Cracking a skill-specific interview, like one for Loading and Unloading Pads, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Loading and Unloading Pads Interview

Q 1. Describe your experience with different types of loading and unloading equipment.

My experience encompasses a wide range of loading and unloading equipment, from basic hand trucks and pallet jacks to sophisticated automated systems. I’m proficient with forklifts of various capacities, reach trucks for high-bay warehousing, and conveyor belt systems for high-volume operations. I’ve also worked extensively with specialized equipment like crane systems for oversized or heavy loads, and even robotic arms in highly automated facilities. Each piece of equipment demands a unique skill set and safety protocol, and I’ve always prioritized safe and efficient operation above all else. For instance, working with forklifts requires a thorough understanding of weight capacity, load stability, and maneuvering in confined spaces. My experience includes regular maintenance checks and troubleshooting common malfunctions to ensure minimal downtime. With automated systems, my expertise lies in programming, monitoring their performance, and identifying areas for optimization.

Q 2. Explain your understanding of safety regulations related to loading and unloading pads.

Safety is paramount in loading and unloading operations. My understanding of safety regulations is comprehensive, covering OSHA standards, company-specific policies, and best practices within the industry. This includes adhering to speed limits for equipment, wearing appropriate Personal Protective Equipment (PPE) like high-visibility vests, safety shoes, and hard hats. Proper load securing techniques are crucial to prevent accidents. I am well-versed in the use of appropriate load-securing devices such as straps, chains, and dunnage to prevent shifting during transit. Furthermore, I understand the importance of maintaining a clean and organized work environment to minimize tripping hazards and ensuring adequate lighting to improve visibility. Regular safety inspections of the loading and unloading pads themselves are essential, looking for cracks, uneven surfaces, and potential obstructions. Proper training and certification on all equipment used are fundamental to safe operation. In short, safety is not just a checklist but a mindset integrated into every step of the process.

Q 3. How do you ensure efficient loading and unloading processes?

Efficient loading and unloading hinges on meticulous planning and execution. It starts with optimized space utilization on the loading pad and within the vehicles. I always ensure proper pre-planning by reviewing the shipping manifest and confirming the order of goods for easy access. Clear communication with drivers and warehouse staff is crucial to avoid bottlenecks. Techniques like cross-docking, where goods are transferred directly from one truck to another, can significantly reduce handling time. Using barcode scanners or RFID tags for tracking inventory streamlines the process and minimizes errors. Employing efficient loading patterns, such as stacking heavy items lower and lighter items higher for stability, improves both efficiency and safety. Regular monitoring of the loading and unloading process using time-motion studies can identify areas for improvement and lead to process refinements. For example, rearranging the layout of the loading bay or implementing a different loading sequence can improve flow and reduce wait times.

Q 4. What methods do you use to prevent damage to goods during loading and unloading?

Preventing damage to goods requires a multi-pronged approach. This begins with proper packaging and handling from the outset. Using protective materials such as bubble wrap, cardboard inserts, and corner protectors minimizes damage during transit. Equipment operation must be meticulous. Forklifts should be used with care to avoid impacts or sudden movements. Pallet jacks need to be maneuvered smoothly to prevent tipping or dropping loads. Proper load securing techniques are essential to prevent shifting and jostling within trucks. Using appropriate dunnage (protective filler material) between stacked goods can greatly reduce the risk of damage. Furthermore, environmental conditions must be taken into account. Protecting sensitive items from extreme temperatures, moisture, or sunlight is crucial. Careful attention to detail throughout the process minimizes the risk of product damage and ensures that goods arrive in perfect condition.

Q 5. How do you handle discrepancies between the shipping manifest and the actual load?

Discrepancies between the shipping manifest and the actual load are handled with a methodical approach. First, a thorough recount and inspection of the goods are conducted. Any discrepancies are meticulously documented, noting the missing or extra items and their corresponding details. Then, I would immediately notify the relevant parties, such as the shipping company, the warehouse manager, and potentially the client. Photographs and video evidence can be crucial in supporting the discrepancy report. Depending on the nature of the discrepancy, different resolutions may be implemented. It could involve a return of excess goods, a request for missing goods, or a revised shipping manifest. Clear communication and documentation throughout the process are essential to ensure a swift and fair resolution. In some cases, an independent audit may be necessary to confirm the discrepancies and establish accountability. The goal is to ensure accuracy and prevent future issues by identifying potential weaknesses in the inventory management system.

Q 6. Describe your experience with different types of loading and unloading techniques.

My experience includes various loading and unloading techniques tailored to different goods and situations. For palletized goods, efficient stacking techniques and the use of forklifts are standard. For bulk goods, specialized equipment like conveyors or chutes may be used. For delicate or fragile items, hand-loading with extra care is often necessary. I’m also adept at using different loading patterns such as block stacking for stability, interleaving (placing cushioning material between layers) for protection, and optimizing weight distribution to prevent overloading on one side of a vehicle. The choice of technique depends on factors such as the type of goods, the quantity, the vehicle used, and the available equipment. I’ve even implemented specific techniques for loading and unloading refrigerated goods to maintain their temperature integrity. My approach is flexible and adaptable to a wide array of circumstances, always prioritizing safety and efficiency.

