Are you ready to stand out in your next interview? Understanding and preparing for Drop Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Drop Installation Interview

Q 1. Describe your experience with different types of cable drops (e.g., fiber, coax, copper).

My experience encompasses a wide range of cable drop installations, including fiber optics, coaxial (coax), and copper. Each type presents unique challenges and requires specialized knowledge. For instance, fiber optic drops demand precision and cleanliness to avoid signal degradation, while coax installations require careful consideration of signal attenuation and impedance matching. Copper drops, often used for telephone or lower-bandwidth data, require a different approach concerning grounding and noise interference. I’ve worked extensively with all three, installing hundreds of drops in various settings, from residential homes to large commercial buildings. This diverse experience has given me a deep understanding of the strengths and limitations of each technology and how to best deploy them in different contexts.

- Fiber Optics: I’m proficient in fusion splicing and the use of various connectors (SC, LC, ST) ensuring minimal signal loss. I’ve handled projects involving both single-mode and multi-mode fiber.

- Coaxial Cable: My experience includes installations using different coax types (RG-6, RG-59) for cable television and internet services. I understand the importance of proper terminations and the impact of signal splitters on overall signal strength.

- Copper Cable: I’m familiar with various copper cable types, including twisted-pair and CAT5e/CAT6 for data networking. My experience includes both structured cabling installations and individual drop installations for telephone and data services. I have also worked with older copper infrastructure, understanding their limitations and how to potentially retrofit them.

Q 2. Explain the process of installing a fiber optic drop.

Installing a fiber optic drop is a meticulous process requiring precision and care. The steps generally involve:

- Planning and Design: This includes determining the optimal route, considering obstacles, and calculating the required fiber length.

- Cable Preparation: This includes cleaning and preparing the fiber ends for splicing or connectorization using specialized tools.

- Splicing or Connectorization: Fusion splicing offers superior performance, but mechanical connectors are also used. I always test splice quality to ensure low losses.

- Cable Routing and Installation: This involves carefully routing the cable, securing it with appropriate fasteners, and minimizing bends to avoid signal degradation. This often includes running cable through conduits or aerial installations.

- Testing and Verification: This is crucial. Using an Optical Time-Domain Reflectometer (OTDR) allows me to identify any breaks, bends, or losses along the entire length of the fiber cable to ensure the system is operating at peak performance.

- Termination and Connection: The fiber is terminated at both ends with appropriate connectors (SC, LC, ST) and connected to the network equipment.

- Documentation: This ensures traceability in case of future problems or maintenance.

Imagine it like building a highly sensitive and intricate network of light pipes – every step needs to be exact to avoid breaking the flow of light signals.

Q 3. What safety precautions do you take when installing drops?

Safety is paramount. Before starting any drop installation, I conduct a thorough site survey to identify potential hazards, such as overhead power lines, underground utilities, and hazardous materials. I always follow these safety precautions:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves, hard hats, and high-visibility clothing.

- Lockout/Tagout Procedures: When working near energized equipment, I always follow lockout/tagout procedures to prevent accidental energization.

- Proper Lifting Techniques: I utilize proper lifting techniques and equipment to avoid injuries when handling heavy cabling or equipment.

- Awareness of Surroundings: I maintain constant awareness of my surroundings and traffic to prevent accidents.

- Fall Protection: If working at heights, I utilize proper fall protection equipment, such as harnesses and safety lines.

- Emergency Procedures: I am always familiar with and prepared to use emergency procedures and communicate effectively.

One instance that highlights the importance of safety involved a potential power line hazard. I carefully measured the distances and coordinated with the local power company to de-energize the line for a short window before proceeding. This is vital for a worker’s safety.

Q 4. How do you troubleshoot common drop installation problems?

Troubleshooting drop installation problems involves a systematic approach. I begin by identifying the symptoms, then use various testing equipment to pinpoint the cause. Common problems and solutions include:

- No Signal: Check all connections, test the cable with an OTDR (for fiber), or a tone generator (for copper), and verify network equipment configuration.

- Intermittent Signal: Look for loose connections, cable damage, or environmental interference (e.g., water ingress). A signal tracer can help locate the breaks.

- Low Signal Strength: Check for excessive cable length, poor-quality connectors, or signal attenuation.

- Excessive Noise: Look for grounding issues, poor cable shielding, or nearby sources of electromagnetic interference (EMI).

