Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Jewelry Manufacturing Equipment Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Jewelry Manufacturing Equipment Operation Interview

Q 1. Describe your experience operating CNC milling machines in jewelry production.

My experience with CNC milling machines in jewelry production spans over seven years. I’ve operated various models, from small benchtop machines ideal for intricate detail work to larger, more robust machines capable of handling bulkier projects. I’m proficient in programming these machines using CAM software, generating G-code to precisely carve wax models, create intricate metal components, or even directly mill designs into precious metals. For example, I recently used a 3-axis CNC mill to create a highly detailed wax master for a limited-edition ring set featuring intertwined Celtic knots. The precision offered by CNC milling ensures consistent quality and significantly reduces production time compared to manual methods.

I’m also experienced in using various tooling materials and selecting appropriate cutting parameters (feed rate, depth of cut, spindle speed) to achieve optimal surface finish and minimize tool wear. Understanding the properties of different metals and alloys is crucial in this process, as it dictates the appropriate cutting strategies to prevent damage or unwanted material deformation.

Q 2. What types of casting methods are you familiar with (e.g., investment casting, centrifugal casting)?

I’m well-versed in several casting methods, each suited for different jewelry applications. Investment casting, also known as lost-wax casting, is my most frequently used method. This technique involves creating a wax model, building an investment mold around it, melting out the wax, and then casting molten metal into the resulting cavity. This allows for intricate designs and excellent detail reproduction. I’ve used this extensively for creating complex ring designs and detailed pendants.

Centrifugal casting is another method I utilize, particularly for creating hollow pieces or items with uniform wall thickness. In this process, molten metal is spun rapidly within a mold, forcing it against the mold walls to create a consistent thickness. This is ideal for bangles and hollow forms where consistent weight and strength are required. I’ve also had experience with pressure casting for larger and more complex pieces needing superior detail and tighter tolerances.

Q 3. Explain the process of polishing and finishing jewelry pieces.

Polishing and finishing are critical steps in jewelry making, transforming rough castings or milled pieces into exquisite, wearable items. The process often involves several stages. It begins with removing excess metal or investment material using techniques like tumbling (using abrasive media in a rotating barrel), followed by progressively finer grades of abrasive papers or polishing wheels.

Different polishing compounds are employed depending on the metal and desired finish. For example, rouge is often used for a high shine on silver and gold, while diamond paste is preferred for extremely fine polishing and mirror-like finishes. I also utilize techniques like buffing (using soft, rotating wheels with polishing compounds), which produces a smooth, highly reflective surface. Finally, a thorough cleaning process is crucial to remove any residual polishing compounds, leaving the jewelry piece pristine.

The selection of techniques depends on the metal, the design complexity, and the desired final finish – from a matte finish to a high polish. A thorough understanding of material science is essential in this process to ensure the piece isn’t damaged during the polishing process.

Q 4. How do you ensure the quality and precision of your work?

Quality and precision are paramount in jewelry manufacturing. I employ several strategies to ensure these standards are met. First, meticulous attention to detail is crucial throughout the entire process, from initial design and wax carving to final polishing. I regularly inspect my work at each stage, utilizing measuring instruments like calipers and micrometers to verify dimensions and tolerances.

Secondly, I regularly maintain and calibrate the equipment. This includes checking the accuracy of CNC milling machines, ensuring the appropriate settings are used for each material, and performing regular maintenance on polishing equipment to prevent inconsistencies. Thirdly, I use advanced quality control methods, including digital inspection techniques, to identify and correct any minor imperfections early on in the manufacturing process. Continuous learning and adopting new technologies allow me to consistently refine my approach and achieve exceptional precision.

Q 5. What safety precautions do you take when operating jewelry manufacturing equipment?

Safety is my top priority when operating jewelry manufacturing equipment. I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and dust masks when dealing with potentially harmful materials or processes. I also ensure the workspace is clean and organized to prevent accidents. When using CNC machines, I always follow the manufacturer’s safety guidelines and lock-out procedures to prevent accidental start-up. Proper disposal of hazardous materials, such as polishing compounds and metal scraps, is strictly adhered to in compliance with all environmental regulations.

Regular machine inspections and preventative maintenance are vital to prevent equipment malfunctions. Furthermore, I’m trained in responding to emergencies, such as machine malfunctions or chemical spills. Training and adhering to strict safety protocols are fundamental to my work, ensuring a safe environment for myself and my colleagues.

