Preparation is the key to success in any interview. In this post, we’ll explore crucial Aerial Bucket Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Aerial Bucket Operation Interview

Q 1. Describe the pre-operational checks you perform on an aerial bucket truck.

Pre-operational checks on an aerial bucket truck are crucial for safety and efficient operation. Think of it like a pilot performing a pre-flight check – every detail matters. My routine involves a methodical approach, covering several key areas:

- Visual Inspection: I start with a thorough visual inspection of the entire truck, checking for any signs of damage, leaks (hydraulic fluid, etc.), or loose components. This includes the boom, bucket, tires, and all control mechanisms.

- Hydraulic System Check: I check the hydraulic fluid levels and look for any leaks or unusual noises. I’ll also test the boom’s functionality, ensuring smooth and controlled movement in all directions. This often involves a slow, careful extension and retraction of the boom to its full reach.

- Electrical System Check: The electrical system is critical for lights, controls, and safety features. I inspect the wiring for any damage or exposed wires and verify that all lights, alarms, and indicators are functioning correctly.

- Safety Equipment Check: This is arguably the most important step. I verify that all safety equipment is in place and functioning correctly, including the bucket’s safety restraints, emergency shut-off switches, and personal protective equipment (PPE) like my harness and gloves. I even test the emergency lowering system.

- Documentation: Finally, I meticulously document all checks performed, noting any issues or discrepancies. This creates a record for traceability and accountability.

For example, once I noticed a small hydraulic leak during a pre-operational check. Addressing this immediately prevented a more significant problem later, possibly avoiding a costly repair or even a dangerous situation.

Q 2. Explain the different types of aerial lifts and their applications.

Aerial lifts come in various types, each suited to different applications. The choice depends on factors like working height, weight capacity, and the specific job requirements. Here are some common types:

- Articulating Boom Lifts: These feature multiple sections that can bend and pivot, allowing for precise positioning in confined spaces. They’re ideal for reaching around obstacles, like working near power lines in a city environment.

- Telescopic Boom Lifts: These extend vertically, offering a significant reach but less maneuverability compared to articulating booms. They’re frequently used for tasks requiring straight-up vertical access, such as window washing on tall buildings.

- Vertical Mast Lifts: These lifts are straightforward, lifting vertically without significant horizontal reach. They’re best for simple, vertical lift needs and are commonly found in warehouses or factories.

- Scissor Lifts: These utilize a scissor-like mechanism, providing a stable, relatively low-height platform. They are commonly used for indoor work, such as maintenance in large buildings.

For instance, when working on a large power line project, an articulating boom lift allows for precise placement of the bucket around existing lines, minimizing risk. Meanwhile, in a warehouse setting, a scissor lift is perfect for reaching shelves without needing a high reach.

Q 3. What are the weight and height limitations of the aerial bucket you typically operate?

The weight and height limitations vary significantly depending on the specific aerial bucket truck model. The truck I typically operate has a maximum working height of approximately 60 feet and a maximum bucket capacity of around 500 pounds. This includes both the weight of the personnel and any materials being lifted. However, it’s crucial to always consult the manufacturer’s specifications for the exact limitations of the equipment before commencing any operation.

These limitations are never exceeded, and I always carefully calculate the total weight in the bucket to ensure it stays within the safe operating limits. It’s better to err on the side of caution.

Q 4. How do you ensure the stability of the aerial bucket during operation?

Ensuring stability is paramount when operating an aerial bucket. It involves several key steps:

- Proper Outrigger Deployment: Before raising the boom, I always fully extend and firmly set the outriggers. This provides a stable base for the truck, preventing it from tipping.

- Ground Conditions Assessment: I always carefully assess the ground conditions before setting up, ensuring it’s level and firm enough to support the truck’s weight, considering factors like soil type and potential obstacles.

- Load Distribution: Weight distribution within the bucket is critical. I ensure materials are evenly distributed to prevent any imbalance that could affect stability.

- Boom Positioning: I carefully position and extend the boom smoothly, avoiding jerky movements, as this can destabilize the platform.

- Monitoring Outrigger Indicators: Some trucks have built-in indicators showing whether outriggers are properly deployed and the truck is stable. This monitoring adds an extra layer of safety.

For example, working on uneven ground, I would adjust the outriggers or, if necessary, relocate the truck to a more stable surface before raising the bucket.

Q 5. What safety procedures do you follow when working at height?

Safety is always the top priority when working at height. My safety procedures follow a strict protocol:

- Harness and Fall Protection: I always wear a properly fitted full-body harness and connect it to the bucket’s safety system. This ensures that in the event of a fall, I am secured.

- Pre-Task Planning: I thoroughly plan the task before starting, identifying any potential hazards and mitigating risks.

- Communication: Maintaining clear communication with ground personnel is essential. We establish a signal system beforehand to avoid misunderstandings.

- Weather Awareness: I check the weather forecast and will suspend operations in case of high winds, lightning, or other hazardous conditions.

- Emergency Procedures Knowledge: I am thoroughly familiar with the emergency procedures in case of equipment malfunction or other unforeseen situations.

- Regular Training and Refresher Courses: I regularly participate in training and refresher courses to stay updated on the latest safety procedures and best practices.

