Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Inspect and maintain equipment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Inspect and maintain equipment Interview

Q 1. Describe your experience with preventative maintenance schedules.

Preventative maintenance schedules are the backbone of keeping equipment running smoothly and avoiding costly breakdowns. I’ve been involved in developing and implementing these schedules for diverse equipment, from complex manufacturing machinery to simpler HVAC systems. My approach always begins with a thorough understanding of the equipment’s specifications, manufacturer’s recommendations, and operational history. This includes analyzing historical maintenance data to identify patterns of failure and predict potential issues.

For example, in my previous role at a food processing plant, I developed a preventative maintenance schedule for the high-speed packaging line. This involved creating a detailed checklist of tasks with specified frequencies (daily, weekly, monthly, etc.), including lubrication of moving parts, inspection of belts and sensors, and cleaning of critical components. The schedule also incorporated predictive maintenance elements, such as vibration analysis of motors, to detect early signs of wear and tear. This proactive approach significantly reduced downtime and increased operational efficiency.

We used a computerized maintenance management system (CMMS) to track tasks, schedule inspections, and generate reports, helping to ensure compliance and facilitating better decision making. The entire process is heavily documented and reviewed regularly to ensure its effectiveness and adapt to changing operational needs.

Q 2. Explain the difference between corrective and preventative maintenance.

Corrective and preventative maintenance are two distinct approaches to equipment upkeep. Think of it like this: preventative maintenance is like regular check-ups at the doctor – it aims to prevent problems before they arise. Corrective maintenance, on the other hand, is like going to the emergency room – it addresses problems after they’ve already occurred.

- Preventative Maintenance (PM): This involves scheduled inspections, lubrication, cleaning, and minor repairs to prevent equipment failure. It’s proactive and aims to extend the lifespan of equipment, reduce downtime, and improve overall efficiency. Examples include regularly changing oil in machinery, inspecting electrical connections, and calibrating instruments.

- Corrective Maintenance (CM): This is reactive and addresses equipment failures after they’ve happened. It involves troubleshooting, repairing, or replacing malfunctioning components. Examples include fixing a broken motor, repairing a leaking pipe, or replacing a faulty sensor.

While both are crucial, a strong focus on preventative maintenance is usually more cost-effective in the long run by minimizing the need for costly corrective maintenance interventions. A balanced approach that incorporates both is ideal.

Q 3. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks in a high-pressure environment requires a structured approach. I usually employ a combination of techniques, including risk assessment and criticality analysis. A criticality matrix, for example, helps to rank equipment based on its importance to production and the potential consequences of failure.

I often use a method like the following:

- Identify critical equipment: Determine which equipment is essential for production and the potential impact of failure (e.g., production downtime, safety risks).

- Assess risk: Evaluate the likelihood of failure for each piece of equipment considering factors such as age, usage, and previous maintenance history.

- Develop a prioritized list: Combine criticality and risk to prioritize maintenance tasks. Focus on high-criticality, high-risk equipment first.

- Utilize CMMS: Employ a CMMS to schedule and track tasks, ensuring that high-priority items are addressed promptly. The CMMS often allows for customizable prioritization rules based on defined criteria.

- Flexibility and adaptation: Remain flexible and be prepared to adjust priorities based on unforeseen events or urgent situations.

This structured approach ensures that critical equipment receives timely attention, while less critical equipment is addressed according to its risk profile. It’s all about optimizing resource allocation to minimize disruptions and maximize overall effectiveness.

Q 4. What are your preferred methods for documenting maintenance activities?

Accurate and comprehensive documentation is paramount in maintenance. My preferred methods involve a combination of digital and physical records.

- Computerized Maintenance Management System (CMMS): I rely heavily on CMMS software for task scheduling, work order management, parts inventory tracking, and generating reports. The CMMS provides a centralized repository for all maintenance-related information and enhances transparency across teams.

- Work Orders and Checklists: Detailed work orders and checklists ensure consistency in maintenance tasks, including before-and-after photos, descriptions of repairs made, and parts used. These documents provide an auditable trail of all maintenance activities.

- Equipment Logbooks: For equipment with less frequent maintenance needs, a physical logbook can be very useful for recording pertinent data. This might include details of past repairs, unusual occurrences, and preventative maintenance schedules.

- Digital File Management: I maintain digital files that store crucial maintenance documents such as manuals, schematics, and service records, ensuring easy accessibility and future reference.

The key is to choose a system that ensures information is readily available, easily searchable, and compliant with relevant regulations. A consistent and detailed approach avoids confusion and provides valuable data for continuous improvement.

Q 5. Describe your experience troubleshooting malfunctioning equipment.

