Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Packaging Machine Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Packaging Machine Operation Interview

Q 1. Describe your experience with different types of packaging machines (e.g., vertical form fill seal, horizontal flow wrapper).

My experience encompasses a wide range of packaging machinery, including vertical form-fill-seal (VFFS) machines, horizontal flow wrappers, and cartoning machines. VFFS machines, for example, are incredibly versatile – I’ve worked with those creating everything from snack bags to pouches for liquids. These machines form, fill, and seal bags in one continuous motion. Horizontal flow wrappers, on the other hand, are ideal for products needing a more rigid, wrapped package, like candy bars or boxes of cookies. I’m also proficient with cartoning machines, used to package products into cardboard boxes for increased protection and branding opportunities. Each machine presents unique challenges in terms of setup, maintenance, and troubleshooting, and my experience spans working with various brands and models, allowing me to quickly adapt to new systems.

For instance, I once had to troubleshoot a VFFS machine that was producing inconsistent seal quality. Through systematic analysis, I identified a worn-out sealing jaw, which was promptly replaced, resolving the issue. This illustrates my ability to not only operate but also diagnose and resolve problems related to packaging equipment.

Q 2. Explain the process of setting up and adjusting a packaging machine for a new product.

Setting up a packaging machine for a new product is a multi-step process requiring precision and attention to detail. It begins with a thorough understanding of the product’s dimensions, weight, and material properties. This information dictates the necessary adjustments to the machine’s parameters.

- Film/Material Selection: The correct film type and dimensions are crucial for proper sealing and aesthetic appeal. This often involves testing different films to find the optimal balance of seal strength and material cost.

- Machine Adjustments: This includes adjusting the length, width, and seal settings of the packaging material to precisely accommodate the product. This process might involve calibrating sensors for accurate product detection and adjusting fill volume settings. For example, if the product is slightly larger than previously packaged items, the film width might need adjusting to ensure proper wrapping without creasing or tearing.

- Testing and Refinement: Once the initial adjustments are made, extensive testing is required to ensure the packaging process is functioning correctly and consistently. This involves monitoring parameters like seal integrity, package aesthetics, and production speed. Adjustments are made iteratively until the desired quality is achieved.

Think of it like baking a cake – you need the right ingredients (product, film), the correct measurements (machine settings), and careful monitoring (testing and adjustments) to ensure a perfect result. My experience allows me to quickly optimize these parameters for maximum efficiency and minimal waste.

Q 3. How do you troubleshoot common malfunctions in packaging machines?

Troubleshooting packaging machine malfunctions requires a systematic approach. My process typically follows these steps:

- Identify the Problem: Precisely define the nature of the malfunction. Is it a complete shutdown, inconsistent sealing, or reduced output?

- Check the Obvious: Begin with simple checks like power supply, material supply, and sensor functionality. Often the problem is a simple fix like a jammed sensor or a low material level.

- Consult Manuals and Documentation: Manufacturer manuals often provide troubleshooting guides with specific error codes and their solutions.

- Systematic Diagnostics: If the problem persists, systematically check individual components, paying attention to potential points of failure. For example, if seals are inconsistent, check the sealing jaws for wear and tear or misalignment.

- Escalation: If the problem cannot be solved through internal troubleshooting, I will escalate the issue to maintenance personnel or the equipment manufacturer.

For example, if a VFFS machine is experiencing frequent jams, I would systematically check the product feed system, film path, and sealing mechanism for obstructions or misalignments.

Q 4. What safety precautions do you follow when operating packaging machinery?

Safety is paramount when operating packaging machinery. I strictly adhere to all safety protocols, including:

- Lockout/Tagout Procedures: Before performing any maintenance or cleaning, I always follow lockout/tagout procedures to prevent accidental machine starts.

- Personal Protective Equipment (PPE): I consistently wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Machine Guards: I ensure all machine guards are in place and functioning correctly to prevent accidental contact with moving parts.

- Regular Inspections: I perform regular safety checks of the machine and its surroundings, reporting any potential hazards immediately.

- Training and Awareness: I am well-versed in the specific safety regulations relevant to the types of machinery I operate and participate in regular safety training.

Prioritizing safety is not just a matter of compliance; it’s a fundamental aspect of my work ethic. A safe work environment is essential for both individual well-being and efficient production.

Q 5. Describe your experience with preventative maintenance on packaging equipment.

Preventative maintenance is crucial for ensuring the longevity and optimal performance of packaging equipment. My preventative maintenance routine includes:

- Regular Cleaning: Regularly cleaning the machine, removing accumulated dust and debris to prevent malfunctions.

- Lubrication: Applying lubricants to moving parts according to the manufacturer’s recommendations to reduce friction and wear.

- Inspections: Regularly inspecting components for wear and tear, identifying potential issues before they escalate into major problems.

- Calibration: Periodically calibrating sensors and other measuring devices to ensure accuracy.

- Scheduled Maintenance: Following a scheduled maintenance plan that includes replacing worn parts and conducting more thorough inspections at set intervals.

Think of it as regularly servicing your car – regular maintenance prevents costly repairs and ensures it runs smoothly for years to come. Similarly, proactive maintenance of packaging equipment minimizes downtime and ensures consistent high-quality output.

Q 6. How do you ensure the quality and consistency of packaging output?

Ensuring quality and consistency in packaging output involves several key strategies:

- Process Monitoring: Continuously monitor critical parameters during operation, such as sealing temperature, film tension, and fill volume, to identify deviations from the set standards. Any variation is promptly investigated and corrected.

- Quality Checks: Performing regular quality checks on the packaged products to ensure they meet specifications, including visual inspection and seal strength testing.

