Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Operating Forklifts and Pallet Jacks interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Operating Forklifts and Pallet Jacks Interview

Q 1. What are the different types of forklifts?

Forklifts come in a variety of types, each designed for specific tasks and environments. The most common classifications are based on their power source and lifting mechanism.

- Counterbalance Forklifts: These are the most common type, using a counterweight at the rear to balance the load on the forks. They are versatile and used in various industries.

- Reach Trucks: These forklifts have a mast that extends forward, allowing them to access narrow aisles and high racking. Think of them as the ‘high-reach’ specialists of the forklift world.

- Sit-Down Rider Forklifts: The operator sits while operating, offering better control and comfort for longer shifts. These are frequently used in warehouses with significant pallet movement.

- Stand-Up Rider Forklifts: Operators stand while operating, often preferred for shorter distances and quick maneuvers. They’re great for navigating tighter spaces.

- Electric Forklifts: Powered by batteries, these are quieter and cleaner than their combustion engine counterparts, ideal for indoor environments and where noise pollution is a concern.

- Internal Combustion Engine (ICE) Forklifts: These are powered by gasoline, propane, or diesel engines. They offer more power and longer runtimes than electric forklifts, often chosen for outdoor use or heavy-duty applications.

- Side Loaders: These specialized forklifts load and unload pallets from the side, ideal for applications with limited access from the front.

The choice of forklift depends heavily on the specific application, considering factors like load capacity, operating environment, and maneuverability requirements.

Q 2. Explain the pre-operational checklist for a forklift.

A pre-operational checklist is crucial for safe forklift operation. Think of it as a pre-flight check for an airplane – essential for preventing accidents.

- Visual Inspection: Check tires for wear and damage, inspect the forks for bends or cracks, and ensure all lights and signals are functioning correctly. Look for any leaks (oil, fuel, hydraulic fluid).

- Fluid Levels: Verify that engine oil, hydraulic fluid, coolant (if applicable), and fuel levels are within acceptable ranges. Low fluids can lead to serious problems.

- Controls and Safety Features: Test the brakes, steering, horn, lift and tilt mechanisms, and safety features like the seatbelt and emergency stops. Make sure everything responds as expected.

- Operational Status: Check the hour meter and any warning lights on the dashboard. Pay close attention to error codes if the forklift has a diagnostic system.

- Surroundings: Assess the immediate area for obstacles, pedestrians, or other hazards. Make sure the path is clear before starting any operation.

Documenting these checks, even with a simple signature on a checklist, is crucial for accountability and helps identify potential issues early on.

Q 3. Describe the proper procedures for loading and unloading pallets.

Loading and unloading pallets safely requires a methodical approach.

- Approach: Position the forklift facing the pallet squarely, ensuring stability and proper alignment.

- Engage Forks: Slowly and carefully insert the forks under the pallet, ensuring they’re evenly positioned and securely engaged. Never rush this step!

- Lift: Gradually lift the pallet to a safe height, checking for stability and ensuring nothing is obstructing the lift path.

- Transport: Maneuver the loaded forklift carefully, maintaining a safe speed and avoiding sudden movements. Always be aware of your surroundings.

- Placement: Position the pallet accurately at the destination point, ensuring it’s stable and won’t tip over.

- Lower: Gently lower the pallet to the ground, ensuring it’s firmly positioned.

- Disengage Forks: Remove the forks from the pallet once it is safely placed.

Remember, always prioritize safety. Use spotters if needed, especially in busy environments. Think through each step before execution.

Q 4. How do you safely navigate tight spaces with a forklift?

Navigating tight spaces with a forklift demands skill and precision.

- Slow and Steady: Reduce your speed considerably, prioritizing control over speed. Remember, it’s better to be slow and safe than fast and sorry.

- Small Movements: Use small steering adjustments, making incremental turns rather than wide, sweeping movements.

- Check Blind Spots: Constantly check your mirrors and surroundings for obstacles, pedestrians, or other hazards. Don’t rely solely on your forward view.

- Plan Your Route: Before starting, mentally map out your route to ensure you have enough clearance and avoid collisions. Imagine yourself performing the maneuver in your head to anticipate potential issues.

