Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Wood Drying Science interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Wood Drying Science Interview

Q 1. Explain the different methods of wood drying.

Wood drying aims to reduce the moisture content of lumber to prevent decay and shrinkage during use. Several methods exist, categorized broadly as natural and artificial drying.

- Air Drying (Natural Drying): This relies on natural air movement and changes in humidity and temperature to gradually remove moisture. It’s a slow process, often taking months or even years, depending on factors like wood species, thickness, and climate. Stacks of lumber are carefully arranged with spacers for airflow.

- Kiln Drying (Artificial Drying): This accelerates the drying process using controlled temperature and humidity within an enclosed chamber called a dry kiln. Various kiln designs and drying schedules allow for precise control, significantly reducing drying time compared to air drying.

- Solar Drying: This utilizes solar energy to heat the lumber and drive off moisture. While environmentally friendly, it’s less controllable than kiln drying and depends heavily on sunlight availability and intensity.

- Vacuum Drying: This method employs a vacuum to reduce the boiling point of water within the wood, allowing moisture to be removed at lower temperatures. It’s beneficial for sensitive species prone to degrade at higher temperatures.

- Dehumidification Drying: This process focuses on lowering the moisture content of the surrounding air to draw moisture from the lumber. It’s often combined with other methods for enhanced control.

The choice of method depends on factors like the wood species, desired drying time, cost, and available resources.

Q 2. Describe the advantages and disadvantages of kiln drying versus air drying.

Kiln drying and air drying offer distinct advantages and disadvantages.

- Kiln Drying:

- Advantages: Faster drying time, greater control over the drying process, reduced risk of degrade (like checking and splitting), consistent final moisture content.

- Disadvantages: Higher initial investment (kiln cost and operation), increased energy consumption, potential for internal stresses if not properly managed.

- Air Drying:

- Advantages: Lower initial investment, environmentally friendly, lower energy consumption.

- Disadvantages: Much slower drying time, susceptible to weather conditions, higher risk of degrade, inconsistent final moisture content, potential for increased degrade due to insects or fungi.

Imagine building a deck: for a small project, air drying might suffice, whereas a large-scale construction project requires the speed and consistency of kiln drying.

Q 3. How do you determine the optimal moisture content for a specific wood species?

The optimal moisture content (MC) varies greatly depending on the wood species and its intended end-use. It’s crucial to balance the need for dimensional stability with the risk of degrade.

For example, furniture typically requires a lower MC (6-8%) to minimize shrinkage and warping, while exterior applications might tolerate a slightly higher MC (10-12%) to improve resistance to checking.

Determining the optimal MC often involves consulting established industry guidelines and standards specific to each wood species. These guidelines account for the species’ properties and its susceptibility to various types of degrade. In addition, experience and testing are invaluable in refining optimal MC for specific applications.

Q 4. What are the common defects associated with improper wood drying?

Improper wood drying can lead to several serious defects, significantly impacting the wood’s quality and value.

- Checking: Cracks that extend from the surface into the wood, often caused by rapid drying.

- Splitting: Cracks that run along the grain, often caused by stresses during drying.

- Case Hardening: A condition where the outer layers of the wood dry faster than the interior, causing the outer layers to be under compression while the interior remains under tension. This can lead to warping and splitting later.

- Honeycombing: Internal voids or cracks, often found in poorly dried lumber.

- Warping: Bending or twisting of the wood due to uneven moisture distribution.

- Shrinkage: Dimensional reduction in size as the wood dries; excessive shrinkage can lead to significant problems.

- Stain and Mold: Improper drying creates conditions where fungi and other microbes can thrive.

These defects can render lumber unusable for many applications, highlighting the importance of proper drying techniques.

Q 5. Explain the role of temperature and humidity in the wood drying process.

Temperature and humidity play crucial, interconnected roles in wood drying. The process is essentially driven by the moisture gradient between the wood and its surroundings.

Temperature: Higher temperatures increase the vapor pressure of moisture within the wood, promoting faster evaporation. However, excessively high temperatures can damage the wood, causing discoloration, cracking, or other defects. A controlled temperature increase throughout the drying process is key.

Humidity: Low humidity encourages moisture movement from the wood to the surrounding air. However, extremely low humidity can lead to excessively rapid surface drying, causing internal stresses and defects like case hardening. Careful control of humidity is essential to maintain a proper drying rate.

