Are you ready to stand out in your next interview? Understanding and preparing for Moisture Monitoring and Control interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Moisture Monitoring and Control Interview

Q 1. Explain the different types of moisture meters and their applications.

Moisture meters are crucial tools for assessing moisture content in various materials. They come in several types, each designed for specific applications. The choice depends on the material being tested and the desired level of accuracy.

- Pin-type meters: These use pins that are inserted into the material to measure electrical resistance, which correlates to moisture content. They are suitable for wood, drywall, and other relatively homogenous materials. Think of them like tiny probes checking the material’s ability to conduct electricity – more moisture means better conductivity.

- Pinless meters: These use electromagnetic waves to measure moisture content without penetrating the material. They are non-destructive and suitable for surfaces like concrete, plaster, and flooring. Imagine them like a radar, sensing moisture from a distance.

- Hygrometers: These measure relative humidity in the air, useful for detecting humidity-related problems and verifying the effectiveness of drying methods. They are like a weather station for your building, indicating the overall dryness of the air.

- Moisture probes: These are more specialized sensors that can be inserted into materials or left in place for long-term monitoring. They provide continuous data and are valuable for tracking moisture levels over time. These are like permanent sensors providing real-time feedback.

- Capacitance meters: These meters work by measuring the material’s capacitance to determine moisture content. They’re useful in a range of applications and are particularly well-suited to measuring moisture content in materials like insulation.

For example, a contractor renovating a historic building might use a pinless meter to assess moisture levels in the plaster walls before beginning any work, avoiding costly damage from unforeseen moisture issues. A homeowner might use a pin-type meter to check for water damage in their wood flooring after a leak.

Q 2. Describe the process of interpreting moisture readings from various materials.

Interpreting moisture readings requires understanding the meter’s units (usually percentage of moisture content or moisture level) and the material’s properties. Each material has a different equilibrium moisture content (EMC), which is the moisture level it naturally reaches when exposed to a specific relative humidity and temperature.

For example, wood will naturally have a higher EMC than concrete at the same relative humidity. Readings above the EMC for a given material indicate a potential moisture problem. It’s essential to consult relevant standards and material specifications to determine acceptable moisture levels. Many moisture meters provide built-in reference values for common materials, simplifying the interpretation process. For instance, if a moisture meter reads 20% in wood flooring, and the EMC is 8%, you know there’s significant moisture intrusion. This should be investigated thoroughly. Visual inspection, such as looking for mold, mildew, or discoloration should supplement instrument readings.

Furthermore, consistent readings across multiple measurements in the same area provide stronger evidence of a moisture problem. Inconsistent readings could indicate localized issues rather than a widespread problem. Always maintain and calibrate your moisture meter according to the manufacturer’s instructions for accurate results.

Q 3. What are the common causes of moisture problems in buildings?

Moisture problems in buildings stem from a variety of sources, often interacting to create complex issues. These can broadly be categorized as:

- Water intrusion: This is the most common cause, including leaks from roofs, plumbing, windows, and exterior walls. Cracked foundations or improperly graded land can lead to water seeping into the building.

- Condensation: This occurs when warm, moist air comes into contact with a cold surface, causing water to condense. This is often seen in poorly insulated walls or attics, or areas with inadequate ventilation. A classic example is condensation on cold windows during winter.

- Rising damp: This occurs when moisture from the ground is drawn upwards into the building’s structure, typically through porous materials like brickwork. This can be exacerbated by poor drainage or a lack of a damp-proof course.

- Lack of ventilation: Inadequate ventilation allows moisture from everyday activities (showers, cooking, breathing) to accumulate in the building, leading to high humidity levels and potential mold growth.

- Material defects: Using materials with insufficient moisture resistance or improper installation techniques can create moisture pathways into the building.

For instance, a leaky roof can cause water damage to ceilings and walls, leading to mold growth and structural damage. Conversely, inadequate ventilation in a bathroom can lead to persistent high humidity and the development of black mold.

Q 4. How do you determine the source of a moisture intrusion?

Pinpointing the source of moisture intrusion requires a systematic approach combining investigation techniques. A simple visual inspection often reveals obvious sources, such as visible leaks or water stains. However, more hidden sources require a detailed investigation.