- Back Up Carefully: Backing up is particularly challenging in tight spaces. Use a spotter if necessary to guide you and ensure safety.

Practice makes perfect. Regular practice in a controlled environment can significantly improve your skills in maneuvering a forklift in tight spaces.

Q 5. What are the weight limits of a typical pallet jack?

The weight capacity of a pallet jack varies depending on the model and manufacturer. However, typical pallet jacks range from 2,500 lbs (1134 kg) to 5,500 lbs (2495 kg). Always check the manufacturer’s specifications for the exact weight limit of your particular pallet jack.

Exceeding the weight limit can lead to damage to the equipment and create serious safety hazards.

Q 6. Explain the safety precautions when operating a pallet jack.

Safety is paramount when operating a pallet jack.

- Weight Limits: Never exceed the rated weight capacity of the jack. Overloading is a major safety hazard.

- Proper Posture: Maintain a good posture and grip while operating the jack. Avoid twisting or straining your back.

- Clear Path: Ensure a clear path before starting and maintain awareness of your surroundings at all times.

- Foot Placement: Always keep your feet clear of the moving parts of the jack.

- Load Stability: Ensure the load is stable and balanced before moving it. Uneven loads can cause tipping.

- Avoid Jerky Movements: Move the jack smoothly and avoid jerky movements that could cause instability.

- Inspection: Regularly inspect the jack for any signs of wear or damage before use.

Remember, a moment of carelessness can lead to injuries or accidents. Treat every operation with respect and caution.

Q 7. How do you handle uneven terrain while operating a forklift?

Uneven terrain presents significant challenges when operating a forklift. Here’s how to handle it safely:

- Reduce Speed: Significantly decrease your speed when approaching uneven terrain. Slow and steady wins the race, particularly in these situations.

- Assess the Terrain: Carefully assess the terrain before proceeding, identifying potential obstacles or areas of instability.

- Choose a Stable Path: Select the smoothest and most level path possible. Avoid inclines and rough patches if feasible.

- Smooth Movements: Make smooth, gradual movements to avoid jarring the load or forklift.

- Avoid Sudden Turns: Avoid abrupt turns, which can destabilize the forklift and lead to tipping.

- Use Caution on Inclines: Approach inclines cautiously, maintaining a slow and controlled speed. Avoid tilting the forks upward too much while going uphill and downwards when going downhill.

- Lower Load: If possible, lower the load to the ground while negotiating uneven terrain. A lower center of gravity increases stability.

If the terrain is too challenging or unstable, it’s best to avoid operating the forklift in that area altogether or seek alternative methods for moving the load.

Q 8. What are the common causes of forklift accidents?

Forklift accidents, unfortunately, are far too common. They stem from a variety of causes, often a combination of human error and equipment malfunction. Let’s break it down:

- Operator Error: This is the leading cause. Examples include speeding, improper load handling (overloading, uneven loads), failing to check surroundings, operating in unsafe conditions (poor visibility, slippery floors), and neglecting safety procedures.

- Equipment Malfunction: Faulty brakes, steering problems, hydraulic leaks, and damaged forks are all major hazards. Regular maintenance is crucial to prevent these.

- Environmental Factors: Slippery floors, poor lighting, cluttered walkways, and obstructed views all contribute to accidents. A clean and organized work environment is paramount.

- Lack of Training: Inadequate training leads to unsafe operating practices. Operators need to be properly certified and regularly retrained on safety procedures.

- Improper Load Securement: Loads that are not properly secured can shift during transport, leading to accidents and damage.

Imagine a scenario: an operator rushing to meet a deadline, neglecting a pre-shift inspection, and then encountering a wet floor. This trifecta of human error, equipment neglect, and environmental factor could easily lead to a serious accident. Prevention requires attention to detail and adherence to safety protocols at all times.

Q 9. How do you perform a pre-shift inspection of a pallet jack?

A pre-shift inspection of a pallet jack is quick but crucial for safety. Think of it as a quick health check for your equipment. I always follow these steps:

- Visual Inspection: Check the jack’s overall condition for any damage, dents, or leaks. Look closely at the pump handle, wheels, forks, and hydraulic system.