Q 7. How do you prioritize tasks during peak loading and unloading periods?

During peak periods, prioritization is key. This involves using a system that optimizes workflow. I typically prioritize shipments with strict deadlines or those containing perishable goods. Utilizing a first-in, first-out (FIFO) system ensures that the oldest shipments are processed first. Real-time tracking of incoming and outgoing shipments aids in making informed decisions about task allocation. Clearly communicating priorities to the team prevents confusion and ensures everyone is working towards the same goals. In some cases, utilizing additional resources, such as temporary staff or extra equipment, may be necessary to handle the increased volume. Regular communication and coordination with drivers and warehouse staff prevents bottlenecks. Flexible scheduling and adapting to unexpected situations are crucial for smooth operations during peak demand. The key is to maintain a calm and organized approach, systematically addressing tasks in a way that minimizes delays and maximizes efficiency.

Q 8. How do you maintain a clean and organized loading and unloading area?

Maintaining a clean and organized loading and unloading area is crucial for safety, efficiency, and preventing damage to goods. Think of it like a well-oiled machine – if parts are scattered and dirty, the whole system breaks down. My approach involves a multi-pronged strategy.

- Designated Areas: Clearly marked zones for different types of cargo, staging areas for awaiting shipments, and designated waste disposal points prevent clutter and confusion.

- Regular Cleaning Schedule: A daily sweep and scheduled deeper cleans (weekly or bi-weekly, depending on volume) remove debris, spills, and potential hazards. This includes cleaning docks, ramps, and surrounding areas.

- Proper Waste Management: Implementing a system for separating and disposing of different types of waste – cardboard, plastic, pallets – ensures efficient waste removal and reduces environmental impact.

- Equipment Maintenance: Regular maintenance of loading equipment like forklifts and pallet jacks ensures they’re functioning optimally and minimizes the risk of leaks or spills.

- Employee Training: Employees are trained on proper procedures for maintaining cleanliness and organization, including the importance of immediately cleaning up spills or debris.

For example, in my previous role, we implemented a color-coded system for waste bins, simplifying sorting and making the process intuitive for all team members. This led to a significant reduction in cleaning time and a cleaner, safer work environment.

Q 9. Explain your experience working with various types of cargo.

My experience encompasses a wide variety of cargo, from delicate electronics and pharmaceuticals requiring climate control to heavy machinery and palletized goods. I’ve adapted my techniques to ensure the safe handling of each type.

- Fragile Goods: These require specialized handling, including extra padding, careful stacking, and potentially the use of air-ride suspensions in transport. I’ve worked with high-value electronics, ensuring every item is handled with extreme care, using protective materials and documenting each step.

- Hazardous Materials: Handling hazardous materials demands strict adherence to safety regulations, including proper labeling, storage, and use of appropriate personal protective equipment (PPE). I have experience with the transportation of chemicals, adhering to all relevant transportation regulations.

- Bulk Goods: Efficient loading and unloading of bulk goods, like grains or powders, requires specialized equipment and procedures to prevent damage and spillage. I have managed the loading and unloading of bulk goods, ensuring proper weighing and documentation.

- Oversized/Heavy Cargo: This necessitates specialized equipment like cranes and rigging techniques, careful planning of load distribution, and awareness of weight limits. I have successfully managed the loading and unloading of oversized machinery, collaborating with specialized equipment operators and engineers.

The key is adaptability and attention to detail. Each cargo type presents unique challenges, and success hinges on understanding those challenges and tailoring your approach accordingly.

Q 10. How do you manage inventory control during the loading and unloading process?

Inventory control during loading and unloading is essential for accuracy and efficiency. It’s like a carefully orchestrated dance where every piece must be accounted for. My process involves:

- Pre-loading Verification: Comparing the packing list against the manifest ensures the correct goods are being loaded. This often involves using barcode scanners or handheld devices.

- Real-time Tracking: Using WMS or similar inventory management systems provides real-time visibility of inventory levels. This allows for immediate detection of discrepancies during loading/unloading.

- Post-loading Reconciliation: After loading, a final count is conducted to verify the number of items loaded against the manifest. Any discrepancies are immediately noted and investigated.

- Damage Reporting: Any damages discovered during the process are immediately reported and documented, including photos or videos, to support claims and track potential sources of damage.

- Regular Audits: Periodic physical inventory checks reconcile system records with physical stock to identify any potential inconsistencies.

For instance, in a previous role, we utilized a WMS that integrated with our shipping software. This real-time data flow minimized errors and improved the accuracy of our inventory records, leading to faster processing times and fewer discrepancies.

Q 11. How do you handle damaged goods during loading and unloading?

Handling damaged goods requires a systematic approach to minimize losses and maintain accountability. My process includes:

- Immediate Documentation: Thoroughly documenting all damage, including taking photos or videos, noting the extent of the damage, and identifying the affected items. This is crucial for insurance claims.

- Segregation: Damaged goods are segregated from undamaged goods to prevent further damage or contamination. They are typically stored in a designated area.

