The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Setup and Operation of Disc Grinding Machines interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Setup and Operation of Disc Grinding Machines Interview

Q 1. Explain the different types of disc grinding wheels and their applications.

Disc grinding wheels are classified based on their bonding material, abrasive grain type, and structure. The choice depends heavily on the material being ground and the desired finish.

- Resinoid bonded wheels: These are strong and versatile, ideal for grinding hardened steels, cast iron, and non-ferrous metals. They offer a good balance of cutting ability and wheel life. Think of them as the ‘all-arounders’ in the grinding world. For example, you’d use a resinoid wheel for sharpening high-speed steel tools.

- Vitrified bonded wheels: These are the most common type, known for their durability and resistance to heat. They are excellent for precision grinding and can handle high speeds. Imagine using a vitrified wheel for precision grinding of a complex shape in a die.

- Rubber bonded wheels: These are flexible and conform well to irregular surfaces, making them suitable for surface finishing and deburring. They’re gentler on the workpiece. A good example is using them for removing burrs from delicate castings.

- Metal bonded wheels: Extremely durable and designed for heavy-duty grinding of tough materials. They’re slower cutting but have a very long lifespan, ideal for applications like grinding very hard materials such as cemented carbides.

- Electroplated wheels: These consist of abrasive grains electroplated onto a metal backing. They are very thin and used for fine grinding and finishing operations, often on intricate parts. Think of using one for creating a very fine surface finish on a jewelry piece.

The abrasive grain (e.g., aluminum oxide, silicon carbide) determines the cutting ability and the type of material it can effectively grind. The structure refers to the spacing of the grains, impacting the aggressiveness of the grind.

Q 2. Describe the process of setting up a disc grinding machine for a specific job.

Setting up a disc grinding machine involves several crucial steps to ensure safety and optimal performance. It’s like preparing a kitchen before cooking a complex meal – you want everything in its place.

- Wheel Selection: Choose the appropriate wheel based on the workpiece material, desired finish, and the machine’s specifications (max speed and power). Refer to the wheel’s marking for details.

- Wheel Mounting: Carefully mount the wheel onto the spindle, ensuring it’s securely fastened and the flanges are properly aligned. An improperly mounted wheel is a major safety hazard!

- Work Rest Adjustment: Adjust the work rest to a safe distance from the wheel, typically about ⅛ to ¼ inch. This prevents excessive wheel wear and workpiece damage.

- Safety Guard Placement: Ensure the safety guard is securely in place and properly adjusted to cover the grinding wheel’s operational area. Never operate without it.

- Machine Alignment: Check the machine’s alignment and ensure that all components are secure and functional. This means no loose parts, no vibrations, and everything running smoothly.

- Test Run: Before starting work, always perform a test run at low speed to ensure there are no vibrations or unusual noises.

Remember to consult the machine’s specific operating manual for detailed setup instructions.

Q 3. How do you determine the correct grinding wheel speed and feed rate?

Determining the correct grinding wheel speed and feed rate is critical for achieving the desired results and preventing damage to both the wheel and the workpiece. It’s akin to finding the right temperature and cooking time for a perfect dish.

The wheel speed is determined by the wheel’s recommended operating speed, indicated on the wheel itself (usually in surface feet per minute or sfpm). Never exceed this speed. The machine should be capable of reaching this speed. Incorrect speed could lead to wheel breakage.

Feed rate refers to how fast the workpiece is moved across the wheel. A slower feed rate is used for fine finishes and for harder materials. A faster feed rate is acceptable for coarser grinding and softer materials. Too fast a feed can overheat the workpiece and the wheel, leading to burns and wheel wear. Too slow a feed can lead to glazing of the wheel and inefficient stock removal.

The manufacturer’s guidelines and experience play a crucial role in determining the ideal parameters for specific materials and finishes. Always start with a slower feed rate and gradually increase it based on your observations. Observe the wheel’s condition and the workpiece’s surface temperature. Excessive heat is a sign you’re going too fast.

Q 4. What safety precautions are essential when operating a disc grinding machine?

Safety is paramount when operating a disc grinding machine. Neglecting safety can lead to serious injury. Think of it like following strict protocols in a chemistry lab.

- Eye Protection: Always wear safety glasses or a face shield to protect against flying debris.

- Hearing Protection: Grinding can be noisy; earplugs or muffs are essential.

- Respiratory Protection: Depending on the material being ground, a dust mask or respirator might be necessary.

- Proper Clothing: Wear close-fitting clothing to avoid entanglement in the machine. No loose sleeves or ties!

- Machine Guarding: Ensure the machine’s safety guards are properly in place and functioning correctly.