Q 6. What is your experience with CAD/CAM software in a jewelry manufacturing setting?

I possess extensive experience using CAD/CAM software in jewelry manufacturing. I’m proficient in industry-standard software packages such as Rhino3D, Matrix, and JewelCAD. I use these tools to design jewelry pieces in 3D, create detailed models, and generate the necessary G-code for CNC machining. This allows for rapid prototyping, intricate designs, and precise manufacturing. For instance, I’ve used Rhino3D to create complex parametric designs that could be easily modified and adapted to client specifications.

My CAD skills extend to rendering photorealistic images of designs for client presentations and also create detailed technical drawings necessary for production. The ability to seamlessly transition from digital design to physical manufacturing using CAM software is a key skill that enhances both efficiency and the final quality of the pieces.

Q 7. Describe your experience with laser welding or other joining techniques in jewelry.

I have significant experience with laser welding in jewelry repair and fabrication. Laser welding offers exceptional precision and minimal heat-affected zones, making it ideal for joining delicate components or repairing intricate pieces. I use this technique for tasks such as repairing broken chains, setting gemstones, and joining various metal components with minimal risk of damage to surrounding areas.

Beyond laser welding, I’m also proficient in other joining techniques such as soldering (using various alloys and fluxes) and brazing. The choice of technique depends on the metals being joined, the design requirements, and the desired aesthetic outcome. For example, I might use soldering for joining smaller components in silver, while brazing would be better suited for joining dissimilar metals such as gold and platinum. A good jeweler must master a variety of joining methods to meet the demands of diverse projects.

Q 8. How do you troubleshoot common problems with jewelry manufacturing equipment?

Troubleshooting jewelry manufacturing equipment requires a systematic approach. Think of it like diagnosing a car problem – you need to identify the symptoms, isolate the cause, and then implement the solution. I begin by carefully observing the malfunction. Is the machine making unusual noises? Is it producing subpar results? Is there a specific error code displayed?

For instance, if a laser welder isn’t functioning correctly, I’d first check the power supply, then the laser itself for alignment issues or damage. I’d also inspect the focusing lens for cleanliness and proper placement. A lack of power could indicate a blown fuse or a problem with the main power circuit. Incorrect laser alignment would result in uneven or weak welds. A dirty lens would diminish the laser’s intensity.

Next, I consult the equipment’s manual and utilize any diagnostic tools provided. Many modern machines have built-in diagnostic systems that pinpoint problems. For older equipment, I may need to use multimeters or other testing instruments to check voltage, current, and other key parameters. Once the issue is identified, I perform the necessary repairs or replacements, always prioritizing safety. Finally, after repairs, I test the equipment to ensure it’s functioning correctly before resuming production. This systematic approach, combined with a strong understanding of the equipment’s mechanics and electronics, is crucial for efficient troubleshooting.

Q 9. What is your experience with electroplating processes?

My experience with electroplating encompasses various metals and finishes. I’m proficient in all stages of the process, from pre-treatment (cleaning and preparation of the jewelry) to the actual plating and post-treatment (rinsing and sealing). I’ve worked extensively with rhodium, gold, silver, and platinum plating. The key to successful electroplating is precision and attention to detail. A poorly cleaned piece, for example, will result in a weak or uneven plating.

I understand the importance of precisely controlling the plating bath’s chemistry, temperature, and current density. These factors directly impact the thickness, color, and durability of the final finish. For instance, too high a current density can lead to burning or pitting, while too low a current density results in a thin, fragile coating. My experience also includes troubleshooting common issues like pitting, peeling, or discoloration, often addressing problems in the pre-treatment stage.

Over the years I have worked with both automated and manual plating systems and have consistently maintained high quality standards across different projects. For example, recently I resolved a plating issue where dull spots appeared despite following standard procedures. By meticulously analyzing the process, I discovered a microscopic layer of oil residue that had not been completely removed from the pre-treatment phase, thus influencing the quality of plating. This highlights the crucial role of proper preparation in achieving superior electroplating results.

Q 10. Describe your experience with stone setting techniques.

Stone setting is a critical and intricate skill in jewelry making. I’m experienced in various setting techniques, including prong, bezel, channel, pave, and flush settings. Each technique requires a different approach and skillset. For example, prong setting necessitates precision and careful manipulation of the prongs to securely hold the stone without damaging it. The skill lies in achieving a balance between strength and aesthetics.