For example, I once encountered a situation where a fiber optic drop had intermittent signal loss. Using an OTDR, I identified a microbend in the cable near a sharp bend. By rerouting the cable and securing it more carefully, the problem was resolved.

Q 5. What tools and equipment are essential for drop installation?

Essential tools and equipment for drop installation vary depending on the type of cable, but generally include:

- Cable Cutters/Strippers: For preparing the cable for termination.

- Connectors and Termination Tools: These depend on the cable type (e.g., fusion splicer for fiber, crimp tools for coax).

- Testing Equipment: Such as OTDRs for fiber, multimeters for copper, and signal generators.

- Hand Tools: Screwdrivers, pliers, wrenches, etc.

- Safety Equipment: As mentioned previously, safety glasses, gloves, hard hats, and harnesses.

- Cable Management Tools: Such as cable ties and conduit.

- Fiber Optic Cleaning Kit: For maintaining cleanliness during fiber optic termination.

The tools used for installing a fiber drop are very different from the tools used to install a copper drop, but every successful install requires proficiency with the tools relevant to the job.

Q 6. Explain your experience with different types of connectors (e.g., SC, LC, ST).

My experience with different fiber optic connectors, such as SC, LC, and ST, is extensive. Each connector type has its advantages and disadvantages. SC connectors are known for their larger size and simpler design, making them less expensive and easier to handle, yet less durable than others. LC connectors are smaller and more robust, becoming the current industry standard for high-density applications. ST connectors feature a bayonet coupling that allows for faster connection and disconnection. The choice of connector depends on the application requirements; SC is often used in older installations, while LC is preferred for higher-density data centers. Proper cleaning and handling are critical to maintaining their performance and achieving a secure connection, which I consistently follow in every project.

Q 7. How do you ensure the integrity of a cable drop installation?

Ensuring the integrity of a cable drop installation involves a multi-faceted approach: Firstly, I always use high-quality materials and follow manufacturer’s instructions meticulously during the installation process. Secondly, thorough testing at every stage is paramount. This includes testing for continuity, signal strength, and attenuation (loss of signal) using appropriate equipment specific to the type of cable being used. Finally, detailed documentation, including cable routing diagrams and testing results, ensures traceability and simplifies troubleshooting in the future. This documentation also becomes crucial for future maintenance or upgrades. For fiber, visual inspection and OTDR testing are essential. For copper, testing with a cable certifier will ensure that the cable meets the specified requirements. This comprehensive approach minimizes the risk of failures and ensures a long-lasting, reliable installation.

Q 8. Describe your experience with aerial and underground cable installation.

My experience encompasses both aerial and underground cable installation, with a strong emphasis on safety and efficiency. Aerial installations involve running cables along poles and structures, requiring proficiency in climbing, using specialized equipment like aerial lifts and ensuring proper cable support and strain relief. I’ve worked on numerous projects involving various cable types, from fiber optics to copper, carefully adhering to industry best practices for securing cables and preventing damage. Underground installations, on the other hand, demand a thorough understanding of trenching techniques, cable placement within conduits, and the importance of proper grounding and shielding to protect against environmental factors and electromagnetic interference. I’m proficient in using directional boring equipment where appropriate to minimize ground disruption. For example, in one project, we utilized directional boring to install fiber optic cable under a busy highway, avoiding lengthy road closures and minimizing disruption to traffic.

Q 9. How do you manage your time effectively during a drop installation project?

Effective time management during a drop installation project is crucial for meeting deadlines and staying within budget. I utilize a project management approach that involves several key steps: First, a thorough pre-installation assessment, including site surveys and a detailed review of blueprints, to anticipate potential challenges and adjust the schedule accordingly. Next, I break down the project into smaller, manageable tasks with clearly defined timelines. I then allocate resources effectively, ensuring the right team and equipment are available at the right time. Throughout the process, I regularly monitor progress, addressing any unforeseen delays promptly and communicating with the client for updates. This proactive approach, combined with experience in optimizing work processes, minimizes downtime and helps deliver the project on schedule.

Q 10. What is your experience with splicing cables?

Splicing cables is a critical skill in drop installations, and I possess extensive experience in various splicing techniques for different cable types. For fiber optic cables, I’m proficient in fusion splicing, using a fusion splicer to precisely align and melt the fiber ends, creating a strong and low-loss connection. For copper cables, I’m experienced in various connectorization and crimping techniques. Proper preparation, including cleaning and stripping the cable ends, is essential for reliable connections. Beyond the technical skills, ensuring proper documentation of splice points and maintaining a clean and organized workspace are vital for minimizing future issues and ensuring the quality of the completed installation. For instance, in a recent high-density fiber optic installation, precise fusion splicing was crucial to maintain the signal integrity across the entire network.

