Are you ready to stand out in your next interview? Understanding and preparing for Maintenance Logs interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Maintenance Logs Interview

Q 1. What are the key elements of a well-maintained maintenance log?

A well-maintained maintenance log is the backbone of any effective maintenance program. It’s more than just a record of repairs; it’s a dynamic tool for proactive maintenance and continuous improvement. Key elements include:

- Asset Identification: Clear and consistent identification of each piece of equipment (e.g., using unique IDs, location details, and descriptions).

- Date and Time Stamps: Precise recording of when maintenance activities occurred, ensuring chronological accuracy.

- Type of Maintenance: Specific details about the work performed (e.g., preventive, corrective, predictive). Using standardized codes or categories improves data analysis.

- Personnel Involved: Identification of the technicians or engineers responsible, improving accountability and tracking expertise.

- Work Description: A detailed account of the work performed, including steps taken, parts used, and any challenges encountered. Using clear, concise language is crucial.

- Materials Used: A complete list of materials, including part numbers and quantities, enabling cost tracking and inventory management.

- Measurements and Readings: Recording relevant data such as temperatures, pressures, or vibration levels. These provide a baseline for detecting future anomalies.

- Work Order Number (if applicable): Linking the log entry to the work order ensures traceability and simplifies reporting.

- Signatures or Digital Approvals: Verification that the work was completed and inspected.

Think of it like a meticulous medical chart – the more detailed and accurate the information, the better the diagnosis and treatment (in this case, equipment maintenance).

Q 2. Describe your experience with different CMMS (Computerized Maintenance Management Systems) and their log functionalities.

I’ve worked extensively with several CMMS, including IBM Maximo, SAP PM, and UpKeep. Each offers unique log functionalities, but the core principles remain consistent. For instance, Maximo excels at managing complex work orders and integrating with other enterprise systems. Its log functionalities allow for detailed recording of maintenance activities, tracking of spare parts, and generating insightful reports. SAP PM provides robust functionality for managing preventive maintenance schedules, and its logs provide excellent visibility into scheduled and unscheduled maintenance events. UpKeep, known for its user-friendly interface, simplifies maintenance log creation and access, particularly beneficial for smaller teams. While each system differs in its interface and specific features, they all provide structured ways to capture, store, and analyze maintenance data – enabling a shift from reactive to proactive maintenance.

Q 3. How do you ensure data accuracy and integrity in maintenance logs?

Data accuracy and integrity are paramount. I ensure this through a multi-pronged approach:

- Standardized Procedures: Implementing clear guidelines for data entry, ensuring consistency across all personnel.

- Data Validation: Using system checks to identify and flag inconsistent or illogical entries (e.g., negative maintenance time).

- Regular Audits: Periodically reviewing the logs for errors, omissions, and inconsistencies.

- Training: Ensuring all maintenance personnel receive thorough training on proper log completion procedures. This includes understanding the importance of accurate data and potential consequences of errors.

- Data Backup and Recovery: Implementing robust backup and recovery systems to protect against data loss.

- Digital Systems: Utilizing digital systems reduces human error inherent in manual data entry and improves data accessibility.

Imagine a pilot meticulously recording flight data – any inaccuracy could have catastrophic consequences. The same principle applies to maintenance logs; accuracy is vital for safety and operational efficiency.

Q 4. Explain your process for identifying and resolving discrepancies in maintenance logs.

Identifying discrepancies involves careful review of the logs, cross-referencing with other data sources (e.g., work orders, inventory records, and equipment performance data). My process is as follows:

- Identify the Discrepancy: Pinpoint inconsistencies or missing information.

- Investigate the Cause: Determine the root cause of the discrepancy (e.g., human error, system glitch, or data corruption).

- Gather Supporting Evidence: Collect supporting information to verify the findings.

- Correct the Discrepancy: Make necessary corrections to the logs, ensuring accuracy and completeness.

- Document the Resolution: Record the steps taken to resolve the discrepancy, including any changes made.

For example, if the log indicates a part was replaced, but inventory records show no reduction in stock, I would investigate to determine if the part was logged incorrectly, or if there was a stock discrepancy. Thorough investigation is key to resolving the issue and preventing future occurrences.

Q 5. How do you prioritize maintenance tasks based on information in the logs?

Prioritization depends on several factors drawn from the logs, including:

- Equipment Criticality: Logs help identify equipment critical to production. Failures of these assets should be addressed immediately.

- Failure History: Frequent failures or recurring issues highlight areas needing immediate attention. Trend analysis reveals patterns, assisting in predictive maintenance.

- Safety Concerns: Logs that indicate safety hazards require immediate action.

- Cost of Downtime: The cost of downtime for various assets determines urgency. High-cost downtime equipment gets priority.

- Preventive Maintenance Schedules: Logs track adherence to preventive maintenance schedules; overdue tasks get prioritized.

I typically use a combination of these factors to create a ranked list of tasks, often employing a scoring system that weights each factor according to its importance. This prioritization ensures resources are efficiently allocated to the most critical maintenance needs.

Q 6. How familiar are you with various maintenance log formats (e.g., digital, paper)?

