The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to USDA Regulations and Standards interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in USDA Regulations and Standards Interview

Q 1. Explain the difference between USDA organic and ‘made with organic’ labeling.

The difference between USDA organic and ‘made with organic’ is significant and relates to the percentage of organic ingredients. A product labeled as “USDA Organic” must contain 95% or more organic ingredients (excluding water and salt). The remaining 5% may consist of non-organic ingredients that are not commercially available as organic. Think of it like this: a truly organic apple pie has organically grown apples, flour, butter, and sugar—nearly everything is organic.

On the other hand, a product labeled ‘made with organic’ means that at least 70% of the ingredients are certified organic. This means a significant portion is organic, but a greater proportion of non-organic ingredients is allowed. For example, an apple pie labeled ‘made with organic’ might use organic apples but conventional flour and sugar. The label must clearly state the percentage of organic ingredients, e.g., ‘Made with 70% organic ingredients’. This distinction is vital for consumers seeking varying degrees of organic content.

Q 2. Describe the process for obtaining USDA organic certification.

Obtaining USDA organic certification involves a multi-step process. First, you need to select a USDA-accredited certifying agent. These agents are third-party organizations that verify farms and processing facilities meet USDA organic standards. Then, you must develop and implement an organic system plan (OSP). This document outlines all your practices, from soil management to pest control and record-keeping. The certifying agent will review your OSP to ensure it meets all requirements. Next comes an on-site inspection of your operation. The inspector will verify your practices align with your OSP and organic regulations. Following the inspection, the certifying agent will review the findings and issue a certificate if everything is compliant. Maintaining certification requires annual inspections and record-keeping. Non-compliance can result in suspension or revocation of the certificate. It’s a rigorous process designed to ensure the integrity of the USDA organic label.

Q 3. What are the key components of a HACCP plan?

A Hazard Analysis and Critical Control Point (HACCP) plan is a preventative food safety management system. It focuses on identifying potential hazards and implementing controls to prevent them from occurring. The key components are:

- Hazard Analysis: Identifying biological, chemical, and physical hazards that could occur at each step of the food production process. For example, Salmonella in poultry, pesticide residue on produce, or metal fragments in a processed food.

- Critical Control Points (CCPs): Determining points in the process where hazards can be controlled. This might be cooking temperature for Salmonella or metal detection for metal fragments.

- Critical Limits: Establishing measurable limits for each CCP. This could be a minimum cooking temperature or maximum level of metal contamination.

- Monitoring Procedures: Defining how CCPs will be monitored. This could include temperature monitoring or regular metal detection checks.

- Corrective Actions: Establishing steps to take if a critical limit is not met. This might involve reprocessing the product or disposing of it.

- Verification Procedures: Implementing procedures to ensure the HACCP plan is effective. This could involve periodic reviews and audits.

- Record-Keeping: Maintaining thorough records of all steps in the HACCP plan.

A well-designed HACCP plan is crucial for ensuring food safety and preventing foodborne illnesses.

Q 4. How does the USDA regulate food labeling claims?

The USDA regulates food labeling claims through the Food and Drug Administration (FDA) and the Agricultural Marketing Service (AMS). These agencies ensure that food labels are truthful and not misleading. They set standards for nutrient content claims (like ‘low fat’ or ‘high fiber’), health claims (linking food to a reduced risk of disease), and structure/function claims (describing the role of a nutrient or dietary ingredient). For example, a claim like “low sodium” must meet specific criteria established by the FDA. Claims about organic content are regulated by the USDA’s organic standards. False or misleading claims can lead to regulatory action, including fines or injunctions. The USDA works to prevent inaccurate or deceptive labels that could confuse consumers.

Q 5. Explain the role of the Food Safety and Inspection Service (FSIS).

The Food Safety and Inspection Service (FSIS) is a public health agency within the USDA responsible for ensuring that the nation’s commercial supply of meat, poultry, and egg products is safe, wholesome, and correctly labeled. They achieve this through inspections of processing plants, enforcing regulations, and conducting research. This includes monitoring for contamination, verifying proper handling procedures, and checking labels for accuracy. FSIS inspectors work on-site at processing facilities, ensuring compliance with federal regulations. Their work is essential for protecting consumers from foodborne illnesses associated with meat and poultry products. Essentially, they are the guardians of meat and poultry safety in the US.