Bezel setting, on the other hand, requires a steady hand and meticulous attention to detail to create a smooth, even bezel that securely holds the stone. Channel setting involves creating grooves to neatly and securely house the stones. I am proficient in selecting the appropriate setting technique based on the type of stone, its size, and the overall design of the piece. Safety is always paramount; I always use appropriate safety glasses and other protective gear when using tools.

My experience also includes working with various stone types, from delicate opals to harder gemstones like diamonds. I understand the properties of each stone and how they affect the setting process. For instance, softer stones require gentler handling and may necessitate adjustments to the setting technique to prevent damage. I consistently strive for precise and secure settings that enhance the beauty of the gemstones while ensuring their longevity.

Q 11. Explain the process of wax modeling for investment casting.

Wax modeling for investment casting is a crucial step in creating intricate jewelry designs. Think of it as creating a three-dimensional blueprint of your final piece. The process starts with designing the jewelry piece, either by hand or using CAD software. This digital design is then translated into a wax model, typically using techniques like carving, molding, or 3D printing. The level of detail in the wax model directly impacts the quality of the final casting.

Once the wax model is complete, it undergoes a process called spruing. This involves attaching small channels (sprues) to the model that allow molten metal to flow into the mold during casting. Accurate spruing is essential to ensure that the metal fills the mold completely and without defects. The sprued wax model is then carefully placed into a ceramic investment material and allowed to set. The investment material acts as a mold, protecting the wax model during the high-temperature casting process.

After the investment has hardened, the wax is carefully burned out in a high-temperature furnace, leaving behind a cavity in the investment material. Molten metal (the desired alloy) is then poured into this cavity and allowed to cool and solidify. Once cooled, the investment material is carefully removed, revealing the metal casting, which is then cleaned and finished.

Q 12. How do you maintain and clean jewelry manufacturing equipment?

Maintaining and cleaning jewelry manufacturing equipment is critical for both its longevity and the quality of the final product. Regular maintenance prevents costly repairs and ensures consistent, high-quality output. My routine includes daily cleaning of all equipment, removing any dust, metal shavings, or wax residue that might interfere with functionality or safety.

More thorough cleaning and lubrication are performed at set intervals, depending on the equipment. For example, laser welders require regular lens cleaning to maintain optimal laser output. Electroplating equipment needs regular checks of the bath’s chemical composition and periodic cleaning to remove buildup on the electrodes and plating tanks. I also regularly inspect all equipment for wear and tear, tightening any loose screws or replacing worn parts as needed. This proactive approach prevents minor problems from escalating into major malfunctions.

I meticulously document all maintenance procedures. This includes recording cleaning dates, lubrication details, parts replacements and any observations. This detailed record helps track equipment performance and ensures that we adhere to recommended maintenance schedules. Safety is paramount – all cleaning and maintenance procedures are followed strictly according to manufacturer’s recommendations and relevant safety guidelines.

Q 13. What is your understanding of different metal alloys used in jewelry making?

My understanding of metal alloys used in jewelry making is extensive. I’m familiar with the properties of various precious metals like gold, silver, platinum, and palladium, as well as their common alloys. The karat system for gold, for instance, indicates the proportion of pure gold in the alloy. 18-karat gold is 75% pure gold, while 14-karat gold is approximately 58% pure gold. The remaining percentage comprises other metals, like copper, silver, or zinc, which affect the alloy’s color, hardness, and durability.

Different alloys have varying properties. For example, sterling silver (92.5% silver) is softer and more malleable than fine silver (99.9% silver), making it more suitable for certain jewelry-making techniques. Platinum alloys are known for their durability and resistance to tarnish. Palladium is often used as a less expensive alternative to platinum. I’m also familiar with the properties of base metals, such as brass and copper, and their use in jewelry components or settings.

Understanding the properties of different alloys is crucial for selecting the appropriate metal for a specific design. For example, a delicate piece might require a more malleable alloy, while a durable ring might need a harder, more resistant alloy. This knowledge allows me to make informed decisions that impact both the aesthetics and the longevity of the final product.

Q 14. What is your experience with quality control procedures in jewelry manufacturing?

Quality control is paramount in jewelry manufacturing. It involves a series of checks and inspections throughout the entire production process, from the initial design stage to the final packaging. My experience includes implementing and adhering to strict quality control procedures to ensure consistent high standards. This typically starts with examining the raw materials, checking for purity and quality.