Once, during a storm, I had to immediately lower the bucket and secure the equipment when lightning struck nearby. This quick action ensured the safety of both myself and my team.

Q 6. Describe your experience with emergency procedures in case of equipment malfunction.

My experience with emergency procedures involves a calm, systematic approach. The key is to stay composed and follow established protocols. I have undergone extensive training in handling various scenarios:

- Equipment Malfunction: If there’s an equipment malfunction (e.g., hydraulic failure), I immediately activate the emergency lowering system, following the manufacturer’s instructions carefully. I communicate my situation to ground personnel immediately.

- Unexpected Situations: In unexpected situations (e.g., sudden high winds), I prioritize lowering the bucket in a controlled manner. Safety is the absolute priority.

- Emergency Communication: I always carry a radio to maintain contact with ground personnel, reporting any unusual occurrences or issues instantly.

- Evacuation Procedures: I am proficient in the safe evacuation procedures and know when to seek additional help or call emergency services if needed.

In one instance, a hydraulic hose failed during an operation. I calmly activated the emergency lowering system, and the backup system worked flawlessly, allowing for a safe descent. Effective training and familiarity with emergency procedures proved invaluable during this experience.

Q 7. How do you communicate with ground personnel during aerial operations?

Clear communication is vital during aerial operations. I primarily use two-way radios to communicate with ground personnel. We establish a simple, unambiguous signal system to confirm instructions and provide updates. This often involves hand signals in conjunction with radio communication for added redundancy.

We practice these communication protocols regularly, ensuring everyone understands the signals and their meanings. For example, a specific hand signal could indicate that the bucket needs to be moved slightly to the left or right, while the radio is used for more detailed instructions or to report any issues.

This practice enhances our ability to coordinate movements and maintain situational awareness, contributing to a safer working environment.

Q 8. Explain the process of securing the aerial bucket in various weather conditions.

Securing an aerial bucket in various weather conditions is paramount for safety. The process adapts to the specific challenges each condition presents.

- High Winds: In windy conditions, the first step is assessing the wind speed. If it exceeds the machine’s operational limits (specified in the manufacturer’s manual), operation is immediately halted. If within limits, we’ll choose a more sheltered location, if possible, and reduce the boom extension as much as practical to minimize sway. Extra caution is taken during movement, with slower, more controlled operation. We might even need to use additional anchors or counterweights, if available and safe to do so.

Example: On a recent job, we had to postpone work due to unexpectedly high winds exceeding the safe operating limit of our boom lift. Safety is always the priority. - Rain/Snow: Wet conditions reduce traction and can affect visibility. We always ensure the area around the base of the lift is clear of debris and free from puddles to prevent slippage. Non-slip mats can be helpful. We utilize slower operating speeds to maintain control and increase awareness of our surroundings and potential risks, like slipping on wet surfaces. Appropriate safety attire including rain gear or winter clothing is essential.

- Ice/Freezing Conditions: Ice is extremely dangerous. Operations should typically cease if icy conditions exist, as even slight movements can cause a catastrophic accident. If operation is absolutely necessary, extreme caution must be exercised, and de-icing agents may be needed (following manufacturer guidelines, and strictly observing all environmental regulations, for responsible use). We meticulously check the ground for ice patches and ensure the aerial platform’s tires have sufficient traction on treated surfaces, if operation is authorized.

In all weather conditions, regular communication between the operator and ground personnel is vital.

Q 9. What are the common causes of aerial bucket malfunctions and how to troubleshoot them?

Aerial bucket malfunctions can stem from various issues. Regular maintenance is crucial in preventing many of them.

- Hydraulic System Problems: Leaks, malfunctioning pumps, or faulty valves can lead to limited or no movement. Troubleshooting involves checking fluid levels, inspecting hoses and connections for leaks, and testing the hydraulic system components using diagnostic tools.

- Electrical Malfunctions: Problems with the electrical system can cause issues with controls, lights, or safety mechanisms. This requires checking wiring, fuses, and circuit breakers, and potentially consulting an electrician specialized in aerial lift equipment.

- Mechanical Failures: Wear and tear on mechanical components like the boom, outriggers, or the platform itself can cause malfunctions. Regular inspections identify and address problems before they escalate.

- Software Errors (on newer models): Some newer aerial buckets have sophisticated computer systems. Software glitches can manifest in various ways. In these cases, diagnostic software and potentially a service technician are necessary.

A systematic approach, starting with a visual inspection, followed by checks on the hydraulic, electrical, and mechanical systems, is key to efficient troubleshooting. If the problem persists, always consult the manufacturer’s manual and involve qualified technicians.

Q 10. How do you handle unexpected obstacles or environmental hazards during operation?

Handling unexpected obstacles or environmental hazards requires quick thinking and adherence to safety protocols.

- Immediate Assessment: The first response is a thorough assessment of the hazard and the best course of action. Does it impact the planned operations? Is it safe to proceed? Does it necessitate a change in the planned work method?

- Communication: Clear communication with the ground crew is essential. They need to know the situation and any adjustments required.

- Risk Mitigation: Implementing necessary precautions is crucial. This might involve adjusting the boom position, choosing an alternative approach, or temporarily halting operations to reassess and develop a safer plan.

