Preparation is the key to success in any interview. In this post, we’ll explore crucial Structural Packaging Design interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Structural Packaging Design Interview

Q 1. Explain the difference between compression, tension, and shear stress in packaging.

In structural packaging, understanding stress types is crucial for ensuring product protection. Let’s break down compression, tension, and shear stress:

- Compression: This occurs when a force pushes on an object, squeezing it. Think of a stack of boxes – the bottom box experiences compression from the weight above. In packaging, this is a major consideration, as we need to design structures that can withstand the compressive forces during stacking, shipping, and handling. The box needs to resist being crushed.

- Tension: This is the opposite of compression; it’s a pulling force. Imagine a plastic bag being stretched. In packaging, tension might occur if a package is suspended or if there’s significant movement during transport. Straps or other elements that secure loads experience tension. We design to ensure the packaging materials don’t tear or break under tension.

- Shear Stress: This involves forces acting parallel to a surface, causing it to slide or deform. Imagine cutting paper with scissors – the shear stress causes the fibers to break. In packaging, shear stress can occur when boxes are stacked and the edges are subjected to lateral forces. We account for this by considering appropriate box dimensions and material properties, often using stronger materials at points of high shear stress.

Understanding these stress types helps us select appropriate materials and design structures that can effectively resist the forces they’ll encounter during their lifecycle.

Q 2. Describe your experience with various packaging materials (e.g., corrugated board, paperboard, plastics).

My experience spans a wide range of packaging materials. I’ve extensively worked with:

- Corrugated Board: This is a staple in the industry due to its excellent strength-to-weight ratio and cost-effectiveness. I’ve worked on optimizing designs using different flute types (A-flute, B-flute, C-flute, etc.) to balance protection with weight and cost. For example, I helped a client transition from heavier A-flute to a lighter C-flute for their product, achieving significant cost savings without compromising product protection.

- Paperboard: This is a versatile material used in folding cartons, book covers, and more. I’ve explored different surface treatments and coatings to enhance print quality, water resistance, and barrier properties. A recent project involved designing a paperboard box with a special grease-resistant coating for food packaging.

- Plastics: I have experience with various plastics, including PET, HDPE, and PP, often used for bottles, films, and thermoformed containers. The key here is understanding the material’s properties like stiffness, impact resistance, and barrier properties to ensure product integrity and shelf life. For instance, I helped select the optimal plastic for a client’s new product, ensuring its protection during transport and its resistance to chemicals while ensuring recyclability.

My understanding of these materials’ properties enables me to choose the most suitable and cost-effective option for each specific packaging application. I always consider factors such as recyclability and environmental impact as well.

Q 3. How do you determine the appropriate wall thickness for a corrugated box?

Determining the appropriate wall thickness for a corrugated box is a critical aspect of structural design, and it’s not a single equation but rather a process that balances several factors:

- Product weight and dimensions: Heavier and larger products require thicker walls to withstand compression and bending.

- Stacking height: Higher stacks necessitate greater wall thickness to prevent crushing.

- Type of corrugated board: Different flute types (A-flute, B-flute, C-flute, etc.) offer varied strengths; A-flute is generally stronger, while C-flute is lighter.

- Transportation conditions: Harsh shipping conditions demand thicker walls for extra protection.

- Environmental factors: High humidity or temperature fluctuations may require adjustments to ensure structural integrity.

We often use industry standards and software tools (like FEA) to simulate loading conditions and predict structural performance. Experience and data analysis are also vital. There’s often a balance between optimal strength and cost-effectiveness. A ‘trial and error’ approach coupled with real-world testing is often necessary to fine-tune the wall thickness for perfect functionality.

Q 4. Explain your understanding of the Beer-Lambert Law and its application in packaging.

The Beer-Lambert Law describes the attenuation of light as it passes through a medium. In packaging, it’s primarily used for:

- Barrier Layer Optimization: Determining the thickness of barrier layers (e.g., in plastic films) required to prevent light from degrading sensitive products like pharmaceuticals or food. The law allows us to calculate the necessary thickness based on the material’s absorption coefficient and the desired level of light protection.

- Color Measurement and Quality Control: This is key for printed packaging. The law helps in calibrating color printing processes, ensuring consistency and accuracy of the final colors. Deviation from expectations suggests a need to investigate the printing method or the quality of the material.