- Statistical Process Control (SPC): Employing SPC techniques to track and analyze key process parameters over time and identify trends that might indicate potential quality issues.

- Operator Training: Providing comprehensive training to operators on proper machine operation and quality control procedures.

- Regular Calibration: Ensuring that the machine’s measuring devices are regularly calibrated to maintain accurate and consistent results.

For example, I might use a seal tester to measure the strength of every tenth package to ensure the seals meet the required standards. If deviations are identified, I can adjust machine settings and investigate root causes to maintain consistent packaging quality.

Q 7. What are the key performance indicators (KPIs) you monitor in packaging operations?

Several key performance indicators (KPIs) are crucial for evaluating the efficiency and effectiveness of packaging operations:

- Overall Equipment Effectiveness (OEE): A comprehensive metric reflecting the machine’s productivity, including availability, performance, and quality.

- Production Rate (Units/Hour): Measures the number of units packaged per hour, reflecting the speed and efficiency of the packaging process.

- Waste Rate (%): Tracks the percentage of materials wasted due to defects, mis-packaging, or other issues. A lower waste rate demonstrates efficient resource utilization.

- Downtime (%): The percentage of time the machine is not operational due to malfunctions, maintenance, or other reasons. Minimizing downtime is critical for maximizing production.

- Defect Rate (%): The percentage of defective packages produced, indicating the consistency and quality of the packaging process.

Regularly monitoring these KPIs provides valuable insights into the performance of the packaging line, allowing for prompt identification of areas requiring improvement and optimization. Data analysis allows proactive adjustments, resulting in higher productivity and lower costs.

Q 8. How do you handle production downtime due to equipment failure?

Production downtime due to equipment failure is a major concern in any packaging operation. My approach is proactive and systematic, focusing on minimizing disruption and maximizing efficiency. It begins with preventative maintenance to reduce the likelihood of failures. When a failure does occur, my first step is to ensure the safety of personnel and the equipment itself. Then, I follow a structured troubleshooting process.

- Immediate Assessment: I quickly assess the situation – is it a minor issue or something more serious? What’s the root cause (if readily apparent)? Is there a backup machine or process that can be temporarily implemented?

- Diagnosis: Based on the initial assessment, I proceed with a diagnostic check, consulting manuals, schematics, and diagnostic tools. This could involve inspecting sensors, checking power supply, examining mechanical components, etc. Sometimes it involves a simple fix, such as replacing a worn part. In other cases, it might necessitate a more in-depth investigation.

- Repair or Replacement: Depending on the severity, I either repair the component or initiate the replacement process. This involves liaising with maintenance personnel and potentially ordering replacement parts. Prioritizing critical components helps minimize downtime.

- Root Cause Analysis: After resolving the immediate issue, I always perform a root cause analysis to prevent similar issues in the future. This ensures that preventative maintenance procedures are updated and future breakdowns are less likely.

- Documentation: Detailed documentation of the incident – the failure type, diagnostic steps, repair process, and root cause – is meticulously maintained. This information is critical for continuous improvement and informed decision-making about maintenance schedules and spare parts inventory.

For example, once I had a situation where a critical sensor on a high-speed case packer failed causing a significant production bottleneck. By using my knowledge of the machine’s architecture and following the troubleshooting steps, I quickly identified the faulty sensor and managed to replace it within an hour, limiting production losses to a minimum.

Q 9. Explain your understanding of different packaging materials (e.g., film, paper, cardboard).

Packaging materials play a crucial role in product protection, preservation, and presentation. My experience encompasses a wide range of materials, each with its own unique properties and applications:

- Film: This includes various types like polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). These are versatile, offering good barrier properties, flexibility, and sealability; ideal for flexible packaging such as pouches, bags, and wraps. Different film types offer various levels of barrier protection against moisture, oxygen, and other environmental factors.

- Paper: Paperboard and paper are common in cartons, boxes, and labels. They provide good printability and are often recyclable and biodegradable. The choice between different paper grades depends on factors like strength, stiffness, and printability requirements.

- Cardboard: This encompasses corrugated cardboard (often referred to as simply cardboard) and solid-board. Corrugated cardboard offers good cushioning and strength; frequently used for shipping boxes. Solid-board is denser and offers superior structural integrity for display boxes or premium packaging.

The selection of packaging material depends on numerous factors including product characteristics (fragility, shelf life), environmental considerations (recyclability), cost, and aesthetic appeal. For instance, a delicate electronic device might need a combination of foam cushioning inside a cardboard box, and a film wrap for additional protection during shipping.

Q 10. How do you identify and resolve issues related to packaging material jams or misfeeds?

Packaging material jams and misfeeds are common challenges. My approach to resolving these issues involves a systematic and methodical approach, combining troubleshooting skills with a deep understanding of the machinery’s mechanics.

- Safety First: Before attempting any repairs or adjustments, I always ensure the machine is safely shut down and locked out/tagged out.

- Visual Inspection: I begin with a visual inspection of the material path, looking for obvious obstructions, wrinkles, or misalignments in the feed system. This often reveals the root cause.

- Check Material Handling: I check the tension and guidance of the material as it moves through the machine. Incorrect tension or misalignment can lead to jams. I pay attention to rollers, guides, and sensors that detect material presence and position.

- Sensor Diagnostics: If sensors are involved, I check their functionality. Defective sensors can lead to incorrect machine response or misfeeding. I often need to check wiring and connections to the PLC system

- Clean the Machine: Accumulated dust, debris, or product residue can obstruct the material path. A thorough cleaning is often a crucial step.