During production, regular inspections are conducted at various stages. For example, after casting, each piece is checked for any casting flaws or imperfections. After stone setting, the security of the settings is verified to prevent future loss of stones. Electroplated pieces are inspected for even plating and adherence. Following finishing processes, pieces are checked for scratches, inconsistencies in polishing, or any other imperfections. This multi-layered inspection strategy helps to identify potential issues early on and minimizes waste.

I also utilize various quality control tools like microscopes and calipers to ensure precision. Detailed records are kept of all inspections, including any defects identified and the corrective actions taken. We adhere to industry standards and best practices to maintain the highest level of quality in our finished products. Our commitment to quality control reflects our dedication to customer satisfaction and producing exceptional, long-lasting jewelry.

Q 15. How do you handle different types of gemstones during the manufacturing process?

Handling gemstones requires meticulous care due to their varied hardness, fragility, and susceptibility to damage. The process begins with careful inspection and sorting by type and size. Harder stones like diamonds and sapphires require different treatments than softer stones like opals or emeralds.

- Hard Stones: These can withstand more aggressive handling and machinery. We use diamond-tipped tools for cutting and polishing, and robust settings for holding them during the manufacturing process.

- Soft Stones: These necessitate gentler techniques. We utilize softer polishing compounds and lower speeds on machinery to prevent scratching or chipping. Specialized jigs and fixtures might be employed to ensure even pressure distribution during shaping and polishing. For instance, when working with emeralds, which have natural inclusions, we are extra cautious to avoid putting pressure on these vulnerable areas.

- Heat Sensitivity: Some stones, such as opals and certain varieties of turquoise, are sensitive to heat. Therefore, laser welding or high-temperature processes are avoided, and alternative methods such as adhesive bonding might be implemented. We always consult gemological reports before selecting manufacturing processes.

In essence, the approach is always customized to the specific characteristics of the gemstone, to ensure its integrity and maximize its brilliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common issues encountered during investment casting, and how do you resolve them?

Investment casting, while precise, presents several challenges. Common issues include:

- Incomplete Filling: This can occur due to insufficient pressure, air bubbles in the mold, or a poorly designed sprue system. Solutions involve adjusting the casting pressure, degassing the investment material, and optimizing the sprue design for proper flow.

- Surface Defects: Rough surfaces, pitting, or inclusions are often caused by improper mold preparation, inadequate investment material, or trapped gases. Careful preparation of the wax pattern and the use of appropriate investment materials are critical here. Techniques such as vibratory finishing can improve the surface finish.

- Dimensional Inaccuracies: Shrinkage during casting is a consistent challenge. Precise wax pattern design and the selection of appropriate investment materials that minimize shrinkage are important steps. Experience plays a significant role in predicting and compensating for these variations.

- Investment Failure: If the investment material cracks or breaks, the casting process is compromised. This can result from rapid heating or cooling, inadequate investment strength, or moisture in the investment. Strict adherence to proper investment techniques is critical.

Troubleshooting often involves analyzing the defects, examining the process parameters, and systematically investigating each step, from wax pattern creation to burnout and casting. Careful record keeping and the use of quality control checks are essential for minimizing these issues.

Q 17. Describe your experience with different finishing techniques (e.g., brushing, sanding, buffing).

My experience encompasses a wide range of finishing techniques. Each technique plays a crucial role in achieving the desired aesthetic and functional properties of the jewelry.

- Brushing: This is used to create a matte finish or texture. Different brush types (wire, nylon, etc.) and pressures are used depending on the desired effect. For example, a wire brush can create a more aggressive texture compared to a softer nylon brush.

- Sanding: Used to remove surface imperfections or to create a smoother finish. This process involves using sandpaper of progressively finer grits to achieve a high level of smoothness. Proper technique is crucial to avoid creating unevenness or scratching.

- Buffing: This employs rotating wheels with polishing compounds to produce high luster. Different compounds and wheel types are selected depending on the metal and the desired shine. For instance, softer metals might require a gentler buffing process compared to harder ones to prevent scratches.

The selection of the right technique and its precise execution are crucial to enhance the final appearance of the jewelry and create the desired aesthetic appeal.

Q 18. How familiar are you with different types of polishing compounds and their applications?

Polishing compounds are essential for achieving a high-quality finish. The choice depends on the metal, desired shine, and the stage of the polishing process.

- Diamond Compounds: Extremely fine diamond particles offer superior cutting ability, ideal for initial stages or for harder metals. They are used to remove scratches and level the surface.

