The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Marking and Layout interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Marking and Layout Interview

Q 1. Explain the difference between bleed and trim.

In print design, bleed and trim are crucial for a professional finish. Think of it like this: your artwork is printed on a larger sheet than the final size, and then the excess is cut off. The bleed is the extra area of your design that extends beyond the intended trim line. This ensures that even after trimming, there’s no unsightly white border around your design, especially if it has images extending to the edges. The trim is the final size of your printed piece after the excess is cut off. For example, if you’re designing a postcard that’s 4×6 inches, you’ll need to design with a bleed area, perhaps 0.125 inches (1/8 inch) on each side, meaning your design file needs to be 4.25 x 6.25 inches. The printer will then trim the excess to the final 4×6 inches.

Failing to account for bleed can result in unsightly white borders or even part of the design being lost during trimming. A simple way to visualize this is imagining a photograph that needs to reach the very edge of a printed piece – the bleed ensures the photo isn’t partially cut off during finishing.

Q 2. Describe your experience with color profiles (CMYK, RGB, etc.).

Color profiles are essential for ensuring color accuracy across different devices and printing processes. RGB (Red, Green, Blue) is the color model used for screens, like monitors and TVs. CMYK (Cyan, Magenta, Yellow, Black) is the subtractive color model used for printing. Understanding the difference is crucial; an image that looks vibrant on screen (RGB) might appear dull or different when printed (CMYK) if not properly converted. I have extensive experience working with both, and I understand the necessity of converting RGB artwork to CMYK for print, making adjustments for color shifts to achieve the most accurate results. I am also familiar with other color spaces such as Pantone for specific color matching, especially for branding or when precise color reproduction is essential, ensuring that the colors used in a logo printed on various materials remain consistent.

In my past projects, I’ve encountered situations where a client’s RGB artwork had to be converted to CMYK while maintaining their brand’s signature colors. I utilized color management tools within my software and soft proofing to get the best possible match, and I also ensured that I worked within the printer’s capabilities to avoid unexpected color discrepancies.

Q 3. What are your preferred software applications for marking and layout?

My preferred software applications for marking and layout include Adobe InDesign, Adobe Illustrator, and Adobe Photoshop. InDesign excels in page layout, typography, and managing large, complex documents, and is my go-to for most projects. Illustrator is ideal for creating and manipulating vector graphics, which are crucial for logos and other sharp images that need to scale without losing quality. Photoshop is my choice for image editing and retouching. I’m also proficient in using Acrobat Pro for PDF creation and preflight checks, ensuring files are printer-ready before sending to the print shop. I can adapt to other software as needed though, as my fundamental understanding of the principles remains consistent regardless of application.

Q 4. How do you ensure color consistency across different printing methods?

Maintaining color consistency across different printing methods requires careful color management throughout the process. This starts with using a consistent color profile (usually CMYK) from design to print. I employ soft proofing, comparing the on-screen representation to the expected printed output using a calibrated monitor profile, to anticipate and correct potential color variations. I also work closely with printers to choose appropriate substrates (paper types) and inks, and request color proofs – physical samples that are printed using the same setup as the final run – for verification. Communication is key: clear instructions, specified color profiles, and regular communication with the print shop helps avoid discrepancies and assures consistent results, irrespective of whether it’s offset, digital, or large format printing. For example, I specify the use of a particular Pantone color if needed to ensure color consistency across different printing techniques.

Q 5. How do you handle trapping and why is it important?

Trapping is the intentional overlapping of colors to prevent small gaps from appearing between them during the printing process, particularly noticeable in areas where two colors meet. It’s essential to minimize the appearance of gaps which are caused by misregistration of the different color inks. Misregistration can happen due to slight inconsistencies in the printing press, leading to gaps or “knockouts” between the colors. I handle trapping by using automated trapping features within InDesign or Illustrator. These features intelligently calculate the necessary overlap based on the colors and line weights involved. There are different trapping methods, such as spread and choke, but the objective is always the same: prevent those unsightly gaps that compromise the professional quality of the final printed piece.

For instance, imagine two adjacent text boxes, one red and one blue. Without trapping, a tiny white gap might appear where they meet. Trapping ensures a seamless transition, enhancing overall design quality and professionalism.

Q 6. Explain the importance of image resolution in prepress.

Image resolution is paramount in prepress. Resolution, measured in dots per inch (DPI), refers to the density of pixels in an image. Insufficient resolution leads to blurry, pixelated output, particularly noticeable when printed at larger sizes. For print, the ideal resolution is typically 300 DPI. Using lower resolution images results in a lower quality printed product, impacting the professionalism and aesthetic appeal of the final result. I always ensure my images are of appropriate resolution for their intended use in the final printed piece. If I have a lower resolution image, I may explore alternative images, or use image upscaling techniques carefully to mitigate the effects of low-resolution content, but this is always done with caution because pushing an image’s resolution too high can result in increased noise and artifacts.