- Wheel Inspection: Inspect the grinding wheel before each use for cracks, damage, or wear. Never use a damaged wheel.

- Work Area: Keep the work area clean, organized, and free of obstructions.

- Proper Technique: Use proper grinding techniques to avoid accidents and obtain quality results. Never force the workpiece.

- Emergency Stop: Familiarize yourself with the machine’s emergency stop procedures.

Q 5. How do you inspect a grinding wheel for damage or wear?

Regular inspection of the grinding wheel is critical for safety and performance. Think of it as a regular checkup for your car’s tires – you wouldn’t drive with worn-out tires.

Before each use, carefully inspect the wheel for the following:

- Cracks: Check the wheel’s surface, sides, and hub for any cracks, even hairline fractures.

- Chips or Breaks: Look for any missing pieces or significant damage to the abrasive surface.

- Excessive Wear: A significantly worn-down wheel may be underperforming and could be more prone to breakage. Refer to manufacturer’s recommendations for minimum thickness.

- Glazing: A glazed wheel indicates that the abrasive grains are dull and need to be dressed or replaced.

- Burning or discoloration: Severe discoloration or burning indicates potential internal damage.

If any of these issues are found, the wheel should be immediately replaced. Don’t take chances!

Q 6. Explain the procedure for dressing and truing a grinding wheel.

Dressing and truing a grinding wheel are crucial maintenance tasks that restore its shape and cutting ability. Imagine sharpening a knife – you wouldn’t expect a dull knife to make clean cuts.

Dressing: This process removes dull or clogged abrasive grains from the wheel’s surface, restoring its cutting action. It’s usually done with a dressing tool, which is a device with hard abrasive points. This process creates a sharp cutting surface on the wheel.

Truing: This involves accurately restoring the wheel’s shape and concentricity. A true wheel is perfectly round, which is essential for precision grinding. This is often done using a diamond dresser or other dedicated truing tools that carefully remove material from the wheel face. This removes any uneven wear or other imperfections on the wheel face.

The specific procedure depends on the type of dressing and truing tool and the machine used. Always follow the manufacturer’s instructions. Improper dressing or truing can damage the wheel and create an unsafe condition.

Q 7. How do you measure the dimensional accuracy of a workpiece after grinding?

Measuring the dimensional accuracy of a workpiece after grinding involves using appropriate measuring instruments and techniques, depending on the workpiece’s geometry and the required tolerance.

For simple shapes like cylinders or flat surfaces, you could use:

- Micrometers: For precise measurements of diameter, thickness, or other linear dimensions.

- Calipers: For measuring various dimensions, including inside and outside diameters.

- Dial indicators: For checking surface flatness, roundness, and parallelism.

For more complex shapes, you may need more advanced equipment:

- Coordinate Measuring Machines (CMMs): These machines provide highly accurate 3D measurements of complex geometries.

- Optical comparators: These are useful for comparing the workpiece to a master template or drawing.

The chosen method will depend on the required accuracy and the complexity of the workpiece. Always use the appropriate instrument for the job and ensure its calibration for reliable measurements. Remember that documentation of the measurement and procedures is equally important.

Q 8. What are the common causes of surface imperfections on a ground workpiece?

Surface imperfections on a ground workpiece, like scratches, waviness, or burns, stem from several factors during the grinding process. Think of it like trying to create a perfectly smooth surface with sandpaper – if you apply too much pressure, use the wrong grit, or have a dirty surface, you won’t get the desired result.

- Wheel Condition: A worn, damaged, or improperly dressed grinding wheel is a major culprit. Imagine trying to sand with a ragged piece of sandpaper – you’ll get an uneven finish. Cracks, glazing, or loading (build-up of material on the wheel) all contribute to poor surface quality.

- Workpiece Setup: Improper clamping, causing workpiece vibration or deflection, can lead to uneven grinding. This is like trying to sand a piece of wood that’s not firmly clamped down – it will move around and the sanding will be inconsistent.

- Grinding Parameters: Incorrect parameters such as excessive downfeed, incorrect speed, or inadequate coolant flow can cause burning, glazing, and other imperfections. Think of it like using too much heat while sanding wood; you’ll burn it.

- Workpiece Material: The material’s properties, hardness, and microstructure will influence the grinding process and surface finish. Some materials are simply more prone to imperfections during grinding than others.

- Coolant Quality and Application: Insufficient or contaminated coolant can lead to excessive heat generation and poor surface quality. The coolant acts as a lubricant and heat sink; inadequate coolant is like sanding without water, leading to friction and burning.

Q 9. Describe your experience with different types of grinding fluids.