- Wheel Check: Ensure the wheels are free from damage and rotate smoothly. Check for any excessive wear or looseness.

- Fork Condition: Inspect the forks for bends, cracks, or damage. Ensure they are properly aligned and securely attached.

- Hydraulic System Check: Check for any leaks around the hydraulic cylinder. Listen for any unusual noises during operation. A slight leak could quickly become a major problem.

- Handle Operation: Test the pump handle’s movement. It should operate smoothly without resistance or binding.

- Load Capacity Check: Always ensure the pallet jack’s load capacity matches the weight of the pallet before attempting to lift it.

If any issues are found, immediately report them to your supervisor and do not operate the pallet jack until it’s repaired. A small problem neglected today can become a costly and dangerous issue tomorrow.

Q 10. Describe the proper lifting techniques for heavy pallets.

Lifting heavy pallets safely involves more than just brute strength. It requires proper technique to prevent injury and damage.

- Assessment: Before lifting, assess the weight and stability of the pallet. Ensure the pallet is properly secured and the load is evenly distributed.

- Stance and Grip: Position yourself close to the pallet with your feet shoulder-width apart. Get a firm grip using your legs, and not your back.

- Lift with Your Legs: Bend your knees and lift the pallet using your leg muscles, keeping your back straight. Avoid twisting your body during the lift.

- Controlled Movement: Move slowly and carefully, maintaining a balanced posture. Avoid sudden jerks or movements.

- Proper Placement: Carefully place the pallet in its designated location, ensuring it is stable and secure.

Think of it like this: Your legs are your strongest muscles. Use them to do the heavy lifting; keep your back straight to avoid strain. Slow, controlled movements prevent accidents.

Q 11. What is the proper procedure for refueling a forklift?

Refueling a forklift is a potentially hazardous procedure that requires caution and adherence to strict safety protocols.

- Engine Off: Always switch off the engine and allow it to cool down completely before refueling. This prevents sparks and fire hazards.

- Ventilation: Ensure the area is well-ventilated to prevent the buildup of flammable gases.

- Spill Prevention: Handle the fuel nozzle carefully to prevent spills or leaks. Use a spill kit if necessary.

- No Smoking: Strictly enforce a no-smoking policy in the refueling area.

- Correct Fuel Type: Use the correct type of fuel specified for your forklift. Incorrect fuel can damage the engine.

- Proper Disposal: Dispose of any spilled fuel according to company regulations.

Imagine a scenario where someone tries to refuel a hot engine. The potential for a fire or explosion is enormous. Following these steps prevents those risks.

Q 12. How do you identify and report forklift malfunctions?

Identifying and reporting forklift malfunctions is critical for safety and maintenance. Here’s how:

- Regular Inspections: Conduct thorough pre-shift inspections as described earlier and report any issues.

- Listen for Unusual Noises: Pay close attention to unusual noises like squealing, grinding, or banging.

- Check Warning Lights: Be alert to any warning lights or indicators on the forklift dashboard.

- Documenting Issues: Keep a detailed record of any observed malfunctions, including date, time, and description of the problem.

- Immediate Reporting: Report all malfunctions to your supervisor immediately. Do not operate the forklift if a malfunction exists.

- Tagging and Removal: If necessary, tag the malfunctioning forklift as “Out of Service” to prevent its use.

Think of it as a medical checkup for your machine. Early detection of problems prevents major breakdowns and avoids accidents.

Q 13. What are the different types of pallet configurations?

Pallet configurations vary depending on the type of goods and the way they are stored. Understanding these configurations is essential for efficient handling and storage.

- Standard Pallets: These are the most common type, with four ways entry.

- Block Pallets: These pallets have stringers running parallel to the deck boards, creating a strong platform for heavier loads. They are also known as full-size stringer pallets.

- Half Pallets: These are smaller versions of standard pallets, useful for lighter loads or smaller items.

- Double-faced Pallets: These have deck boards on both sides, making them stronger and more durable for double-sided loading.

- Nested Pallets: These pallets are designed to be nested on top of each other when empty, saving space during storage and transport.

Knowing the different types helps you choose the right equipment and loading techniques for efficient and safe handling of the goods.