Think of it like boiling water: higher temperature (faster evaporation) corresponds to lower humidity (easier evaporation).

Q 6. How do you monitor and control the drying process in a dry kiln?

Monitoring and controlling the drying process in a dry kiln involves a multi-step process.

- Sensors: Dry kilns use sensors to constantly monitor temperature, humidity, and sometimes MC within the wood itself. This data is crucial for real-time adjustments.

- Control System: A sophisticated control system adjusts heating, ventilation, and humidification based on the sensor data and the programmed drying schedule. This ensures that the environment remains optimized throughout the process.

- Drying Schedule: A pre-determined plan specifies the temperature and humidity levels throughout the drying cycle. Schedules are tailored to the wood species, thickness, and desired final MC.

- Regular Inspection: Visual inspection of the lumber is important to detect any potential problems early on and make necessary adjustments to the drying schedule.

- Data Logging: Kiln controllers typically log all the data related to the drying process, which is critical for process optimization and troubleshooting.

Modern kilns often utilize computer-based control systems that allow for precise and efficient management of the drying process.

Q 7. Describe the different types of dry kilns and their applications.

Several types of dry kilns exist, each with specific advantages and applications:

- Conventional Kilns: These are the most common type and utilize fans to circulate heated and humidified air within the kiln chamber. They are suitable for a wide range of wood species and sizes.

- Dehumidification Kilns: These kilns focus on controlling humidity by removing moisture from the air rather than relying solely on heating. This can lead to gentler drying and reduced risk of defects.

- Vacuum Kilns: These kilns use a vacuum to lower the boiling point of water in the wood, facilitating drying at lower temperatures. Ideal for species sensitive to high temperatures.

- Solar Kilns: These utilize solar energy to heat the kiln, offering an environmentally friendly option but with less precise control than conventional kilns.

The choice of kiln type often depends on factors like budget, energy costs, wood species being dried, and the desired drying time.

Q 8. What are the safety precautions associated with operating a dry kiln?

Operating a dry kiln involves inherent risks, so safety is paramount. Think of it like handling a powerful oven – you need to be cautious and informed. Key precautions include:

- Proper ventilation: Dry kilns release moisture and potentially harmful fumes. Adequate exhaust systems are critical to prevent buildup and ensure a safe working environment. Regular checks and maintenance of these systems are non-negotiable.

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection (the kilns can be noisy), and appropriate work gloves. In some cases, respirators might be needed, especially when dealing with certain wood species or if there are concerns about dust or chemical exposure.

- Fire prevention: Wood is flammable. Kilns should be inspected regularly for electrical issues, ensure proper grounding, and maintain a clean environment to minimize the risk of fire. Fire extinguishers rated for wood fires should be readily accessible.

- Temperature and humidity monitoring: Regularly check the kiln’s internal conditions to ensure the drying process is proceeding as planned and within safe parameters. Malfunctions can lead to overheating or other hazards.

- Emergency procedures: Develop and regularly review emergency procedures, including shut-down protocols and evacuation plans. All workers should be fully briefed on these procedures.

- Regular maintenance: Preventative maintenance is key. Scheduled inspections and servicing of all kiln components will identify potential issues before they become safety hazards. This includes checking heating elements, sensors, and the kiln’s structural integrity.

Ignoring these precautions can lead to serious injuries, equipment damage, or even fire. Safety training is crucial for anyone working with a dry kiln.

Q 9. How do you calculate the drying schedule for a specific wood species and dimension?

Calculating a drying schedule is a crucial step, and it’s not a one-size-fits-all process. It’s like baking a cake – you need the right recipe for the specific ingredients. The schedule depends heavily on the wood species, its dimensions (thickness, width, and length), and the desired final moisture content. Several factors are considered:

- Wood species: Different species have varying densities and permeability, affecting how quickly they dry. Hardwoods generally dry slower than softwoods.

- Dimensions: Thicker lumber dries much slower due to the longer distances moisture needs to travel. Think of it like trying to dry a thick sponge compared to a thin one.

- Desired final moisture content (FMC): The target moisture content for the end use of the wood impacts the drying time. Furniture typically requires a lower FMC than structural lumber.

- Kiln type and capacity: Different kilns have varying capabilities; their size, ventilation, and heating systems directly affect the drying process.

Professionals often use specialized software or lookup tables based on extensive research data to determine appropriate schedules. These tools consider the interaction of temperature, humidity, and airflow to minimize drying stresses and defects. While manual calculation is possible using advanced formulas, software provides a far more accurate and efficient method. Experienced dry kiln operators often refine schedules based on their observations and experience to achieve optimal results.