My experience encompasses a range of grinding fluids, each tailored to specific applications and materials. The choice depends on factors like material being ground, the desired surface finish, and environmental concerns.

- Water-based coolants: These are common, relatively inexpensive, and environmentally friendly. However, their lubricating and cooling capabilities can be limited in demanding applications.

- Oil-based coolants: Provide superior lubrication and cooling, often used for difficult-to-grind materials or high-speed operations. But they can present disposal challenges due to environmental concerns.

- Synthetic coolants: Offer a good balance between performance and environmental impact. They often exhibit better lubricity and cooling than water-based coolants while being more environmentally friendly than oil-based ones. I’ve found these to be particularly effective in precision grinding.

- Specialty coolants: For specific materials or operations, specialized coolants with additives may be required to enhance performance or address unique challenges. For example, some coolants are designed to minimize corrosion or reduce the risk of wheel glazing.

I always assess the specific application before selecting a coolant and regularly monitor its condition to ensure optimal performance and prevent contamination.

Q 10. How do you handle a grinding wheel malfunction or breakage?

Grinding wheel malfunction or breakage is a serious safety hazard. My immediate response always prioritizes safety.

- Emergency Stop: Immediately activate the machine’s emergency stop button to halt all operations.

- Evacuation: Clear the immediate area of personnel to prevent injury from flying debris.

- Assessment: After ensuring everyone’s safety, I assess the damage, determining the cause of the malfunction (e.g., wheel breakage, spindle failure).

- Investigation: A thorough investigation is crucial to identify the root cause, preventing recurrence. This might involve inspecting the wheel for defects, checking machine settings, and reviewing operating procedures.

- Repair/Replacement: The damaged components are repaired or replaced, and the machine is thoroughly inspected before restarting operation.

- Documentation: All incidents are documented, including the cause, corrective actions, and preventative measures implemented.

Prevention is key. Regular wheel inspections and adherence to safety protocols are crucial in minimizing the risk of wheel malfunction or breakage. I always prioritize safe operation and maintenance of the machines.

Q 11. Explain the importance of maintaining proper wheel balance.

Maintaining proper wheel balance is essential for safe and efficient grinding. An unbalanced wheel creates excessive vibration, leading to several problems.

- Surface Finish: Vibration results in an uneven surface finish, compromising the quality of the workpiece. Think of trying to write with a shaky hand; the lines won’t be smooth.

- Machine Wear: The vibration puts extra stress on machine components, leading to premature wear and tear.

- Safety Hazards: Excessive vibration can lead to machine instability and potential accidents.

- Reduced Accuracy: The accuracy of the grinding process is compromised, affecting dimensional tolerances.

Regular wheel balancing using appropriate equipment is crucial. I always ensure that wheels are balanced before mounting them and periodically check for balance throughout the wheel’s lifespan. This prevents significant issues and contributes to consistent, high-quality results.

Q 12. What are the signs of a worn-out grinding wheel?

Recognizing a worn-out grinding wheel is vital to prevent damage and ensure optimal grinding performance. Think of it like a dull knife; it won’t cut effectively and could be dangerous.

- Reduced Grinding Efficiency: Noticeably slower material removal rate indicates significant wear.

- Increased Heat Generation: Excessive heat during grinding, even with adequate coolant, signals a worn wheel.

- Glazing: The wheel surface becomes glazed, losing its cutting ability. You’ll notice a shiny, smooth surface on the wheel that no longer cuts effectively.

- Cracks or Chips: Visible cracks or chips in the wheel structure are signs of significant wear and potential failure.

- Excessive Wheel Wear: Measure the wheel diameter regularly. Excessive reduction in diameter indicates significant wear and necessitates replacement.

- Poor Surface Finish: The ground surface shows signs of poor quality, such as waviness or scratches.

Regular wheel inspections are critical to avoid catastrophic failure and maintain high-quality results. I routinely check for these signs and replace worn wheels promptly.

Q 13. How do you troubleshoot common problems like chatter or burning during grinding?

Chatter and burning are common problems in disc grinding, often stemming from issues with machine setup and parameters. Think of it like playing a violin – if the bow pressure or speed is wrong, you get a scratchy, unpleasant sound (chatter) or you burn the strings (burning).

- Chatter: Usually caused by excessive downfeed, improper workpiece clamping, an unbalanced wheel, or excessive machine vibrations. Addressing this requires careful tuning of the downfeed rate, checking workpiece clamping, and ensuring proper wheel balance.

- Burning: Occurs due to excessive heat generation, often from insufficient coolant flow, improper wheel speed, excessive downfeed, or dull grinding wheels. Solutions include optimizing coolant flow, adjusting grinding parameters, and replacing worn wheels.