Troubleshooting malfunctioning equipment is a key part of my role and often requires a systematic and analytical approach. I typically start with a thorough assessment of the problem. This includes gathering information from operators, reviewing operational logs and historical data, and visually inspecting the equipment.

My troubleshooting process often follows these steps:

- Gather information: What are the symptoms? When did the problem start? What were the operating conditions at the time of failure?

- Visual Inspection: Look for obvious signs of damage, such as loose connections, leaks, or worn parts.

- Check Sensors and Controls: Ensure that sensors are functioning correctly and controls are properly set.

- Systematic Testing: Use diagnostic tools to isolate the cause of the malfunction. This might involve checking voltage, current, pressure, or temperature readings.

- Component Replacement: If necessary, systematically replace suspected faulty components and retest. This is done while carefully documenting each step.

- Documentation: Thoroughly document the problem, troubleshooting steps, and corrective actions taken. This information is invaluable for preventing future occurrences.

For example, when troubleshooting a malfunctioning conveyor belt, I’d start by checking the motor, then the drive belt, and so on, methodically eliminating possibilities. Experience helps to quickly identify potential causes and focus efforts on the most likely culprits. Successful troubleshooting relies on a combination of technical skills, analytical thinking, and patience.

Q 6. How familiar are you with various diagnostic tools and techniques?

I’m proficient with a range of diagnostic tools and techniques, both mechanical and electrical. My experience spans various types of equipment and diagnostic approaches.

- Electrical Diagnostic Tools: Multimeters, oscilloscopes, clamp meters, and insulation testers are regularly used for diagnosing electrical faults. I understand how to interpret readings from these tools to identify short circuits, open circuits, and other issues.

- Mechanical Diagnostic Tools: I utilize vibration analyzers, infrared thermometers, and ultrasonic detectors for identifying mechanical problems like bearing wear, misalignment, and lubrication issues. I also use specialized tools for specific equipment, such as pressure gauges for hydraulic systems or leak detectors for pneumatic lines.

- Predictive Maintenance Techniques: I’m experienced in utilizing predictive maintenance techniques such as vibration analysis, oil analysis, and thermography to identify potential problems before they cause equipment failure.

- Software-Based Diagnostics: I am familiar with using software that is integrated into many modern machines for remote monitoring and diagnostics, allowing for early detection of potential issues and remote troubleshooting.

The choice of diagnostic tools depends entirely on the specific equipment and the nature of the problem. My expertise lies in selecting the appropriate tools and interpreting the results accurately to effectively solve the issue at hand.

Q 7. How do you identify and address potential safety hazards during maintenance?

Safety is always the top priority during maintenance activities. I adhere to strict safety protocols and procedures to minimize risks. My approach starts with a thorough risk assessment before commencing any work.

Here’s how I identify and address safety hazards:

- Lockout/Tagout (LOTO) Procedures: I strictly follow LOTO procedures to isolate energy sources (electrical, hydraulic, pneumatic) before working on equipment to prevent accidental starts or releases of energy.

- Personal Protective Equipment (PPE): I ensure the appropriate PPE is used, including safety glasses, gloves, hearing protection, and other necessary gear, tailored to the specific task and equipment.

- Confined Space Entry Procedures: If work requires entering confined spaces, I follow established procedures, including atmospheric testing, proper ventilation, and having a standby person present.

- Hazard Communication: I communicate clearly with other workers about potential hazards and necessary safety precautions, ensuring everyone is informed and working safely.

- Regular Safety Audits: I participate in regular safety audits to identify potential hazards and ensure that safety procedures are being effectively implemented.

- Emergency Response Procedures: I’m familiar with emergency response procedures and know how to handle incidents appropriately, including knowing the location of emergency equipment and evacuation routes.

By proactively identifying and addressing potential safety hazards, I contribute to a safe and productive work environment. Safety is not just a procedure, it’s a mindset integrated into every aspect of maintenance work.

Q 8. What is your experience with CMMS (Computerized Maintenance Management Systems)?

My experience with CMMS software spans over eight years, encompassing various systems like IBM Maximo, SAP PM, and UpKeep. I’m proficient in using these systems for scheduling preventative maintenance, tracking work orders, managing inventory, and generating reports on equipment performance and maintenance costs. For instance, in my previous role at a large manufacturing facility, I utilized Maximo to implement a predictive maintenance program for our assembly line robots. This involved integrating sensor data with the CMMS to predict potential failures and schedule maintenance proactively, reducing downtime by 25%. I’m also experienced in configuring CMMS systems to meet specific business needs, customizing workflows and dashboards to enhance operational efficiency.

