Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Water Infrastructure Inspection and Maintenance interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Water Infrastructure Inspection and Maintenance Interview

Q 1. Describe your experience with different types of water pipe materials (e.g., PVC, ductile iron, steel).

My experience encompasses a wide range of water pipe materials, each with its own strengths and weaknesses. Let’s consider three common types: Polyvinyl Chloride (PVC), ductile iron, and steel.

- PVC: PVC pipes are known for their lightweight, corrosion resistance, and relatively low cost. They are ideal for low-pressure applications and are commonly used in residential and smaller diameter distribution systems. However, they have limitations in high-pressure situations and can be susceptible to damage from UV radiation and extreme temperature fluctuations. I’ve worked on projects where we’ve seen the benefits of PVC’s ease of installation, particularly in areas with challenging terrain. But I’ve also witnessed instances where prolonged sun exposure has led to degradation, highlighting the need for proper protection.

- Ductile Iron: Ductile iron pipes offer superior strength and durability compared to PVC, making them suitable for high-pressure mains and larger diameter applications. They are resistant to corrosion but can be more expensive than PVC. My experience includes inspecting ductile iron mains where we used specialized tools to assess the condition of internal pipe coatings. I’ve seen the resilience of ductile iron pipes in areas with significant ground movement, minimizing the risk of breaks compared to other materials.

- Steel: Steel pipes, though strong, are prone to corrosion, requiring regular maintenance including coatings and cathodic protection. They’re often found in older infrastructure, and their lifespan can be extended through diligent inspection and timely intervention. I was part of a team that assessed a section of aging steel pipe using advanced non-destructive testing techniques, allowing us to pinpoint corrosion areas before major failures occurred. This proactive approach prevented costly emergency repairs and ensured continued service reliability.

Understanding the specific properties of each material is crucial for effective maintenance planning and selecting appropriate repair or replacement strategies. The choice depends heavily on factors such as pressure, soil conditions, and project budget.

Q 2. What are the common signs of pipe corrosion and how would you assess its severity?

Pipe corrosion is a significant concern in water infrastructure. Identifying and assessing its severity is vital to prevent failures and maintain water quality. Common signs include:

- External Corrosion: Pitting, scaling, rust, and general deterioration of the pipe’s outer surface. This is often influenced by soil conditions and stray electrical currents.

- Internal Corrosion: Tuberculation (the formation of nodules on the inner pipe surface), pitting, scaling, and general wall thinning. These can restrict water flow and compromise water quality.

- Leakage: Leaks, even small ones, are a clear indication of pipe deterioration, particularly at joints and fittings.

Assessing severity involves a multi-faceted approach:

- Visual Inspection: A thorough visual inspection, often using cameras or remotely operated vehicles (ROVs) for internal assessment. This provides an initial overview of the corrosion extent.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing, magnetic particle inspection, and electromagnetic techniques are employed to determine the remaining pipe wall thickness and identify flaws beneath the surface.

- Water Quality Monitoring: Increased levels of iron, manganese, or other metals in the water can indicate corrosion within the pipes.

Severity is often categorized based on the extent of corrosion, remaining wall thickness, and the rate of deterioration. A detailed assessment helps to prioritize repairs and determine whether simple patching or complete pipe replacement is necessary. For instance, I once used data from NDT to create a corrosion map for a particular water main, this information was critical in determining the best time and approach for repairs.

Q 3. Explain your understanding of water pressure management and its importance in infrastructure maintenance.

Water pressure management is the practice of controlling and optimizing water pressure within a distribution system. It’s crucial for effective infrastructure maintenance for several reasons:

- Leak Reduction: High pressure accelerates leakage rates. By managing pressure, we reduce the driving force behind leaks, minimizing water loss and conserving resources. Think of it like inflating a tire – the higher the pressure, the more likely it is to leak. In the water system, this translates to a direct financial impact and potential environmental concerns from excessive water loss.

- Pipe Failure Prevention: Excessive water pressure significantly increases stress on pipes, leading to premature failures and costly repairs. Proper pressure management extends the lifespan of the infrastructure and improves system reliability.

- Improved Water Quality: Sustained high pressure can cause water hammer (sudden pressure surges), potentially leading to pipe damage and water quality issues. Consistent pressure management mitigates these risks.

- Reduced Energy Costs: Lower pressure usually translates to lower pumping energy requirements, resulting in financial savings for the utility.

Effective water pressure management requires sophisticated monitoring systems, pressure-reducing valves, and advanced data analytics to identify pressure fluctuations and optimal pressure zones. In my experience, using pressure sensors, Supervisory Control and Data Acquisition (SCADA) systems and hydraulic modelling have allowed me to create better control schemes leading to significant improvements in efficiency.

Q 4. How do you perform a visual inspection of a water main?

Visual inspection of a water main is a critical step in assessing its condition. The method depends on whether the main is exposed or buried. For exposed mains, the inspection can be straightforward. For buried mains, more advanced techniques are required.

- Exposed Mains: A visual inspection involves a thorough examination of the pipe’s exterior surface looking for signs of corrosion, damage, leaks, and proper support systems. I’ve often used high-resolution cameras and drones to capture images and videos for documentation, which aids in the detection of anomalies that might be missed during a simple visual inspection.

- Buried Mains: For buried mains, we often use specialized tools and techniques. This may involve excavation to expose sections of the pipe for detailed assessment, or the use of closed-circuit television (CCTV) cameras inserted into the pipe to inspect the internal condition. We may also use ground-penetrating radar (GPR) to locate and assess the pipe’s condition without excavation, thereby minimizing disruption.

During a visual inspection, a detailed log is kept, noting all observations. Photographs and videos are essential for documentation and future reference. We would carefully record details like location, type of damage, dimensions of corrosion, and any other relevant information.

Q 5. What are the key indicators of a potential water main break?

Several key indicators suggest a potential water main break:

- Sudden drop in water pressure: A significant and localized reduction in water pressure is a strong indicator of a break.