My troubleshooting approach is systematic. I begin by checking the machine setup, parameters, and wheel condition. I’ll make small adjustments while carefully monitoring the process, observing for improvement. Detailed records help me track the effectiveness of these adjustments and refine the grinding process for optimal performance.

Q 14. Describe your experience with CNC-controlled disc grinding machines.

My experience with CNC-controlled disc grinding machines is extensive. The precision and repeatability offered by CNC technology are invaluable in high-volume production and demanding applications. Instead of manual adjustments, the CNC system precisely controls all parameters, ensuring consistent results.

- Programming: I am proficient in programming CNC grinding machines, utilizing CAM software to generate optimized toolpaths for complex part geometries. This involves defining cutting parameters, speeds, feeds, and depths to achieve the desired surface finish and tolerances.

- Operation: I’m skilled in setting up and operating CNC disc grinders, ensuring proper alignment, workpiece fixturing, and coolant delivery.

- Troubleshooting: My expertise extends to troubleshooting CNC-related issues, diagnosing problems related to machine parameters, toolpaths, or sensor feedback.

- Maintenance: I understand the importance of preventive maintenance to ensure optimal machine performance and accuracy, which minimizes downtime.

CNC grinding dramatically improves efficiency, precision, and repeatability compared to manual grinding, leading to higher quality and lower production costs. It allows for the production of complex parts with tight tolerances that are impractical to achieve through manual methods.

Q 15. What programming languages are you familiar with in relation to disc grinders?

While disc grinders themselves aren’t directly programmed like computers, understanding programming concepts is crucial for interacting with modern CNC (Computer Numerical Control) grinding machines. My experience includes working with systems that use G-code, a programming language specifically designed for CNC machine tools. I’m proficient in interpreting and sometimes modifying G-code programs to optimize grinding cycles, adjust parameters, and troubleshoot issues. For example, I can modify feed rates within the G-code to achieve a finer finish on a workpiece. I’ve also used software packages such as Mastercam and Siemens NX for creating and simulating CNC programs before running them on the disc grinder. Familiarity with these technologies allows for improved precision and efficiency in the grinding process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the consistent quality of ground workpieces?

Consistent workpiece quality hinges on meticulous control over several factors. First, precise machine setup is paramount. This includes accurate alignment of the workpiece, grinding wheel, and machine components. Regular calibration and verification of machine parameters are essential. Secondly, consistent grinding parameters (feed rate, depth of cut, wheel speed, and coolant flow) are maintained throughout the process. Monitoring these parameters in real-time and making minor adjustments when needed is critical. Thirdly, careful selection and regular dressing of the grinding wheel is crucial. A worn or improperly dressed wheel will lead to inconsistencies in the surface finish. Finally, meticulous attention to workpiece material characteristics and proper workholding procedures are vital. For instance, in grinding hardened steel, I would use a different wheel and parameters compared to aluminum to prevent burning or damage to the workpiece. All these aspects contribute to a consistently high-quality output.

Q 17. Explain your experience with different types of grinding operations (e.g., surface grinding, cylindrical grinding).

My experience encompasses a broad range of grinding operations. I have extensive experience with surface grinding, where the goal is to achieve a precise flat surface on the workpiece. I’ve worked with various surface grinders, from simple manual machines to sophisticated CNC controlled machines, tackling workpieces ranging from small precision parts to large, heavy castings. Similarly, I have significant experience with cylindrical grinding, where the objective is to grind cylindrical shapes to precise dimensions and tolerances. This has involved working with both internal and external cylindrical grinders, creating components with highly accurate diameters and surface finishes. I’ve encountered challenges such as handling complex profiles, achieving high surface quality, and maintaining tight tolerances. In both cases, proper wheel selection and precise machine setup are key to success.

Q 18. What are your methods for optimizing grinding parameters for improved efficiency?

Optimizing grinding parameters for improved efficiency involves a systematic approach. This begins with understanding the material properties of the workpiece and selecting the appropriate grinding wheel. Then, experimentation and data analysis play a crucial role. I typically start with a set of initial parameters based on experience and then systematically vary one parameter at a time (e.g., feed rate, depth of cut) while monitoring the results. Data such as surface finish (Ra), workpiece temperature, and grinding wheel wear are closely monitored. This allows me to identify the optimal combination of parameters that maximize material removal rate while maintaining desired surface quality and minimizing wheel wear. Software simulations can also play a significant role in predicting optimal parameter settings before physical experimentation. For example, I might use software to predict the optimal wheel speed and feed rate for a specific material and desired surface finish.

Q 19. How do you manage and interpret grinding machine data (e.g., machine logs)?