Beyond data entry and report generation, I understand the importance of data integrity and accuracy within a CMMS. I’ve led training sessions for colleagues on best practices for using the system, ensuring everyone understands the importance of accurate data input for effective maintenance planning and analysis. In short, I see the CMMS not just as a tool, but as a critical component of a comprehensive maintenance strategy.

Q 9. Describe your experience with different types of machinery and equipment.

My experience encompasses a wide range of machinery and equipment, including industrial robots, HVAC systems, conveyor belts, pumps, compressors, and various types of processing equipment. I’ve worked on both mechanical and electrical systems, familiarizing myself with their operating principles, components, and common failure points. For example, I’ve successfully troubleshooted and repaired complex PLC (Programmable Logic Controller) systems in automated production lines and performed preventative maintenance on high-pressure hydraulic systems. In one instance, I diagnosed a recurring issue with a malfunctioning industrial oven by meticulously inspecting the heating elements and control circuits, ultimately identifying a faulty thermocouple that was causing inconsistent temperatures.

I’m comfortable working with various diagnostic tools including multimeters, oscilloscopes, infrared cameras, and vibration analyzers to identify problems efficiently. My experience extends beyond repair; I’m also skilled in performing installations and upgrades of equipment, adhering to all safety and operational procedures.

Q 10. How do you ensure compliance with safety regulations during maintenance?

Safety is paramount in all my maintenance activities. I rigorously adhere to all relevant safety regulations, including OSHA standards, and any company-specific safety protocols. This involves using appropriate personal protective equipment (PPE) such as safety glasses, gloves, hearing protection, and steel-toe boots, depending on the task. Before beginning any work, I conduct thorough job safety analyses (JSAs) to identify potential hazards and mitigate risks. This includes lock-out/tag-out procedures to prevent accidental energization of equipment during maintenance.

I regularly participate in safety training and am knowledgeable about hazard communication, confined space entry, and emergency response procedures. For example, I’ve led safety briefings for my team before commencing a major equipment overhaul, ensuring everyone understood the specific risks involved and the necessary precautions. Furthermore, I actively report any unsafe conditions or near-miss incidents to ensure proactive measures are taken to prevent future occurrences.

Q 11. Explain your experience with root cause analysis techniques.

I’m experienced in using various root cause analysis (RCA) techniques, including the 5 Whys, fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis (FTA). These methods help identify the underlying causes of equipment failures, rather than just addressing the symptoms. For instance, if a pump repeatedly fails, simply replacing the pump isn’t a solution. Using the 5 Whys, I’d systematically ask ‘why’ five times to uncover the root cause. This might reveal a problem with the piping system, inadequate lubrication, or even operator error.

I’ve found that combining different RCA techniques often provides the most comprehensive understanding of a problem. For example, a fishbone diagram can help brainstorm potential causes, while a Fault Tree Analysis can help visualize the relationships between these causes and the ultimate failure. My goal is always to identify the root cause to prevent future recurrences and improve the overall reliability of the equipment.

Q 12. How do you handle unexpected equipment failures?

Unexpected equipment failures require a swift and organized response. My approach involves a structured process: first, I prioritize safety by ensuring the area is secure and that all necessary safety precautions are in place. Next, I assess the situation to determine the extent of the failure and its impact on production. This often involves communicating with operators and other relevant personnel to gather information. Then, I initiate the troubleshooting process, starting with a visual inspection and using appropriate diagnostic tools.

Depending on the complexity of the failure, I might need to consult technical manuals, schematics, or seek assistance from specialists. My goal is to restore equipment functionality as quickly and safely as possible, minimizing downtime. Once the equipment is operational, I document the failure, the troubleshooting steps taken, and the corrective actions implemented. This information is then used for root cause analysis and to prevent future similar occurrences.

Q 13. Describe your experience working with technical manuals and schematics.

I’m proficient in interpreting and utilizing technical manuals, schematics, and parts lists. I understand the importance of these documents for understanding equipment operation, troubleshooting malfunctions, and performing repairs and maintenance. I’m comfortable working with both electrical and mechanical schematics, identifying components, tracing circuits, and understanding the relationships between different parts of the system. For example, using a wiring diagram, I’ve successfully traced a short circuit in a control panel, saving significant time and effort.

I also utilize parts lists and manuals to ensure I’m using the correct replacement parts and performing maintenance procedures according to manufacturer specifications. This helps maintain the integrity and performance of the equipment and also helps avoid voiding warranties. In my previous role, this skill was crucial in troubleshooting a complex industrial control system by understanding the logic gates and relay systems depicted in its schematic.

Q 14. How do you manage your workload and prioritize tasks effectively?

