Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Monitor and adjust machine settings interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Monitor and adjust machine settings Interview

Q 1. Explain the process of calibrating a machine’s settings.

Calibrating a machine involves adjusting its settings to ensure it operates within its specified tolerances and produces consistent, high-quality output. Think of it like tuning a musical instrument – you need to fine-tune various parameters to achieve the desired sound. The process typically involves several steps:

- Understanding the specifications: First, you need to know the machine’s design specifications, including the acceptable ranges for various parameters like speed, temperature, pressure, or voltage.

- Using calibration tools: This might involve using precision instruments like micrometers, pressure gauges, thermometers, or specialized software to measure the machine’s actual performance against the specifications.

- Making adjustments: Based on the measurements, you’ll adjust the machine’s settings using control knobs, software interfaces, or other mechanisms. This might involve tweaking feed rates, adjusting tolerances, or changing the power supply.

- Verification and iteration: After making adjustments, you’ll re-measure the performance to verify that the calibration is accurate. This is an iterative process – you might need to make several adjustments until you reach the desired level of accuracy.

- Documentation: Finally, you document the calibration process, including the date, time, settings, and measured values. This is crucial for maintaining accurate records and ensuring traceability.

For example, calibrating a CNC milling machine might involve adjusting the spindle speed, feed rate, and tool offsets to ensure accurate cutting of a workpiece. Inaccurate calibration can lead to dimensional inaccuracies, surface finish problems, or even machine damage.

Q 2. Describe your experience monitoring machine performance indicators.

Monitoring machine performance indicators is essential for ensuring optimal efficiency and product quality. My experience involves utilizing a variety of methods, from visually inspecting the machine for anomalies to employing sophisticated data analytics. I’m proficient in using both real-time and historical data to identify trends and potential problems. I regularly monitor key indicators like:

- Production Rate: Units produced per hour or other relevant time unit. Significant deviations can indicate problems with the machine’s efficiency or material supply.

- Defect Rate: The percentage of defective products. A sudden increase points to a potential issue with machine settings, material quality, or operator error.

- Downtime: The amount of time the machine is not producing. Identifying recurring downtime causes can pinpoint areas for improvement.

- Energy Consumption: Monitoring energy usage can help identify inefficiencies and potential areas for energy savings.

- Temperature and Pressure: For machines that involve these parameters, continuous monitoring is essential to prevent damage or malfunctions.

I use various data logging and monitoring systems, including SCADA (Supervisory Control and Data Acquisition) systems and dedicated machine control software. Analyzing this data allows for proactive maintenance and optimization of the machine’s performance, minimizing downtime and maximizing output.

Q 3. How do you identify and troubleshoot common machine malfunctions?

Troubleshooting machine malfunctions requires a systematic approach. I typically follow these steps:

- Safety First: Always prioritize safety. Before attempting any troubleshooting, ensure the machine is powered off and locked out to prevent accidental injury.

- Gather Information: Collect data on the malfunction. What are the symptoms? When did the problem start? Were there any unusual events before the malfunction occurred? Error codes or logs are crucial here.

- Visual Inspection: Check for obvious problems such as loose connections, worn parts, or leaks.

- Consult Documentation: Refer to the machine’s manuals, schematics, and troubleshooting guides.

- Check Sensor Readings: Verify the readings from various sensors to ensure they are within the acceptable ranges.

- Systematic Testing: If the problem isn’t obvious, I’ll conduct systematic tests to isolate the cause. This might involve checking individual components or subsystems.

- Seek External Expertise: If necessary, I’ll consult with colleagues, manufacturers, or other experts.

For example, if a packaging machine is consistently producing misaligned labels, I would systematically check the label feeder mechanism, the conveyor belt alignment, and the label applicator settings before potentially investigating more complex issues within the machine’s control system.

Q 4. What methods do you use to ensure consistent product quality through machine adjustments?

Maintaining consistent product quality requires a multi-faceted approach. I use a combination of methods:

- Regular Calibration: As discussed earlier, regular calibration ensures the machine operates within its specified tolerances.

- Statistical Process Control (SPC): SPC techniques involve using control charts and other statistical methods to monitor the process and identify any variations that might lead to defects.

- Preventive Maintenance: Regular maintenance, including lubrication, cleaning, and component replacement, helps prevent malfunctions and ensures the machine continues to operate at its optimal performance.

- Operator Training: Well-trained operators are crucial for consistent product quality. Training on proper machine operation and quality control procedures is essential.

- Material Quality Control: Maintaining consistent material quality is just as important as machine maintenance. Careful inspection and selection of materials prevent defects caused by material inconsistencies.

By implementing these methods, I can minimize variations in the production process and ensure consistent product quality. For instance, in a food processing plant, maintaining consistent temperature and pressure during the pasteurization process is vital to prevent spoilage and ensure food safety.

Q 5. How do you interpret machine error codes and logs?

