosing issues related to boom movement (e.g., jerky movements, failure to extend or retract). This may involve checking hydraulic cylinders, hoses, and control valves.

- Outrigger Problems: Addressing issues with outrigger deployment, retraction, and stability. Ensuring proper leveling and stability before operation is critical.

For example, I once encountered a situation where the boom wouldn’t retract smoothly. Through systematic troubleshooting (checking hydraulic fluid levels, inspecting hoses for kinks, and checking the control system), I identified a faulty hydraulic valve. Knowing the appropriate safety procedures and having the necessary tools allowed for a quick and safe resolution. I always prioritize safety, and if a problem is beyond my expertise, I defer to a qualified mechanic.

Q 18. Explain the process of securing the aerial bucket truck before leaving the worksite.

Securing an aerial bucket truck at the end of a workday is critical for safety. The process involves a series of steps:

- Lower the Boom: Completely lower the aerial boom to its resting position.

- Retract Outriggers: Fully retract all outriggers and ensure they are securely stowed.

- Lower the Bucket: If a bucket is attached, lower it completely to the ground.

- Engage Parking Brake: Engage the parking brake firmly.

- Chock the Wheels: Place wheel chocks behind and in front of the wheels to prevent rolling.

- Turn Off All Systems: Turn off the engine, hydraulics, and any other power systems.

- Remove Attachments (If Necessary): If any attachments are used, remove them and store them properly.

- Secure the Truck: Lock the truck, keeping keys in a secure location.

- Inspect for Hazards: Before leaving, conduct a final inspection of the immediate area for any potential hazards or loose equipment.

This routine safeguards the equipment from theft, vandalism, and accidental movement, ensuring workplace safety.

Q 19. What are your experiences with working on energized lines or near high voltage equipment?

Working on or near energized lines or high-voltage equipment requires specialized training, certification, and strict adherence to safety protocols. My experience in this area includes working on energized lines under the direct supervision of a qualified supervisor, using specialized insulated equipment, and employing proper lockout/tagout procedures (discussed in the next question). I have a detailed understanding of the risks associated with this type of work, including the potential for severe electric shock, burns, and falls. My work always prioritizes safety, and I would never undertake such work without proper training, supervision, and the correct safety equipment.

It’s essential to remember that even seemingly de-energized lines can retain hazardous voltages. Always treat all lines as energized unless explicitly confirmed otherwise by a qualified electrician using proper testing equipment.

Q 20. How do you ensure compliance with OSHA regulations and other relevant safety standards?

Compliance with OSHA regulations and other relevant safety standards is paramount in aerial bucket truck operation. This involves many aspects, including:

- Regular Inspections: Conducting daily pre-operational inspections to identify any potential hazards or malfunctions, keeping a detailed log of these inspections.

- Training and Certification: Maintaining current certifications in aerial lift operation and relevant safety training, such as OSHA 10 or 30.

- Personal Protective Equipment (PPE): Consistent use of appropriate PPE, including hard hats, safety glasses, gloves, high-visibility clothing, and fall protection equipment.

- Safe Operating Procedures: Strict adherence to established safe operating procedures, including appropriate boom angles, weight limits, and working distances.

- Risk Assessments: Conducting thorough risk assessments before commencing any work, identifying and mitigating potential hazards.

- Emergency Procedures: Being fully aware of and trained in emergency procedures, including rescue and evacuation plans.

Compliance isn’t just a set of rules; it’s a commitment to safety that protects both myself and others in the workplace.

Q 21. Describe your experience with lockout/tagout procedures for aerial bucket trucks.

Lockout/Tagout (LOTO) procedures are fundamental when working on or near equipment that could cause injury. In the context of aerial bucket trucks, this primarily applies when performing maintenance or repair work on the truck itself or on equipment powered by the truck’s hydraulic or electrical systems. The process usually follows these steps:

- Preparation: Identify the energy source(s) to be controlled (hydraulic, electrical). Identify the appropriate LOTO devices (locks, tags).