Effective workload management is critical for maintaining equipment reliability. I use several strategies to prioritize tasks and manage my workload. I typically start by reviewing work orders in the CMMS and assigning priority levels based on factors such as the criticality of the equipment, the potential impact of failure, and safety concerns. Urgent tasks, such as repairing critical equipment failures, are prioritized over routine maintenance tasks.

I also utilize scheduling tools and techniques to plan my work effectively and allocate sufficient time for each task. I regularly review my schedule and adjust it as needed based on changing priorities and unforeseen circumstances. Communication is key, so I actively communicate with my team and supervisors about my workload, potential delays, and any resource constraints. This proactive approach ensures that tasks are completed efficiently and effectively, while maintaining a balance between preventative and corrective maintenance.

Q 15. What are your skills in using hand and power tools?

My skills with hand and power tools are extensive, encompassing both proficient use and meticulous maintenance. I’m comfortable with a wide range of tools, including various types of wrenches, screwdrivers, hammers, saws, drills, grinders, and specialized equipment like torque wrenches and dial indicators. For example, I’ve used precision screwdrivers to carefully disassemble and reassemble delicate electronic components, and I’ve also operated heavy-duty impact wrenches to quickly and efficiently tighten large bolts on industrial machinery. I always prioritize safety, ensuring proper use and regular inspection of all tools to prevent accidents and ensure optimal performance. Furthermore, I understand the importance of selecting the right tool for the job, understanding torque specifications and the consequences of using incorrect tools.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate records of maintenance activities and parts usage?

Maintaining accurate records is crucial for effective equipment maintenance. I utilize a Computerized Maintenance Management System (CMMS) – software designed for this purpose – to meticulously track all maintenance activities and parts usage. This system allows me to record details such as the date, time, equipment involved, work performed, parts used (including serial numbers and quantities), and associated labor costs. The CMMS generates reports that provide valuable insights into maintenance trends, helping identify recurring problems and optimize maintenance schedules. For instance, by analyzing parts usage data, we can identify parts prone to frequent failure, potentially indicating design flaws or the need for preventative measures. In situations without a CMMS, I’ve successfully used spreadsheets coupled with a detailed filing system, ensuring all information is well-organized and easily retrievable. Accurate record-keeping is essential for compliance, warranty claims, and effective troubleshooting.

Q 17. Describe a time you had to work independently to resolve a maintenance issue.

During a night shift, our main conveyor belt unexpectedly stopped, halting the entire production line. The maintenance team lead was unavailable, so I took the initiative to diagnose and fix the problem independently. After a thorough visual inspection, I discovered a broken drive belt. I systematically assessed the situation, carefully noting the belt’s specifications, and located a replacement from our inventory. I then safely replaced the belt, following all safety procedures, and restarted the conveyor belt. The entire process, from diagnosis to resolution, took approximately one hour, minimizing production downtime. This experience highlighted my problem-solving skills, resourcefulness, and ability to work effectively under pressure in a high-stakes situation.

Q 18. How do you communicate maintenance issues and findings to others?

Effective communication is essential in maintenance. I use a multi-faceted approach. For immediate issues, I communicate directly with the affected team using clear and concise language, detailing the problem, its potential impact, and any temporary solutions implemented. For more complex issues or findings from inspections, I prepare detailed reports using clear visuals like photographs and diagrams, supplemented by precise written descriptions. I also utilize our CMMS to formally document all findings and updates, ensuring that relevant personnel have access to the information. Furthermore, I regularly participate in team meetings to discuss maintenance strategies and to address any emerging concerns proactively. I always prioritize clear and unambiguous communication, ensuring everyone is on the same page and understands the situation fully.

Q 19. What is your experience with performing equipment inspections?

My experience in equipment inspections spans various industries and equipment types. I’m proficient in conducting both planned preventative maintenance (PPM) inspections, following established checklists and procedures, and unplanned inspections triggered by equipment malfunction or safety concerns. Inspections cover various aspects – checking for wear and tear, lubrication levels, fluid leaks, loose connections, unusual noises, vibrations, and overall equipment functionality. I use a combination of visual inspection, specialized tools (like thermal cameras for detecting overheating), and functional testing to assess the equipment’s condition. I meticulously document all findings, including photographs and measurements, to support my assessment. For example, I’ve conducted regular inspections on large industrial presses, ensuring the safety mechanisms are functioning correctly, and performed thorough inspections on delicate laboratory equipment to ensure precise operation and calibration.

Q 20. What are your skills in interpreting maintenance reports and data?