Q 7. Describe your experience with imposition software.

I have significant experience with imposition software, using it to efficiently arrange pages for printing. Imposition software automates the process of setting up pages for printing sheets, arranging them to minimize waste and optimize the printing process. Tools like imposition software allow for the creation of multi-page documents from single-page designs, taking into account factors such as bleed, margins, and fold lines. I’m adept at creating different layouts for various printing methods such as imposition for booklets, brochures, and calendars; this reduces the errors and maximizes the efficiency of the whole print production process. A familiarity with imposition software is a valuable skill that directly benefits both efficiency and cost-effectiveness in printing.

Q 8. How do you manage and organize large files for a print project?

Managing large files for print projects requires a systematic approach. Think of it like organizing a large library – you wouldn’t just throw all the books on the floor! I use a combination of techniques to maintain efficiency and prevent errors. First, I employ a robust file naming convention. This usually involves incorporating the project name, date, and version number (e.g., ProjectAlpha_20241027_v3.indd). This ensures easy identification and retrieval. Second, I utilize a well-structured folder system. This might involve separate folders for high-resolution images, low-resolution previews, fonts, and final print-ready files. I often use subfolders for different components within a project (e.g., a folder for each page of a brochure). Finally, I leverage the power of asset management software or cloud storage to keep all related files in a centralized and easily accessible location. This not only keeps things organized but also helps with version control, preventing accidental overwrites or deletions. This organized approach becomes invaluable especially when handling multiple large projects concurrently.

Q 9. What are your methods for proofing and quality control?

Proofing and quality control are crucial for ensuring a successful print project. My methods are multi-layered, akin to a security system with multiple checkpoints. I start with a thorough self-check, looking for issues like typos, missing images, incorrect font sizes, and inconsistencies in the layout. Next, I perform a soft proof, viewing the file on screen with calibrated color settings to simulate the printed output as closely as possible. This allows me to catch any color discrepancies or design flaws. Then, I generate a hard proof – a physical printed copy – to examine the final result. This is critical as it captures potential issues not easily visible on a screen, such as incorrect bleed or color shifts during the printing process. Finally, I always conduct a comprehensive final review with the client before sending the files to print. This collaborative approach ensures that everyone is on the same page and that the final product meets the client’s expectations. Each step utilizes a checklist to ensure thoroughness and consistency.

Q 10. How do you handle client revisions in a timely and efficient manner?

Handling client revisions efficiently involves clear communication, organization, and a streamlined workflow. I always request revisions in writing, clarifying the specific changes needed and ideally providing a visual reference. I use version control to track revisions and clearly label each version (e.g., Rev1.indd, Rev2.indd). This allows easy comparison and rollback if necessary. A digital proofing platform can further improve this process by incorporating annotation tools, making comments precise and reducing the back-and-forth. I aim to provide a revised file within the agreed upon timeframe and maintain transparent communication with the client throughout the process. For instance, if a revision request requires more than anticipated time, I inform the client promptly, setting revised expectations to avoid delays. I think of it like managing a project with milestones and deadlines.

Q 11. Explain the concept of ‘live area’ in layout design.

The ‘live area’ in layout design refers to the printable area of a document. Imagine a sheet of paper; the live area is the space within the edges where your content will actually be printed. Anything outside the live area might be trimmed off during the printing process. This area is crucial because the trim may vary slightly, so anything important should be within the live area’s safe zone. To illustrate, if you’re designing a business card, important text or images should be placed well within the live area’s boundaries to prevent them from being partially cut off after printing. The area outside the live area, usually including the ‘bleed’, is where you add background colors or images that extend beyond the trim line for a clean look. Understanding the live area is paramount to prevent errors and ensure that your design is printed as intended.

Q 12. What file formats are you comfortable working with?

I’m proficient in a wide range of file formats commonly used in print design. These include industry standards such as .PDF (Portable Document Format) for final print-ready files, .AI (Adobe Illustrator) for vector graphics, .PSD (Adobe Photoshop) for raster images, and .INDD (Adobe InDesign) for page layout. I also have experience with .EPS (Encapsulated PostScript) for vector graphics and .TIFF (Tagged Image File Format) for high-resolution images. My expertise extends to understanding the strengths and limitations of each format and selecting the most appropriate one for a specific task. For instance, PDFs are ideal for final outputs due to their universally supported format, while AI is preferred when working with vector graphics requiring scalability. This knowledge allows me to efficiently manage various file types throughout a project’s lifecycle.

