The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Dock and Yard Management interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Dock and Yard Management Interview

Q 1. Explain your experience with different types of dock equipment (e.g., forklifts, conveyors).

My experience with dock equipment encompasses a wide range, from basic forklifts to sophisticated automated conveyor systems. I’m proficient in operating various forklift types – counterbalance, reach trucks, order pickers – each suited for different tasks and load capacities. For example, I’ve used counterbalance forklifts for moving palletized goods across the yard, while reach trucks proved invaluable for accessing higher racking in our warehouse. My experience extends to managing and troubleshooting conveyor systems, including belt conveyors for bulk materials and roller conveyors for individual items. I understand the importance of regular maintenance schedules and safety checks for all equipment to prevent downtime and accidents. In one instance, I identified a recurring issue with a conveyor belt’s misalignment, leading to a simple adjustment that significantly improved efficiency and reduced product damage.

- Forklifts: Counterbalance, Reach Truck, Order Picker

- Conveyors: Belt Conveyors, Roller Conveyors, Sortation Conveyors

Q 2. Describe your experience managing dock operations during peak seasons.

Managing dock operations during peak seasons requires meticulous planning and efficient resource allocation. My approach involves forecasting anticipated volume increases, adjusting staffing levels accordingly, and optimizing workflow processes. This includes implementing overtime schedules for existing staff, coordinating with temporary staffing agencies, and proactively communicating with transportation providers to ensure timely arrivals and departures. For instance, during last year’s holiday rush, we successfully managed a 30% increase in volume by implementing a color-coded system for prioritizing shipments, clearly designating loading zones, and utilizing real-time tracking software to monitor shipment status. Clear communication with the team and proactive problem-solving were key to overcoming challenges like unexpected delays and equipment malfunctions.

Q 3. How do you ensure the safety of dockworkers and maintain a safe working environment?

Safety is paramount in any dock environment. I prioritize a comprehensive safety program that includes regular safety training, enforcement of safety protocols, and a culture of reporting near misses. This starts with providing dockworkers with appropriate personal protective equipment (PPE), such as high-visibility vests, safety shoes, and gloves. We conduct regular safety inspections to identify and mitigate potential hazards like uneven flooring, damaged equipment, or inadequate lighting. Moreover, we implement stringent procedures for operating machinery, including pre-operational checks and safe operating procedures. A crucial aspect is fostering a culture of safety through regular safety meetings, promoting open communication, and rewarding safe work practices. One successful initiative was implementing a ‘buddy system’ where workers paired up during tasks, ensuring a second set of eyes and preventing lone-worker incidents.

Q 4. What methods do you use to optimize dock space and improve efficiency?

Optimizing dock space and improving efficiency requires a multi-pronged approach. This includes implementing a well-defined layout that minimizes travel distances for equipment and personnel. We utilize advanced dock scheduling software to optimize loading and unloading sequences, reducing congestion and waiting times. Lean principles like 5S (Sort, Set in Order, Shine, Standardize, Sustain) play a key role in maintaining a clutter-free work environment, ensuring smooth operations. For instance, we implemented a dedicated staging area for inbound and outbound shipments, improving organization and reducing the risk of misplaced goods. Furthermore, regular audits of our dock operations identify bottlenecks and areas for process improvement, which we continuously refine using data-driven insights. Efficient space management includes implementing vertical storage solutions and utilizing every available square foot.

Q 5. How do you manage incoming and outgoing shipments to minimize delays?

Managing incoming and outgoing shipments to minimize delays involves careful planning and coordination. This starts with accurate forecasting of inbound shipments, collaborating closely with suppliers to ensure timely deliveries. We leverage Transportation Management Systems (TMS) to track shipments in real-time, providing visibility throughout the entire process. Efficient scheduling using software, coupled with clear communication with carriers and internal teams, helps minimize delays. We employ a first-in, first-out (FIFO) system for managing inventory, ensuring that older goods are shipped out before newer ones. Moreover, we have contingency plans in place to address unforeseen delays, such as inclement weather or traffic congestion. A key aspect is proactive communication – keeping all stakeholders informed of potential delays and working collaboratively to find solutions.

Q 6. Explain your experience with inventory management systems within a dock/yard environment.

My experience with inventory management systems in a dock/yard environment includes using both Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. These systems provide real-time visibility into inventory levels, allowing for efficient tracking of goods from the moment they enter the dock until they are shipped out. I’m familiar with barcode and RFID technologies for accurate inventory tracking and management. For example, using a WMS, we can track the location of every pallet in real time, improving accuracy of picking and reducing the risk of stockouts. I also have experience integrating these systems with our Transportation Management System (TMS) to streamline the entire supply chain. Regular data analysis from the system allows us to identify slow-moving items, optimize storage strategies, and improve overall inventory management.

Q 7. Describe your experience with different loading and unloading techniques.

My experience encompasses various loading and unloading techniques, tailored to the specific requirements of different goods and transportation modes. This includes using forklifts for palletized goods, conveyor systems for bulk materials, and manual handling for smaller, delicate items. I’m proficient in techniques such as cross-docking, where goods are transferred directly from incoming to outgoing shipments, reducing storage time and improving efficiency. I also have experience with specialized loading techniques for oversized or heavy cargo, ensuring safe and secure transportation. For instance, we use specific techniques for loading fragile goods, employing protective materials and careful handling to avoid damage. The choice of unloading technique depends on the characteristics of the goods, and we tailor it to maximize efficiency and minimize risks.