- Shutdown: Shut down all energy sources to the equipment and machinery involved.

- Isolation: Isolate the energy source, ensuring that it cannot be accidentally reactivated.

- Lockout/Tagout: Apply locks and tags to the energy isolation devices, indicating that the equipment is locked out and cannot be operated.

- Verification: Verify that the energy is completely isolated by testing or other appropriate means.

- Work Performance: Perform the necessary maintenance or repair work.

- Lockout/Tagout Removal: Only the person who applied the lockout/tagout devices can remove them, ensuring that all work is completed safely and the energy source can be safely re-engaged. Each person involved should check their work to ensure they did not miss anything before removing their tag or lock.

- Start-up: Carefully restore the power and operation of the equipment.

- Verification: Verify that the equipment is functioning correctly after the energy source has been restored.

Proper LOTO procedures are crucial for preventing accidental start-ups during maintenance or repairs, ensuring the safety of all personnel involved.

Q 22. How do you handle challenging situations, such as difficult terrain or adverse weather conditions?

Safety is paramount when operating an aerial bucket truck in challenging conditions. My approach involves a multi-step process starting with a thorough risk assessment. This includes evaluating the terrain for potential hazards like uneven ground, soft soil, or obstacles. For adverse weather, factors like wind speed, rain, ice, and visibility are crucial.

For difficult terrain, I’d choose the most stable approach path, potentially using ground personnel to spot and guide me. I’d ensure the outriggers are properly positioned and extended, maximizing stability. In strong winds, I wouldn’t operate the truck unless absolutely necessary, and would constantly monitor wind speed and direction using an anemometer, following company safety protocols. In icy conditions, I’d prioritize safety and likely postpone the work unless it’s an emergency. If operation is required, I’d proceed with extreme caution, potentially employing additional safety measures like sandbags or chains for enhanced stability.

Imagine working on a hillside during a light rain. I’d first assess the slope, choose a level spot for the outriggers, and use the truck’s stabilizing features to the fullest extent. I’d then communicate clearly with my ground crew, ensuring their cooperation in spotting any unforeseen hazards and ensuring safety. Continuous monitoring throughout the operation is crucial. A rigorous post-job inspection, including the truck and the work area, is the final step, making sure everything is secure and safe.

Q 23. What are your skills in using aerial bucket trucks for specific tasks, such as line maintenance or tree trimming?

My experience with aerial bucket trucks spans various tasks, including line maintenance and tree trimming. For line maintenance, I’m proficient in using the bucket to access power lines for inspection, repair, and installation of new equipment. This involves careful maneuvering of the bucket to avoid contact with lines and using insulated tools to prevent electrical shock.

Tree trimming requires a different approach. I’m skilled in using the bucket to safely position myself and equipment near trees, enabling efficient and safe pruning. Here, precise control and awareness of surroundings, including potential obstacles and powerlines, are vital. I always coordinate with ground crew for proper communication and safety. For example, during line maintenance, I’d use specialized tools like hot sticks and insulated gloves to ensure safety when working near energized conductors. During tree trimming, I’d use various cutting tools, ensuring the work is done without damaging the power lines.

Safety is always at the forefront; I’d never compromise my safety or that of others for efficiency.

Q 24. How do you maintain accurate records and documentation related to aerial bucket truck operations?

Maintaining accurate records is non-negotiable in aerial bucket truck operations. I utilize both digital and paper-based systems to meticulously document every aspect of my work. This includes pre-operational checklists which I would complete before any operation, daily inspection reports detailing the truck’s condition and any repairs, and detailed job reports documenting the tasks performed, materials used, and any incidents or near misses.