Q 10. What are the effects of different wood species on the drying process?

Wood species significantly influence the drying process due to inherent differences in their physical and chemical properties. It’s like comparing apples and oranges – their textures and compositions differ, impacting how they respond to drying.

- Density: Denser woods (e.g., oak) have slower drying rates because moisture must move through a more compact structure. Less dense woods (e.g., pine) dry faster.

- Permeability: The ease with which moisture moves through the wood varies significantly between species. Woods with high permeability dry more readily.

- Shrinkage: Different species exhibit different shrinkage patterns and rates during drying. High shrinkage can lead to cracking and warping.

- Susceptibility to defects: Some species are more prone to certain drying defects, like checking (surface cracks) or honeycombing (internal cracks), than others. Understanding these propensities is vital for designing effective drying schedules.

For example, drying a thick piece of oak requires a much slower and more controlled schedule compared to drying a thinner piece of pine. Failure to account for these species-specific characteristics can result in significant quality issues, including warping, checking, and case hardening.

Q 11. Explain the concept of equilibrium moisture content.

Equilibrium moisture content (EMC) refers to the moisture level wood reaches when it’s in equilibrium with the surrounding environment. Think of it as a balance point. When the moisture content of the wood equals the moisture content of the air, there’s no net movement of moisture.

EMC depends primarily on the relative humidity (RH) and temperature of the surrounding air. Higher RH leads to higher EMC, and vice versa. Different wood species have slightly different EMC values at the same RH and temperature, but these differences are relatively small compared to the impact of the environment. Knowing the EMC is crucial because wood will absorb or release moisture until it reaches equilibrium with its surroundings.

For example, wood stored in a dry room with low RH will lose moisture until it reaches a low EMC, while wood stored in a humid environment will absorb moisture until it achieves a higher EMC. Understanding EMC helps in predicting how wood will behave in different environments and in designing effective storage and drying strategies.

Q 12. How do you prevent case hardening and other drying stresses?

Case hardening and other drying stresses arise from uneven moisture distribution within the wood. It’s like cooking a steak unevenly – the outside might be charred while the inside is still raw. To prevent these issues:

- Slow and controlled drying: The most effective method is a gradual reduction in moisture content, allowing time for moisture to diffuse uniformly throughout the wood. Rushing the drying process often results in severe stresses.

- Proper ventilation: Good airflow around the lumber ensures even moisture removal from all surfaces. Stagnant air can create pockets of high moisture content.

- Low initial drying temperatures: Starting the drying process at low temperatures minimizes surface drying and reduces the risk of case hardening. This allows the internal moisture to migrate outwards more gradually.

- Optimized drying schedules: As mentioned earlier, species-specific drying schedules are essential. Software and expert knowledge can help create schedules that mitigate the risk of stresses.

- Conditioning: After drying, a conditioning phase is crucial to equalize moisture throughout the wood and relieve any residual stresses.

By carefully managing the drying process, these stresses can be minimized, leading to higher quality, less-defective lumber. Think of it as precision craftsmanship – the more careful and meticulous the process, the better the final product.

Q 13. What are the different types of wood drying sensors and how do they work?

Various sensors are employed in modern dry kilns to monitor the drying process precisely. These sensors provide real-time data, enabling adjustments to maintain optimal conditions.

- Temperature sensors: These sensors, often thermocouples or resistance temperature detectors (RTDs), measure the air temperature within the kiln. They ensure the kiln operates within the prescribed temperature range for the specific wood and drying schedule.

- Humidity sensors: These sensors, such as capacitance or psychrometric sensors, measure the relative humidity (RH) of the kiln air. Accurate RH measurement is crucial for controlling the drying rate and preventing excessive moisture loss.

- Moisture sensors: These sensors directly measure the moisture content of the wood itself. They are often embedded within test pieces of wood in the kiln. Types include electrical resistance sensors and capacitance sensors. They provide valuable feedback on the progress of the drying process.

- Airflow sensors: These sensors measure the air circulation within the kiln. Ensuring appropriate airflow helps prevent uneven drying and promotes uniform moisture removal.

The data from these sensors are often fed into a kiln control system, which automatically adjusts parameters like temperature, humidity, and airflow to maintain the desired drying schedule. This automated control significantly improves the efficiency and consistency of the drying process while reducing defects.