- Damage Assessment: A thorough assessment determines the extent of the damage and the potential for repair or salvage. This might involve consultations with engineers or quality control personnel.

- Reporting and Investigation: A formal report is filed, detailing the damage, its cause (if known), and the steps taken to mitigate further damage. An investigation may be launched to identify the root cause of the damage and prevent future occurrences.

- Disposal or Return: Depending on the assessment, the damaged goods may be disposed of appropriately or returned to the supplier for credit or replacement.

In one instance, we discovered damaged pallets during unloading. By immediately documenting the damage and investigating, we found a flaw in the pallet stacking procedure. By adjusting our methods, we eliminated the problem completely.

Q 12. Describe your experience using warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with several different systems, adapting my skills to efficiently leverage their capabilities. WMS streamlines inventory management, tracking, and reporting, improving overall efficiency. Key aspects of my WMS experience include:

- Inventory Management: Using WMS for tracking inventory levels, location tracking, and managing stock rotation. This minimizes storage costs and reduces the risk of stockouts.

- Order Fulfillment: Utilizing the WMS to generate picking lists, optimizing picking routes, and managing the order fulfillment process from receipt to shipment. This leads to faster processing and improved accuracy.

- Reporting and Analytics: Leveraging the reporting capabilities of the WMS to analyze key performance indicators (KPIs), identify areas for improvement, and make data-driven decisions.

- Integration with other systems: Successfully integrating the WMS with other enterprise resource planning (ERP) systems and transportation management systems (TMS) to ensure seamless data flow across the supply chain.

For example, I was instrumental in implementing a new WMS in my previous company. This resulted in a 20% reduction in order fulfillment times and a significant improvement in inventory accuracy.

Q 13. How do you ensure the security of goods during loading and unloading?

Ensuring the security of goods during loading and unloading is paramount. This requires a layered approach, combining physical security with procedural controls. My strategies include:

- Access Control: Restricting access to the loading and unloading area to authorized personnel only, using security gates, access cards, or surveillance systems.

- Surveillance: Implementing CCTV cameras to monitor activity in the loading dock area, providing visual deterrence and a record of events. This aids in incident investigation.

- Security Personnel: Employing security guards, particularly during overnight or high-risk periods, to deter theft and vandalism.

- Secure Storage: Providing secure storage for goods that are not immediately being loaded or unloaded, especially high-value or sensitive items. This could involve locked containers or secured warehouses.

- Regular Audits: Conducting regular inventory audits to identify any discrepancies and potential security breaches.

- Employee Training: Educating employees about security procedures, including reporting suspicious activities and the proper handling of valuable items.

In a previous role, we implemented a system combining security cameras with motion sensors, instantly alerting security personnel to any unauthorized entry. This proactive measure significantly reduced the risk of theft.

Q 14. What are your strategies for preventing accidents in the loading and unloading area?

Preventing accidents in the loading and unloading area is a top priority. A proactive approach, combining safety procedures with employee training, is crucial. My strategies focus on:

- Proper Training: Providing comprehensive safety training to all personnel involved in loading and unloading, including forklift operation, safe lifting techniques, and hazard awareness.

- Clear Signage and Markings: Utilizing clear signage to indicate speed limits, pedestrian walkways, and hazardous areas, promoting a visual understanding of safety protocols.

- Equipment Maintenance: Regular inspection and maintenance of loading equipment, including forklifts, pallet jacks, and dock levelers, to ensure they are in safe operating condition.

- Safe Loading Procedures: Implementing standardized procedures for loading and unloading, including secure stacking techniques and the use of appropriate safety equipment like straps and restraints.

- Hazard Identification and Mitigation: Regularly conducting safety inspections to identify potential hazards, such as uneven surfaces, damaged equipment, or poor lighting, and taking steps to mitigate these risks.

- Personal Protective Equipment (PPE): Ensuring that all personnel use appropriate PPE, such as safety vests, gloves, and safety shoes, to protect themselves from injury.

For example, in one case, we identified a blind spot near a dock door. By installing a mirror and rearranging equipment, we significantly reduced the risk of pedestrian-vehicle accidents.

Q 15. How do you work effectively with other team members during loading and unloading?

Effective teamwork during loading and unloading is crucial for efficiency and safety. It’s all about clear communication, shared responsibility, and mutual respect. I believe in a collaborative approach, where everyone understands their role and works together seamlessly.

- Pre-load planning: Before we even begin, I ensure that everyone understands the loading plan, including the sequence of items, weight distribution, and any special handling requirements. This often involves a quick team meeting to clarify any questions.

- Clear assignments: I delegate tasks based on individual strengths and experience, ensuring everyone feels valued and empowered. For instance, someone particularly adept at securing loads might take the lead on that aspect, while others focus on efficient stacking and palletizing.

- Continuous communication: Throughout the process, open and constant communication is key. This can be anything from a simple ‘heads up’ before moving a heavy item to discussing any unexpected challenges that arise. I am always receptive to suggestions and feedback from my team members.