I possess strong skills in interpreting maintenance reports and data. I can analyze data from various sources, including CMMS reports, equipment logs, and sensor data, to identify trends, predict potential failures, and optimize maintenance strategies. For example, I can analyze historical maintenance data to identify equipment components that frequently fail and recommend preventative measures or replacement strategies. I can interpret statistical data, such as mean time between failures (MTBF) and mean time to repair (MTTR), to evaluate equipment reliability and the effectiveness of maintenance interventions. My analytical skills help me make data-driven decisions to improve equipment reliability and reduce downtime.

Q 21. Explain your experience with different types of maintenance strategies (e.g., RCM, TPM).

I have practical experience with various maintenance strategies. Reliability-Centered Maintenance (RCM) involves analyzing equipment failure modes and developing maintenance strategies based on their criticality and potential consequences. This approach focuses on preventing catastrophic failures by prioritizing maintenance activities. Total Productive Maintenance (TPM) is a proactive approach that involves all employees in equipment maintenance, aiming to improve overall equipment effectiveness (OEE). I’ve been involved in implementing both strategies in different settings. For instance, in a previous role, we used RCM to analyze the failure modes of a critical production machine, leading to a change in lubrication schedules and early detection of potential issues, significantly reducing downtime. In another context, we implemented TPM principles, empowering the operational staff to perform basic maintenance tasks, fostering ownership and significantly increasing overall equipment effectiveness.

Q 22. Describe your experience working in a team environment.

Throughout my career, I’ve consistently thrived in team environments. I believe effective teamwork is crucial for efficient and safe equipment maintenance. My experience encompasses collaborative problem-solving, where we collectively diagnose complex equipment malfunctions, leveraging each team member’s specialized skills. For instance, in one project involving a malfunctioning conveyor belt system, our team, comprising electricians, mechanics, and myself, collaborated seamlessly. I focused on the mechanical aspects while others tackled electrical issues. We communicated regularly through daily stand-up meetings and shared a centralized documentation system to ensure everyone was informed and on the same page. This collaborative approach led to a swift resolution, minimizing downtime and improving overall efficiency.

Furthermore, I’ve always actively contributed to a positive and supportive team atmosphere by offering assistance, sharing knowledge, and mentoring junior technicians. I believe in fostering open communication, ensuring every team member feels valued and empowered to contribute their best. I’ve found that creating a safe space for open discussion of challenges and potential solutions is essential for effective problem-solving within a team.

Q 23. How do you stay updated on the latest maintenance technologies and practices?

Staying current with maintenance technologies and practices is paramount in this ever-evolving field. I employ a multi-pronged approach. Firstly, I actively participate in professional development opportunities, attending conferences, workshops, and webinars focused on the latest advancements in equipment maintenance and predictive technologies. This allows me to learn about new tools, techniques, and best practices directly from industry experts. For example, I recently attended a seminar on implementing predictive maintenance using vibration analysis, which significantly improved my diagnostic abilities.

Secondly, I subscribe to relevant industry publications and journals, keeping abreast of the latest research and innovations. Thirdly, I leverage online resources such as professional networking sites and manufacturer websites to access technical manuals, updates, and case studies. Finally, I encourage continuous learning within my team, initiating internal knowledge-sharing sessions to disseminate information on new technologies and maintenance techniques. This collaborative learning approach ensures the entire team remains at the forefront of industry standards.

Q 24. What is your experience with hydraulic or pneumatic systems?

I possess extensive experience with both hydraulic and pneumatic systems. My expertise spans troubleshooting, repair, and preventative maintenance. With hydraulic systems, I’m proficient in diagnosing leaks, identifying faulty components like pumps, valves, and cylinders, and performing repairs or replacements. For example, I successfully diagnosed and repaired a hydraulic leak in a large industrial press, preventing costly downtime and potential safety hazards. The repair involved tracing the leak to a faulty seal, its replacement, and subsequent system pressure testing.

My pneumatic system experience includes working with various components such as air compressors, valves, actuators, and sensors. I’m adept at troubleshooting pneumatic circuits, identifying air leaks using specialized equipment, and repairing or replacing damaged components. One notable experience involved troubleshooting a faulty pneumatic system on a robotic arm. I systematically checked each component, identified a faulty pressure regulator, replaced it, and restored the arm’s functionality. My understanding extends to the safety aspects of working with both hydraulic and pneumatic systems, emphasizing proper safety protocols and the use of personal protective equipment.

Q 25. How do you ensure equipment is operating at optimal performance?

Ensuring optimal equipment performance requires a proactive and multi-faceted approach. It starts with implementing a robust preventative maintenance program, scheduling regular inspections, and performing routine tasks such as lubrication, cleaning, and component replacements according to manufacturer recommendations. This minimizes the likelihood of unexpected breakdowns and extends the lifespan of the equipment.