- Adjustments: After identifying the problem, adjustments might be needed in the feed rollers, guides, or other components to ensure smooth material flow. This step might involve using specialized tools for precise calibration.

- Maintenance: Regularly scheduled preventative maintenance, such as cleaning and lubrication, significantly reduces jams and misfeeds. This also helps prolong the life of components.

For example, I once had a recurring misfeed issue on a vertical form-fill-seal machine. Through a systematic inspection, I found that a small build-up of film residue was causing friction and inconsistencies in the material path. After thorough cleaning and making minor adjustments to the film tension, the issue was resolved.

Q 11. What experience do you have with PLC programming or troubleshooting?

I possess extensive experience in PLC programming and troubleshooting, a crucial skillset for maintaining and optimizing packaging equipment. My expertise involves both ladder logic programming and troubleshooting using diagnostic software. I am proficient in reading and interpreting ladder logic diagrams, identifying faulty logic, and implementing corrective measures.

My experience includes:

- PLC Programming: I’ve worked with various PLC brands (e.g., Allen-Bradley, Siemens) to program and modify machine control systems to enhance efficiency, safety, and functionality.

- Troubleshooting: I utilize diagnostic software and hardware tools to identify the root cause of PLC-related issues – malfunctioning I/O modules, communication failures, incorrect program logic, etc. For instance, I once resolved a situation where a production line halted because a sensor was incorrectly reporting a low-level condition.

- Data Acquisition: I have experience using PLC systems to acquire real-time production data (speed, output, etc.) for performance analysis and optimization. This includes setting up data logging systems for analyzing trends and identifying potential problems before they escalate.

For example, I was able to optimize a bagging machine’s PLC program to improve its output rate by 15% by implementing a more efficient control algorithm for the bag sealing process. This involved reviewing the existing ladder logic, identifying inefficiencies in the timing and sequence of operations, and rewriting sections of the code to improve speed without compromising quality.

Q 12. Describe your experience with cleaning and sanitizing packaging equipment.

Cleaning and sanitizing packaging equipment is critical for maintaining hygiene standards and preventing cross-contamination, particularly in food processing environments. My experience encompasses various cleaning and sanitizing procedures depending on the equipment type and regulatory requirements.

My process typically involves:

- Shutdown and Lockout/Tagout: Safety is paramount. I ensure the equipment is properly shut down, locked out, and tagged out before starting any cleaning or sanitizing process.

- Disassembly (where necessary): Some equipment requires partial or complete disassembly for thorough cleaning; this is done carefully and according to manufacturer instructions.

- Cleaning: I use appropriate cleaning agents and techniques, including high-pressure water jets (where applicable), brushes, and specialized cleaning solutions. The cleaning process focuses on removing all debris, product residue, and any potential contaminants.

- Sanitization: After cleaning, I apply suitable sanitizing agents to kill bacteria and other microorganisms. The choice of sanitizer depends on the material compatibility of the equipment and regulations.

- Rinsing: After sanitization, thorough rinsing is essential to remove all traces of cleaning and sanitizing agents.

- Reassembly (where necessary): Once cleaning and sanitization are complete, I carefully reassemble any disassembled components, ensuring everything is correctly positioned and functioning.

- Documentation: I maintain detailed records of the cleaning and sanitizing process, including dates, times, cleaning agents used, and personnel involved. This record keeping is crucial for meeting regulatory requirements.

For instance, I’ve developed standardized cleaning procedures for several different packaging lines, ensuring consistency and efficiency while always prioritizing safety. We use a color-coded system to track cleaning frequency and different solutions for different components to avoid cross-contamination.

Q 13. How do you ensure compliance with food safety regulations in packaging operations?

Ensuring compliance with food safety regulations is paramount in packaging operations. My experience encompasses a detailed understanding and implementation of various food safety standards such as HACCP (Hazard Analysis and Critical Control Points), GMP (Good Manufacturing Practices), and relevant regulations specific to different regions.

Key aspects of my approach include:

- HACCP Implementation: I’m proficient in conducting hazard analyses to identify potential food safety risks within the packaging process. I contribute to the development and implementation of control measures at critical control points to minimize these risks.

- GMP Adherence: I ensure that all personnel follow strict GMP guidelines, including proper hygiene practices, sanitation procedures, and appropriate use of personal protective equipment (PPE).

- Material Traceability: I maintain meticulous records for all packaging materials, ensuring their traceability from source to finished product. This facilitates rapid response in case of any recall situations.

- Allergen Control: I have experience implementing procedures to prevent cross-contamination from allergens, ensuring the integrity of products for those with allergies.

- Regular Audits and Inspections: I actively participate in internal and external audits and inspections, demonstrating our commitment to food safety and regulatory compliance.

- Training: I ensure that all staff involved in packaging operations receive thorough training on food safety regulations and procedures. This includes regular refresher training to stay up-to-date on the latest requirements.

For example, we recently updated our packaging line procedures to comply with new allergen regulations, including implementing a strict cleaning protocol and color-coded equipment to prevent cross-contamination of peanut-containing products.

Q 14. Explain your understanding of different packaging machine speeds and output rates.

Packaging machine speeds and output rates are critical parameters that determine overall production efficiency. My understanding encompasses various factors influencing these parameters.

- Machine Type: Different packaging machines have varying capabilities. High-speed machines such as form-fill-seal units can achieve significantly higher output rates compared to slower, more specialized machines.

- Product Characteristics: Product size, shape, and fragility dictate the speed of handling. Fragile products require slower speeds to prevent damage.

- Packaging Material: The type and properties of the packaging material (e.g., film thickness, stiffness) affect the speed of the packaging process. Thicker, stiffer materials might slow down operations.

