The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Operating Forklifts and Heavy Equipment interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Operating Forklifts and Heavy Equipment Interview

Q 1. What are the different types of forklifts and their applications?

Forklifts come in a variety of types, each designed for specific tasks and environments. The choice depends on factors like load capacity, terrain, and the type of goods being handled.

- Counterbalance Forklifts: These are the most common type, using counterweights to balance the load. They’re versatile and suitable for most warehouse and outdoor applications. Think of your typical forklift you see in a loading dock.

- Reach Trucks: These forklifts have a mast that extends forward, allowing them to access pallets in narrow aisles. They are ideal for high-density storage environments like warehouses with limited space.

- Sit-down Rider Forklifts: The operator sits while operating the machine, offering better comfort and control, particularly for extended use. These are widely used in warehouses and manufacturing settings.

- Stand-up Rider Forklifts: The operator stands while operating, which is better suited for shorter tasks and situations requiring more maneuverability in tight spaces. Often seen in smaller warehouses or retail environments.

- Order Pickers: These are designed for efficient order picking in high-bay warehouses. They allow the operator to reach different levels without moving the forklift.

- Side Loaders: These forklifts load and unload goods from the side, making them ideal for handling long or awkward loads.

- Rough Terrain Forklifts: Built for uneven ground, these are essential for construction sites, logging yards, and outdoor applications requiring stability on inclines and rough surfaces.

For instance, a construction site would utilize rough terrain forklifts for moving materials across uneven ground, while a grocery warehouse would likely employ reach trucks for maximizing storage space and order pickers for efficient order fulfillment.

Q 2. Describe the pre-operational checks you perform on a forklift.

Before operating a forklift, a thorough pre-operational check is crucial for both safety and efficiency. I always follow a checklist, ensuring that all systems are functioning correctly and that the equipment is safe to operate.

- Visual Inspection: I start with a visual inspection, checking for any visible damage to the forklift, such as leaks, cracks, or loose parts. This includes the tires, forks, mast, and body of the machine.

- Fluid Levels: I check the levels of engine oil, hydraulic fluid, coolant, and fuel, ensuring they are within the appropriate ranges. Low fluid levels can lead to mechanical failures.

- Tire Pressure: Proper tire inflation is vital for stability and handling. Under-inflated tires can cause instability, while over-inflated tires can lead to premature wear.

- Lights and Signals: I verify that all lights (headlights, brake lights, turn signals) and warning devices (horn, backup alarm) are working correctly. This ensures other workers’ safety.

- Brakes and Steering: I test the brakes and steering mechanism to ensure they are responsive and functioning properly. I’ll gently test the responsiveness to avoid sudden movements.

- Forks and Attachments: I check the forks and any attachments to ensure they are secure, undamaged, and properly aligned. Bent or damaged forks pose a significant safety risk.

- Safety Devices: I check the safety devices such as seatbelts, horn, and emergency shut-off switch to ensure they are functioning correctly.

Skipping these checks can lead to accidents, costly repairs, and downtime. It’s a habit I’ve developed over years of experience, prioritizing safety above all else.

Q 3. Explain the proper procedures for loading and unloading cargo using a forklift.

Loading and unloading cargo using a forklift requires precision and adherence to safety protocols to prevent accidents and damage.

- Assess the Load: Before approaching a load, I carefully assess its weight, dimensions, and center of gravity. Knowing this information is crucial for safe handling.

- Approach the Load: I approach the load slowly and cautiously, ensuring the area is clear of obstructions and pedestrians. Maintaining a safe distance from other equipment is also paramount.

- Engage the Forks: I carefully engage the forks under the load, ensuring they are centered and stable. I avoid sudden movements that could cause the load to shift or fall.

- Raise and Transport: I slowly raise the load to a safe height and transport it to its designated location, maintaining a slow and steady pace. I avoid sudden turns or jerky movements.

- Lower and Disengage: I carefully lower the load and disengage the forks, ensuring the load is securely placed and stable. I never leave a load unattended while in elevated position.

- Clean Up: After completing the task, I tidy up the area, ensuring there are no loose items or hazards that could cause accidents.

For example, when unloading a pallet of boxes, I’d ensure the forks are properly positioned under the pallet’s support structure to prevent damage. Incorrect positioning could cause the pallet to break and the boxes to scatter, creating a potential hazard.

Q 4. How do you ensure the safety of pedestrians and other equipment operators while operating a forklift?

Pedestrian and equipment safety are my top priorities. I consistently employ strategies to mitigate risks and ensure a safe work environment.

- Horn and Signals: I always use the horn and appropriate signals (lights, hand signals) to alert pedestrians and other equipment operators of my movements. This is especially important in busy areas.

- Visual Checks: Before moving, I always perform a visual check to ensure the area is clear. I never assume that someone has seen me.