A = εbc where:

Ais the absorbanceεis the molar absorptivity of the materialbis the path length (thickness of the material)cis the concentration of the absorbing species

By understanding the Beer-Lambert Law, we can optimize packaging designs to achieve the desired level of light protection or color consistency based on material properties and product requirements.

Q 5. How do you design for stackability and palletization efficiency?

Designing for stackability and palletization efficiency is crucial for optimizing shipping costs and minimizing damage during transit. Key considerations include:

- Base Design: A stable and strong base is essential. The bottom of the packaging should be designed to distribute weight evenly and prevent collapsing under the load of other packages.

- Interlocking Features: Designing interlocking features into the package helps maintain stack stability and prevent shifting during transit. This can involve specially designed corners or interlocking flaps.

- Uniform Dimensions: Packages within a pallet should be of uniform size and shape to maximize space utilization and enhance stability.

- Pallets and Pallet Load optimization: The dimensions of the packaged goods must work efficiently with standard pallet sizes, minimizing gaps and optimizing the number of units per pallet. Using software to determine best possible arrangements is crucial.

- Center of Gravity: The center of gravity of the packaged product should be low and centrally located to prevent tipping or instability during transport.

Effective stackability and palletization lead to reduced shipping costs, minimized product damage, and improved logistics efficiency.

Q 6. What are the key considerations for designing environmentally friendly packaging?

Designing environmentally friendly packaging involves several critical considerations:

- Material Selection: Prioritizing recyclable, biodegradable, or compostable materials is paramount. This often involves a trade-off between material properties, cost, and environmental impact. Life cycle assessments help determine the best options.

- Reduced Material Usage: Optimizing designs to minimize material usage without compromising product protection. This might involve employing lighter materials or redesigning the packaging structure.

- Recyclability and Compostability: Designing packages that are easily recyclable or compostable at the end of their life. This includes considering aspects like material compatibility and labeling.

- Reduced Carbon Footprint: Minimizing the carbon footprint across the packaging lifecycle, from raw material sourcing to manufacturing and transportation. This can be challenging but is vital to achieving a sustainable solution.

- Sustainable Sourcing: Ensuring materials are sourced from responsible and sustainable forestry practices or recycled materials.

The goal is to create packaging that minimizes its environmental impact while still providing adequate product protection. This requires a holistic approach considering the entire lifecycle of the packaging.

Q 7. Describe your experience with finite element analysis (FEA) in packaging design.

Finite Element Analysis (FEA) is an indispensable tool in my packaging design workflow. It’s a computational method used to predict the structural behavior of a package under various loading conditions. My experience with FEA includes:

- Predicting Structural Performance: FEA allows me to simulate the stresses and strains on a package under different conditions (e.g., compression, vibration, impact). This helps identify potential weak points and optimize the design for improved strength and durability.

- Material Optimization: FEA helps in selecting the most appropriate materials for a given application based on strength, cost, and environmental impact. By simulating different material properties, we can find the most cost-effective and environmentally sound solution.

- Design Iteration and Refinement: FEA allows for iterative design improvements. We can run multiple simulations with different design parameters and select the optimum design that meets performance criteria and constraints.

- Drop and Impact Testing Simulation: This is especially crucial for fragile items. FEA allows us to simulate drop tests to determine the likelihood of damage and enhance the design for improved protection.

FEA isn’t just about numbers; it translates complex engineering concepts into actionable insights, driving informed decision-making throughout the design process and enhancing the robustness of the final package.

Q 8. How do you balance the need for robust protection with cost-effectiveness in packaging?

Balancing robust protection with cost-effectiveness in packaging is a crucial aspect of structural design. It’s all about finding the optimal balance between material strength, structural integrity, and minimizing material usage and manufacturing costs. Think of it like building a house – you need sturdy walls and a strong foundation (protection), but you don’t want to use unnecessarily expensive materials or overbuild (cost-effectiveness).

This is achieved through a combination of techniques:

- Material Selection: Choosing the right materials is paramount. For instance, using corrugated board with appropriate flute size for the product’s fragility and weight is key. Recycled materials can reduce costs without compromising protection in many cases.

- Design Optimization: Sophisticated CAD software helps optimize the design. We can use Finite Element Analysis (FEA) simulations to test different designs and identify areas where material can be reduced without sacrificing structural integrity. This is like refining a building plan to use the most efficient amount of concrete and steel.

- Minimalist Design: Avoiding unnecessary features reduces material usage and manufacturing complexity. A simpler design, if structurally sound, is almost always more cost-effective.