- Emergency Procedures: For serious hazards, emergency procedures need to be followed, potentially including evacuating the aerial bucket and contacting emergency services. Knowing where emergency shut-offs are located is vital.

Example: Once, while working near a power line, a strong gust of wind unexpectedly moved a branch into contact with our boom. We immediately lowered the boom, reported the incident, and waited for the branch to be safely cleared before resuming work.

Q 11. What are the relevant safety regulations and standards you adhere to?

Adhering to relevant safety regulations and standards is non-negotiable. These standards vary by region but generally encompass several key areas:

- Manufacturer’s Guidelines: We always strictly follow the manufacturer’s instructions and safety manuals specific to each aerial bucket model used.

- OSHA Regulations (or equivalent in other jurisdictions): Occupational Safety and Health Administration (OSHA) in the US, or the equivalent safety regulations in other countries, provide a comprehensive framework for safe operation of aerial lifts, including pre-operational inspections, safe operating procedures, and training requirements.

- Local Regulations: Local regulations, which might include permits, site-specific requirements, and traffic management rules, add further layers of compliance.

- Industry Best Practices: Staying updated on industry best practices, attending relevant training courses, and adopting safety procedures from reputable organizations adds another crucial layer to our safety consciousness.

Our commitment to safety is unwavering, and we regularly review and update our procedures to ensure full compliance with all regulations.

Q 12. Describe your experience with different types of aerial lift controls.

My experience includes various aerial lift control types, ranging from simple, mechanical controls to advanced, electronically controlled systems.

- Mechanical Controls: These utilize levers and handwheels for movement and are generally found on older or simpler models. Understanding the mechanical linkages and the responsiveness of these controls requires thorough training and practice.

- Proportional Controls: Proportional controls provide more precise control over boom movements. These often feature joysticks or hand levers with varying degrees of sensitivity, allowing smoother and more precise positioning of the bucket.

- Electronic Controls with Computer Interfaces: Modern aerial buckets often incorporate electronic controls, sometimes with sophisticated computer interfaces. These systems allow for diagnostics, self-checks, and potentially integrated safety features. Understanding the software and operating the associated control screens is crucial for efficient and safe operation.

Regardless of the control system, mastering the machine’s specific controls and practicing smooth, controlled movements are fundamental for safe and effective operation. The ability to quickly react to unexpected events requires regular practice and maintenance of sharp operational skills.

Q 13. How do you maintain the aerial bucket and its components?

Maintaining the aerial bucket and its components is a continuous process. This involves both preventative measures and addressing any detected issues.

- Daily Inspections: Before each use, a comprehensive inspection is conducted, checking tire pressure, hydraulic fluid levels, safety devices, and any visible damage to the boom, platform, or other components.

- Regular Lubrication: Moving parts need regular lubrication to ensure smooth operation and reduce wear. This includes hinges, joints, and other moving mechanical components.

- Hydraulic System Maintenance: This involves regularly checking fluid levels and condition, inspecting hoses and connections for leaks, and replacing filters as per the manufacturer’s recommendations.

- Electrical System Checks: Wiring, connections, lights, and safety devices in the electrical system should be regularly checked for damage or wear.

- Component Replacements: Worn or damaged components should be replaced promptly to maintain safety and operational efficiency. This might include replacing tires, hoses, or other parts, as needed.

Detailed records of all inspections and maintenance procedures are meticulously kept, complying with legal and safety regulations.

Q 14. Explain the importance of regular inspections and maintenance.

Regular inspections and maintenance are not merely recommended; they are essential for safe and reliable aerial bucket operation. Think of it like this: a car needs regular servicing; neglecting this can lead to breakdowns and accidents. Similarly, neglecting aerial bucket maintenance dramatically increases the risk of malfunctions that can lead to serious injury or even death.

- Safety: Regular inspections detect potential problems before they escalate into hazards, minimizing the risk of accidents caused by mechanical or electrical failures.

- Efficiency: Well-maintained equipment works more efficiently, reducing downtime and increasing productivity. A properly maintained lift will operate smoothly and reliably, without unexpected delays.

- Longevity: Regular maintenance extends the lifespan of the aerial bucket, preventing premature wear and tear and saving money in the long run.

- Compliance: Regular inspections and maintenance are frequently mandated by regulations, ensuring compliance with legal requirements and demonstrating a commitment to safety.

By prioritizing regular inspections and maintenance, we not only ensure the safety of our personnel, but also contribute to operational efficiency and the longevity of our valuable equipment.

Q 15. How do you perform a thorough inspection before each operation?

A thorough pre-operation inspection of an aerial bucket is crucial for ensuring safety and preventing accidents. It’s like a pilot performing a pre-flight check – you wouldn’t take off without it! My inspection follows a standardized checklist, but it’s always tailored to the specific job and equipment.

- Visual Inspection: I start with a visual check of the entire lift, including the boom, bucket, hydraulic lines, and electrical components. I look for any signs of damage, leaks, cracks, or wear and tear. I pay close attention to welds, pins, and moving parts.

- Functional Check: Next, I test all the controls – elevation, rotation, extension – ensuring smooth operation and responsiveness. I check the emergency stop mechanism multiple times. I also verify the functionality of the lights and alarms.