- Maintain Safe Distances: I maintain a safe distance from pedestrians and other equipment, allowing sufficient space for maneuvering. This prevents collisions and close calls.

- Designated Routes: I adhere to designated routes and pathways to minimize the chance of encountering pedestrians or other equipment unexpectedly. Stick to the established lanes.

- Speed Control: I always operate the forklift at a safe and appropriate speed, reducing the risk of accidents. Speed is enemy of safety.

- Awareness of Surroundings: I’m constantly aware of my surroundings, watching for pedestrians, other equipment, and potential hazards. Situational awareness is paramount.

- Communication: I communicate clearly with other workers, letting them know my intentions and movements. Teamwork and communication are key.

For instance, if I’m working in a crowded warehouse, I’ll proceed slowly and use my horn frequently to avoid surprising anyone.

Q 5. What are the load capacity limits and weight distribution guidelines for forklifts?

Load capacity limits and weight distribution are critical safety considerations. Exceeding these limits can lead to equipment damage, injury, or even death. Each forklift has a data plate that specifies its maximum load capacity. This capacity is not uniform across all forklifts and depends heavily on the model.

Load Capacity: The data plate displays the maximum weight the forklift can safely lift. This is usually expressed in pounds or kilograms.

Weight Distribution: Proper weight distribution is just as important as the overall weight. The center of gravity of the load needs to be within the forklift’s specified limits. An improperly balanced load can cause instability and tip-overs. For example, a load that is too far forward or backward can cause the forklift to become unbalanced.

Factors Affecting Capacity: Several factors affect the load capacity, including the forklift’s condition, the type of forks, and the terrain. Always refer to the forklift’s operational manual for precise guidelines.

Ignoring these limits can result in serious accidents. It’s always better to err on the side of caution and avoid overloading the forklift.

Q 6. What are the different types of heavy equipment you have experience operating?

Beyond forklifts, I have extensive experience operating various types of heavy equipment, including:

- Excavator/Backhoe Loaders: Proficient in digging, trenching, lifting, and loading materials using excavators and backhoes.

- Bulldozers: Experienced in land clearing, earthmoving, and grading using bulldozers.

- Wheel Loaders: Skilled in loading and transporting materials using wheel loaders, often used in construction and demolition.

- Graders: Familiar with leveling and smoothing surfaces using graders.

- Crane (Mobile & Tower): Experienced with lifting and placing heavy objects using both mobile and tower cranes.

My experience with this diverse range of equipment has provided me with a comprehensive understanding of heavy equipment operation and safety procedures. Each machine presents unique operational challenges and demands a thorough understanding of its specific safety protocols.

Q 7. Describe your experience with preventative maintenance on heavy equipment.

Preventative maintenance is key to ensuring the longevity and safe operation of heavy equipment. I’ve always been meticulous about performing regular maintenance checks and adhering to manufacturer’s recommendations.

My preventative maintenance typically involves:

- Daily Inspections: Checking fluid levels, tire pressure, and overall condition of the equipment before each use.

- Scheduled Maintenance: Performing scheduled maintenance tasks like oil changes, filter replacements, and lubrication as per manufacturer’s guidelines. I meticulously record these maintenance activities.

- Component Checks: Regularly inspecting components like brakes, hydraulic systems, and electrical systems for any signs of wear or damage. I report any issues immediately.

- Operator Training: Staying up-to-date on proper operating procedures through continuing education and training to maintain proficiency and knowledge of best practices.

I believe that proactive maintenance prevents costly repairs and downtime, and more importantly, helps maintain a safe working environment for everyone. A well-maintained machine is a safe machine.

Q 8. How do you handle equipment malfunctions or breakdowns?

My approach to equipment malfunctions begins with prioritizing safety. I immediately shut down the machine and secure the area, preventing anyone from approaching. Next, I perform a visual inspection to identify the problem, focusing on any obvious damage or leaks. If the issue is minor and within my skillset (e.g., a loose bolt), I’ll attempt a safe repair, always consulting the equipment’s manual first. However, if the problem is beyond my capabilities or involves complex systems, I immediately report it to my supervisor and follow the company’s established reporting procedures, providing detailed information about the malfunction and any preceding events. For instance, once I encountered a hydraulic leak on a forklift. Following protocol, I secured the machine, notified my supervisor, and completed an incident report, preventing further damage or injury. The crucial part is ensuring safety and adherence to proper reporting channels.

Q 9. Explain the importance of daily equipment inspections.

Daily equipment inspections are paramount for safety and preventative maintenance. Think of it like a medical checkup for your machine – catching small problems early prevents major breakdowns later. These inspections cover everything from fluid levels (hydraulic fluid, engine oil, coolant) and tire pressure to checking for leaks, wear and tear on belts and hoses, and ensuring all safety devices (lights, horns, seatbelts) are functioning correctly. I document my findings meticulously, noting any irregularities that require attention. This proactive approach helps prevent costly repairs, minimizes downtime, and, most importantly, ensures the equipment is safe to operate, preventing accidents. For instance, I once noticed a small crack in a forklift’s hydraulic hose during a routine inspection. Addressing it immediately prevented a potential major hydraulic failure later.