Q 8. How do you handle unexpected delays or disruptions in dock operations?

Unexpected delays are inevitable in dock operations. My approach is proactive and multi-faceted. First, I rely on robust real-time tracking systems to identify delays as they emerge. This could be anything from late-arriving trucks to equipment malfunctions. Once a delay is identified, I immediately assess its impact – which shipments are affected, what are the knock-on effects on subsequent operations?

Next, I implement a contingency plan. This might involve rerouting trucks, prioritizing urgent shipments, re-allocating resources (personnel, equipment), or communicating proactively with clients to manage expectations. For instance, if a critical piece of equipment breaks down, we have backup equipment and a maintenance team on standby to minimize downtime. If a driver is significantly delayed, I’ll coordinate with dispatch to reroute or adjust the schedule. Finally, a post-incident review helps us identify root causes and prevent similar delays in the future. This involves analyzing data and looking for patterns, be it traffic congestion at certain times, equipment reliability, or staffing issues.

Q 9. How do you prioritize tasks and manage multiple priorities simultaneously in a fast-paced dock environment?

Prioritization in a dock environment is crucial. I use a combination of methods, prioritizing based on several factors: urgency (e.g., perishable goods), delivery deadlines, shipment value, and pre-arranged appointments. I often use a Kanban-style board, both physical and digital, to visualize the workflow and track progress. This provides a clear picture of tasks and their statuses. I also employ a system of color-coded labels for shipments – red for urgent, yellow for high priority, green for standard – to instantly communicate priorities to the entire team. For managing multiple priorities, I break down large tasks into smaller, manageable ones. Regular team meetings and communication are vital to ensuring everyone is aligned and aware of the shifting priorities throughout the day. It’s akin to conducting an orchestra; each section (receiving, loading, dispatching) must be coordinated for a harmonious and efficient operation.

Q 10. What metrics do you use to measure the performance of dock/yard operations?

Measuring dock performance requires a balanced scorecard approach. I use key performance indicators (KPIs) across several areas. These include:

- Throughput Time: The total time it takes for a shipment to move through the dock, from arrival to departure. Lower is better.

- Dock-to-Stock Time: The time from unloading to inventory being available in the warehouse. Faster time indicates smoother operations.

- On-Time Delivery Rate: Percentage of shipments delivered on schedule, demonstrating efficiency and reliability.

- Driver Turnaround Time: The time a driver spends at the dock, minimizing wait times and improving efficiency.

- Inventory Accuracy: Measures the discrepancy between physical inventory and system records, crucial for operational integrity.

- Damage Rate: Tracks the percentage of damaged goods, reflecting handling and safety practices.

Regular monitoring and analysis of these KPIs provide insights into operational strengths and weaknesses, enabling data-driven improvements.

Q 11. How do you address driver issues or communication challenges at the dock?

Driver issues and communication challenges are addressed through a proactive and communicative approach. Clear and consistent communication is paramount. We utilize a dock scheduling system with real-time updates, ensuring drivers know their assigned dock door and estimated wait times. Providing designated waiting areas with amenities improves driver experience and reduces frustration. A clear communication protocol, including phone lines and designated personnel to address queries or concerns, ensures prompt issue resolution. If problems arise, such as late arrivals or incorrect paperwork, we address them promptly and fairly, striving to find solutions that are beneficial to all parties involved. We also actively solicit driver feedback through surveys and informal discussions, helping us identify areas for improvement and address recurring concerns. Fostering positive relationships with drivers contributes to overall dock efficiency and reduces friction.

Q 12. Describe your experience with warehouse management systems (WMS) or transportation management systems (TMS).

I have extensive experience with both WMS and TMS. My experience includes implementing and managing both independently and in an integrated fashion. For example, I worked with a WMS that integrated seamlessly with our TMS, streamlining the entire supply chain process. The WMS optimized inventory management, enabling real-time visibility of stock levels, automated picking and packing processes, and precise tracking of goods. The integration with TMS allowed for efficient order fulfillment, optimized route planning, and real-time tracking of shipments. Using the data from the WMS, I was able to make decisions about optimizing storage space and prevent stockouts. The TMS data facilitated accurate reporting on delivery performance and helped anticipate potential delays or problems. Both systems allowed us to generate reports such as inventory turnover rates, delivery times, and cost savings.

Q 13. How do you track and manage inventory levels to prevent stockouts or overstocking?

Inventory management is crucial for preventing stockouts and overstocking. I use a combination of techniques including ABC analysis (classifying inventory by value and usage), forecasting models, and robust inventory tracking systems integrated with the WMS. ABC analysis helps prioritize inventory control efforts, focusing resources on high-value items. Forecasting models, like moving averages or exponential smoothing, predict future demand to inform ordering decisions. Regular cycle counting and physical inventory checks ensure accuracy and identify discrepancies promptly. We also actively monitor sales data, lead times, and seasonal trends to refine our forecasting and adjust order quantities as needed. This proactive approach minimizes storage costs, prevents shortages, and ensures optimal stock levels.

Q 14. Explain your experience with implementing and managing dock scheduling systems.

