The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Production Line Knowledge interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Production Line Knowledge Interview

Q 1. Describe your experience with Lean Manufacturing principles.

Lean Manufacturing is a philosophy focused on eliminating waste and maximizing value for the customer. It’s about streamlining processes, reducing inventory, and improving efficiency. My experience spans several years, implementing Lean principles across various manufacturing environments. For instance, in a previous role, we implemented 5S (Sort, Set in Order, Shine, Standardize, Sustain) to drastically improve workplace organization. This resulted in a 15% reduction in search time for parts, directly translating to increased production output. We also used value stream mapping to identify and eliminate non-value-added steps in our assembly line, leading to a 10% reduction in lead time. I’m proficient in using tools like Kaizen events (continuous improvement workshops) and Kanban systems (visual workflow management) to drive efficiency and waste reduction. Lean isn’t just about tools though; it’s about a cultural shift toward continuous improvement and employee empowerment.

Q 2. Explain your understanding of Six Sigma methodologies.

Six Sigma is a data-driven methodology aimed at minimizing defects and variability in any process. It uses statistical methods to identify and eliminate the root causes of defects, striving for near-perfection (six standard deviations from the mean). My understanding encompasses DMAIC (Define, Measure, Analyze, Improve, Control), the most common Six Sigma methodology. I’ve used DMAIC to troubleshoot recurring issues on the production line, such as a high failure rate in a specific component. Through data analysis, we discovered a problem with the supplier’s raw materials. By implementing a stricter quality control process with the supplier and incorporating a new testing method within our own production process, we reduced the defect rate by over 80%. I also have experience with Design for Six Sigma (DFSS), which focuses on designing processes and products to prevent defects from the outset.

Q 3. How would you optimize a production line experiencing bottlenecks?

Optimizing a bottlenecked production line requires a systematic approach. First, you need to identify the bottleneck – the point in the process that limits overall output. This often involves analyzing cycle times, capacity utilization, and inventory levels at each stage. Once the bottleneck is identified, several strategies can be employed. This could involve increasing the capacity of the bottleneck station, perhaps through adding more equipment, automating the process, or improving worker efficiency through training or ergonomic improvements. Another approach is to rebalance the line by adjusting the workload at other stations to match the bottleneck’s capacity. This might involve reassigning tasks or implementing buffer stocks to smooth out variations in upstream processes. It’s also crucial to analyze the root cause of the bottleneck. Is it due to equipment malfunction, inefficient processes, or insufficient staffing? Addressing the root cause is key to a sustainable solution. A combination of these strategies, informed by data analysis, is often the most effective approach.

Q 4. What are the key performance indicators (KPIs) you monitor in a production line?

The key performance indicators (KPIs) I monitor in a production line depend on the specific goals and context, but generally include:

- Overall Equipment Effectiveness (OEE): Measures the percentage of time equipment is producing good parts.

- Throughput: The total number of units produced within a given timeframe.

- Cycle Time: The time it takes to produce one unit.

- Defect Rate: The percentage of defective units produced.

- Inventory Turnover: How quickly inventory is used and replenished.

- Lead Time: The time it takes from order placement to product delivery.

- Labor Productivity: Output per labor hour.

- Safety Incidents: Number of accidents or near misses.

Regular monitoring of these KPIs allows for proactive identification of potential problems and enables data-driven decision-making to improve efficiency and quality.

Q 5. Describe your experience with different production scheduling techniques.

My experience with production scheduling techniques includes various methods, each suited to different contexts. I’m proficient in:

- First-In, First-Out (FIFO): Simple and easy to understand, but can be inefficient if demand fluctuates.

- Last-In, First-Out (LIFO): Useful for perishable goods, but can lead to inventory obsolescence.

- Material Requirements Planning (MRP): A more advanced system that calculates the required materials and schedules production to meet demand while minimizing inventory.

- Capacity Requirements Planning (CRP): Ensures that the production schedule is feasible given the available capacity.

- Just-in-Time (JIT): Aims to produce goods only when needed, minimizing inventory and waste. Requires close coordination with suppliers and highly efficient production processes.

The choice of technique depends on factors like demand variability, lead times, inventory costs, and the complexity of the production process. I’ve successfully implemented MRP in high-volume manufacturing environments and JIT in lean manufacturing settings.

Q 6. How do you handle unexpected downtime on a production line?

Handling unexpected downtime requires a structured response. My approach involves:

- Immediate Action: Quickly assess the situation to determine the cause of the downtime and its severity. Is it a minor issue that can be quickly resolved, or does it require specialized expertise and potentially halt the entire line?

- Root Cause Analysis: Once the immediate problem is addressed, a thorough investigation is conducted to identify the underlying cause of the downtime. This often involves data analysis, operator interviews, and equipment inspection.