- Weight Capacity: I always confirm the weight capacity of the lift and the load to be lifted, making sure we stay well within the safe working limits. Overloading can lead to catastrophic failures.

- Documentation: All findings are documented in a pre-operational checklist, which is then signed and dated by myself and a supervisor. Any issues are reported immediately and addressed before operation commences.

For example, I once discovered a small crack in a hydraulic line during a routine inspection. This could have easily led to a hydraulic failure mid-operation, potentially causing a serious accident. By catching it early, we avoided a costly and dangerous situation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with confined space entry from an aerial bucket.

Confined space entry from an aerial bucket requires additional precautions and permits, above and beyond normal aerial lift procedures. It’s a high-risk activity requiring strict adherence to safety protocols. My experience includes numerous confined space entries, mainly for inspection and maintenance tasks in tanks, silos, and other enclosed spaces.

- Permit-to-Work System: Before any entry, a permit-to-work is obtained, outlining the hazards, precautions, and emergency procedures. This involves atmospheric testing to check for oxygen levels, flammable gases, and toxic substances.

- Rescue Plan: A detailed rescue plan is always in place, ensuring a swift and safe retrieval if an emergency occurs. This includes having appropriate rescue equipment readily available.

- Communication: A constant communication system is essential, with a designated attendant outside the confined space monitoring the worker’s condition and ready to provide assistance.

- Personal Protective Equipment (PPE): Appropriate PPE goes beyond the standard harness. It includes respiratory protection, such as SCBA (Self-Contained Breathing Apparatus) in oxygen-deficient atmospheres, and specialized clothing for protection against hazards within the confined space.

For instance, during a confined space entry into a large water tank for inspection, we had a detailed atmospheric test performed, and a rescue plan was prepared in advance, including the positioning of a safety harness and rope system. The attendant maintained constant communication with me through a radio, and I wore a full-body harness and SCBA.

Q 17. How do you calculate safe working loads for different tasks?

Calculating safe working loads is paramount. It’s not just about the weight of the materials, but also the position of the load relative to the boom’s center of gravity and the lift’s capacity at different boom angles. We utilize load charts specific to each aerial lift model, which take all these factors into account.

- Load Charts: These charts provide the maximum permissible load for various boom configurations (height and reach). These charts are critical and must be consulted for every task.

- Weight of Materials and Equipment: The precise weight of all materials being lifted, including the bucket, personnel, and any tools, must be accurately determined and summed up.

- Boom Angle: The angle of the boom significantly influences the lift’s capacity. Steeper angles reduce the load capacity. The load chart will show safe load limits for different boom angles.

- Environmental Factors: Wind speed and direction can dramatically affect stability and load capacity. Operations might need to be halted or modified in strong winds.

For example, if I’m lifting a heavy piece of equipment that weighs 500kg, I wouldn’t simply look at the total weight. I’d consult the load chart to find the safe working load at the specific boom angle required for the task, ensuring that the combined weight of equipment, personnel, and bucket remains well below that limit.

Q 18. How do you assess and mitigate risks associated with aerial operations?

Risk assessment in aerial operations is a systematic process. It involves identifying potential hazards, assessing their likelihood and severity, and implementing control measures to mitigate risks. This is an ongoing process – not a one-time event.

- Hazard Identification: This involves identifying all potential hazards, such as electrical hazards, falls from height, collisions with obstacles, weather-related risks, and equipment malfunctions.

- Risk Assessment: For each hazard identified, the likelihood and severity are assessed. This often uses a matrix-based approach, with different levels of risk (low, medium, high).

- Risk Control: Once risks are assessed, control measures are implemented. These can include administrative controls (e.g., training, permits), engineering controls (e.g., using safety harnesses, barriers), and personal protective equipment (PPE).

- Monitoring and Review: The effectiveness of control measures is continuously monitored, and the risk assessment is reviewed regularly, especially after incidents or changes in the working environment.

For instance, working near power lines always requires a detailed risk assessment, including the distance from the lines, the voltage, and the presence of any insulated tools. We may opt for a different approach if the risks are too high.

Q 19. What is your understanding of fall protection and its implementation in aerial work?

Fall protection is non-negotiable in aerial work. It’s the primary defense against falls from height, which are often fatal. My understanding includes the use of various systems and stringent adherence to regulations.

- Full Body Harnesses: These are the cornerstone of fall protection, distributing the impact force across the body in case of a fall. Harnesses must be properly fitted and inspected regularly.

- Anchor Points: Secure anchor points are critical. These need to be independently certified and capable of withstanding substantial forces. These are typically on the bucket itself.

- Lanyards and Shock Absorbers: Lanyards connect the harness to the anchor point, and shock absorbers help reduce the impact forces during a fall.

- Regular Inspections and Training: All fall protection equipment must be regularly inspected and maintained. Workers must also receive comprehensive training on the correct use and care of the equipment.

In practice, this means ensuring every worker in the bucket is wearing a correctly fitted harness attached to a robust anchor point via a lanyard and shock absorber. We never compromise on fall protection – it’s a matter of life and death.

Q 20. Describe your experience working with different types of aerial bucket attachments.