- Operational Parameters: The machine’s operational parameters, such as filling speed, sealing temperature, and conveyor speed, are adjusted based on product and packaging requirements. Optimizing these parameters is crucial for balancing speed and quality.

- Maintenance: Regular maintenance and preventative actions are essential to keep the machine running smoothly and at its optimal speed. A well-maintained machine will have a higher output rate than one neglected.

- Output Rate Calculation: The output rate is usually expressed as units (pieces, packages, etc.) per minute or hour. This varies greatly depending on the machine and the specific application; a typical high speed bagging machine might output rates in the hundreds or thousands of units per minute.

I have experience in using various methods to determine optimal output rates that balance production requirements with the need for high-quality packaging. This involves careful analysis of production data and adjustments to the machine parameters. The goal is always to find the sweet spot where output is maximized without sacrificing product quality or machine longevity.

Q 15. What experience do you have with different types of packaging seals (e.g., heat seal, ultrasonic seal)?

My experience encompasses a wide range of packaging seals, each with its own strengths and weaknesses. Heat sealing, for instance, is a common and cost-effective method using heat to melt and fuse thermoplastic materials. I’ve extensively worked with various heat sealers, adjusting parameters like temperature, dwell time, and pressure to optimize seal integrity for different film types, from polyethylene (PE) to polypropylene (PP). I’ve also worked extensively with ultrasonic sealing, a technique that uses high-frequency vibrations to create a strong, hermetic seal without the need for heat. This is particularly useful for heat-sensitive materials. I’m also familiar with induction sealing, which creates a tamper-evident seal using electromagnetic induction to heat a foil liner. Choosing the right seal depends heavily on the product, packaging material, and desired level of protection. For example, heat sealing is great for flexible pouches, while ultrasonic sealing is perfect for sealing sensitive medical devices.

- Heat Sealing: I’ve troubleshooted issues like weak seals caused by improper temperature settings or worn-out heating elements, resulting in significant improvements in production line efficiency.

- Ultrasonic Sealing: I’ve optimized ultrasonic seal parameters to ensure consistent, high-quality seals on various materials, reducing product rejects and improving product shelf life.

- Induction Sealing: My experience includes troubleshooting issues with foil liner adhesion, ensuring consistent tamper-evidence, and maintaining optimal induction field strength for various seal sizes and shapes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate packaging machine efficiency?

Packaging machine efficiency is calculated by comparing the actual output to the theoretical maximum output over a specific period. It’s often expressed as a percentage. The formula is straightforward:

Efficiency = (Actual Output / Theoretical Maximum Output) x 100%Actual Output refers to the number of units packaged successfully during a given timeframe (e.g., units per hour, units per day).

Theoretical Maximum Output represents the machine’s maximum production capacity under ideal conditions. This is usually determined by the machine’s specifications (e.g., cycles per minute).

Example: A packaging machine is designed to package 100 units per minute (theoretical maximum). During an hour of operation, it successfully packaged 5500 units. The efficiency would be: Efficiency = (5500 / (100 units/min * 60 min)) x 100% = 91.67%

Factors impacting efficiency include machine downtime due to maintenance, changeovers, or breakdowns, as well as operator skill and material handling.

Q 17. How do you maintain accurate records of packaging machine operation and maintenance?

Maintaining accurate records is crucial for effective preventative maintenance and identifying potential issues before they escalate. I typically use a combination of methods:

- Computerized Maintenance Management System (CMMS): This software allows for centralized data storage, scheduling of preventative maintenance, tracking repair history, and generating reports. It’s especially useful for tracking machine performance metrics and identifying trends.

- Logbooks: A physical logbook remains essential for recording immediate observations, quick notes on daily operations, or details not directly tracked by the CMMS. This ensures a comprehensive record of daily performance.

- Data Acquisition Systems (DAS): For more sophisticated machinery, DAS can provide real-time data on parameters such as speed, temperature, pressure, and cycle times. This data is invaluable for performance monitoring and troubleshooting.

These records include details on machine performance metrics, maintenance tasks performed, materials used, and any downtime experienced. Detailed records allow for trend analysis to predict potential failures and schedule maintenance proactively, minimizing disruptions and maximizing operational efficiency. Think of it like a health record for the machine; it helps us keep it running smoothly.

Q 18. Describe your experience with packaging machine changeovers.

Changeovers, the process of switching a packaging machine from one product or packaging format to another, are a critical aspect of efficient production. My experience spans various types of packaging machines, from vertical form-fill-seal (VFFS) machines to horizontal flow wrappers. The steps are generally similar, although the specifics vary with the machine type:

- Planning and Preparation: Before initiating a changeover, I review the specifications for the new product and packaging, ensuring I have the necessary tools, parts, and materials. This includes checking for any specific tooling adjustments or material configurations. This is like planning a move; proper preparation makes things significantly smoother.

- Shutdown and Cleaning: I safely shut down the machine, perform a thorough cleaning to eliminate residue from the previous product and prevent contamination, and review all aspects of the machine for any potential issues.

- Format Change: This is where the specific details vary. I adjust settings, change tooling (e.g., different film rolls, cutting knives, or sealing jaws), and replace any parts as needed. This is the most hands-on part of the process.

- Test Run: Before commencing full-scale production, a test run is crucial. This allows me to verify the settings are correct, detect any flaws in the process, and fine-tune the machine to ensure optimal performance. This includes checks for seal integrity, packaging alignment, and consistent product delivery.

- Documentation: I carefully document the entire changeover process, noting any adjustments or modifications made, for future reference and to improve efficiency in subsequent changeovers.