- Visible water on the surface: This could be a noticeable flow of water from the ground, a flooded area, or a sinkhole.

- Saturated ground: The area surrounding the suspected break may appear unusually wet or muddy.

- Ground subsidence: A settling or collapsing of the ground around the break.

- Noisy pipes: Unusual sounds such as hissing or gurgling noises coming from pipes.

- Reduced water flow: Lower water flow in connected buildings or areas than normal.

- Reports from residents: The most reliable way for us to find issues is to have residents relaying water issues in their neighbourhoods.

It’s crucial to respond promptly to reported issues. A rapid assessment of the situation is essential to minimize disruption to service and prevent further damage.

Q 6. Describe your experience with leak detection techniques.

My experience covers a variety of leak detection techniques. The best method depends on factors like the size and location of the suspected leak and the type of pipe.

- Acoustic Leak Detection: This involves using specialized listening devices (correlation sensors) to pinpoint the location of leaks by detecting the high-frequency sounds they produce. This is particularly useful for detecting leaks in buried pipes without excavation.

- Ground Penetrating Radar (GPR): GPR can create images showing the subsurface conditions including the location and extent of leaks. This non-destructive method helps to locate leaks in concrete, asphalt and other dense mediums.

- Tracer Gas Leak Detection: A tracer gas (like helium or sulfur hexafluoride) is introduced into the pipe system. A leak allows the gas to escape, which can then be detected by specialized equipment. This technique is particularly helpful for detecting leaks in pipes that are difficult to access.

- Leak Detection Dye: Fluorescent dye can be introduced into the water system, and it will make its way out at leaks. Using UV light, the dye can be detected visually. This method is less suitable for large, deep leaks but is useful for some surface leaks.

- Pressure Monitoring: Continuous monitoring of water pressure fluctuations can help to identify potential leaks, particularly in areas with known issues.

Choosing the right technique is based on several factors. For example, acoustic methods are extremely efficient for buried pipe, while GPR is a great way to get a more complete image of the subsurface environment. I often combine several techniques for a more comprehensive assessment.

Q 7. Explain your knowledge of different types of water meters and their maintenance.

Water meters measure the amount of water consumed by individual users or zones. Different types exist, each with its own maintenance requirements.

- Mechanical Meters: These traditional meters use moving parts to register water flow. They are relatively simple but require regular maintenance, including cleaning and lubrication, to ensure accuracy. I’ve seen instances where mineral buildup interfered with the meter’s operation, causing inaccurate readings and revenue loss. Regular maintenance programs helped prevent these issues.

- Electronic Meters: These meters utilize electronic sensors to measure water flow. They offer advantages such as remote reading capabilities, higher accuracy, and lower maintenance. However, they are usually more expensive than mechanical meters. My experience with electronic meters involved remote monitoring of data and early detection of malfunctions. The system flagged anomalies enabling timely replacement and avoiding substantial customer billing errors.

- Smart Meters: These advanced electronic meters offer communication capabilities to transmit consumption data remotely. They often include features like leak detection and advanced diagnostics. They can significantly improve efficiency of operations by allowing for remote data collection and efficient billing systems. They require specialized tools and knowledge for maintenance and repair.

Maintenance requirements vary depending on the meter type and operating environment. Regular inspection, cleaning, and testing are needed to ensure accuracy and prolong the meter’s lifespan. Some meters require replacement after a certain number of years, while others may be repairable depending on the extent of the damage.

Q 8. How familiar are you with SCADA systems and their role in water infrastructure management?

SCADA, or Supervisory Control and Data Acquisition, systems are crucial for managing water infrastructure. They act as the nervous system, allowing for remote monitoring and control of various components across the entire water network. Think of them as a central dashboard displaying real-time data from pumps, reservoirs, treatment plants, and more. This data includes flow rates, pressure levels, tank levels, and even water quality parameters. I have extensive experience working with SCADA systems, specifically using platforms like

OSIsoft PI and Schneider Electric's Wonderware. My experience includes configuring alarm systems, creating custom reports, and troubleshooting network issues to ensure continuous data flow and efficient operational management. For example, I once used SCADA data to pinpoint a failing pump in a remote location, preventing a potential service disruption by scheduling proactive maintenance.

SCADA’s role extends beyond simply monitoring; it enables proactive interventions. Anomalies in data, such as a sudden drop in pressure, can trigger automated alerts, allowing for immediate response and potentially preventing significant damage or service disruptions. Moreover, SCADA facilitates data analysis for long-term planning, helping identify trends, predict future needs, and optimize the overall efficiency of the water system.

Q 9. Describe your experience with water quality testing and analysis.

Water quality testing and analysis is a fundamental aspect of my work. I’m proficient in a range of analytical methods, including those for testing turbidity, pH, chlorine residual, coliform bacteria, and various other chemical parameters. I’ve used both field testing kits for rapid onsite assessments and sophisticated laboratory equipment for detailed analysis. My experience extends to interpreting results, identifying potential sources of contamination, and recommending corrective actions. For instance, I once identified elevated levels of nitrates in a well water supply by performing regular water quality monitoring. This led to the implementation of a new filtration system and prevented contamination of the drinking water supply.

My experience includes adhering to strict regulatory guidelines and maintaining detailed records of all testing procedures and results. I also understand the importance of using appropriate quality control measures to ensure the accuracy and reliability of the data obtained. Furthermore, I have experience in working with various databases for water quality data management and analysis to spot trends and anomalies.

Q 10. What are the common causes of water contamination and how are they mitigated?

Water contamination can stem from various sources, broadly categorized as:

- Point Source Pollution: This involves contamination from a specific, identifiable location, such as a leaking industrial pipe or an improperly managed landfill.

- Non-Point Source Pollution: This is more diffuse and comes from multiple sources spread over a larger area, like agricultural runoff carrying fertilizers or pesticides.