Machine error codes and logs are invaluable tools for troubleshooting. Error codes usually indicate specific problems, while logs provide a detailed record of the machine’s operation, including timestamps and sensor readings. I approach interpreting them as follows:

- Consult the Manual: The machine’s manual should have a list of error codes and their corresponding meanings.

- Analyze the Log Files: Examine the log files for patterns or trends that might help pinpoint the cause of the problem. Look for unusual sensor readings or events that coincided with the error.

- Correlate Error Codes and Logs: Cross-reference the error codes with the log files to get a more comprehensive understanding of the problem. For example, an error code related to a low-pressure sensor might be confirmed by reviewing the pressure readings in the log files.

- Use Diagnostic Tools: Some machines have built-in diagnostic tools that can help identify the cause of the problem.

Example: Error Code E123 - Low Pressure Sensor. Log file shows pressure dropped below 10 PSI at 10:30 AM, coinciding with the error code. This suggests a problem with the pressure sensor or the system supplying the pressure.

Q 6. Describe a time you had to adjust machine settings to meet production demands.

During a peak production season, our packaging line experienced a significant bottleneck. The existing machine settings were designed for average production, but demand increased by 40%. The resulting slow-down threatened to disrupt the entire production schedule and lead to missed deadlines.

To address this, I first analyzed the machine’s performance data to identify the bottlenecks. The analysis revealed that the speed of the conveyor belt and the filling mechanism were the limiting factors. After careful review of the machine’s capabilities and safety parameters, I made incremental adjustments to the conveyor belt speed and the filling mechanism’s cycle time. I meticulously monitored the machine’s performance following each adjustment, ensuring that the increased speed didn’t compromise the product quality or the machine’s structural integrity.

Through a series of controlled adjustments, I successfully increased the production rate by 35%, meeting the increased demand without compromising quality. This experience highlighted the importance of understanding the machine’s limits and the need for data-driven decision making when adjusting settings under pressure.

Q 7. What safety protocols do you follow when operating and adjusting machinery?

Safety is my paramount concern when operating and adjusting machinery. I always adhere to strict safety protocols, including:

- Lockout/Tagout (LOTO): Before performing any maintenance or adjustments, I always ensure the machine is properly locked out and tagged out to prevent accidental startup.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, such as safety glasses, gloves, and hearing protection, as required by the machine’s safety guidelines.

- Following Standard Operating Procedures (SOPs): I strictly follow all SOPs for machine operation and maintenance.

- Machine Guards: I ensure that all machine guards are in place and functioning correctly to prevent accidental contact with moving parts.

- Awareness of Surroundings: I maintain constant awareness of my surroundings and take precautions to avoid hazards.

- Reporting Hazards: I immediately report any unsafe conditions or potential hazards to my supervisor.

Regular safety training and continuous vigilance are crucial for preventing accidents and maintaining a safe working environment. My commitment to safety ensures both my well-being and the safety of my colleagues.

Q 8. How do you prioritize multiple machine adjustments or maintenance tasks?

Prioritizing machine adjustments and maintenance tasks requires a structured approach. I typically use a system that combines urgency, impact, and preventive measures. Think of it like a triage system in a hospital – the most critical issues get immediate attention.

- Urgency: Immediate safety hazards or production stoppages take precedence. For example, a machine emitting sparks or leaking oil needs immediate attention.

- Impact: Tasks impacting production volume or product quality are prioritized higher. A misaligned machine producing defective parts needs fixing before a large batch is ruined.

- Preventive Maintenance: Scheduled maintenance, like lubrication or filter changes, is essential to prevent future problems. These tasks are planned in advance to minimize downtime.

I often use a task management system (either software or a whiteboard) to visually track all tasks, their priority, and deadlines. This allows for efficient scheduling and resource allocation.

Q 9. Explain your experience with different types of machine control systems (e.g., PLC, HMI).

I have extensive experience with various machine control systems, including PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces). PLCs form the ‘brains’ of the machine, controlling its automated functions using ladder logic or structured text. HMIs provide the interface for operators to monitor and interact with the PLC.

For example, I’ve worked with Allen-Bradley PLCs and their associated PanelView HMIs extensively. I am proficient in troubleshooting PLC programs by identifying and correcting faulty logic, understanding error codes, and utilizing diagnostic tools within the PLC. With HMIs, I’m skilled in configuring screens for intuitive operator control and monitoring, ensuring clear visualization of process variables and alarms.

My experience extends to other systems as well, including Siemens PLCs and various HMI platforms. The fundamental principles of control system interaction remain the same across different vendors, but my knowledge allows me to adapt quickly to new technologies.

Q 10. How do you document machine adjustments and maintenance performed?

Meticulous documentation is crucial for maintaining machine history and ensuring consistent performance. I utilize a combination of digital and physical records.