Beyond preventative maintenance, I utilize predictive maintenance techniques to identify potential issues before they lead to failures. This often involves using condition monitoring tools, such as vibration analysis, infrared thermography, and oil analysis, to detect early signs of wear or degradation. For example, by detecting increased vibration in a motor using vibration analysis, we could schedule a preventative repair before it caused a catastrophic failure. Regular performance testing and data analysis are also crucial to pinpoint areas for improvement and optimization. Finally, accurate record-keeping and a well-documented history of equipment performance allow for informed decision-making regarding repairs and upgrades.

Q 26. How do you handle conflicting priorities in a maintenance schedule?

Handling conflicting priorities in a maintenance schedule requires a systematic and organized approach. I prioritize tasks based on several factors, including the criticality of the equipment, potential safety risks, production impact, and the urgency of the repair. I use a prioritization matrix, weighing these factors to assign a priority score to each task. This matrix ensures that critical maintenance tasks are addressed first.

Effective communication is also key. I communicate openly with stakeholders, including production managers and operations teams, to explain the prioritization rationale and any potential delays. Flexibility is also important; sometimes, unforeseen issues require adjustments to the schedule. I continuously monitor the progress of tasks and proactively adjust the schedule as needed, ensuring that any potential conflicts are addressed quickly and efficiently. Utilizing scheduling software and collaborative tools such as shared calendars enhances team coordination and allows for real-time adjustments to the schedule.

Q 27. Describe your experience with welding or other fabrication techniques.

I have experience with various welding techniques, including MIG, TIG, and stick welding. My proficiency extends to different welding processes and material types, including ferrous and non-ferrous metals. I can perform repairs, fabricate custom parts, and create structural components using welding. For instance, I’ve successfully repaired damaged structural components on heavy machinery using MIG welding, restoring their functionality and structural integrity.

Beyond welding, I’m also experienced with other fabrication techniques such as cutting, grinding, drilling, and using various hand tools. This broader skillset allows me to handle a wide range of maintenance and repair tasks effectively. I always adhere to safety regulations and use appropriate personal protective equipment (PPE) when performing welding or fabrication work to ensure the safety of myself and those around me.

Q 28. What is your experience with electrical safety procedures?

Electrical safety is of utmost importance in my work. I’m thoroughly familiar with and strictly adhere to all relevant safety procedures, including lockout/tagout procedures (LOTO), which are essential for preventing accidental energization of equipment during maintenance. I’m proficient in using various electrical testing equipment, including multimeters, clamp meters, and insulation testers, to ensure electrical systems are safe and operating correctly.

I’m also knowledgeable about arc flash hazards and the necessary precautions, including using appropriate personal protective equipment (PPE) like arc flash suits and face shields. I understand the importance of working with qualified electricians when dealing with high-voltage systems or complex electrical circuits. My experience includes participating in regular safety training and staying updated on the latest electrical safety regulations and best practices. Continuous learning in this area is crucial to ensure a safe work environment for myself and my colleagues.

Key Topics to Learn for Inspect and Maintain Equipment Interview

- Preventive Maintenance Schedules: Understanding the importance of planned maintenance, developing effective schedules, and utilizing various maintenance management systems (CMMS).

- Diagnostic Techniques: Mastering troubleshooting methodologies, using diagnostic tools (e.g., multimeters, pressure gauges), and interpreting data to identify equipment malfunctions.

- Safety Regulations and Procedures: Deep understanding of relevant safety standards (e.g., OSHA), lockout/tagout procedures, and personal protective equipment (PPE) usage.

- Equipment Specific Knowledge: Thorough familiarity with the types of equipment you’ll be working with (specify if possible, e.g., HVAC systems, industrial machinery). This includes understanding their operational principles, common failure points, and maintenance requirements.

- Repair and Replacement Techniques: Practical skills in repairing and replacing components, sourcing parts, and documenting maintenance activities.

- Record Keeping and Reporting: Maintaining accurate and organized maintenance logs, generating reports on equipment performance, and communicating findings effectively.

- Problem-Solving and Critical Thinking: Applying logical reasoning to diagnose issues, assess risks, and implement efficient solutions in a timely manner.

- Continuous Improvement: Identifying areas for improvement in maintenance processes, suggesting innovative solutions, and contributing to a culture of safety and efficiency.

