Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Tufting interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Tufting Interview

Q 1. Describe your experience with different tufting methods (e.g., hand tufting, punch needle, machine tufting).

My experience spans across all three major tufting methods: hand tufting, punch needle, and machine tufting. Each offers unique advantages and challenges. Hand tufting, while slower, provides incredible control and allows for intricate, highly customized designs. Think of creating a one-of-a-kind rug with incredibly detailed floral patterns – this is where hand tufting excels. Punch needle, a more accessible method, uses a tool to punch loops of yarn through a fabric backing, creating a textured effect. It’s great for smaller projects and quick prototyping, and the results can be quite impressive, particularly for wall hangings or smaller rugs. Machine tufting, however, is where high-volume production shines. It’s faster, more efficient for larger projects, and allows for precise control over pile height and density, resulting in rugs with consistent quality. I’ve worked extensively with all three, leveraging each technique’s strengths depending on the project requirements and client expectations.

Q 2. Explain the process of setting up a tufting machine for a specific project.

Setting up a tufting machine for a project is a multi-step process requiring precision. First, I select the appropriate backing fabric based on the design’s requirements – a sturdier backing for high-traffic rugs, for example. Then, I carefully load the fabric onto the machine’s frame, ensuring it’s taut and wrinkle-free to prevent uneven tufting. Next, I choose the yarn, considering its fiber content, color, and thickness to match the design specifications. The yarn is then loaded onto the machine’s yarn feeder, carefully adjusting the tension to maintain consistent loop height throughout the project. Finally, I program the machine, using the CAD design to dictate the tufting pattern, the speed of the machine, and other parameters like pile height and density. For instance, a dense, plush rug requires slower speed and higher density settings than a more loosely textured design.

Q 3. How do you troubleshoot common issues encountered during the tufting process?

Troubleshooting is a crucial part of tufting. Common issues include yarn breakage, inconsistent pile height, and machine malfunctions. Yarn breakage is usually due to improper tension or low-quality yarn; I address this by adjusting the tension settings and using higher quality yarn. Inconsistent pile height can be caused by uneven backing fabric or machine settings. Here, I’d inspect the fabric for wrinkles and readjust the machine’s settings to ensure uniform tufting. Machine malfunctions require careful diagnosis; I often start by checking power supply, inspecting the motor, and ensuring that all mechanical components are properly lubricated and functioning. A systematic approach, combined with knowledge of the machine’s workings, is essential to quickly resolve these issues and minimize downtime.

Q 4. What are the different types of yarns used in tufting, and their suitability for various projects?

The choice of yarn dramatically impacts the final product’s look, feel, and durability. We use various types: wool, for its natural softness and warmth (ideal for rugs in colder climates); cotton, for its breathability and affordability (suitable for rugs in warmer climates or for less demanding areas); acrylic, for its durability and vibrant color options (a versatile choice for many projects); and even blends, combining the best characteristics of multiple fibers. The selection depends entirely on the intended use and the desired aesthetic. For instance, a high-traffic rug might benefit from a durable acrylic blend, while a delicate nursery rug might call for softer, hypoallergenic wool.

Q 5. Describe your experience with different tufting patterns and designs.

My experience encompasses a wide variety of tufting patterns and designs, from simple geometric shapes and stripes to complex, intricate floral motifs and abstract designs. I’ve worked on projects incorporating both hand-drawn designs and those created using digital design software. One particularly memorable project involved recreating a client’s antique tapestry using machine tufting. This required meticulous attention to detail and color matching to capture the texture and nuances of the original. I’m comfortable working with both traditional and modern designs, adapting my techniques as needed to create unique and visually appealing rugs and wall hangings.

Q 6. How do you ensure consistent yarn tension throughout the tufting process?

Maintaining consistent yarn tension is paramount for a high-quality finished product. Uneven tension results in an uneven pile height and a less professional appearance. I achieve this through a combination of techniques. Firstly, I use high-quality yarn that is consistent in its thickness. Secondly, I carefully monitor the machine’s tension settings throughout the tufting process, making adjustments as needed. Regularly checking the yarn feeder and ensuring there are no knots or tangles is crucial. Finally, I regularly inspect the finished product for any inconsistencies in pile height to catch any issues early. Imagine creating a perfectly symmetrical design – consistent yarn tension is the foundation for achieving that perfection.

Q 7. Explain the importance of proper cleaning and maintenance of tufting machines.