- Negotiating with Suppliers: Building strong relationships with material suppliers can lead to better pricing and access to innovative, cost-effective materials.

For example, I once worked on a project for a client shipping delicate electronics. Through FEA simulations and careful material selection, we were able to reduce the packaging weight by 15% without impacting protection, resulting in significant cost savings for the client.

Q 9. Explain your process for designing and testing a new packaging structure.

My process for designing and testing a new packaging structure involves several stages:

- Understanding the Product: This includes analyzing its fragility, weight, dimensions, and any special handling requirements. It’s like understanding the blueprint of the house before you start building.

- Concept Development: We brainstorm different design concepts, considering factors like material type, stacking strength, and ease of assembly. This is like sketching out different architectural designs.

- Prototyping: We create prototypes using CAD software and physical mock-ups to visualize and test the design’s functionality and feasibility. This is like building a small-scale model of the house.

- Testing: We conduct rigorous testing to evaluate the prototype’s ability to withstand various environmental conditions and handling stresses. This could involve drop tests, vibration tests, and compression tests. Think of it like stress-testing the house model against different weather conditions and earthquakes.

- Refinement: Based on the test results, we refine the design to improve its performance and cost-effectiveness. This is an iterative process, going back to the design stage until we achieve optimal results.

- Production: Once the design is finalized, we work with manufacturers to ensure efficient production. We ensure our design is compatible with their machinery and processes.

Throughout this process, we maintain meticulous documentation and track all design changes and test results. This helps maintain consistency and ensure that the final design meets all specified requirements.

Q 10. What are the different types of packaging closures and their applications?

Packaging closures are vital for ensuring product safety and maintaining its integrity. Different applications require different closure types.

- Screw Caps: These are widely used for bottles and jars, offering good sealability and reusability. Common on beverage bottles and jars of condiments.

- Press-on Caps: These snap onto containers, offering ease of use but potentially less secure sealing than screw caps. Ideal for many food and cosmetic items.

- Child-Resistant Closures: Designed to prevent children from easily accessing hazardous products. Mandatory for certain pharmaceuticals and household chemicals.

- Tamper-Evident Seals: These indicate whether a package has been opened or tampered with. Frequently used for pharmaceuticals, food, and other sensitive items.

- Spout Pouches: Flexible packaging with integrated spouts allows easy dispensing of liquids or semi-liquids. Common in juice boxes and sauce packages.

- Zipper Closures: Resealable closures providing repeated access to the contents. Often used in stand-up pouches for snacks or coffee.

The choice of closure depends heavily on the product’s nature, its required shelf life, and the target audience. For instance, a child-resistant closure is crucial for medicines, while a simple press-on cap is suitable for many food products.

Q 11. How do you ensure packaging meets regulatory requirements (e.g., FDA, ASTM)?

Ensuring packaging meets regulatory requirements, such as those set by the FDA (Food and Drug Administration) and ASTM (American Society for Testing and Materials), is paramount. Non-compliance can lead to product recalls, fines, and damage to reputation.

Our process involves:

- Material Compliance: We select materials that comply with relevant FDA regulations for food contact or other specific product requirements. We meticulously check certificates of compliance from our suppliers.

- Testing and Certification: We conduct necessary tests to ensure the packaging meets relevant ASTM standards for strength, durability, and other performance characteristics. We often use independent labs for unbiased results.

- Labeling and Marking: We ensure that all labeling requirements are met, including ingredient declarations, nutritional information, and warnings as necessary. This must comply with both domestic and international regulations.

- Documentation: We maintain comprehensive documentation of all tests, certifications, and regulatory approvals. This ensures full traceability and aids in case of audits.

Failure to meet these standards can have severe consequences. For example, incorrect labeling of food products can result in allergic reactions and serious health risks, leading to costly recalls and legal battles.

Q 12. Describe your experience with CAD software for packaging design.

I have extensive experience using CAD software for packaging design, primarily SolidWorks and Autodesk Inventor. These tools allow for creating detailed 3D models of packaging, facilitating design optimization and realistic simulations.

My expertise includes:

- 3D Modeling: Creating accurate and detailed 3D models of packaging structures, incorporating all relevant dimensions and features.

- FEA Simulations: Using FEA to analyze the structural integrity of the packaging under various stresses and conditions, helping to optimize design for strength and durability while minimizing material usage.

- Rendering and Visualization: Generating photorealistic renderings to communicate designs effectively to clients and stakeholders.

- Data Management: Organizing and managing design files efficiently, utilizing version control systems to track changes and revisions throughout the design process.