- Biological Contamination: This arises from pathogens like bacteria (e.g., E. coli) or viruses that enter the water supply through fecal contamination or inadequate disinfection.

- Chemical Contamination: This involves the presence of harmful chemicals like heavy metals (lead, mercury), industrial solvents, or pesticides.

Mitigating contamination involves a multi-pronged approach. Point source pollution can be addressed by repairing leaks, implementing proper waste disposal techniques, and enforcing environmental regulations. Non-point source pollution requires broader strategies like implementing best management practices in agriculture, reducing urban runoff, and promoting responsible land use. Biological contamination is tackled primarily through effective water treatment processes, involving disinfection and filtration. Chemical contamination demands stricter industrial regulations, appropriate treatment technologies, and careful monitoring of water quality.

Q 11. Explain your understanding of water treatment processes (filtration, disinfection, etc.).

Water treatment involves a series of processes to make water safe for consumption. The common stages are:

- Coagulation and Flocculation: Chemicals are added to clump together suspended particles.

- Sedimentation: These clumps settle out of the water.

- Filtration: Water passes through filters to remove remaining particles.

- Disinfection: Chemicals like chlorine, chloramine, or UV light kill harmful microorganisms.

These processes may vary depending on the source water quality and the desired level of treatment. For example, a water source with high turbidity will require more extensive filtration, while a source with high levels of organic matter might necessitate additional coagulation and flocculation steps. My expertise lies in understanding the design, operation, and maintenance of various water treatment technologies, ensuring optimal performance and water quality compliance.

Q 12. What are the key aspects of wastewater treatment?

Wastewater treatment aims to remove pollutants from wastewater, making it safe to discharge into the environment or reuse. The process typically involves:

- Preliminary Treatment: Removing large debris (screens, grit removal).

- Primary Treatment: Settling of solids (sedimentation tanks).

- Secondary Treatment: Biological processes break down organic matter (activated sludge, trickling filters).

- Tertiary Treatment: Advanced processes to remove nutrients (nitrogen, phosphorus) and other pollutants.

- Disinfection: To eliminate harmful pathogens (chlorination, UV disinfection).

The specific processes used depend on the wastewater characteristics, regulatory requirements, and intended use of the treated effluent. I have practical experience in designing, operating, and maintaining wastewater treatment plants, ensuring compliance with environmental regulations and optimized plant performance.

Q 13. How do you identify and address issues related to wastewater overflows?

Wastewater overflows are serious incidents that can lead to environmental contamination and public health risks. Identifying the causes involves a thorough investigation, often combining SCADA data analysis with physical inspections. Common causes include:

- Pump failures: SCADA systems often detect anomalies like high amperage or low flow, signaling pump problems.

- Blockages in pipes or sewers: Inspections with CCTV cameras can pinpoint blockages.

- Heavy rainfall exceeding capacity: This requires robust infrastructure design and overflow management strategies.

Addressing overflows involves immediate response actions, such as deploying emergency bypass systems and implementing appropriate cleanup procedures. Long-term solutions depend on the identified cause. It might involve pump replacement, sewer rehabilitation, upgrades to treatment plant capacity, or improved stormwater management practices. I have experience in coordinating emergency responses to overflows, conducting root cause analyses, and implementing comprehensive mitigation plans.

Q 14. Explain your experience with pump maintenance and troubleshooting.

Pump maintenance and troubleshooting are essential for reliable water infrastructure operation. I have extensive experience maintaining various pump types, including centrifugal, submersible, and positive displacement pumps. My expertise covers preventative maintenance schedules, predictive maintenance techniques using vibration analysis, and corrective maintenance procedures. For instance, I am skilled in diagnosing pump failures by analyzing operational data, such as flow rates, pressure differentials, and power consumption. I can also identify problems such as bearing wear, impeller damage, seal leaks, and cavitation using both visual inspection and specialized tools.

Troubleshooting involves a systematic approach, starting with analyzing SCADA data for clues, followed by visual inspection, and if necessary, disassembling the pump to inspect internal components. This could involve replacing worn parts, aligning the pump, or repairing leaks. I’m proficient in working safely with high-voltage equipment, ensuring all safety protocols are followed throughout the maintenance and repair process. I also emphasize the importance of proper documentation of all maintenance activities, creating a detailed record for future reference.

Q 15. How do you prioritize maintenance tasks for optimal system performance?

Prioritizing maintenance tasks is crucial for ensuring optimal water infrastructure performance and preventing costly failures. We employ a risk-based approach, combining several factors to create a prioritized list.

- Criticality: We assess the impact of a failure on water supply, public health, and the environment. For example, a main water transmission line failure has far higher criticality than a minor leak on a residential service line.

- Condition Assessment: Regular inspections, using techniques like visual assessments, pressure testing, and internal video inspections, reveal the current state of assets. This informs the urgency of maintenance. A pipe showing significant corrosion will be prioritized over one with minor surface rust.

- Remaining Life Expectancy: We use data and predictive modeling to estimate the remaining lifespan of infrastructure components. This allows proactive maintenance before a complete failure, preventing costly emergency repairs.

- Cost-Benefit Analysis: We weigh the cost of maintenance against the potential costs of a failure. Sometimes, a proactive, albeit more expensive, repair is less costly than dealing with the consequences of a catastrophic failure.

We typically use software to manage this process, integrating data from inspections, asset registers, and hydraulic models. This allows for dynamic prioritization as conditions change or new information becomes available. For example, following a significant rainfall event, we might prioritize inspection and maintenance of drainage systems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety precautions do you take when inspecting water infrastructure?

Safety is paramount in water infrastructure inspection and maintenance. We adhere to strict safety protocols, which include:

- Lockout/Tagout Procedures: Before working on any equipment, we ensure complete isolation to prevent accidental energization or activation.

- Personal Protective Equipment (PPE): Appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing, is mandatory at all times. Specific PPE, like respirators or confined-space entry equipment, is used as required.