Q 10. What are the safety regulations and procedures for operating heavy equipment?

Safety regulations and procedures for heavy equipment operation are extremely stringent and rightfully so. They encompass various aspects:

- Pre-operation checks: Thorough inspection of the machine and its surroundings before starting.

- Personal Protective Equipment (PPE): Always wearing appropriate safety gear, including hard hats, safety glasses, gloves, and high-visibility clothing.

- Load Capacity: Never exceeding the rated load capacity of the equipment.

- Safe Operating Procedures: Adhering to specific procedures for starting, stopping, maneuvering, and lifting loads.

- Environmental awareness: Being mindful of surroundings, pedestrians, other equipment and potential hazards.

- Communication: Using hand signals, radios, or other communication methods to coordinate with other workers.

- Training and Certification: Holding valid certifications and undergoing regular training to stay updated on safety regulations and best practices.

Q 11. How do you maintain stability and control while operating heavy equipment on uneven terrain?

Maintaining stability and control on uneven terrain requires a combination of skill and awareness. First, I assess the terrain before proceeding, choosing the safest and most stable route. I operate the equipment at a reduced speed, avoiding sudden movements or sharp turns. Smooth and controlled operation is key. I always keep my weight centered in the equipment and adjust my speed and trajectory based on the ground conditions. It’s like driving a car on a snowy road – slow and steady wins the race. Experience plays a vital role here, allowing for instinctive adjustments in response to changes in terrain. For example, when operating a bulldozer on a hillside, I’d prioritize a gradual approach, ensuring a firm grip and awareness of the center of gravity to avoid tipping.

Q 12. Describe your experience with operating heavy equipment in confined spaces.

Operating heavy equipment in confined spaces demands extreme precision and caution. Space limitations necessitate precise maneuvering and awareness of all surroundings. I always assess the space before I start, noting potential obstacles like walls, pillars, or other equipment. I use mirrors or spotters if necessary to enhance visibility, ensuring no collisions occur. I move slowly and deliberately, prioritizing safety above speed. Careful planning and execution are essential in such environments to prevent accidents and damage. For instance, I’ve had experience moving large pieces of machinery in tight warehouse spaces, requiring meticulous planning and extremely careful maneuvering to avoid damaging the goods, the building structure, or the machinery itself.

Q 13. How do you assess the load capacity and stability of materials before lifting with a forklift?

Assessing load capacity and stability is crucial before lifting any material with a forklift. I begin by visually inspecting the load to identify any damage or instability. I then check the load’s weight and dimensions against the forklift’s rated capacity plate, ensuring it’s within the safe operating limits. I also consider the load’s center of gravity – a crucial aspect that affects stability. A high center of gravity increases the risk of tipping. I ensure the load is evenly distributed and securely strapped or palletized to prevent shifting during lifting and transport. Neglecting this step could result in accidents, damage, or injury. I always err on the side of caution; if I have any doubts, I’ll seek assistance or refuse the lift.

Q 14. Explain your understanding of load centers and their impact on stability.

The load center is the point where the weight of a load is concentrated. It significantly impacts stability when lifting with a forklift. A load with a high load center is more prone to tipping because the weight is distributed higher, increasing the lever arm effect. Conversely, a low load center provides greater stability. Understanding the load center is critical when positioning forks and managing the lift. I always aim to keep the load center as low as possible, maintaining a balanced distribution and ensuring the load is properly secured to prevent shifting. This minimizes the risk of tipping, promoting safer and more efficient operations. Imagine trying to balance a broom – much easier with the handle down (low load center) than held upright (high load center).

Q 15. What are the different types of attachments used with forklifts and their functions?

Forklifts are incredibly versatile machines, and their functionality is greatly expanded through the use of various attachments. Think of them as specialized tools that allow the forklift to handle a wider range of materials and tasks beyond simply lifting pallets. Here are a few common examples:

- Fork Extensions: These increase the length of the forks, allowing for handling longer or wider loads. I’ve used these extensively when moving lumber or long pipes, ensuring stability and preventing damage.

- Side Shifters: These attachments allow you to laterally shift the forks, useful for precise placement of loads in tight spaces. For instance, when loading a truck, I can perfectly position pallets without needing to reposition the entire forklift.

- Clamp Attachments: These are perfect for handling materials like lumber, metal sheets, or other items that don’t fit neatly onto standard forks. I once used clamps to efficiently move large bundles of sheet metal for a construction project.

- Rotators: These attachments allow you to rotate the load, often 360 degrees, which is invaluable when placing items in specific orientations. This was especially helpful when positioning large steel beams for a building’s framework.