Implementing and managing dock scheduling systems requires a structured approach. I begin by analyzing existing processes and identifying areas for improvement. This includes mapping the workflow, understanding current resource constraints, and collecting data on arrival and departure times, dwell times, and equipment utilization. Then, I select a suitable scheduling software based on our requirements, considering factors such as scalability, integration with existing systems (WMS/TMS), and user-friendliness. Implementing the system typically involves training personnel, configuring the software to our specific needs, and establishing clear communication protocols. Post-implementation, continuous monitoring and refinement are critical. This involves tracking KPIs, collecting user feedback, and adjusting the system to optimize performance and ensure its alignment with business needs. Regular system updates and maintenance are also crucial to ensure its long-term effectiveness.

Q 15. How do you ensure compliance with all relevant safety regulations and company policies?

Ensuring compliance with safety regulations and company policies is paramount in dock and yard management. It’s not just about ticking boxes; it’s about fostering a safety-first culture. My approach is multifaceted and proactive.

- Regular Training and Audits: I initiate and oversee regular safety training for all dockworkers, covering topics like safe equipment operation, hazard identification, and emergency procedures. These are supplemented by frequent safety audits to identify potential risks and ensure compliance with OSHA (or equivalent) regulations and company-specific safety protocols. For example, we’d conduct weekly equipment inspections and monthly safety meetings.

- Clear Communication and Documentation: Safety rules and procedures are clearly communicated through various channels – from laminated posters at work stations to digital training modules and regular email updates. All incidents, near misses, and corrective actions are meticulously documented and analyzed to prevent future occurrences. We use a digital incident reporting system which allows for immediate communication and tracking of remedial actions.

- Leading by Example: I believe in leading by example. Strict adherence to safety protocols by management sets the tone for the entire team. I actively participate in safety inspections and training, demonstrating a commitment to safety that resonates throughout the workforce.

- Incentivizing Safe Practices: We implement incentive programs to reward safe work practices. This could involve recognition programs, safety bonuses, or simply public acknowledgement of employees who consistently demonstrate safe behaviours. This creates a positive feedback loop that encourages safe work habits.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with managing budgets and resources in a dock/yard setting.

Budget and resource management in a dock/yard environment requires a blend of strategic planning, cost control, and efficient allocation. My experience involves:

- Budget Forecasting and Control: I’m proficient in developing detailed budget forecasts based on historical data, projected workload, and anticipated cost fluctuations. This involves analyzing factors like fuel costs, maintenance expenses, labor costs, and potential equipment upgrades. Regular monitoring and variance analysis help identify areas for cost optimization.

- Resource Allocation: This encompasses the efficient allocation of personnel, equipment, and materials to maximize productivity and minimize downtime. For instance, I’ve optimized equipment scheduling through sophisticated software to reduce idle time and improve turnaround times. This reduces operational costs while maintaining service levels.

- Vendor Negotiation and Contract Management: I have experience negotiating favorable contracts with vendors for equipment maintenance, repairs, and supplies. This involves leveraging my understanding of market pricing and negotiating favorable terms to secure cost-effective solutions.

- Performance Measurement: I employ Key Performance Indicators (KPIs) to monitor budget performance, resource utilization, and operational efficiency. These metrics inform decision-making and allow for proactive adjustments to optimize resource allocation and stay within budget constraints. Examples of KPIs would include container throughput per hour, equipment uptime, and cost per container handled.

Q 17. How do you motivate and manage a team of dockworkers effectively?

Motivating and managing a team of dockworkers requires a blend of strong leadership, clear communication, and fair treatment. I believe in creating a positive and supportive work environment.

- Open Communication and Feedback: I foster open communication channels, encouraging feedback from my team. Regular team meetings provide opportunities to address concerns, celebrate successes, and discuss challenges. I also utilize one-on-one meetings to provide constructive feedback and support individual career development.

- Recognition and Appreciation: I actively recognize and appreciate the contributions of each team member. This can involve verbal praise, employee-of-the-month awards, or other forms of recognition that acknowledge their hard work and dedication. Recognising individuals who consistently demonstrate good safety habits will also be prioritised.

- Fair and Consistent Treatment: Fairness and consistency in treatment are crucial for maintaining morale and productivity. This means applying rules and procedures consistently and resolving disputes fairly. Open and transparent decision-making can foster trust and reduce conflict.

- Skill Development and Training: I am committed to investing in the professional development of my team. This involves providing opportunities for skill enhancement through training programs, certifications, and cross-training opportunities. A skilled workforce is a motivated workforce.

- Empowerment and Delegation: Empowering team members by delegating tasks and responsibilities fosters a sense of ownership and responsibility. Providing opportunities for growth and development improves their skills and increases job satisfaction.

Q 18. Explain your problem-solving approach when dealing with dock equipment malfunctions.

My problem-solving approach to dock equipment malfunctions is systematic and proactive. It aims at minimizing downtime and ensuring safe operations.

- Assessment and Safety: The first step is a thorough assessment of the malfunction, prioritizing safety. Secure the area, ensuring no one is at risk before proceeding.

- Diagnosis: Once the situation is safe, I diagnose the problem using a combination of visual inspection, operational checks, and consultation with maintenance personnel or relevant manuals. If necessary, I would leverage diagnostic tools to help identify the issue.

- Prioritization: I prioritize repairs based on the severity of the malfunction and its impact on operations. Critical malfunctions requiring immediate attention are addressed first.

- Repair or Replacement: Depending on the nature and severity of the issue, we either repair the equipment or initiate the replacement process. This may involve contacting maintenance, external service providers, or ordering replacement parts.