For instance, using FEA in SolidWorks, I was able to identify a weak point in a previous design of a shipping container, leading to a structural redesign that enhanced protection during transit by 30%.

Q 13. What are the key considerations for designing packaging for international shipping?

Designing packaging for international shipping presents unique challenges due to varying environmental conditions, handling procedures, and regulatory requirements across different countries.

Key considerations include:

- Climate Resilience: The packaging must withstand extreme temperatures, humidity, and pressure fluctuations during transit. This might involve selecting materials resistant to moisture or temperature changes.

- Robustness: The packaging needs to endure rough handling and stacking during transportation. This requires robust designs that can withstand impacts and compression forces.

- Compliance with International Standards: Adherence to regulations such as those set by the International Air Transport Association (IATA) for air freight, and specific country-level requirements is essential.

- Clear Labeling and Marking: Clear and accurate labeling, including appropriate hazard warnings and shipping instructions, is vital for smooth customs clearance and safe handling.

- Customization: Packaging may need to be customized for specific destinations, taking into account regional preferences or regulations.

For example, I designed packaging for a client shipping temperature-sensitive pharmaceuticals internationally. This involved using insulated materials and implementing a sophisticated temperature monitoring system to ensure the products arrived in perfect condition.

Q 14. How do you handle design changes or revisions during the packaging development process?

Design changes and revisions are inevitable in the packaging development process. Managing them efficiently is crucial for maintaining project timelines and budget.

Our approach involves:

- Version Control: We use version control systems, such as SolidWorks’ PDM, to track all design changes and revisions, allowing us to easily revert to previous versions if necessary.

- Change Management Process: We have a formal process for documenting and approving design changes, ensuring all stakeholders are informed and agree on the modifications.

- Communication: Open and effective communication between the design team, the client, and manufacturing partners is essential to address any design issues or requests promptly.

- Prototyping and Testing: We often create new prototypes to test and validate design changes before implementation.

- Impact Assessment: Before implementing any change, we assess its potential impact on cost, production schedule, and overall product quality.

For instance, during a recent project, a client requested a change in the packaging artwork. We seamlessly implemented the modification using our version control system, keeping all stakeholders informed and ensuring the change did not affect the production schedule.

Q 15. What are some common failure modes in packaging and how do you mitigate them?

Packaging failure modes are the ways a package can fail to protect its contents or fulfill its intended purpose. These failures can significantly impact product quality, shelf life, and brand reputation. Common failure modes include:

- Compression Failure: The package collapses under its own weight or external pressure (e.g., stacking on a pallet). This is often mitigated by selecting appropriate materials with high compressive strength, optimizing the package design for structural integrity, and using appropriate stacking patterns.

- Edge Crush Failure: The edges of the package crush or deform, often affecting stability. This can be addressed through the use of edge protectors, reinforced corners, and proper material selection.

- Puncture Failure: The package is pierced or penetrated, damaging the contents. This can be mitigated by using puncture-resistant materials (e.g., corrugated board with higher burst strength), designing with appropriate thicknesses, and adding protective inserts.

- Moisture Damage: Water vapor or liquids enter the package, potentially damaging the contents. This requires careful material selection (e.g., water-resistant barriers like films or laminates), proper sealing techniques, and design features to prevent moisture ingress.

- Temperature Damage: Extreme temperatures can affect package integrity and product quality. This can be addressed with insulated packaging, temperature-controlled shipping, and the use of materials that maintain their properties over a wide temperature range.

Mitigation strategies often involve a combination of material science, design optimization (e.g., using ribs and corrugations for strength), and rigorous testing to ensure the package can withstand anticipated stresses and conditions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of package testing methods (e.g., drop testing, vibration testing).

Package testing methods are crucial to ensuring the structural integrity and ability of a package to protect its contents throughout the supply chain. These methods simulate the real-world stresses a package experiences.

- Drop Testing: This involves dropping the packaged product from various heights and orientations (corner, edge, flat) onto different surfaces (e.g., concrete, wood). This helps evaluate the package’s ability to withstand impacts, and data helps in improving design for impact resistance.

- Vibration Testing: This simulates the vibrations a package endures during transport by truck, train, or plane. It assesses the package’s ability to prevent damage from continuous shaking and resonance. The test involves placing the package on a vibration table and subjecting it to specific frequencies and amplitudes. Failure modes observed here can guide design changes towards greater stability and shock absorption.