Q 13. Describe your experience working with different paper stocks and their implications for layout.

My experience encompasses a variety of paper stocks, each impacting the layout differently. For instance, the choice of paper influences color reproduction, the overall look and feel of the printed piece, and even the choice of fonts and images. Uncoated paper, with its porous surface, can absorb ink, resulting in slightly muted colors, making vibrant colors unsuitable. Coated paper, on the other hand, provides a smooth surface that results in sharper, more vibrant colors and details. Thick card stock requires a different layout approach compared to thin paper, often necessitating adjustments to font weights and image resolution. The paper’s weight impacts the overall feel and sturdiness of the printed piece, influencing design decisions. The tactile aspect of the final product is integral to its overall effect. Therefore, understanding these nuances is key to creating an appropriate and effective layout.

Q 14. How do you ensure fonts are embedded correctly for print?

Embedding fonts correctly for print is crucial to avoid font substitution issues. A common pitfall is using fonts that are not embedded in the final document; this often leads to the wrong font showing up. To prevent such issues, I always embed fonts within the print-ready PDF. Most PDF creation software has settings that allow for this. Alternatively, I may outline the text, converting the font to vector shapes which bypasses the need for embedded fonts. However, this eliminates the ability to edit the text after the conversion. I meticulously check the final PDF to ensure the fonts appear correctly before sending it to print. I also communicate with the printer to clarify their preferred font embedding methods to ensure a consistent and error-free result. This rigorous approach avoids costly reprints and ensures the final piece reflects the designer’s intent.

Q 15. How do you troubleshoot common prepress issues?

Troubleshooting prepress issues involves a systematic approach. Think of it like detective work – you need to gather clues, analyze them, and then implement a solution. Common issues range from low-resolution images causing pixelation to missing fonts or incorrect color profiles. My process begins with a careful review of the preflight report (more on that later).

- Missing Fonts: If fonts are missing, I’ll identify the missing ones and replace them with suitable alternatives or request the correct fonts from the client. I often keep a library of common fonts on hand.

- Low-Resolution Images: I use image-editing software to check the resolution (dpi) of all images. If below the required resolution for the intended print output, I’ll either replace them with higher-resolution versions or optimize the existing ones (carefully to avoid quality loss). I always communicate the need for higher-resolution images early in the process.

- Color Profile Mismatches: Inconsistent color profiles can lead to unexpected color shifts. I meticulously check that all files use the correct color profile (e.g., CMYK for print) and perform color conversions accurately using professional software like Adobe Acrobat.

- Overprinting Issues: If elements aren’t overprinting as expected, I check the overprint settings in the software to ensure they are correctly enabled for the appropriate layers or objects.

- Bleed Issues: I carefully examine bleed margins to confirm the design extends beyond the trim line to avoid unsightly white borders after printing. A lack of bleed is a very common issue.

Ultimately, proactive communication with clients and careful attention to detail at each stage of the process are key to preventing many prepress issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of color separation.

Color separation is the process of breaking down a full-color image into its individual CMYK (Cyan, Magenta, Yellow, and blacK) components. Imagine a colored pencil drawing: you can create a vast array of colors by combining cyan, magenta, yellow, and black. Similarly, a printing press uses these four inks to recreate the colors in your design. Each color is printed as a separate layer. This process is crucial for four-color printing because the printer needs separate plates for each ink to properly reproduce the image.

For instance, a vibrant red might require a specific combination of Magenta, Yellow, and a touch of Cyan. Color separation software calculates the precise amount of each ink needed to achieve the desired color in the original design. This ensures accurate color reproduction in the final print. I regularly use this process, and it’s important to choose the right separation settings (like the dot-gain compensation) based on the printing method and paper stock.

Q 17. What is your experience with Pantone Matching System (PMS)?

The Pantone Matching System (PMS) is a standardized color reproduction system that uses a library of pre-mixed inks with specific color formulas. Think of it like a paint store with a numbered catalog for each color. Instead of relying on the CMYK model’s approximations, PMS guarantees consistency across various print runs and printers. This is incredibly useful for brand consistency, where accurate color reproduction is paramount.

My experience with PMS involves specifying PMS colors in design software, ensuring the client’s brand colors are accurately represented. I’ve handled situations where a client provides specific PMS codes for their logo and brand elements. My role is to incorporate these codes correctly to avoid any color discrepancies. I am familiar with various Pantone color guides and their applications in different print processes.

Q 18. How do you optimize images for print to avoid large file sizes?

Optimizing images for print to avoid large file sizes requires a balance between image quality and file size. It’s about getting the best possible print quality with the smallest possible file size. Too large of files slow down the printing process and can lead to errors.