- Visual inspection: Look for signs of water damage such as discoloration, staining, bubbling paint, or mold growth.

- Moisture mapping: Using a moisture meter to systematically scan surfaces and identify areas with elevated moisture levels provides a visual representation of moisture distribution within the building.

- Thermal imaging: Infrared cameras can detect temperature differences, which can indirectly indicate moisture problems since wet areas tend to be colder. It allows for the detection of moisture behind walls or other building materials.

- Tracer dye testing: In some cases, dye can be added to the water supply to identify the source of a leak by tracking the dye’s movement.

- Destructive testing: In extreme cases where the source is not readily apparent, destructive testing may be required. This might include opening up walls or ceilings to inspect for water damage or plumbing leaks.

For example, if moisture mapping reveals high moisture levels in a specific section of a wall, further investigation might involve opening the wall to uncover a hidden plumbing leak or damaged flashing.

Q 5. Explain the different methods used for moisture remediation.

Moisture remediation involves a range of techniques tailored to the source and extent of the problem. The key is to address the source of the moisture intrusion, not just the symptoms.

- Drying: Dehumidifiers, air movers, and other drying equipment can remove excess moisture from the air and materials. This is frequently used after water damage events.

- Ventilation improvements: Installing exhaust fans, increasing air circulation, and adding mechanical ventilation can reduce humidity levels and prevent moisture buildup.

- Repairing leaks: Addressing the root cause of water intrusion is crucial. This might involve repairing a leaky roof, fixing damaged plumbing, or replacing compromised flashing.

- Structural repairs: In cases of significant water damage or rising damp, structural repairs may be necessary. This could involve replacing damaged materials, installing a new damp-proof course, or improving drainage around the building.

- Chemical treatments: In some cases, chemical treatments, such as the application of fungicides or biocides, may be needed to eliminate mold or other biological growth that resulted from excessive moisture.

For instance, after a flood, a combination of drying equipment, structural repairs, and possibly chemical treatments might be required for a complete remediation.

Q 6. What are the health risks associated with high moisture levels in buildings?

High moisture levels in buildings pose significant health risks, primarily due to the growth of mold and other microorganisms. These can trigger various health problems including:

- Respiratory issues: Mold spores can irritate the respiratory system, causing coughing, wheezing, shortness of breath, and asthma attacks. People with pre-existing respiratory conditions are particularly vulnerable.

- Allergies and sensitivities: Mold and other allergens thriving in damp environments can trigger allergic reactions in susceptible individuals, leading to symptoms such as sneezing, runny nose, itchy eyes, and skin rashes.

- Infectious diseases: Some molds produce mycotoxins, which are toxic substances that can cause various health problems. In addition, damp conditions can provide breeding grounds for other infectious agents like bacteria.

- Neurological symptoms: Some studies have linked exposure to mold and dampness to neurological symptoms, such as headaches, dizziness, and cognitive impairment. This is still an active area of research.

It is critical to address moisture problems promptly, as the health consequences can range from mild discomfort to serious illness. Regular inspection and preventative measures are paramount to maintain a healthy indoor environment.

Q 7. What are the relevant building codes and standards related to moisture control?

Building codes and standards related to moisture control vary by region and jurisdiction but generally aim to prevent moisture problems and ensure a healthy and durable building envelope. Key areas covered include:

- Waterproofing: Requirements for proper waterproofing of roofs, basements, and exterior walls. For example, the International Building Code (IBC) has specific requirements for waterproofing materials and their installation.

- Drainage: Regulations for proper grading, drainage systems, and gutters to prevent water accumulation around the building. Improper drainage is a leading cause of foundation problems and subsequent moisture issues.

- Ventilation: Minimum ventilation requirements for bathrooms, kitchens, and other moisture-prone areas are often specified to prevent condensation and mold growth. The ASHRAE standards provide guidelines for building ventilation.

- Moisture barriers and vapor retarders: Building codes usually mandate the use of moisture barriers and vapor retarders in walls, roofs, and other parts of the building envelope to control moisture migration. The specific type and installation method are subject to regional climate conditions.