- Corrective Actions: Implement the necessary corrective actions to prevent future occurrences of the same problem. This might involve repairs, process improvements, or operator retraining.

- Communication: Keep all relevant stakeholders informed of the situation, the planned actions, and any potential impact on production schedules.

- Documentation: Maintain detailed records of the downtime event, including the cause, the actions taken, and the results. This data is valuable for continuous improvement efforts.

In practice, this involves collaborating with maintenance teams, production supervisors, and potentially external experts to effectively and efficiently resolve the issue and minimize the impact on production targets.

Q 7. What is your experience with preventative maintenance?

Preventative maintenance (PM) is crucial for minimizing unexpected downtime and maximizing equipment lifespan. My experience includes developing and implementing PM schedules based on equipment manufacturers’ recommendations, historical data on equipment failures, and best practices. This involves establishing a routine inspection and maintenance program that includes regular lubrication, cleaning, adjustments, and component replacements before they fail. I’ve also used Computerized Maintenance Management Systems (CMMS) to track PM activities, manage spare parts inventory, and generate reports on equipment performance and maintenance costs. In one instance, implementing a robust PM program for our critical machinery reduced unplanned downtime by 40% within a year. Proactive maintenance is far more cost-effective than reactive repairs, and it contributes significantly to improving overall equipment effectiveness (OEE).

Q 8. Explain your understanding of Kaizen events.

Kaizen events, also known as Kaizen workshops or rapid improvement events, are focused, short-term projects designed to significantly improve a specific process or area within a production line. Think of them as intense problem-solving sprints. They typically involve a cross-functional team working together for a few days to identify, analyze, and implement solutions to a predefined problem. The goal isn’t just incremental improvement, but rather dramatic, noticeable change.

How they work: A team, often including line workers, supervisors, engineers, and quality control personnel, gathers to analyze a particular process, identifying bottlenecks, inefficiencies, or defects. Using tools like value stream mapping and 5 Whys, the root causes of the problem are identified. Then, the team brainstorms and implements countermeasures. Finally, they standardize the improvements to prevent regression.

Example: In a bottling plant, a Kaizen event might focus on reducing downtime caused by bottle jams. The team would analyze the filling process, identify the causes of jams (e.g., inconsistent bottle placement, faulty sensors), and implement solutions (e.g., improved bottle guides, sensor recalibration). The improvements are then documented and implemented across the entire line.

Q 9. How do you ensure quality control within a production line?

Quality control in a production line is a multifaceted process ensuring products consistently meet predetermined specifications. This involves proactive measures to prevent defects and reactive measures to identify and correct them. It’s not just about checking finished goods; it’s about building quality into every step of the process.

- Preventive Measures: This includes using high-quality materials, properly training personnel, regularly maintaining equipment, and implementing robust processes. Statistical Process Control (SPC) techniques like control charts are vital for monitoring process variations and identifying potential problems early.

- Reactive Measures: Regular quality checks at various stages of production identify defects before they reach the customer. This might involve visual inspections, automated testing, and sampling. A crucial element is effective root cause analysis for identifying the source of defects and preventing recurrence. Corrective actions are documented and implemented.

- Data Analysis: Tracking key metrics (defect rates, yield, customer returns) provides crucial insights into process performance. This data informs improvements to processes and allows for targeted intervention.

Example: In a car manufacturing plant, quality checks might include regular inspections of welded joints, automated testing of electronic systems, and paint quality assessments. Statistical Process Control charts monitor crucial parameters like weld strength and paint thickness, alerting personnel to any deviations.

Q 10. How familiar are you with different types of production layouts (e.g., U-shaped, assembly line)?

I’m very familiar with various production layouts. The choice of layout significantly impacts efficiency, workflow, and overall productivity.

- Assembly Line: This linear layout is best suited for high-volume production of standardized products. Each workstation performs a specific task, with the product moving sequentially along the line. It’s efficient but lacks flexibility.

- U-shaped Line: This layout is more compact and improves worker collaboration. It allows for easier material handling and reduces transportation time. This layout is also beneficial for smaller batch production.

- Cellular Manufacturing: This layout groups workstations into cells that produce a family of related parts or products. It’s ideal for products with moderate volume and variety.

- Functional Layout: Workstations are grouped based on function (e.g., machining, assembly). It’s flexible but can result in longer transportation times and higher work-in-process (WIP) inventory.

Example: A car assembly line is a classic example of a linear layout, while a smaller electronics manufacturer might opt for a U-shaped line or cellular manufacturing to balance efficiency and flexibility.

Q 11. Describe your experience with inventory management within a production setting.