Q 14. Describe the process of wood conditioning after drying.

Wood conditioning is a crucial post-drying step that involves holding the dried lumber at a specific relative humidity and temperature. It’s like letting a cake cool slowly and evenly after baking, to ensure it sets correctly.

The primary purpose is to equalize the moisture content throughout the wood and to relieve any residual internal stresses that may have developed during the drying process. This conditioning typically involves holding the wood at a slightly elevated humidity and temperature for a specific period. This allows the moisture to redistribute internally, reducing the likelihood of warping or checking after the wood has left the kiln. The duration and conditions of conditioning depend on the wood species, thickness, and desired final moisture content.

Proper conditioning is crucial for obtaining high-quality, stable lumber. Without it, even wood dried to the correct final moisture content can still warp or crack later due to uneven internal moisture distribution. Conditioning represents a final critical step in optimizing the wood’s dimensional stability and overall quality.

Q 15. How do you troubleshoot common problems in a dry kiln, such as uneven drying or excessive shrinkage?

Troubleshooting uneven drying or excessive shrinkage in a dry kiln requires a systematic approach. Uneven drying often stems from inadequate air circulation, leading to some areas drying faster than others. This results in stresses within the wood, causing warping or checking. Excessive shrinkage, on the other hand, is usually linked to overly aggressive drying schedules or insufficient initial moisture content assessment.

- Step 1: Inspect the Kiln and Lumber: Carefully examine the lumber for any signs of uneven drying (e.g., warping, checking, splitting). Check the kiln’s air circulation system for blockages, malfunctioning fans, or inadequate air distribution. Look for areas where airflow might be restricted.

- Step 2: Review the Drying Schedule: Analyze the current drying schedule. Is it appropriate for the wood species and its initial moisture content? Too rapid a drying schedule can lead to excessive shrinkage and degrade. Consult drying charts specific to the wood species being processed.

- Step 3: Adjust the Drying Parameters: Based on your inspection, make adjustments to the kiln’s settings. This might involve increasing air circulation, reducing drying temperature, or lengthening the drying time. For example, if you notice one end of the lumber is drying significantly faster, consider strategic placement of boards or adjustment of internal baffles.

- Step 4: Monitor and Iterate: Continuously monitor the lumber’s moisture content using reliable instruments like moisture meters. Adjust the kiln’s parameters as needed to achieve even drying. This iterative approach allows you to fine-tune the process for optimal results. Remember to keep detailed records of each drying cycle.

Example: I once encountered a situation where a kiln was producing excessively warped lumber. Upon inspection, I discovered a malfunctioning fan leading to poor air circulation in one section of the kiln. Replacing the fan and adjusting the lumber placement resolved the issue.

Career Expert Tips:

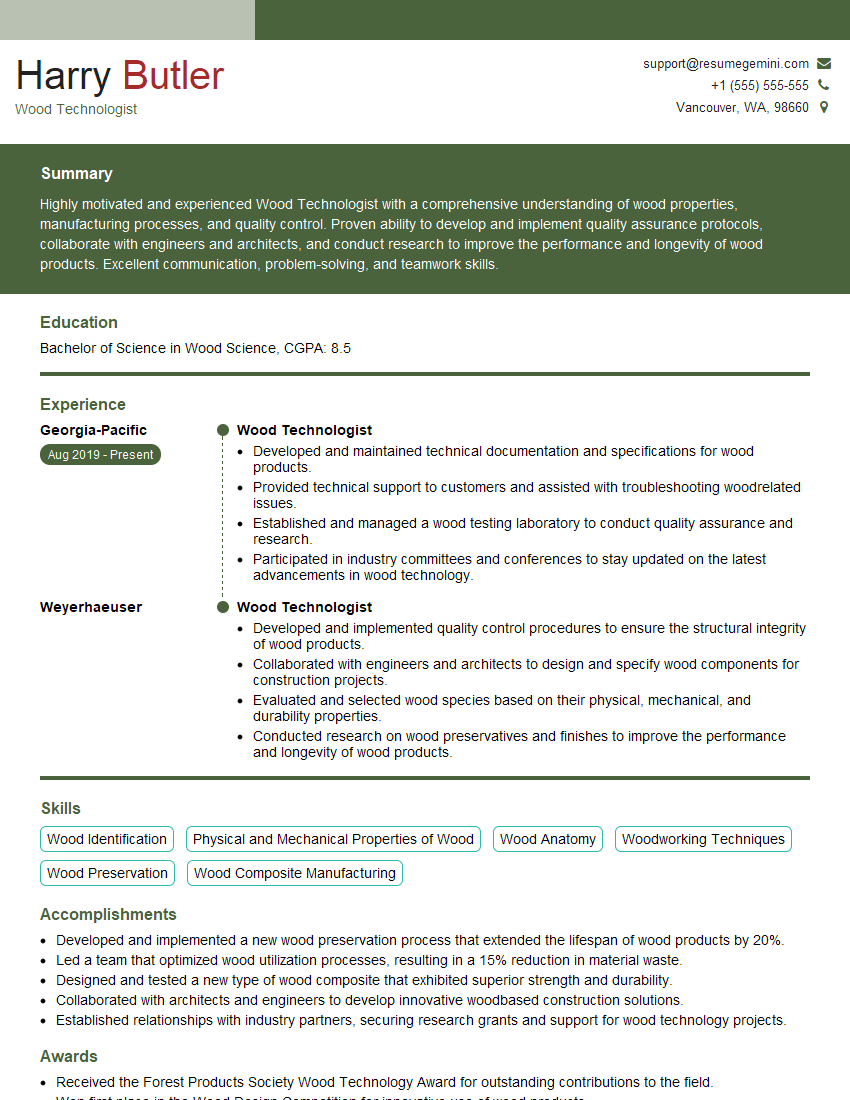

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper ventilation in a dry kiln.

Proper ventilation is paramount in a dry kiln because it ensures even moisture removal from the wood. It’s the lifeblood of the drying process. Without sufficient ventilation, moisture remains trapped within the wood, leading to several problems.

- Even Moisture Removal: Air circulation helps maintain a uniform temperature and humidity gradient across the lumber stack, preventing uneven drying and the associated defects.

- Reduced Drying Time: Efficient air movement accelerates the rate of moisture removal, reducing the overall drying time and increasing kiln throughput.

- Prevention of Mold and Decay: Adequate ventilation helps reduce humidity levels within the kiln, thus minimizing the risk of fungal growth and decay. A stagnant air environment is ideal for mold and mildew.

- Improved Lumber Quality: Even drying results in higher-quality lumber with fewer defects, increasing its value and marketability.

Think of it like this: drying wood is like baking a cake. You need proper airflow within the oven (kiln) to ensure the cake (lumber) cooks evenly. Insufficient airflow will result in a poorly baked cake.

Q 17. What are the environmental considerations associated with wood drying?

Wood drying has significant environmental implications. The process itself consumes energy, typically in the form of electricity or fuel, contributing to greenhouse gas emissions. Moreover, the release of volatile organic compounds (VOCs) during drying can impact air quality. Efficient kiln operation and the choice of drying methods directly impact these aspects.

- Energy Consumption: Traditional dry kilns can be energy-intensive. Using energy-efficient kilns, such as those utilizing heat recovery systems, can significantly reduce energy consumption and the associated carbon footprint.

- Volatile Organic Compound (VOC) Emissions: Certain wood species release VOCs during drying, contributing to air pollution. Implementing proper ventilation systems and employing effective emission control technologies can mitigate these emissions.

- Water Usage: Some drying methods, particularly those involving steaming, require significant water usage. Minimizing water use through efficient practices and water recycling strategies is crucial.

- Waste Management: Proper disposal of sawdust and other wood waste generated during drying is also important. Implementing effective waste management strategies, including recycling and responsible disposal, minimizes environmental impact.

Sustainable wood drying practices are increasingly important. The industry is moving towards implementing more environmentally friendly techniques, including solar drying and the use of alternative energy sources.

Q 18. How do you ensure the quality and consistency of the dried wood?

Ensuring the quality and consistency of dried wood involves a multifaceted approach, starting from the selection of raw materials to the implementation of rigorous quality control measures throughout the drying process.

- Careful Selection of Raw Material: Begin with high-quality, defect-free logs and lumber. Proper assessment of initial moisture content is crucial for determining appropriate drying schedules.

- Precision Drying Schedules: Utilize appropriate drying schedules tailored to the specific wood species, dimensions, and intended end-use. These schedules are essential for minimizing defects.

- Regular Monitoring and Control: Continuously monitor the kiln’s temperature, humidity, and air circulation to ensure optimal drying conditions. Utilize moisture meters for regular checks of lumber moisture content.