- Material specifications: Standards for materials such as concrete, wood, and insulation often include moisture-related requirements, specifying acceptable moisture content levels or resistance to water damage.

Staying current with relevant local building codes and standards is crucial for architects, engineers, contractors, and building inspectors to ensure compliance and prevent future moisture-related issues. Non-compliance can lead to costly repairs and litigation.

Q 8. Describe your experience with various moisture remediation techniques.

Moisture remediation techniques vary greatly depending on the source and extent of the moisture problem. My experience encompasses a wide range, from relatively simple solutions to complex, multi-faceted approaches.

Drying Techniques: This includes using dehumidifiers, air movers, and desiccant dehumidification for situations involving high humidity or standing water. For example, I’ve successfully used high-velocity air movers to dry out a water-damaged basement after a plumbing leak, significantly reducing drying time and minimizing mold growth.

Water Removal: This is the crucial first step in any remediation project. It involves extracting standing water using pumps, wet-dry vacuums, and specialized extraction equipment. I remember a project involving a burst pipe in a multi-story building; rapid water removal prevented extensive damage to lower floors.

Mold Remediation: When moisture leads to mold growth, specialized techniques are needed. This involves removing affected materials, cleaning surfaces with antimicrobial agents, and addressing the underlying moisture source to prevent recurrence. I’ve handled numerous mold remediation projects, adhering strictly to industry best practices and safety protocols.

Structural Repairs: Often, moisture problems necessitate structural repairs, such as fixing leaks in roofs, foundations, or pipes. This might involve working with contractors specializing in roofing, foundation repair, or plumbing to ensure a complete solution. For instance, I collaborated with a structural engineer to address a persistent basement leak stemming from a foundation crack.

Vapor Barriers and Insulation: Installing or repairing vapor barriers and improving insulation are crucial for preventing future moisture problems. I frequently advise clients on the proper placement and type of vapor barriers to prevent moisture migration. A recent project involved installing a continuous vapor barrier in a crawl space, dramatically reducing the humidity levels and preventing further moisture damage.

Q 9. How do you determine the appropriate course of action for different moisture problems?

Determining the appropriate course of action for moisture problems requires a systematic approach. It starts with a thorough investigation to pinpoint the source and extent of the problem.

Visual Inspection: A careful visual inspection identifies visible signs of moisture damage, such as water stains, mold growth, or warping of materials.

Moisture Meter Readings: Using various moisture meters (pinless, pin-type, and surface meters), I precisely measure the moisture content of building materials. This data helps identify areas of high moisture concentration.

Thermal Imaging: Thermal imaging can reveal hidden moisture problems by detecting temperature differences associated with moisture. Cold spots often indicate areas of elevated moisture content.

Hygrometer Readings: Relative humidity measurements pinpoint areas of high humidity, identifying potential sources of moisture intrusion. In conjunction with temperature readings, it also helps determine the potential for condensation.

Data Analysis & Reporting: I compile all data to produce a comprehensive report that details the moisture problem, its source(s), and a recommended remediation plan. The plan addresses the problem directly, minimizes disruption, and ensures long-term effectiveness. I present different options for clients, focusing on cost-effectiveness and minimizing environmental impact.

Q 10. What is the role of vapor barriers in moisture control?

Vapor barriers play a critical role in moisture control by preventing the movement of water vapor through building materials. Think of them as a shield against moisture intrusion. They’re typically composed of impermeable materials like polyethylene sheeting or specialized vapor-retardant paints.

Their primary function is to control the diffusion of water vapor, either from the outside into the building (in cold climates) or from the inside out (in humid climates). Proper installation is crucial; gaps or tears in the vapor barrier can negate its effectiveness. For example, a poorly installed vapor barrier in a wall cavity can lead to condensation within the wall assembly, promoting mold growth and structural damage. The location and type of vapor barrier depend on climate, building materials, and construction methods. Incorrect placement can lead to moisture accumulation, so careful consideration is essential.

Q 11. Explain the concept of dew point and its importance in moisture control.

The dew point is the temperature at which the air becomes saturated with water vapor, and condensation begins to form. It’s crucial in moisture control because when the temperature of a surface drops below the dew point of the surrounding air, moisture condenses on that surface. This condensation can lead to a number of issues, including mold growth, structural damage, and discomfort. Imagine a cold glass of water on a humid day; the condensation forming on the glass illustrates the dew point in action.