- Carriage Rollers: Ideal for handling long, heavy items such as pipes or beams. The rollers help reduce stress on the forks and improve maneuverability.

- Bale Clamps: These specialized clamps are designed for handling tightly compacted bales of materials such as paper, cotton, or hay. Safety is paramount when using these.

The choice of attachment depends entirely on the material being handled and the specific task at hand. Safety training on the proper use of each attachment is absolutely crucial.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle situations where visibility is limited while operating a forklift or heavy equipment?

Limited visibility is a significant safety concern when operating heavy machinery. My approach is multifaceted and prioritizes proactive measures over reactive ones. First, I always conduct a thorough pre-operational check, ensuring all lights, mirrors, and backup alarms are functioning correctly. Before starting any movement, I carefully assess my surroundings – I literally walk the area, looking for obstructions, personnel, or potential hazards.

When visibility is inherently poor, such as during night operations or in foggy conditions, I employ additional safety measures. These can include using spotters—another trained individual who assists by guiding the forklift operator and alerting them to potential hazards—or using additional lighting sources such as high-powered work lights on the equipment itself. Driving slowly and cautiously is paramount. I frequently stop and reassess my surroundings, especially at intersections or corners.

Finally, I rely heavily on the machine’s safety features. If the forklift is equipped with a reversing camera or proximity sensors, I use them extensively to gain a better understanding of my immediate surroundings. Remember, it’s always better to err on the side of caution. A slight delay is much better than an accident.

Q 17. What are the emergency procedures in case of a forklift accident or equipment malfunction?

Emergency procedures are critical for mitigating harm during a forklift accident or equipment malfunction. My response is always guided by the principles of safety and securing the area.

In case of an accident:

- Immediate Stop: Secure the forklift immediately, engaging the parking brake.

- Assess Injuries: Check for injuries to myself and others involved. Administer first aid if trained to do so, and call emergency medical services immediately.

- Secure the Scene: Establish a safe perimeter around the accident site to prevent further incidents. Use warning cones or other visual aids to alert others.

- Report the Incident: Report the accident to my supervisor and follow company protocol for accident reporting, including filling out necessary paperwork.

In case of equipment malfunction:

- Safe Shutdown: Shut down the forklift according to the manufacturer’s instructions.

- Assessment: Determine the nature of the malfunction; if possible and safe to do so, I make a preliminary assessment.

- Report and Isolation: Report the malfunction to my supervisor and isolate the equipment to prevent further use until repairs are carried out.

- No Unauthorized Repairs: Never attempt to repair the equipment myself unless I am specifically trained and authorized to do so. Only qualified technicians should perform repairs.

Regular preventative maintenance, thorough pre-operational checks, and adherence to safety regulations are key to preventing incidents.

Q 18. How do you communicate with other workers or supervisors during operations?

Effective communication is essential for safe and efficient material handling operations. I utilize a variety of methods depending on the context and environment:

- Visual Signals: Hand signals are crucial, especially in noisy environments. I am thoroughly familiar with standard hand signals for direction, stopping, and other necessary instructions.

- Verbal Communication: When distance or noise levels allow, I use clear and concise verbal communication. I always ensure I’m heard and understood before proceeding.

- Two-Way Radios: Two-way radios are highly effective for coordinating movements between workers, especially in larger warehouses or construction sites. Clear, consistent communication is key here. I always use a radio code for the forklift to communicate with the workers.

- Written Communication: Written instructions, such as work orders or delivery slips, are important for tracking work progress and ensuring accurate material delivery.

I always maintain respectful and professional communication with colleagues and supervisors, ensuring everyone understands their roles and responsibilities.

Q 19. Describe your experience working with different types of cargo.

My experience encompasses a wide range of cargo types, each demanding a unique approach to safe and efficient handling. I’ve worked with:

- Palletized Goods: This is the most common type. I have experience handling various pallet sizes and weights, ensuring proper load securing and stable stacking.

- Bulk Materials: I’ve handled bulk materials using specialized attachments such as buckets or clamps, ensuring safe loading and unloading procedures and preventing spillage.

- Hazardous Materials: I have received specialized training in the safe handling of hazardous materials. This includes understanding proper labeling, storage requirements, and emergency procedures.

- Fragile Goods: Handling fragile items requires extra caution and care. I’ve used techniques like slow movements, appropriate cushioning, and specialized attachments to minimize the risk of damage.

- Oversized Loads: I have experience with securing and moving oversized or unusually shaped loads, often requiring specialized techniques and equipment.

Adaptability and a keen eye for detail are crucial for handling diverse cargo safely and efficiently.

Q 20. How do you ensure the safe storage and handling of materials?

Safe storage and handling of materials is paramount. My approach involves a combination of best practices and adherence to company policies and regulations:

- Proper Stacking: I ensure pallets are stacked correctly to prevent collapse or damage, respecting weight limits and distribution. I follow the “First In, First Out” (FIFO) system whenever possible.