- Proper Kiln Maintenance: Regular kiln maintenance is crucial for optimal performance and consistent drying. This includes cleaning, inspecting, and repairing any mechanical issues.

- Post-Drying Inspection: Conduct a thorough inspection of the dried lumber to check for defects like checking, warping, and discoloration. Proper sorting and grading based on quality help ensure consistency.

Example: Implementing a sophisticated kiln control system with sensors monitoring various parameters allows for precise control of the drying process. This precision leads to consistent lumber quality, reducing defects and waste.

Q 19. What are the different types of wood preservatives and their applications?

Wood preservatives are used to protect wood from biological degradation caused by fungi, insects, and marine borers. The choice of preservative depends largely on the intended use and the type of degradation risk.

- Chromated Copper Arsenate (CCA): This was a widely used preservative but has been largely phased out due to its arsenic content. It’s still found in older structures.

- Copper Azole (CA): This is a water-borne preservative containing copper and azole fungicides, offering protection against decay and insects.

- Copper Quaternary Ammonium (CQA): This preservative combines copper and quaternary ammonium compounds, effective against decay and insects.

- Borates: Borates are naturally occurring minerals that provide protection against fungi and insects. They are environmentally friendly and are often used in applications where food contact is possible.

- Oil-borne Preservatives: These are typically creosote or pentachlorophenol, offering excellent protection, but are less environmentally friendly due to their toxicity and persistence in the environment.

Applications: CCA was commonly used for utility poles, railroad ties, and outdoor structures. CA and CQA are used in residential and commercial applications, including decking, fencing, and siding. Borates are used in applications where environmental concerns are high, such as children’s toys and some food-contact applications.

Q 20. Describe the process of identifying and grading dried lumber.

Identifying and grading dried lumber involves a thorough assessment of its quality and characteristics. It’s a crucial step in determining its value and suitability for various applications.

- Visual Inspection: Begin with a visual inspection, checking for defects such as knots, checks, splits, warping, and discoloration. The size, number, and location of these defects influence the grade.

- Moisture Content Measurement: Precisely measure the moisture content using a calibrated moisture meter to ensure it meets the required standards for the intended use.

- Strength Testing (Optional): Depending on the application, strength testing might be conducted to evaluate the lumber’s structural integrity.

- Grading Standards: Lumber grades are typically defined by specific standards, like those published by organizations such as the American Lumber Standard Committee. These standards define the allowable defects and the resulting grade classifications (e.g., No. 1, No. 2, etc.).

- Grading Rules: Apply the appropriate grading rules based on the species of wood and its intended use. Different species have different grading standards. A board with a small knot might be acceptable for one grade but unacceptable for another.

Example: A visually clear board with minimal defects and the correct moisture content would receive a higher grade than one with numerous large knots and significant warping. The grading process ensures consistent quality and helps consumers make informed decisions when choosing lumber for their projects.

Q 21. How do you maintain and repair a dry kiln?

Regular maintenance and timely repairs are crucial for extending the lifespan of a dry kiln and maintaining its operational efficiency. A well-maintained kiln produces consistently high-quality lumber.

- Regular Cleaning: Keep the kiln clean by regularly removing sawdust and debris. This prevents blockages in the air circulation system and minimizes fire hazards.

- Inspecting Heating and Ventilation Systems: Regularly check the heating elements, fans, and ductwork for any signs of damage or wear. Replace or repair damaged components promptly.

- Monitoring Sensors and Controls: Ensure the accuracy of temperature, humidity, and moisture content sensors. Calibrate them as needed to maintain accurate readings.

- Checking Insulation: Inspect the kiln’s insulation for any damage or deterioration. Repair or replace damaged insulation to maintain optimal energy efficiency.

- Lubricating Moving Parts: Regularly lubricate moving parts such as fans and motors to ensure smooth operation and reduce wear and tear.

- Preventative Maintenance Schedule: Establish a comprehensive preventative maintenance schedule that outlines regular inspections and service tasks. This schedule will help you identify potential problems early and prevent costly repairs.

Example: A regular inspection might reveal a slight leak in the kiln’s seals. Addressing this minor issue promptly prevents significant moisture loss and ensures consistent drying conditions, ultimately saving money and improving the quality of the finished product. Neglecting maintenance can lead to costly breakdowns and inconsistent lumber quality.

Q 22. Explain the concept of lumber stress grading.