Modern disc grinders generate substantial amounts of data, which can be invaluable for performance monitoring and improvement. I’m adept at interpreting machine logs, which typically include information such as grinding time, wheel speed, feed rate, depth of cut, and power consumption. Analysis of this data helps identify trends, anomalies, and potential areas for optimization. For instance, a sudden increase in power consumption might indicate a problem with the grinding wheel or workpiece clamping. Similarly, consistent variations in surface finish might suggest the need for adjustments in grinding parameters. I use data analysis tools and statistical methods to identify correlations and extract meaningful insights from this data, using this information to fine-tune the grinding process for better efficiency and product quality.

Q 20. Describe your experience with various workpiece materials and their corresponding grinding techniques.

My experience spans a wide variety of workpiece materials, each demanding a unique grinding approach. For instance, grinding hardened steel requires specific wheel types and coolant to prevent burning or cracking. The process involves slower feed rates and potentially multiple passes to avoid excessive heat generation. On the other hand, softer materials like aluminum require different wheel types and higher feed rates. I’ve also worked with ceramic materials, which demand careful consideration of wheel selection and cutting parameters to prevent chipping or fracturing. My approach is always to carefully assess the material properties and choose the optimal grinding wheel, parameters, and coolant to ensure an efficient and high-quality result, minimizing defects and maximizing productivity. For example, I would use a vitrified bonded wheel for grinding hardened steel and a resinoid bonded wheel for aluminum.

Q 21. How do you maintain and perform preventative maintenance on a disc grinding machine?

Preventative maintenance is crucial for ensuring the longevity and optimal performance of a disc grinding machine. This involves a regular schedule of inspections and cleaning. I routinely inspect the grinding wheel for wear and damage, replacing it when necessary. I also check the coolant system for proper flow and contamination, ensuring the coolant is clean and adequately lubricates the grinding process and prevents heat damage to the machine. Regular lubrication of moving parts is vital. This prevents wear and tear and ensures smooth operation. Machine alignment is also critically checked to ensure accuracy and prevent premature wear on the machine components. I document all maintenance activities, including dates, procedures, and any parts replaced, ensuring adherence to a preventive maintenance schedule to minimize downtime and maintain optimal operational efficiency. This proactive approach keeps the machine running smoothly and minimizes the risk of unexpected breakdowns.

Q 22. What are the key performance indicators (KPIs) you monitor during grinding operations?

Monitoring Key Performance Indicators (KPIs) during grinding operations is crucial for ensuring efficiency, quality, and safety. Think of it like a pilot constantly checking their instruments – essential for a smooth flight. The KPIs I focus on include:

- Surface Finish: Measured using a surface roughness tester, this indicates the smoothness of the ground surface. A smoother finish often translates to better performance and aesthetics, depending on the application. For example, a finely ground turbine blade needs a much smoother surface than a roughly ground agricultural tool.

- Dimensional Accuracy: This refers to how closely the ground part meets its specified dimensions. We use micrometers and calipers to ensure tolerances are met. Inaccurate dimensions can lead to part failure or incompatibility in assemblies. Imagine building a complex engine – even small dimensional errors could lead to catastrophic failure.

- Material Removal Rate (MRR): This indicates the speed at which material is being removed, influencing productivity and cost. We track this by monitoring the grinding time and the amount of material removed. Higher MRR isn’t always better – it can lead to excessive heat and damage if not managed carefully.

- Wheel Wear Rate: This KPI measures how quickly the grinding wheel is wearing down. Excessive wear indicates potential issues with the grinding process, such as improper wheel selection or excessive force. Regular monitoring prevents unexpected downtime.

- Power Consumption: Tracking energy usage provides insights into the efficiency of the grinding process. High power consumption could point to inefficiencies, such as dull grinding wheels or excessive pressure.

Q 23. Describe your experience with different types of grinding wheel bonding materials.

Grinding wheel bonding materials are the glue that holds the abrasive grains together. Different bonding materials offer unique properties suitable for different applications. My experience encompasses several types:

- Vitrified Bonds: These are the most common, made from ceramic materials. They offer good strength, wear resistance, and heat resistance, making them versatile for a wide range of materials. I’ve used them extensively for grinding steels and hard alloys.

- Resinoid Bonds: Made from synthetic resins, these bonds are flexible and offer high cutting rates. They are ideal for grinding softer materials or intricate shapes. I’ve used resinoid bonds successfully on non-ferrous metals and plastics.

- Silicate Bonds: These bonds offer a good balance of strength and cutting ability. I’ve found them useful for grinding tougher materials requiring moderate aggressiveness.