Proper cleaning and maintenance are crucial for extending the lifespan of tufting machines and ensuring consistent, high-quality output. Regular cleaning involves removing lint, yarn scraps, and dust buildup from the machine’s various components. This prevents clogs and ensures the machine runs smoothly. Lubrication of moving parts is equally important – preventing wear and tear. I perform scheduled maintenance checks, inspecting mechanical components and belts for any signs of wear or damage. This preventative maintenance not only extends the machine’s lifespan but also minimizes costly repairs and ensures the machine continues to produce high-quality work. Think of it like maintaining a car – regular maintenance is far cheaper and more efficient than waiting for major repairs.

Q 8. Describe your experience with different tufting gun types and their functionality.

My experience encompasses a wide range of tufting guns, from basic single-needle models to advanced multi-needle machines. The functionality differs primarily in speed, precision, and yarn handling capabilities. Single-needle guns are ideal for intricate designs and detailed work, offering excellent control but slower production. They’re like using a fine paintbrush – perfect for nuance. Multi-needle guns, on the other hand, significantly increase speed, allowing for faster coverage of larger areas, much like using a roller for a base coat of paint. However, they often sacrifice some precision for speed. I’ve also worked with electric and pneumatic guns; pneumatic guns are powerful but require an air compressor, while electric ones are more convenient but may have slightly less power. The choice depends greatly on the project’s scale and desired level of detail.

- Single-needle: Precise, slow, ideal for detailed designs.

- Multi-needle: Fast, less precise, suitable for large areas.

- Electric: Convenient, moderate power.

- Pneumatic: Powerful, requires air compressor.

Q 9. How do you calculate the amount of yarn needed for a specific project?

Calculating yarn requirements involves several factors. First, you need the dimensions of your project (length and width). Then, you need the pile height (the length of the yarn loops) and the density of the tufting. Density refers to how closely packed the yarn loops are—a higher density means more yarn. I typically use a formula that takes these into account. It’s not a perfect science as yarn types vary in thickness and how much they compress. I often add a buffer of 10-15% to account for waste and unforeseen circumstances.

For example, let’s say we have a 2ft x 3ft rug with a 1-inch pile height and a medium density. I would estimate yarn requirements based on past projects with similar specifications and then factor in the 10-15% buffer to avoid running short. Experienced tufters often develop a ‘feel’ for yarn usage over time, allowing for more accurate estimates. Sampling a small section of the project with the intended yarn and density is crucial for determining an accurate quantity.

Q 10. Explain the process of creating a tufting stencil or pattern.

Creating a tufting stencil or pattern involves several methods. The simplest is using a hand-drawn design on a sturdy material like clear acetate or a durable plastic sheet. More complex designs often involve digital art programs. The design is then printed on a suitable material and transferred to the backing fabric either via tracing paper or a projector, ensuring precise placement on the backing fabric. This step is crucial for consistent results. The stencil acts as a guide to help maintain accurate shapes and lines while tufting.

For intricate designs, I often use a combination of techniques. For example, I might start with a digital design and then create a physical template using vinyl cutting. It’s all about finding the method that best suits the design’s complexity and the desired level of precision. Once the stencil is ready, it’s securely attached to the backing fabric to create the design guide.

Q 11. How do you manage yarn waste and ensure efficient yarn usage?

Managing yarn waste is critical for both cost-effectiveness and environmental responsibility. I employ several strategies to minimize waste. Firstly, I carefully plan my designs, making efficient use of available space and minimizing unnecessary yarn consumption. Secondly, I use yarn feeders to prevent excessive stretching and breaking during operation. Thirdly, I save yarn scraps for smaller projects or for filling in gaps or creating experimental pieces, following principles of ‘zero-waste’ design. Finally, I meticulously plan my yarn colors to avoid using excessive amounts of each individual shade.

For example, if I’m working with a design that requires a gradual color shift, I carefully calculate the amount of yarn needed for each shade, often using gradient yarn to further reduce waste. This careful planning ensures that yarn is used efficiently and waste is minimized.

Q 12. How do you handle quality control during the tufting process?

Quality control is an ongoing process throughout the tufting process. Regularly checking for consistent pile height, density, and color accuracy is vital. I use a variety of tools, including rulers, calipers, and color swatches to ensure every aspect of the design meets the specified standards. Additionally, I frequently inspect the tufting gun itself to ensure the needles are in good condition and the yarn feed is operating correctly. Any inconsistency should be addressed promptly, and any imperfections may need to be repaired immediately before proceeding.

For instance, I might check the pile height at several points across the rug, using a caliper to measure the exact length. Any deviations would prompt an investigation into the cause. This proactive approach prevents large-scale issues from developing, ensuring a consistently high-quality final product.