Understanding dew point allows us to predict potential condensation issues. By analyzing temperature and humidity levels, we can determine the likelihood of condensation occurring and take preventive measures, such as improving insulation or ventilation. For instance, in a building with poor insulation, we might see condensation forming on cold surfaces during winter months, indicating that the surface temperature has dropped below the dew point of the indoor air.

Q 12. How do you assess the effectiveness of moisture remediation efforts?

Assessing the effectiveness of moisture remediation involves a multi-pronged approach, ensuring both short-term and long-term success.

Re-testing Moisture Levels: After remediation, I conduct repeat moisture meter readings to verify that the moisture levels have returned to acceptable ranges. This provides a quantitative measure of the success of the intervention.

Visual Inspections: Visual inspections are done to observe the absence of visible signs of moisture damage, such as water stains, mold, or mildew growth. This confirms the visual improvement resulting from the remediation efforts.

Monitoring Relative Humidity: Ongoing monitoring of relative humidity levels helps ensure that the remediation has addressed the underlying cause of the moisture problem and that conditions remain within acceptable parameters.

Client Feedback: Finally, client feedback is crucial. Feedback on the comfort levels and absence of related problems provides qualitative assessment of the project’s success and client satisfaction.

These methods, together, provide a comprehensive evaluation of the effectiveness of the moisture remediation, ensuring that the problem has been thoroughly addressed and that the building is protected from future moisture-related damage.

Q 13. What are some common challenges you encounter during moisture control projects?

Moisture control projects present unique challenges. Some of the most common include:

Hidden Moisture Sources: Locating the source of a moisture problem can be difficult, particularly when the source is hidden within wall cavities or beneath flooring. Advanced techniques like thermal imaging and moisture meters are necessary in these cases.

Accessibility Issues: Difficult-to-access areas, such as crawl spaces or attics, can make moisture remediation challenging and time-consuming. Specialized equipment and techniques are sometimes necessary to reach and treat these areas.

Material Compatibility: Certain remediation techniques may not be compatible with all building materials. For example, some cleaning agents may damage certain finishes. Careful consideration of material compatibility is crucial to avoid further damage during remediation.

Unforeseen Circumstances: During demolition or repair, unforeseen circumstances, such as discovering extensive rot or hidden plumbing issues, can complicate the project and increase costs.

Client Expectations: Managing client expectations regarding timeframes, costs, and disruption is crucial. Open communication throughout the project ensures mutual understanding and avoids conflict.

Q 14. How do you prioritize different moisture problems in a large building?

Prioritizing moisture problems in a large building requires a risk-based approach. The most critical problems pose the greatest risk to the building’s structure, occupant health, or valuable assets. Here’s a step-by-step framework:

Identify all moisture problems: Conduct a thorough assessment of the entire building to identify all moisture-related issues, no matter how seemingly insignificant.

Assess risk: Categorize each problem based on its potential impact. Consider factors such as the extent of damage, risk of mold growth, potential structural damage, and the cost to repair.

Prioritize based on urgency and impact: Prioritize problems that pose the most immediate risks. For example, active leaks or severe mold infestations must be addressed promptly. Less urgent issues can be addressed in a phased approach.

Develop a remediation plan: Create a detailed remediation plan outlining the steps to address each problem, prioritizing them based on the risk assessment.

Allocate resources: Allocate resources—including time, personnel, and budget—effectively to tackle the prioritized problems efficiently.

Regular monitoring and review: Implement regular monitoring to track progress and identify any new or emerging moisture problems. This allows for ongoing adjustments to the remediation plan.

This systematic approach ensures that the most critical issues are addressed first, minimizing damage and preserving the building’s integrity while considering cost and efficiency.

Q 15. Explain the difference between relative humidity and absolute humidity.

Relative humidity (RH) and absolute humidity are both measures of water vapor in the air, but they express it differently. Think of it like this: absolute humidity is the total amount of water vapor present, while relative humidity is the percentage of how much water vapor the air could hold at a given temperature.