- Compression Testing: This measures the package’s resistance to crushing under load, critical for stacking stability. It utilizes a compression machine to apply force to the package until failure, providing valuable data for optimizing package design and material selection for increased load-bearing capacity.

- Climate Testing: This exposes the package to varying temperature and humidity levels to assess its resistance to these environmental stressors. This is critical for protecting products sensitive to moisture or temperature changes. It is vital for packaging that will be stored for extended periods or shipped across varied climates.

Data from these tests, typically recorded through sensors and high-speed cameras, inform design improvements to enhance product protection and prevent costly damage during distribution.

Q 17. How do you incorporate sustainability principles into the packaging design process?

Sustainability is a key consideration in modern packaging design. It’s about minimizing environmental impact throughout the package’s lifecycle, from sourcing materials to end-of-life disposal. This involves:

- Material Selection: Prioritizing recycled content, renewable resources (e.g., plant-based materials), and biodegradable or compostable materials. For example, using recycled paperboard instead of virgin materials significantly reduces carbon footprint.

- Lightweighting: Designing packages that use less material without compromising protection. This reduces transportation costs and the overall amount of waste generated.

- Design for Recyclability: Creating packages that are easy to recycle and compatible with existing recycling streams. This often involves minimizing the number of materials used and ensuring materials are easily separable.

- Reducing Packaging Waste: Optimizing package sizes to minimize empty space and exploring alternative packaging formats that reduce material usage (e.g., using less packaging overall or replacing bulky packaging with more efficient designs).

- Sustainable Printing Techniques: Using inks and printing processes that minimize the environmental impact. Water-based inks and printing techniques that use less energy and produce less waste are crucial.

Life Cycle Assessments (LCAs) can be used to quantify the environmental impact of different packaging options, allowing for data-driven decisions focused on sustainability. For example, a recent project involved switching to a fully compostable packaging solution, resulting in a 70% reduction in landfill waste.

Q 18. Describe your experience with different printing techniques used in packaging.

I have extensive experience with various printing techniques used in packaging, each offering unique advantages and limitations:

- Flexography: A cost-effective method suitable for high-volume printing on flexible substrates like films and foils. It’s known for its versatility in printing on various materials and its ability to produce high-quality images.

- Gravure Printing: Produces high-quality images with excellent color consistency, particularly suitable for large-scale printing on flexible materials like films, labels, and pouches.

- Offset Lithography: Produces sharp, detailed images and is often used for high-quality printing on paperboard cartons and labels. However, it can be less cost-effective for shorter print runs.

- Digital Printing: Offers significant advantages in short-run printing and personalization, reducing setup costs and enabling customized packaging. While it may not be as cost-effective for extremely large volumes, its flexibility is a huge benefit.

- Screen Printing: Provides excellent results for bold graphics and specialized applications. It’s particularly useful for thick-layer applications and textured surfaces.

The choice of printing technique depends on factors like the substrate, print quality requirements, volume, budget, and desired effects. Understanding the capabilities and limitations of each method is crucial for successful packaging design.

Q 19. Explain your understanding of packaging graphics and their impact on consumer appeal.

Packaging graphics play a vital role in attracting consumers and conveying brand identity. They are the first point of contact for a product, influencing purchase decisions.

- Brand Identity: Graphics should reinforce the brand’s visual identity, including logo, colors, and typography, ensuring consistency across all packaging.

- Product Information: Clear and concise communication of product information (e.g., ingredients, usage instructions) is essential, complying with relevant regulations.

- Shelf Appeal: The design should stand out on the shelf, using color, imagery, and typography to attract attention in a crowded marketplace. This involves understanding consumer psychology and visual hierarchy.

- Consumer Engagement: Interactive elements and storytelling can enhance consumer engagement, fostering a deeper connection with the brand.

- Emotional Connection: Effective graphics can evoke emotions and create a positive association with the brand and product. This may include the use of imagery that conveys trust, quality, or excitement.

Understanding principles of graphic design, including color theory, typography, and visual communication, is essential for creating impactful packaging that attracts consumers and drives sales.

Q 20. How do you manage conflicting requirements from different stakeholders (e.g., marketing, manufacturing)?

Managing conflicting requirements from different stakeholders is a common challenge in packaging design. Marketing often prioritizes aesthetics and brand messaging, while manufacturing focuses on cost-effectiveness and production feasibility. A successful approach involves:

- Collaborative Communication: Establish clear lines of communication and regular meetings with all stakeholders to understand their needs and priorities.