Q 14. How do you ensure the stability of stacked pallets?

Ensuring the stability of stacked pallets is critical to prevent collapses. The key lies in careful planning and execution:

- Proper Pallet Selection: Use pallets of the same size and type to create a uniform stack.

- Even Load Distribution: Ensure the load on each pallet is evenly distributed to prevent imbalances.

- Stacking Height: Adhere to recommended stacking heights for the type of pallet and load. Over-stacking is a common cause of collapses.

- Interlocking Pallets: When stacking, align the stringers of the pallets to create a stable, interlocking structure.

- Racking Systems: Use appropriate racking systems to support the pallets and prevent them from toppling over.

- Regular Inspections: Inspect the stacked pallets periodically to ensure they remain stable.

Imagine a pyramid of blocks. If the base is unstable, the whole structure will fail. The same applies to pallet stacking. A stable base and uniform stacking are key to success.

Q 15. What are the safety regulations regarding forklift operation?

Forklift safety regulations are paramount and vary slightly by jurisdiction, but core principles remain consistent. They prioritize preventing accidents through operator training, equipment maintenance, and safe operating procedures.

- Pre-operational Checks: Before each shift, a thorough inspection of the forklift is mandatory, checking tires, brakes, lights, horn, fluid levels, and mast stability. Any issues must be reported immediately. Think of it like a pre-flight checklist for an airplane – crucial for safety.

- Operator Training and Certification: Only trained and certified operators should operate forklifts. This training covers safe operating procedures, load stability, pre-operational checks, and emergency procedures. A valid certificate is essential, demonstrating competency.

- Load Capacity and Stability: Never exceed the forklift’s rated load capacity. Improperly loaded or unstable loads are a major cause of accidents. Understanding the center of gravity is critical; imagine balancing a stack of books – too high, and it tips.

- Speed and Maneuvering: Operate at safe speeds, appropriate to the conditions. Avoid sharp turns and sudden stops, especially with a load. Remember, a loaded forklift has significantly reduced maneuverability.

- Pedestrian Safety: Always be aware of pedestrians and other equipment. Use horns and lights appropriately to warn others of your presence. Think of yourself as a large vehicle sharing a busy space; constant vigilance is essential.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety shoes, high-visibility clothing, and hearing protection. This is a personal safety net.

- Refueling and Maintenance: Follow proper procedures for refueling and routine maintenance. Never refuel a running forklift; it’s a fire hazard. Regular maintenance keeps the equipment reliable and safe.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of load stability.

Load stability is crucial for safe forklift operation. An unstable load can easily shift, causing the forklift to tip over, resulting in serious injury or damage. Understanding and maintaining load stability involves several factors:

- Proper Load Centering: The load’s center of gravity should be kept as close to the forklift’s center of gravity as possible. This prevents imbalance and tipping. Imagine carrying a heavy suitcase – you hold it close to your body for stability.

- Load Securing: Use appropriate straps, chains, or nets to secure the load, preventing it from shifting during transport. This is particularly important for uneven or unstable loads.

- Load Weight: Never exceed the forklift’s rated load capacity. Overloading can dramatically reduce stability and increase the risk of tipping.

- Travel Speed: Reduce speed when operating with a load, especially on uneven surfaces or inclines. This allows for better control and reduces the chance of accidents.

- Fork Position: Ensure the forks are properly positioned and engaged with the load before lifting. Incorrect positioning can lead to load instability.

- Ground Conditions: Be aware of ground conditions. Uneven surfaces, potholes, or inclines can significantly affect load stability.

In short, load stability is a multifaceted concept that requires attention to detail and a commitment to safety practices.

Q 17. How do you handle spills or leaks while operating a forklift?

Handling spills or leaks while operating a forklift requires a cautious and systematic approach, prioritizing safety above all else.

- Stop and Assess: Immediately stop the forklift in a safe location, away from traffic and the spill. Assess the nature of the spill – is it hazardous material? This dictates your next steps.

- Warning and Containment: Use warning cones or other safety devices to alert others to the hazard and prevent accidental contact. If possible, contain the spill to prevent further spread. Think about using absorbent materials if safe to do so.