Lumber stress grading is a crucial process in the wood industry that assesses the strength and structural integrity of lumber based on its internal stresses and grain characteristics. It’s not simply about measuring dimensions; it’s about predicting how a piece of wood will perform under load. Graders visually inspect the wood, looking for features like knots, checks (splits), and grain slope, which indicate potential weaknesses. These features affect the wood’s ability to resist bending, tension, and compression. The grading process ensures that lumber is used appropriately for its intended application, preventing structural failures and maximizing efficiency.

Different grading agencies use various visual grading rules, often resulting in different grades for the same piece of wood. For example, a piece of lumber might be graded as ‘No. 1’ (highest grade) by one agency and ‘No. 2’ by another. These grades are visually assigned and are not based on precise machine measurements of strength properties.

Imagine building a house. You wouldn’t want to use low-grade lumber for load-bearing beams, as this could lead to catastrophic failure. Stress grading ensures that the right grade of lumber is used for each application – ensuring safety and structural soundness.

Q 23. What are the different types of drying defects and their causes?

Drying defects are imperfections in wood caused by improper drying techniques. These defects can significantly reduce the value and usability of the lumber. Here are some common ones:

- Check: A lengthwise separation of the wood, often starting at the surface and extending inwards. This happens due to uneven drying, causing stresses that exceed the wood’s strength. Think of it like cracking a dried-out mud pie.

- Honeycombing: Internal voids within the wood, creating a honeycomb-like structure. This usually results from excessively fast drying, causing the surface to dry faster than the interior, leading to internal stresses and collapse.

- Casehardening: The outer layers of the wood dry faster than the interior, creating compressive stresses on the outside and tensile stresses in the center. This can lead to warping and splitting when the stresses are released. It’s like squeezing a balloon; the pressure builds up until it bursts.

- Warping: Changes in the shape of the wood, such as bowing, crooking, or twisting. This is often caused by uneven drying or internal stresses.

- Surface Checking: Small cracks on the surface of the wood, usually caused by too-rapid drying or low relative humidity. Imagine sunburnt skin; that’s similar to surface checking.

The causes of these defects are largely related to the drying schedule, including temperature, humidity, and air circulation. Other factors, such as the wood species and initial moisture content, also play a role. Understanding these factors is key to preventing drying defects.

Q 24. How do you interpret and utilize drying data to optimize the process?

Drying data, typically gathered from sensors within a kiln, is essential for optimizing the drying process. This data includes temperature, humidity, and moisture content readings at various points within the lumber pile. Analyzing this data helps to understand the drying rate, predict potential problems, and adjust the drying schedule accordingly.

For example, if the moisture content readings show that the wood is drying too quickly, we might lower the kiln temperature or increase the humidity. Conversely, if the drying is too slow, we can increase the temperature or improve air circulation. Sophisticated drying software allows for real-time monitoring and control of the drying process, leading to more efficient and defect-free lumber.

By plotting moisture content over time, we can create drying curves that visually represent the drying process. These curves help to identify any abnormalities and to compare the performance of different wood species or drying schedules. The goal is to achieve a uniform moisture content throughout the wood while minimizing drying defects.

Q 25. What software or technology are you familiar with in relation to wood drying?

I am familiar with various software and technologies used in wood drying, including:

- Kiln control systems: These systems use sensors and algorithms to monitor and control the drying environment in kilns. Many systems offer data logging and reporting capabilities.

- Data acquisition systems (DAQ): These systems collect data from various sensors within the kiln and allow for real-time monitoring and analysis.

- Drying simulation software: This software uses mathematical models to predict the drying behavior of wood under different conditions, allowing for the optimization of drying schedules before they are implemented in a real kiln. This saves time and reduces risk.

- Moisture meters: Essential tools for measuring the moisture content of wood at various stages of drying, giving valuable real-time feedback.

My experience includes working with both proprietary and open-source software platforms and integrating them into various drying systems.

Q 26. Describe your experience with different wood species and their drying characteristics.

My experience encompasses a wide range of wood species, each possessing unique drying characteristics. For example, hardwoods like oak and maple are generally more difficult to dry than softwoods like pine and fir due to their higher density and greater tendency to check and caseharden. Hardwoods require slower, more controlled drying schedules to avoid defects.