- Confined Space Entry Procedures: For tasks in confined spaces like manholes or tanks, we follow stringent protocols to ensure adequate ventilation, atmospheric monitoring, and rescue procedures are in place.

- Traffic Control and Signage: When working near roads or traffic areas, we implement traffic control measures and clear signage to warn and protect workers and the public.

- Emergency Response Plans: We develop and regularly practice site-specific emergency response plans, including procedures for handling spills, injuries, or equipment malfunctions.

- Site-Specific Risk Assessments: Before each inspection, we conduct a thorough risk assessment to identify and mitigate potential hazards, tailoring our safety procedures to the specific site and task.

Regular safety training and toolbox talks reinforce safe work practices and promote a safety-conscious culture within the team. Safety is not just a set of rules; it’s a mindset that permeates every aspect of our work.

Q 17. Describe your experience with creating and interpreting water infrastructure inspection reports.

I have extensive experience in creating and interpreting water infrastructure inspection reports. My reports typically include:

- Asset Identification: Clear identification of the inspected asset, including location, type, size, and age.

- Inspection Date and Personnel: Documentation of when and by whom the inspection was performed.

- Inspection Methodology: A description of the techniques used (visual, pressure testing, etc.).

- Findings: Detailed description of observed conditions, including any defects, damage, or anomalies. This may include photographs, sketches, or video footage.

- Severity Assessment: Classification of defects based on their severity and potential impact (e.g., minor, moderate, critical).

- Recommendations: Specific and prioritized recommendations for repairs, maintenance, or further investigation.

- Compliance Status: Assessment of compliance with relevant regulations and standards.

I use software to streamline report generation and ensure consistency. The reports are critical for tracking asset conditions, making informed decisions about maintenance, and demonstrating compliance. I also use data analysis techniques to identify trends and patterns in asset degradation, which helps in predictive maintenance and resource allocation.

Q 18. How do you ensure compliance with relevant regulations and standards?

Compliance with relevant regulations and standards is crucial for ensuring the safety and reliability of water infrastructure. We adhere to all applicable federal, state, and local regulations, including those related to water quality, safety, and environmental protection. These often include:

- Drinking Water Regulations: Meeting standards for water quality parameters, such as disinfection byproduct levels and microbial contaminants.

- Occupational Safety and Health Administration (OSHA) Regulations: Adhering to safety standards for workers in construction, maintenance, and operation.

- li>Environmental Protection Agency (EPA) Regulations: Complying with regulations related to wastewater discharge and environmental protection.

- American Water Works Association (AWWA) Standards: Following industry best practices for the design, construction, and operation of water systems.

We use a combination of regular audits, internal reviews, and external inspections to ensure ongoing compliance. Documentation is meticulously maintained, and training programs keep our staff updated on current regulations and best practices. Non-compliance is addressed immediately through corrective actions and preventative measures. A documented compliance management system ensures a proactive approach to regulatory adherence.

Q 19. How familiar are you with GIS mapping and its application in water infrastructure management?

I’m highly proficient in using Geographic Information Systems (GIS) mapping for water infrastructure management. GIS provides a powerful tool for visualizing, analyzing, and managing our extensive network of pipes, valves, hydrants, and other assets.

- Asset Mapping: GIS allows for accurate mapping of all infrastructure components, providing a visual representation of the network.

- Spatial Analysis: We use GIS to perform spatial analysis, such as identifying areas with high density of aging infrastructure or proximity to critical facilities. This helps target maintenance efforts efficiently.

- Network Modeling: GIS integrates with hydraulic modeling software, allowing for simulation and analysis of water flow within the network.

- Work Order Management: GIS is used to assign work orders to crews, track progress, and manage resources in the field. This optimizes the efficiency of maintenance operations.

- Public Access and Reporting: GIS can be used to provide the public with accessible maps and information about the water system.

For example, we used GIS to identify a cluster of aging pipes in a particular area that were showing signs of significant corrosion. This analysis allowed us to prioritize these pipes for replacement before a major failure, saving significant cost and disruption.

Q 20. Describe your experience with hydraulic modeling and analysis.

Hydraulic modeling and analysis are essential for understanding and managing water flow within a system. My experience includes using various software packages to develop and interpret hydraulic models. This involves:

- Data Acquisition: Gathering data on pipe diameters, lengths, roughness coefficients, and pump characteristics.

- Model Calibration and Validation: Using field data to calibrate and validate the model’s accuracy.

- Scenario Analysis: Simulating various scenarios, such as peak demand, pipe failures, or pump outages, to assess system performance and identify vulnerabilities.

- Optimization: Using models to optimize system operations, such as pump scheduling or pressure regulation.

- Emergency Response: Using models to assess the impacts of emergency situations and guide response strategies.

For instance, we used hydraulic modeling to identify pressure zones within the water distribution network that were experiencing consistently low pressure. This led us to optimize pump operations and upgrade parts of the system to ensure adequate water pressure for all customers.

Q 21. What are your strategies for managing emergencies and unplanned maintenance?

Managing emergencies and unplanned maintenance requires a well-defined and practiced protocol. Our approach includes:

- Emergency Response Plan: A detailed plan outlining roles, responsibilities, communication protocols, and procedures for handling various emergency scenarios, such as pipe bursts or power outages.

- 24/7 Monitoring and Alert Systems: We use SCADA systems and other monitoring technologies to detect anomalies and provide immediate alerts to appropriate personnel.

- Rapid Response Teams: Dedicated teams are on call to address emergencies and perform critical repairs.

- Spare Parts Inventory: Maintaining a sufficient inventory of critical spare parts to minimize downtime.

- Communication Protocols: Clear communication protocols are in place to ensure seamless information flow between field crews, management, and customers.

- Post-Incident Review: Following an emergency, we conduct a thorough review to identify lessons learned and improve our response capabilities.

For example, when a major pipe burst occurred during a severe storm, our emergency response plan enabled a rapid response, minimizing service disruption and preventing widespread damage. Post-incident review helped us implement preventative measures such as improved pipe inspections and early warning systems to decrease the likelihood of similar incidents in the future.