- Report the Incident: Immediately report the spill to your supervisor or designated authority. This is crucial for proper cleanup and potential investigation.

- Do Not Attempt Cleanup (Unless Trained): Unless you are specifically trained to handle the type of spilled material, do not attempt cleanup. Many materials are hazardous and require specialized equipment and procedures. Your safety is paramount.

- Follow Company Protocol: Adhere to your company’s established spill response plan. This plan will outline the appropriate procedures for different types of spills.

Remember, your primary concern is your safety and the safety of others. Following proper procedures prevents further accidents and ensures a safe working environment.

Q 18. What is your experience with different forklift attachments?

My experience encompasses a range of forklift attachments, each designed for specific tasks. This includes:

- Side Shifters: These allow lateral movement of the forks, enabling precise placement of pallets in tight spaces. I’ve utilized these extensively in narrow aisle environments.

- Paper Roll Clamps: Designed for handling rolls of paper or other cylindrical materials, offering a secure and efficient method for transportation. These are essential for materials that wouldn’t be easily handled by standard forks.

- Carriage Rotators: These allow the load to be rotated 90 degrees, useful for placing pallets in specific orientations. Increased efficiency in stacking and storage areas.

- Fork Extensions: Increase the length of the forks, accommodating longer or wider loads. Essential for specific tasks, improving accessibility.

- Push-Pull Attachments: Allows the operator to move heavy loads that are not easily lifted using traditional forks. Often used in conjunction with pallet jacks.

My proficiency extends to safely attaching and detaching these attachments, understanding their limitations, and adjusting operating techniques accordingly. This versatile experience makes me adaptable to different material handling challenges.

Q 19. Describe your experience with inventory management systems.

My experience with inventory management systems involves using them to track and manage pallet movement and storage locations. This includes:

- WMS (Warehouse Management Systems): I am proficient in using WMS to receive, store, and retrieve pallets according to predefined locations. This ensures efficient inventory management and minimizes search times. Think of it as a detailed map of the warehouse.

- Data Entry: Accurately entering data into the system, including pallet IDs, locations, and quantities, is crucial for maintaining accurate inventory records. Precise data entry ensures seamless operations.

- Reporting and Analysis: I understand how to generate reports from the system, providing insights into inventory levels, turnover rates, and potential areas for improvement. Data analysis helps optimize warehouse efficiency.

- Integration with RF Scanners: My experience includes using RF scanners to quickly and efficiently scan barcodes on pallets, providing real-time updates to the inventory management system. This real-time integration is crucial for accuracy.

I am adaptable to different WMS platforms and can quickly learn new systems, ensuring consistent efficiency in any warehouse setting.

Q 20. How do you maintain accurate records of pallet movement?

Maintaining accurate records of pallet movement is essential for inventory control and efficient warehouse operations. My approach involves a combination of:

- Barcoding and Scanning: Utilizing RF scanners to scan barcodes on pallets provides real-time data on their movement. This eliminates manual data entry errors and speeds up the process.

- Data Entry (Manual and Electronic): In situations where barcodes aren’t available, I meticulously record pallet movements manually, later entering them into the inventory management system. Accuracy is paramount.

- Paper Logs: I maintain detailed paper logs as a backup, recording critical details including pallet ID, source, destination, time, and any discrepancies. This provides an additional layer of verification.

- Digital Documentation: Using digital tools to capture images or videos of pallet placements, especially in areas prone to errors, provides visual confirmation of location accuracy.

- Regular Audits: Participate in regular inventory audits to reconcile recorded data with physical inventory, identifying and rectifying discrepancies promptly. Audits ensure data integrity.

By combining these methods, I ensure complete and accurate records of pallet movement, contributing to efficient warehouse operations and minimizing errors.

Q 21. What is your experience with RF scanners or similar technology?

I have extensive experience using RF scanners and similar technologies for efficient inventory management and pallet tracking. My proficiency includes:

- Barcode Scanning: I can quickly and accurately scan barcodes on pallets, updating inventory systems in real-time. This improves speed and reduces errors associated with manual data entry.

- Data Entry and Verification: Using RF scanners often involves verifying the scanned data against the system’s information, ensuring accuracy before processing the transaction. This double-checks the information.