Q 13. What are the safety precautions you take while operating tufting machinery?

Safety is paramount when operating tufting machinery. I always ensure the machine is properly grounded and that safety guards are in place before starting any work. I wear appropriate personal protective equipment (PPE), including safety glasses to protect my eyes from flying debris, and hearing protection to reduce noise exposure. I maintain a clean and organized workspace to prevent tripping hazards. Regular maintenance of the equipment is also crucial to avoid unexpected malfunctions. Never operating the machine while fatigued or under the influence of substances is also important to maintain safety.

Before every tufting session, I perform a safety check on the machine and the workspace, which I document to ensure accountability and build a culture of safety. This includes checking the power supply, air compressor (if using a pneumatic gun), and the overall condition of the machine itself. It’s a checklist that has become second nature.

Q 14. Describe your experience with different tufting backing materials.

My experience includes working with various tufting backing materials, each with its strengths and weaknesses. Common materials include cotton canvas, monk’s cloth, and various blends. Cotton canvas offers a soft, durable base, ideal for rugs that prioritize comfort and a natural feel. Monk’s cloth, with its open weave, allows for excellent breathability and is widely used in rugs that need to be lightweight and have good air circulation. The choice depends on the desired characteristics of the final product—from texture and durability to the intended use and cost considerations.

For example, a high-traffic area rug may benefit from a sturdy cotton canvas backing, while a wall hanging might prefer a lighter-weight and more breathable option like a blended fabric. I select the backing material based on the specific project requirements and discuss the options with my clients to ensure we choose the material that best matches their needs and expectations.

Q 15. How do you ensure the proper adhesion of the backing to the tufted fabric?

Proper adhesion between the backing fabric and the tufted yarn is paramount for the longevity and quality of a rug. Think of it like the foundation of a house – if it’s weak, the whole structure suffers. We achieve this through a combination of factors, primarily the type of adhesive used and the application process.

- Adhesive Selection: The choice of adhesive depends on the backing material (e.g., cotton canvas, burlap) and the desired level of flexibility and durability. We typically use high-quality latex, which offers a strong bond, flexibility, and good resistance to wear and tear. Other options include specialized adhesives designed for specific backing materials.

- Application Technique: The adhesive must be applied evenly and thinly to prevent clumping and ensure even adhesion. We use specialized application tools like rollers or sprayers to achieve consistent coverage. Over-application can lead to a stiff, inflexible rug, while under-application results in weak adhesion and shedding.

- Drying Process: After application, the backing needs adequate drying time in a controlled environment to fully cure the adhesive. Humidity and temperature play a crucial role, and improper drying can lead to adhesion issues. We often use climate-controlled spaces to ensure optimal drying conditions.

For example, on a large-scale project using burlap backing, we might opt for a heavy-duty latex adhesive applied with a specialized roller, followed by a 24-hour drying period in a climate-controlled room. This ensures a strong, durable bond that can withstand the wear and tear of high-traffic areas.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or programs are you familiar with for designing tufting patterns?

Designing tufting patterns requires software capable of handling vector graphics and intricate details. I’m proficient in several programs, each offering unique advantages:

- Adobe Illustrator: This is my go-to software for creating intricate and detailed patterns. Its vector-based nature allows for easy scaling without loss of quality, perfect for generating designs for rugs of varying sizes.

- Procreate (iPad): This is a fantastic tool for sketching initial ideas and experimenting with color palettes. Its intuitive interface allows for quick iterations and exploration of different styles.

- AutoCAD: While less intuitive for artistic design, AutoCAD excels at precision and is essential when working with complex geometric patterns or large-scale projects requiring exact measurements and dimensions.

I often begin with hand-drawn sketches in Procreate, refining them in Illustrator before finalizing the pattern for production. The ability to seamlessly integrate these programs maximizes efficiency and ensures the design translates flawlessly to the tufting process. For example, a recent project required a complex geometric pattern repeating across a large area. Using AutoCAD’s precision tools ensured the pattern remained consistent and perfectly aligned, crucial for a visually appealing final product.

Q 17. Explain your understanding of color theory and how it relates to tufting.

Color theory is fundamental to successful tufting. It’s not just about choosing pretty colors; it’s about creating a cohesive and visually appealing design that evokes the desired mood and atmosphere. I apply the principles of color harmony, contrast, and value to create balanced and impactful rug designs.

- Color Harmony: Understanding color schemes like analogous (colors next to each other on the color wheel), complementary (opposite colors on the color wheel), and triadic (three evenly spaced colors) helps create visually pleasing combinations. A rug featuring analogous blues and greens, for instance, offers a serene and calming effect.