Q 11. Explain the process of testing a completed cable drop.

Testing a completed cable drop involves a series of steps to ensure signal quality and overall functionality. This begins with visual inspections, checking for any signs of damage or loose connections. Next, I utilize OTDR (Optical Time Domain Reflectometer) for fiber optic cables to identify any attenuation or reflections indicating faults along the cable’s length. For copper cables, I use a cable tester to measure signal strength, resistance, and continuity. The specific tests depend on the cable type and application. A comprehensive test report is crucial documentation, detailing the test results and confirming that the drop installation meets the required specifications. Failing to conduct thorough testing can lead to connectivity problems and costly repairs later on.

Q 12. How do you handle challenging installations (e.g., difficult terrain, weather conditions)?

Challenging installations, such as those involving difficult terrain or inclement weather, require adaptability and safety precautions. Difficult terrain might necessitate the use of specialized equipment like All-Terrain Vehicles (ATVs) or even helicopters for cable placement. In inclement weather, safety protocols take precedence, possibly involving temporary work stoppages when conditions become too hazardous. I always prioritize safety, utilizing appropriate personal protective equipment (PPE) and adhering to strict safety protocols. Thorough risk assessments are done beforehand, and contingency plans are formulated to handle unexpected situations. For example, during a mountainside installation during a snowstorm, we had to postpone work until conditions improved, ensuring the safety of the team and preventing potential accidents.

Q 13. What are the different types of drop installation methods you are familiar with?

I’m familiar with various drop installation methods, including aerial, underground, and buried installations. Aerial installations utilize poles, aerial cable, and other supporting structures. Underground installations use trenches and conduits to protect the cables from damage. Buried installations involve directly burying the cable in the ground. The choice of method depends on factors like terrain, cable type, and environmental conditions. Each method necessitates specialized equipment and expertise. For example, using micro-trenching for fiber optic installations in urban areas minimizes the disruption to streets and pavements while still ensuring cable protection.

Q 14. Describe your experience with working from heights.

Working from heights is an inherent aspect of many drop installations, and I have extensive experience and training in this area. I’m certified in fall protection techniques and proficient in using various fall arrest systems, including harnesses, lifelines, and anchor points. Before undertaking any work at heights, thorough risk assessments are conducted to identify and mitigate potential hazards. I always prioritize safety, double-checking equipment and ensuring all safety measures are in place before starting work. This includes regular equipment inspections and adherence to strict safety procedures. My training ensures that I can handle various scenarios and adapt to different environmental conditions when working at heights.

Q 15. How do you adhere to industry standards and regulations during installation?

Adhering to industry standards and regulations is paramount in drop installation. This ensures safety, quality, and legal compliance. I always begin by familiarizing myself with the specific codes and standards applicable to the project location, which might include the National Electrical Code (NEC), local building codes, and any client-specific requirements. For example, when working with fiber optic cables, I meticulously follow the safety protocols to prevent damage to the fibers and ensure proper grounding to avoid electrical hazards. This includes using the right tools, following manufacturer instructions, and employing proper safety measures like wearing safety glasses and gloves. Regularly updating my knowledge on the latest standards through industry publications and training programs is a crucial part of my professional development.

Documentation is key. I maintain detailed records of every step, from initial site survey to final testing and sign-off. This provides a clear audit trail and ensures we meet all regulatory requirements. In the event of a dispute or issue, these records are invaluable.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of termination?

My experience encompasses a wide range of termination types, including fusion splicing for fiber optics, crimp termination for twisted-pair copper cabling, and various connector types such as RJ45, SC, LC, and ST connectors. Fusion splicing, for instance, requires specialized equipment and precision to achieve a strong, low-loss connection. It’s a delicate process that demands a steady hand and a thorough understanding of the fiber’s properties. Crimp terminations, while seemingly simpler, also require careful attention to detail to ensure proper wire placement and secure crimping to avoid signal degradation. I’m proficient in testing each termination type using OTDRs (Optical Time-Domain Reflectometers) for fiber and cable testers for copper, ensuring optimal performance and reliability before handing over the installation to the client.