- Rouge: A soft compound typically made from iron oxide, rouge is suitable for final polishing, imparting a high luster to softer metals.

- Tripoli: This compound is typically used for intermediate polishing, removing fine scratches before the final polishing step with rouge.

- White Rouge: Offers a very high polish to platinum and white gold.

Each compound has its unique characteristics and is applied using different techniques and buffing wheels. A systematic progression through different compounds is crucial to achieve the ultimate shine.

Q 19. What is your experience with automated plating lines?

I have extensive experience operating and maintaining automated plating lines, specifically those utilizing barrel plating, rack plating, and selective plating technologies. Automated lines significantly improve efficiency and consistency compared to manual processes.

My experience includes troubleshooting automated systems, ensuring proper chemical management, and monitoring the plating process parameters such as current density, temperature, and solution composition. Experience with different types of automation systems, including programmable logic controllers (PLCs), is vital for efficient operation and problem solving. Regular maintenance of the equipment and strict adherence to safety protocols are paramount.

Q 20. How do you ensure consistent plating thickness and quality?

Consistent plating thickness and quality rely on precise control of various factors. These include:

- Solution Concentration: Regular analysis and adjustments are crucial to maintain the correct concentration of plating solutions. Automated monitoring systems often provide real-time feedback, aiding in maintaining optimal conditions.

- Current Density: Precise control is critical to achieve uniform plating across the entire surface. Higher current densities can lead to uneven plating or burning, while lower densities result in slow plating rates. Careful adjustments based on the geometry of the pieces being plated are necessary.

- Temperature: Maintaining a constant temperature is essential as it impacts the plating process significantly. Automated systems with temperature controllers help in maintaining consistency.

- Agitation: Proper agitation is necessary to ensure even distribution of the plating solution and prevent concentration gradients.

Regular quality control checks, including thickness measurements using techniques like X-ray fluorescence (XRF), are essential to ensure adherence to specifications. Statistical process control (SPC) methods are often used to track plating parameters and identify potential issues proactively.

Q 21. What are the potential hazards associated with electroplating, and how do you mitigate them?

Electroplating involves working with chemicals that pose several hazards:

- Toxicity: Many plating solutions contain toxic heavy metals like cyanide, chromium, and nickel. Proper handling, ventilation, and personal protective equipment (PPE) are essential to minimize exposure.

- Flammability: Some solvents and cleaning agents used in electroplating are flammable. Strict adherence to fire safety protocols and appropriate storage are critical.

- Electrical Hazards: High voltages are involved in electroplating processes, posing risks of electric shock. Proper grounding, insulation, and safety training are mandatory.

- Acid Burns: Many plating solutions are highly acidic or alkaline, leading to potential skin and eye burns. PPE such as gloves, goggles, and lab coats are essential.

Mitigation strategies include implementing strict safety protocols, providing comprehensive training to all personnel, regularly maintaining equipment, utilizing proper ventilation, and implementing emergency response plans. Regular monitoring of workplace air quality and employee health are also vital for maintaining a safe and healthy working environment.

Q 22. Explain your experience with laser engraving techniques.

Laser engraving is a subtractive manufacturing process that uses a highly focused laser beam to remove material from a workpiece, creating intricate designs or markings. My experience spans several years working with both CO2 and fiber lasers, utilizing them for various jewelry applications, from delicate filigree work on precious metals to detailed personalization on custom pieces. I’m proficient in operating various laser engraving machines, adjusting parameters such as power, speed, frequency, and focal length to achieve the desired results. For example, I once used a CO2 laser to engrave intricate floral patterns onto a silver pendant, requiring precise control over the laser’s power to avoid burning the delicate metal. In another project, I employed a fiber laser for engraving customer names and dates onto gold rings, demanding high precision and repeatability.

Q 23. What safety measures should be followed when operating laser equipment?

Safety is paramount when operating laser equipment. The key safety measures include wearing appropriate personal protective equipment (PPE), such as laser safety glasses with the correct optical density (OD) rating for the laser wavelength being used. This is crucial to protect your eyes from the intense laser beam. Additionally, the work area must be properly enclosed to prevent accidental exposure. This often involves using laser safety enclosures, carefully controlled ventilation systems to remove laser fumes, and fire safety precautions because some materials can ignite. Regular machine maintenance and safety checks are essential. Finally, clear and concise operating procedures must be followed, and adequate training is crucial for all personnel involved. Ignoring these measures can lead to serious eye injuries or even fires.