- Metal Bonds: These are exceptionally durable and suitable for heavy-duty grinding operations. However, they are more difficult to dress and have lower cutting rates compared to others. I’ve used them for applications requiring superior wheel life, such as grinding hardened steels.

The choice of bonding material significantly affects the grinding process, and selecting the wrong one can lead to poor surface finish, premature wheel wear, or even damage to the workpiece.

Q 24. How do you ensure the safety of yourself and others in the grinding environment?

Safety is paramount in any grinding operation. My approach to ensuring safety is proactive and multi-layered:

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including safety glasses, face shields, hearing protection, gloves, and appropriate clothing, is non-negotiable. This is the first line of defense against flying debris, sparks, and noise.

- Machine Guards: Ensuring all machine guards are in place and functioning correctly prevents accidental contact with moving parts. Regular inspection is vital.

- Proper Workholding: Securely clamping the workpiece prevents it from moving unexpectedly during grinding, minimizing the risk of injury.

- Safe Handling of Grinding Wheels: Following manufacturer guidelines for proper wheel storage, mounting, and inspection is crucial. Damaged or improperly mounted wheels can shatter, causing serious injuries.

- Regular Machine Maintenance: Maintaining the machine in optimal condition helps prevent malfunctions that could compromise safety. This includes regular lubrication, inspection of moving parts, and vibration checks.

- Emergency Procedures: I’m familiar with and regularly practice emergency procedures, including the location and use of fire extinguishers and first aid kits. I also understand the shutdown procedures for the machine in case of unexpected issues.

Safety is not just a set of rules; it’s a mindset. I constantly evaluate potential hazards and implement corrective actions before any incident occurs.

Q 25. What is your experience with various types of coolant systems for disc grinders?

Coolant systems are critical for managing the heat generated during grinding. Efficient cooling prolongs wheel life, improves surface finish, and prevents workpiece damage. My experience includes various systems:

- Flood Coolant Systems: These systems provide a continuous flow of coolant directly onto the grinding zone. This is highly effective for heat removal but can lead to higher coolant consumption. I’ve used this extensively for high-speed grinding operations.

- Mist Coolant Systems: These systems atomize the coolant into a fine mist, reducing coolant consumption compared to flood systems. It’s effective for many applications, though sometimes less efficient at removing heat in high-intensity grinding.

- Minimum Quantity Lubrication (MQL): This is a very precise system delivering a minimal amount of coolant directly to the grinding zone. It minimizes coolant waste and is excellent for applications where minimizing coolant usage is critical.

The selection of coolant type also matters. Water-based coolants are common and cost-effective but can lead to rust formation on certain materials. Oil-based coolants offer better lubrication but present environmental challenges. The choice depends heavily on the specific application and the material being ground.

Q 26. How do you select the correct grinding wheel based on the material being ground?

Selecting the right grinding wheel is paramount for achieving optimal results. It’s like choosing the right tool for a specific job – using a hammer to screw a nail won’t work. My approach involves considering several factors:

- Material to be Ground: The hardness, toughness, and machinability of the material directly influence wheel selection. Harder materials require harder wheels, while softer materials may benefit from softer wheels. For example, grinding hardened steel requires a significantly different wheel than grinding aluminum.

- Desired Surface Finish: A finer grit wheel produces a smoother finish, while a coarser grit wheel removes material faster but produces a rougher surface. The choice depends on the application’s requirements. Fine finishes are necessary for precision parts, whereas rough finishes are suitable for some functional parts.

- Wheel Speed: The wheel speed affects the material removal rate and surface finish. The correct speed is specified by the wheel manufacturer and must be adhered to.

- Wheel Type: Different wheel types, like Type 1, Type 5, etc., are designed for specific applications, depending on the shape of the workpiece and the type of grinding operation involved.

- Wheel Bond: As discussed earlier, the bonding material affects wheel life and performance. Choosing the correct bond is crucial for the application.

Consulting wheel manufacturer’s recommendations and applying knowledge of material science are crucial steps in wheel selection.

Q 27. Explain your approach to problem-solving when encountering unexpected issues during grinding.

Problem-solving is an integral part of my job. When encountering unexpected issues, my approach is systematic and data-driven:

- Identify the Problem: Carefully observe and document the issue. What’s happening? What are the symptoms?

- Analyze the Problem: Gather data. Are there unusual vibrations? Unusual sounds? Is the wheel wearing prematurely? Is the surface finish poor? This stage helps pinpoint the root cause.

- Develop Potential Solutions: Based on the analysis, brainstorm potential solutions. This could involve adjusting machine parameters, changing the grinding wheel, modifying the coolant system, or checking workpiece clamping.

