The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Drywall Repair and Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Drywall Repair and Installation Interview

Q 1. Describe your experience with different types of drywall.

Drywall comes in various types, each suited for different applications. The most common is standard drywall, also known as gypsum board. It’s readily available, relatively inexpensive, and perfect for most residential projects. Then there’s moisture-resistant drywall (MR), identified by a green backing. This is crucial in bathrooms, kitchens, and basements, areas prone to humidity. Fire-resistant drywall (FR), typically pink or purple, offers superior fire protection and is often mandated in commercial buildings or specific areas of a home. Finally, there’s a type with a higher density for soundproofing, offering superior sound dampening compared to standard drywall. Choosing the right type depends entirely on the project’s requirements and location within the building.

For example, in a recent renovation project, I used moisture-resistant drywall in a bathroom remodel to prevent water damage and mold growth. In another project, I specified fire-rated drywall in a stairwell to meet building codes.

Q 2. Explain the process of hanging drywall.

Hanging drywall involves precision and teamwork. It begins with careful measurement and cutting of the drywall sheets to fit the framing. Next, we lift the sheet into place, ensuring it’s flush with the surrounding studs. We then secure it using drywall screws, typically spaced every 6-8 inches, taking care to avoid over-tightening (this can cause dimpling). The process is repeated for each sheet, ensuring proper alignment and minimizing gaps. For large sheets, a second person is essential for safe and efficient handling. It’s critical to have a solid understanding of the framing to ensure proper alignment and avoid issues later during finishing.

Imagine hanging a picture on a wall. It’s similar, but instead of a single picture, we’re working with large, relatively fragile sheets. The accuracy of the initial placement is crucial for a professional finish. Any gaps or unevenness will be magnified once the taping and mudding process begins.

Q 3. How do you prepare a surface for drywall installation?

Surface preparation is paramount for a successful drywall installation. It begins with cleaning the studs or framing, removing any debris, dust, or loose materials. Next, you inspect the framing for any unevenness or gaps, addressing these issues by shimming or using additional framing members as needed. This ensures a smooth, even surface for the drywall to be applied against. Any significant irregularities would lead to problems later on. For instance, gaps between studs can create stress points, causing cracking and imperfections.

Think of it like preparing a canvas for painting. A smooth, clean canvas ensures a superior finished product. Similarly, preparing the surface properly for drywall eliminates imperfections from the start, resulting in a flawless final wall.

Q 4. What tools and equipment are essential for drywall installation and repair?

The right tools are essential for efficient and high-quality drywall installation and repair. These include a measuring tape, pencil, utility knife, drywall saw, level, drywall screws, screwdriver (preferably a cordless one), a taping knife (various sizes), a putty knife, a sanding block or sander, and joint compound (also known as mud). Safety equipment like safety glasses and dust masks are non-negotiable. A lift or helper is a significant asset, particularly when working with large sheets.

For example, having a good quality taping knife ensures smooth, even mud application, which is vital for achieving a seamless finish. The right sander minimizes sanding time and prevents damage to the drywall.

Q 5. Explain the taping and mudding process.

Taping and mudding is the process of covering the joints between drywall sheets and the screw heads with joint compound. We start by embedding fiberglass tape into the joint compound, pressing it firmly to adhere to the drywall. This tape strengthens the joint and prevents cracking. Then, we apply thin coats of joint compound over the tape, feathering it out to create a smooth transition. Multiple coats are usually necessary, allowing each coat to dry completely before applying the next. The final coat is carefully sanded to a smooth, flawless finish. This process requires patience and attention to detail. Insufficient mudding will lead to visible seams, affecting the overall aesthetics.

Imagine baking a cake. Each layer of mud is like a layer of frosting. You need multiple layers to create a smooth, even surface.

Q 6. How do you achieve a smooth, even finish on drywall?

Achieving a smooth, even finish on drywall requires meticulous attention to detail throughout the taping and mudding process. The key is applying thin, even coats of joint compound, allowing ample drying time between coats. The use of a quality taping knife helps create smooth transitions and feathering of the compound. Sanding is critical for removing imperfections and achieving a flawless finish. The final sanding should be done with fine-grit sandpaper to avoid scratching the surface. Remember, patience is key; rushing the process will lead to an uneven finish.

Think of it as sculpting. Each layer of mud is refined until a perfect, smooth surface is achieved. The final sanding is the polishing touch.

Q 7. What are the different types of drywall joints and how are they treated?