- Designated Storage Areas: Materials are stored in designated areas according to their type, ensuring compatibility and preventing cross-contamination. Flammable materials have their own storage area for example.

- Clear Aisles and Pathways: I maintain clear aisles and pathways, allowing for safe forklift navigation and preventing obstructions.

- Load Securing: I secure all loads properly, using straps, chains, or other appropriate methods to prevent shifting or falling during transport.

- Regular Inspections: Regular inspections of storage areas identify potential hazards, such as damaged pallets or unstable stacks, allowing for prompt corrective action.

- Proper Labeling: All materials are clearly labeled with appropriate information, such as contents, weight, and handling instructions.

Following these practices minimizes risks and helps maintain a safe and efficient work environment.

Q 21. What is your experience with inventory management systems related to material handling?

My experience with inventory management systems related to material handling includes using Warehouse Management Systems (WMS). These systems play a vital role in optimizing the efficiency and accuracy of material handling operations. I’m familiar with using WMS software to:

- Track Inventory: WMS provides real-time visibility into inventory levels, locations, and movement. This allows for informed decision-making and optimized stock management.

- Manage Storage Locations: I use WMS to identify the optimal location for storing materials, considering factors such as product type, size, and frequency of access.

- Guide Material Handling: WMS directs forklift operators on the most efficient routes for picking, putting away, and moving materials, reducing travel time and improving overall efficiency. I’ve used systems that provide visual cues via handheld scanners, directing me to each location.

- Generate Reports: WMS generates various reports, providing valuable insights into inventory turnover, storage capacity utilization, and overall operational efficiency. These reports help optimize logistics and streamline processes.

My experience with WMS has significantly improved my productivity and accuracy in material handling operations. I’m comfortable learning and adapting to different WMS platforms, demonstrating my flexibility and commitment to continuous improvement.

Q 22. How do you adapt to changes in work schedules or assignments?

Adaptability is crucial in this line of work, as schedules and assignments can change rapidly due to unforeseen circumstances like urgent deliveries or equipment malfunctions. I handle these changes proactively. For example, if a new task arises, I prioritize it based on urgency and safety, confirming the details with my supervisor before proceeding. I’m comfortable with unexpected shifts – I’ve worked on projects where deadlines were compressed, requiring me to adjust my daily plan on the fly. This involves prioritizing tasks efficiently and communicating any potential delays transparently to ensure workflow isn’t impacted.

My approach is always to maintain focus on safety and efficiency. I’m also familiar with various equipment, which allows me to quickly adapt to operating different machinery as needed.

Q 23. Describe a time you had to troubleshoot a problem with a piece of equipment. What was your approach?

During a recent project involving a pallet jack with a faulty hydraulic lift, I noticed the jack was struggling to lift heavier pallets. My approach was systematic:

- Safety First: I immediately secured the area, preventing access to others and ensuring the faulty jack wasn’t used.

- Initial Assessment: I visually inspected the jack for any obvious leaks, damage, or obstructions.

- Troubleshooting: I checked the hydraulic fluid levels. It was low, indicating a leak. I then carefully examined the hydraulic lines for any visible damage or leaks.

- Reporting: As the leak required professional repair, I reported the issue to my supervisor, providing a detailed description of the problem and the steps I’d already taken.

This methodical approach ensured safety while efficiently identifying the core problem. Waiting for management without taking initial safety precautions could have resulted in accidents or further damage. This experience highlighted the importance of both technical understanding and effective communication.

Q 24. What safety certifications do you hold related to forklift or heavy equipment operation?

I hold a valid OSHA 30 certification, demonstrating my commitment to workplace safety. Beyond that, I’m certified to operate various types of forklifts, including sit-down counterbalanced forklifts and reach trucks. My certifications are all current and up-to-date, reflecting my continued dedication to safe operational practices. I regularly participate in refresher training to remain proficient and aware of evolving safety regulations.

Q 25. What are your strengths and weaknesses as a heavy equipment operator?

My strengths as a heavy equipment operator include my meticulous attention to detail, my proactive approach to safety, and my ability to work efficiently under pressure. I am highly skilled at operating various types of equipment and am quick to adapt to new machinery. I am also a team player who effectively communicates with colleagues.

A weakness I’m actively working on is delegating tasks when under time constraints. In the past, I’ve sometimes taken on too much, compromising efficiency. To address this, I’m consciously prioritizing tasks and communicating workload more effectively with supervisors and team members to ensure balanced task assignment. This allows for optimal resource utilization and prevents potential burnout.

Q 26. Why are you interested in this specific position?

I’m highly interested in this position because it aligns perfectly with my skills and experience, especially your company’s focus on [mention something specific you know about the company, e.g., sustainable practices, innovative logistics]. The opportunity to contribute to a company with a strong safety record and commitment to its employees is particularly appealing. I’ve been following your company’s work in [mention a specific area] for some time, and I’m confident I can make significant contributions to your team.