- Resolution: Ensure images are at the appropriate resolution (typically 300 dpi for print) but no higher. Higher resolution doesn’t translate to better print quality beyond this threshold and only increases file size.

- File Format: Use lossy compression formats like JPEG for photographs, but avoid JPEG for images with text or sharp lines. Lossy compression discards some data, which affects the image quality, but it makes the file significantly smaller.

- Image Editing: Before embedding the image, I often use software like Adobe Photoshop to reduce the image size (while maintaining resolution). I carefully crop out any unnecessary areas.

- Compression Level: Use appropriate compression levels for JPEG files, balancing quality and size.

Example: A 5MB image can be reduced to 1MB with a small quality reduction that is insignificant when printed.

Q 19. Describe your experience with preflighting documents.

Preflighting documents is like performing a pre-flight check on an airplane before takeoff – it’s a critical step to ensure everything is in order before sending the files to print. It involves using software to automatically check a document for potential problems that could cause printing errors. Think of it as a quality control check.

My experience includes using preflight software that checks for: missing fonts, low-resolution images, color profile issues, bleed problems, and other potential printing errors. I’ve used various preflight tools, both standalone and those integrated into design programs. I use this step meticulously, as it often prevents costly reprints. A thorough preflight check is integral to a smooth printing process and minimizes the risk of costly mistakes.

Q 20. What is your understanding of PDF/X standards?

PDF/X standards are a set of specifications for creating portable document format (PDF) files that are print-ready. They’re designed to ensure that the document’s appearance and content will be consistent across different systems and printers. They act as a universal language for print production.

Different PDF/X versions exist (like PDF/X-1a, PDF/X-3, PDF/X-4), each with varying levels of complexity and features. My understanding of these standards allows me to create files that are compatible with the requirements of different printers and prepress workflows. For instance, PDF/X-1a is ideal for simple documents with CMYK colors, while PDF/X-4 offers more flexibility for complex documents with embedded ICC profiles.

I ensure that the PDF/X files I create include all necessary fonts, images, and color profiles and are free from errors. It’s essential to know which version of PDF/X is required for a specific project to ensure print readiness.

Q 21. How do you work within tight deadlines and manage project priorities?

Working within tight deadlines requires a proactive and organized approach. It’s like a well-orchestrated symphony – each part needs to be played in harmony and on time.

- Prioritization: I use project management tools to clearly outline tasks and deadlines. I prioritize the most critical tasks first, ensuring that the most important aspects are completed even if some less crucial aspects may need to wait.

- Time Management: I break down large projects into smaller, manageable tasks and allocate specific time slots for each one. Regularly checking progress helps me stay on track.

- Clear Communication: Open communication with clients and team members is crucial. If unexpected delays occur, I immediately inform the relevant parties to avoid surprises. I’m transparent about potential obstacles.

- Efficient Workflow: I streamline my workflow using automation tools where applicable to reduce manual effort and improve efficiency. I focus on avoiding unnecessary steps and using the right tools for the job.

Ultimately, effective time management and proactive problem-solving are key to successfully handling tight deadlines in a calm and efficient manner. I’ve learned to manage stress effectively and prioritize tasks to deliver high-quality results even under pressure.

Q 22. How do you handle complex layout designs with multiple elements?

Handling complex layouts with numerous elements requires a methodical approach. Think of it like building with LEGOs – you need a plan before you start snapping pieces together. I begin by establishing a clear hierarchy: what elements are most important and need the most visual prominence? This often involves creating a visual mockup or wireframe, which might involve using software like Adobe InDesign or QuarkXPress. Then, I meticulously organize elements using layers and master pages (InDesign) or similar functionalities in my chosen software. This allows for efficient editing and avoids accidental overlaps or inconsistencies. For instance, in a multi-page brochure, I would establish master pages for consistent header and footer elements, leaving only the content area variable across pages. This prevents repetitive work and maintains a professional, unified look. I also utilize grids and guides to align elements precisely, creating a balanced and visually appealing design. For extremely complex layouts with a lot of data, I often break it down into smaller, more manageable modules, which are then assembled as the project progresses. This modular approach greatly streamlines the workflow and minimizes errors.

Q 23. Explain your experience with variable data printing.