Drywall joints vary depending on the wall’s configuration. Butt joints are where two sheets meet edge to edge, requiring careful attention during installation to ensure alignment. Inside corners use a corner bead, a metal or plastic profile that protects and strengthens the joint. Outside corners also use a corner bead, but it’s positioned differently to create a sharp, defined edge. Each joint type requires a specific approach to taping and mudding. Butt joints usually need more coats of compound than inside or outside corners to ensure a seamless finish. Failure to properly treat these joints can lead to cracks and other imperfections.

Inside corners are like the meeting point of two walls in a room, while outside corners are similar to an exterior edge of a room. These require specific techniques and materials to ensure strength and a professional appearance.

Q 8. How do you repair holes and cracks in drywall?

Repairing holes and cracks in drywall depends heavily on the size and type of damage. Small holes, like those from a picture hook, can be easily patched. Larger holes require a more involved process. Think of it like patching a road – a pothole needs a different approach than a crack in the pavement.

- Small Holes (<1 inch): For small holes, I use a patching compound (joint compound) and a putty knife. I clean the area, apply the compound, let it dry, sand it smooth, and prime before painting.

- Medium Holes (1-6 inches): These require a drywall patch cut to fit the hole. I use a utility knife to create clean edges, apply construction adhesive to the back of the patch, press it firmly into place, and then apply joint compound to blend it seamlessly with the surrounding wall. Multiple coats of compound and sanding are often necessary.

- Large Holes (>6 inches): Large holes necessitate a more substantial repair. This often involves cutting out a larger section of drywall to create a square or rectangular opening. A new piece of drywall is then cut to size, installed using screws, and finished with joint compound. This approach ensures a stronger, more stable repair.

In all cases, proper sanding is crucial to achieve a smooth, paintable surface. I always use fine-grit sandpaper to avoid damaging the surrounding drywall. Think of it like sculpting – you need to carefully refine the shape until it’s flawless.

Q 9. Describe your experience with drywall texture applications.

My experience with drywall texture applications is extensive. I’ve worked with a variety of textures, from smooth finishes to more intricate patterns like knockdown, orange peel, and skip trowel. Each texture requires a different technique and tool. It’s like painting, but with a three-dimensional effect.

For instance, applying a knockdown texture involves applying a thick layer of joint compound, then using a knockdown knife to create a textured pattern. The timing of this process is crucial – you must work quickly before the compound dries completely. Orange peel texture, on the other hand, is created using a hopper gun, which sprays the compound onto the wall, producing a uniform, slightly textured finish.

Understanding the specific properties of different joint compounds is also vital. Some compounds are designed for specific textures and drying times. Choosing the right compound is critical to achieving the desired result. Over the years, I’ve developed a keen eye for texture matching. I can often replicate an existing texture perfectly, ensuring a seamless blend with the surrounding area, even on older walls.

Q 10. How do you handle different types of drywall damage?

Drywall damage varies widely – from small nail holes to water damage and even structural issues. My approach is systematic and tailored to the specific type of damage:

- Nail Holes: Easily patched with spackle and sanded smooth.

- Cracks: Require careful cleaning and filling with joint compound, ensuring proper adhesion for longevity. Hairline cracks might only need a thin coat, while larger cracks might need reinforcement, possibly using mesh tape.

- Water Damage: This is more complex. It often requires removing the damaged drywall, addressing the source of the moisture, allowing the area to dry completely, and then replacing the drywall. Mold remediation may also be necessary.

- Holes from Impact: The repair method depends on the size of the hole, as outlined in my answer to question 1.

- Structural Damage: This often involves collaborating with other professionals, such as structural engineers or framing contractors, to ensure the repair is both safe and effective. I don’t tackle structural issues alone.

Proper diagnosis is key. I always inspect the damage carefully before deciding on the appropriate repair method. A rushed diagnosis can lead to inadequate repairs that may require costly rework later.

Q 11. What are the common issues encountered during drywall installation?

Common issues during drywall installation include:

- Improper Seam Taping: Failing to properly tape and mud seams can lead to cracking and unsightly imperfections. Using the correct tape and compound, along with sufficient coats and sanding, is crucial for a smooth finish.

- Uneven Hanging: Incorrectly spaced or aligned drywall panels result in uneven walls and a unprofessional appearance. Using a level and straight edge during installation is essential.

- Nail Pops: Nails that work loose and push through the surface of the drywall are a common problem, usually caused by improper nailing or insufficient support.