For example, I recently worked on a project that required both fiber optic and copper cabling terminations within a data center environment. I successfully completed both types, adhering to the strict standards required for high-bandwidth, low-latency connectivity.

Q 17. How do you document your work and ensure accurate record-keeping?

Accurate record-keeping is non-negotiable. I use a combination of digital and physical documentation. Digital records include detailed spreadsheets or databases, often linked to a project management system, where I meticulously log every cable, connection point, testing result, and any other relevant information. I always include photographs showing cable routing, labeling, and termination points. Physical documentation usually involves cable labels attached directly to the cables. These labels are crucial for future maintenance and troubleshooting. I maintain a consistent labeling system, including a unique identifier for each cable segment, to facilitate easy tracking and organization. This organized approach ensures that every aspect of the installation is fully documented and traceable, simplifying future maintenance and troubleshooting.

Q 18. Describe your experience with working with different types of customers (residential, commercial).

I’ve worked extensively with both residential and commercial clients. Residential projects often involve smaller-scale installations, focusing on individual homes or apartments. These installations might involve setting up home networks, connecting security systems, or installing home entertainment systems. In these situations, clear communication and attention to detail are essential to manage client expectations, especially regarding cable routing and aesthetics. Commercial installations, on the other hand, often involve more complex projects, such as setting up data centers, office networks, or large-scale building infrastructure. These projects demand a more structured approach, a deep understanding of network architecture, and adherence to strict safety and compliance regulations. For example, a recent project for a major bank required meticulous adherence to security protocols and compliance regulations, and successful completion reinforced my ability to manage complex, large-scale projects.

Q 19. How do you prioritize multiple tasks during a workday?

Prioritizing tasks during a workday involves a combination of planning, organization, and efficient time management. I typically begin each day by reviewing my schedule and prioritizing tasks based on urgency and importance. I utilize project management tools to break down large projects into smaller, manageable tasks. I use time-blocking techniques to allocate specific time slots for particular tasks, ensuring that I remain focused and avoid distractions. Unexpected issues do arise, and I’m adept at quickly assessing the situation and re-prioritizing tasks based on their impact on the overall project timeline. Flexibility and adaptability are key to maintaining productivity in a dynamic environment.

Q 20. Explain your familiarity with different types of cable labeling systems.

My familiarity with cable labeling systems is extensive. I understand and use various methods, including color-coded labels, numerical sequencing, alphanumeric labeling, and barcode systems. The choice of system depends on the project’s scale and complexity. For instance, in small residential projects, a simple color-coding system might suffice, whereas larger commercial projects often require a more sophisticated alphanumeric or barcode system for detailed tracking and management. I’m adept at interpreting and utilizing existing labeling systems to quickly identify and troubleshoot issues. This includes understanding industry-standard color codes and interpreting the information embedded within complex alphanumeric or barcode labels.

Q 21. How do you diagnose and resolve connectivity issues?

Diagnosing and resolving connectivity issues requires a systematic approach. I begin by gathering information from the client, understanding the nature of the problem, and when it started. Then, I conduct a thorough visual inspection of the cabling and connections, checking for obvious issues like loose connections, damaged cables, or incorrect terminations. I use specialized testing equipment, such as network testers, OTDRs, and cable certifiers, to pinpoint the exact location and cause of the problem. Once identified, I proceed with the necessary repairs or replacements, meticulously documenting every step. For example, I recently resolved a connectivity issue in a large office building by identifying a faulty patch panel using a cable certifier. This systematic approach, combined with my knowledge and experience, ensures efficient and effective troubleshooting.

Q 22. What are your skills in using test equipment (OTDR, power meter, etc.)?

My proficiency with test equipment like OTDRs (Optical Time-Domain Reflectometers) and power meters is extensive. I’m adept at using OTDRs to identify faults, measure fiber optic cable length and attenuation, and locate splices or connectors. This involves understanding how to interpret the OTDR trace, recognizing different types of events (like reflections and losses), and troubleshooting issues based on the trace. With power meters, I can accurately measure the optical power levels at various points in the fiber optic system, ensuring sufficient signal strength for reliable operation. I’m also comfortable using other relevant test equipment such as visual fault locators (VFLs) for quickly identifying fiber breaks or bends.

For example, during a recent installation, an OTDR trace revealed unexpected high attenuation mid-span. Using my knowledge of OTDR interpretation, I quickly identified a microbend in the fiber caused by improper cable management. By carefully re-routing the cable and eliminating the bend, I restored the link to optimal performance. My experience extends to calibrating and maintaining this equipment, ensuring accurate measurements throughout the installation process.