Q 22. How do you assess the structural integrity of dams and reservoirs?

Assessing the structural integrity of dams and reservoirs is a multifaceted process requiring a combination of visual inspections, instrumental monitoring, and advanced analytical techniques. It’s like giving a thorough health check-up to a giant structure.

Visual Inspections: We start with a thorough visual examination, checking for cracks, erosion, seepage, vegetation growth, and any signs of distress in the dam’s structure, spillways, and surrounding areas. This often involves using drones for aerial surveys to access difficult-to-reach areas and provide high-resolution imagery.

Instrumental Monitoring: This involves installing various sensors to continuously monitor key parameters. These might include:

- Strain gauges: Measure stress and deformation within the dam’s concrete or earthfill.

- Piezometers: Measure pore water pressure within the dam, crucial for assessing stability.

- Inclinometers: Measure changes in the dam’s inclination, indicating potential movement or settlement.

- Settlement markers: Track vertical movement of the dam over time.

Advanced Analytical Techniques: Data from instrumental monitoring, along with geological surveys and hydrological modeling, are used in sophisticated computer simulations to predict the dam’s behavior under various loading conditions (e.g., extreme rainfall, seismic activity). This helps us identify potential weaknesses and assess the overall safety and longevity of the structure.

Example: During an inspection of an aging earthfill dam, we detected increased seepage rates. Using piezometers, we identified a localized zone of high pore water pressure, indicating potential instability. This prompted a detailed investigation, including drilling boreholes to assess the dam’s internal structure and implementing remedial measures to reduce the seepage and improve stability.

Q 23. What are common issues with water storage tanks, and how are they repaired?

Water storage tanks, while seemingly simple, are susceptible to various issues. Think of it like a giant bathtub that needs regular cleaning and maintenance to stay in top shape.

Common Issues:

- Corrosion: This is a major concern, especially in tanks made of steel. Corrosion can lead to leaks, structural weakening, and contamination of the stored water. Different types of corrosion exist (e.g., pitting, galvanic).

- Leaks: These can be caused by corrosion, cracks, faulty welds, or improper installation. Locating leaks accurately can be challenging and often requires specialized equipment.

- Cracking: This can be caused by thermal stresses (temperature fluctuations), settlement of the foundation, or seismic activity.

- Biological Growth: Bacteria and algae can grow within the tank, impacting water quality and potentially clogging pipelines.

Repairs: Repair methods depend on the nature and severity of the issue. Minor leaks might be repaired using epoxy resins or specialized sealants. More extensive damage might require patching, replacing sections of the tank wall, or even complete tank refurbishment. For corrosion control, we might employ techniques like cathodic protection (explained further in a later answer). Removing biological growth often involves thorough cleaning and disinfection.

Example: A steel water storage tank showed signs of significant pitting corrosion. We implemented a cathodic protection system to mitigate further corrosion and then repaired the existing pitted areas using a combination of grinding, filling, and painting with a corrosion-resistant coating.

Q 24. Explain your understanding of cathodic protection and its application in corrosion control.

Cathodic protection (CP) is an electrochemical technique used to protect metallic structures from corrosion by making them a cathode in an electrochemical cell. Imagine it like creating a shield that prevents the metal from reacting with its environment.

How it works: CP works by introducing a sacrificial anode (a metal that corrodes more readily than the structure being protected) or an impressed current source. This creates a flow of electrons from the anode to the structure, preventing the metal from losing electrons and thus preventing corrosion. The anode corrodes instead of the protected structure.

Application in Corrosion Control: CP is widely used in water infrastructure, protecting pipelines, storage tanks, and other metallic components. For example, in pipelines, anodes are installed along the pipeline’s length; for storage tanks, anodes might be attached to the tank’s interior or exterior surfaces.

Types:

- Sacrificial Anode System: Uses a more reactive metal (e.g., zinc, magnesium) as an anode. This method is relatively simple and cost-effective, but the anodes need periodic replacement.

- Impressed Current Cathodic Protection (ICCP): Uses an external power source to drive the current flow. This allows for more precise control and greater protection but requires a more complex system.

Example: We implemented an ICCP system on a large diameter water pipeline. The system constantly monitors the pipeline’s potential and adjusts the current flow to maintain optimal protection, preventing corrosion and ensuring the long-term integrity of the pipeline.

Q 25. How do you manage and interpret data from water quality monitoring systems?

Water quality monitoring systems generate vast amounts of data, providing critical insights into water quality parameters like pH, turbidity, chlorine levels, and the presence of contaminants. Efficient data management and interpretation are crucial for maintaining safe and reliable water supplies. Think of it like a comprehensive health report for your water system.

Data Management: Modern systems often employ SCADA (Supervisory Control and Data Acquisition) systems to collect and store data from various sensors. Data is frequently transmitted to a central database for analysis and visualization. Regular calibration and maintenance of the monitoring instruments are essential to ensure data accuracy.

Data Interpretation: We analyze the data to identify trends and anomalies. This involves using statistical methods, graphical representations (like charts and graphs), and advanced analytical tools. For example, a sudden spike in turbidity might indicate a problem with the treatment plant or a leak in the distribution system. Consistent monitoring allows for early detection of problems, preventing large-scale contamination events.

Example: During routine analysis of water quality data from a treatment plant, we observed a gradual increase in nitrates over several weeks. Further investigation revealed a problem with a malfunctioning component in the nitrate removal process. Prompt action prevented the delivery of contaminated water to consumers.

Q 26. Describe your experience with different types of valves and their operation and maintenance.

Valves are critical components in water infrastructure, controlling the flow and pressure of water. Think of them as the on/off switches and regulators of the water system. Different types of valves are used depending on their specific application.

Types and Operation:

- Gate Valves: Used for on/off control, not suitable for throttling (fine flow control). They operate by a sliding gate that opens or closes the flow path.