Q 6. What are the main provisions of the Food Safety Modernization Act (FSMA)?

The Food Safety Modernization Act (FSMA) represents a major shift from responding to foodborne illness outbreaks to proactively preventing them. Key provisions include:

- Preventive Controls for Human Food: Requires food facilities to develop and implement preventive controls to minimize hazards.

- Preventive Controls for Animal Food: Similar to the human food rule, but for animal food.

- Produce Safety Rule: Establishes science-based minimum standards for the safe growing, harvesting, packing, and holding of produce.

- Foreign Supplier Verification Program: Requires importers to verify that foreign suppliers meet US food safety standards.

- Sanitary Transportation of Human and Animal Food: Sets standards for transporting food safely.

FSMA emphasizes a preventative approach, shifting the focus from reacting to contamination to actively preventing it. It significantly impacts how food is grown, processed, and transported across the country and internationally.

Q 7. Describe the requirements for Good Agricultural Practices (GAPs).

Good Agricultural Practices (GAPs) are a set of minimum standards for the safe production and handling of agricultural products. These practices aim to minimize microbial contamination, pesticide residue, and other hazards that could compromise food safety. Key requirements include:

- Worker Health and Hygiene: Proper handwashing, sanitation facilities, and training for workers.

- Soil Health: Proper soil management to prevent contamination.

- Water Management: Safeguarding water sources from contamination and using safe irrigation practices.

- Pest Management: Implementing integrated pest management strategies to minimize pesticide use.

- Equipment Cleaning and Sanitation: Maintaining clean and sanitized equipment to prevent contamination.

- Harvesting and Handling: Proper harvesting techniques and careful handling to minimize damage and contamination.

GAPs are crucial for ensuring the safety of fresh produce and protecting consumers from foodborne illnesses. Compliance helps build consumer confidence and enhances the reputation of the farm and its products.

Q 8. What are the USDA regulations regarding pesticide residues in food?

The USDA sets tolerance levels for pesticide residues on food, ensuring they don’t pose a health risk. These tolerances are established based on extensive scientific research, considering factors like the toxicity of the pesticide, the amount likely to remain on the food after application, and the potential exposure levels for consumers. The Food and Drug Administration (FDA) also plays a significant role in enforcing these tolerances, conducting sampling and testing of foods to ensure compliance.

Think of it like this: Imagine a scale. On one side is the amount of pesticide residue allowed, the tolerance. On the other side is the actual amount found on the food. If the residue amount exceeds the tolerance, the food is considered unsafe and may be subject to action.

For example, the EPA (Environmental Protection Agency) sets the maximum residue levels (MRLs) for specific pesticides on specific crops. The USDA then ensures that these MRLs are respected during the production and processing stages. If a grower exceeds the MRL for a certain pesticide on their apples, they could face repercussions and the apples may be rejected or recalled.

Q 9. How are meat and poultry products inspected by the USDA?

The USDA’s Food Safety and Inspection Service (FSIS) inspects meat and poultry products to ensure they are safe, wholesome, and properly labeled. This inspection occurs at various stages, from the slaughterhouse to the processing plant, and includes verification of sanitary conditions, proper handling procedures, and disease prevention measures. Inspectors visually examine carcasses for disease or injury, check processing equipment for cleanliness, and verify labeling accuracy.

The inspection process isn’t just about checking for visible problems. FSIS uses various testing methods, including microbiological testing to identify pathogens like Salmonella or E. coli. They also conduct random sampling to maintain a high standard of quality control. The goal is to prevent contaminated meat and poultry from reaching consumers. Failure to meet these standards can result in plant closures or product recalls.

Q 10. Explain the process for recalling a food product under USDA jurisdiction.

Recalling a food product under USDA jurisdiction is a serious matter initiated when a product is found to be unsafe or mislabeled. The process begins with the company identifying the problem, usually through internal testing or consumer complaints. Then, the company must immediately notify FSIS and cooperate fully in the recall process. FSIS will then classify the recall based on its severity (Class I, II, or III) and work with the company to remove the product from the market.