- Safety first: Safety is paramount. I actively monitor everyone’s actions, ensuring that all safety protocols are followed, such as using appropriate lifting techniques and wearing protective gear. I’m not afraid to stop the process if I see any unsafe practices.

For example, during a recent project involving oversized equipment, I coordinated with my team to create a custom loading plan that addressed weight distribution and securement concerns. By working together and proactively addressing potential challenges, we completed the loading safely and efficiently.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with drivers and other stakeholders?

Effective communication with drivers and stakeholders is the cornerstone of successful loading and unloading operations. I strive for clear, concise, and respectful communication at all times, adapting my approach based on the audience and situation.

- Pre-trip briefing: Before the driver arrives, I ensure that I have all necessary paperwork, including manifests and delivery instructions, ready. I then brief the driver on the specifics of the load, including the quantity, weight, and any special handling instructions.

- Clear and concise instructions: I use simple, direct language to explain procedures and avoid industry jargon. For example, instead of saying ‘ensure proper dunnage placement’, I would say, ‘Make sure the wood supports are properly positioned under the load to prevent shifting’.

- Active listening: I listen attentively to drivers’ concerns or questions, addressing them promptly and professionally. Sometimes, drivers have valuable insights that can improve efficiency or safety.

- Documentation: I maintain detailed records of all communication, including any issues that arise. This allows for clear traceability and accountability.

For instance, I once had to explain to a driver the proper procedure for securing a load of fragile items. By using clear visuals and demonstrating the techniques, I was able to build trust and ensure the safe transport of the goods.

Q 17. What are your experience with different types of packaging?

My experience encompasses a wide range of packaging types, from simple corrugated boxes to specialized crates and containers. Understanding the different materials and their strengths and weaknesses is crucial for safe and efficient handling.

- Corrugated cardboard: I’m experienced in handling various grades and sizes of corrugated boxes, aware of their limitations in terms of weight and stacking height.

- Wooden crates and pallets: I’m proficient in inspecting wooden crates and pallets for damage, ensuring they meet safety standards and are suitable for the load.

- Plastic containers and shrink wrap: I have expertise in using plastic containers and shrink wrap to secure and protect goods during transport.

- Specialized packaging: I’ve worked with specialized packaging for delicate or hazardous materials, understanding the specific handling requirements for each.

For example, I once handled a shipment of antique furniture requiring custom-built crates with interior bracing to protect them from damage during transport. My experience allowed me to oversee the proper packaging and ensure a safe arrival.

Q 18. How do you resolve conflicts related to loading and unloading operations?

Conflicts during loading and unloading operations are best addressed through calm, professional communication and a focus on finding mutually agreeable solutions.

- Identify the root cause: The first step is to identify the underlying cause of the conflict. This might be a misunderstanding, a scheduling issue, or a problem with equipment.

- Active listening: Listen carefully to all parties involved, trying to understand their perspectives and concerns.

- Collaborative problem-solving: Work with all parties involved to develop a solution that addresses everyone’s needs and concerns.

- Documentation: Document all aspects of the conflict, including the resolution and any agreed-upon actions.

For instance, I once had a conflict between two team members over the correct stacking procedure for a particular product. By listening to both sides and reviewing the relevant guidelines, we were able to reach a consensus that ensured both safety and efficiency.

Q 19. How do you maintain accurate records of loading and unloading activities?

Maintaining accurate records is vital for accountability, traceability, and efficient inventory management. I use a combination of digital and physical methods to ensure accurate record-keeping.

- Digital tracking systems: I’m proficient in using various software programs and inventory management systems to track loading and unloading activities, recording shipment details, quantities, and timestamps.

- Paper-based documentation: I also use paper-based forms and checklists to record relevant information, especially in situations where digital access is limited.

- Regular reconciliation: I regularly reconcile the digital and physical records to ensure accuracy and identify any discrepancies.

- Data backup and archiving: I understand the importance of data backup and archiving to ensure data integrity and compliance with regulatory requirements.

For example, I utilize a barcode scanning system to track individual pallets throughout the loading process, automatically updating the inventory system with real-time data, minimizing the risk of errors.

Q 20. How familiar are you with load-bearing capacities of loading pads?

Understanding load-bearing capacities is fundamental to safe loading and unloading operations. I am well-versed in calculating load limits based on various factors and identifying potential safety hazards.

- Pad specifications: I am familiar with the load ratings provided by manufacturers for various types of loading pads, understanding the importance of selecting the appropriate pad for the intended load.

- Weight distribution: I understand how to distribute weight evenly across the loading pad to minimize stress and prevent damage.

- Environmental factors: I consider environmental factors such as ground conditions and weather conditions when assessing load-bearing capacities.

- Regular inspections: I advocate for regular inspections of loading pads to identify any signs of damage or deterioration that might affect load-bearing capacity.

For example, before loading a heavy piece of machinery onto a loading pad, I carefully calculate the weight distribution and ensure that the pad’s load rating is adequate for the task. If the pad is deemed unsuitable, I would initiate a procedure for using alternative equipment or reinforcing the loading area.

Q 21. What is your experience with different types of pallets and their handling?