- Prioritization and Compromise: Identify key requirements and prioritize them based on their importance. Sometimes, compromises need to be made to balance competing needs.

- Data-Driven Decision Making: Use data from market research, consumer testing, and cost analysis to support design decisions and justify compromises.

- Prototyping and Iteration: Create prototypes to visualize design concepts and test feasibility. Iterate on the design based on feedback from stakeholders and testing results.

- Documentation and Traceability: Maintain clear documentation of design decisions, rationale, and trade-offs to ensure transparency and accountability.

For example, in a recent project, marketing wanted a complex, multi-layered design for maximum visual impact, while manufacturing raised concerns about production costs and complexity. Through collaborative discussion and prototyping, we arrived at a modified design that balanced aesthetic appeal with manufacturing feasibility, resulting in a successful launch.

Q 21. Describe a time you had to solve a complex packaging design problem.

A particularly challenging project involved designing packaging for a delicate, temperature-sensitive product that required long-distance shipping. The product was prone to damage from shock, vibration, and temperature fluctuations.

The initial design, based solely on aesthetic considerations, was inadequate. The product arrived damaged in testing. To solve this, I employed a multi-faceted approach:

- Material Selection: I carefully evaluated various materials based on their protective properties, cost-effectiveness, and environmental impact. The selection ultimately landed on a combination of a double-walled corrugated box for increased cushioning and a custom-fit foam insert for secure product containment.

- Design Optimization: Through finite element analysis (FEA) simulations, I optimized the box geometry to redistribute stress and minimize weak points. This involved adding strategically placed reinforcements and optimizing the internal structure for shock absorption.

- Testing and Iteration: Rigorous testing, including drop tests from varying heights and vibration tests simulating transportation conditions, was employed to refine the design. Several design iterations were needed before a design met the required protection levels.

- Temperature Control: To address temperature sensitivity, I incorporated temperature-sensitive indicators within the packaging to monitor temperature fluctuations during transit and alert customers to potential issues.

The final solution successfully protected the product throughout the supply chain. The FEA simulations reduced testing time and costs, while the use of the temperature indicators improved transparency and accountability.

Q 22. What are your preferred methods for conducting packaging material testing?

Material testing is crucial for ensuring packaging integrity and performance. My preferred methods depend on the specific material and its intended function, but generally include a combination of approaches.

- Compression Testing: This determines the maximum load a package can withstand before collapsing. I use a universal testing machine to apply force until failure, measuring the force and deformation.

- Drop Testing: Simulates real-world drops from various heights to assess impact resistance. Specific drop heights and orientations are chosen based on expected handling conditions. For example, a package designed for shipping might undergo drops from 4 feet onto different faces.

- Burst Testing: Measures the internal pressure a package can withstand before bursting, vital for flexible packaging like bags and pouches. It helps determine the material strength and seal integrity.

- Edge Crush Test (ECT): Specifically for corrugated board, this measures the resistance to compression along the board’s edge. This data is crucial for calculating box strength and stackability.

- Moisture Resistance Testing: This involves exposing the packaging material to controlled humidity levels and measuring any changes in its properties like strength or dimensions. This is important for food and pharmaceutical packaging.

The results from these tests guide design improvements and ensure the packaging meets its intended performance requirements.

Q 23. What software are you proficient in for structural analysis of packaging designs?

Proficiency in specialized software is essential for efficient and accurate structural packaging design. I’m highly proficient in several software packages, including:

- Autodesk Inventor: Excellent for 3D modeling and creating detailed package designs, allowing for precise measurements and visualizations. I use it to create realistic prototypes before physical production.

- SolidWorks: Similar to Inventor, SolidWorks allows for complex 3D modeling and analysis, enabling simulations of various stress scenarios.

- ANSYS: A powerful Finite Element Analysis (FEA) software package. I use this for advanced structural analysis, simulating real-world conditions like impact, compression, and vibration to identify potential weaknesses and optimize the design for strength and durability.

I also have experience with specialized packaging design software that helps in creating dielines, optimizing material usage and generating manufacturing specifications.

Q 24. How do you stay current with the latest trends and technologies in structural packaging?

Staying updated in this dynamic field requires a proactive approach.

- Industry Publications and Journals: I regularly read publications like Packaging World, Packaging Digest, and other specialized journals to keep abreast of new materials, technologies, and design trends.

- Industry Conferences and Webinars: Attending conferences and webinars allows direct interaction with experts, access to cutting-edge research, and networking opportunities.