I’m proficient in both digital and paper-based maintenance log formats. Paper-based logs, while less efficient, are still sometimes used, particularly in certain industries. Understanding their limitations and the challenges they present (e.g., data retrieval, searchability, version control) is crucial. I’m experienced in managing the transition from paper to digital, knowing the advantages of digital systems such as improved searchability, accessibility, and data analysis capabilities. Regardless of the format, the core principles of accuracy, completeness, and consistency remain paramount.

Q 7. Describe your experience using data from maintenance logs to improve equipment reliability.

Maintenance logs are goldmines of data for improving equipment reliability. By analyzing historical maintenance data, I can identify failure patterns, predict future failures, and implement preventive measures. For example, if the logs reveal a specific component consistently fails after a certain number of operating hours, I can schedule preventive replacements before failure occurs, minimizing downtime and improving operational efficiency. This data-driven approach allows me to move from reactive to proactive maintenance, enhancing equipment lifespan and reducing maintenance costs. Further, root cause analysis based on the log data helps prevent recurrence of similar problems. In essence, the maintenance log facilitates a continuous feedback loop for improving reliability and cost-effectiveness.

Q 8. How do you handle missing or incomplete data in maintenance logs?

Missing or incomplete data in maintenance logs is a common challenge, but it’s crucial to address it to maintain data integrity. My approach involves a multi-pronged strategy. First, I investigate the reason for the missing data. Is it due to a system error, human error (e.g., forgotten entries), or a change in procedures? Understanding the root cause helps prevent future occurrences.

Next, I attempt to recover the missing information. This might involve reviewing related documentation, interviewing personnel who were involved during the relevant time period, or checking backup systems. If recovery is impossible, I document the gap, explaining why the data is missing. This transparency is key. Instead of fabricating data, which would compromise the log’s integrity, I clearly indicate the missing information with notations like “Data unavailable due to system outage on [date]” or “Maintenance performed but record incomplete; details unavailable.”

Finally, I use data imputation techniques where appropriate and justifiable, especially for numerical data like operating hours. For example, I might calculate the average maintenance interval for a specific machine and use that to estimate the missing data point. However, I always clearly indicate these estimations and avoid making assumptions that could lead to inaccurate analysis.

Q 9. How do you use maintenance logs to track preventative maintenance schedules?

Maintenance logs are essential for tracking preventative maintenance (PM) schedules. We typically use a system that integrates PM schedules directly with the log. This might involve a computerized maintenance management system (CMMS) or even a well-organized spreadsheet. The system allows for scheduling specific tasks (e.g., oil changes, filter replacements) at predetermined intervals or based on operating hours.

Each PM task is recorded in the log, including the date, time, performed by, and any findings. This allows us to monitor adherence to the schedule, identify potential delays, and ensure timely completion of crucial tasks. For instance, a simple entry might look like this: "2024-10-27, 10:00 AM, John Doe, PM - Machine X - Oil change completed, no issues found." Regular review of these entries helps us identify trends, assess the effectiveness of our PM program, and adjust the schedules as needed. Flags or alerts might be set if PM tasks are overdue or not completed as scheduled.

Q 10. How do you utilize maintenance logs for reporting and analysis?

Maintenance logs are a treasure trove of information for reporting and analysis. We use the data to generate reports that cover various aspects of maintenance performance. These reports can be as simple as a summary of completed tasks or as complex as a comprehensive analysis of equipment reliability and maintenance costs.

For example, we regularly generate reports on:

- Total maintenance costs (broken down by equipment type, task type, and labor vs. parts)

- Mean Time Between Failures (MTBF) for different assets, revealing which equipment requires more attention

- Mean Time To Repair (MTTR), highlighting areas for efficiency improvements in our repair processes

- Downtime analysis, showing the impact of maintenance activities on overall production

- Compliance with PM schedules, identifying potential gaps in our preventative measures

Q 11. Explain your experience with generating reports from maintenance log data.

I have extensive experience generating reports from maintenance log data, using various software tools including CMMS software (like UpKeep, Fiix, or MPulse), spreadsheet software (Excel, Google Sheets), and business intelligence tools (Tableau, Power BI). My approach always begins by defining the specific questions the report needs to answer. This ensures that the report provides valuable insights and avoids becoming overwhelming with unnecessary information.

For example, if management wants to understand the cost-effectiveness of preventative maintenance, I’d generate a report comparing the costs of preventative maintenance tasks with the costs associated with unplanned repairs over a specific period. This might involve creating custom formulas within the spreadsheet software or utilizing the reporting functionalities within the CMMS system. I then design the report to be clear, concise, and visually appealing, using charts and graphs to highlight key trends and insights.

I also ensure that the data presented is accurate and reliable, carefully checking for data integrity issues before generating the final report. This attention to detail is crucial to build trust and ensure decision-making is based on factual information.

Q 12. What key performance indicators (KPIs) do you track using maintenance logs?

Several key performance indicators (KPIs) are tracked using maintenance logs to assess the effectiveness and efficiency of our maintenance operations. Here are some examples:

- Mean Time Between Failures (MTBF): The average time between equipment failures. A higher MTBF indicates better equipment reliability.