Q 23. Describe a time you had to solve a complex technical problem during a drop installation.

One time, I encountered a challenging situation where a buried fiber optic cable was damaged during excavation. The location was difficult to access, and the exact point of damage was unclear. Initially, we attempted to use a standard tracing method but were unsuccessful. To solve the problem, I implemented a multi-pronged approach. First, I utilized the OTDR to pinpoint the general area of the fault. Then, I employed a refined tracing method with improved ground penetrating radar (GPR) to narrow down the precise location of the damage. Finally, careful excavation, using small hand tools to avoid further damage, allowed us to locate and repair the broken fiber. This involved splicing the cable using fusion splicing equipment to ensure a low-loss connection. The meticulous approach ensured minimal disruption and a speedy restoration of service.

Q 24. What is your experience with using different types of ladders and lift equipment?

I am experienced with various ladders and lift equipment, including extension ladders, step ladders, bucket trucks, and aerial lifts. My experience includes safe and proper setup, operation, and takedown procedures for each. I understand the importance of regular inspections for damage or wear and tear and adhere strictly to weight limits and safety guidelines. I’m proficient in using fall protection equipment like harnesses and lanyards and always prioritize safety, regardless of the equipment used. For example, I have experience working from bucket trucks to install drops in high-rise buildings, ensuring a safe working environment at all times.

Q 25. How do you ensure the safety of yourself and others during a drop installation project?

Safety is my top priority. Before any drop installation, I conduct a thorough risk assessment, identifying potential hazards such as overhead power lines, underground utilities, and traffic. This assessment informs my safety plan, which includes selecting appropriate personal protective equipment (PPE), such as safety glasses, gloves, hard hats, and high-visibility clothing. I meticulously follow all relevant safety regulations and company procedures. When working at heights, I use appropriate fall protection systems and ensure that all equipment is properly inspected and maintained. Furthermore, I always communicate clearly with my team and anyone nearby about potential risks and safety measures. Regular toolbox talks are crucial for reinforcing safe work practices and addressing any potential concerns.

Q 26. What is your understanding of the National Electrical Code (NEC) as it pertains to drop installations?

My understanding of the NEC (National Electrical Code) as it relates to drop installations is comprehensive. I’m familiar with the articles pertaining to grounding and bonding requirements for aerial and underground fiber optic cable systems, ensuring the safety of both personnel and equipment. I understand the requirements for proper cable support, the use of appropriate connectors and terminations, and the installation methods to minimize the risk of damage. This includes knowledge of the specific requirements for different types of drops and the use of grounding conductors to protect against electrical surges or lightning strikes. I make sure to always follow the NEC guidelines precisely, ensuring compliance with all relevant safety codes and regulations.

Q 27. Explain your knowledge of grounding and bonding techniques in drop installations.

Grounding and bonding are critical aspects of drop installations to ensure electrical safety and protect against surges. My experience includes both aerial and underground installations. In aerial installations, I use grounding wires connected to the drop cable’s sheath and a suitable earth ground to dissipate static electricity and lightning strikes. For underground installations, grounding techniques depend on the type of conduit and cabling. Metallic conduits typically provide a natural path to ground, but it is still crucial to ensure proper bonding at various points. I utilize bonding techniques like wire braids or clamps to create a continuous low-impedance path to ground, minimizing the risk of electrical shock or damage to the equipment. This ensures the long-term integrity and safety of the entire system.

Q 28. Describe your experience working as part of a team on a drop installation project.

I thrive in team environments. Effective teamwork is essential in drop installations. My experience includes collaboration with various team members, from supervisors and engineers to fellow installers and technicians. I’m skilled in communicating effectively, coordinating tasks, and sharing my expertise with others. I am comfortable taking direction and contributing my skills to a larger project, ensuring that we work together efficiently and safely. For example, on a large-scale project, I collaborated effectively with my team, coordinating our efforts to meet deadlines and deliver high-quality results. My ability to listen and share ideas, along with my technical skills, resulted in seamless and efficient teamwork.

Key Topics to Learn for Drop Installation Interview

- Understanding Drop Installation Methodologies: Explore various approaches to drop installation, including considerations for different environments and project scales. Consider the advantages and disadvantages of each.