- Material Suppliers’ Information: Collaborating with material suppliers provides access to the latest material developments, including sustainable options like bioplastics and recycled content.

- Online Resources and Databases: Regularly searching online databases and relevant websites for research papers, case studies, and news helps keep my knowledge current.

Continuously learning and adapting is vital in this industry – it allows me to offer innovative solutions and make informed decisions for my clients.

Q 25. Describe your experience with designing packaging for various product types and sizes.

My experience spans a wide range of products and sizes. I’ve worked on packaging for:

- Fragile Electronics: Designing custom foam inserts and protective packaging to safeguard sensitive electronic components during transit.

- Food Products: Developing shelf-ready packaging for various food items, including considerations for food safety, shelf life, and branding.

- Pharmaceuticals: Designing tamper-evident and child-resistant packaging that meets strict regulatory requirements, ensuring product safety and integrity.

- Cosmetics: Creating visually appealing and functional packaging solutions for a variety of cosmetic products, incorporating sustainable materials wherever possible.

- Large-Scale Industrial Goods: Designing robust and cost-effective packaging for heavy machinery parts, often employing corrugated board, pallets, and specialized handling systems.

Adapting my design approach to meet the unique needs of each product and size is a core competency.

Q 26. What is your approach to designing for recyclability and compostability?

Designing for recyclability and compostability is a crucial element of modern packaging design; it’s no longer an option, but a necessity.

- Material Selection: Prioritizing materials with high recyclability rates, such as recycled paperboard, PET plastics (with appropriate recycling infrastructure), and compostable bioplastics like PLA.

- Design for Disassembly: Simplifying the package structure to ease sorting and recycling. This includes minimizing the use of mixed materials and adhesive glues.

- Clear Labeling: Using clear and concise labeling to guide consumers on proper recycling or composting methods.

- Collaboration with Recyclers: Working closely with recycling facilities to understand their processes and constraints, ensuring the designs are compatible with their infrastructure.

The goal is to create packaging that minimizes environmental impact throughout its lifecycle, from production to disposal.

Q 27. Explain your knowledge of different types of packaging machinery and processes.

Understanding packaging machinery and processes is vital for effective design. My knowledge includes:

- Cartoning Machines: Used for forming, filling, and sealing cartons, with different types handling various sizes and speeds.

- Case Packing Machines: Automatically packing cartons into cases, optimizing space and efficiency. I consider the case packing process during initial design to ensure compatibility and prevent issues.

- Filling Machines: Various types exist, from liquid filling to powder and granular filling, each with specific requirements that influence packaging design.

- Labeling Machines: Applying labels accurately and securely to packages, often integrating with other machinery for a fully automated line.

- Pallet Wrapping Machines: Securing pallets for shipment and storage, a crucial factor in overall supply chain protection.

I consider the entire production line when designing packaging, ensuring compatibility with the available machinery and minimizing production challenges.

Q 28. How do you ensure the accuracy and precision of your packaging designs?

Accuracy and precision are paramount. I utilize several methods to ensure high quality:

- Precise 3D Modeling: Using CAD software like Inventor or SolidWorks to create highly accurate 3D models with exact dimensions, tolerances, and material specifications. This allows for detailed analysis and minimizes potential errors during manufacturing.

- Rigorous Testing and Prototyping: Creating physical prototypes and subjecting them to thorough testing to validate the design’s performance and identify any discrepancies. This iterative approach refines the design until the desired levels of accuracy and precision are achieved.

- Detailed Manufacturing Specifications: Providing comprehensive manufacturing specifications to the production team, including clear instructions, tolerances, and material requirements. This minimizes ambiguity and ensures consistent production quality.

- Quality Control Procedures: Implementing robust quality control measures throughout the production process to detect and address any deviations from the design specifications.

This multi-faceted approach ensures my designs are both functional and accurately produced.

Key Topics to Learn for Structural Packaging Design Interview

- Material Science & Selection: Understanding the properties of various packaging materials (paperboard, corrugated board, plastics, etc.) and their suitability for different products and applications. Consider factors like strength, durability, printability, and recyclability.

- Design Principles & Software: Familiarity with fundamental design principles like structural integrity, ergonomics, and aesthetics. Proficiency in relevant CAD software (e.g., SolidWorks, AutoCAD) for creating and analyzing packaging designs.

- Packaging Types & Applications: In-depth knowledge of various packaging types (e.g., folding cartons, corrugated boxes, trays, sleeves) and their optimal applications based on product characteristics and supply chain requirements.