I have extensive experience working with a variety of aerial bucket attachments, each tailored to specific tasks. This experience allows me to select the most appropriate attachment for any job, ensuring efficiency and safety.

- Insulated Buckets: Used for working near power lines, these buckets provide protection from electrical shock.

- Extended Reach Buckets: These are ideal for accessing difficult-to-reach areas.

- Personnel Baskets: These prioritize personnel safety during high-altitude operations.

- Specialized Tool Trays: These allow for easy access to tools and equipment, enhancing efficiency and reducing the need for constant climbing up and down.

- Material Handling Buckets: These are designed to lift and carry various materials, including heavy items.

For example, when working on a power line repair, I would use an insulated bucket. During tree trimming, I might use an extended-reach bucket with a specialized saw attachment. The right attachment minimizes risk and improves productivity.

Q 21. How do you respond to an emergency situation involving a malfunctioning aerial lift?

Responding to emergencies involving malfunctioning aerial lifts demands quick thinking, calm action, and adherence to established emergency protocols. Safety is paramount in these situations.

- Activate Emergency Stop: Immediately hit the emergency stop button on the lift.

- Evacuate the Bucket: If safe to do so, safely evacuate the bucket. If unable, stay calm and await rescue.

- Alert Emergency Services: Contact emergency services immediately, providing them with the location, the nature of the malfunction, and the number of people involved.

- Secure the Area: Ensure the area around the lift is secured, preventing unauthorized access or further accidents.

- Follow Established Procedures: Adhere to established emergency procedures and cooperate fully with emergency personnel.

I once experienced a hydraulic failure in the middle of a job. I immediately activated the emergency stop, safely evacuated the bucket, and alerted the emergency team. The incident emphasized the importance of having a comprehensive emergency plan, regular equipment maintenance, and a clear communication system.

Q 22. What are the signs of fatigue and how do you manage them to avoid accidents?

Fatigue is a serious hazard in aerial bucket operations, significantly impacting judgment, reaction time, and overall safety. Signs can include drowsiness, difficulty concentrating, muscle aches, and decreased awareness of surroundings. For example, I once noticed a colleague exhibiting slow responses and slight slurring of speech – clear indicators of fatigue.

Managing fatigue requires proactive measures. This includes getting adequate sleep before a shift, staying hydrated, taking regular breaks, and ensuring proper nutrition. We use a buddy system, where co-workers watch out for each other. If someone seems fatigued, we encourage them to take a break or, if necessary, rest for the remainder of the shift. Our company also emphasizes the importance of reporting fatigue and encourages open communication regarding physical and mental well-being. Ignoring fatigue is not an option; it’s a risk to ourselves and everyone on the ground.

Q 23. Explain your understanding of load balancing and center of gravity.

Load balancing and center of gravity are crucial for safe aerial bucket operations. Load balancing ensures the weight in the bucket is distributed evenly, preventing instability and potential tipping. The center of gravity is the point where the weight of an object is concentrated. Understanding this is vital because if the center of gravity shifts too far outside the bucket’s base, it can easily become unbalanced.

Imagine a bucket with heavy equipment concentrated on one side; this creates an uneven load distribution and shifts the center of gravity, making the boom truck more prone to tipping. Proper load balancing is achieved through careful placement of materials within the bucket, ensuring the weight is distributed evenly across the base. We use checklists and training to reinforce these principles. Regular inspection of the load and adjustments as needed, are standard practices.

Q 24. Describe your experience with working near power lines.

Working near power lines is inherently dangerous and demands extreme caution. My experience involves strict adherence to safety protocols, including maintaining a safe distance, employing spotters, and utilizing specialized equipment. I’ve worked on projects involving trimming trees near high-voltage lines. We use a dedicated spotter to maintain constant visual contact with the power lines to warn of any potential encroachment. We also use specialized tools designed to minimize the risk of accidental contact.

Furthermore, before commencing any work near power lines, we always conduct a thorough risk assessment to identify potential hazards and implement appropriate control measures. This includes contacting the utility company to de-energize the lines if necessary or to implement safety measures to prevent accidental contact.

Q 25. What are the different types of insulators used in aerial bucket operations?

Various insulators are used in aerial bucket operations, each designed for specific applications and voltage levels. Common types include:

- Rubber Insulators: These provide excellent dielectric strength and are frequently used in lower-voltage applications.

- Composite Insulators: These combine multiple materials (e.g., fiberglass and silicone rubber) for improved strength, durability, and resistance to environmental factors. They’re common in higher-voltage situations.

- Ceramic Insulators: Known for high strength and resistance, these are used in high-voltage applications where exceptional insulation is essential.

The selection of the appropriate insulator is based on factors such as voltage levels, environmental conditions, and the specific requirements of the operation. Choosing the wrong insulator can lead to serious accidents.

Q 26. How do you ensure the proper grounding of equipment before commencing work?

Ensuring proper grounding is paramount before starting any work. We use ground rods driven into the earth, creating a path for any electrical current to safely flow into the ground. The ground connection is then made to the aerial bucket using heavy-gauge grounding cables. Before connecting the ground cable, we visually inspect the cable to make sure it’s undamaged and the connectors are securely attached.