The recall process involves tracing the affected products back to their origin and working with distributors and retailers to ensure complete removal. FSIS provides guidance and support throughout this process, including public notification strategies. The severity of the recall impacts the speed and scope of the response – a Class I recall, indicating a serious health risk, demands immediate and widespread action.

Think of it as a coordinated effort to contain a potential health crisis, working backwards from the consumer to the source of the problem. The company has a responsibility, but the USDA also has a significant role in overseeing and validating the efficacy of the recall.

Q 11. What are the requirements for handling and processing organic products?

Handling and processing organic products demands strict adherence to USDA’s National Organic Program (NOP) standards. These standards cover the entire production chain, from farming practices to processing and packaging. Organic farmers must use approved methods, avoiding synthetic pesticides, fertilizers, and genetically modified organisms (GMOs). They must also maintain detailed records and undergo regular inspections to certify their operations.

Processing organic products requires separate facilities and equipment to prevent cross-contamination with non-organic materials. The use of approved substances in processing is crucial. Labels must clearly indicate that the product is certified organic, and the USDA’s organic seal ensures consumers know the product meets the stringent requirements.

For example, a company processing organic apples would need to ensure that the apples are handled separately from conventional apples at all stages, from washing to slicing and packaging, to avoid contamination. Any deviation from the NOP standards can lead to loss of certification.

Q 12. Describe the various grades and standards used by the USDA for agricultural products.

The USDA uses various grades and standards for agricultural products to assess their quality. These standards are based on factors such as size, shape, color, and defects. The grading system provides consumers and the industry with a consistent way to evaluate the quality of products. Examples include grades for fruits (like apples or oranges), vegetables (like potatoes or broccoli), and grains (like wheat or corn).

Different grades represent different levels of quality. For instance, ‘Grade A’ typically signifies the highest quality, while lower grades may still be suitable for consumption but might have more blemishes or imperfections. These grades are not necessarily indicators of safety, but rather indicators of appearance, size, and uniformity. This helps consumers make informed decisions and ensures fair trading within the agricultural industry.

Imagine buying apples. Knowing the grade helps you anticipate the quality. A ‘Grade A’ apple would likely be larger, more uniform in shape, and have fewer blemishes than a ‘Grade B’ apple. Both could be safe to eat, but the quality and price might differ. The grades provide a standardized way to compare apples from different growers.

Q 13. Explain the USDA’s role in ensuring the safety and quality of imported food.

The USDA plays a vital role in ensuring the safety and quality of imported food through the Animal and Plant Health Inspection Service (APHIS) and FSIS. APHIS focuses on protecting U.S. agriculture from pests and diseases, inspecting imported plants, animals, and plant products to prevent entry of harmful organisms. FSIS inspects imported meat and poultry to ensure compliance with U.S. safety and labeling requirements.

This inspection process involves verifying that imported food products meet the same safety and quality standards as domestically produced goods. APHIS uses risk assessment to prioritize inspections, focusing on products or regions with a higher likelihood of carrying pests or diseases. The agency collaborates with international organizations and other countries to implement effective border protection measures. FSIS works similarly in ensuring the safety of imported meat and poultry, conducting both on-site and laboratory testing to verify compliance.

The USDA’s role is crucial to protect both U.S. agriculture and consumers from potential risks associated with imported food products. The agency’s proactive approach contributes to food security and safety, preventing the spread of plant and animal diseases while also ensuring imported food meets the same high standards as domestically produced food.

Q 14. What are the penalties for non-compliance with USDA regulations?

Penalties for non-compliance with USDA regulations can vary depending on the severity and nature of the violation. These penalties can range from warning letters and temporary suspension of operations to significant fines and even criminal prosecution in serious cases. The USDA can also issue stop-sale orders, preventing the distribution of non-compliant products.

For example, a company repeatedly found to be violating food safety standards could face substantial fines, potential facility closures, and criminal charges. Less serious infractions, like minor labeling violations, might result in a warning and a requirement to correct the problem. The USDA’s enforcement actions aim to deter non-compliance, protect consumers, and maintain the integrity of the nation’s food supply.

The severity of the penalties reflects the potential harm caused by the violation. Violations posing a direct risk to public health generally carry the most serious consequences.

Q 15. How does the USDA address foodborne illnesses?