- Mean Time To Repair (MTTR): The average time it takes to repair failed equipment. A lower MTTR indicates faster and more efficient repairs.

- Maintenance Cost per Unit Produced: This shows the cost of maintenance relative to production output. Lower costs indicate higher efficiency.

- Preventative Maintenance Compliance Rate: The percentage of scheduled preventative maintenance tasks completed on time. High compliance reduces unplanned downtime.

- Downtime Percentage: The percentage of time equipment is unavailable due to maintenance or repairs. Lower percentages indicate higher production uptime.

- Maintenance Backlog: The number of outstanding maintenance requests. This indicator helps identify potential bottlenecks.

Tracking these KPIs allows us to benchmark performance, identify areas for improvement, and justify investments in new technologies or processes.

Q 13. Describe a situation where you used maintenance log data to troubleshoot a problem.

We experienced a recurring issue with a critical piece of production equipment that would unexpectedly shut down. Initial troubleshooting efforts were unsuccessful. That’s when I decided to delve into the detailed maintenance logs. I analyzed the logs over several months, focusing on entries related to this specific machine. I noticed a pattern: the shutdowns consistently occurred after periods of high utilization, always on days with unusually high ambient temperature.

By examining the maintenance records, I found no indication of mechanical failure. Instead, the pattern suggested an issue related to overheating. Further investigation revealed a malfunctioning cooling system fan, barely recorded in previous logs as a “minor issue” with no follow-up. Replacing the fan resolved the problem completely, highlighting the importance of thorough record-keeping and the power of data analysis in identifying root causes that might otherwise be missed.

Q 14. How do you ensure the security and confidentiality of maintenance logs?

Security and confidentiality of maintenance logs are paramount. We implement several measures to protect the data. First, access to the logs is restricted using a robust access control system. Only authorized personnel with a legitimate need for access can view the data, with different levels of access based on roles and responsibilities (e.g., technicians may have read/write access, while managers may only have read access).

The logs themselves are stored securely, typically in a database or a dedicated CMMS system, protected by firewalls, intrusion detection systems, and regular security audits. Data encryption is used to protect the data both at rest and in transit. We also adhere to strict data backup and recovery procedures to minimize the risk of data loss due to hardware failure or cyberattacks. Regular training sessions educate staff on security protocols and the importance of data protection. Finally, we maintain a comprehensive audit trail of all access to and modifications of the maintenance logs, enabling us to track and investigate any suspicious activity.

Q 15. How do you collaborate with other teams using maintenance log data?

Collaboration with other teams using maintenance log data is crucial for efficient operations. I typically share relevant data through various channels depending on the team and the urgency. For instance, for proactive maintenance planning, I’d share summarized reports with the engineering team, perhaps using a shared dashboard displaying key metrics like equipment downtime and recurring issues. For immediate troubleshooting, I might directly communicate with the operations team via instant messaging or email, providing specific log entries indicating the nature of the problem.

For instance, if the operations team reports a consistent failure in a specific machine, I’d generate a report summarizing all maintenance entries related to that machine over the last six months. This report would highlight any recurring problems, the parts replaced, and the time taken for each repair. This collaborative process allows for informed decision-making, whether it’s scheduling preventative maintenance or identifying design flaws requiring changes.

- Shared Dashboards: Real-time visualization of key metrics for proactive planning.

- Regular Meetings: Discussions and presentations of insights from log analysis.

- Direct Communication: Quick responses to critical issues via instant messaging/email.

- Data Extracts/Reports: Providing targeted data sets to specific teams.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or tools are you proficient in for managing maintenance logs?

I’m proficient in several software and tools for managing maintenance logs. My experience includes using Computerized Maintenance Management Systems (CMMS) such as Fiix, UpKeep, and IBM Maximo. These systems allow for centralized log storage, automated reporting, and integration with other enterprise systems. I’m also comfortable using more general-purpose databases like MySQL and PostgreSQL for managing and querying large log datasets. Additionally, I have experience with spreadsheet software (Excel, Google Sheets) for simpler tasks and data analysis.

For example, in a previous role, we used Fiix CMMS to track all maintenance activities. This allowed us to generate reports on equipment downtime, maintenance costs, and the performance of individual technicians. The system’s built-in reporting features saved considerable time compared to manually compiling reports from spreadsheets. In other projects involving larger datasets or complex queries, using PostgreSQL provided the flexibility and scalability required.

Q 17. How do you handle emergency maintenance situations and update the logs accordingly?

Emergency maintenance situations require immediate action and meticulous log updating. My approach begins with a rapid assessment of the situation to ensure the safety of personnel and equipment. Then, I immediately document every step taken in the log, starting with a timestamped entry describing the emergency and the initial assessment. This includes details of the malfunction, the affected equipment, and the initial steps taken to mitigate the problem. As the situation evolves, I add updates with timestamps for each action, including personnel involved, parts used, and any observations.

For example, if a critical pump fails, I’d log the time of the failure, initial safety precautions taken, the emergency team dispatched, the parts ordered, the repair steps undertaken, and the time of successful restoration of service. Post-emergency, I’d analyze the log to identify contributing factors and potential improvements to preventative maintenance schedules. The log will also incorporate a thorough post-mortem analysis detailing what happened, root cause analysis, and steps to prevent future similar events.