- Documentation and Prevention: All malfunctions, repairs, and preventative maintenance are meticulously documented. This information is analyzed to identify recurring problems and implement preventative measures to minimize future malfunctions.

For example, if a forklift malfunctions, I’d first ensure the area is clear, then check for obvious issues like low battery or hydraulic fluid leaks. If the problem persists, I’d consult the maintenance team for specialized troubleshooting.

Q 19. How do you handle customer complaints or concerns related to dock operations?

Handling customer complaints or concerns requires a calm, professional, and empathetic approach. My strategy focuses on prompt resolution and maintaining positive customer relationships.

- Active Listening: I begin by actively listening to the customer’s complaint, allowing them to fully explain their concerns without interruption. This shows respect and helps me understand the issue fully.

- Empathy and Acknowledgement: I acknowledge their frustration and express empathy for their experience. A simple phrase like “I understand your frustration, and I apologize for the inconvenience” can go a long way.

- Investigation and Fact-Finding: I thoroughly investigate the complaint, gathering all relevant information from dockworkers, drivers, and any available documentation. This ensures a fair and accurate assessment of the situation.

- Resolution and Follow-up: I work towards a resolution that satisfies the customer, whether that involves compensation, a revised process, or a clear explanation of the situation. I follow up with the customer to confirm that the issue has been resolved to their satisfaction.

- Documentation and Improvement: All complaints are documented, analyzed to identify recurring issues, and utilized to implement process improvements to prevent similar problems in the future.

Q 20. What experience do you have with different types of shipping containers and their handling?

I have extensive experience with various types of shipping containers, including standard 20-foot and 40-foot containers, high-cube containers, refrigerated containers (reefers), and specialized containers for oversized or hazardous cargo. My experience encompasses:

- Container Identification and Tracking: I’m proficient in using container numbers, markings, and tracking systems to efficiently locate and manage containers within the yard.

- Container Handling Equipment: I’m familiar with the safe and efficient operation of various container handling equipment, such as reach stackers, forklifts, and yard cranes. I understand their limitations and operational requirements.

- Container Inspection and Damage Assessment: I can identify and assess potential damage to containers, ensuring that any damaged containers are appropriately handled and reported.

- Container Storage and Placement: I’m experienced in optimizing container storage strategies to maximize yard space utilization and ensure efficient retrieval.

- Specialized Container Handling: I have experience handling specialized containers, considering their unique requirements and potential hazards. For example, understanding the proper ventilation and temperature control procedures for reefer containers, and the safety procedures involved with handling hazardous materials.

Q 21. How do you ensure efficient communication between dockworkers, drivers, and other departments?

Efficient communication between dockworkers, drivers, and other departments is essential for smooth dock operations. My approach uses a multi-pronged strategy:

- Clear Communication Protocols: Establishing standardized communication protocols, using clear and concise language, prevents misunderstandings. For instance, using standardized terminology, forms and checklists will ensure everyone is on the same page.

- Real-time Communication Systems: Implementing real-time communication systems, such as two-way radios, mobile data terminals (MDTs), or dedicated communication software, enables immediate updates on container locations, arrival times, and any potential delays. This system can cut down on delays and improves the overall efficiency of the operation.

- Centralized Information System: Utilizing a centralized information system, accessible to all relevant parties, ensures that everyone has access to the same, up-to-date information regarding container status, scheduling, and other pertinent details. This could involve a Transportation Management System (TMS).

- Regular Meetings and Briefings: Conducting regular meetings and briefings with dockworkers, drivers, and other departments ensures that any changes, issues, or concerns are quickly addressed.

- Feedback Mechanisms: Establishing feedback mechanisms allows for continuous improvement in communication processes. Regularly soliciting feedback from all stakeholders helps identify and resolve communication barriers.

Q 22. Describe your experience with implementing new technologies or processes to improve dock efficiency.

Improving dock efficiency often involves leveraging technology and optimizing processes. In my previous role, we implemented a Warehouse Management System (WMS) integrated with a Yard Management System (YMS). This allowed us to track shipments in real-time, from arrival at the yard to departure from the dock. Before this, we relied on manual processes and spreadsheets, leading to significant delays and inaccuracies. The new system automated tasks like appointment scheduling, gate management, and labor allocation. For example, we used to manually assign dock doors; now, the system optimizes door assignments based on truck arrival times and shipment priorities, minimizing congestion and dwell time. We also implemented a Radio Frequency Identification (RFID) system for tracking containers and pallets, dramatically reducing the time spent on manual inventory checks. The result was a 25% reduction in cycle times and a 15% decrease in labor costs.

Another initiative involved implementing a dock scheduling system that optimized truck arrivals. We analyzed historical data to identify peak arrival times and worked with carriers to stagger deliveries. This strategy significantly reduced dock congestion and improved on-time performance. Before this, we frequently experienced long queues and delays causing significant disruption.

Q 23. How do you deal with damaged goods or discrepancies during receiving or shipping?

Handling damaged goods and discrepancies is crucial for maintaining customer satisfaction and minimizing financial losses. Our process begins with a thorough inspection upon receipt or prior to shipment. Any damage or discrepancy is immediately documented using a standardized form, including photographs or video evidence. This form details the nature of the damage, quantity affected, and potential causes. We then initiate a claims process with the carrier or supplier, providing them with all the supporting documentation. For internal discrepancies, we conduct a thorough internal investigation to identify the root cause and implement corrective actions to prevent recurrence. For instance, if damage is consistently occurring on a specific route, we might investigate the carrier’s handling procedures. Similarly, internal discrepancies might highlight issues with our own inventory management or picking processes. A clear and detailed record-keeping system ensures transparency and facilitates prompt resolution of such issues.