The USDA employs a multi-pronged approach to combat foodborne illnesses, focusing on prevention and intervention throughout the food production chain. This involves a combination of regulatory oversight, inspection programs, and educational initiatives.

- Inspection and Enforcement: The USDA’s Food Safety and Inspection Service (FSIS) conducts routine inspections of meat, poultry, and egg processing facilities to ensure compliance with safety regulations, including proper sanitation, temperature control, and hazard analysis and critical control points (HACCP) implementation. Non-compliance can lead to sanctions, ranging from warnings to facility closures.

- Regulations and Standards: The USDA sets stringent regulations for food safety, covering everything from slaughtering and processing methods to labeling and transportation. These regulations are designed to minimize the risk of contamination and illness. For example, specific temperature requirements for holding perishable foods are strictly enforced.

- Traceability Systems: The USDA promotes the use of traceability systems to quickly identify and remove contaminated products from the market in the event of an outbreak. This allows for rapid response and limits the scope of the problem.

- Education and Outreach: The USDA conducts educational programs for food producers, processors, and consumers to promote safe food handling practices. This includes initiatives on proper hygiene, cooking temperatures, and avoiding cross-contamination.

For example, the USDA’s response to a salmonella outbreak might involve tracing the source of contamination back to a specific processing facility, implementing corrective actions at the facility, and issuing a recall of affected products. This integrated approach minimizes the risk and impact of foodborne illnesses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your understanding of the USDA’s National Organic Program (NOP).

The USDA’s National Organic Program (NOP) is a comprehensive regulatory framework governing the production, handling, and labeling of organic agricultural products in the United States. It establishes national standards for organic certification, ensuring that products labeled ‘organic’ meet specific criteria for production, handling, and processing.

- Production Standards: These standards specify allowable inputs, such as fertilizers, pesticides, and livestock management practices. Synthetic pesticides and fertilizers are prohibited, and organic farming relies on natural methods for pest and weed control and soil fertility management.

- Certification Process: Organic producers must obtain certification from a USDA-accredited certifying agent. These agents conduct on-site inspections to verify compliance with the NOP standards. The certification process provides consumers with assurance that the products they purchase meet organic requirements.

- Handling and Processing: The NOP also regulates the handling and processing of organic products, ensuring that they are kept separate from non-organic materials throughout the supply chain. This prevents contamination and maintains the integrity of the organic label.

- Labeling Requirements: Specific labeling requirements ensure that consumers are fully informed about the organic status of a product. The ‘USDA Organic’ seal is a key element, and specific claims, such as ‘made with organic ingredients,’ are also subject to detailed guidelines.

Imagine a farmer transitioning to organic practices. They would need to develop an organic system plan, undergo a certification process, and maintain strict records to demonstrate compliance. This rigorous system ensures consumer trust and protects the integrity of the organic market.