- Test and Refine: Implement the chosen solution, carefully monitoring the results. Is the problem resolved? If not, iterate and refine the solution.

- Document the Solution: Record the problem, analysis, solution, and results. This helps in future problem-solving and process improvement.

For example, if I encounter excessive wheel wear, I might check the wheel speed, the coolant flow, the workpiece clamping, or even the wheel itself for potential defects before making changes. A methodical approach ensures I address the root cause, not just the symptoms.

Q 28. How do you stay updated with the latest advancements in disc grinding technology?

Staying updated is vital in any field, and disc grinding is no exception. My approach to keeping abreast of the latest advancements includes:

- Industry Publications: I regularly read trade journals and industry magazines focusing on manufacturing and grinding technology.

- Professional Conferences and Workshops: Attending industry conferences and workshops allows me to network with other professionals and learn about cutting-edge technologies and best practices.

- Online Resources: I utilize online resources, including manufacturers’ websites and technical databases, to access the latest information on equipment, materials, and techniques.

- Manufacturer Training: I actively participate in training programs offered by grinding machine and wheel manufacturers to enhance my skills and knowledge.

Continuously updating my knowledge base ensures I can adopt the most efficient and effective grinding techniques, leading to improved productivity, quality, and safety.

Key Topics to Learn for Setup and Operation of Disc Grinding Machines Interview

- Machine Familiarization: Understanding the different components of disc grinding machines, their functions, and safety features. This includes identifying various types of disc grinding machines and their applications.

- Setup Procedures: Mastering the correct procedures for setting up the machine for different grinding tasks, including wheel selection, mounting, balancing, and truing. Practical application includes demonstrating the ability to select the appropriate wheel based on material type and desired finish.

- Operational Techniques: Developing proficiency in operating the machine safely and efficiently. This includes understanding the importance of proper workpiece clamping, feed rates, and coolant application. Consider the impact of different operational parameters on the final product.

- Safety Regulations and Procedures: Demonstrating a thorough understanding of all relevant safety regulations and procedures, including the proper use of personal protective equipment (PPE).

- Troubleshooting and Maintenance: Knowing how to identify and troubleshoot common machine malfunctions, perform basic maintenance tasks, and understand preventative maintenance schedules. Practical problem-solving includes diagnosing issues based on observed symptoms.

- Material Science Fundamentals: Understanding the properties of different materials and how they affect the grinding process. This includes knowledge of material hardness, machinability, and the effects of grinding on the material’s microstructure.

- Quality Control and Inspection: Understanding the methods for inspecting the quality of the finished workpiece, identifying defects, and implementing corrective actions.