- Globe Valves: Used for throttling and on/off control. They operate by a disc that moves up and down to restrict or allow the flow.

- Butterfly Valves: Used for both on/off and throttling applications, especially in larger diameter pipelines. They operate by a rotating disc that partially or completely blocks the flow.

- Check Valves: Prevent backflow in pipelines. They automatically open in the direction of flow and close when the flow reverses.

- Ball Valves: Simple on/off valves. They use a rotating ball with a hole to control the flow.

Operation and Maintenance: Regular inspection and maintenance of valves are crucial. This includes lubricating moving parts, checking for leaks, and ensuring proper operation. Automated valve monitoring systems can alert operators to malfunctions, allowing for timely intervention. Failure to maintain valves can lead to disruptions in water service, leaks, and damage to the pipeline system.

Example: During an inspection, we found a partially obstructed globe valve leading to reduced water pressure in a residential area. After cleaning and lubricating the valve, the water pressure was restored to normal levels.

Q 27. What are your methods for documenting and tracking maintenance activities?

Maintaining accurate and readily accessible records of maintenance activities is critical for effective management of water infrastructure. It’s like keeping a detailed health log for the entire water system.

Methods: We use a combination of computerized maintenance management systems (CMMS) and physical documentation. CMMS software enables us to track:

- Work orders: Details of all maintenance tasks, including scheduling, personnel involved, and materials used.

- Inspection reports: Records of routine and special inspections, including observations and any identified issues.

- Repair history: Comprehensive history of repairs and replacements, enabling predictive maintenance.

- Inventory management: Tracking of spare parts and equipment.

Physical Documentation: While CMMS provides a centralized digital record, physical documentation like drawings, schematics, and operational manuals is also crucial for reference and emergency situations.

Example: We utilize a CMMS that automatically generates work orders based on scheduled preventative maintenance tasks, such as valve lubrication or pump inspections. Each completed work order is digitally signed and archived for future reference. This allows for efficient tracking of maintenance history and identification of trends.

Q 28. How do you communicate effectively with stakeholders regarding water infrastructure issues?

Effective communication with stakeholders (government agencies, residents, contractors) is critical for successful water infrastructure management. Transparency and timely information are key to maintaining public trust and ensuring cooperation.

Methods:

- Regular reports and updates: Providing stakeholders with regular reports on water quality, maintenance activities, and any potential issues.

- Public meetings and forums: Engaging with stakeholders directly through meetings, public hearings, and community forums to address concerns and provide updates.

- Website and social media: Utilizing online platforms to disseminate information, share updates, and respond to inquiries.

- Emergency notification systems: Establishing effective emergency notification systems to communicate critical information during emergencies, such as water outages or contamination events.

- Clear and concise communication: Using simple language, avoiding technical jargon, and ensuring that the information is easily understood.

Example: During a planned water main replacement project, we proactively communicated with residents through door-to-door flyers, online updates, and public meetings, outlining the project timeline, potential disruptions, and ways to minimize inconvenience. This open communication ensured community buy-in and resulted in a smoother project execution.

Key Topics to Learn for Water Infrastructure Inspection and Maintenance Interview

- Water Quality Monitoring and Analysis: Understanding water quality parameters, testing methods, and interpreting results to identify potential contamination sources and compliance issues. Practical application includes using field testing kits and understanding regulatory limits.

- Pipe and Infrastructure Materials: Knowledge of various pipe materials (e.g., PVC, ductile iron, concrete), their strengths, weaknesses, and common failure modes. Practical application includes recognizing signs of corrosion, cracking, or leakage during inspections.

- Leak Detection and Repair Techniques: Understanding various leak detection methods (e.g., acoustic listening, pressure monitoring, dye tracing) and common repair techniques. Practical application includes applying appropriate repair methods based on leak severity and pipe material.

- Hydraulic Modeling and System Analysis: Basic understanding of water flow dynamics, pressure management, and hydraulic modeling software. Practical application involves using this knowledge to diagnose system performance issues and optimize water distribution.

- Safety Protocols and Regulations: Familiarity with OSHA and other relevant safety regulations for working in confined spaces, around water, and with heavy equipment. Practical application includes performing safe and compliant inspections and maintenance tasks.

- Preventive Maintenance Strategies: Developing and implementing effective preventive maintenance plans to minimize equipment failures and extend the lifespan of water infrastructure. Practical application involves scheduling and coordinating routine inspections and repairs.

- Data Management and Reporting: Effectively documenting inspection findings, maintenance activities, and repairs through clear and concise reports. Practical application includes using digital tools to manage data and generate professional reports.

- Emergency Response and Repair Procedures: Understanding procedures for handling water main breaks, sewer overflows, and other emergencies. Practical application includes effectively managing emergency situations and minimizing service disruptions.