My focus is always on minimizing downtime during changeovers; I’ve implemented techniques like pre-setting components and employing standardized procedures to significantly reduce the time required. The goal is to get the machine running smoothly and efficiently on the new product as quickly as possible.

Q 19. What is your experience with different types of labeling machines?

My experience with labeling machines includes various types, each suited for different applications and packaging formats. I’m proficient with:

- Pressure-sensitive labelers: These apply labels using adhesive backing, commonly used for individual products or cartons. I’m familiar with both roll-fed and sheet-fed variations.

- Wrap-around labelers: Ideal for labeling cylindrical containers, these machines wrap labels around the product. I have experience adjusting label placement and tension for various container sizes and shapes.

- Apply labelers: These apply labels using glue or hot melt adhesive, ideal for labeling boxes or other rigid packaging. I have experience working with different types of adhesives.

- In-line labelers: These integrate directly into the packaging line, applying labels concurrently with other packaging operations, maximizing efficiency. My experience includes working with such systems to align label placement and ensure smooth integration with other parts of the packaging line.

Understanding the strengths and limitations of each type is key to selecting the appropriate labeling machine for a specific packaging task. For instance, pressure-sensitive labelers are excellent for flexibility, but wrap-around labelers offer speed and efficiency for uniform containers.

Q 20. How do you ensure the accuracy of packaging labeling?

Ensuring accurate packaging labeling is critical for legal compliance, brand consistency, and consumer trust. Accuracy is maintained through a multi-pronged approach:

- Regular Calibration: Labeling machines require regular calibration to ensure precise label placement and dispensing. I perform these calibrations according to manufacturer guidelines using standardized procedures and precision tools.

- Label Verification: I implement rigorous quality checks at each stage, including verifying that labels are correctly printed and that the label placement aligns with specifications. This often involves visual inspection and potentially using automated vision systems for high-throughput operations.

- Data Integration: Where possible, I integrate labeling systems with other parts of the packaging line to ensure that label information matches product details, preventing mislabeling incidents. This might involve barcode scanning or data-driven label printing.

- Operator Training: Well-trained operators are crucial. They are responsible for monitoring the labeling process, identifying any potential issues, and reporting them immediately. This includes understanding the critical control points in the labeling process.

Addressing potential issues proactively, like worn rollers or misaligned components, through preventative maintenance is also critical to long-term accuracy and overall line efficiency.

Q 21. Describe your experience with using hand tools and power tools for packaging machine maintenance.

Packaging machine maintenance frequently requires the use of both hand tools and power tools. My proficiency includes:

- Hand Tools: I’m adept at using wrenches, screwdrivers, pliers, and other hand tools for routine maintenance tasks such as tightening bolts, replacing small parts, and performing minor adjustments. Precision and attention to detail are essential when using hand tools.

- Power Tools: For more demanding tasks, I use power tools such as drills, impact wrenches, and grinders. Safety is paramount when using power tools; I always follow safety protocols, wearing appropriate protective gear (gloves, safety glasses, etc.) and ensuring proper tool maintenance.

I’m also skilled in using specialized tools specific to particular packaging machine types; for instance, film splicing tools for VFFS machines or alignment tools for labelers. My approach is always one of prioritizing safety and efficiency, ensuring that the tools are correctly selected and maintained for the task at hand.

Q 22. What are your skills in reading and interpreting mechanical drawings and schematics?

Reading and interpreting mechanical drawings and schematics is fundamental to my role. I’m proficient in understanding various types of drawings, including orthographic projections, isometric views, and assembly drawings. I can easily identify components, understand their relationships, and follow the assembly sequence. For instance, I recently used schematics to troubleshoot a jam in a vertical form-fill-seal (VFFS) machine. By carefully examining the diagram, I pinpointed the source of the problem to a misaligned component in the forming section, which I then successfully adjusted. My experience also extends to understanding pneumatic and hydraulic schematics, allowing me to diagnose and resolve issues involving those systems. I’m familiar with using software such as AutoCAD and SolidWorks to view and interact with these drawings, enhancing my understanding and troubleshooting capabilities.

Q 23. How do you work effectively as part of a team in a fast-paced packaging environment?

In a fast-paced packaging environment, teamwork is crucial. I thrive in collaborative settings, contributing actively to problem-solving and ensuring smooth production. I believe in clear communication – I readily share information, listen attentively to colleagues’ perspectives, and actively participate in brainstorming sessions. For example, during a production line slowdown, I collaborated with the electrical technician and the line operator to quickly diagnose and fix a sensor malfunction, minimizing downtime. I’m also adaptable; I adjust my approach to accommodate changing priorities and seamlessly integrate with different team members and their skill sets. My experience working on multiple projects concurrently has honed my ability to manage my time effectively and prioritize tasks in a demanding environment.

Q 24. What is your experience with different types of packaging formats (e.g., pouches, bags, boxes)?

My experience encompasses a wide range of packaging formats. I’ve worked extensively with pouch packaging machines, handling various pouch styles – from stand-up pouches to three-side seal pouches. This includes experience with different sealing techniques, including heat sealing, ultrasonic sealing, and adhesive sealing. I’m also proficient with bagging machines, both horizontal and vertical, handling various bag materials like polyethylene, polypropylene, and foil laminates. Furthermore, I’ve worked with cartoners and case packers, understanding the intricacies of automatic box forming, filling, and sealing processes. My background includes experience with both rigid and flexible packaging, catering to a wide range of products with varied sizes and shapes. I’m familiar with the specific requirements for each format, ensuring efficient and effective packaging solutions.

Q 25. Describe your experience with troubleshooting electrical issues in packaging machines.