- Troubleshooting: I can troubleshoot common RF scanner issues, such as connectivity problems or low battery alerts, ensuring minimal downtime. It’s about knowing how to keep the tech running.

- Different Scanner Types: I am comfortable using various RF scanners, from handheld devices to wearable scanners, adapting to different warehouse technologies and preferences. This flexibility is essential.

- Integration with WMS: I understand how RF scanner data integrates with warehouse management systems, ensuring data accuracy and efficient inventory tracking. The seamless integration is crucial.

My experience with RF scanners has significantly increased my efficiency and accuracy in managing pallet movement and inventory.

Q 22. How do you prioritize tasks in a fast-paced warehouse environment?

In a fast-paced warehouse, efficient task prioritization is crucial. I use a combination of techniques to manage my workload. First, I assess the urgency and importance of each task. Urgent and important tasks, like fulfilling rush orders, take priority. I then use a system of visual cues, like color-coded task lists or flags on my route sheet, to further organize my tasks. This allows me to quickly scan and identify what needs immediate attention. For example, if a red-flagged order requires immediate loading for a specific delivery time, I’ll prioritize that over other tasks even if it means slightly adjusting my established route. Finally, I regularly communicate with my supervisor and team members to ensure I’m working on the most critical tasks and to identify any changes in priorities.

Q 23. Describe your experience working in a team.

Teamwork is essential in a warehouse environment. In my previous role, I was part of a team responsible for receiving, storing, and shipping goods. We relied heavily on clear communication and collaboration. For instance, if a pallet was too heavy for one person to move, we’d work together using a team lift technique, ensuring safety and efficiency. I’m adept at working within a team structure, contributing my skills while supporting my colleagues. I believe in mutual respect and open communication; I actively listen to ideas and offer assistance where needed. This collaborative approach not only improves productivity but also fosters a positive and supportive work environment.

Q 24. How do you handle difficult or demanding situations?

Difficult situations in a warehouse can include equipment malfunctions, unexpected order surges, or even workplace conflicts. My approach is methodical. First, I assess the situation calmly and identify the root cause. If it’s a mechanical issue, for instance, I’ll follow the appropriate safety procedures and report it to maintenance immediately. In the case of an order surge, I’ll prioritize tasks based on urgency and communicate with my team to distribute the workload efficiently. If there’s a conflict, I’ll try to resolve it through open and respectful communication, focusing on finding solutions that benefit everyone involved. My goal is always to maintain safety and productivity, resolving the problem while minimizing disruption to the workflow.

Q 25. What are your strengths and weaknesses as a forklift operator?

My strengths as a forklift operator include my proficiency in operating various types of forklifts (reach trucks, counterbalance, etc.), my meticulous attention to detail, and my strong safety record. I’m highly skilled at maneuvering in tight spaces and loading/unloading quickly and safely. A weakness I’m actively working on is optimizing my route planning for maximum efficiency. While I’m proficient at navigation, I’m continually seeking ways to streamline my routes and reduce unnecessary travel time. I actively participate in training to enhance my skills and address this area for improvement.

Q 26. What is your experience with different types of warehouse layouts?

I’ve worked in various warehouse layouts, from traditional linear racking systems to high-bay warehouses with automated guided vehicles (AGVs). My experience includes working in narrow-aisle environments, requiring precision and careful maneuvering of the forklift. I’m also familiar with block stacking, bulk storage, and pick-and-pack areas. Adapting to different layouts is straightforward for me; I quickly learn the specific routes, safety procedures, and equipment requirements of each new environment. I thoroughly review layout maps and receive hands-on training before operating in a new facility.

Q 27. How do you adapt to changing work demands?

Adaptability is essential in warehousing. I approach changing work demands with a positive and proactive attitude. If new procedures are implemented, I carefully review the training materials and ask clarifying questions to ensure complete understanding. If there’s a shift in priorities, I prioritize tasks accordingly, communicating with supervisors and team members to ensure smooth workflow. For example, if a new product requires a different stacking method, I’ll immediately seek training and implement the new technique safely and accurately. My flexibility allows me to adjust efficiently to new challenges and maintain consistent productivity.