Next Steps

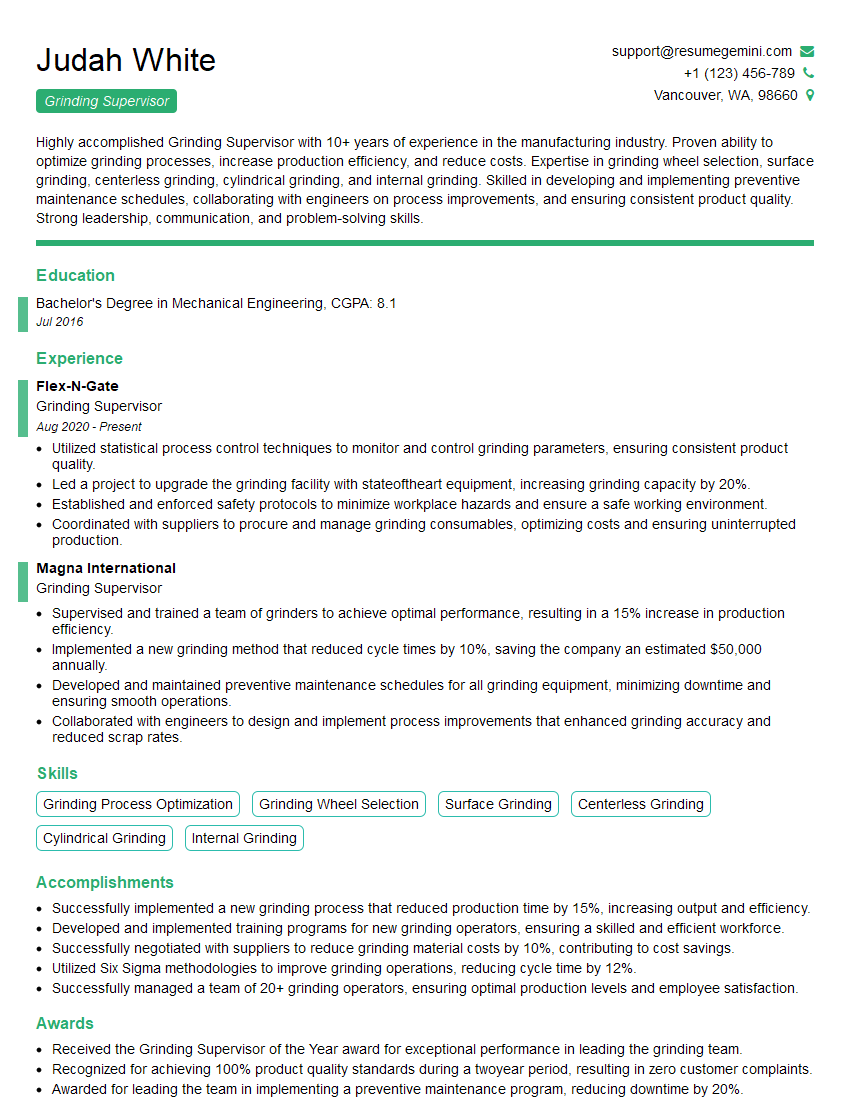

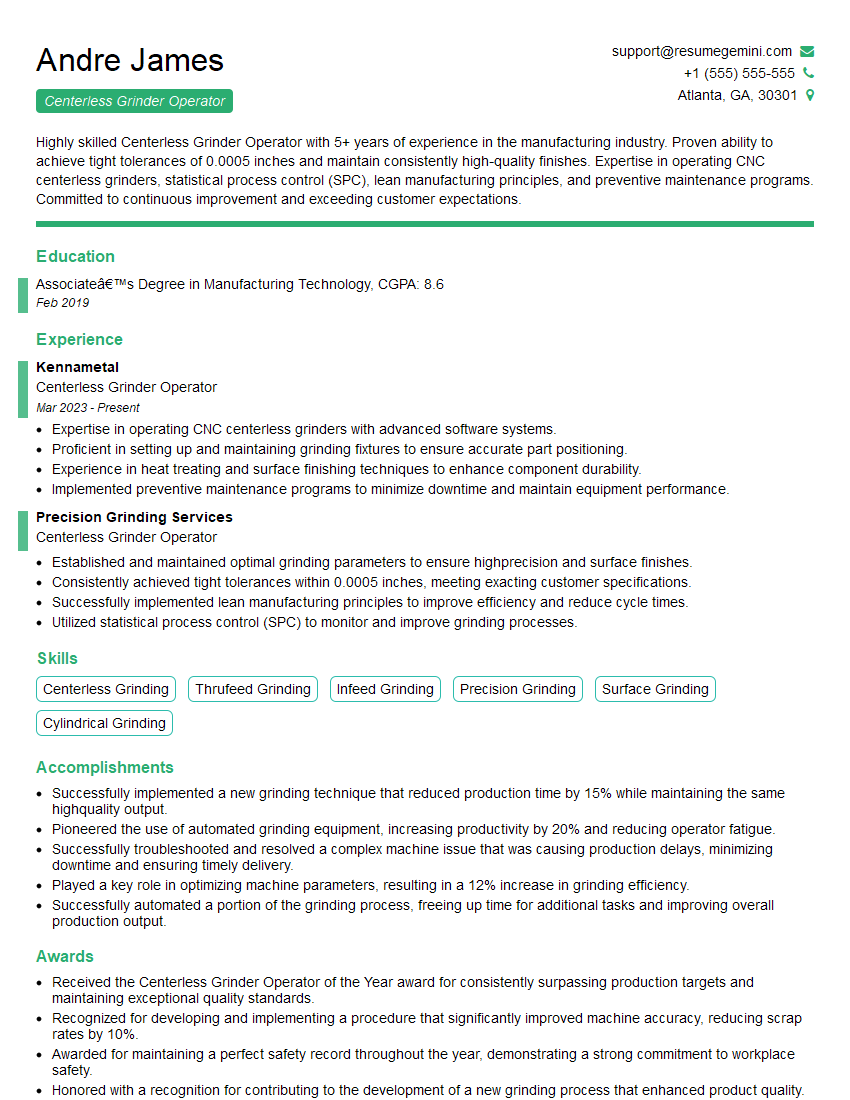

Mastering the setup and operation of disc grinding machines is crucial for career advancement in many manufacturing and machining industries. Proficiency in this area significantly enhances your value to potential employers. To increase your job prospects, it’s vital to create a professional and ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to build a compelling resume tailored to your specific experience. ResumeGemini offers a streamlined process and provides examples of resumes specifically designed for candidates specializing in the Setup and Operation of Disc Grinding Machines, helping you showcase your expertise and secure your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good