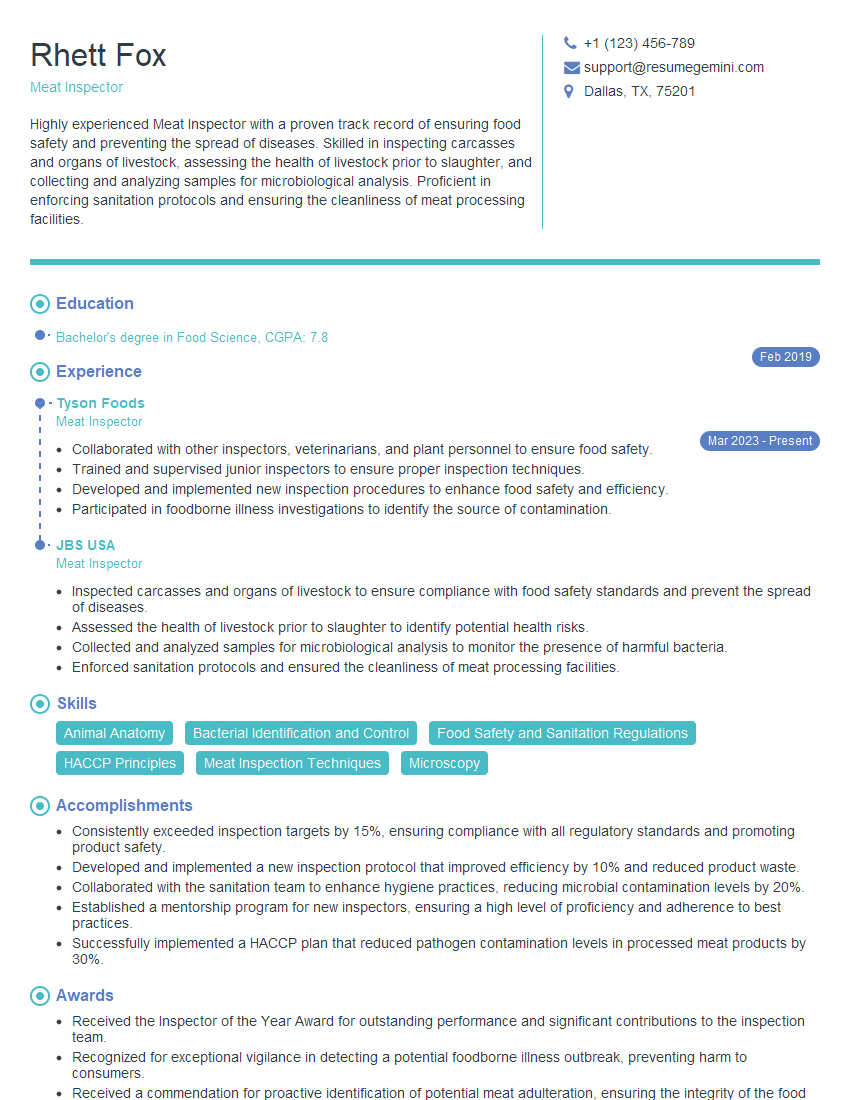

Q 17. What is your experience with auditing food processing facilities for USDA compliance?

My experience in auditing food processing facilities for USDA compliance spans over [Number] years. I’ve conducted numerous audits across various sectors, including meat processing, dairy, and fruit and vegetable processing. My audits focus on verifying compliance with FSIS regulations and ensuring the implementation of effective food safety systems.

- HACCP Verification: A significant part of my work involves assessing the effectiveness of a facility’s Hazard Analysis and Critical Control Point (HACCP) plan. This entails reviewing the plan’s documentation, observing operational procedures, and verifying the implementation of critical control points.

- Sanitation and Hygiene Audits: I meticulously assess sanitation practices, including cleaning and disinfection procedures, pest control measures, and employee hygiene protocols. These are critical aspects for preventing contamination.

- Traceability System Review: I evaluate the effectiveness of traceability systems, which are essential for tracking products throughout the production process. This allows for rapid response in case of contamination or recalls.

- Record Keeping Review: I review the facility’s record-keeping procedures to ensure compliance with USDA documentation requirements. Accurate and comprehensive records are vital for demonstrating compliance and traceability.

For example, during a recent audit, I identified a gap in a facility’s HACCP plan concerning temperature control during the cooling process. I worked with the facility management to develop corrective actions to address this issue and ensure compliance.

Q 18. Explain the concept of traceability in the food supply chain.

Traceability in the food supply chain refers to the ability to track a food product through all stages of its production, processing, and distribution. This system enables the quick identification of the source of contamination in case of a food safety incident and facilitates efficient product recalls.

- Farm to Table Tracking: A complete traceability system allows you to trace a product from the farm where it was grown or the animal where it originated, through all processing steps, to the point of sale. This provides a complete history of the product’s journey.

- Lot and Batch Numbers: Tracking systems rely on unique lot and batch numbers assigned to products at different stages. This allows for precise identification and isolation of contaminated products.

- Electronic Systems: Modern traceability systems often involve electronic record-keeping, barcodes, and RFID technology, making tracking more efficient and accurate.

- Benefits: Effective traceability systems are vital for responding to food safety incidents, managing recalls, and maintaining consumer trust. They also support investigations into the causes of contamination and help improve food safety practices.

Imagine a case of contaminated lettuce. With a robust traceability system, the source of the contamination can be quickly pinpointed to a specific farm or field, minimizing the scope of the recall and preventing further illnesses.

Q 19. How do you stay updated on changes and updates to USDA regulations?