Q 24. What is your experience with yard management systems (YMS)?

I have extensive experience with Yard Management Systems (YMS). I’ve implemented and managed several YMS across different organizations, ranging from small distribution centers to large-scale logistics hubs. My experience encompasses various functionalities including gate management, yard optimization, container tracking, equipment management, and integration with other systems like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS). I’m familiar with both cloud-based and on-premise YMS solutions and have experience selecting, implementing, and configuring these systems to meet specific operational requirements. For example, in one project, we implemented a YMS that reduced our yard congestion by 30% by optimizing trailer placement and improving the efficiency of our yard trucks. This was achieved through intelligent routing algorithms and real-time visibility of yard activities within the system.

Q 25. How do you maintain accurate records of all dock activities and transactions?

Maintaining accurate records is paramount in dock and yard management. We utilize a combination of technology and standardized procedures to achieve this. This typically involves a robust WMS/YMS which records every transaction automatically. This includes inbound and outbound shipments, inventory movements, and labor activities. All transactions are time-stamped and linked to specific personnel and equipment. Manual processes are minimized, but when they occur, detailed records are entered into the system. For example, every time a pallet is moved, the system tracks its location, who moved it, and when. Regular audits are conducted to ensure data integrity and identify any discrepancies. Any exceptions or deviations from standard procedures are thoroughly investigated and documented. This data is essential for performance monitoring, reporting, and regulatory compliance. The data is also critical for identifying bottlenecks and areas needing improvement.

Q 26. Explain your understanding of various transportation modes and their impact on dock operations.

Understanding various transportation modes and their impact on dock operations is crucial. Each mode has unique characteristics that influence dock design, equipment requirements, and operational procedures. For example, handling intermodal containers requires specialized equipment like reach stackers and top handlers, and dedicated areas for container storage and transfer. Trucking operations demand efficient loading and unloading processes, optimized dock doors, and clear communication with carriers. Rail transport necessitates scheduling coordination and potentially larger buffer zones for rail cars. Maritime shipping involves customs clearance, specialized handling equipment for different cargo types, and careful planning for vessel arrival times. My experience includes managing operations involving all of these transportation modes, requiring me to adapt dock operations to each mode’s specific constraints and optimize overall efficiency across modes.

Q 27. How do you ensure the security of goods within the dock and yard areas?

Ensuring goods security is critical. Our approach involves a multi-layered security strategy, combining physical security measures with technological solutions. Physical security includes controlled access points with security personnel, CCTV surveillance covering all dock and yard areas, perimeter fencing, and adequate lighting. Technological solutions include access control systems using RFID or biometric authentication, and GPS tracking of equipment and containers. Regular security audits and employee training are essential components of our security program. Procedures such as regular checks of containers and seals help to prevent theft or damage. For example, we might employ a system where access to specific areas is granted only to authorized personnel with proper credentials. This multi-layered approach aims to deter unauthorized access and prevent theft or damage to goods.

Q 28. Describe your experience with using reporting tools to analyze dock performance and identify areas for improvement.

Reporting and data analysis are essential for continuous improvement. I’m proficient in using various reporting tools to analyze key performance indicators (KPIs) related to dock operations. This includes dwell time, throughput, on-time performance, labor productivity, and equipment utilization. I use these tools to identify bottlenecks and areas for improvement. For instance, analyzing dwell time data can reveal inefficiencies in loading/unloading processes or inadequate dock scheduling. Low labor productivity might point to the need for additional training or process optimization. Analyzing equipment utilization can highlight opportunities for improved maintenance or more efficient equipment allocation. Data-driven insights help to prioritize improvement initiatives and track the effectiveness of implemented changes. I often create customized reports and dashboards to visualize key data and present findings to stakeholders. These reports are crucial for driving informed decision-making and continuous improvement within the dock and yard operations.

Key Topics to Learn for Dock and Yard Management Interview

- Inventory Management: Understanding inventory control systems, stock rotation, and optimizing warehouse space. Practical application: Explain how you would manage a sudden surge in inbound shipments while maintaining efficient order fulfillment.

- Yard Operations & Logistics: Mastering the flow of goods within the yard, including truck scheduling, gate management, and equipment utilization. Practical application: Describe your approach to minimizing congestion and maximizing throughput during peak operational hours.

- Safety Regulations & Compliance: Demonstrating knowledge of OSHA regulations, hazardous material handling, and safety protocols within dock and yard environments. Practical application: Explain how you would implement and enforce safety procedures to prevent accidents and ensure compliance.

- Technology & Software: Familiarity with Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and other relevant software used in dock and yard operations. Practical application: Discuss your experience with specific WMS/TMS software and how you used it to improve efficiency or solve problems.

- Personnel Management & Team Leadership: Understanding effective team management techniques, conflict resolution, and motivating a workforce in a demanding environment. Practical application: Describe a situation where you successfully managed a team to achieve a challenging goal under pressure.

- Cost Optimization & Efficiency: Identifying areas for improvement in operational costs, reducing waste, and maximizing resource utilization. Practical application: Explain how you would analyze operational data to identify areas for cost reduction and efficiency gains.