Q 18. Describe your experience with auditing maintenance logs.

Auditing maintenance logs is crucial for ensuring data integrity, regulatory compliance, and continuous improvement. My experience includes both internal and external audits. Internal audits focus on ensuring consistency in data entry, completeness of records, and adherence to internal procedures. This involves randomly sampling logs, verifying data accuracy against original work orders and inspection reports, and identifying areas needing improvement in data entry practices. External audits typically involve regulatory bodies or external auditors verifying compliance with industry standards and regulations.

For example, I’ve been involved in audits where we used a checklist to systematically review log entries, checking for missing information, inconsistencies, and deviations from established procedures. Findings from these audits are used to improve our processes and training, ensuring that maintenance logs provide a reliable and accurate record of all maintenance activities.

Q 19. What are the common challenges you’ve faced while managing maintenance logs?

Managing maintenance logs presents several challenges. One common issue is incomplete or inaccurate data entry, often resulting from time pressures, lack of training, or inconsistent procedures. This can lead to inaccurate reporting and ineffective maintenance planning. Another challenge is integrating data from disparate systems – for example, coordinating data from various field technicians, contractors, and CMMS databases. This integration is crucial for creating a holistic view of maintenance activities. Maintaining the accessibility and usability of logs across different departments and personnel also poses a significant challenge. Data security and compliance are another major concern.

For instance, in one project, we implemented a standardized data entry template and provided training to technicians, significantly improving the quality of the log data. To address data integration challenges, we leveraged a CMMS system that allowed for seamless data consolidation from different sources. For ensuring accessibility, we implemented a user-friendly system with role-based access control, while data encryption and backup protocols are in place for security and compliance.

Q 20. How do you maintain the organization and accessibility of maintenance logs?

Maintaining the organization and accessibility of maintenance logs is paramount. I use a multi-pronged approach. Firstly, I employ a structured system of file naming and organization, ensuring easy retrieval of specific logs based on date, equipment ID, or other relevant criteria. For instance, I’d use a consistent naming convention like ‘YYYY-MM-DD_EquipmentID_Log.pdf’ or storing the data in a relational database with efficient indexing. Secondly, I use CMMS or database systems to implement robust search and filtering capabilities. This allows easy retrieval of logs based on various criteria and helps in generating reports quickly.

In addition, I ensure that access to the logs is controlled and restricted to authorized personnel only. This maintains the confidentiality and integrity of the data. Clear documentation of data entry procedures and log structure is also key. This assists in consistent data entry and aids new personnel in quickly understanding the system. Training is also provided to ensure everyone understands the importance of accurate and complete log entries.

Q 21. How do you ensure compliance with relevant regulations regarding maintenance logs?

Compliance with relevant regulations is a high priority. This involves understanding and adhering to industry-specific standards and regulations, such as those related to occupational safety, environmental protection, and data privacy. Compliance is typically achieved through systematic documentation, regular internal audits, and proactive management of potential non-compliance issues. This includes appropriate record retention policies, data security measures, and training for all personnel involved in data entry and handling. My approach involves staying updated on the latest regulations, participating in industry events, and leveraging compliance management software to track and manage compliance activities.

For example, if working in a regulated industry like aviation or healthcare, I ensure that the maintenance logs strictly adhere to the specific standards and reporting requirements outlined by the relevant regulatory bodies. This includes meticulous documentation of all inspections, repairs, and maintenance activities. Regular reviews are conducted to ensure compliance and to identify areas for improvement.

Q 22. How would you improve the efficiency of a poorly maintained maintenance log system?

Improving a poorly maintained maintenance log system requires a multifaceted approach focusing on standardization, digitization, and user training. Think of it like reorganizing a messy garage – you need a system to find things efficiently.

- Standardization: Implement a consistent format for log entries. This includes using predefined fields for date, time, equipment ID, problem description, actions taken, parts used, and technician’s signature. Inconsistent logging makes data analysis impossible.

- Digitization: Transition to a computerized Maintenance Management System (CMMS). This allows for easier data entry, searching, reporting, and analysis. A CMMS is like having a digital filing cabinet for all your maintenance records.

- Data Cleansing: Review existing logs and clean up any inconsistencies. This may involve consolidating duplicate entries, correcting errors, and adding missing information. This is the equivalent of decluttering your garage before organizing it.

- User Training: Train maintenance personnel on the proper use of the new system, emphasizing the importance of accurate and timely data entry. Provide clear instructions and readily available support. This ensures everyone understands how to use the ‘new garage’ effectively.

- Regular Audits: Conduct regular audits to ensure adherence to the new system and identify areas for improvement. Regular checks help maintain the organization and efficiency of your system.

For example, moving from handwritten logs to a CMMS with automated reporting capabilities will drastically reduce data entry time and improve data accuracy, leading to better maintenance planning and reduced downtime.

Q 23. Explain your understanding of different types of maintenance (preventive, corrective, predictive).

Maintenance types are categorized by their objective and timing. They are crucial for equipment longevity and operational efficiency.