- Drywall Damage During Handling: Careless handling can cause dents, tears, or cracks in the drywall panels before installation. Proper lifting techniques and storage are crucial.

- Poor Surface Preparation: Installing drywall over an improperly prepared surface can lead to adhesion issues and other problems down the road. This includes uneven framing, exposed wires, or pipes.

Experienced installers know how to prevent these issues through careful planning and meticulous execution. I always emphasize quality over speed to avoid future problems.

Q 12. How do you ensure proper alignment and spacing of drywall panels?

Ensuring proper alignment and spacing is fundamental to successful drywall installation. It’s all about precision and attention to detail. Imagine building a brick wall – each brick needs to be perfectly placed. Drywall is the same!

I use a level, plumb bob, and measuring tape to verify the vertical and horizontal alignment of each panel. Spacing between panels is usually determined by the manufacturer’s recommendations, typically around 1/8 of an inch. This allows for expansion and contraction without causing issues. Proper spacing also contributes to the overall strength of the wall. We use spacers, which are small pieces of material, to maintain consistent spacing. I also double-check my work consistently, not just at the beginning or the end of the process.

Finally, I use a drywall square to check the corners for 90-degree angles, ensuring that the panels fit together seamlessly. Accuracy in this stage saves a lot of time and hassle later on.

Q 13. How do you manage and dispose of drywall waste?

Managing and disposing of drywall waste responsibly is a crucial aspect of the job. Drywall contains gypsum, which can be irritating if not handled correctly. It’s also bulky and takes up a lot of space.

On-site, I sort the waste. Scraps and small pieces that might be reusable are set aside. Larger pieces are broken down to reduce their volume. We use proper waste disposal bags and ensure all sharp edges are covered for safety. I make sure we are compliant with all local regulations regarding disposal. In most cases, drywall ends up at a landfill, but some regions have recycling options.

It’s about efficiency and environmental awareness. Minimizing waste during the cutting and installation process helps reduce disposal costs and our environmental footprint.

Q 14. What safety precautions do you take during drywall work?

Safety is paramount in drywall work. We use personal protective equipment (PPE) consistently. This includes safety glasses to protect against dust and debris, hearing protection during cutting and sanding, and a dust mask or respirator to prevent inhaling harmful particles. Work gloves are always worn to protect against cuts and abrasions.

I also emphasize safe handling practices to prevent injuries. Heavy drywall panels require proper lifting techniques to avoid back strain. We use appropriate tools and equipment to minimize risk, and always ensure the work area is well-lit and free of obstructions. If working at heights, proper scaffolding and fall protection are essential.

Furthermore, we are aware of potential hazards from electrical wiring and plumbing. We always coordinate with electricians and plumbers to avoid damaging any systems. We always call 811 before beginning any work to ensure there are no underground utilities that we might damage.

Q 15. Explain your experience working with different types of drywall tools.

My experience with drywall tools spans a wide range, from basic hand tools to specialized power equipment. I’m proficient with utility knives for precise cutting, various taping knives for smooth finishes (ranging from 4” to 12”), drywall saws for accurate cuts in various materials, and power tools like automatic tapers for efficiency in large projects. I also have experience using specialized tools like corner bead rollers for neat, professional corners and mud mixers for preparing consistent drywall compound. For example, on a recent project involving intricate curved walls, I utilized a specialized drywall saw with a flexible blade to achieve perfectly smooth curves. In another project with a large volume of taping, using an automatic taper significantly sped up the process, improving efficiency and reducing fatigue.

- Utility Knives: Essential for precise cuts and scoring.

- Taping Knives: Used for applying and smoothing drywall compound.

- Drywall Saws: For accurate cuts in various drywall types.

- Automatic Tapers: Improve efficiency in large projects.

- Corner Bead Rollers: Create crisp, straight corners.

- Mud Mixers: Ensure consistent drywall compound consistency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working from blueprints or plans.

Reading and interpreting blueprints is fundamental to my work. I’ve consistently utilized architectural plans to accurately determine wall locations, dimensions, and specifications for various drywall types and finishes. For instance, I recently worked on a project with complex angles and curves. By carefully studying the blueprints, I was able to pre-cut the drywall pieces precisely, minimizing on-site adjustments and waste. Understanding the plans also helps me anticipate potential challenges and plan my work accordingly. This includes identifying areas requiring specialized drywall (like fire-rated or moisture-resistant) and coordinating my work with other trades, like electricians and plumbers. Properly interpreting the plans ensures the project meets the design specifications and avoids costly mistakes. I’m confident in my ability to handle complex blueprints and translate them into precise drywall installation.