Q 28. What are your salary expectations?

My salary expectations are in line with the market rate for experienced forklift operators in this region with my skill set and experience. I am open to discussing a competitive compensation package that reflects my contributions and value to your company. I am more focused on finding a long-term position with opportunities for growth and development than solely on salary.

Key Topics to Learn for Operating Forklifts and Pallet Jacks Interview

- Safe Operation Procedures: Understanding and applying all safety regulations, pre-operation checks, and emergency procedures for both forklifts and pallet jacks.

- Equipment Functionality: Thorough knowledge of the mechanical components, controls, and operational limitations of both forklifts and pallet jacks. This includes understanding load capacity limits and stability considerations.

- Load Handling Techniques: Mastering the safe and efficient loading, unloading, stacking, and transporting of various materials using both forklifts and pallet jacks. This includes understanding proper load balancing and securing techniques.

- Maintenance and Inspection: Familiarity with routine maintenance tasks, pre-shift inspections, and the ability to identify potential mechanical issues. Knowing when to report problems and the importance of preventative maintenance.

- Warehouse Navigation and Layout: Understanding efficient warehouse navigation, including traffic patterns, designated walkways, and safe operating zones within a warehouse environment. This also includes awareness of blind spots and potential hazards.

- Regulations and Compliance: Knowledge of relevant OSHA (or equivalent) safety standards and regulations for operating forklifts and pallet jacks. Understanding company-specific safety protocols.

- Problem-Solving and Troubleshooting: Ability to identify and resolve common operational issues, such as equipment malfunctions or loading difficulties. Demonstrating a proactive approach to problem-solving.