- Digital Records: I maintain detailed logs in a computerized maintenance management system (CMMS). These logs include the date, time, machine ID, adjustments made, parts replaced, and any relevant notes or observations. Images or videos are often included to illustrate the issue and the solution.

- Physical Records: I also keep hard copies of important documentation, including schematics, manuals, and maintenance reports, often in a dedicated binder for each machine. This ensures data redundancy and accessibility even in case of digital system failure.

All entries are clear, concise, and consistent, following a pre-defined template to maintain uniformity across different machines and technicians.

Q 11. Describe your experience with preventative maintenance on machinery.

Preventative maintenance is key to maximizing machine lifespan and minimizing unexpected downtime. My approach is proactive, focusing on regular inspections and scheduled maintenance tasks.

I develop a preventative maintenance schedule tailored to each machine, based on the manufacturer’s recommendations and historical data. This schedule typically includes tasks like lubrication, cleaning, inspection of wear parts, and calibration of sensors. For example, on a packaging machine, this might include checking the tension of the belts, cleaning the rollers, and lubricating moving parts at set intervals.

I use checklists during these inspections to ensure consistency and thoroughness. Deviations from expected parameters are noted and investigated to prevent potential failures before they occur. This proactive approach significantly reduces the likelihood of unexpected breakdowns and extends machine lifespan.

Q 12. What are the key performance indicators (KPIs) you monitor for machine efficiency?

Several KPIs are crucial for evaluating machine efficiency. These metrics provide insights into the machine’s performance and identify areas for improvement.

- Overall Equipment Effectiveness (OEE): This combines availability, performance, and quality rates to provide a holistic view of efficiency.

- Mean Time Between Failures (MTBF): This indicates the average time between machine failures.

- Mean Time To Repair (MTTR): This represents the average time taken to repair a machine after a failure.

- Production Rate/Output: Measures the amount of product produced within a given time frame.

- Defect Rate: Tracks the percentage of defective products produced.

By consistently monitoring these KPIs, I can identify trends, pinpoint bottlenecks, and implement necessary adjustments to optimize machine performance and reduce waste.

Q 13. How do you handle unexpected machine downtime or malfunctions?

Unexpected downtime requires a swift and structured response. My approach involves a systematic troubleshooting process.

- Assess the situation: Identify the nature of the malfunction and its immediate impact on production.

- Isolate the problem: Determine the root cause of the downtime through visual inspection, diagnostic tools (e.g., PLC error codes), and sensor data.

- Implement immediate fixes: If possible, perform quick fixes to restore partial or full functionality. For example, resetting a tripped breaker or replacing a simple fuse.

- Document findings and solutions: Record all actions taken, observations made, and parts replaced in the CMMS.

- Engage support if necessary: If the issue is complex or requires specialized knowledge, I consult with engineers or external service providers.

- Prevent future occurrences: Analyze the root cause to identify potential improvements in preventative maintenance routines or operator training.

Effective communication with the team and management is vital during downtime, ensuring everyone is informed and coordinated.

Q 14. Describe your experience using measuring tools to verify machine settings.

Accurate measurements are critical for verifying machine settings. I use a variety of measuring tools depending on the specific application.

- Micrometers and Calipers: For precise measurements of dimensions and tolerances.

- Dial Indicators: To measure runout, parallelism, and alignment.

- Leveling Devices: To ensure proper machine leveling and prevent vibrations.

- Pressure Gauges: To monitor and verify pressure settings in pneumatic or hydraulic systems.

- Thermometers and Infrared Thermometers: To check for overheating components.

Before using any tool, I always ensure its proper calibration and accuracy. I meticulously record measurements and compare them against the specified tolerances to ensure the machine is operating within acceptable parameters. For example, when setting the gap between a cutting tool and the workpiece on a CNC machine, I would use a micrometer to ensure the gap is within the specified tolerance.

Q 15. How familiar are you with various machine types and their specific settings?

My familiarity with various machine types and their settings is extensive. Over the years, I’ve worked with a wide range of machinery, including CNC milling machines, injection molding machines, automated assembly lines, and robotic systems. Each machine type presents a unique set of parameters and adjustments. For example, a CNC milling machine requires precise control over feed rates, spindle speed, and depth of cut, while an injection molding machine demands careful management of injection pressure, melt temperature, and cycle time. I understand the intricacies of these settings and how they impact the final product’s quality and efficiency. I approach each new machine with a structured learning process, beginning with manufacturer documentation and safety protocols, followed by hands-on experience under the guidance of experienced operators when possible.

- CNC Machining: I’m proficient in interpreting G-code and adjusting parameters to optimize cutting speed and surface finish.

- Injection Molding: I possess a deep understanding of plastic material properties and their impact on molding process parameters.

- Robotics: I have experience programming and troubleshooting robotic systems, focusing on precise movement and part handling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your approach to optimizing machine settings for maximum efficiency?