Absolute humidity is the mass of water vapor per unit volume of air, usually expressed in grams per cubic meter (g/m³). It’s a direct measurement of the actual water vapor content. For example, an absolute humidity of 10 g/m³ means there are 10 grams of water vapor in every cubic meter of air.

Relative humidity, on the other hand, is expressed as a percentage. It compares the amount of water vapor present to the maximum amount the air could hold at that specific temperature. Warm air can hold more moisture than cold air. So, if the air is holding 50% of the maximum water vapor it could at a given temperature, the relative humidity is 50%. A high relative humidity, even with a relatively low absolute humidity, can still lead to moisture problems because the air is close to saturation.

In moisture control, understanding both is crucial. Absolute humidity helps determine the total moisture load, while relative humidity predicts the likelihood of condensation and mold growth.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience using thermal imaging for moisture detection.

Thermal imaging is an invaluable tool in my moisture detection arsenal. It doesn’t directly measure moisture content, but it reveals temperature differences that often indicate hidden moisture problems. Water, even when trapped behind walls or under flooring, retains heat differently than dry materials. This difference shows up as temperature variations on a thermal image.

My experience includes using thermal cameras on various projects, from detecting leaks in roofs and walls to identifying areas of high humidity in crawl spaces. For example, I once used thermal imaging to locate a hidden leak behind a wall in an older building. The thermal image clearly showed a cold spot indicating moisture saturation. This led to the precise location of the leak, saving time and money compared to exploratory demolition. The images are analyzed in conjunction with other testing methods, like moisture meters, to confirm findings.

Proper technique is key. Environmental factors like ambient temperature and air currents can influence the thermal image. I always ensure the environment is stable and that appropriate emissivity settings are applied to the camera based on the material being inspected. The data is then meticulously documented, with images and detailed notes.

Q 17. How do you document moisture findings and remediation procedures?

Documentation is paramount in moisture control. I use a standardized reporting format to ensure consistency and clarity. My reports always include:

- Client information: Contact details and project address.

- Date and time of inspection: Essential for traceability.

- Methods used: A detailed list of all testing methods employed (e.g., thermal imaging, moisture meter readings, visual inspection).

- Findings: Clear and concise description of the moisture-related issues found, including locations and severity (e.g., using moisture content percentages).

- Photographs and thermal images: Visual evidence supporting the findings.

- Remediation recommendations: Step-by-step plan for addressing the problems found. This includes specifying materials, techniques, and contractors where necessary.

- Moisture maps: Graphical representation of moisture levels.

I utilize digital tools to organize all this information. My reports are often compiled using specialized software that allows for easy integration of images, diagrams, and data, along with electronic signatures for all parties. I maintain a detailed record of all my projects for future reference and quality control.

Q 18. What software or tools do you use for moisture data analysis?

My work relies on several software tools and applications for data analysis. These help me to efficiently process, analyze, and visualize moisture data. The specific tools vary depending on the project scope and data type.

For example, I often use specialized moisture mapping software to create 2D and 3D visualizations of moisture distribution within a structure. This allows for identification of patterns and more informed decision-making regarding remediation strategies. I use spreadsheets for compiling and organizing data from multiple testing instruments. Data loggers provide real-time moisture monitoring and the data can be imported into other analysis software for trend identification. Advanced software packages allow for correlating various data inputs from different testing methods to generate comprehensive moisture reports.

Q 19. How do you communicate technical information about moisture to non-technical stakeholders?

Communicating technical information about moisture to non-technical stakeholders requires clear, concise language and visual aids. I avoid using jargon as much as possible and instead use analogies to explain complex concepts.

For instance, I might explain relative humidity as a ‘sponge’ – a full sponge has high relative humidity; a dry one has low relative humidity. I use visuals like color-coded moisture maps and diagrams to illustrate the findings. I emphasize the consequences of moisture issues, like mold growth and structural damage, to highlight the urgency of addressing them. I usually prepare a summary report in simpler terms for non-technical stakeholders alongside the detailed technical report.

Client meetings are interactive. I make sure to answer their questions clearly, addressing any concerns they might have. This process fosters trust and ensures everyone is on the same page.

Q 20. What are the environmental considerations related to moisture control?