- Preventive Maintenance (PM): This is scheduled maintenance performed to prevent equipment failures. Think of it as regular car servicing – changing oil, rotating tires, etc., to avoid major breakdowns. Examples include lubrication, inspections, and cleaning. This extends the life of equipment and reduces unplanned downtime.

- Corrective Maintenance (CM): This is unplanned maintenance performed to restore equipment to a functional state after a failure. This is akin to roadside assistance after a car breakdown. Examples include repairs, replacements, and troubleshooting. It is often more expensive and disruptive than preventive maintenance.

- Predictive Maintenance (PdM): This uses data analysis and monitoring to predict when equipment is likely to fail, allowing for proactive intervention. This is like using a car’s diagnostic system to identify potential problems before they become major issues. Examples include vibration analysis, thermal imaging, and oil analysis. This minimizes downtime by addressing problems before they cause failures.

A well-balanced maintenance program uses a combination of all three types, prioritizing preventive and predictive maintenance to minimize the need for corrective maintenance.

Q 24. How do you use maintenance logs to predict future equipment failures?

Maintenance logs are a treasure trove of information for predicting future equipment failures. By analyzing historical data, we can identify patterns and trends that indicate potential problems.

- Trend Analysis: Tracking the frequency and type of maintenance performed on a piece of equipment can reveal patterns. For instance, frequent repairs to a specific component might suggest a design flaw or impending failure. A graph showing the frequency of repairs of a specific pump over time can clearly highlight such a trend.

- Mean Time Between Failures (MTBF): Calculating the MTBF provides a statistical measure of how often a piece of equipment fails. A decreasing MTBF indicates an increasing likelihood of future failures and potentially points to a problem needing attention.

- Failure Modes and Effects Analysis (FMEA): Analyzing past failures to identify potential causes and their effects can help in predicting future failures. For example, identifying a recurring problem with a specific part allows for proactive replacement or redesign.

- Data Mining and Machine Learning: Using advanced analytics on large datasets can help identify subtle patterns and predict failures with greater accuracy. More sophisticated CMMS systems often offer predictive analytics built-in.

For example, if a pump consistently fails after 1000 operating hours, we can schedule preventive maintenance at 900 hours to mitigate the risk of failure. This proactive approach is far more cost-effective than reactive repairs.

Q 25. How do you train others on the proper use and maintenance of maintenance logs?

Training others on proper maintenance log use is essential for data quality. I use a layered approach, combining hands-on training with ongoing support.

- Initial Training: Start with a clear presentation covering the purpose of the system, the log format, and data entry procedures. Use visual aids and interactive exercises to improve retention.

- Hands-on Practice: Provide supervised practice using real or simulated data. This is crucial for building confidence and competency. Consider a scenario-based training, using hypothetical equipment malfunctions.

- Documentation and Templates: Provide easily accessible documentation, including clear instructions, templates, and FAQs. This serves as a quick reference for daily work.

- Ongoing Support: Offer ongoing support and mentorship, addressing questions and providing guidance. Regularly scheduled refresher sessions help reinforce good practices.

- Gamification: Consider incorporating gamification elements, such as friendly competitions or reward systems, to increase engagement and encourage accurate record-keeping.

A well-trained team is the backbone of a successful maintenance logging system. By making the process clear, engaging, and supported, you foster buy-in and ensure high-quality data.

Q 26. Describe your experience integrating maintenance log data with other business systems.

Integrating maintenance log data with other business systems offers valuable insights and improves overall operational efficiency. This is like connecting different pieces of a puzzle to see the bigger picture.

- ERP Systems: Integrating with Enterprise Resource Planning (ERP) systems provides a holistic view of operations, including inventory management, procurement, and financial tracking. This allows for automated ordering of parts based on maintenance needs.

- Inventory Management Systems: Linking with inventory management systems ensures accurate tracking of parts and supplies, reducing stockouts and optimizing inventory levels.

- SCADA Systems: Integration with Supervisory Control and Data Acquisition (SCADA) systems provides real-time equipment data, allowing for more proactive maintenance decisions based on live equipment performance.

- Business Intelligence (BI) Tools: Combining maintenance data with BI tools allows for deeper analysis and data visualization, providing valuable insights into maintenance costs, equipment reliability, and operational efficiency.

In a previous role, I integrated our CMMS with our ERP system, automating the procurement process for maintenance parts. This streamlined operations and significantly reduced lead times for repairs.

Q 27. What are some best practices for managing digital maintenance logs?

Managing digital maintenance logs effectively requires a combination of technological tools and best practices.

- Choosing the Right CMMS: Select a CMMS that fits your organization’s needs and integrates with existing systems. Consider scalability, user-friendliness, and reporting capabilities.

- Data Backup and Security: Implement robust data backup and security measures to protect against data loss or unauthorized access. Regular backups are crucial to prevent data loss.

- Access Control: Establish appropriate access control measures to ensure data integrity and confidentiality. Only authorized personnel should have access to sensitive information.

- Regular Data Cleaning: Regularly clean and organize data to maintain data accuracy and efficiency. This includes removing duplicates and correcting errors.

- Automated Reporting and Alerts: Utilize automated reporting and alert features to proactively identify potential issues and improve maintenance planning. Automated reports can track key metrics like MTBF.