- Problem-solving & Decision-Making: Demonstrating the ability to quickly assess situations, identify problems, and make effective decisions under pressure. Practical application: Describe a time you had to make a critical decision in a fast-paced environment and explain the outcome.

Next Steps

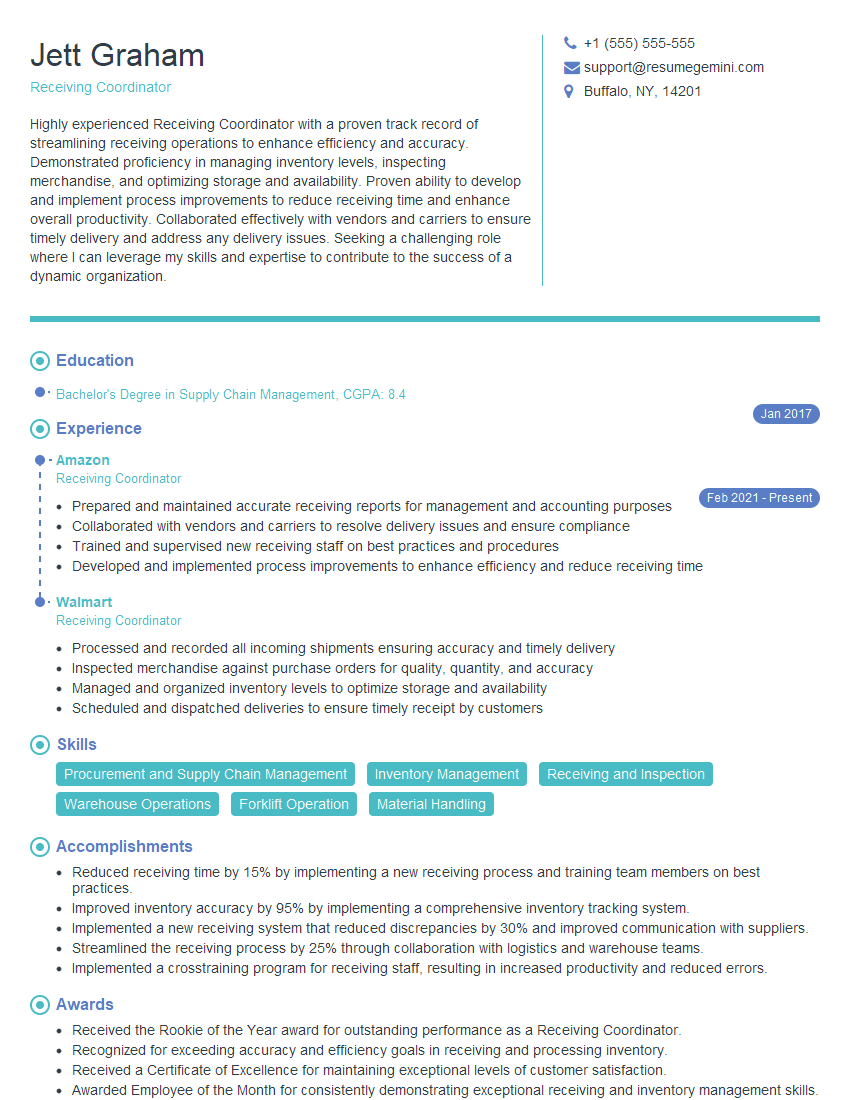