Environmental considerations are crucial in moisture control. Our actions must minimize negative impacts. Here are some key points:

- Energy efficiency: Proper moisture control improves energy efficiency by reducing the need for excessive heating or cooling to compensate for humidity issues. This lessens energy consumption and reduces the carbon footprint.

- Material selection: Choosing materials with appropriate moisture resistance properties is crucial. This is important not only for building longevity but also for the environmental impact of material production and disposal.

- Waste management: Remediation often generates waste. Proper disposal according to local regulations is essential.

- Indoor air quality: Moisture issues can lead to mold growth, negatively impacting indoor air quality. Remediation should focus on improving air quality and reducing the risk of health problems.

- Water conservation: Implementing efficient moisture control systems reduces water waste, particularly in plumbing-related issues.

Sustainable practices are essential. I always consider the long-term environmental implications of my recommendations, focusing on strategies that reduce environmental impact while effectively controlling moisture.

Q 21. Explain the concept of capillary action and its role in moisture migration.

Capillary action is the ability of a liquid to flow in narrow spaces without the assistance of, or even in opposition to, external forces like gravity. In moisture migration, it plays a significant role by allowing water to move upward against gravity through tiny pores and spaces in building materials like wood, concrete, and plaster.

Imagine a thin straw in a glass of water. The water rises up the straw due to the cohesive forces between water molecules (they stick together) and adhesive forces between water molecules and the straw (they stick to the straw). This is capillary action.

In buildings, capillary action allows moisture from the ground or from leaks to climb through porous materials, causing damage and dampness. This is why proper damp-proofing and the use of moisture barriers are essential in construction. The size of pores directly affects capillary action; smaller pores allow for higher water ascension. Understanding capillary action helps in designing effective moisture control strategies, like using vapor barriers or materials with low capillary absorption to prevent water migration.

Q 22. How do you handle unexpected moisture-related issues during a project?

Unexpected moisture issues are a reality in construction and building maintenance. My approach prioritizes a systematic investigation, swift action, and thorough documentation. First, I’d assess the extent of the problem using non-destructive methods like moisture meters to determine the type and severity of moisture intrusion. This helps avoid unnecessary demolition. Next, I’d pinpoint the source – is it a plumbing leak, roof damage, inadequate vapor barrier, or something else? Once identified, the source is addressed immediately, often involving temporary solutions to mitigate further damage while a permanent fix is planned. For example, if a roof leak is causing widespread water damage, I’d implement immediate temporary repairs such as tarps and strategically placed buckets to prevent further ingress while a proper roof repair is scheduled. Finally, a detailed report is generated, documenting the issue, the remediation process, and preventative measures. This ensures accountability and helps prevent recurrence.

Q 23. Describe your experience with different types of moisture intrusion, such as leaks or condensation.

I’ve extensive experience with various moisture intrusion types. Leaks are often straightforward – a burst pipe, faulty flashing, or damaged roof results in visible water damage. Identifying the source is usually the most challenging aspect. Condensation, however, is more subtle. It’s caused by warm, moist air coming into contact with a cold surface, leading to moisture buildup. This often occurs in poorly ventilated areas like basements or attics. I differentiate between these by checking for visual signs of water flow (leaks) versus a more uniform dampness (condensation). I also use specialized tools such as thermal cameras to detect temperature variations indicative of condensation, and humidity sensors to measure relative humidity levels within the structure. In one project, we discovered condensation in a newly constructed office building due to inadequate ventilation. We addressed it by installing a proper ventilation system, thereby resolving the moisture problem.

Q 24. What safety precautions do you follow when working with moisture-related hazards?

Safety is paramount. When dealing with moisture-related hazards, I strictly adhere to OSHA guidelines and follow these safety procedures:

- Personal Protective Equipment (PPE): Always using appropriate PPE like rubber boots, gloves, eye protection, and respirators to prevent exposure to mold, bacteria, and potentially hazardous materials.

- Ventilation: Ensuring adequate ventilation in affected areas to reduce the concentration of mold spores and other airborne contaminants. This often involves using industrial-strength air scrubbers.

- Moisture Control Measures: Implementing measures such as dehumidifiers and drying equipment to control moisture levels and prevent further growth of mold or bacteria.