For example, using a cloud-based CMMS offers enhanced data security and accessibility from multiple locations. Regular data backups and access controls are essential for safeguarding the integrity of your maintenance data.

Q 28. How do you reconcile discrepancies between planned and actual maintenance activities?

Reconciling discrepancies between planned and actual maintenance activities is crucial for accurate reporting and continuous improvement. Think of it as balancing your budget – understanding the variances between planned and actual spending.

- Root Cause Analysis: Investigate the reasons for any discrepancies. Were there unforeseen problems, equipment failures, or scheduling conflicts? This is about finding the ‘why’ behind the difference.

- Data Verification: Verify data accuracy by cross-referencing information from multiple sources, such as work orders, technician reports, and equipment logs. This helps ensure data integrity.

- Performance Evaluation: Use the data to evaluate the effectiveness of the maintenance plan and identify areas for improvement. This is about learning from past differences to improve future planning.

- Documentation: Document all discrepancies, including the root cause and corrective actions taken. This helps track patterns and prevent similar issues in the future. This information is crucial for continuous improvement.

- Adjusting Plans: Based on the analysis, adjust future maintenance plans to reflect the realities of actual work performed. This involves updating schedules, adjusting resource allocation, and refining preventative maintenance protocols.

For example, if a planned maintenance task took longer than anticipated due to unexpected component failure, this should be documented and used to refine future maintenance schedules and resource allocation.

Key Topics to Learn for Maintenance Logs Interview

- Understanding Log Structures: Learn different log formats (text-based, database-driven), their purpose, and how to effectively interpret them. Consider various levels of detail and the importance of consistent formatting.

- Data Analysis & Troubleshooting: Practice analyzing log entries to identify patterns, pinpoint anomalies, and diagnose system issues. Develop skills in correlating information across multiple logs.

- Log Management Systems: Familiarize yourself with common log management tools and techniques, including centralized logging, log aggregation, and log monitoring. Understand the benefits and trade-offs of different systems.

- Security & Compliance: Explore the role of maintenance logs in security audits and compliance. Learn about secure log storage, access control, and data retention policies.

- Best Practices for Log Entry: Understand the principles of creating clear, concise, and informative log entries. This includes proper timestamping, error codes, and relevant contextual information.

- Practical Application: Case Studies: Explore real-world scenarios where analyzing maintenance logs helped resolve critical system failures or performance bottlenecks. Develop your problem-solving skills through these examples.

- Automation & Scripting (Advanced): For senior roles, explore how scripting languages can be used to automate log analysis, filtering, and alerting.