A ground continuity tester verifies a proper connection between the equipment and the ground. We never assume that a ground connection is working correctly; we always test it before beginning work. This simple step prevents potential electrocution and is a fundamental part of our safety procedures.

Q 27. What is your experience with using lockout/tagout procedures?

Lockout/Tagout (LOTO) procedures are critical for isolating energy sources and preventing accidental start-ups during maintenance or repairs. My experience includes extensive training and practical application of LOTO procedures on a variety of equipment, including aerial lifts. We use standardized LOTO devices, clearly labeled with the worker’s name, date, and equipment identified. The procedure is meticulously documented, and a team member verifies the lockout before any work begins and releases it afterward following a clear step-by-step process.

For instance, before working on the hydraulic system of the boom truck, we use LOTO to ensure the hydraulic power is completely shut off and cannot be accidentally reactivated. This is crucial to prevent sudden movement of the boom or bucket, a critical safety hazard.

Q 28. Describe a time you had to make a quick, critical decision during an aerial operation.

During a high-wind operation, a sudden gust caused the bucket to swing violently, threatening to hit a nearby structure. My initial reaction was to immediately signal the ground crew to stop the boom truck’s movement. I then carefully and slowly maneuvered the bucket to regain stability, avoiding any further movement until the wind subsided. Assessing the situation rapidly and prioritizing safety was paramount. The experience reinforced the need for constant situational awareness and swift decisive action during unexpected events.

This incident highlighted the importance of constantly monitoring weather conditions and adjusting our operations as needed. We’ve since incorporated additional safety briefings covering extreme wind conditions and refined our communication procedures.

Key Topics to Learn for Aerial Bucket Operation Interview

- Safety Procedures and Regulations: Understanding and application of OSHA regulations, pre-operation checks, and emergency protocols for aerial bucket operations.

- Equipment Operation and Maintenance: Familiarity with different types of aerial work platforms (AWPs), their operational limitations, and routine maintenance procedures. Practical experience with troubleshooting common equipment malfunctions is valuable.

- Job Site Assessment and Planning: Analyzing work areas for potential hazards, planning efficient work sequences, and understanding load limits and weight distribution within the bucket.

- Communication and Teamwork: Effective communication with ground personnel, understanding hand signals, and collaborating safely with colleagues in potentially hazardous environments.

- Aerial Bucket Operation Techniques: Mastering smooth and controlled movements, maneuvering in confined spaces, and understanding the impact of wind and weather conditions on operation.

- Advanced Techniques (as applicable): Depending on the specific role, this could include specialized knowledge such as working at height, confined space entry, or specific industry regulations (e.g., telecom, power lines).

- Problem-Solving and Decision-Making: Demonstrating the ability to assess and react to unexpected situations, make sound judgments under pressure, and prioritize safety.