My experience with variable data printing (VDP) is extensive. I’ve worked on numerous projects requiring personalized mailers, customized brochures, and even personalized product labels. Understanding VDP involves not only design skills but also a deep understanding of data handling and merge functionality. In a recent project involving personalized fundraising letters, I integrated a database containing donor information with the letter template using a data merge feature in InDesign. This allowed for the automatic insertion of names, donation history, and personalized messages, resulting in thousands of unique letters efficiently produced without manual intervention. Another project involved creating personalized labels for different product variants. I had to manage multiple data fields – SKU, product name, and specific details – and ensure they were correctly integrated and clearly displayed on each label without overlapping or causing visual clutter. Error checking and data validation are crucial steps in VDP to ensure accuracy and prevent errors. I use rigorous checks to catch missing or inconsistent data before printing to prevent costly reprints.

Q 24. How do you maintain a high level of accuracy in your work?

Maintaining accuracy is paramount in my work. It’s not just about aesthetics; it’s about ensuring the information is correct and presented in a professional manner. My strategies include a multi-layered approach. First, I always meticulously review the source material for any errors or inconsistencies before starting the layout process. Second, I employ strict quality control measures throughout the production. This involves proofing each element individually and then proofing the complete layout multiple times before sending to print. I use tools like spellcheckers, grammar checkers, and preflight software to catch errors early. Furthermore, I rely on a ‘proofreading checklist’ to ensure every aspect – including fonts, images, spacing, and alignment – adheres to the design specifications. Finally, I collaborate closely with clients during the proofing stages, allowing them to review the design and provide feedback before final printing. Regular calibration of my monitors and printers also helps in maintaining consistency and accuracy.

Q 25. Describe your experience with different printing processes (offset, digital, etc.).

I have extensive experience with both offset and digital printing processes, understanding the strengths and limitations of each. Offset printing is ideal for large-volume projects requiring high-quality results, particularly on heavier stocks such as brochures or magazines. The process of creating offset-ready files involves specific considerations, such as color profiles (CMYK), bleeds, and trapping. Digital printing, on the other hand, is perfect for shorter runs, personalized items, and faster turnaround times. The process is less complex as it handles variable data seamlessly, making it suitable for quick, personalized prints. My experience also encompasses large format printing, which I’ve employed for producing posters and banners. I understand the importance of file resolution and print settings to achieve crisp and high-quality results regardless of the print method. Choosing the appropriate printing process often depends on factors like budget, quantity, and required turnaround time. My expertise lies in knowing which process is most effective for each project, ensuring both quality and cost-efficiency.

Q 26. How do you collaborate with designers and other team members?

Collaboration is essential in the design process. I value open and transparent communication with designers, printers, and clients. With designers, I work closely to understand their vision and translate their creative ideas into accurate and printable layouts. This often involves clarifying design details, suggesting technical solutions, and providing feedback to refine the design for optimal printing. My experience includes participating in regular project meetings, discussing creative direction, and providing technical guidance to ensure feasibility. With printers, I maintain clear communication regarding print specifications, ensuring the final printed piece matches the approved design. With clients, I ensure they are fully involved in the proofing process, addressing their questions and concerns throughout. Effective communication, active listening, and a collaborative spirit are key to my success in teamwork.

Q 27. What are your strategies for managing version control in your projects?

Version control is critical for managing large projects and maintaining a clear history of changes. I utilize a combination of methods to ensure accurate version tracking. For smaller projects, I might use a simple file-naming convention (e.g., ‘projectname_v1.indd’, ‘projectname_v2.indd’). For larger or collaborative projects, however, I prefer using dedicated version control systems, such as Adobe Creative Cloud libraries which provide a centralized repository to track revisions. This allows for easy access to older versions and the ability to revert to previous states if necessary. This approach greatly reduces confusion and ensures everyone is working on the most up-to-date version. I also maintain detailed notes documenting each change made, explaining the reason for the modification. This documentation is extremely valuable for troubleshooting and future reference.

Q 28. Describe your experience with automated workflow systems in prepress.

My experience with automated workflow systems in prepress is significant. I’m proficient in using various prepress automation tools and software, which streamline tasks and increase efficiency. For example, I have experience using automated imposition software to create efficient press sheets, reducing manual effort and minimizing errors. I’m also skilled in using automated color management systems to ensure color consistency across different devices and printing methods. This involves creating and utilizing color profiles to calibrate monitors and printers, resulting in more accurate color representation in the final product. I also utilize automated PDF creation and validation tools to ensure that files meet the necessary specifications for the chosen printing method before sending them to the press. These automated systems dramatically reduce manual tasks, saving time, and minimizing the risk of errors throughout the prepress stage, ultimately contributing to smoother and more efficient production.

Key Topics to Learn for Your Marking and Layout Interview

- Pre-press Preparation: Understanding file formats (PDF, InDesign, etc.), color spaces (CMYK, RGB), resolution requirements, and bleed/trim settings. Practical application: Preparing files for optimal print production, avoiding common pitfalls like low-resolution images or incorrect bleed.