- Training and Awareness: Receiving regular safety training to stay up-to-date on the latest safety regulations and best practices.

Q 25. How do you stay up-to-date with the latest technologies and best practices in moisture control?

Keeping abreast of advancements in moisture control is crucial. I achieve this through a multi-pronged approach:

- Professional Organizations: Active membership in organizations like the American Society for Testing and Materials (ASTM) and attending their conferences and workshops.

- Industry Publications: Regularly reading industry journals and publications that focus on moisture control, building science, and remediation.

- Online Resources and Webinars: Participating in online courses and webinars offered by reputable institutions and industry experts.

- Manufacturer Training: Attending training sessions and workshops conducted by manufacturers of moisture control equipment and materials.

Q 26. What is your experience with mold remediation and its relation to moisture control?

Mold remediation is intrinsically linked to moisture control. Mold thrives in damp environments; therefore, addressing the underlying moisture problem is crucial for effective mold remediation. My experience encompasses a wide range of mold remediation projects, from small localized infestations to large-scale commercial building remediation. The process typically involves:

- Assessment and Testing: Thorough inspection to determine the extent of mold growth using air and surface sampling.

- Containment: Isolating the affected area to prevent mold spore dispersal.

- Removal: Removing mold-infested materials, disposing of them properly and following all relevant regulations.

- Cleaning: Cleaning surfaces with antimicrobial solutions to kill remaining mold spores.

- Restoration and Prevention: Repairing the damaged area and implementing preventative measures to prevent future mold growth. This always involves addressing the root cause of the moisture problem.

Q 27. How do you prevent future moisture problems after remediation?

Preventing future moisture problems after remediation requires a proactive and multi-faceted approach:

- Addressing the Root Cause: This is critical; simply removing mold without fixing the leak or ventilation problem will lead to recurrence. Repairing damaged roofs, fixing plumbing leaks, and ensuring proper drainage are crucial.

- Improved Ventilation: Ensuring adequate ventilation in all areas, especially basements, bathrooms, and attics, to prevent condensation buildup. This may involve installing exhaust fans, improving air circulation, or introducing dehumidifiers.

- Moisture Barriers: Implementing proper vapor barriers in walls and ceilings to prevent moisture migration. This may involve adding or upgrading existing barriers.

- Regular Maintenance: Regular inspections to identify potential issues early on. This includes checking for leaks, monitoring humidity levels, and inspecting for signs of mold growth.

Q 28. Describe a time you had to troubleshoot a complex moisture problem. What was your approach?

One particularly challenging case involved a historic building with persistent moisture problems in the basement. Initial assessments pointed to a simple drainage issue. However, after extensive investigation using moisture meters, thermal imaging, and even ground-penetrating radar, we discovered a combination of issues: inadequate drainage, rising damp due to poor foundation sealing, and even some historical water damage not previously disclosed. My approach was to systematically address each identified problem:

- Improved Drainage: Regrading the surrounding soil and installing a French drain system to divert water away from the foundation.

- Foundation Repair: Addressing the rising damp by applying a specialized waterproofing membrane to the foundation walls.

- Interior Remediation: Removing damaged materials, treating the affected areas with antimicrobial solutions, and installing a dehumidification system.

Key Topics to Learn for Your Moisture Monitoring and Control Interview

- Fundamentals of Moisture Measurement: Understand different moisture measurement techniques (e.g., gravimetric, electrical resistance, capacitance, infrared) and their applications in various industries.

- Types of Moisture Sensors: Familiarize yourself with the working principles, advantages, and limitations of various moisture sensors (e.g., resistive, capacitive, microwave, optical).

- Data Acquisition and Analysis: Learn how to collect, analyze, and interpret moisture data using various software and tools. Practice interpreting graphs and charts to identify trends and anomalies.

- Moisture Control Strategies: Explore different methods for controlling moisture levels, such as ventilation, dehumidification, desiccation, and the use of moisture barriers.

- Material Science and Moisture Interaction: Understand how different materials react to moisture and the impact of moisture on material properties (e.g., dimensional stability, strength, durability).