Staying updated on changes and updates to USDA regulations requires a multifaceted approach. I utilize several key strategies to ensure I remain current with the latest information.

- USDA Website and Publications: I regularly consult the official USDA website, specifically the FSIS and AMS websites, for updates, announcements, and newly released regulations. I subscribe to their email newsletters and alerts.

- Industry Journals and Publications: I subscribe to relevant industry journals and trade publications that provide analysis and commentary on new USDA regulations and their impact.

- Professional Networks and Associations: Active participation in professional networks and associations, such as the International Association for Food Protection (IAFP), provides access to updates, training, and discussions on current issues.

- Webinars and Seminars: I regularly attend webinars and seminars conducted by USDA officials and industry experts to learn about new developments and best practices.

Staying informed is critical because the food industry’s regulatory landscape is dynamic. By actively engaging in these different information channels, I can ensure I am providing the best possible guidance and compliance support.

Q 20. Describe your experience with implementing and maintaining HACCP plans.

My experience with HACCP (Hazard Analysis and Critical Control Point) plan implementation and maintenance is extensive. I have been involved in developing, implementing, and auditing HACCP plans for numerous food processing facilities. This includes working with various stakeholders, from management to line workers.

- Hazard Analysis: I have considerable experience in conducting thorough hazard analyses, identifying potential biological, chemical, and physical hazards that could contaminate food products.

- Critical Control Point (CCP) Identification: I’m skilled in identifying critical control points (CCPs) within the production process—the steps where control can prevent or eliminate hazards.

- Critical Limits and Monitoring: I work on establishing critical limits for each CCP and developing effective monitoring procedures to ensure the CCPs remain under control.

- Corrective Actions: I have experience in developing and implementing corrective actions to address deviations from critical limits.

- Record-Keeping and Documentation: Meticulous record-keeping and documentation are crucial for demonstrating HACCP compliance. I help facilities maintain accurate and comprehensive records.

For example, I assisted a meat processing facility in improving its HACCP plan by implementing a more rigorous temperature monitoring system at its critical control points, which significantly reduced the risk of bacterial contamination.

Q 21. How do you handle situations where there is a conflict between USDA regulations and company policy?

Handling conflicts between USDA regulations and company policy requires a careful and systematic approach. The primary principle is that USDA regulations always supersede company policy.

- Identify the Conflict: The first step is to clearly identify and document the specific points of conflict between the USDA regulation and the company policy.

- Consult the Regulations: Thoroughly review the relevant USDA regulations to ensure a clear understanding of the requirements.

- Assess the Risk: Evaluate the potential risks associated with non-compliance with USDA regulations. This might involve food safety risks, economic penalties, or reputational damage.

- Develop a Solution: Develop a solution that ensures compliance with USDA regulations while minimizing disruption to company operations. This might involve modifying company policy, implementing new procedures, or investing in new equipment.

- Document the Changes: Thoroughly document all changes made to company policy or procedures to ensure transparency and traceability.

- Communication: Open communication with all stakeholders, including management, employees, and USDA officials, is essential throughout the process.

For instance, if a company’s policy on cleaning and sanitizing equipment fell short of USDA standards, a revised policy that aligns with the USDA’s guidelines would be implemented. Transparency and a commitment to compliance are vital for maintaining a strong reputation and ensuring food safety.

Q 22. What is your experience working with USDA inspectors?

My experience with USDA inspectors spans over fifteen years, encompassing various roles within the food processing industry. I’ve worked closely with inspectors from both the Food Safety and Inspection Service (FSIS) and the Agricultural Marketing Service (AMS), focusing primarily on meat and poultry processing. This collaboration has involved everything from pre-inspection facility preparation and on-site audits to addressing non-compliance issues and implementing corrective actions. I’ve built strong professional relationships based on mutual respect and a shared commitment to food safety and quality. For example, during a recent facility audit, proactive collaboration with the inspector regarding a minor procedural issue prevented a potential major issue later. Open communication and a willingness to adapt procedures based on their feedback proved invaluable.

Q 23. Describe your familiarity with the USDA’s Agricultural Marketing Service (AMS).