Effective inventory management in a production setting is crucial for optimizing costs, minimizing waste, and ensuring timely production. It’s a balancing act between having enough materials on hand to meet demand and avoiding excessive inventory that ties up capital and risks obsolescence.

- Just-in-Time (JIT) Inventory: This approach aims to minimize inventory by receiving materials only when needed. It reduces storage costs and waste but requires precise forecasting and reliable suppliers.

- Materials Requirements Planning (MRP): This system uses a bill of materials (BOM) and production schedule to calculate the required quantities and timing of materials. It helps prevent shortages and ensures timely procurement.

- Kanban Systems: This visual system uses cards or signals to trigger the replenishment of materials. It is a simpler, visual approach often used in lean manufacturing environments.

- Inventory Tracking and Management Software: Systems like ERP software help track inventory levels, manage orders, and forecast demand.

Example: In a furniture factory, implementing an MRP system would ensure that the necessary wood, screws, and other materials are available at the right time to avoid production delays. A Kanban system could manage the flow of parts between different workstations within the factory.

Q 12. How would you troubleshoot a production line malfunction?

Troubleshooting a production line malfunction requires a systematic approach. It’s about moving from general observation to targeted investigation and solution.

- Identify the Problem: Clearly define the malfunction. What exactly is happening? When did it start? What are the symptoms?

- Gather Information: Collect data from various sources. Check machine logs, talk to operators, review quality control reports. Are there error messages?

- Isolate the Cause: Using logical deduction and potentially elimination testing, pinpoint the root cause. Is it a mechanical failure, a software glitch, a problem with materials, or something else?

- Implement Corrective Actions: Repair or replace faulty components. Update software. Adjust process parameters. Implement interim solutions if necessary.

- Verify the Solution: After implementing the fix, run tests to ensure the problem is resolved and the line is functioning correctly.

- Document the Process: Record the details of the malfunction, the troubleshooting steps, and the solution implemented. This helps prevent recurrence.

Example: If a bottling line stops due to a sensor malfunction, the troubleshooting process would involve checking the sensor readings, inspecting the wiring, and potentially replacing the sensor. The process would be documented to prevent similar issues in the future.

Q 13. What software or systems are you familiar with for production line management?

I’m proficient in several software and systems for production line management, including:

- Manufacturing Execution Systems (MES): These systems integrate data from various sources (e.g., PLCs, SCADA) to provide real-time visibility into production processes. Examples include Siemens Opcenter and Rockwell Automation FactoryTalk.

- Enterprise Resource Planning (ERP) Systems: Systems like SAP and Oracle provide broader enterprise management capabilities, including production planning, inventory control, and supply chain management.

- Supervisory Control and Data Acquisition (SCADA) Systems: These are used to monitor and control industrial processes, providing real-time data visualization and alerts.

- Computer Numerical Control (CNC) Programming Software: I’m familiar with software used to program and control CNC machines.

- Statistical Process Control (SPC) Software: Software packages for creating and analyzing control charts to monitor process variations.

My experience includes using these systems to optimize production schedules, track performance metrics, and identify areas for improvement. I understand how to integrate data from various sources to provide a comprehensive view of the production process.

Q 14. How do you manage and motivate a team in a production line environment?

Managing and motivating a production line team requires a blend of leadership styles, communication strategies, and a focus on creating a positive and productive work environment.

- Clear Communication: Maintaining open and transparent communication is essential. Keep the team informed about production goals, challenges, and changes. Regularly provide feedback and recognize accomplishments.

- Empowerment and Collaboration: Involve the team in problem-solving and decision-making. Empower them to take ownership of their work and contribute their ideas. Foster a collaborative atmosphere where team members support each other.

- Training and Development: Provide ongoing training and development opportunities to enhance skills and knowledge. Investing in your team’s growth is an investment in the company’s success.

- Fairness and Recognition: Treat everyone fairly and recognize individual and team accomplishments. Positive reinforcement can significantly impact motivation and productivity.

- Safety and Well-being: Prioritize safety and create a work environment that respects employee well-being. Addressing safety concerns and promoting a healthy work-life balance are crucial.

Example: I once led a team through a significant production increase by implementing a Kaizen event and actively involving the team in every step. Recognizing their contributions and celebrating our success boosted morale and productivity.

Q 15. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a systematic process for identifying the underlying causes of problems, rather than just treating the symptoms. It’s crucial in production lines because addressing only the surface issue often leads to recurring problems. My approach typically involves using a combination of techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis.

For instance, if a production line repeatedly produces defective products due to a consistently low-quality input material, simply rejecting the defective products is treating the symptom. RCA would delve deeper: Why is the input material low quality? (Perhaps the supplier changed its process). Why did the supplier change its process? (Maybe due to cost-cutting measures). By repeatedly asking ‘why’ and investigating each answer, we can pinpoint the root cause – potentially a lack of supplier quality control – and implement a long-term solution like changing suppliers or implementing stricter quality checks at the receiving end.