- Testing & Validation: Understanding the importance of testing and validation methodologies to ensure packaging meets performance criteria (e.g., drop tests, compression tests, vibration tests). This includes interpreting test results and making design improvements.

- Sustainability & Environmental Impact: Knowledge of sustainable packaging practices, including material selection, reduced waste, recyclability, and compliance with environmental regulations.

- Cost Optimization & Manufacturing: Understanding the manufacturing process and its impact on cost. Ability to optimize designs for efficient production and minimize material waste.

- Graphic Design & Branding Considerations: Understanding the interplay between structural design and graphic design to create visually appealing and brand-consistent packaging.

- Regulations & Compliance: Familiarity with relevant industry regulations and standards related to food safety, transportation, and labeling requirements.

- Problem-Solving & Analytical Skills: Demonstrate your ability to approach design challenges systematically, analyze constraints, and develop creative solutions.

Next Steps

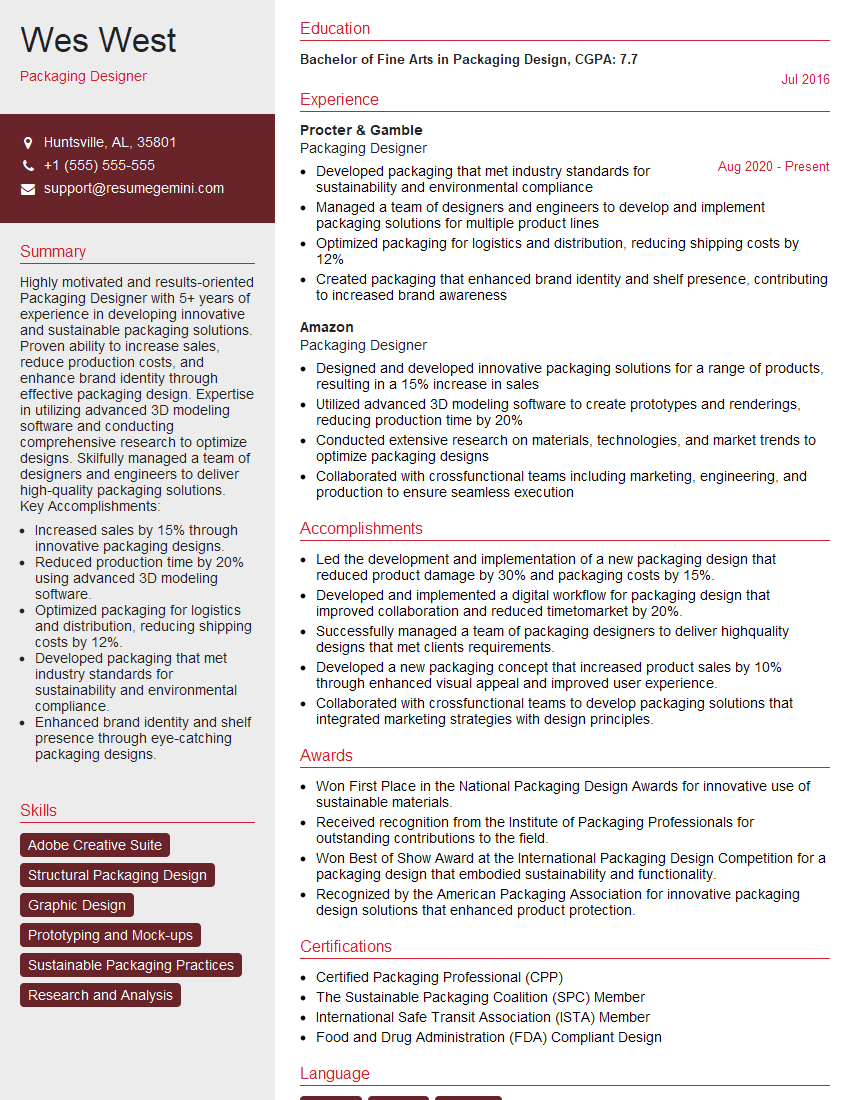

Mastering Structural Packaging Design opens doors to exciting and rewarding career opportunities in a dynamic industry. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. This will ensure your qualifications are effectively communicated to potential employers. We highly recommend leveraging ResumeGemini to build a professional and impactful resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Structural Packaging Design to help you showcase your skills effectively. Take the next step in your career journey and create a resume that stands out!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good