Digital documentation frequently utilizes job management software, allowing for efficient recording and retrieval of information. Paper records are kept in organized files, often stored in a secure location for regulatory compliance. Crucially, both digital and paper-based records maintain the same information for redundancy. This detailed documentation is essential for safety audits, insurance claims, and tracking operational efficiency. For example, if a component needs replacement, I’d record the date of the issue, the replaced part’s serial number, and details about the repair in both the daily inspection report and the job report.

Q 25. Describe your experience in working as part of a team during aerial bucket truck operations.

Teamwork is the foundation of safe and efficient aerial bucket truck operations. Clear communication is paramount. I thrive in collaborative environments, always ready to listen to and learn from my colleagues. My role involves not only operating the truck but also actively participating in pre-job briefings, providing updates during the operation, and participating in post-job debriefings.

I’ve been part of teams where everyone has specific roles and responsibilities—ground personnel for spotting and traffic control, supervisors for overseeing the operation, and myself as the operator. Effective teamwork ensures a smooth workflow and prevents potential accidents. For example, during a tree trimming project, I’d rely on the spotters’ guidance to ensure the bucket’s positioning is safe and efficient, preventing accidental contact with the power lines or the tree itself. My feedback about the work conditions from the bucket helps my ground crew adjust their actions.

Q 26. Explain your understanding of the different types of insulators and their purpose.

Insulators are critical components in electrical systems, designed to prevent the flow of electricity between conductors or between a conductor and the ground. Different types of insulators are used depending on the voltage level and environmental conditions.

- Pin-type insulators: Commonly used on transmission lines, these insulators are shaped like a stack of discs and designed to withstand high voltages. They support the conductor and keep it isolated from the supporting structure.

- Suspension insulators: Used extensively in high-voltage transmission lines. They consist of several disc insulators strung together, providing greater overall insulation strength and flexibility.

- Strain insulators: Designed to handle the tension of the transmission lines where they change direction or connect to towers.

- Bushings: Insulators that pass conductors through a wall (for example, in transformers).

Understanding the different types and their limitations is vital for safe operation. For example, using an insulator with insufficient voltage rating could lead to electrical flashover and serious consequences. Proper selection of insulators is critical for both safety and system reliability.

Q 27. How do you perform a thorough inspection of the aerial bucket truck’s electrical system?

A thorough inspection of the aerial bucket truck’s electrical system is essential for safe operation. My inspection follows a structured process, beginning with a visual check of all wiring harnesses, connectors, and components for any signs of damage, wear, or loose connections. I’d then check the battery terminals for corrosion and proper connections. Next, I’d test the functionality of all electrical systems, including lights, wipers, and the bucket’s controls. I’d also check the insulation on wires for any signs of degradation. Any issues found are immediately addressed.

Furthermore, using a multimeter, I’d check voltage and current levels at various points in the system, confirming that everything is operating within the specified parameters. Any deviation needs further investigation. Specialized equipment like a high-voltage tester may be employed if dealing with high-voltage components. A meticulous approach prevents electrical malfunctions during operation, which can have serious safety repercussions.

Q 28. What is your experience with using specialized tools and equipment related to aerial bucket truck operation?

My experience encompasses a broad range of specialized tools and equipment integral to aerial bucket truck operation. This includes various types of insulated tools for working on energized lines, like hot sticks and insulated pliers. I am familiar with different types of cutting tools such as chain saws and pole saws, used for tree trimming. I am also skilled in using aerial lifts and specialized equipment like rope access gear for difficult locations.

Equipment knowledge extends to diagnostic tools such as multimeters, clamp meters, and high-voltage testers. The proper use of these tools ensures accurate assessment of electrical systems, preventing safety hazards. For example, using the correct size and type of insulated gloves is crucial to prevent electrical shocks while working near power lines. Similarly, proficiency with specialized cutting tools is essential for efficient and safe tree trimming operations near power lines. Regular training and familiarization with new tools are ongoing parts of my professional development.