Softwoods, while easier to dry, can still exhibit defects if the drying process isn’t properly managed. Species like redwood, known for its high extractive content, require specialized drying techniques to avoid staining and other issues. I’ve worked extensively with different species, tailoring drying strategies based on their specific properties. Understanding the inherent variability within a species is also crucial; even within a single batch of lumber, some boards might dry faster than others.

One project involved drying a large quantity of cherry lumber for high-end furniture. Because cherry is prone to casehardening, a very slow, carefully controlled drying schedule was implemented to mitigate this defect, resulting in a high-quality final product.

Q 27. Explain your understanding of the physics and chemistry of wood drying.

Wood drying is a complex process governed by both physics and chemistry. From a physics perspective, the process involves the movement of moisture from within the wood to the surrounding air. This movement is driven by the difference in water vapor pressure between the wood and the air. Factors like temperature and relative humidity influence this vapor pressure difference, directly affecting the drying rate.

Chemically, the drying process involves the breaking of hydrogen bonds between water molecules and the wood cell walls. Extractives within the wood can also impact drying behavior. For example, some extractives can inhibit drying, while others can accelerate it. The chemical composition of the wood, therefore, plays a significant role in determining the appropriate drying parameters.

Understanding these physical and chemical interactions allows for the development of effective drying strategies that minimize defects and maximize the quality of the final product. Imagine wood cells as tiny sponges; we’re carefully removing the water from these sponges without damaging their structure.

Q 28. How would you handle a situation where a batch of lumber is drying too quickly or too slowly?

If a batch of lumber is drying too quickly, it’s likely experiencing excessive stress leading to defects like checking, casehardening, or honeycombing. My response would involve immediately adjusting the kiln’s parameters to slow down the drying process. This would likely involve:

- Lowering the kiln temperature: This reduces the vapor pressure gradient, slowing the rate of moisture removal.

- Increasing the relative humidity: This creates a less aggressive drying environment, reducing the stress on the wood.

- Improving air circulation: Ensuring uniform drying throughout the lumber pile minimizes localized stress points.

Conversely, if the drying process is too slow, it means the lumber is not releasing moisture efficiently. The solutions could include:

- Increasing the kiln temperature (carefully): This increases the vapor pressure gradient.

- Lowering the relative humidity: This increases the driving force for moisture removal.

- Improving air circulation: This enhances moisture transport from within the wood.

- Checking for potential blockages within the lumber stack: Poor airflow in a specific area can cause slow drying in that region.

In both scenarios, continuous monitoring of moisture content is vital. The goal is to find the optimal balance between drying speed and minimizing defects. The specific adjustments would depend on the wood species, thickness of the boards, and the specific defects observed.

Key Topics to Learn for Wood Drying Science Interview

- Wood Anatomy and Properties: Understanding wood structure (cell walls, lumens, etc.) and how it impacts drying behavior. This includes knowledge of different wood species and their unique drying characteristics.

- Moisture Content and Equilibrium Moisture Content (EMC): Mastering the concepts of moisture content, its measurement, and the importance of reaching EMC for dimensional stability and preventing defects.

- Drying Methods and Technologies: Familiarize yourself with various drying techniques (kiln drying, air drying, solar drying) and the equipment used. Understand the advantages and disadvantages of each method.

- Drying Stress and Defects: Learn to identify and explain common drying defects (checking, splitting, warping) and how they relate to drying stresses within the wood. Knowing how to prevent these defects is crucial.

- Drying Schedules and Control: Understand the principles of designing and implementing effective drying schedules to minimize defects while optimizing drying time. This includes knowledge of temperature, humidity, and airflow control.

- Quality Control and Assessment: Learn about methods for assessing the quality of dried lumber, including visual inspection and moisture content measurement. This includes understanding industry standards and grading systems.

- Mathematical Modeling and Simulation: Familiarize yourself with the use of mathematical models to predict drying behavior and optimize drying schedules. Understanding the underlying principles is key.

- Sustainability and Environmental Considerations: Explore the environmental impact of different drying methods and best practices for sustainable wood drying.

- Problem-solving Approaches: Practice diagnosing and troubleshooting problems related to wood drying, such as uneven drying, excessive shrinkage, or defect formation. Be prepared to discuss your approach to problem-solving in a practical setting.

Next Steps

Mastering Wood Drying Science is essential for a successful and rewarding career in this field, opening doors to diverse opportunities in manufacturing, research, and consulting. To maximize your job prospects, creating a strong, ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Wood Drying Science positions. Examples of resumes tailored to this field are available to help guide you in creating your own. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good