The USDA’s Agricultural Marketing Service (AMS) is extremely relevant to my work. AMS sets standards for a vast array of agricultural products, including grading, standardization, and certification programs. My familiarity with AMS extends to understanding their various market news reports, which inform pricing strategies and market analysis. I’m specifically knowledgeable in the AMS’s role in organic certification (NOP), and various grading standards for fruits, vegetables, and grains. For instance, understanding the AMS’s standards for organic certification is crucial for producers seeking that label. Compliance with their detailed guidelines, including record-keeping and third-party inspections, impacts the entire supply chain.

Q 24. How do you ensure compliance with specific USDA regulations concerning your area of expertise?

Ensuring compliance with specific USDA regulations is a multifaceted process. It starts with thorough training of our staff on the relevant regulations and standards. We maintain detailed Standard Operating Procedures (SOPs) aligned with these standards, implementing a robust food safety management system (FSMS). Regular internal audits evaluate our adherence to these SOPs. We proactively invest in new technologies and methodologies to improve our procedures and reduce risks. For example, we recently implemented a new traceability system to meticulously track products from farm to table, greatly simplifying recall management and enhancing our ability to demonstrate compliance in audits. This preventative approach minimizes the likelihood of non-compliance issues.

Q 25. Explain the different types of USDA certifications and their requirements.

The USDA offers a wide range of certifications, each with its unique requirements. These include:

- Organic Certification (NOP): Regulates the production and handling of organic products, requiring adherence to strict standards for soil health, pest control, and prohibited substances. This requires comprehensive record-keeping and third-party certification.

- BioPreferred® Program: Promotes the use of biobased products. Certification ensures the product meets specific biobased content requirements.

- Process Verified Program (PVP): Verifies that a product or production process meets certain standards beyond those required by law. Examples include humane handling or sustainability certifications.

- Grading Standards: AMS sets grades for various agricultural products, indicating quality. Meeting these standards is often a marketing advantage.

Q 26. How would you handle a situation where a product fails to meet USDA standards?

If a product fails to meet USDA standards, a structured response is crucial. First, we’d conduct a thorough investigation to identify the root cause of the non-compliance. This involves reviewing production records, testing samples, and interviewing staff. Then, depending on the severity, we’d implement immediate corrective actions to prevent further issues. This might include isolating the affected product, adjusting production procedures, or retraining personnel. We’d promptly notify the USDA and fully cooperate with any investigation or recall process. Transparency and a proactive approach are essential to maintaining our reputation and regaining compliance. For example, a past incident involving a batch of produce failing pesticide residue testing triggered a full review of our supplier selection and monitoring protocols, resulting in stricter quality controls and improved documentation.

Q 27. What are your strategies for ensuring continuous compliance with evolving USDA regulations?

Ensuring continuous compliance with evolving USDA regulations requires a proactive, multi-pronged strategy. This includes:

- Regular monitoring of updates: We subscribe to USDA newsletters and actively check for updates to regulations and guidance.

- Collaboration with industry experts: Attending industry conferences and workshops keeps us informed about changes and best practices.

- Internal training programs: Regular staff training ensures everyone is up-to-date on current regulations.

- Investing in technology: Utilizing software and systems that aid compliance, such as traceability systems and data management tools, simplifies tracking and reporting.

Key Topics to Learn for USDA Regulations and Standards Interview

- Food Safety and Inspection Service (FSIS) Regulations: Understanding the core principles of meat, poultry, and egg product inspection, including sanitation, labeling, and traceability requirements. Practical application: Analyzing a hypothetical scenario involving a food safety incident and applying relevant FSIS regulations to determine the appropriate course of action.

- Organic Certification: Mastering the National Organic Program (NOP) standards, including allowed substances, prohibited methods, and organic labeling requirements. Practical application: Evaluating a farm’s practices to determine compliance with NOP standards and identifying potential areas for improvement.

- Agricultural Marketing Service (AMS) Standards: Familiarizing yourself with grading standards for various agricultural products, including fruits, vegetables, and grains. Practical application: Interpreting grading reports and understanding their implications for market value and trade.

- Food Labeling and Nutrition: Understanding the requirements for accurate and truthful labeling of food products, including nutrition facts panels and ingredient declarations. Practical application: Analyzing a food label to identify potential compliance issues and suggesting corrective actions.