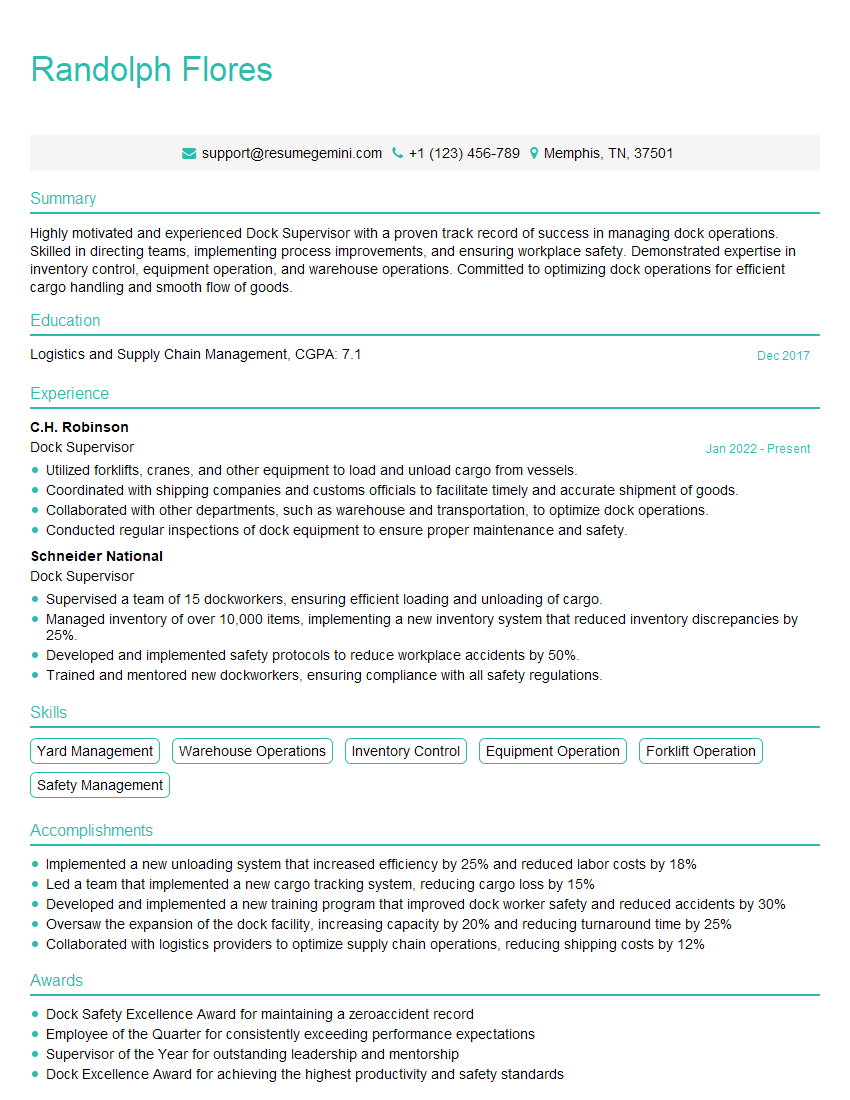

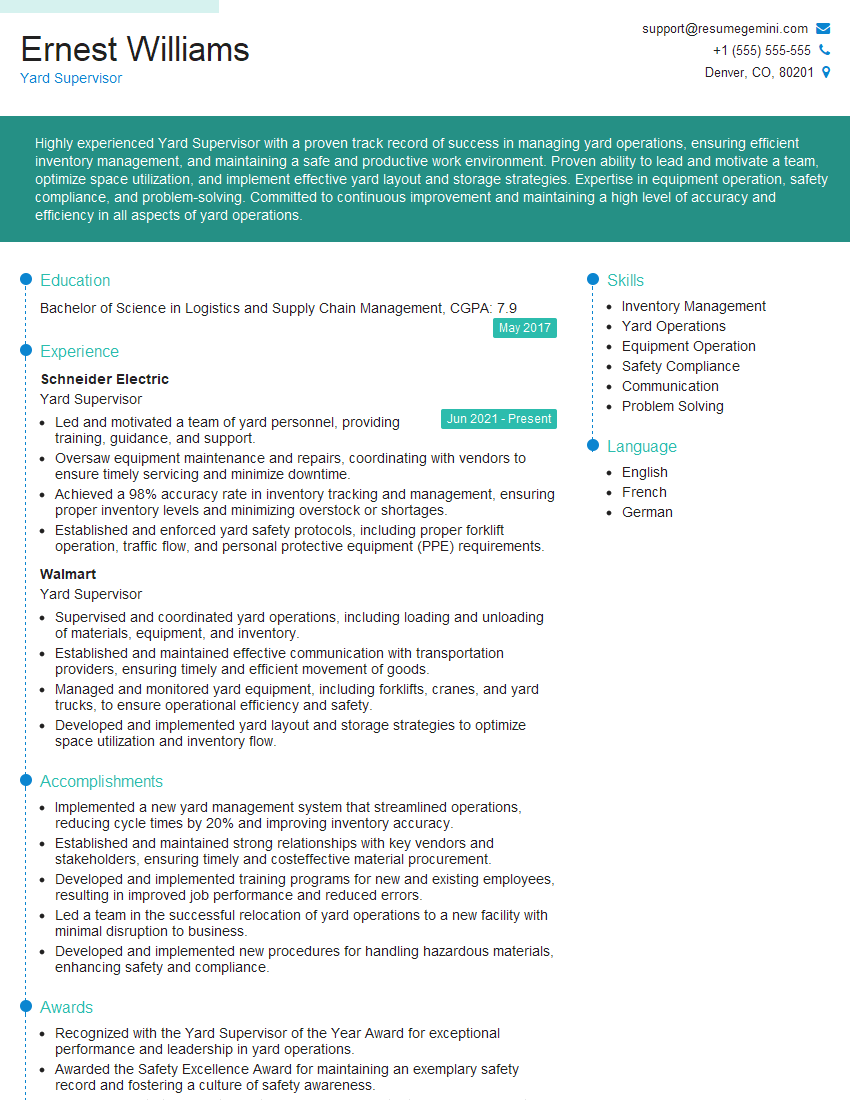

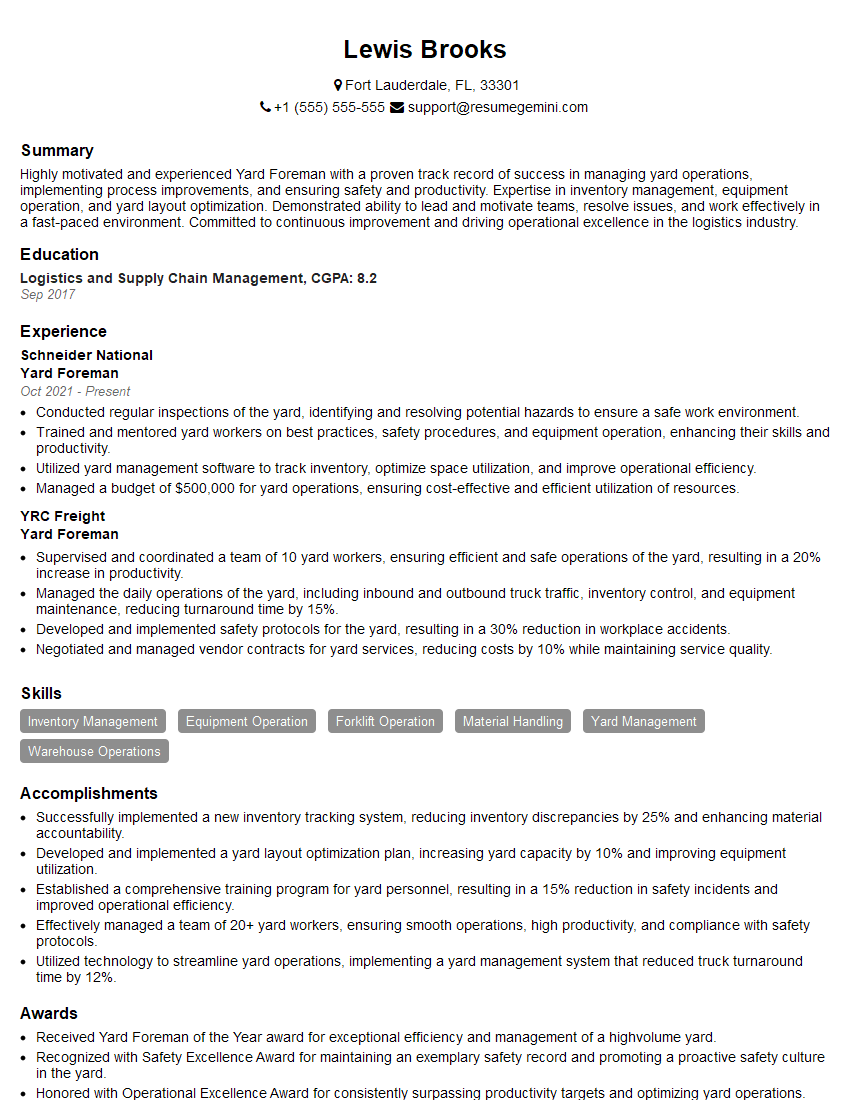

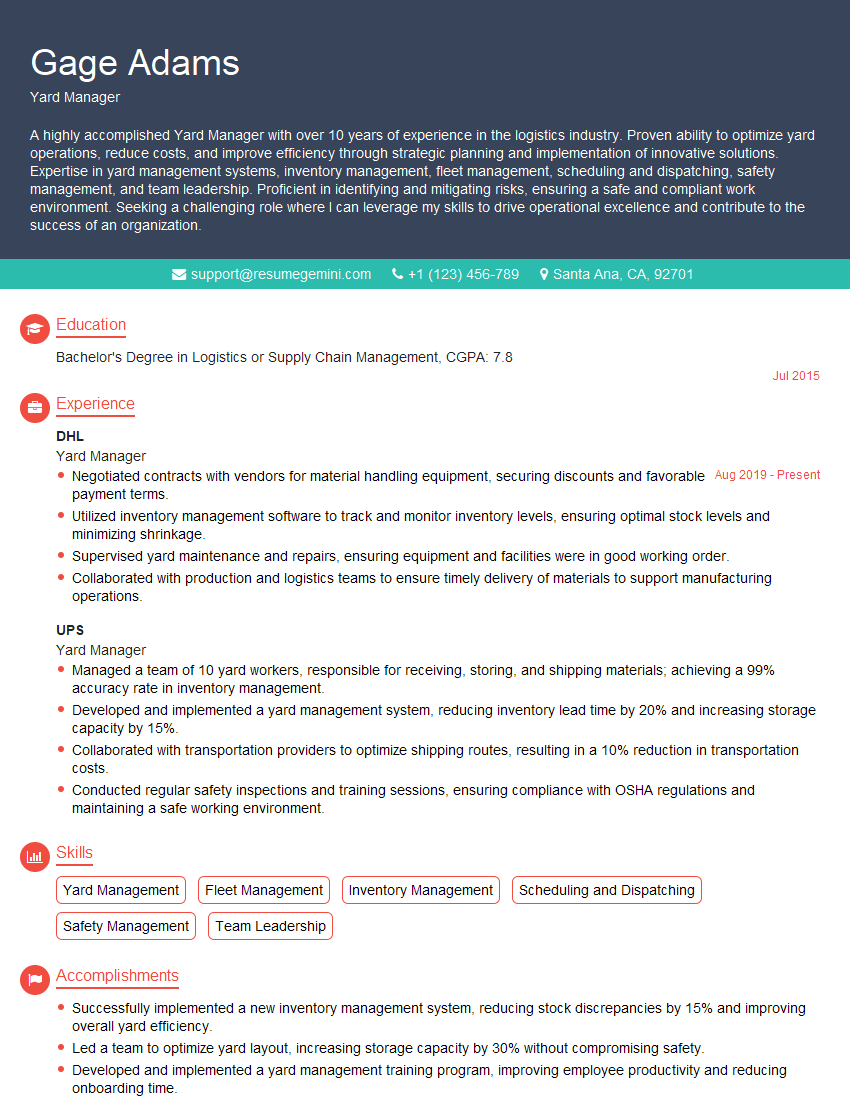

Mastering Dock and Yard Management opens doors to exciting career advancements, offering opportunities for increased responsibility and higher earning potential. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Dock and Yard Management roles. Examples of resumes tailored to this field are available to help guide your resume creation process. Invest in your future – build a strong resume that showcases your capabilities and helps you land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good