Q 24. How do you ensure the accuracy of laser engraving parameters?

Ensuring the accuracy of laser engraving parameters is critical for consistent, high-quality results. This starts with selecting the correct parameters based on the material being engraved and the desired depth and detail of the engraving. I typically begin by performing test engravings on a sample piece of the same material. This allows for fine-tuning of the power, speed, and frequency settings. Advanced laser engraving machines offer software that allows for precise control and even allows for importing vector designs directly. Regular calibration of the laser machine is also important to maintain accuracy and prevent drift in settings over time. For instance, when working with different metal alloys, even slight variations in composition can necessitate adjustments to laser parameters to achieve the desired engraving depth and quality. Continuous monitoring during the engraving process also helps in identifying and correcting any deviations from the expected outcome.

Q 25. Describe your experience with 3D printing techniques in jewelry manufacturing.

My experience with 3D printing in jewelry manufacturing includes working with various techniques, primarily Stereolithography (SLA) and Selective Laser Sintering (SLS). I’ve utilized SLA for producing intricate wax models for investment casting – a crucial step in creating detailed jewelry pieces. This allows for the creation of complex geometries and designs that would be difficult or impossible to achieve using traditional methods. SLS has been beneficial for creating prototypes and directly manufacturing jewelry components from materials like nylon or metal powders. For example, I used SLA to create a highly detailed wax model of a dragonfly, which was then cast in sterling silver. The fine details of the dragonfly’s wings were captured flawlessly, a level of detail that would be challenging to achieve with traditional carving techniques. I’ve also experimented with using SLS to produce durable nylon prototypes to test the fit and feel of a design before investing in precious metal casting.

Q 26. What are the advantages and disadvantages of using 3D printing for jewelry?

3D printing offers several advantages in jewelry manufacturing. It enables rapid prototyping, allowing designers to quickly iterate on designs and test different concepts. It also facilitates the creation of complex geometries and intricate designs that are impossible to achieve using traditional methods. The process can be highly automated, leading to increased production efficiency in certain applications. However, there are disadvantages. The resolution of 3D-printed jewelry might not always match the precision of traditional techniques, especially for very fine details. The cost of 3D printing equipment and materials can be significant, and post-processing steps are often required depending on the material and final application, potentially adding time and cost to the production process.

Q 27. What types of 3D printing materials are you familiar with for jewelry?

My experience encompasses several 3D printing materials used in jewelry making. For wax casting, I’ve worked extensively with various wax resins suitable for investment casting. For direct manufacturing, I’m familiar with nylon powders and metal powders like stainless steel, silver, and gold. Each material presents unique properties, influencing the final piece’s strength, durability, surface finish, and cost. The choice of material is always dictated by the design’s requirements, budget, and desired aesthetic qualities. For example, I might use a high-strength nylon for a functional piece, like a clasp, while a fine-detail wax resin would be preferable for creating a complex, delicate pendant model.

Q 28. How would you address a production delay due to equipment malfunction?

Addressing production delays due to equipment malfunction requires a systematic approach. The first step involves identifying the source of the malfunction. This might require troubleshooting the equipment, checking error codes, and examining the machine’s logs for clues. If the issue is minor, I would attempt to fix it myself if I’m sufficiently trained. If the issue requires specialized expertise or replacement parts, I would contact the equipment manufacturer or a qualified technician immediately. In the meantime, I’d evaluate the impact of the delay on the overall production schedule and communicate the issue to relevant stakeholders. This could involve shifting priorities, re-allocating resources to other tasks, or finding alternative methods to complete the delayed portion of the production run. For example, if the laser engraver malfunctions, I might temporarily switch to manual engraving for less intricate pieces to maintain production flow. Transparency and proactive communication are key to mitigating the effects of unexpected equipment failures.

Key Topics to Learn for Jewelry Manufacturing Equipment Operation Interview

- Understanding Different Equipment Types: Become familiar with various machines used in jewelry manufacturing, including casting machines, rolling mills, lathes, polishing equipment, and laser welders. Understand their specific functions and applications.

- Safe Operating Procedures: Mastering safe operating procedures for each machine is crucial. This includes understanding safety protocols, lockout/tagout procedures, and proper handling of materials.

- Maintenance and Troubleshooting: Demonstrate knowledge of basic maintenance tasks, preventative maintenance schedules, and common troubleshooting techniques for different equipment malfunctions. Be prepared to discuss your experience identifying and resolving issues.