- Animal Welfare: Knowledge of regulations and guidelines related to the humane handling and treatment of animals in agricultural settings. Practical application: Evaluating animal welfare practices on a farm and identifying potential areas for improvement.

- Environmental Regulations: Understanding the environmental impact of agricultural practices and relevant regulations related to water quality, pesticide use, and soil conservation. Practical application: Assessing the environmental footprint of a farming operation and recommending strategies for compliance and sustainability.

- Program Implementation and Enforcement: Understanding the processes involved in implementing and enforcing USDA regulations, including inspections, investigations, and compliance actions. Practical application: Developing a plan for conducting an effective compliance audit.

Next Steps

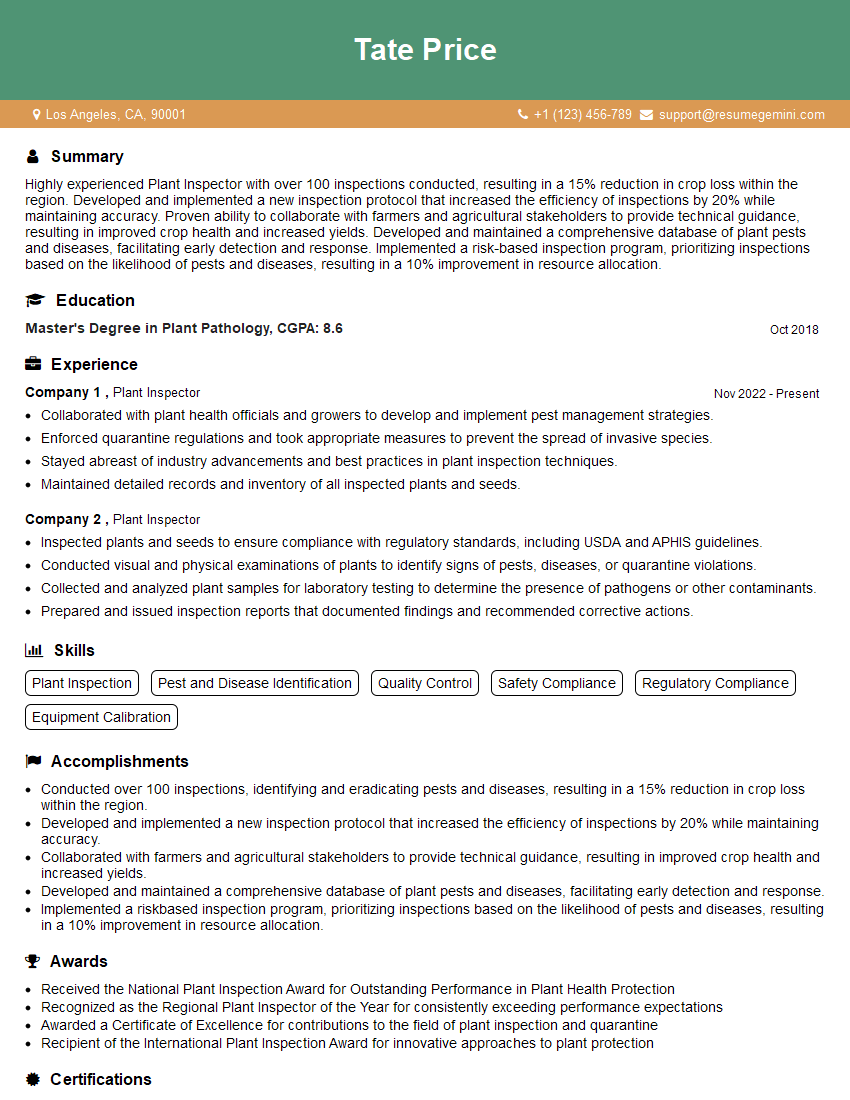

Mastering USDA Regulations and Standards is crucial for advancing your career in agriculture, food safety, and related fields. Demonstrating this expertise through a strong resume is key to securing your dream role. An ATS-friendly resume significantly increases your chances of getting noticed by recruiters. We strongly recommend leveraging ResumeGemini to build a compelling and effective resume that showcases your skills and experience in a way that Applicant Tracking Systems (ATS) can easily process. ResumeGemini provides examples of resumes tailored specifically to USDA Regulations and Standards, offering valuable guidance and inspiration for crafting your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good