Q 27. What are your salary expectations?

My salary expectations are in line with the industry standard for experienced heavy equipment operators with my certifications and experience. I’m open to discussing a specific range after learning more about the full scope of responsibilities and benefits package.

Q 28. Do you have any questions for me?

I have a few questions: First, could you describe the typical day-to-day responsibilities of this role? Second, what opportunities for professional development and advancement are available within the company? Finally, what is your company’s approach to maintaining and updating its equipment?

Key Topics to Learn for Operating Forklifts and Heavy Equipment Interview

- Safe Operating Procedures: Understanding and applying all relevant safety regulations, pre-operation checks, and emergency procedures for various equipment types.

- Equipment Operation: Demonstrating proficiency in starting, operating, maneuvering, and safely stopping forklifts and other heavy equipment (e.g., loaders, excavators). This includes practical knowledge of load capacity, stability, and appropriate speeds for different terrains and loads.

- Load Handling and Stability: Understanding principles of load balancing, weight distribution, and safe lifting techniques to prevent accidents and equipment damage. This includes knowledge of load centers and potential hazards associated with uneven loads.

- Maintenance and Inspection: Familiarizing yourself with routine maintenance checks, identifying potential mechanical issues, and understanding the importance of reporting any malfunctions promptly.

- Logistics and Efficiency: Demonstrating understanding of efficient warehouse or job site layout, traffic flow, and strategies for optimizing material handling processes.

- Communication and Teamwork: Highlighting the importance of clear communication with supervisors, colleagues, and other personnel on the job site to ensure safety and coordination.

- Regulations and Compliance: Understanding relevant industry standards, safety regulations, and licensing requirements for operating heavy equipment.

- Problem-Solving and Troubleshooting: Demonstrating the ability to identify and resolve minor mechanical problems, or know when to call for assistance with more complex issues.