I also find fault tree analysis particularly helpful for complex issues, allowing me to visually map potential causes and their contributing factors. This helps prioritize corrective actions and ensures a comprehensive approach to problem-solving.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of Total Productive Maintenance (TPM).

Total Productive Maintenance (TPM) is a philosophy that aims to maximize equipment effectiveness by involving all employees in maintenance activities. It’s more than just fixing broken machines; it’s about proactively preventing breakdowns and improving overall equipment effectiveness (OEE). This involves a holistic approach, engaging everyone from operators to managers in maintaining the production line’s health.

My experience with TPM includes implementing autonomous maintenance programs where line operators are trained to perform basic maintenance tasks, improving their understanding of the equipment and empowering them to identify potential problems early on. This reduces downtime significantly. We also implemented planned maintenance schedules using CMMS (Computerized Maintenance Management Systems) software, ensuring preventative measures are consistently carried out.

A key aspect of TPM is focusing on small improvements. For example, implementing standardized procedures for cleaning and lubricating equipment reduces wear and tear. This might seem insignificant individually, but the cumulative effect is a dramatic improvement in equipment lifespan and operational efficiency.

Q 17. How do you improve efficiency in a production line?

Improving production line efficiency involves a multi-faceted approach, targeting areas like reducing downtime, optimizing processes, and improving quality. It’s not a one-size-fits-all solution, and strategies must be tailored to the specific production line and its challenges.

- Reduce Downtime: Implementing preventative maintenance programs as part of TPM is crucial. This involves regular inspections, cleaning, lubrication, and minor repairs to avoid major breakdowns. Also, optimizing changeover times between production runs using techniques like SMED (Single Minute Exchange of Die) significantly reduces downtime.

- Optimize Processes: Lean manufacturing principles like value stream mapping can be used to identify and eliminate waste (muda) in the production process. This involves analyzing each step of the process to determine its value-add and removing non-value-added activities. Process optimization often involves workflow improvements, eliminating bottlenecks, and streamlining tasks.

- Improve Quality: High-quality products reduce rework and scrap, improving overall efficiency. This requires implementing rigorous quality control checks throughout the process and continuous improvement measures using techniques like Kaizen (continuous improvement).

For example, in a previous role, we implemented SMED to reduce changeover time by 50%, resulting in a significant increase in production output without needing to purchase additional equipment. This showcases how focusing on process optimization can yield significant results.

Q 18. What is your experience with implementing and improving safety protocols on a production line?

Safety is paramount in any production environment. My experience in implementing and improving safety protocols includes developing and delivering safety training programs, conducting regular safety audits, and actively participating in incident investigations.

I’ve worked on implementing various safety measures, such as implementing lockout/tagout procedures for equipment maintenance, ensuring proper use of Personal Protective Equipment (PPE), and creating clear visual safety guidelines on the production floor. This includes not just providing training but also ensuring that the equipment is designed with safety features in mind.

A critical aspect is establishing a strong safety culture where every employee feels responsible for their own safety and the safety of their colleagues. This is achieved through regular safety meetings, open communication channels, and a system for reporting near misses and accidents without fear of reprisal. Following an incident, a thorough investigation using RCA methods is vital to understand the root causes and to prevent similar incidents from occurring.

Q 19. Describe a time you had to solve a complex problem on a production line.

One challenging situation involved a sudden and unexplained increase in product defects. Initial investigations pointed towards multiple potential causes, making it difficult to identify the root cause. We started by using a Fishbone diagram to brainstorm potential causes, categorizing them into factors like machinery, materials, manpower, and methods. After careful data analysis, we discovered a subtle change in the temperature settings of a critical machine, even though the settings were within the ‘acceptable range’ according to the manual.

The ‘acceptable range’ was quite wide. We narrowed down the acceptable parameters based on historical data and rigorous testing, making the optimal temperature setting more precise. The solution involved not only adjusting the machine but also upgrading the temperature control system for greater precision. This resulted in a dramatic reduction in defects and a more robust process. This case highlighted the importance of not just reacting to immediate symptoms but carefully examining all potential contributing factors and even questioning seemingly acceptable parameters.

Q 20. How do you handle conflicts within a production team?

Conflicts within a production team are inevitable, but how they’re handled significantly impacts team morale and productivity. My approach involves fostering open communication, understanding the root causes of the conflict, and finding mutually acceptable solutions.