Next Steps

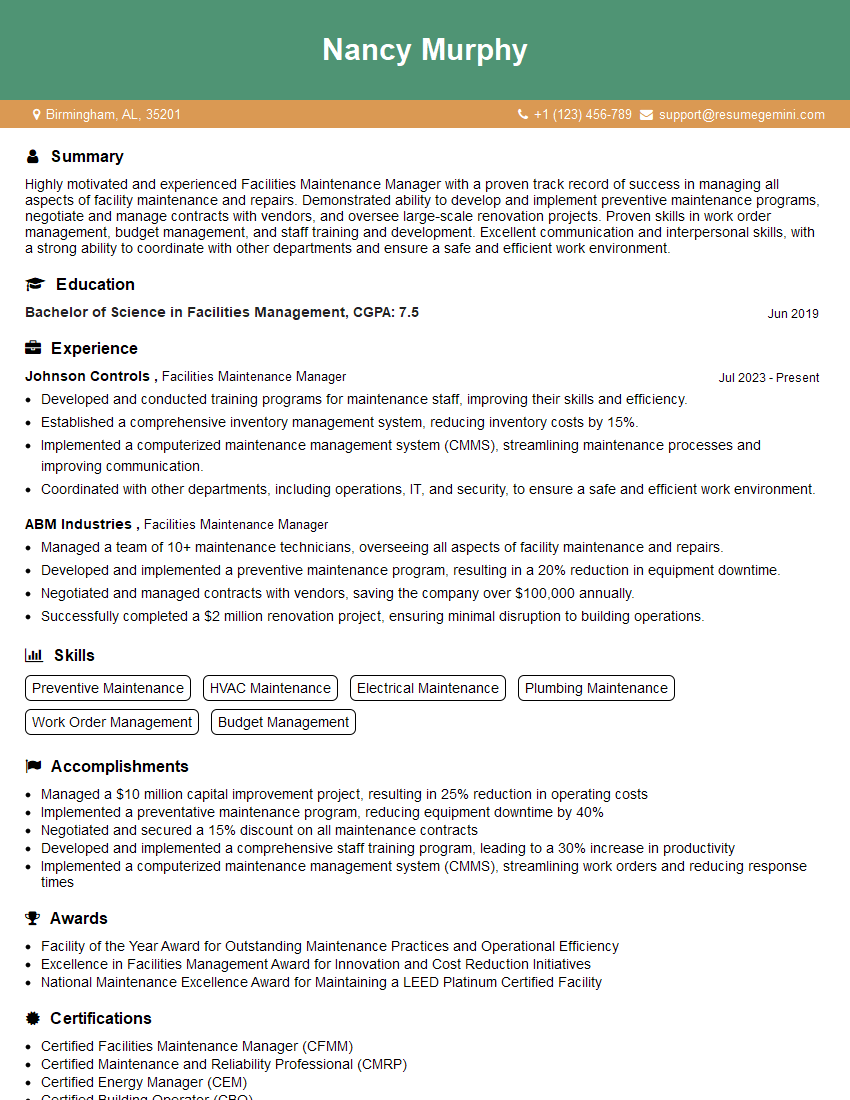

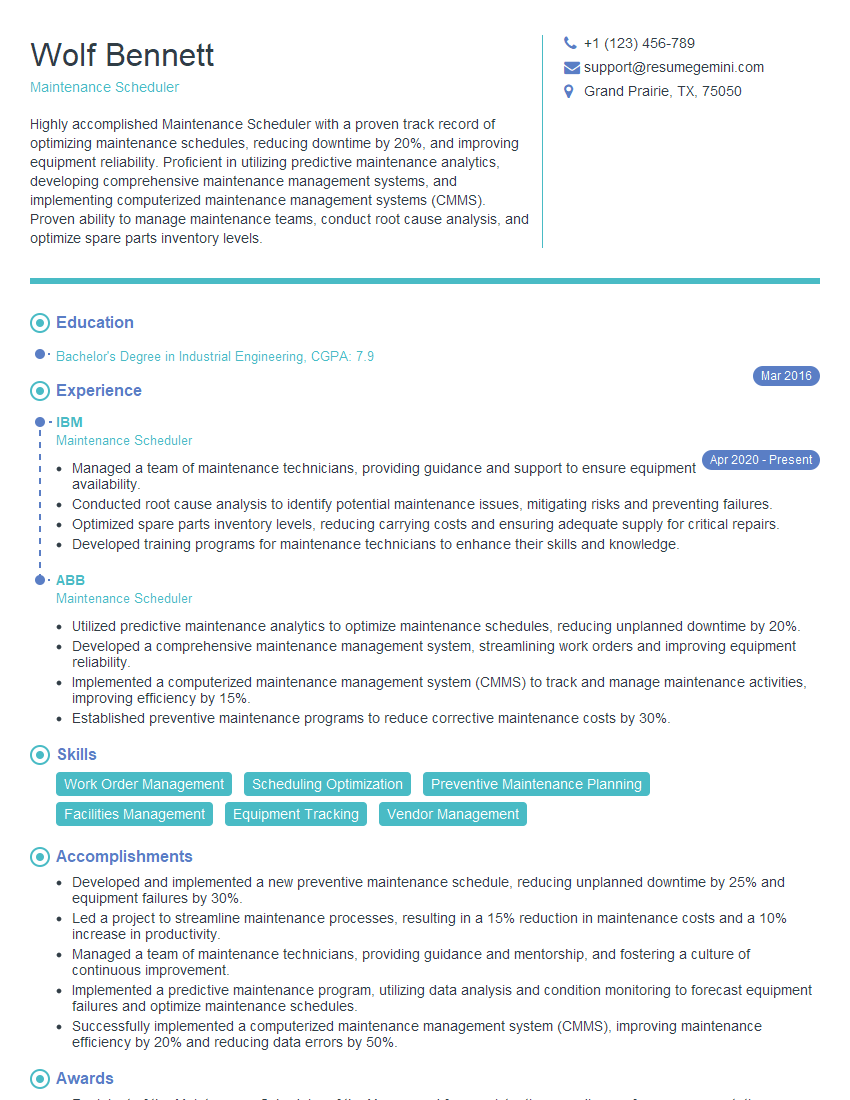

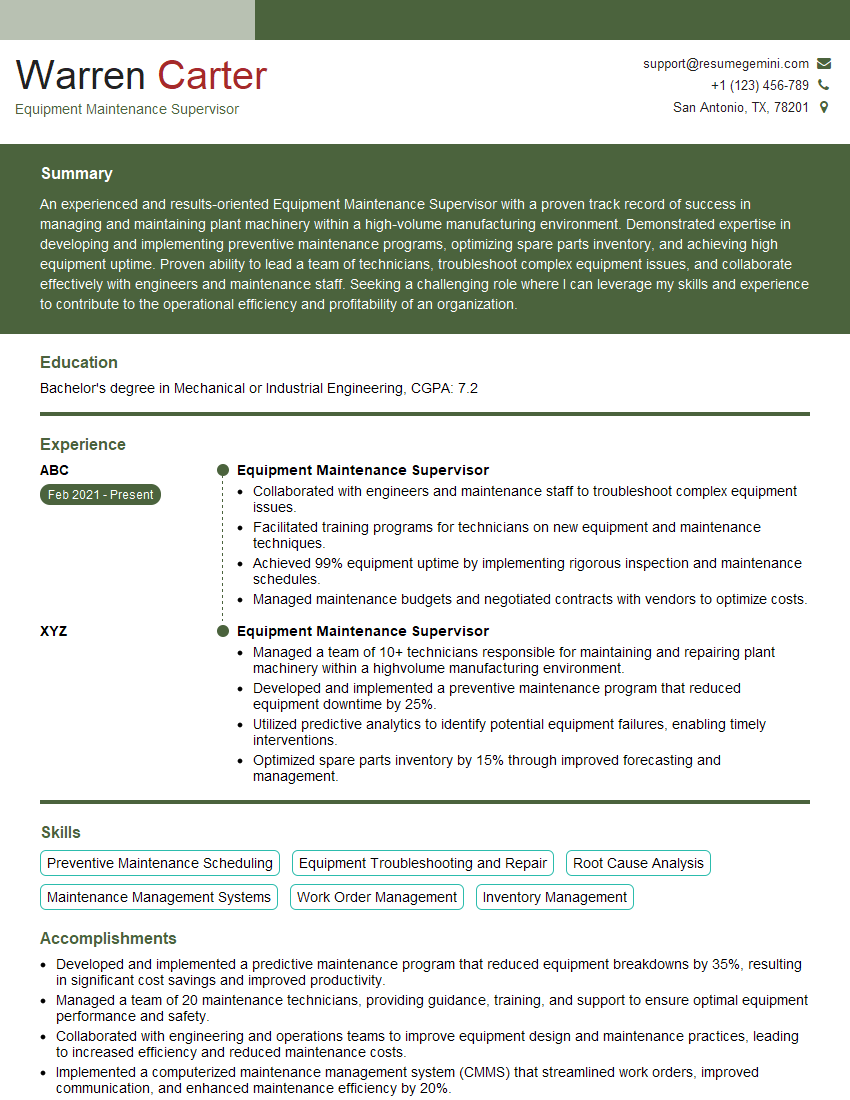

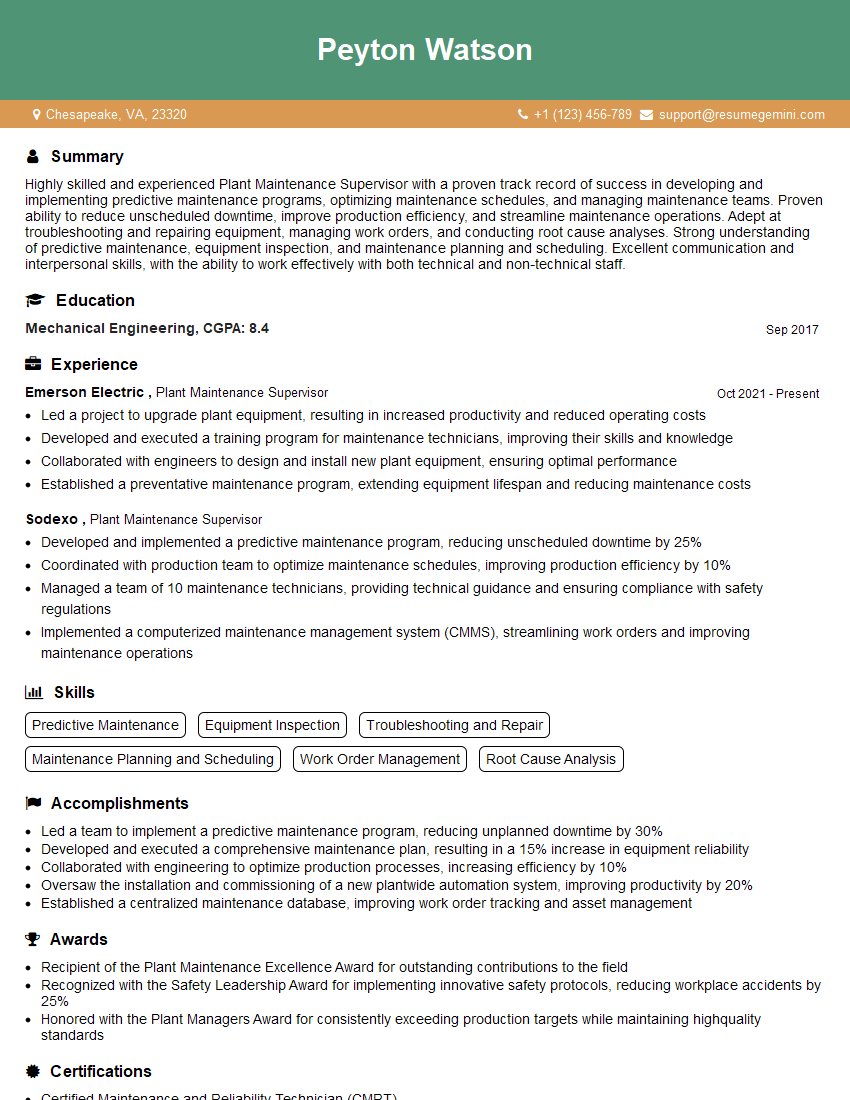

Mastering the intricacies of Maintenance Logs is crucial for career advancement in IT and related fields. Your ability to effectively analyze and interpret these logs directly impacts system reliability, security, and efficiency. To maximize your job prospects, create an ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource to help you build a professional and compelling resume that highlights your skills and experience. Examples of resumes tailored to Maintenance Logs professionals are available below to help guide your resume creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good