- Health and Safety Regulations: Be aware of relevant safety regulations and best practices related to moisture monitoring and control in different settings (e.g., construction, food processing).

- Troubleshooting and Problem Solving: Develop your ability to diagnose moisture-related problems, identify root causes, and recommend effective solutions. Practice explaining your problem-solving process clearly and concisely.

- Industry-Specific Applications: Research the specific applications of moisture monitoring and control within your target industry (e.g., construction, pharmaceuticals, agriculture). Understanding real-world applications will demonstrate your practical knowledge.

Next Steps: Unlock Your Career Potential

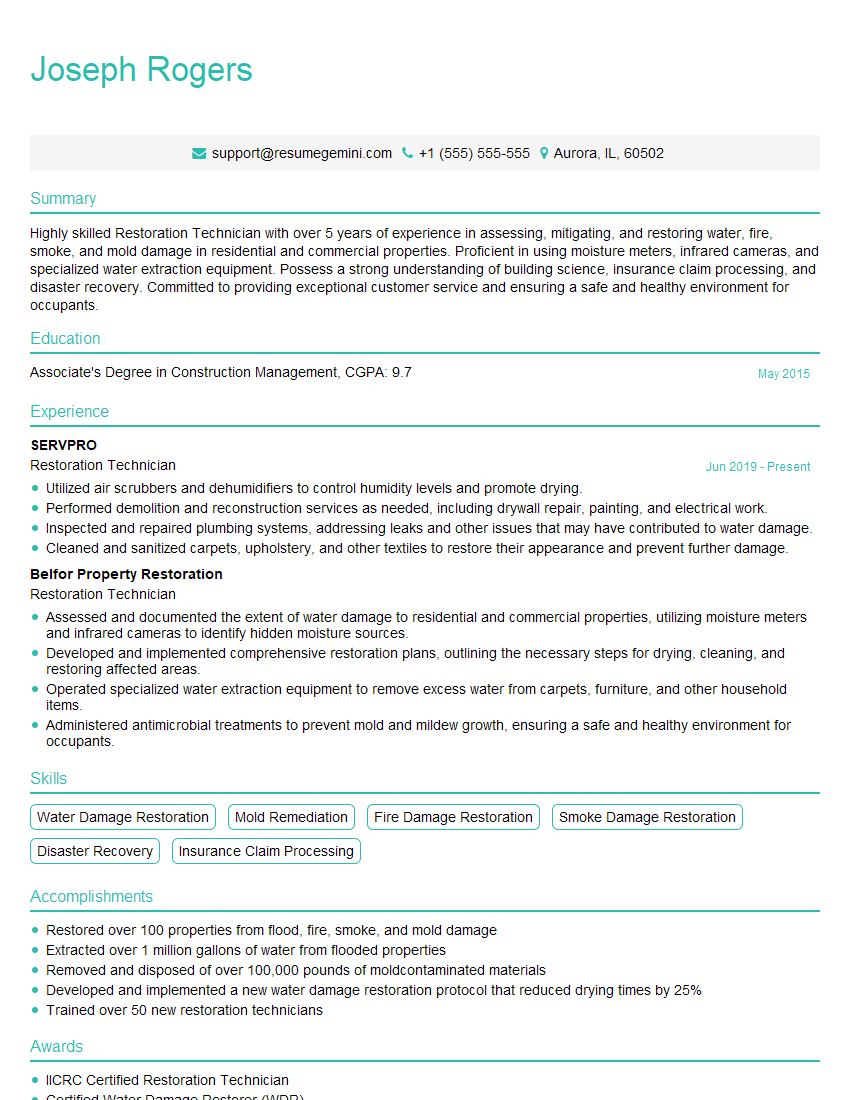

Mastering moisture monitoring and control opens doors to exciting and rewarding career opportunities in various sectors. To maximize your chances of landing your dream job, crafting a compelling and ATS-friendly resume is crucial. A well-structured resume highlights your skills and experience effectively, increasing your visibility to recruiters.

We recommend using ResumeGemini to build a professional and impactful resume tailored to the specifics of your moisture monitoring and control experience. ResumeGemini provides the tools and resources to create a resume that stands out. Examples of resumes specifically crafted for Moisture Monitoring and Control professionals are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good