Q 17. What is your experience with acoustical drywall?

Acoustical drywall is a specialized type of drywall designed to reduce sound transmission. I have significant experience installing it in various settings, from residential theaters to commercial office spaces. It differs from standard drywall in its composition and often requires specialized installation techniques to maximize its sound-dampening properties. For example, I have worked on projects where special attention was paid to the sealing of joints and the application of additional soundproofing materials in conjunction with the acoustical drywall. It’s crucial to understand the specific requirements of the chosen acoustical drywall product, such as density and thickness, and to ensure proper sealing and joint finishing to achieve optimal performance.

Q 18. How do you measure and cut drywall accurately?

Accurate measurement and cutting are critical in drywall installation. I begin by carefully reviewing the plans to determine the precise dimensions needed. Then, I use a measuring tape to accurately measure the required length and width of each drywall piece. A square is used to ensure the cuts are at perfectly 90-degree angles. For curves, I’ll use a drywall saw with a flexible blade or score and snap the drywall carefully. I always double-check my measurements before making any cuts to minimize waste and ensure a perfect fit. For example, on a recent project involving a complex angled ceiling, my precise measurements and cuts helped avoid visible gaps or misalignments, leading to a clean and professional finish. The use of a utility knife for precise scoring and snapping ensures clean breaks and reduces the chance of chipping.

Q 19. Explain your knowledge of fire-rated drywall installation.

Fire-rated drywall, also known as fire-resistant drywall, is crucial for building safety. I’m experienced in installing various types of fire-rated drywall, understanding the importance of adhering to building codes and ensuring proper installation techniques. This often involves using specialized fire-rated drywall, as well as maintaining specific joint taping and finishing methods. I also understand the importance of properly sealing all penetrations through fire-rated walls. For example, installing fire-rated drywall around fireplaces, and stairwells requires meticulous attention to detail and precise cuts to ensure the integrity of the fire barrier. Neglecting to follow proper installation techniques can severely compromise the fire protection provided by the drywall. This includes making sure there are no gaps around electrical outlets and light fixtures, and using appropriate fire-rated sealant.

Q 20. Describe your experience with moisture-resistant drywall.

Moisture-resistant drywall, or greenboard, is essential in areas prone to moisture like bathrooms and kitchens. My experience includes installing this type of drywall and understanding its distinct properties and installation requirements. It’s crucial to understand that while moisture-resistant, it’s not waterproof. Therefore, proper ventilation and sealing are key to preventing moisture damage. For example, I recently completed a bathroom remodel where I used greenboard to ensure long-term durability and prevent mold growth. I paid meticulous attention to sealing the joints with appropriate moisture-resistant compound and ensuring proper ventilation was in place. Using regular drywall in these environments is a common mistake that leads to costly repairs.

Q 21. How do you troubleshoot common problems during drywall installation?

Troubleshooting during drywall installation involves identifying and addressing issues promptly. Common problems include uneven surfaces, gaps between sheets, and cracks in the mud. Uneven surfaces can be addressed by using shims or additional layers of drywall compound. Gaps are dealt with by filling them completely with compound and properly taping the joints. Cracks are addressed by carefully removing the cracked compound, reapplying, and then sanding smooth. Other problems such as damaged boards, inaccurate cuts, or inconsistent mud application can be identified during inspection and addressed by replacing damaged sections, recutting the affected area, and reapplying the compound. I always start by carefully inspecting the installed drywall, and make sure to pay close attention to the details like the alignment, the quality of the taping, and the overall smoothness of the surface. Effective troubleshooting requires attention to detail and a methodical approach. The key is proper preparation, precise cuts and application of the appropriate materials.

Q 22. What is your experience with different types of drywall mud?

My experience with drywall mud encompasses a wide range of types, each suited for different applications. All-purpose mud is my go-to for most repairs and finishing coats due to its versatility. It’s readily available, relatively inexpensive, and offers a good balance of workability and drying time. For larger repairs or areas requiring a quick set, I often use a setting-type compound. This dries much faster, allowing for quicker multiple coat applications. However, it requires more skill to avoid cracking as it shrinks during the drying process. Finally, I utilize lightweight all-purpose mud for ceilings and large areas. It’s easier on the body and doesn’t put as much stress on the seams during the drying process, reducing the risk of cracking. The choice depends entirely on the job’s specific requirements.