Key Topics to Learn for Aerial Bucket Truck Operation Interview

- Vehicle Operation & Maintenance: Understanding the mechanics, pre-operation checks (daily inspections), and troubleshooting common mechanical issues. This includes familiarity with hydraulic systems, electrical components, and safety devices.

- Safety Procedures & Regulations: Deep knowledge of OSHA regulations, fall protection, lockout/tagout procedures, and emergency response protocols specific to aerial bucket truck operation. Practical application includes explaining how you’d handle a specific safety hazard.

- Aerial Lift Operation & Positioning: Mastering the techniques of safe and efficient bucket operation, including understanding load limits, proper positioning for various tasks (e.g., trimming trees, power line maintenance), and working safely at heights.

- Job Site Awareness & Communication: Demonstrating an understanding of working around power lines, other equipment, and personnel. This includes clear communication with ground crews, supervisors, and other stakeholders on the job site.

- Advanced Techniques & Problem-Solving: Being able to explain how you would handle unexpected situations, such as equipment malfunctions, adverse weather conditions, or complex rigging requirements. This showcases your problem-solving skills and ability to adapt.

- Understanding different types of aerial lifts: Familiarity with various aerial lift types and their applications. This demonstrates a broad understanding of the industry and equipment.

Next Steps

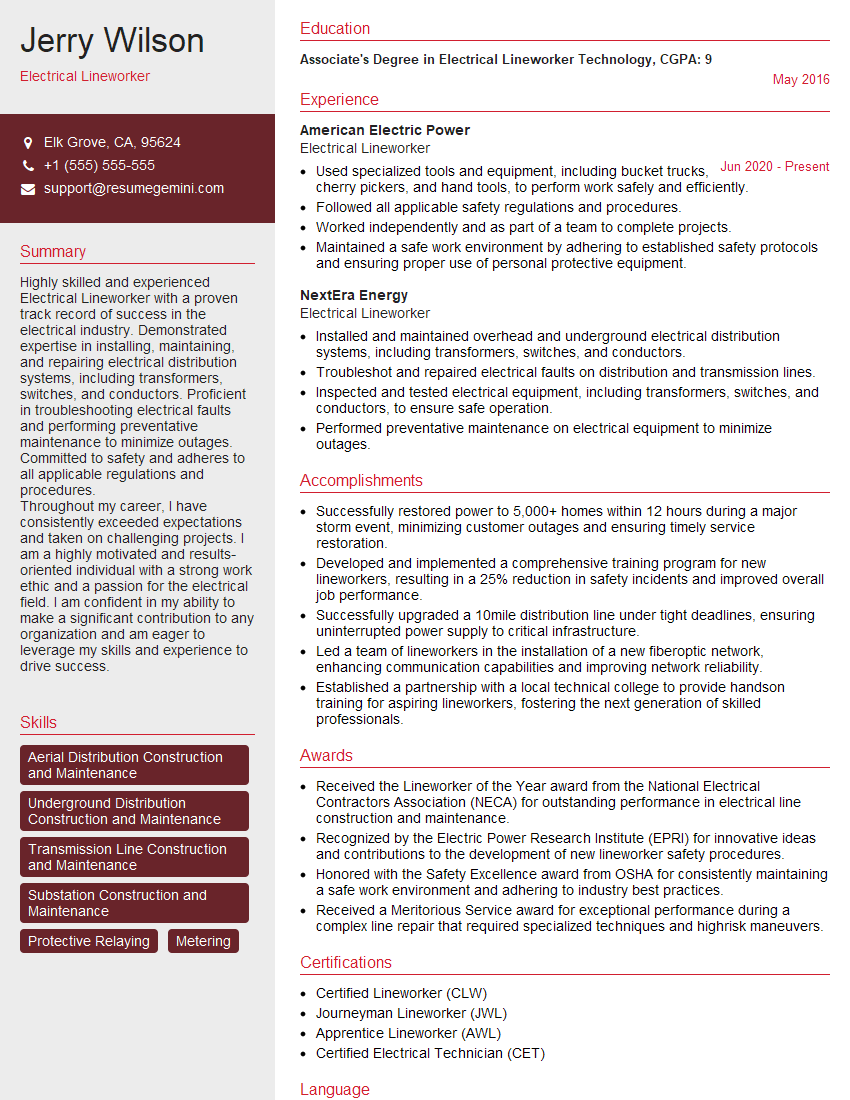

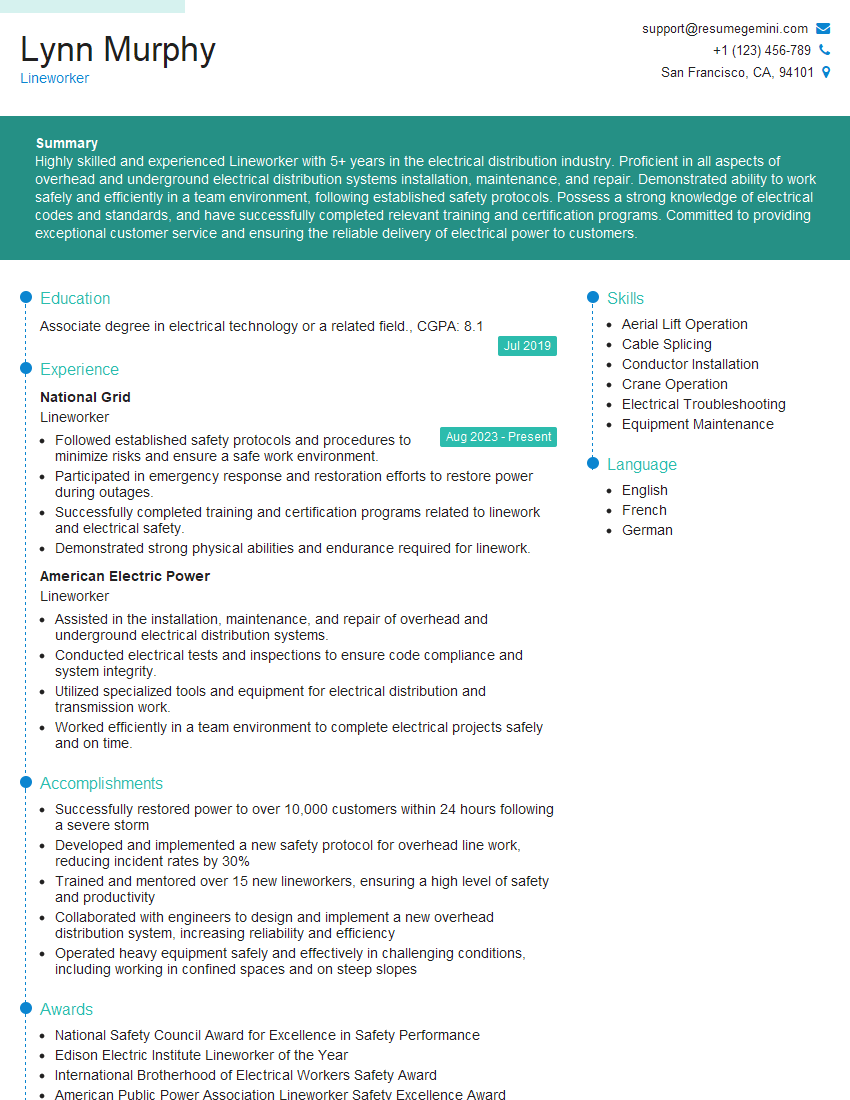

Mastering Aerial Bucket Truck Operation opens doors to a rewarding career with excellent earning potential and opportunities for advancement. The demand for skilled operators is consistently high, making it a valuable and sought-after profession. To maximize your job prospects, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is essential to ensure your application gets noticed by potential employers. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Aerial Bucket Truck Operation are provided to guide you in building your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good