Troubleshooting electrical issues is a significant part of my skillset. I’m comfortable working with PLC (Programmable Logic Controller) systems, understanding ladder logic programming and using diagnostic tools to identify electrical faults. I can troubleshoot problems related to sensors, actuators, motors, and control circuits. For instance, I recently resolved an issue where a packaging machine intermittently stopped due to a faulty proximity sensor. I used a multimeter to check the sensor’s output and traced the problem to a loose wire connection. My experience also extends to working with safety systems such as emergency stops and light curtains, ensuring the machine’s safe operation. I prioritize safe practices and adhere to all relevant safety regulations when troubleshooting electrical components.

Q 26. What is your experience with packaging machine calibration and validation?

Packaging machine calibration and validation are essential for ensuring consistent product quality and compliance with regulations. I’m experienced in performing both tasks, using calibrated instruments and following established procedures. Calibration involves adjusting the machine parameters to meet specific specifications, such as fill weight, seal strength, and package dimensions. Validation involves demonstrating that the machine consistently produces products within the defined parameters. I’ve used statistical process control (SPC) techniques to monitor the machine’s performance and ensure consistent output. I meticulously document all calibration and validation activities, adhering to GMP (Good Manufacturing Practices) and other relevant standards. This ensures traceability and compliance with regulatory requirements. For example, I recently validated a new filling system for a pharmaceutical product, documenting every step of the process and generating a comprehensive validation report.

Q 27. How do you handle emergency situations and safety concerns related to packaging machinery?

Safety is my top priority. I’m trained in lockout/tagout procedures and follow established safety protocols meticulously. In emergency situations, my approach is systematic: First, I ensure the safety of personnel by activating emergency stops and clearing the area. Second, I assess the situation to identify the cause of the emergency. Third, I take appropriate corrective action, following established procedures, and if necessary, seek assistance from colleagues or supervisors. For example, during a minor fire incident near a packaging machine, I immediately activated the fire suppression system, evacuated personnel, and contacted emergency services. After the situation was resolved, I participated in a thorough review of the incident to identify any potential improvements to safety procedures. I believe that a proactive safety approach is essential to prevent accidents and maintain a safe working environment.

Q 28. What are your strengths and weaknesses in relation to operating packaging machinery?

One of my greatest strengths is my ability to quickly troubleshoot and resolve mechanical and electrical issues in packaging machinery. My experience and methodical approach allow me to efficiently diagnose and fix problems, minimizing downtime and maximizing production. I’m also a highly motivated and adaptable team player. However, a potential area for improvement is my knowledge of the latest advancements in advanced packaging automation systems. While I am proficient in current technologies, I plan to dedicate time to upskilling myself in this area to remain at the forefront of the industry.

Key Topics to Learn for Packaging Machine Operation Interview

- Machine Setup and Operation: Understanding the process of setting up different types of packaging machines (e.g., filling, sealing, labeling) according to specifications, including pre-operational checks and safety procedures.

- Troubleshooting and Maintenance: Identifying and resolving common malfunctions, performing basic maintenance tasks, and understanding preventative maintenance schedules to minimize downtime and ensure consistent production.

- Quality Control and Assurance: Implementing quality control checks throughout the packaging process, identifying defects, and ensuring adherence to company standards and regulatory requirements. This includes understanding statistical process control (SPC) principles.

- Safety Procedures and Regulations: Demonstrating a thorough understanding of all safety protocols related to operating packaging machinery, including lockout/tagout procedures and proper handling of materials.

- Production Efficiency and Optimization: Identifying and implementing strategies to improve production efficiency, reduce waste, and optimize machine performance. This may involve understanding concepts like Overall Equipment Effectiveness (OEE).

- Material Handling and Storage: Understanding proper techniques for handling packaging materials, ensuring efficient storage and minimizing waste. This also involves knowledge of inventory management principles.

- GMP (Good Manufacturing Practices): Familiarity with GMP guidelines and their application in a packaging environment to maintain product quality and safety.

- Reading and Interpreting Technical Documentation: Demonstrating the ability to understand and follow technical manuals, schematics, and operational instructions.

- Teamwork and Communication: Highlighting your ability to collaborate effectively with colleagues, supervisors, and maintenance personnel to achieve production goals.