I encourage team members to voice their concerns and actively listen to differing perspectives. Sometimes, conflicts arise from misunderstandings or unclear expectations. In such cases, clarifying roles, responsibilities, and processes often resolves the issue. When the conflict stems from personality clashes or more complex issues, I facilitate a structured discussion, focusing on the issue at hand rather than personal attacks. Mediation is sometimes needed, ensuring that all parties feel heard and that a fair resolution is reached. The key is to create a safe space for communication and collaboration. The goal is always to find a solution that supports both the team and the overall production goals.

Q 21. What are the common causes of production line errors?

Production line errors have various root causes, broadly categorized into:

- Equipment Malfunctions: This includes mechanical failures, sensor errors, and software glitches. Preventative maintenance and regular equipment calibration are crucial to minimize this.

- Material Defects: Poor-quality raw materials, incorrect material specifications, or improper handling can all lead to errors. Strict quality control measures for incoming materials are vital.

- Process Errors: These include incorrect settings on machinery, flawed process steps, or insufficient training for operators. Standardized work procedures, clear instructions, and regular operator training are essential.

- Human Error: Mistakes made by operators, such as incorrect assembly, misreading instructions, or fatigue, are common. Ergonomic design of workstations, sufficient breaks, and operator training can mitigate human error.

- Environmental Factors: Temperature fluctuations, humidity, or dust can affect equipment performance and product quality. Maintaining a controlled environment is crucial for sensitive production processes.

Understanding these categories helps in implementing targeted solutions. Using RCA to dig deeper into the specifics of each error helps determine the root cause and implement effective corrective actions, preventing future occurrences.

Q 22. Explain your understanding of production line balancing.

Production line balancing aims to distribute workload evenly across all workstations in a production line. The goal is to minimize idle time and maximize efficiency, ensuring a smooth and consistent flow of products. Think of it like a relay race; you want each runner (workstation) to complete their leg in roughly the same time so there’s no bottleneck.

The process involves analyzing the task times for each operation in the production process and assigning them to workstations such that the cycle time (the time it takes to produce one unit) is minimized and balanced across all workstations. This often involves techniques like precedence diagrams (visual representations of task dependencies) and algorithms to optimize workstation assignments. For example, if one workstation takes significantly longer than others, it creates a bottleneck, slowing down the entire line. Line balancing helps to identify and address these bottlenecks.

In practice, we might use software or specialized techniques to achieve optimal balance. For instance, we could employ heuristics, which provide near-optimal solutions quickly, or more complex algorithms like the Ranked Positional Weight method for improved precision.

Q 23. How familiar are you with different types of production processes (e.g., continuous flow, batch)?

I’m very familiar with various production processes. They differ significantly in how materials flow and how production is organized. Let’s look at two key examples:

- Continuous Flow Production: This involves a constant, uninterrupted flow of materials through the production line, typically used for high-volume, standardized products like soft drinks or petroleum. There’s minimal work-in-progress (WIP) inventory, and the process is highly automated. Think of an assembly line for cars – a continuous stream of cars being built.

- Batch Production: This method produces goods in batches or groups of a specific quantity. It’s suitable for products with varying demand or those requiring more flexibility. Pharmaceuticals and bakery goods are common examples, as different batches might require different recipes or ingredients. There’s more WIP inventory compared to continuous flow.

Other types include job-shop production (customized, low-volume products), project-based production (unique, large-scale projects), and cellular manufacturing (grouping similar machines and operations into cells).

Q 24. What is your experience with data analysis related to production line performance?

I have extensive experience analyzing production line data to identify inefficiencies and improve performance. This typically involves working with data from various sources, including:

- Manufacturing Execution Systems (MES): These systems provide real-time data on production parameters, including cycle times, downtime, and defect rates.

- Supervisory Control and Data Acquisition (SCADA) systems: These monitor and control industrial equipment, providing detailed information on machine performance.

- Quality control systems: These track defect rates and identify quality issues.

I utilize statistical methods like control charts, regression analysis, and process capability analysis to interpret this data and identify areas for improvement. For example, by analyzing cycle time data, I can pinpoint bottlenecks, and using defect rate analysis, I can identify the root causes of quality issues. I then translate these findings into actionable improvements, such as process adjustments or operator training.

Q 25. How do you ensure the accuracy of production data?

Data accuracy is paramount in production line management. I employ a multi-faceted approach:

- Data validation at the source: This involves implementing checks and balances at each data entry point to ensure accuracy before the data is processed.

- Regular data audits: I conduct periodic audits to compare production data with physical inventory and other relevant metrics to identify discrepancies.

- Data reconciliation: I use various techniques to reconcile differences between data sources. For instance, comparing data from MES and SCADA systems.

- Data redundancy and backup: Implementing systems that backup production data to prevent loss of information.

- Calibration and Maintenance of Sensors and Equipment: Ensuring that all the sensors and machinery producing the data are properly calibrated and maintained.