- Imposition and Finishing: Knowledge of different imposition techniques for various print products (e.g., booklets, brochures), and familiarity with finishing options (e.g., binding, folding, lamination). Practical application: Designing efficient layouts for cost-effective printing and aesthetically pleasing final products.

- Proofreading and Quality Control: Thorough understanding of proofreading techniques, including identifying typographical errors, inconsistencies in style, and image quality issues. Practical application: Ensuring print-ready files meet the highest quality standards before production.

- Color Management: Understanding color profiles, color separation, and achieving color consistency across different output devices. Practical application: Maintaining accurate color reproduction across various printing processes.

- Workflow and Automation: Familiarity with industry-standard software and automation tools to streamline the marking and layout process. Practical application: Increasing efficiency and reducing errors in high-volume projects.

- Print Production Knowledge: Basic understanding of printing processes (offset, digital, etc.) and their limitations. Practical application: Making informed decisions about file preparation and print specifications to achieve the desired results.

Next Steps

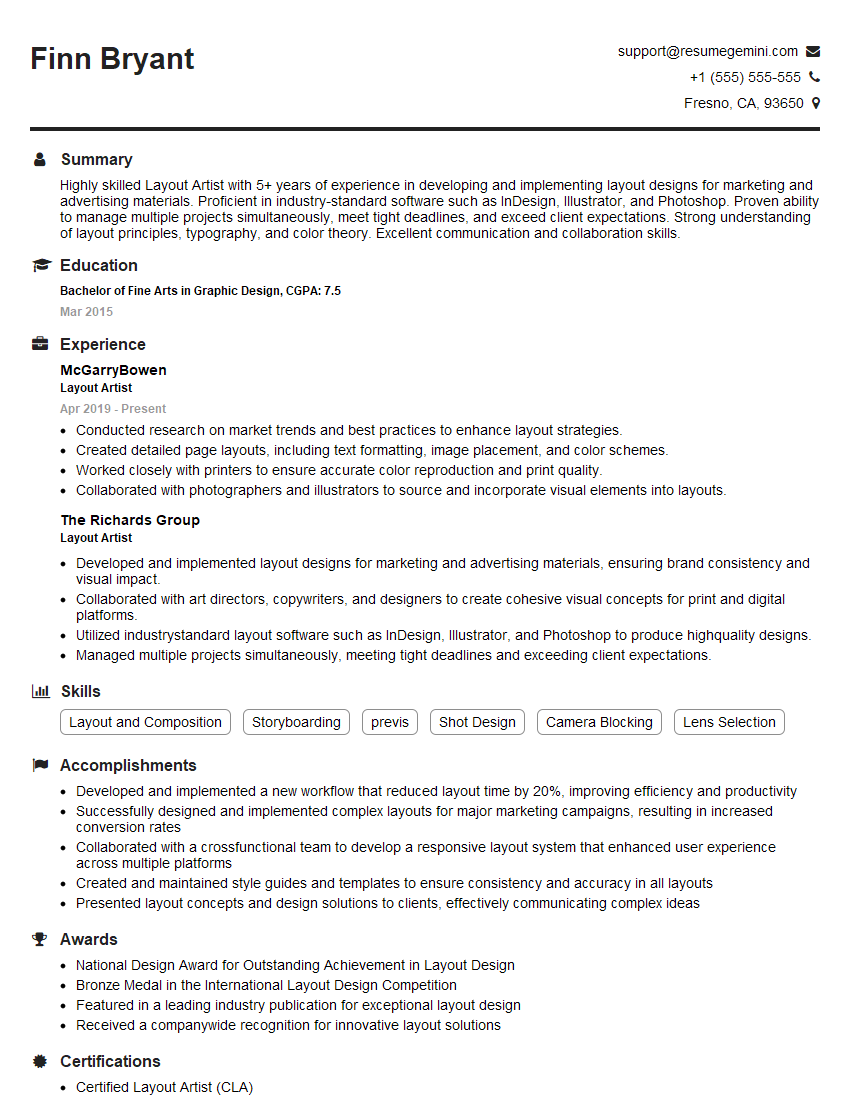

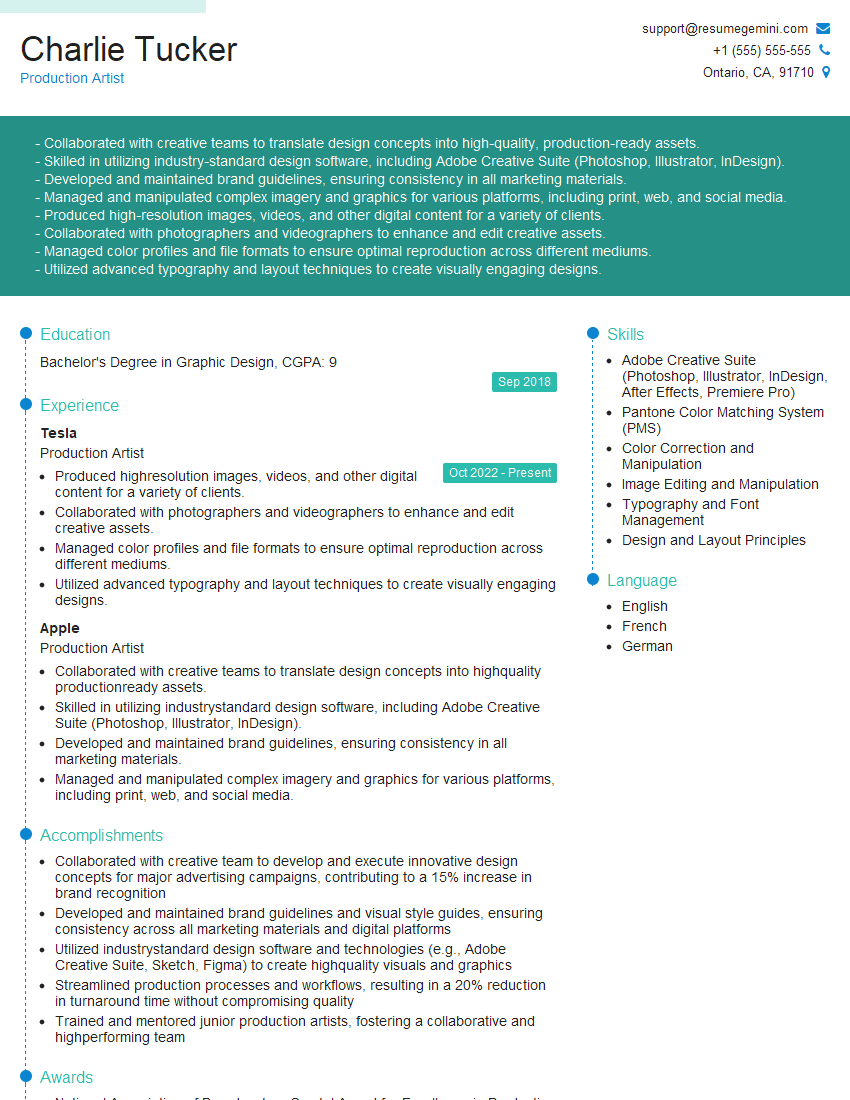

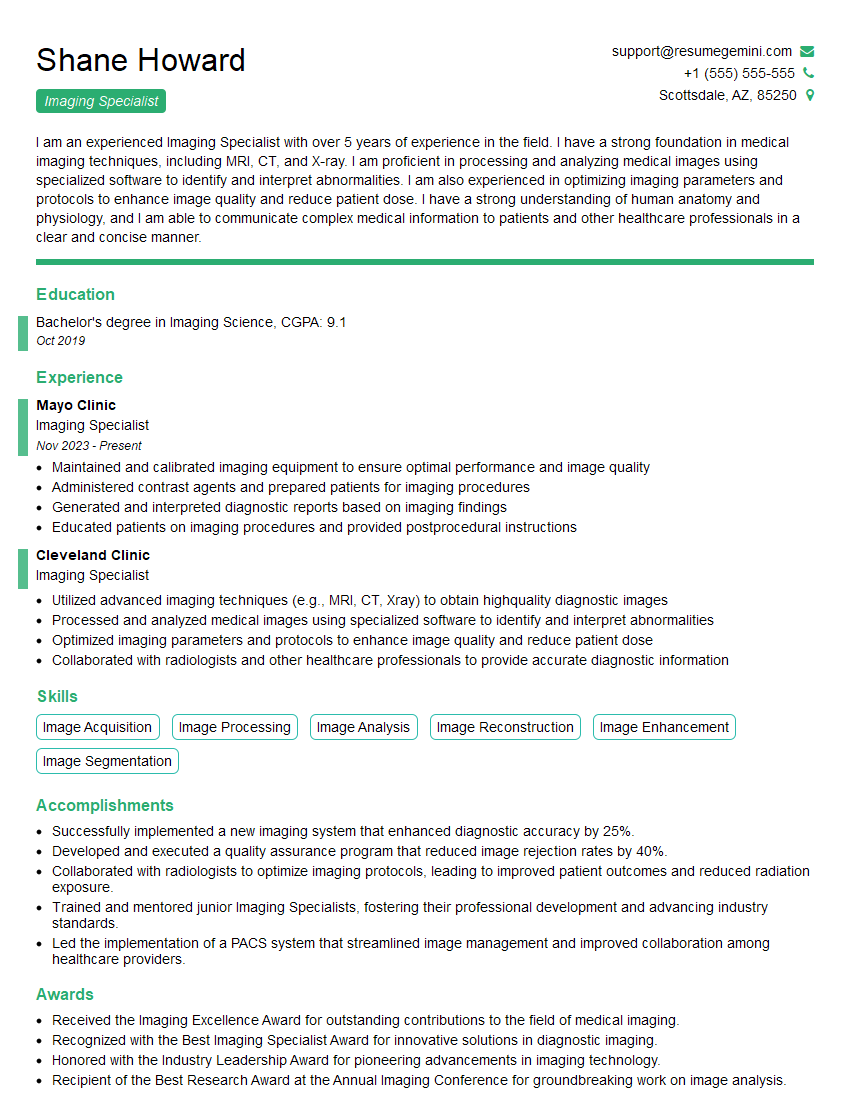

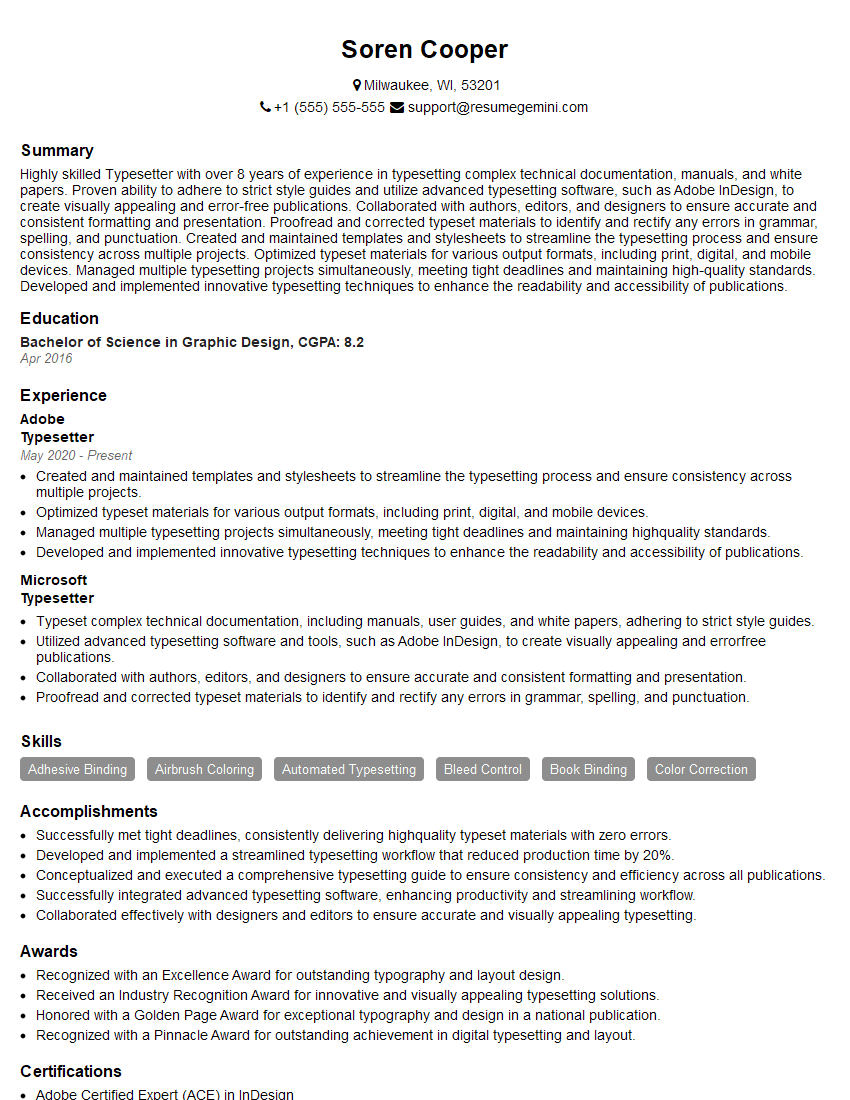

Mastering Marking and Layout opens doors to exciting opportunities in the publishing, printing, and design industries. A strong understanding of these skills is highly valued, leading to greater career progression and higher earning potential. To maximize your job prospects, invest time in creating an ATS-friendly resume that effectively highlights your expertise. ResumeGemini is a trusted resource that can help you craft a professional and compelling resume tailored to the specific requirements of Marking and Layout roles. Examples of resumes tailored to this field are available to guide you. Take the initiative – invest in yourself and your future success!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good