For instance, on a recent project with extensive water damage, I started with a setting-type compound to quickly seal the affected area and prevent further moisture penetration. Then I transitioned to all-purpose for the smoother finishing coats.

Q 23. How do you maintain the quality of your work?

Maintaining quality is paramount. It starts with meticulous preparation—properly taping, bedding, and feathering the joints before applying the first coat of mud. I always use high-quality tools: sharp knives for clean cuts, broad knives for efficient application, and sanding tools for smooth finishes. Between each coat, I thoroughly inspect my work under bright lighting to catch any imperfections early. This prevents costly rework later. I meticulously sand every coat to achieve a flawless finish, paying special attention to avoiding over-sanding, which can weaken the wall. I also prioritize proper ventilation to allow the mud to cure appropriately, avoiding cracks or other defects.

Think of it like baking a cake: If you rush the process or skip a step, the final product will suffer. The same applies to drywall finishing. Every step, from preparation to finishing, must be executed correctly to ensure a high-quality result.

Q 24. What is your experience with working on high ceilings?

Working on high ceilings is a regular part of my work, and I’ve developed efficient and safe techniques. I use lightweight mud to reduce fatigue, and I employ scaffolding or a stable lift platform to access all areas comfortably and safely. Safety harnesses and proper fall protection are always in place. For larger areas, I might use a pump sprayer to pre-wet the drywall prior to taping, which is both efficient and ensures proper adhesion. Planning is crucial; I meticulously measure and pre-cut the drywall boards to minimize the time spent working at height, reducing potential risks.

On a recent project in a high-ceilinged warehouse, using the scaffolding and a pump sprayer for wetting saved significant time and minimized effort. The pre-wetting significantly reduced the amount of mud needed to complete the project.

Q 25. How do you work effectively in a team environment?

Effective teamwork is essential in drywall installation and repair. I thrive in collaborative environments. Open communication is key; I ensure everyone is informed about the project goals, schedules, and any challenges that might arise. I actively participate in problem-solving, offering my expertise and considering everyone’s input. I believe in delegating tasks according to individual strengths, ensuring everyone feels valued and empowered. Finally, mutual respect and a positive attitude are crucial in maintaining team morale and ensuring efficient project completion.

For example, on a recent large commercial project, I worked closely with the electricians and plumbers, ensuring that all necessary electrical and plumbing work was completed before we began installing drywall. This coordinated effort saved considerable time and avoided conflicts.

Q 26. Describe a challenging drywall project and how you overcame it.

One of the most challenging projects I encountered involved repairing extensive water damage in an old Victorian home. The walls were severely warped and the existing lath and plaster was crumbling. Simply replacing the drywall wasn’t an option; the structure needed reinforcement. First, I carefully assessed the damage and identified the areas requiring structural repair. Then, I worked with a structural engineer to develop a plan to reinforce the walls with additional framing and specialized moisture-resistant materials. Once the structural integrity was restored, I could begin the drywall installation and finishing. This required patience, attention to detail, and creative problem-solving, but the final result was a beautifully restored space.

The key to overcoming this challenge was a methodical approach. I broke the project into manageable steps, carefully documenting each stage, and collaborating with specialists whenever needed. It wasn’t about speed; it was about accuracy and achieving lasting results.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skill set, and are in line with the industry standard for experienced drywall installers/repair specialists in this region. I’m open to discussing specific figures based on the details of the position and the benefits package offered.

Q 28. What are your career goals?

My career goals involve continuing to develop my skills and expertise in drywall installation and repair. I am keen to advance into more challenging and complex projects, possibly into project management or supervision. I’m also interested in staying current with the latest techniques, materials, and industry standards through ongoing training and professional development. My long-term ambition is to contribute to a company’s success and become a leading expert in the field.

Key Topics to Learn for Your Drywall Repair and Installation Interview

- Understanding Drywall Types: Knowing the differences between various drywall types (e.g., gypsum board, moisture-resistant, fire-resistant) and their appropriate applications is crucial. This includes understanding their properties and limitations.

- Repair Techniques: Master the practical application of patching holes, repairing cracks, and smoothing surfaces using various techniques like taping, mudding, and sanding. Be prepared to discuss different tools and materials used in these processes.

- Installation Procedures: Demonstrate your knowledge of installing drywall sheets, including cutting, fastening, and finishing techniques. Discuss safety precautions and best practices for efficient installation.

- Finishing and Texture: Explain the different finishing techniques for achieving smooth, flawless surfaces. Discuss various textures and how to create them, along with the tools and materials involved.