My approach to optimizing machine settings for maximum efficiency is a systematic process combining data analysis, process understanding, and continuous improvement. It begins with a thorough understanding of the machine’s capabilities and limitations, as well as the desired output specifications. I then collect data on key performance indicators (KPIs), such as cycle time, defect rate, and material usage. This data informs adjustments to parameters like feed rates, temperatures, pressures, or other relevant settings. I use statistical methods (like Design of Experiments or DOE) to systematically test different settings and identify the optimal combination. Once optimized, continuous monitoring is critical to ensure that these settings remain effective and to detect potential deviations. For instance, if I’m working with an injection molding machine, I might adjust the injection pressure and temperature to minimize cycle time while maintaining consistent part quality. Regular monitoring of the melt flow rate and pressure readings would then allow for immediate correction if any drifts or anomalies are detected.

Q 17. Explain your understanding of Statistical Process Control (SPC) in relation to machine settings.

Statistical Process Control (SPC) is fundamental to maintaining optimal machine settings. SPC uses statistical methods to monitor and control a process to ensure that it remains within predefined limits. In the context of machine settings, SPC involves collecting data on key process variables (like dimensions, weight, or temperature) at regular intervals. These data points are then plotted on control charts, which visually display the process’s variability over time. By analyzing control charts, I can identify patterns, trends, and deviations from the desired target values. For example, if I notice a trend of increasing part dimensions on a control chart, it may indicate a need to adjust a particular machine setting, such as the tool wear compensation on a CNC machine or the mold temperature on an injection molding machine. The timely identification and correction of these deviations prevent the production of defective parts and maintain consistent output quality. The use of control charts, along with other statistical tools like capability analysis, enables data-driven decision-making in fine-tuning machine parameters for sustained performance.

Q 18. How do you ensure the accuracy and precision of machine settings?

Ensuring the accuracy and precision of machine settings requires a multi-faceted approach. Firstly, regular calibration and verification of the machine itself are crucial. This involves using calibrated instruments and comparing readings against known standards. Secondly, I meticulously follow the manufacturer’s guidelines and best practices for setting up the machine. This includes using appropriate tooling, checking for proper alignment, and confirming the settings against blueprints or specifications. Thirdly, I utilize various measurement tools (calipers, micrometers, laser measurement systems) to verify the accuracy of the output. For instance, after making adjustments to a CNC machine, I’ll measure several parts to confirm the dimensions are within tolerance. If there are discrepancies, I’ll investigate the cause, potentially adjusting settings or replacing worn tooling. Furthermore, continuous monitoring using SPC charts provides real-time feedback, ensuring that the machine’s performance stays within acceptable limits.

Q 19. Describe your experience with machine automation and programming.

I have significant experience with machine automation and programming. I’ve worked with Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and various industrial communication protocols (like Ethernet/IP and Profibus). My experience includes developing and implementing automated sequences for robotic systems, integrating sensors and actuators, and designing efficient control programs for various automated machines. For example, in one project, I automated a pick-and-place process using a robotic arm, programming the robot’s movements and integration with vision systems to ensure accurate part handling. I am comfortable with ladder logic programming (for PLCs), and I have experience using SCADA systems for monitoring and controlling large-scale automated systems. My approach to automation prioritizes safety, reliability, and maintainability.

Q 20. What software or systems are you proficient in for monitoring and controlling machines?

I am proficient in several software and systems for monitoring and controlling machines. My expertise includes using SCADA systems (like Wonderware and Ignition) for real-time data acquisition and visualization of machine parameters. I’m also familiar with PLC programming software (like RSLogix and TIA Portal), allowing me to modify and troubleshoot control programs. I regularly utilize data analysis tools (like Excel and Minitab) for statistical process control and optimization. Furthermore, my experience extends to using Computer-Aided Manufacturing (CAM) software to generate machine control programs for CNC machining operations. My proficiency in these systems allows me to efficiently monitor, analyze, and optimize machine performance, ensuring consistent quality and productivity.

Q 21. How do you maintain cleanliness and order around your work area and equipment?

Maintaining a clean and organized work area is critical for safety and efficiency. I follow a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to keep my workspace and equipment tidy. This includes regularly cleaning equipment, removing unnecessary items, and organizing tools and materials in designated locations. Proper cable management is also a priority to prevent hazards and facilitate easy access to equipment. I believe a clean and organized environment promotes safer working conditions, reduces the risk of errors, and improves overall efficiency. A well-maintained work area also facilitates quicker troubleshooting and repair of equipment, minimizing downtime. I also ensure regular preventative maintenance tasks are carried out to maintain the cleanliness and operability of the machinery.

Q 22. Describe a time you had to deal with a challenging machine setting issue. How did you resolve it?

One particularly challenging issue involved a high-speed packaging machine experiencing inconsistent sealing on its output. Initially, the problem seemed related to the sealing pressure, so I adjusted the pneumatic cylinder’s pressure setting, but the issue persisted. This led me to believe there might be another variable at play.