Next Steps

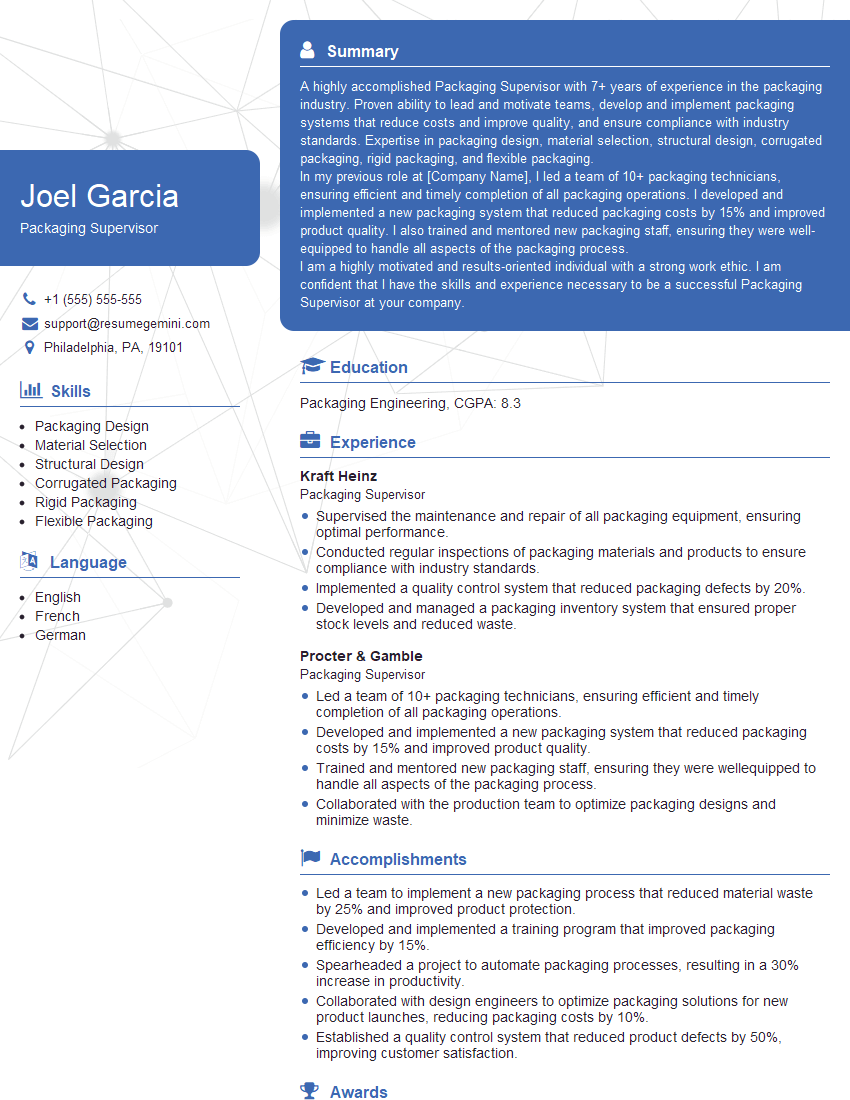

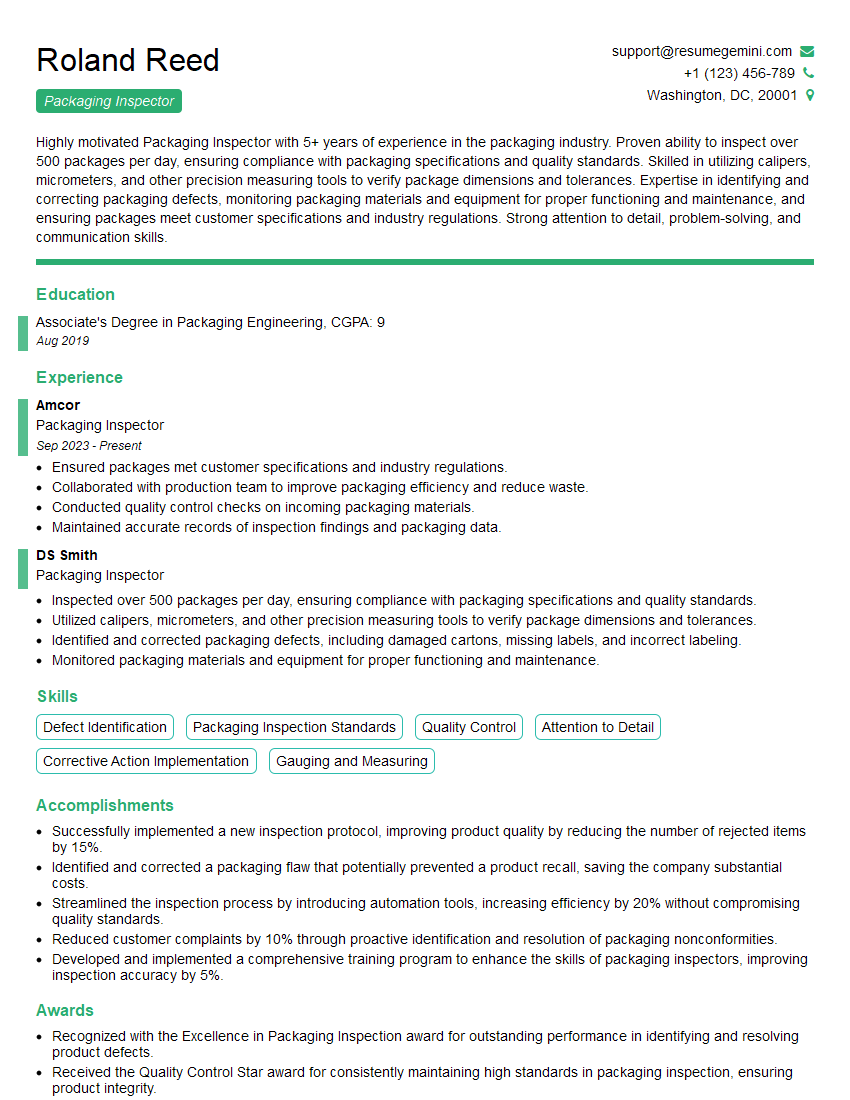

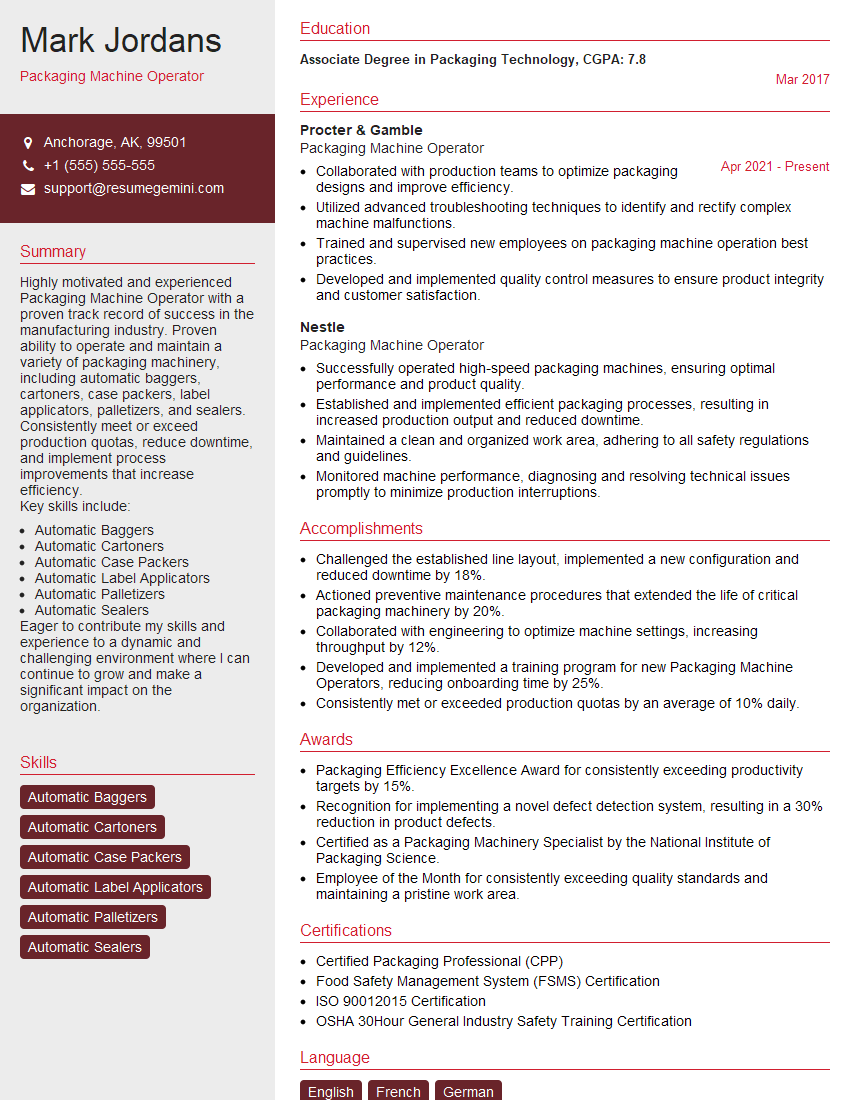

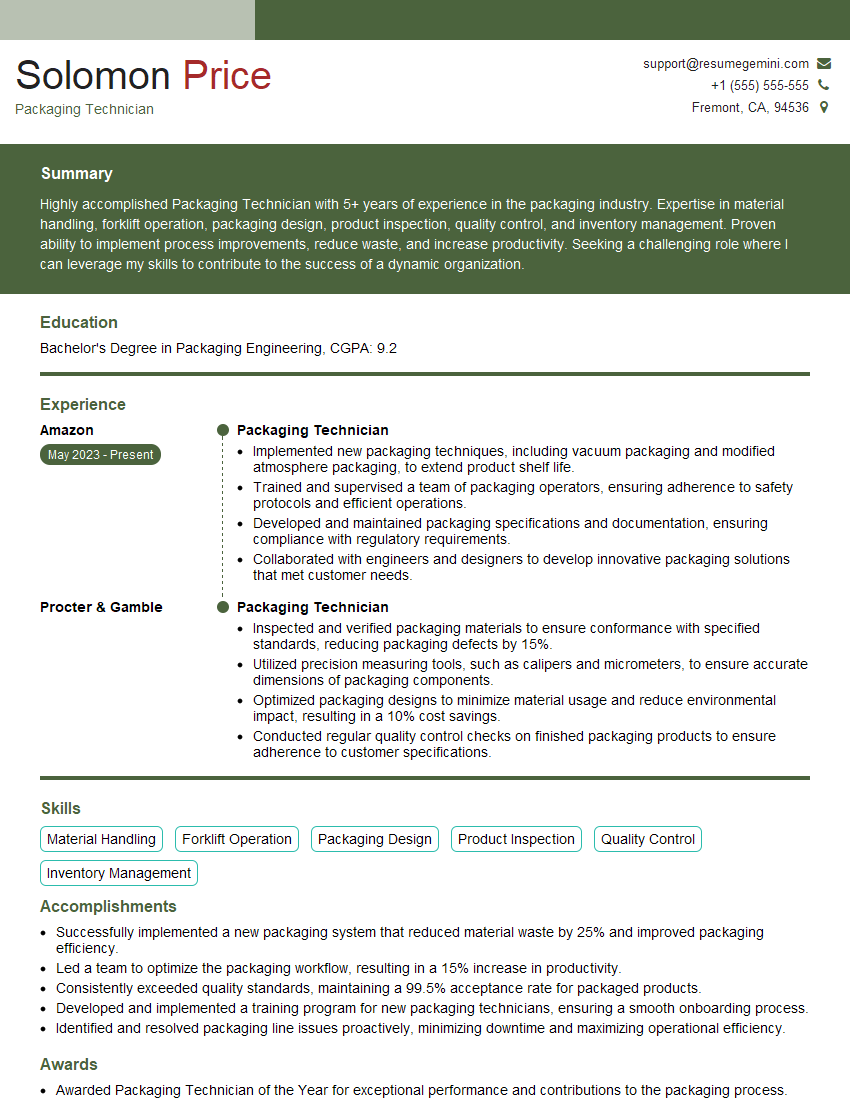

Mastering Packaging Machine Operation opens doors to rewarding career advancements, offering opportunities for specialization, increased responsibility, and higher earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Packaging Machine Operation are available to help guide your creation process. Investing time in a well-crafted resume significantly increases your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good