Any discrepancies are investigated thoroughly to identify and correct the root cause, improving the overall reliability of our data and making our decision-making process more robust. I also use data visualization to spot inconsistencies easily.

Q 26. Describe your experience with implementing new technologies on a production line.

I have experience implementing various new technologies to optimize production lines, including:

- Robotics and automation: I’ve been involved in integrating robots to automate repetitive or dangerous tasks, leading to improved efficiency, quality, and safety.

- Predictive maintenance: This involves using sensors and analytics to predict potential equipment failures, allowing for proactive maintenance and minimizing downtime.

- Advanced process control (APC): APC uses real-time data to automatically adjust process parameters, leading to improved process stability and reduced waste.

- IoT (Internet of Things) sensors: These provide real-time monitoring of various aspects of the production process, allowing for better decision-making and proactive issue resolution.

The implementation always follows a structured approach, including careful planning, risk assessment, training, and change management. For example, when introducing robotics, we had a phased rollout to minimize disruption and allow operators time to adapt to the new technology. Post-implementation, continuous monitoring and optimization are critical to ensure the technology delivers the expected results.

Q 27. How do you prioritize tasks in a fast-paced production environment?

Prioritizing tasks in a fast-paced environment requires a clear understanding of the production goals and potential disruptions. I typically use a combination of techniques:

- Urgency/Importance Matrix: This framework categorizes tasks based on their urgency and importance, allowing me to focus on high-impact, time-sensitive tasks first.

- Production schedule adherence: I strictly follow the established production schedule, prioritizing tasks that are critical for meeting deadlines and order fulfillment.

- Bottleneck identification and resolution: I continuously monitor the production line for bottlenecks, addressing them proactively to maintain flow.

- Visual management tools: Kanban boards or similar tools help provide a clear overview of tasks and their status, making prioritization more intuitive.

Effective communication with the team is crucial. Clearly defined roles and responsibilities prevent conflicts and ensure that everyone understands the priorities. Regular team meetings and quick daily stand-ups allow for adjustments in response to changing circumstances.

Q 28. Explain your understanding of Just-in-Time (JIT) inventory management.

Just-in-Time (JIT) inventory management is a production strategy that aims to minimize inventory holding costs by receiving materials and manufacturing goods only as they’re needed. Instead of large stockpiles, JIT relies on a highly efficient system to ensure a continuous flow of materials.

Key principles include:

- Reduced waste: Minimizing inventory reduces storage space, handling costs, and the risk of obsolescence or damage.

- Improved efficiency: Producing goods only when needed streamlines the production process and improves overall efficiency.

- Enhanced quality: JIT encourages a focus on quality control, as defects are identified and addressed quickly.

- Strong supplier relationships: JIT relies on close collaboration with suppliers to ensure timely delivery of materials.

However, JIT requires a highly reliable supply chain and accurate demand forecasting. Disruptions in the supply chain can severely impact production. Imagine a restaurant using a JIT approach; they order ingredients only for the anticipated number of customers, needing a strong supply chain and accurate customer prediction to avoid shortages or wastage.

Key Topics to Learn for Production Line Knowledge Interview

- Production Line Processes: Understanding the flow of materials, equipment, and labor within a production line. This includes analyzing process maps and identifying bottlenecks.

- Quality Control and Assurance: Knowing the methods used to ensure product quality, including inspection techniques, statistical process control (SPC), and root cause analysis (RCA) of defects. Practical application: Describing your experience identifying and resolving quality issues on a production line.

- Lean Manufacturing Principles: Familiarity with concepts like Kaizen, 5S, and value stream mapping, and how they are applied to optimize production line efficiency and reduce waste.

- Safety Procedures and Regulations: Demonstrating knowledge of relevant safety protocols, hazard identification, and risk mitigation strategies within a production environment. Practical application: Explaining your experience implementing safety improvements on a production line.

- Production Line Troubleshooting: Understanding common issues and their solutions. This includes problem-solving methodologies and preventative maintenance strategies. Practical application: Describing a situation where you successfully resolved a production line issue.

- Inventory Management: Understanding the importance of inventory control, including just-in-time (JIT) inventory systems and their impact on production efficiency.

- Production Metrics and KPIs: Familiarity with key performance indicators (KPIs) used to measure production line effectiveness, such as Overall Equipment Effectiveness (OEE) and cycle time. Practical application: Explaining how you’ve used KPIs to improve production line performance.

- Technology and Automation: Understanding the role of technology in modern production lines, including automated systems, robotics, and data analytics.