My systematic approach involved carefully reviewing the machine’s operational logs, checking the temperature sensors for the sealing jaws, and visually inspecting the sealing mechanism. I discovered that the temperature sensor was slightly miscalibrated, resulting in inconsistent heat application to the sealing jaws even though the pressure was correct.

The solution involved recalibrating the temperature sensor using a precision thermometer. After this adjustment and a few test runs, the inconsistent sealing was resolved. This experience highlighted the importance of considering multiple factors and using a methodical approach for troubleshooting.

Q 23. How do you stay up-to-date on advancements in machine technology and maintenance practices?

Staying current in this field demands a multi-pronged approach. I actively participate in professional organizations like the Society of Manufacturing Engineers (SME), attending webinars and conferences to learn about the latest technologies and best practices. I also subscribe to industry-specific journals and publications, such as Manufacturing Engineering and Control Engineering.

Furthermore, I regularly explore online resources like manufacturer websites, technical blogs, and online courses offered by platforms such as Coursera and LinkedIn Learning. This continuous learning ensures I’m aware of new sensor technologies, predictive maintenance techniques, and automation advancements.

Q 24. Explain your experience with different types of sensors and their role in machine monitoring.

My experience encompasses a wide range of sensors, including:

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors are crucial for monitoring heat generation and preventing overheating in machines. For example, I’ve used thermocouples to monitor the temperature of bearings in high-speed motors, triggering an alarm if temperatures exceed a safe threshold.

- Pressure Sensors: These are essential for monitoring pneumatic and hydraulic systems. I’ve utilized pressure transducers in various applications, such as regulating hydraulic press pressure to ensure consistent product quality.

- Vibration Sensors: Accelerometers and proximity sensors detect vibrations indicative of imbalance or impending mechanical failure. For instance, I used vibration data to predict bearing failure on a large industrial fan, allowing for proactive replacement and avoiding costly downtime.

- Optical Sensors: Photoelectric sensors are widely used in automation and quality control. They help detect product presence or absence, ensuring proper operation and reducing defects.

Understanding sensor types, their limitations, and how to interpret their data is fundamental to effective machine monitoring and preventative maintenance.

Q 25. How do you collaborate with other team members to ensure efficient machine operation and maintenance?

Effective collaboration is vital. I utilize various communication and coordination tools. Our team uses a shared maintenance management system to track work orders, schedule maintenance, and record findings. This system keeps everyone informed about ongoing issues and scheduled maintenance.

Regular team meetings are essential for discussing challenges, sharing best practices, and planning improvements. In addition, I actively participate in cross-functional discussions with engineers, production supervisors, and quality control personnel to align on machine performance goals and address any concerns collaboratively.

Open communication, active listening, and a willingness to share expertise are fundamental to building a strong collaborative environment that optimizes machine uptime and efficiency.

Q 26. Describe your understanding of different types of machine lubricants and their application.

Lubricants are critical for reducing friction, wear, and heat in machinery. My experience includes working with various types:

- Mineral Oils: These are widely used general-purpose lubricants, cost-effective and suitable for many applications. The choice depends on viscosity and temperature requirements.

- Synthetic Oils: Offer superior performance in extreme temperatures or harsh environments. They provide better oxidation resistance and longer service life compared to mineral oils. I’ve used synthetic oils in high-temperature applications to improve machine reliability.

- Grease: Used for applications requiring long-term lubrication and protection against dust and moisture. Different grease types exist, each tailored to specific load, temperature, and speed conditions.

- Specialty Lubricants: These include high-temperature greases, food-grade lubricants, and extreme pressure (EP) lubricants designed for specific applications with high stress or load.

Selecting the appropriate lubricant is critical. Improper lubrication can lead to premature wear, component failure, and increased maintenance costs.

Q 27. What is your experience with hydraulic and pneumatic systems in machinery?

I possess extensive experience with both hydraulic and pneumatic systems. Hydraulic systems use pressurized liquids to generate force and motion, while pneumatic systems use compressed air.

In hydraulic systems, I’ve worked with troubleshooting leaks, adjusting pressure regulators, and maintaining hydraulic fluid levels. Understanding hydraulic schematics and pressure-flow relationships is critical for effective maintenance and repair. I am also proficient in diagnosing problems related to hydraulic pumps, valves, and actuators.

With pneumatic systems, my experience involves troubleshooting air leaks, inspecting air filters and regulators, and maintaining proper air pressure. I am skilled in identifying problems in pneumatic cylinders, valves, and related components.

Q 28. How do you handle situations where machine settings need to be adjusted due to material changes?

Material changes often necessitate adjustments to machine settings to maintain optimal performance and product quality. This requires a careful understanding of the properties of the new material and how they affect the machining process.