- Material Properties and Selection: Showcase your understanding of different metals (gold, silver, platinum, etc.) and alloys used in jewelry making. Know how material properties influence the selection of specific equipment and manufacturing processes.

- Quality Control and Inspection: Explain your experience with quality control measures, including inspection techniques and the identification of defects during various stages of the manufacturing process.

- Production Processes and Workflow: Demonstrate a clear understanding of the entire jewelry manufacturing process, from design to finishing. Be prepared to discuss optimizing workflow and efficiency.

- Advanced Techniques (Optional): Depending on the seniority of the role, you may be asked about more advanced techniques like CAD/CAM integration, 3D printing in jewelry manufacturing, or specific specialized equipment.

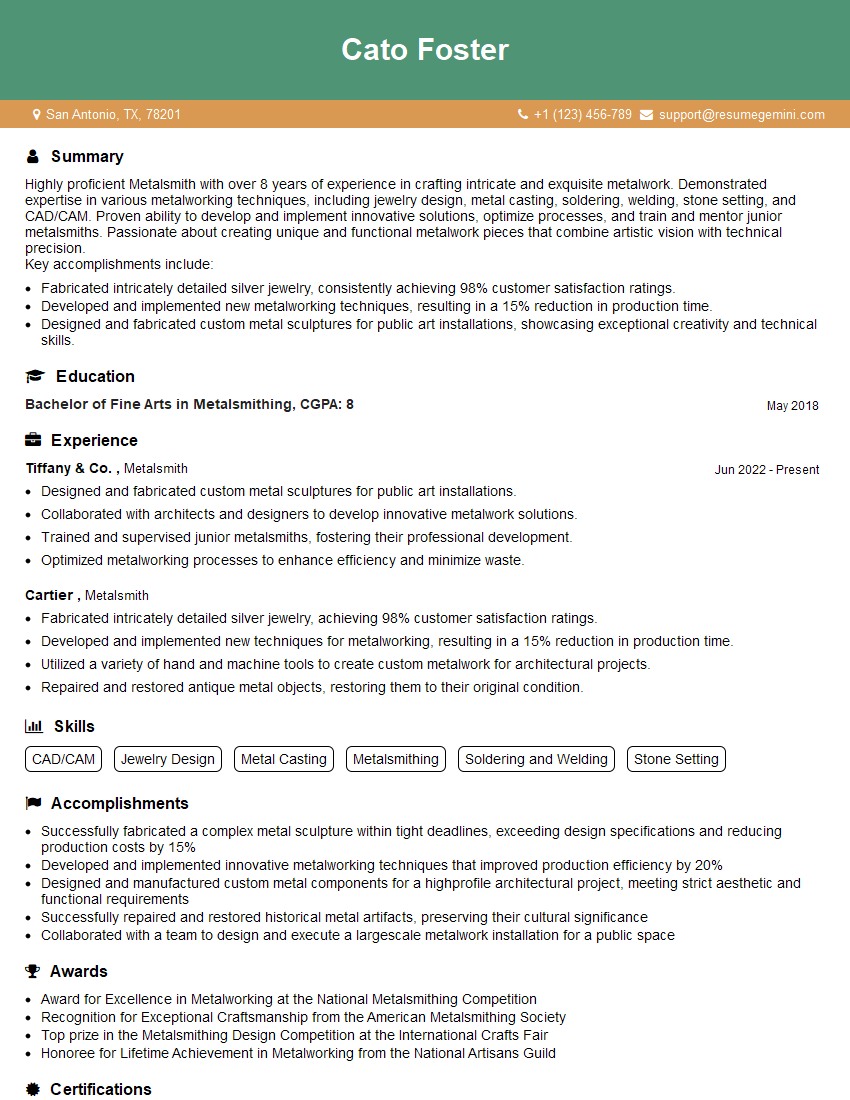

Next Steps

Mastering Jewelry Manufacturing Equipment Operation opens doors to exciting career advancements, offering opportunities for specialization, increased responsibility, and higher earning potential. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. A well-structured resume highlights your skills and experience effectively, ensuring your application gets noticed. ResumeGemini is a trusted resource for building professional resumes that get results. They offer examples of resumes tailored to Jewelry Manufacturing Equipment Operation to help you create a compelling application that showcases your expertise. Take the next step in your career journey – build a winning resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good