Experience with various pallet types is essential for efficient and safe handling. I’m proficient in identifying, handling, and securing different pallet types based on their materials, construction, and load capacities.

- Wood pallets: I’m familiar with various sizes and types of wooden pallets, understanding their strengths, weaknesses, and proper handling techniques, including heat treatment and fumigation requirements for international shipments.

- Plastic pallets: I’m experienced in handling plastic pallets, understanding their advantages in terms of durability and hygiene, as well as their limitations regarding load capacity and potential for warping under extreme temperatures.

- Metal pallets: I have experience with metal pallets, aware of their exceptional strength and durability, but also their potential for damage to other goods if not handled carefully.

- Handling techniques: I’m proficient in using various equipment such as forklifts, pallet jacks, and conveyor systems for safe and efficient pallet handling.

For instance, I recently managed a shipment involving both wooden and plastic pallets. Knowing the differences in weight capacity and material properties, I organized the loading to optimize space and ensure the structural integrity of the load, preventing damage and delays.

Q 22. How do you identify and report safety hazards related to loading and unloading?

Identifying and reporting safety hazards in loading and unloading is paramount. My approach involves a proactive, multi-layered system. First, I conduct a thorough pre-operation inspection of the loading dock, equipment, and surrounding areas. This includes checking for potential trip hazards like loose materials, damaged flooring, or inadequate lighting. I also assess the condition of loading equipment, ensuring everything from forklifts to ramps is in proper working order and properly maintained. Secondly, I observe the loading and unloading process itself, looking for unsafe practices such as improper lifting techniques, unsecured loads, or insufficient communication between workers and drivers. Finally, I utilize checklists and reporting systems to document any identified hazards, immediately reporting any serious issues to supervisors. For example, if I notice a damaged ramp, I’d immediately halt operations and report it, preventing potential accidents. Any minor hazards, like loose cables, would be documented and addressed promptly. This system ensures a safe working environment for everyone involved.

Q 23. Describe your approach to problem-solving in a fast-paced loading and unloading environment.

Problem-solving in a fast-paced environment requires a structured approach. My strategy is based on the principle of prioritizing and acting swiftly. I first identify the root cause of the problem; this might be equipment malfunction, unexpected delays, or even poor communication. Once identified, I develop a prioritized list of solutions, focusing on the most critical issues first. For instance, if a forklift malfunctions causing a delay, my priority would be to either get it repaired quickly or find a replacement, before addressing secondary concerns. Efficient communication is crucial; I keep all stakeholders – supervisors, drivers, warehouse staff – informed of the situation and the steps being taken. Finally, I constantly reassess the situation and adjust my plan as needed, adapting to unforeseen developments with flexibility. This might involve reassigning tasks or modifying procedures to maintain productivity.

Q 24. How do you handle unexpected delays or disruptions in the loading and unloading process?

Unexpected delays are inevitable. My response involves a combination of proactive measures and reactive adaptations. I start by identifying the source of the delay – traffic congestion, late deliveries, or even unforeseen weather conditions. Then, I immediately communicate the delay to all relevant parties, including clients and internal teams. Transparency is key to managing expectations. Next, I explore options to mitigate the impact of the delay. This could involve re-prioritizing tasks, reallocating resources, or finding alternative transportation methods if necessary. For example, if a shipment is delayed due to traffic, I may coordinate with the driver to find alternative routes or adjust the loading schedule to accommodate the changed arrival time. The goal is always to minimize disruption and keep the overall operation running as smoothly as possible.

Q 25. What is your experience with specialized equipment for loading and unloading hazardous materials?

I have extensive experience handling specialized equipment for hazardous materials, including proper use of placards, safety data sheets (SDS), and personal protective equipment (PPE). This includes working with forklifts equipped with specialized handling attachments for containers of hazardous substances, using specialized containment systems to prevent spills, and ensuring proper ventilation in loading areas. I am proficient in using equipment for the safe transfer of materials like acids, solvents, and flammable materials. Before handling any hazardous material, I always thoroughly review the SDS to understand the risks and the necessary precautions. Safety is paramount when dealing with these materials, and adherence to all regulations is non-negotiable. Proper training and certification in handling hazardous materials are essential, and I maintain all necessary qualifications.

Q 26. Explain your understanding of weight distribution and its impact on loading and unloading.

Understanding weight distribution is critical for safe and efficient loading and unloading. Uneven weight distribution can lead to structural damage to vehicles, instability during transit, and even accidents. My approach focuses on ensuring the load is balanced and evenly distributed throughout the vehicle. This involves utilizing load securing techniques, carefully placing heavier items lower and towards the center of gravity, and strategically distributing lighter items to fill any gaps. I use measuring tools and weight scales to ensure that the weight limits of the vehicle are not exceeded and the load stays within safe parameters. Imagine loading a truck with heavy boxes; placing all the heavy boxes on one side would make the truck unstable. Proper weight distribution ensures safe transportation and prevents potential damage.

Q 27. How do you adapt your approach to loading and unloading based on the type of goods and destination?