Next Steps

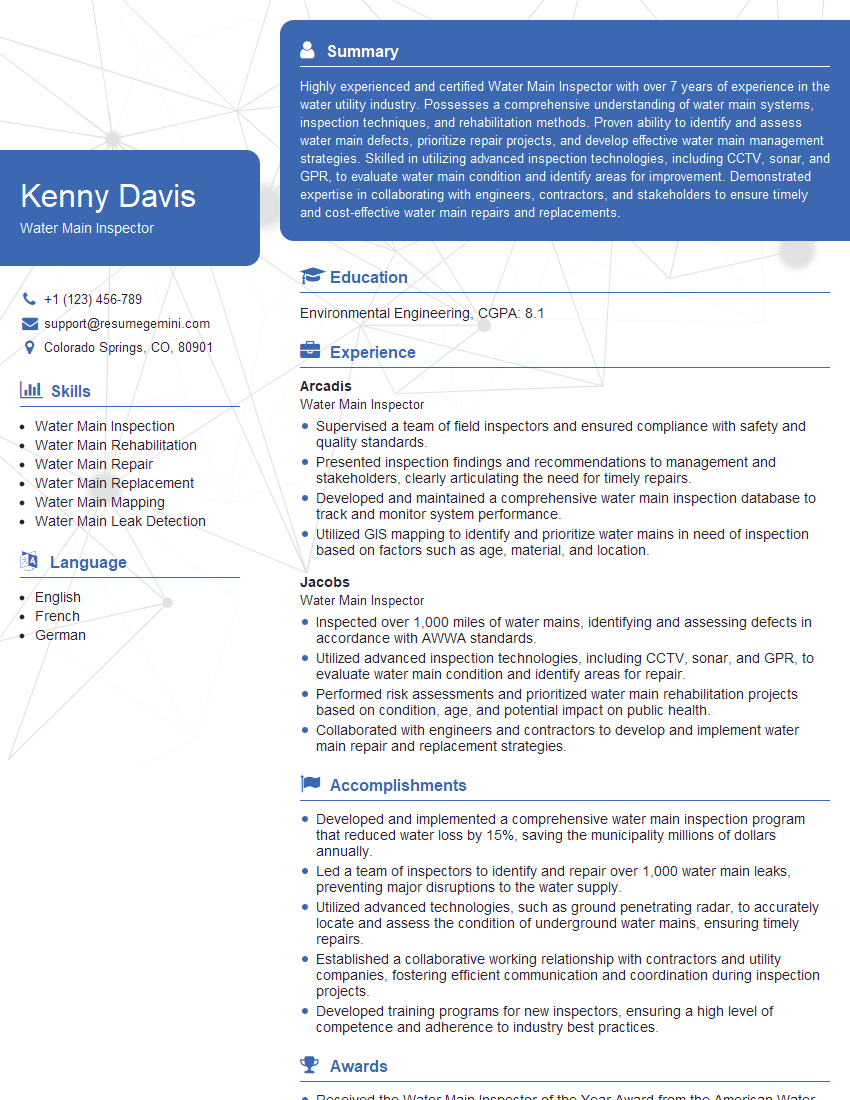

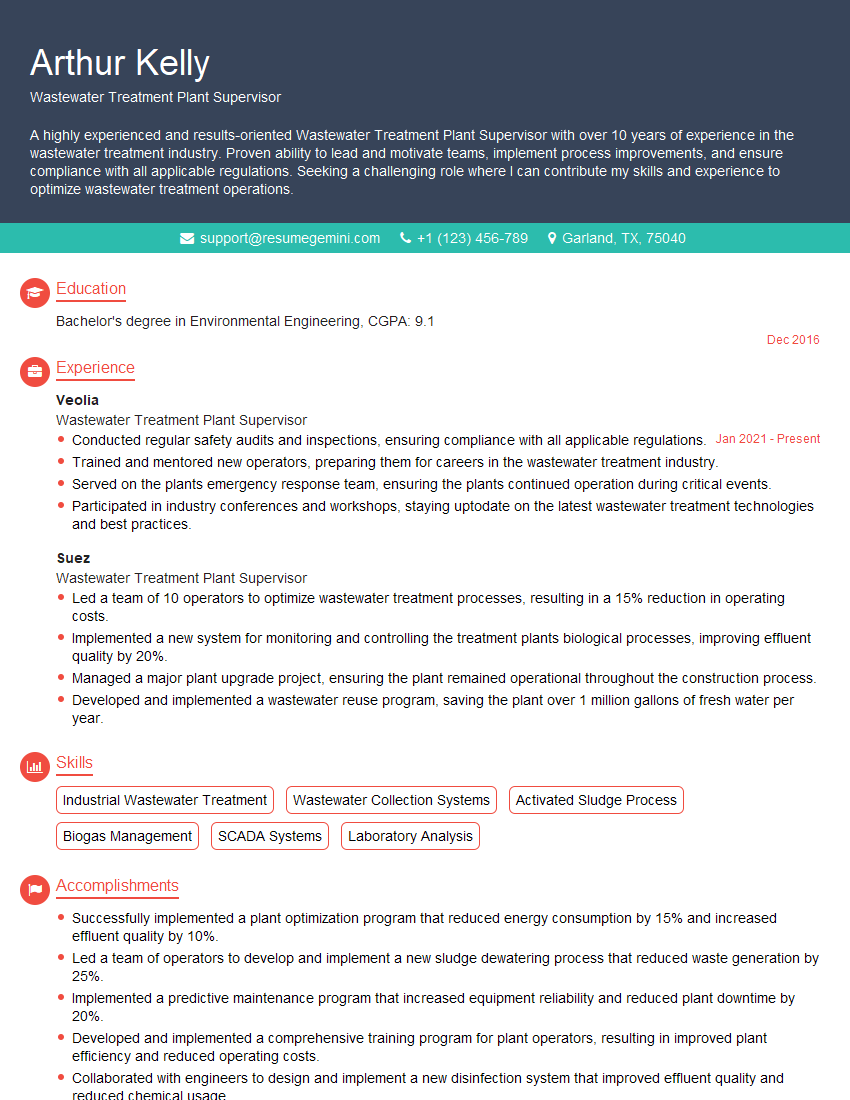

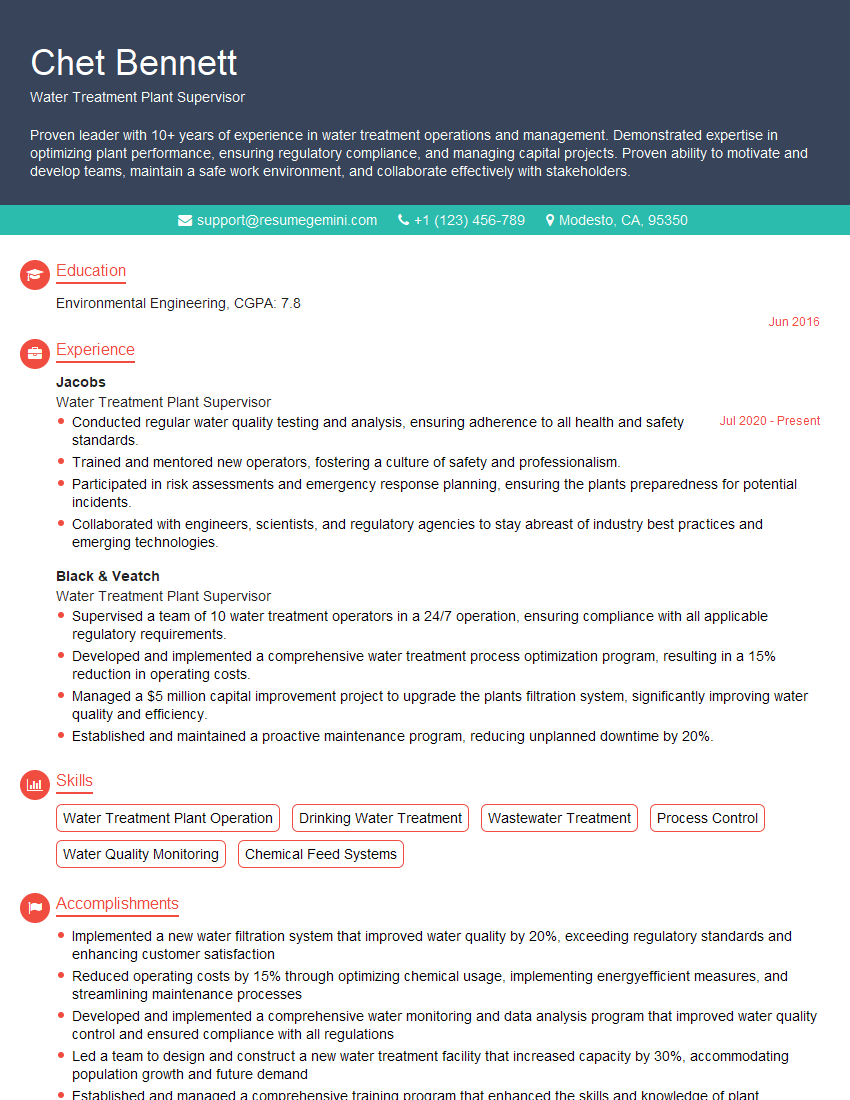

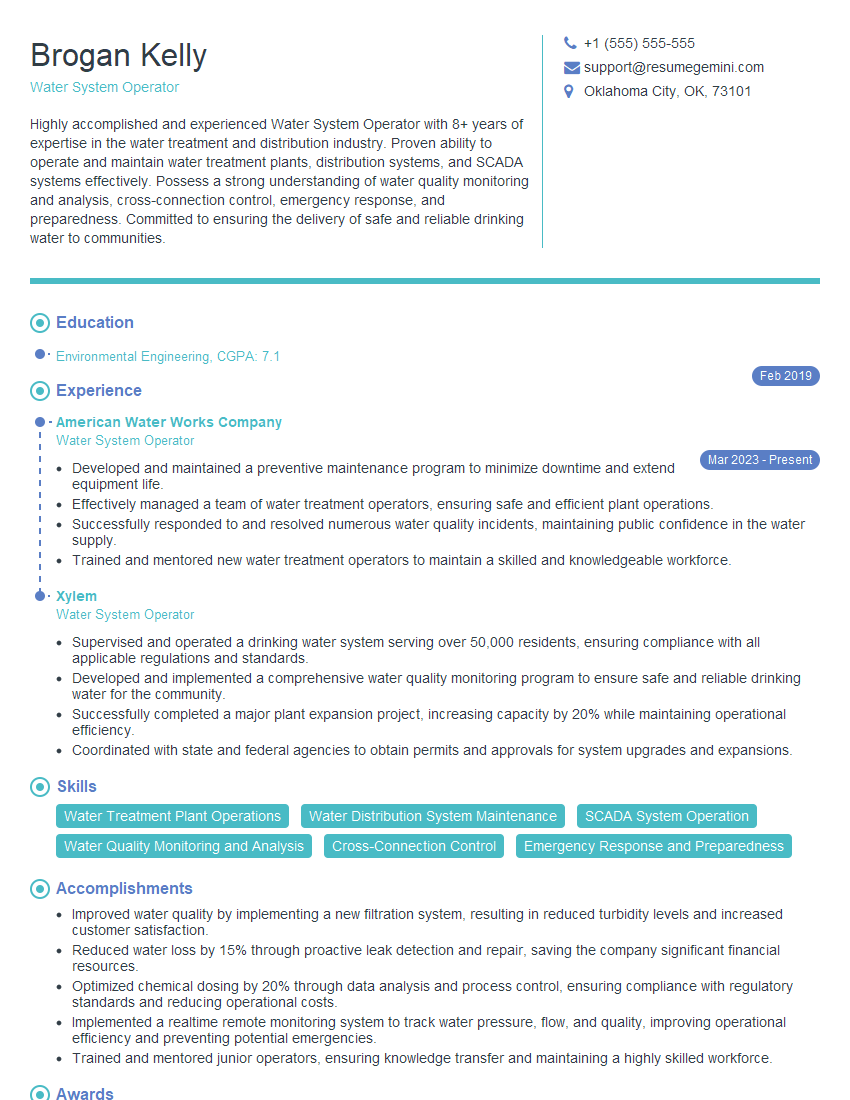

Mastering Water Infrastructure Inspection and Maintenance opens doors to a rewarding career with significant growth potential. This field offers opportunities for advancement into supervisory roles, specialized technical expertise, and leadership positions within utilities and engineering firms. To maximize your job prospects, it’s crucial to create a resume that effectively showcases your skills and experience to Applicant Tracking Systems (ATS). We strongly encourage you to leverage ResumeGemini to build a professional, ATS-friendly resume that highlights your qualifications. ResumeGemini provides examples of resumes tailored to Water Infrastructure Inspection and Maintenance, helping you present yourself in the best possible light to prospective employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good