My approach involves first reviewing the material specifications—including hardness, density, and machinability—and consulting relevant process documentation. Based on this information, I make informed adjustments to parameters like feed rate, speed, depth of cut (for machining operations), pressure (for forming operations), or temperature (for processes involving heat).

I conduct careful test runs after each adjustment, monitoring for changes in quality, efficiency, and overall machine performance. Data logging and analysis are vital for optimizing settings and minimizing waste. This iterative process ensures efficient and safe operation with the new material.

Key Topics to Learn for Monitor and Adjust Machine Settings Interview

- Understanding Machine Operation: Grasp the fundamental principles behind the machines you’ll be monitoring. This includes understanding their input, process, and output stages.

- Parameter Identification and Adjustment: Learn to identify key parameters that influence machine performance (e.g., speed, temperature, pressure). Practice adjusting these parameters safely and effectively based on established procedures and best practices.

- Data Interpretation and Analysis: Develop your skills in interpreting data from machine monitoring systems. Learn to recognize trends, anomalies, and potential issues based on real-time and historical data.

- Troubleshooting and Problem Solving: Practice diagnosing and resolving common machine malfunctions. This includes using diagnostic tools and following established troubleshooting procedures.

- Safety Procedures and Protocols: Demonstrate a thorough understanding of safety regulations and protocols related to machine operation and maintenance. This is crucial for ensuring a safe working environment.

- Preventive Maintenance Techniques: Familiarize yourself with preventative maintenance procedures to minimize downtime and extend machine lifespan. Understanding the importance of regular checks and cleaning is vital.

- Documentation and Reporting: Practice documenting machine settings, maintenance activities, and any issues encountered. Clear and concise reporting is essential for effective communication within a team.

- Quality Control and Assurance: Understand the role of machine settings in ensuring consistent product quality. Learn how to adjust settings to meet specific quality standards.