Adaptability is crucial. My approach varies significantly depending on the type of goods and their destination. For fragile items, I use protective packaging and padding and prioritize gentle handling. Temperature-sensitive goods, like pharmaceuticals or food products, require climate-controlled storage and transportation. Heavy machinery needs specialized equipment like cranes or forklifts, and specific securing methods. The destination also influences my approach; loading for a local delivery might differ drastically from preparing a shipment for international transport, requiring different documentation and packaging considerations. For example, loading a truck with furniture requires careful placement and securing to prevent damage, while transporting chemicals needs specialized containers and safety precautions.

Q 28. What are your strategies for improving efficiency and productivity in loading and unloading operations?

Improving efficiency and productivity involves a multi-pronged approach. First, I focus on optimizing the workflow, minimizing unnecessary movements and ensuring efficient use of space. This includes implementing lean principles, like eliminating waste and streamlining processes. Second, I encourage teamwork and communication to ensure seamless coordination between all team members. Third, I embrace technology – using barcoding systems, warehouse management systems (WMS), and other software solutions to improve tracking and reduce manual errors. Finally, regular training and feedback are vital to upskill the team and identify areas for improvement. Implementing these strategies often leads to significant reductions in loading and unloading times, fewer accidents, and increased overall productivity.

Key Topics to Learn for Loading and Unloading Pads Interview

- Safety Procedures and Regulations: Understanding and adhering to OSHA regulations, safe lifting techniques, and hazard identification within loading and unloading environments. This includes knowing how to properly use personal protective equipment (PPE).

- Efficient Loading and Unloading Techniques: Mastering techniques for optimizing speed and efficiency while minimizing risk of damage to goods and equipment. This includes understanding different types of loading equipment and their limitations.

- Inventory Management and Tracking: Understanding the importance of accurate inventory counts, proper documentation, and using technology (e.g., scanners) for tracking goods throughout the loading and unloading process. This also includes understanding the consequences of discrepancies.

- Equipment Operation and Maintenance: Familiarity with common loading and unloading equipment (forklifts, pallet jacks, conveyors) including basic maintenance and troubleshooting procedures. This also includes knowing when to report malfunctioning equipment.

- Communication and Teamwork: Effective communication with colleagues, supervisors, and drivers to ensure smooth operations and problem-solving in challenging situations. This includes understanding the importance of clear and concise communication to avoid misunderstandings.

- Logistics and Supply Chain Awareness: Understanding the broader context of your role within the supply chain, including the impact of delays and inefficiencies on the overall process. This includes understanding the importance of on-time delivery and minimizing delays.