Next Steps

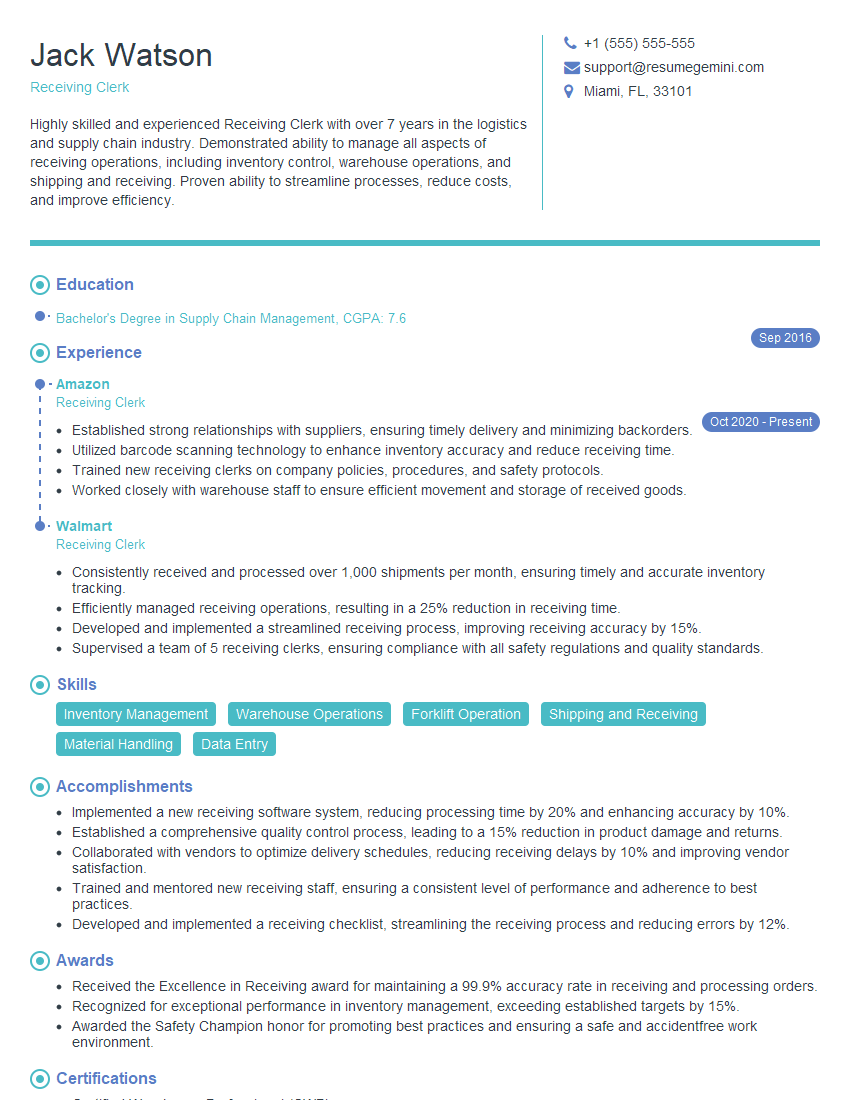

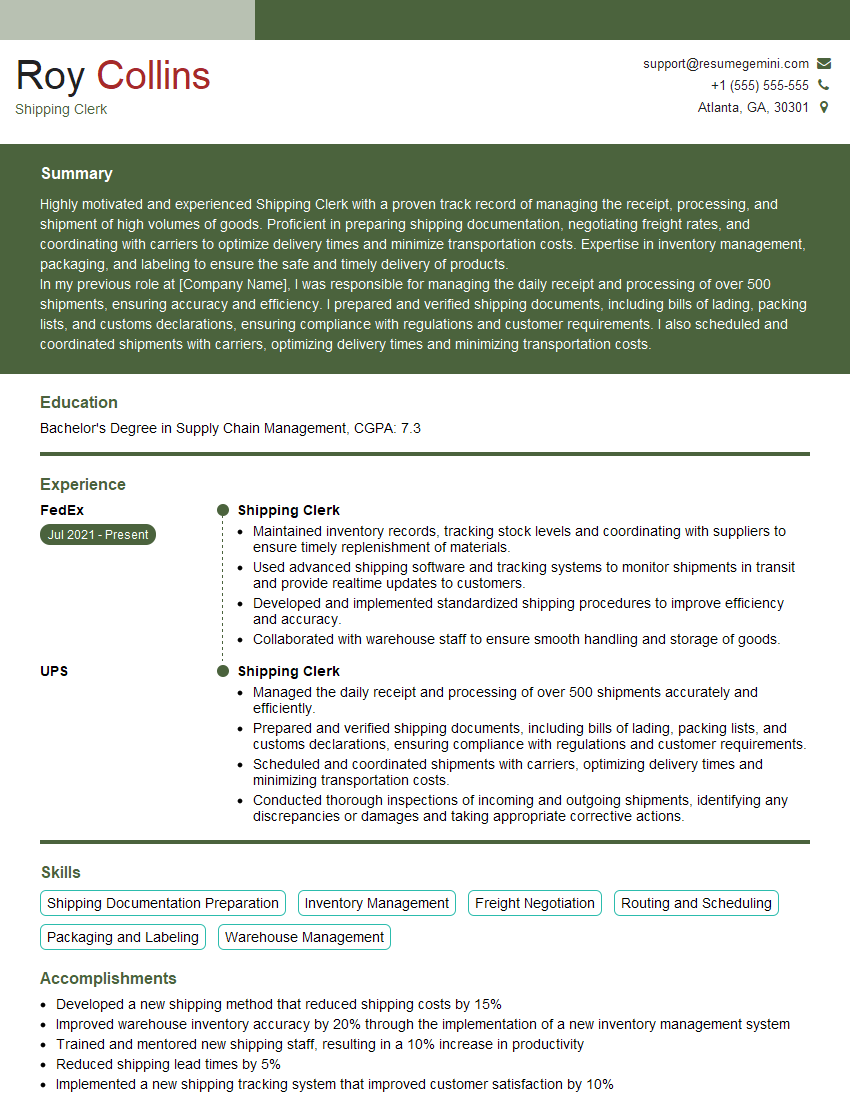

Mastering the operation of forklifts and pallet jacks opens doors to numerous opportunities within logistics, warehousing, and distribution. These skills are highly valued and are essential for efficient and safe workplace operations. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. A well-structured resume highlights your abilities and experience effectively, increasing your chances of getting noticed by potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to create a compelling resume tailored to your specific skills, including examples specifically designed for Operating Forklifts and Pallet Jacks positions. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good