Next Steps

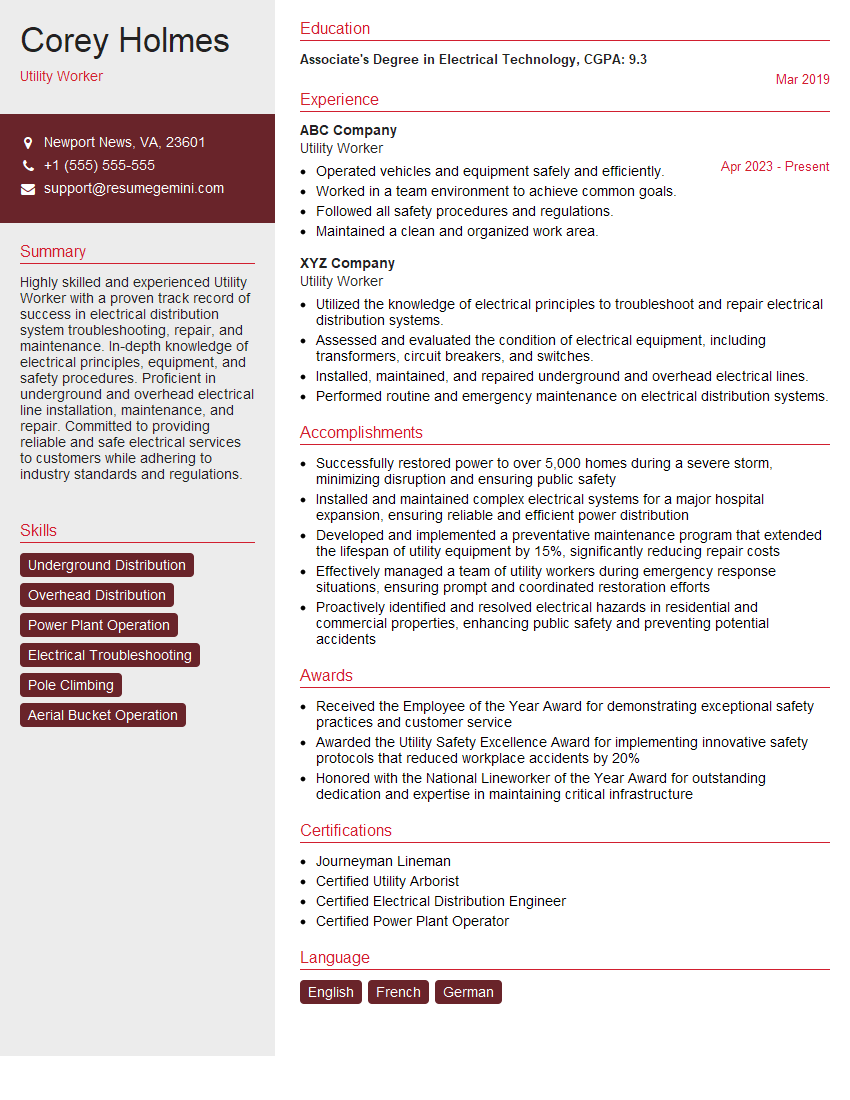

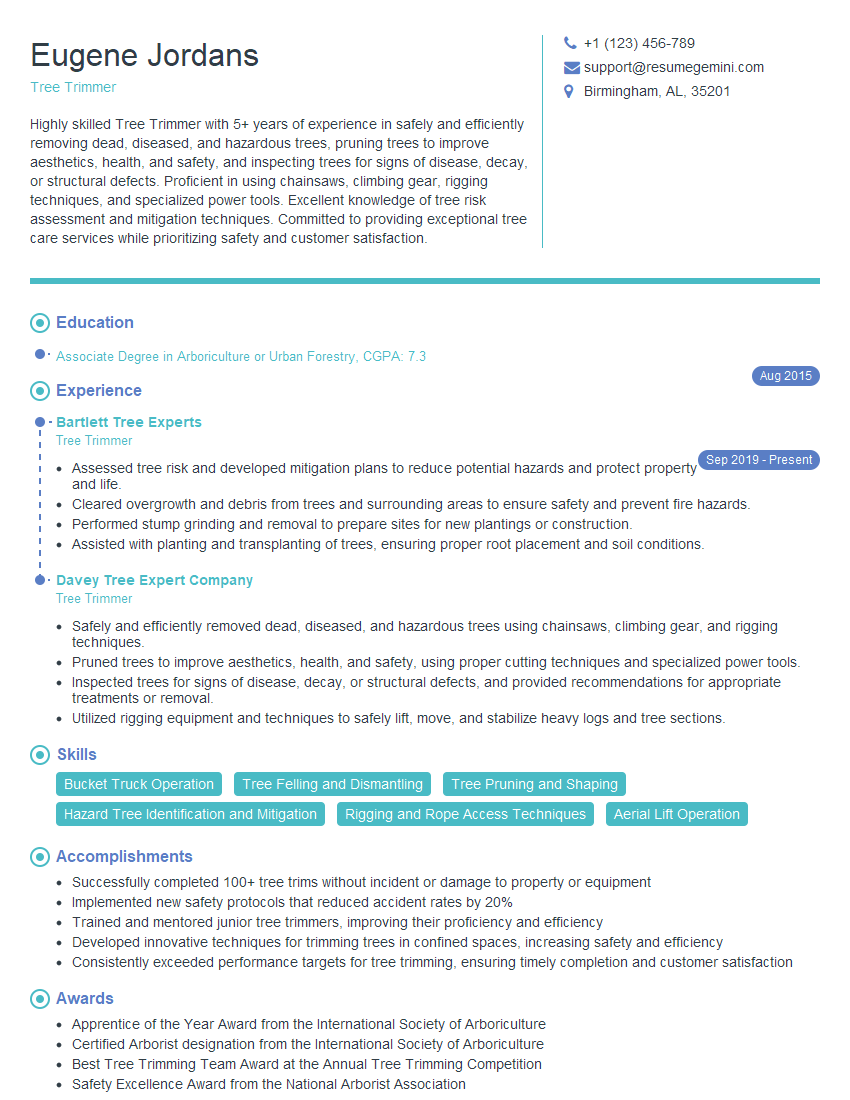

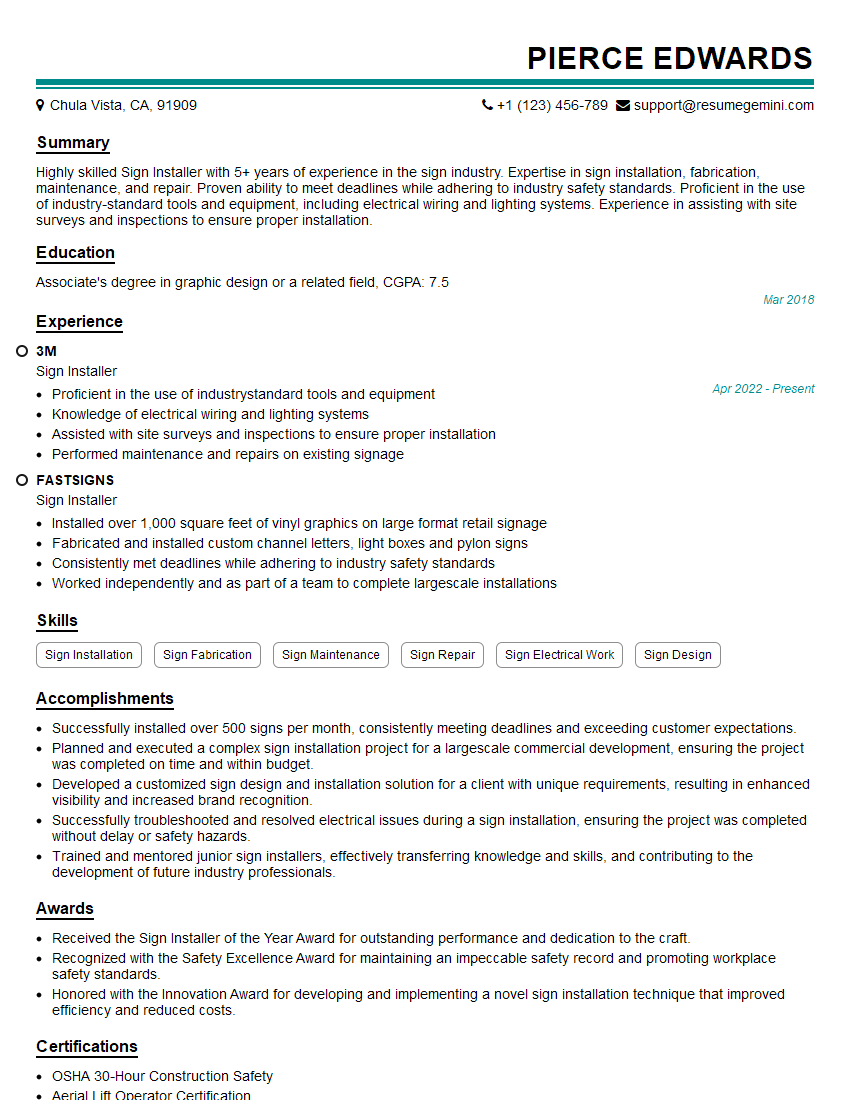

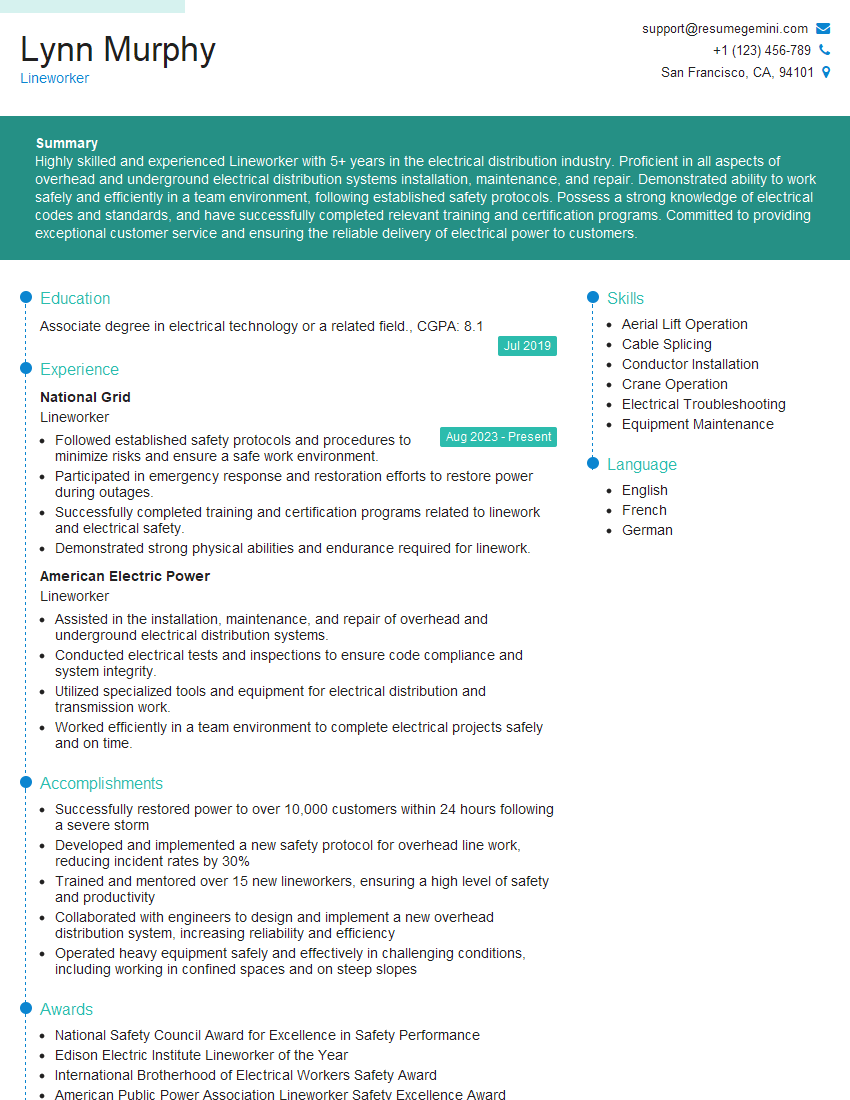

Mastering Aerial Bucket Operation opens doors to rewarding and specialized careers in various industries. To stand out, crafting a compelling, ATS-friendly resume is crucial. This ensures your qualifications are effectively highlighted to potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the demands of this exciting field. We provide examples of resumes specifically designed for Aerial Bucket Operation roles to guide you. Invest time in building a strong resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good