Next Steps

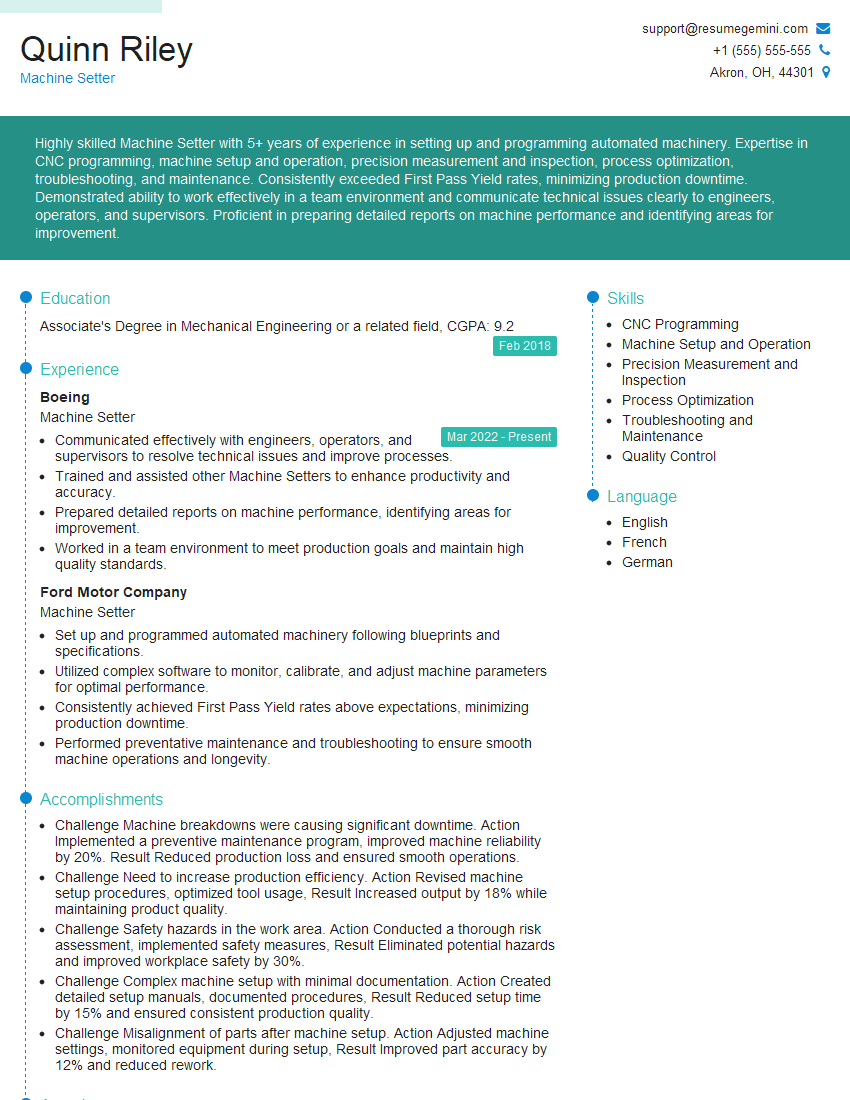

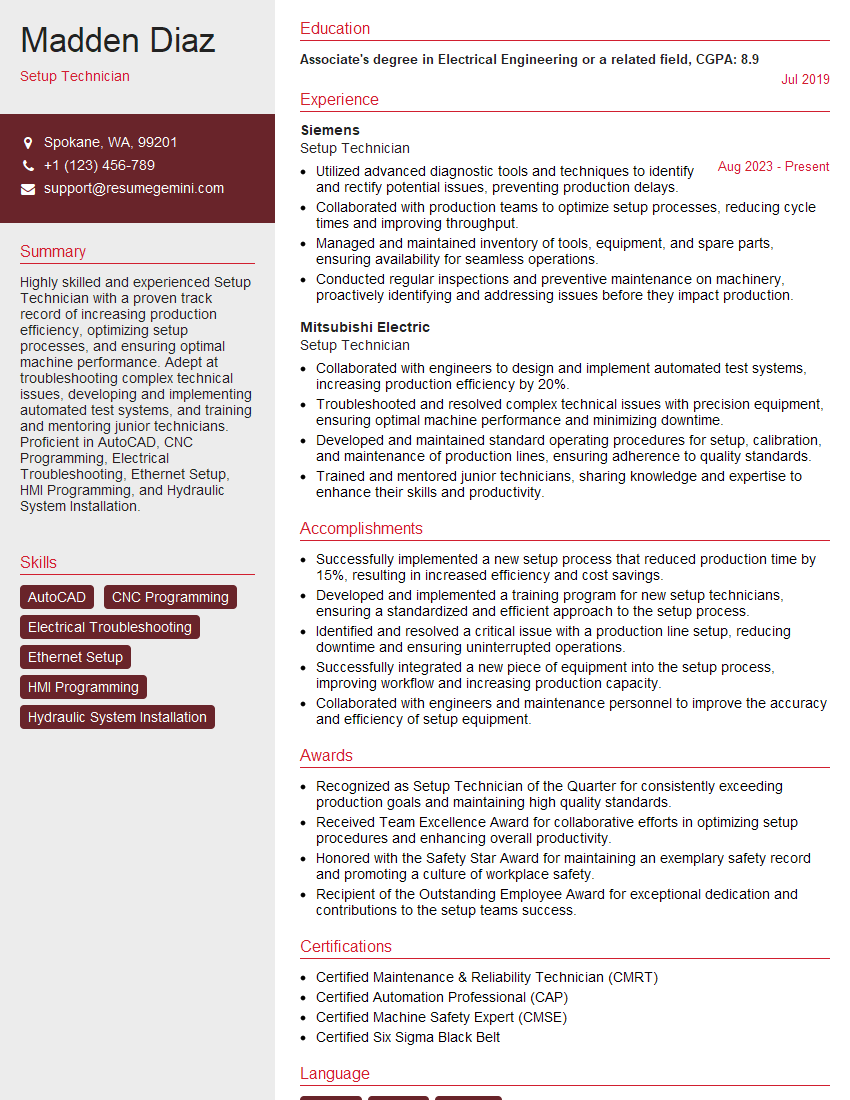

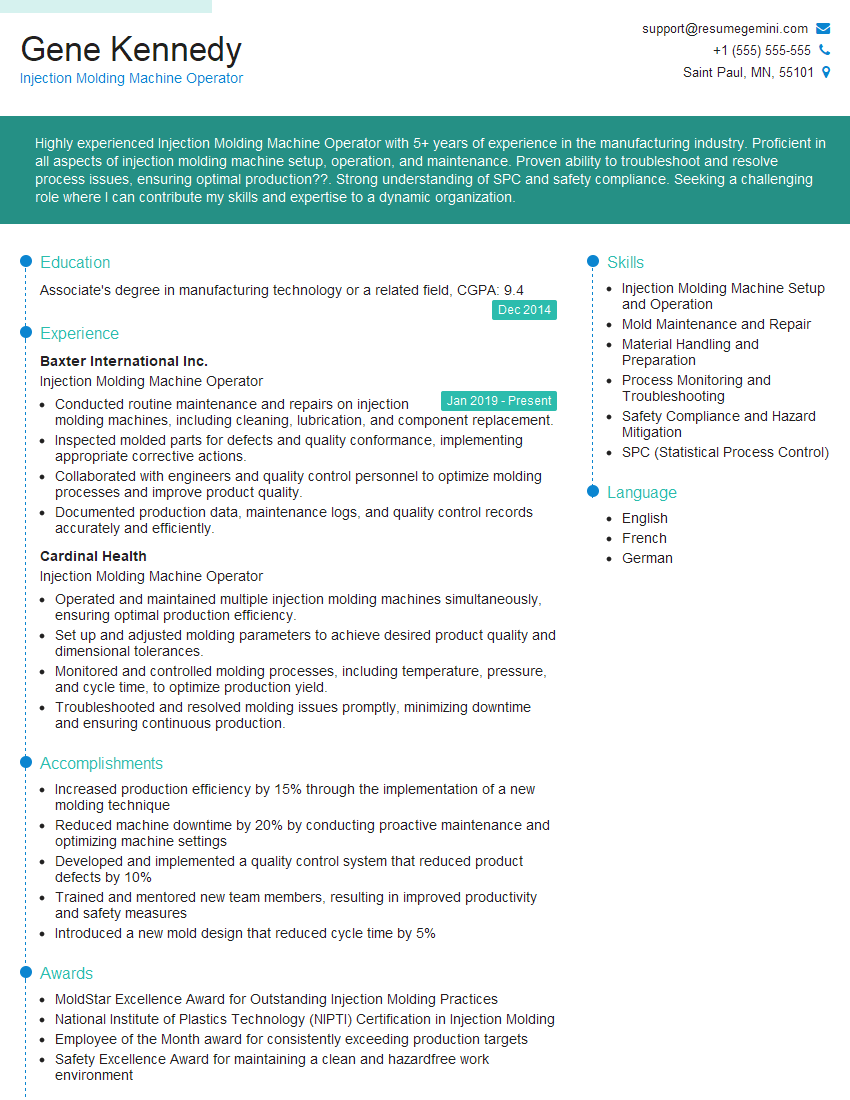

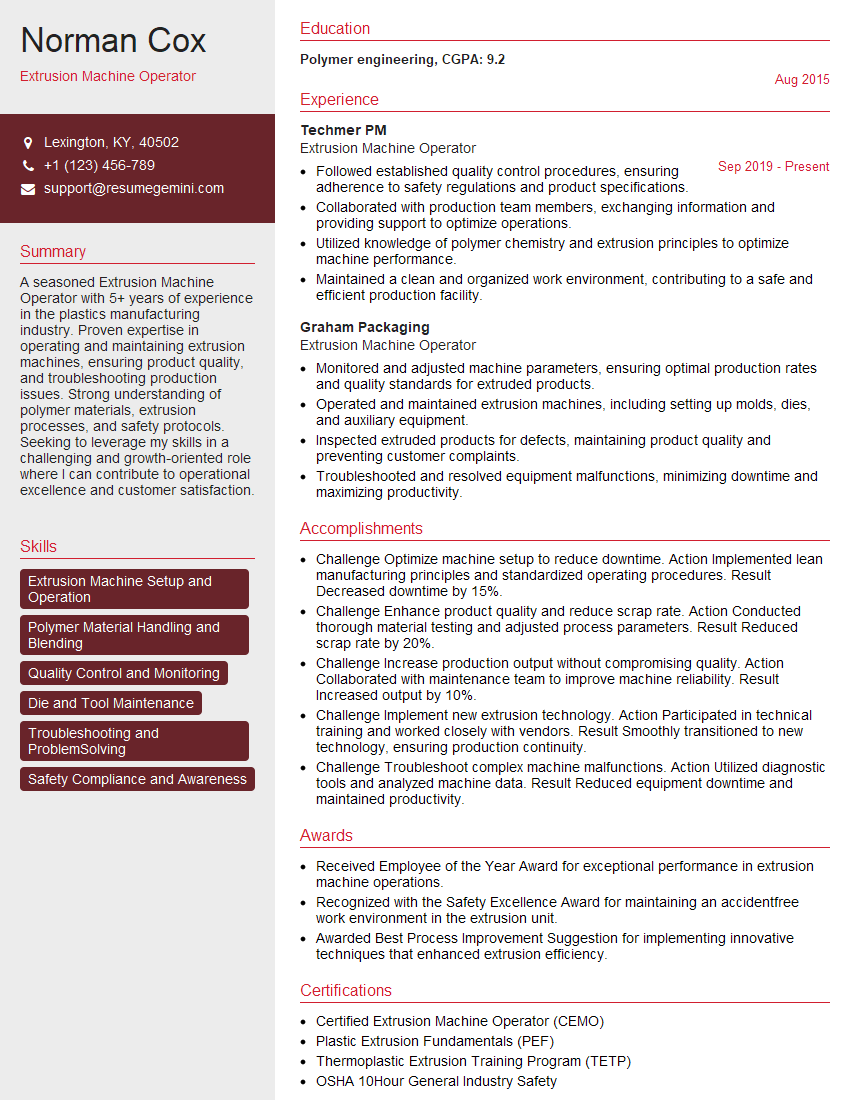

Mastering the skills of monitoring and adjusting machine settings is paramount for career advancement in many technical fields. It demonstrates your practical abilities, problem-solving skills, and commitment to efficiency and quality. To significantly boost your job prospects, create an ATS-friendly resume that highlights these crucial skills. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to the “Monitor and adjust machine settings” role to help you get started. Take advantage of these resources to showcase your abilities and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good