Next Steps

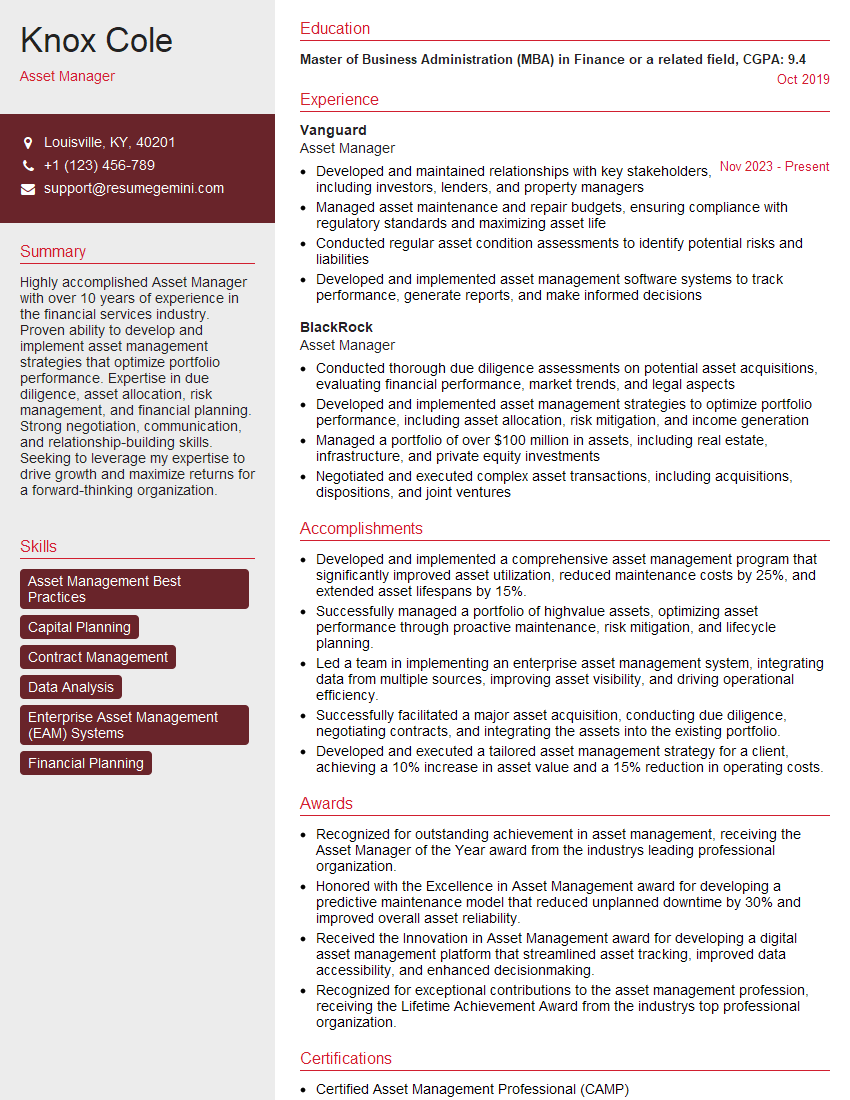

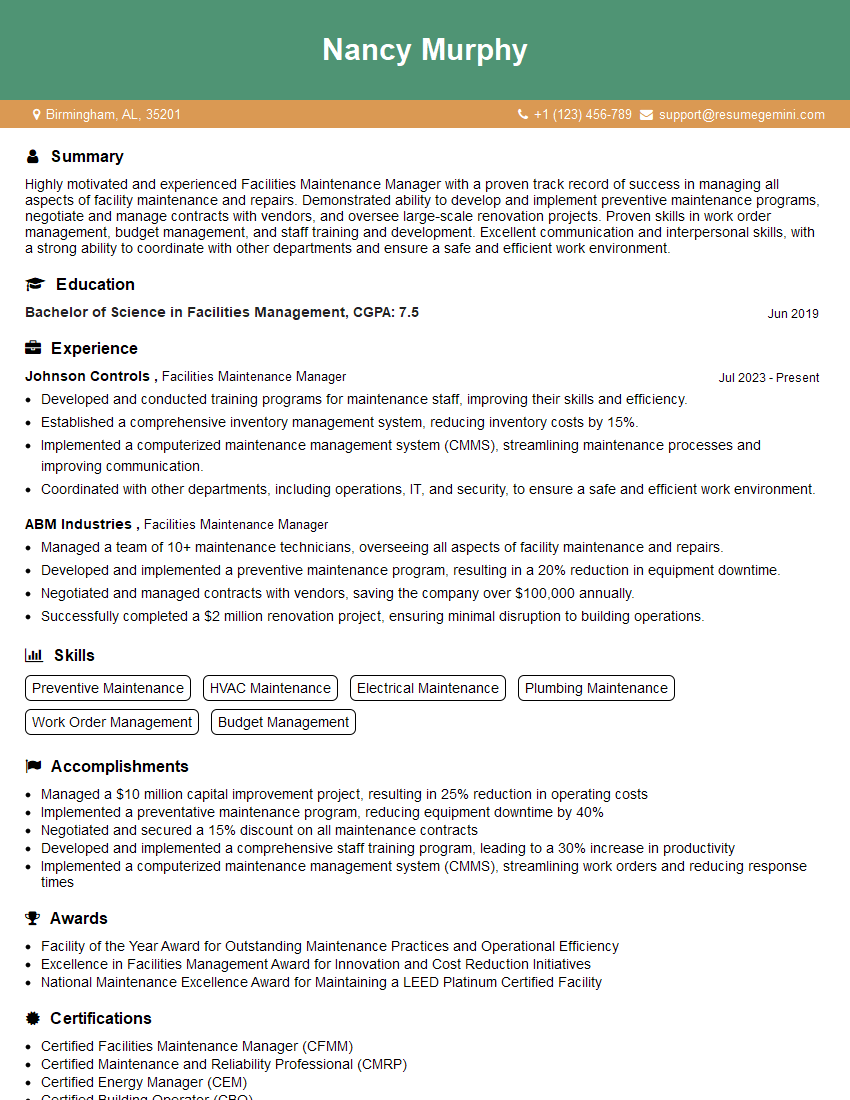

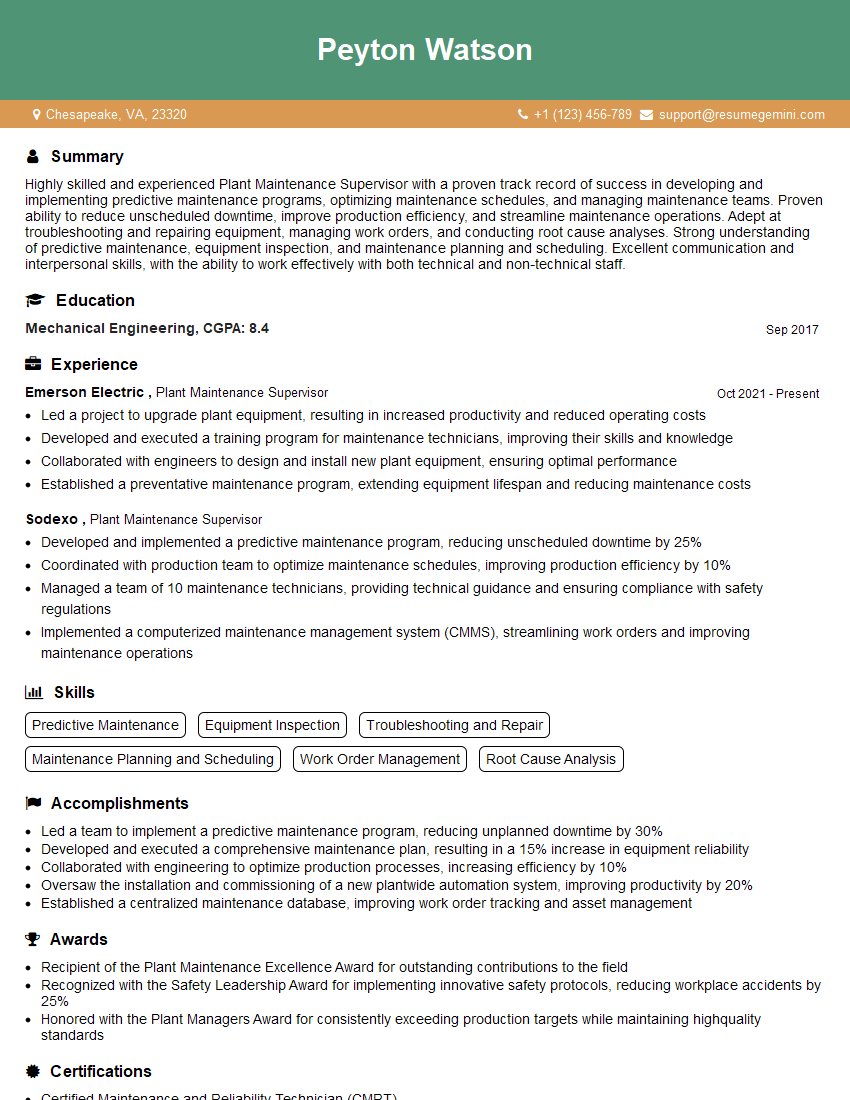

Mastering the skills of inspecting and maintaining equipment is crucial for career advancement in many industries. A strong foundation in these areas demonstrates reliability, technical proficiency, and a commitment to safety – highly sought-after qualities by employers. To significantly boost your job prospects, invest time in creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Inspect and Maintain Equipment roles are available to further guide your resume creation. Take this opportunity to showcase your abilities and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good