- Pre-Installation Planning & Assessment: Learn how to effectively plan a drop installation, including site surveys, risk assessment, and resource allocation. Discuss practical examples of overcoming site-specific challenges.

- Component Selection & Integration: Understand the criteria for selecting appropriate components for a successful drop installation. Discuss methods for seamless integration and compatibility testing.

- Safety Procedures & Regulations: Master the safety protocols and regulatory compliance required for drop installations. This includes risk mitigation strategies and emergency procedures.

- Troubleshooting & Problem-Solving: Develop your ability to diagnose and resolve common issues encountered during drop installation. Practice your approach to problem-solving under pressure.

- Post-Installation Verification & Maintenance: Learn the critical steps involved in verifying the successful completion of a drop installation and establishing ongoing maintenance strategies.

- Documentation & Reporting: Understand the importance of thorough documentation throughout the installation process, including reports and data logging.

Next Steps

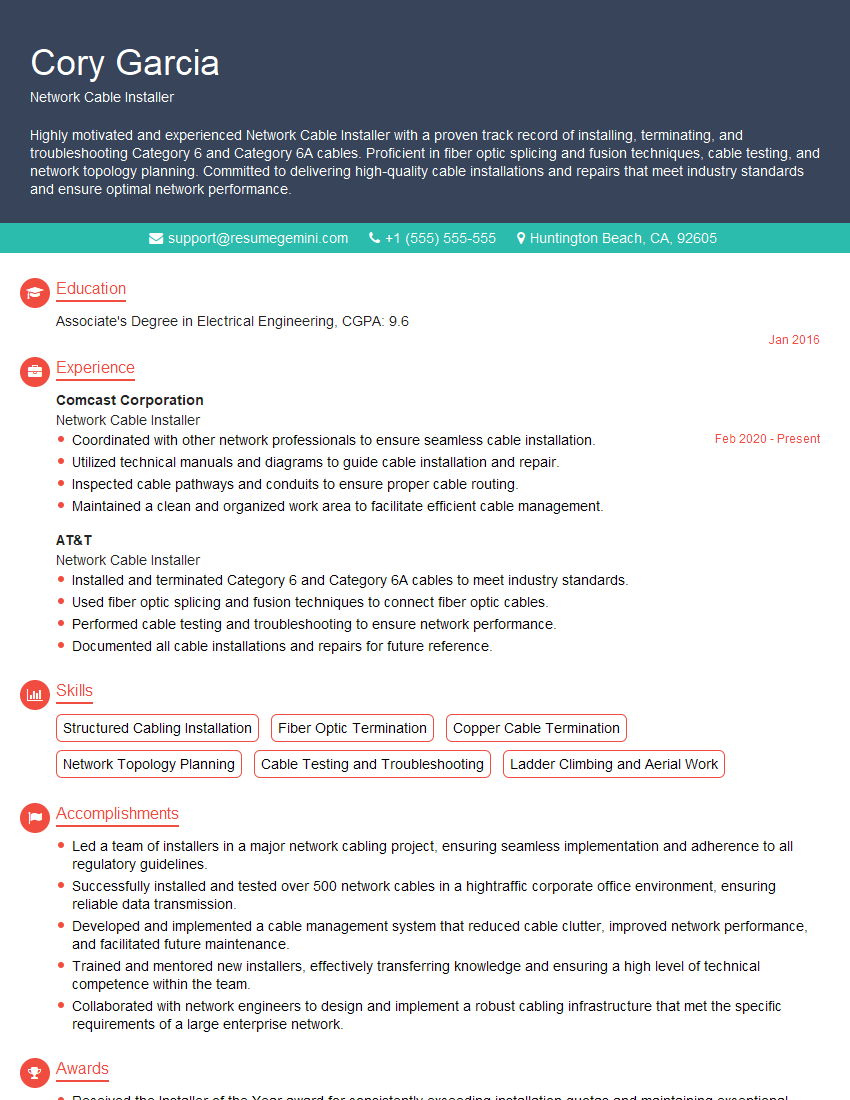

Mastering Drop Installation opens doors to exciting career opportunities in a rapidly growing field. A strong understanding of these techniques is highly sought after by employers, significantly increasing your job prospects. To stand out, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource for building professional resumes that catch the eye of recruiters. We offer examples of resumes tailored to Drop Installation to help you craft a compelling application that highlights your expertise. Take the next step towards your dream job—build a resume that reflects your capabilities and lands you that interview!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good