Next Steps

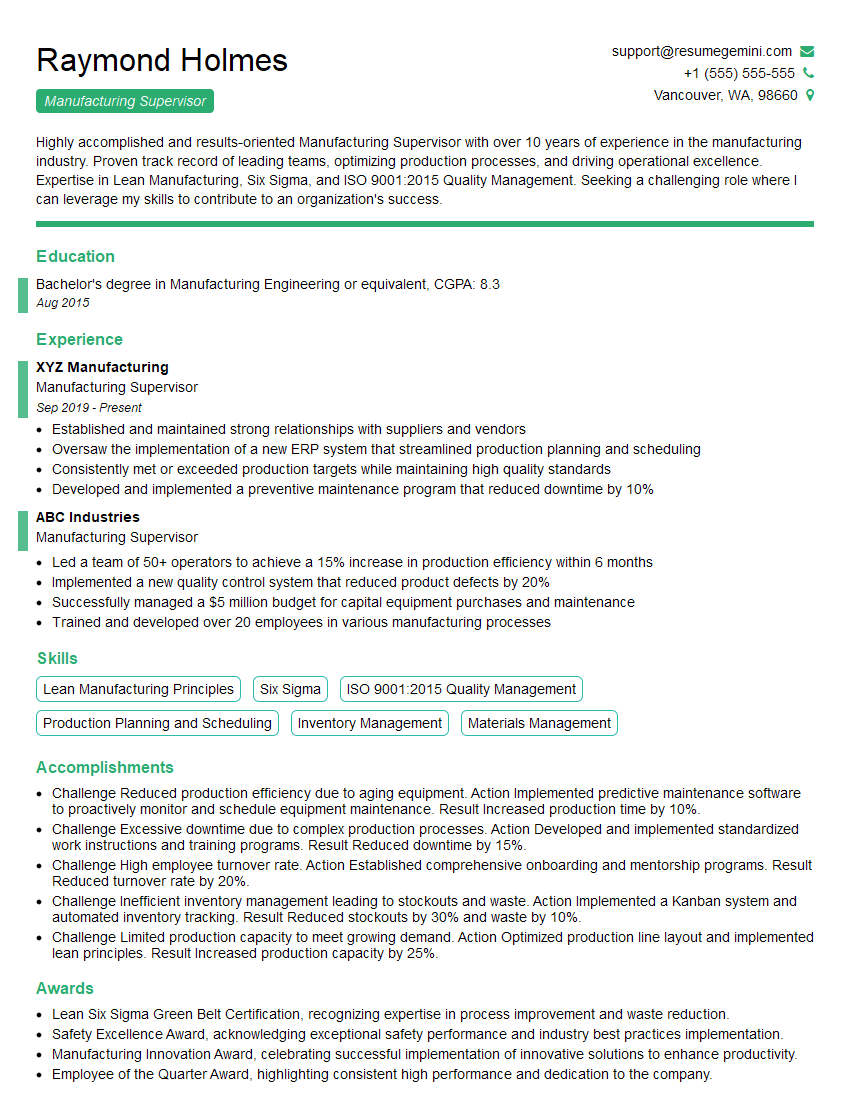

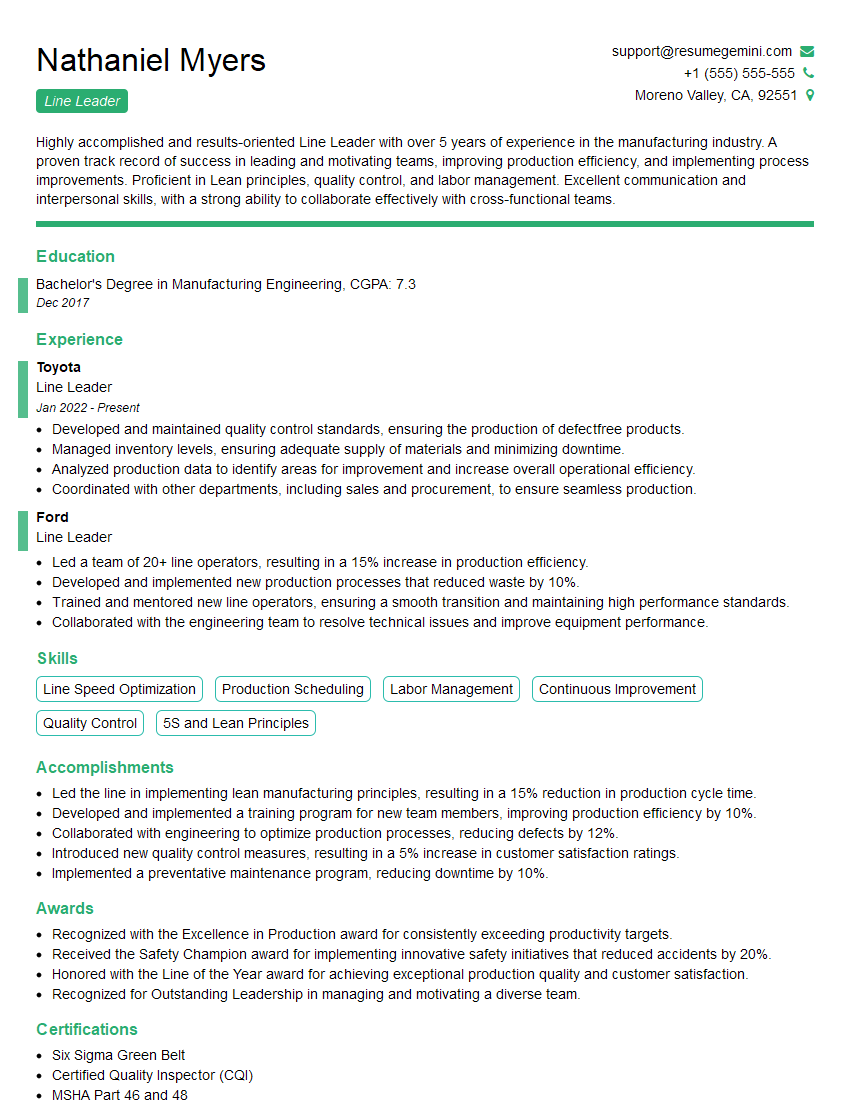

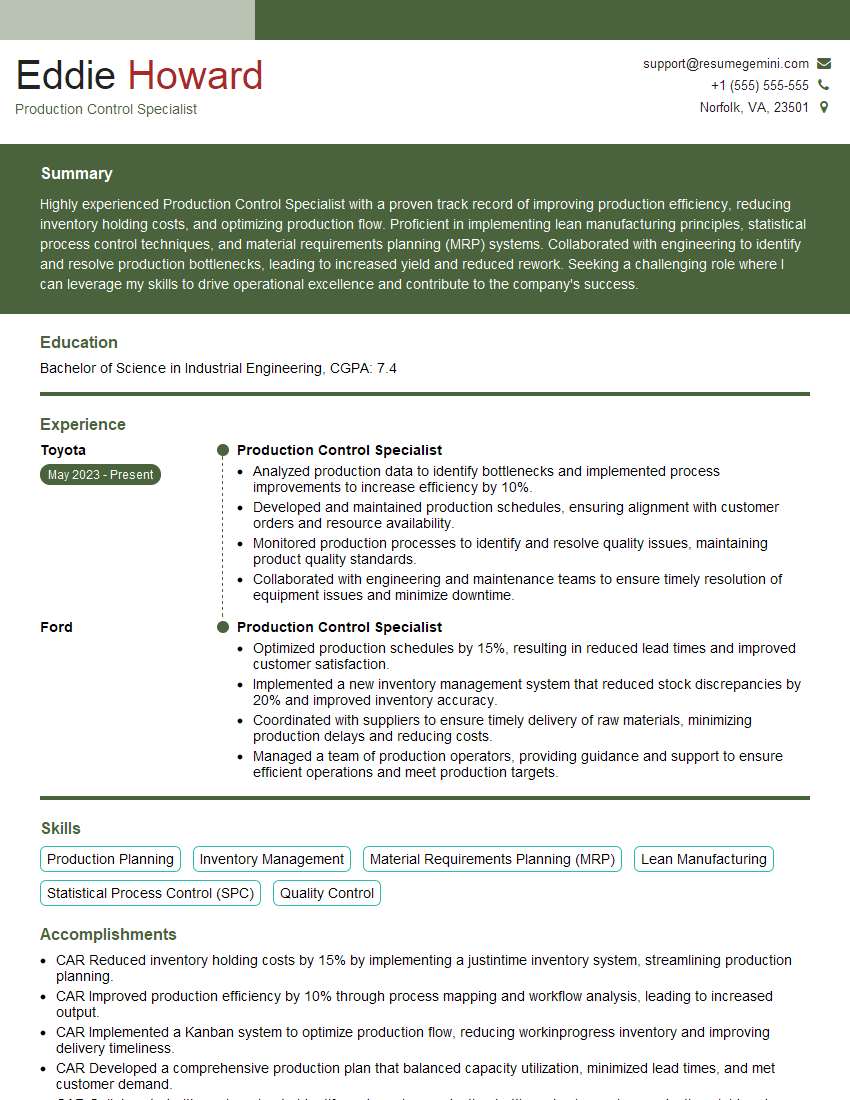

Mastering Production Line Knowledge is crucial for career advancement in manufacturing and related fields. It showcases your ability to contribute effectively to a team, solve complex problems, and drive efficiency improvements. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience clearly. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Production Line Knowledge expertise are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good