Next Steps

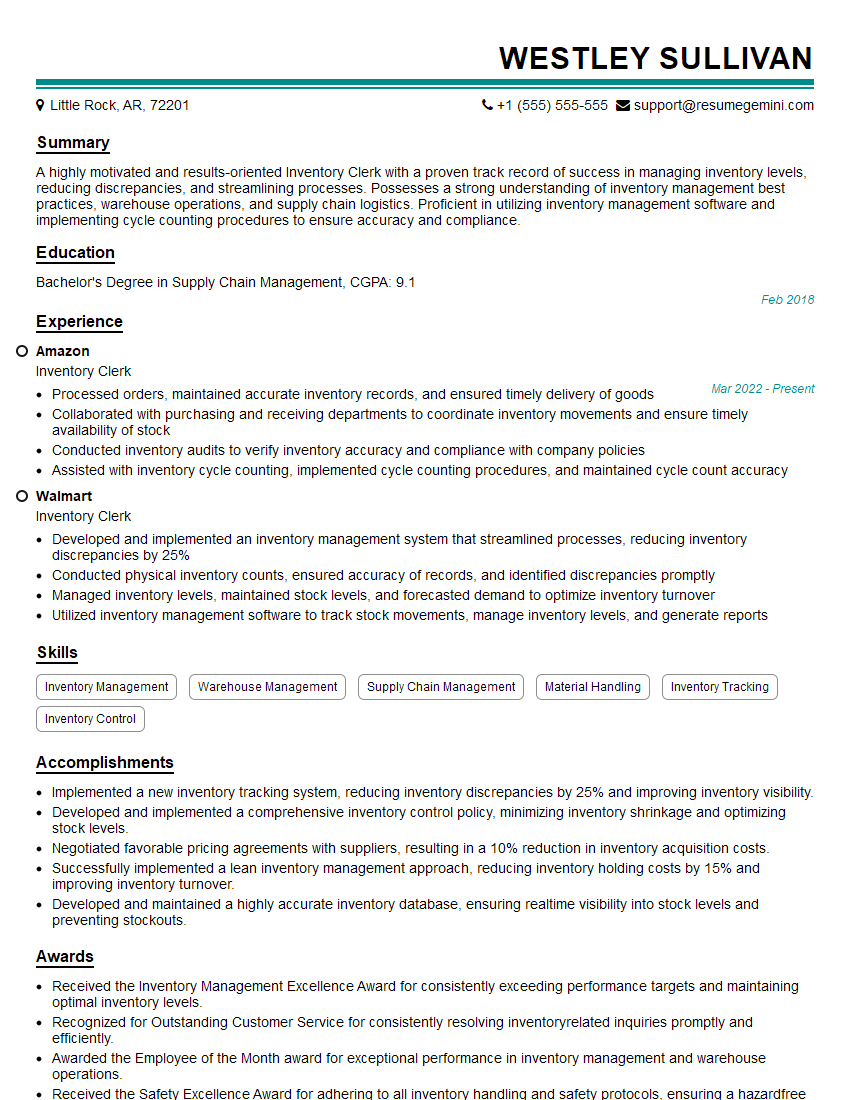

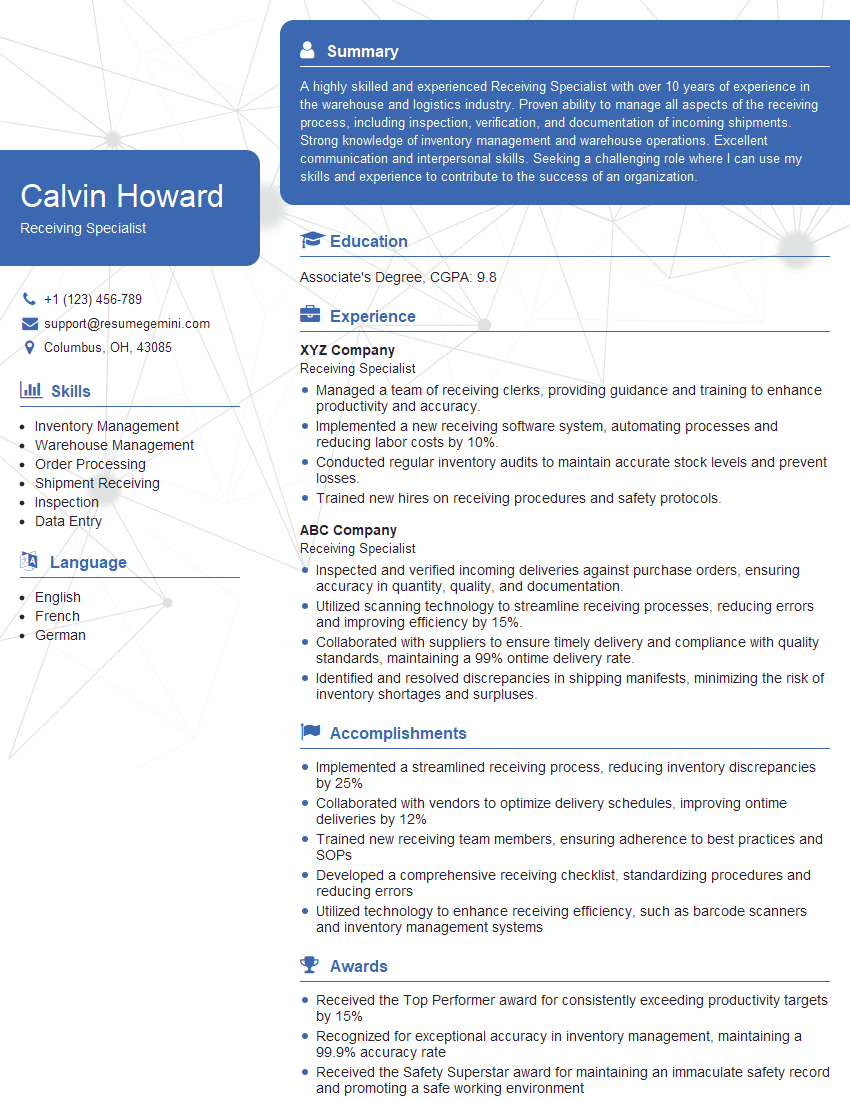

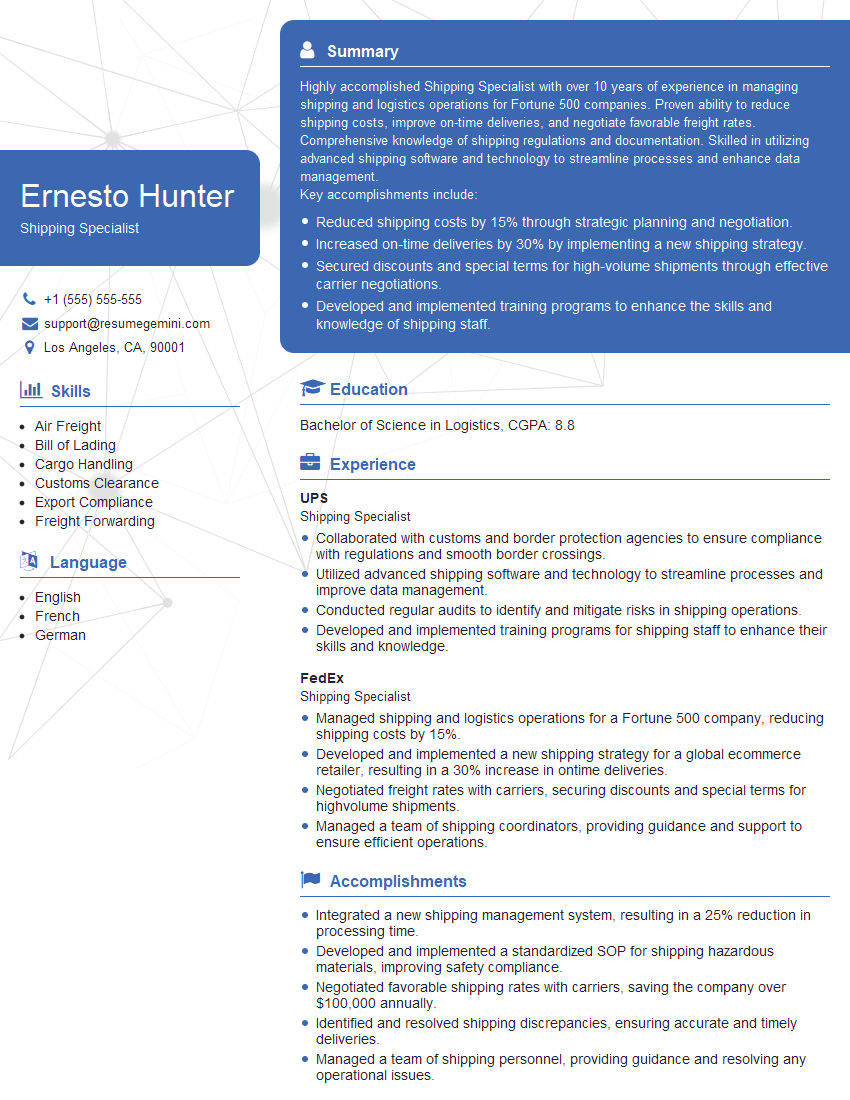

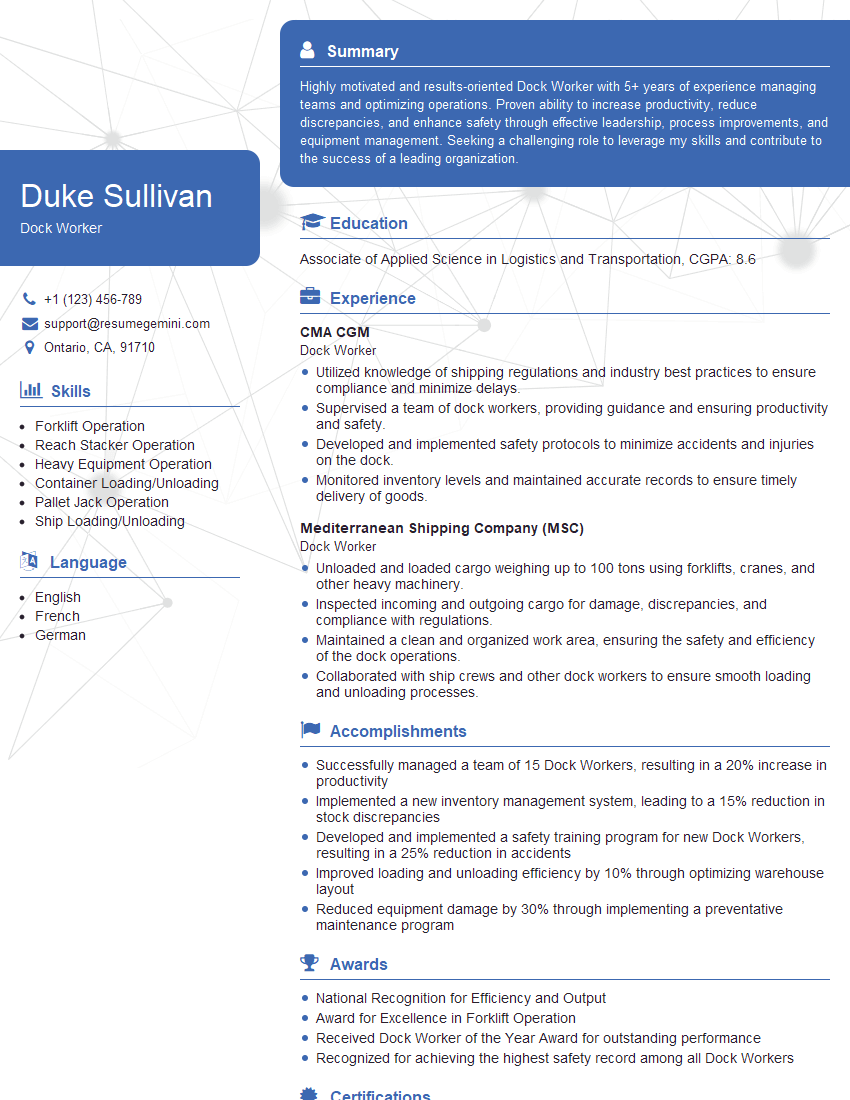

Mastering loading and unloading procedures is crucial for career advancement in logistics and warehousing. A strong understanding of these skills demonstrates reliability, efficiency, and commitment to safety—qualities highly valued by employers. To significantly improve your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and effective resume that showcases your qualifications. Examples of resumes tailored to Loading and Unloading Pads positions are available through ResumeGemini to guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good