Next Steps

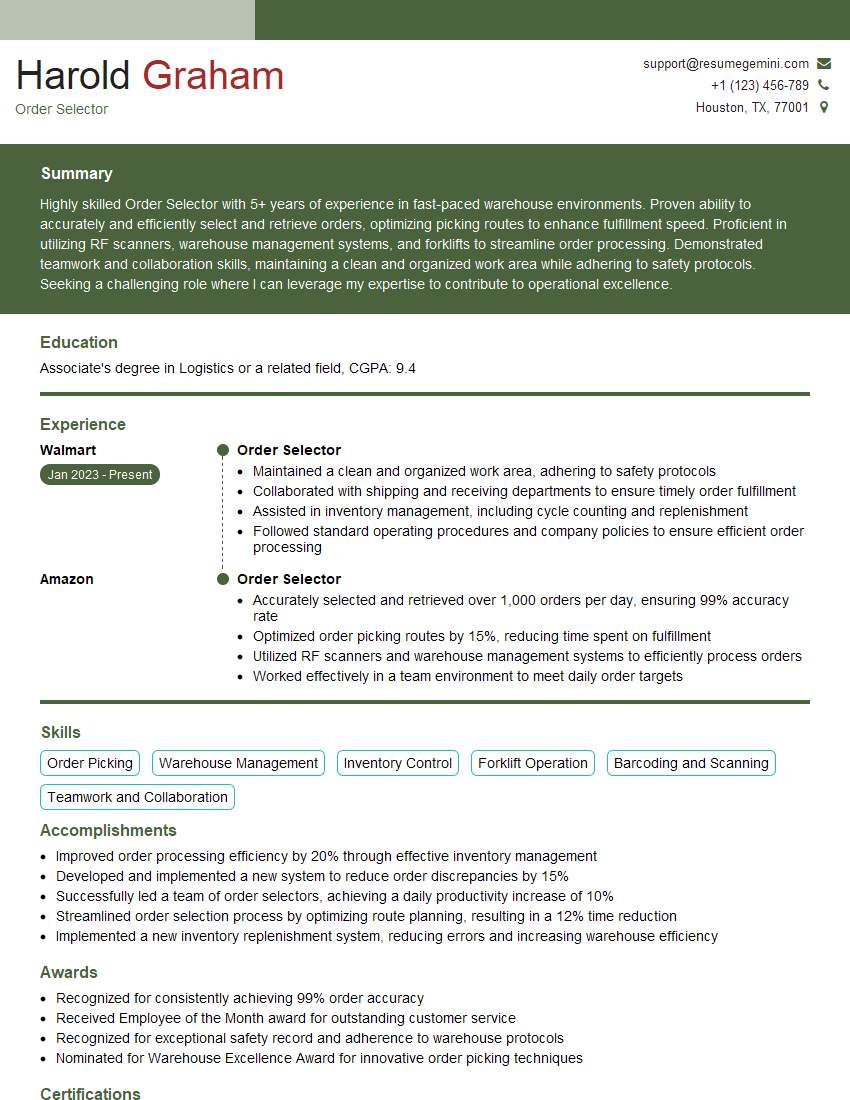

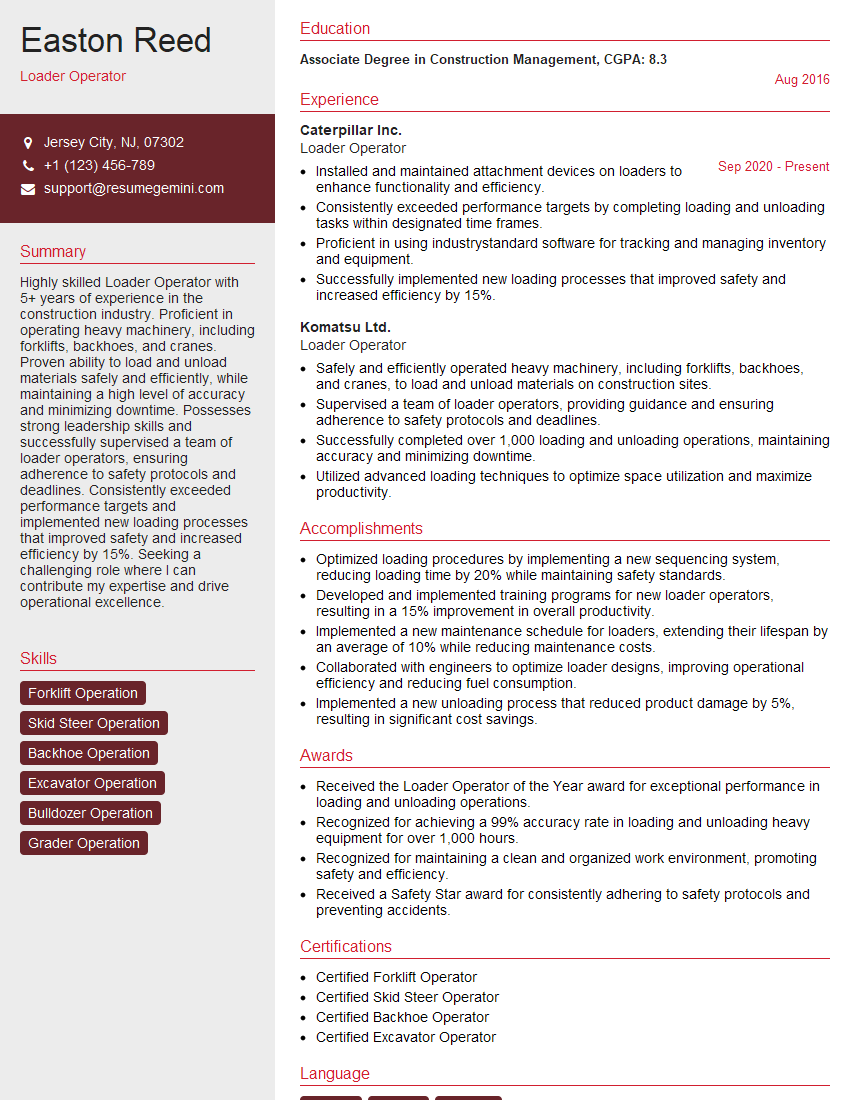

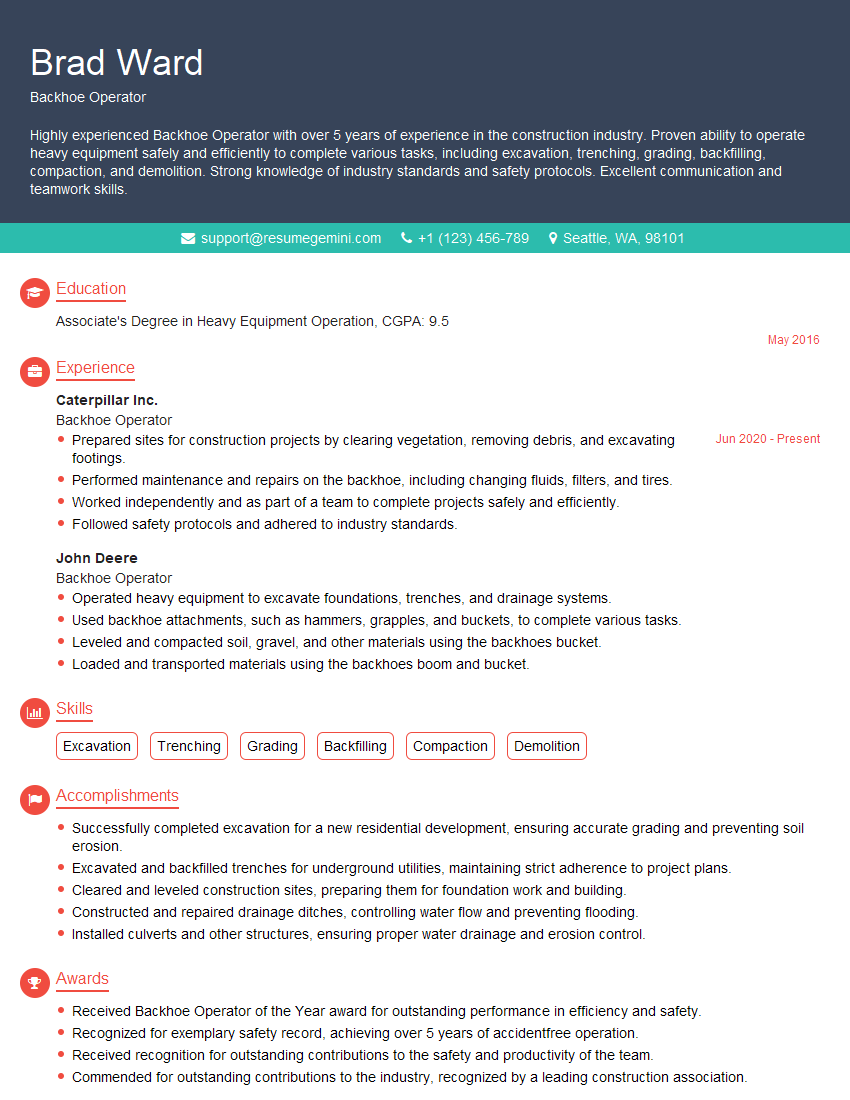

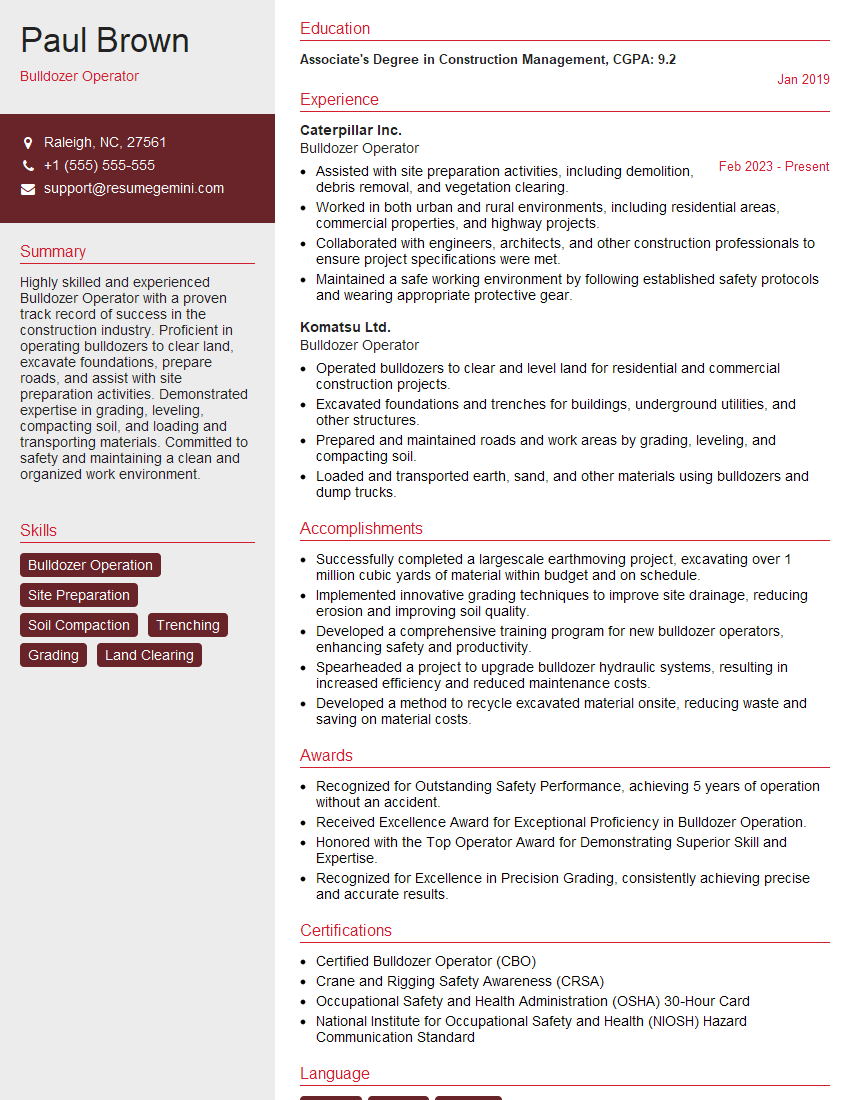

Mastering the operation of forklifts and heavy equipment opens doors to rewarding careers with excellent growth potential in logistics, construction, and manufacturing. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you create a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Operating Forklifts and Heavy Equipment industry to help you get started. Take the next step in your career journey – build a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good