- Troubleshooting Common Issues: Be prepared to discuss common problems encountered during repair and installation, such as nail pops, cracks, and uneven surfaces. Outline your problem-solving approach for these scenarios.

- Safety Regulations and Practices: Highlight your understanding of safety regulations and practices related to drywall handling, tools, and working at heights. This demonstrates your commitment to a safe work environment.

- Estimating and Project Management: Discuss your ability to estimate material needs, project timelines, and overall costs. This showcases your organizational and planning skills.

Next Steps

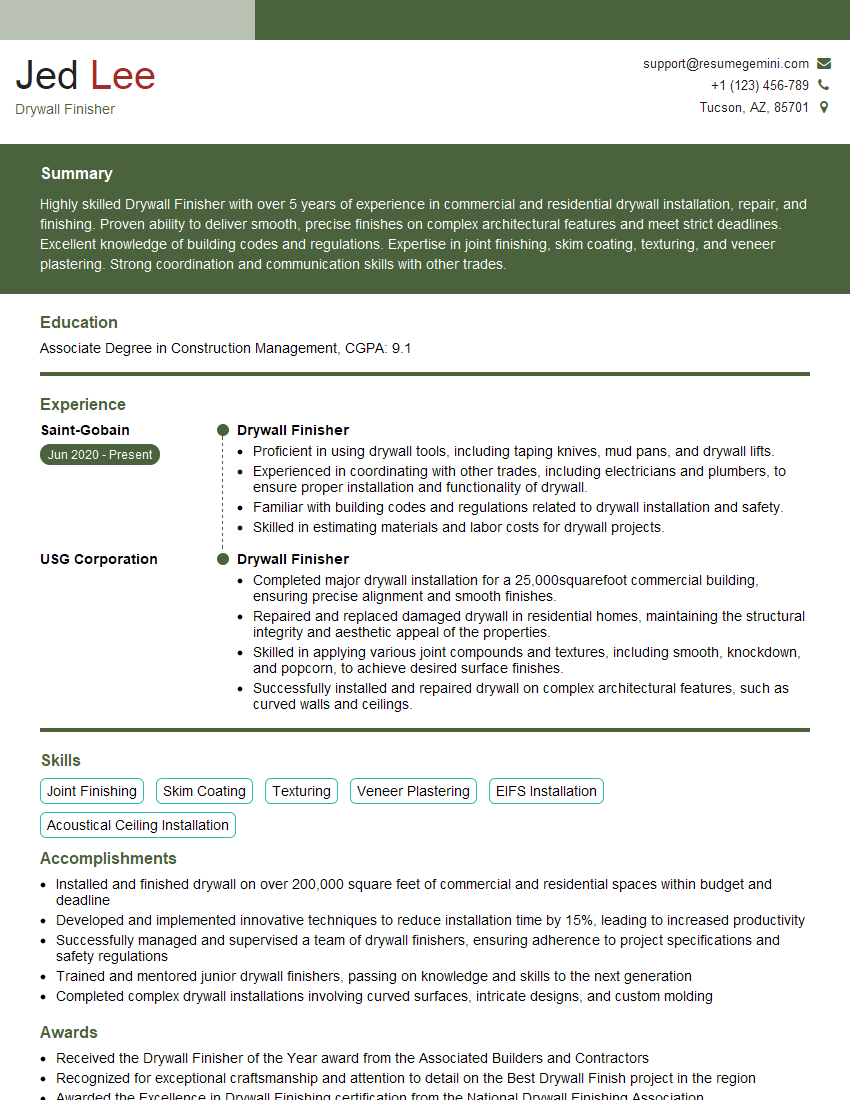

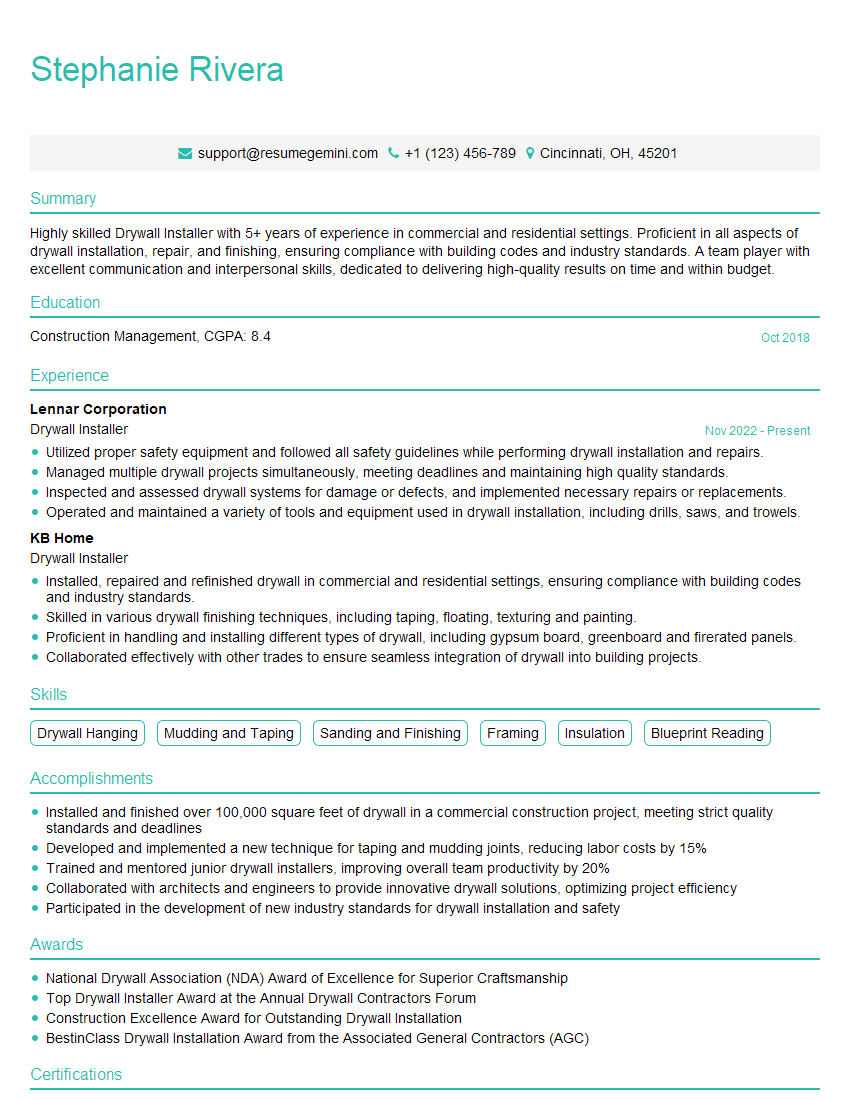

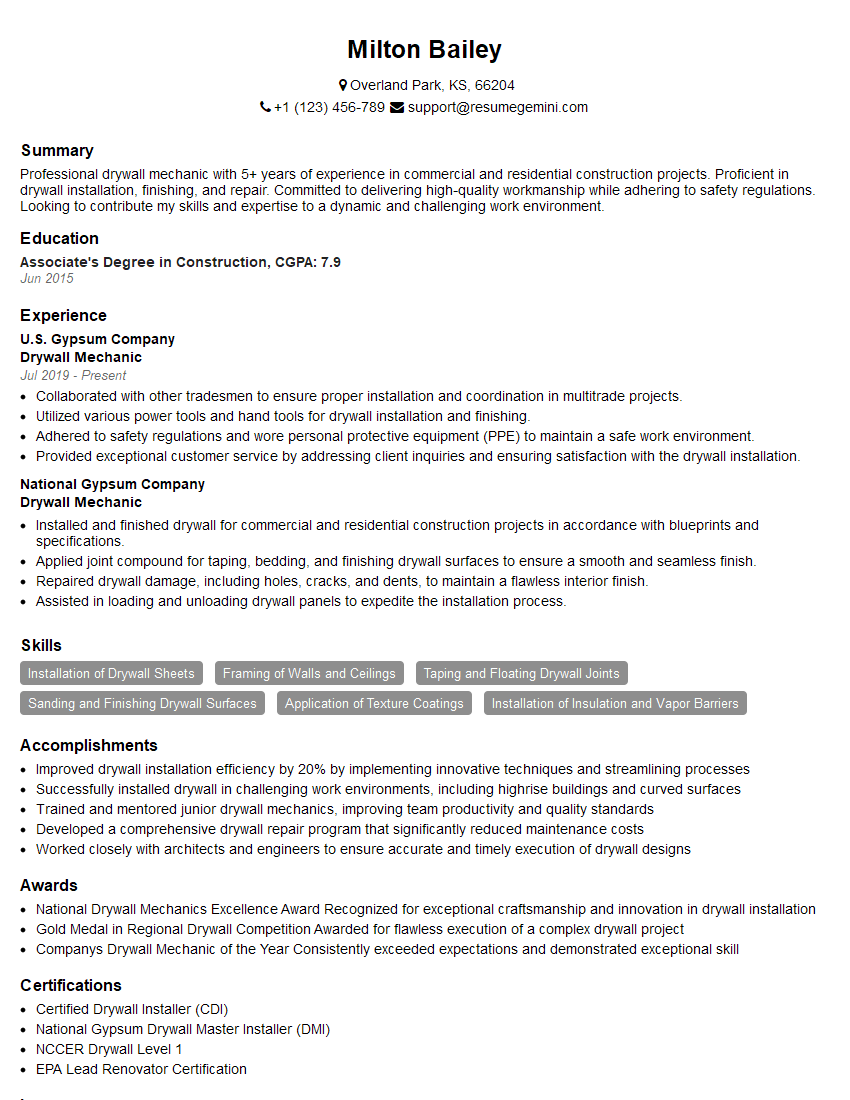

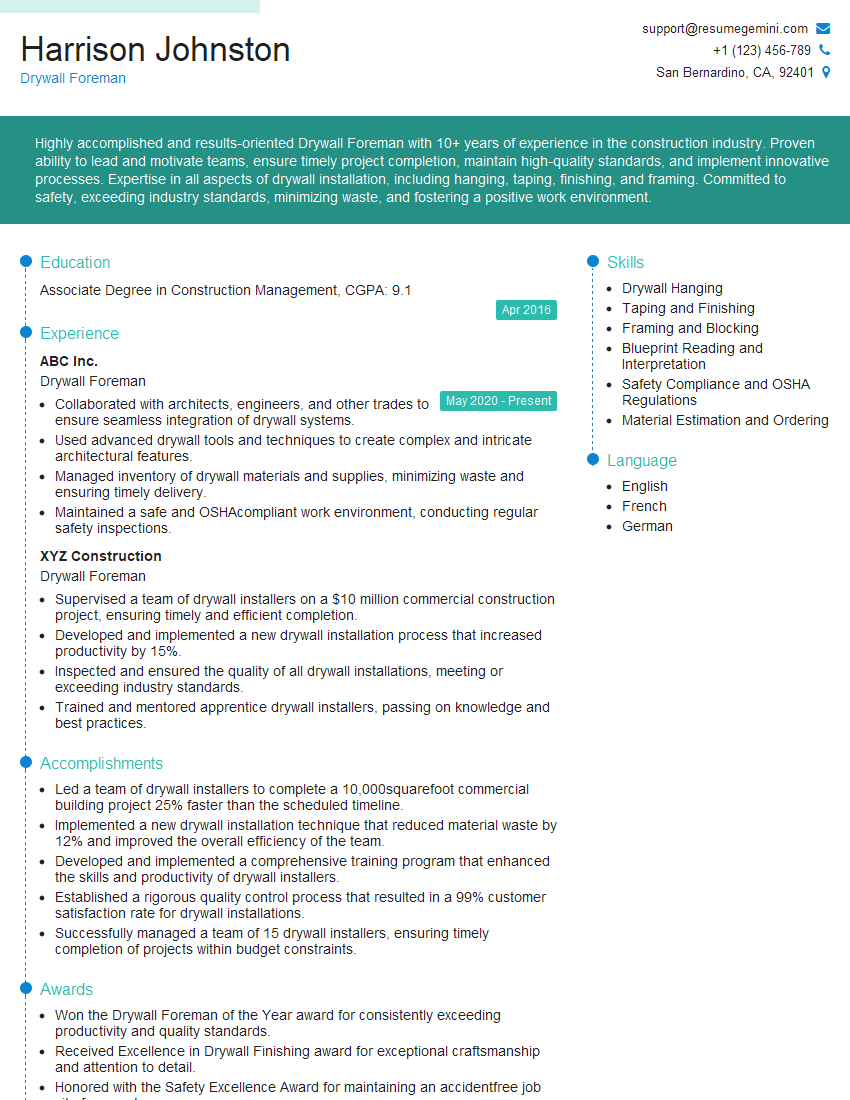

Mastering drywall repair and installation opens doors to a rewarding career with excellent growth potential. Demand for skilled professionals in this field remains consistently high, offering opportunities for advancement and specialization. To maximize your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored to the Drywall Repair and Installation field, providing you with valuable templates and guidance to create a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good