- Color Contrast: Effective use of contrast helps create visual interest and hierarchy within a design. Pairing a bold, saturated color with a muted neutral creates a focal point and draws the eye. Imagine a vibrant red accent against a neutral beige background.

- Color Value: This refers to the lightness or darkness of a color. Mastering value helps create depth and dimension in the design. A rug with varying shades of blue, ranging from light sky blue to deep navy, will feel richer and more textured than one using only one shade of blue.

In a recent project, I used a triadic color scheme of teal, orange, and purple to create a vibrant and playful rug, using contrast to highlight certain areas. Consideration of color theory at the design stage is essential to create a final product that looks as beautiful in reality as it does on screen.

Q 18. How do you handle large-scale tufting projects and meet deadlines?

Managing large-scale tufting projects requires meticulous planning and efficient execution. It’s akin to orchestrating a complex symphony – each section needs to be perfectly timed and coordinated for a harmonious outcome.

- Project Breakdown: We divide large projects into smaller, manageable tasks with clearly defined timelines. This allows for better resource allocation and facilitates progress tracking.

- Teamwork: Collaborating with a skilled team is crucial. Each team member has specific roles and responsibilities, ensuring seamless workflow and efficient task completion.

- Material Management: Accurate material estimation and procurement are paramount to avoid delays. We establish a robust inventory management system to ensure sufficient yarn, backing, and other supplies are available throughout the project.

- Quality Control: Regular quality checks at each stage prevent accumulation of minor errors and ensure the final product meets the highest standards. This saves time and resources in the long run.

For instance, a recent large-scale commercial project required precise coordination between design, tufting, and finishing teams. By breaking down the project into phases and employing a rigorous quality control process, we delivered the finished product on time and within budget, exceeding client expectations.

Q 19. What is your experience with different tufting machine brands and models?

My experience encompasses a variety of tufting machine brands and models. Each machine has its strengths and weaknesses, impacting productivity and the final rug’s quality.

- Standard Electric Tufting Machines: I’m highly proficient in operating several models of standard electric tufting machines, including those from [mention specific brands if comfortable, e.g., ‘XYZ’ and ‘ABC’]. These are versatile machines suitable for a wide range of projects.

- Punch Needle Machines: I have experience using various punch needle machines, both manual and electric, for creating unique textures and effects. These are particularly well-suited for smaller, more detailed projects.

- High-Speed Tufting Machines: I’ve worked with high-speed industrial machines on large commercial projects, which offer significant productivity improvements but require specialized skills and expertise.

The choice of machine depends on several factors, including the project’s scale, complexity, and budget. My expertise extends to understanding the unique capabilities of each machine type, enabling me to select the optimal machine for any given project. For example, a highly detailed, custom rug would likely be best crafted using a punch needle machine, whereas a large, commercial carpet would benefit from the speed and efficiency of a high-speed tufting machine.

Q 20. How do you troubleshoot issues with yarn breakage or knotting?

Yarn breakage and knotting are common issues in tufting, often stemming from several factors. Troubleshooting requires a systematic approach.

- Yarn Quality: Inferior yarn quality is a major culprit. We use only high-quality yarn that is strong, consistent, and free from defects. Using improperly stored yarn or yarn that is too dry or too wet also causes issues.

- Machine Maintenance: Regular machine maintenance is essential. This includes cleaning the needles, ensuring proper tension, and checking for any mechanical issues. A poorly maintained machine can damage the yarn and cause frequent breakage.

- Tufting Technique: Improper tufting technique can also lead to breakage and knotting. Consistent and even pressure is crucial. Working too quickly or applying uneven pressure can put undue stress on the yarn.

My troubleshooting process involves first identifying the cause – inspecting the yarn, checking the machine’s condition, and observing the tufting technique. For example, if the problem is consistently occurring with one specific needle, it suggests a machine issue needing repair. If the breakage is random, it might indicate a problem with the yarn itself.

Q 21. Describe your experience with latex application in the tufting process.

Latex application is a critical step in the tufting process, affecting the rug’s durability, texture, and overall quality. It acts as the binding agent, securing the tufts to the backing fabric. It’s akin to the mortar in a brick wall – it holds everything together.

- Latex Type: We use high-quality latex specifically designed for rug backing. The type chosen depends on factors such as backing material and desired rug properties (e.g., flexibility, durability).

- Application Method: The latex can be applied via roller, sprayer, or dipping, each method having its advantages and disadvantages. A sprayer allows for even coverage on large areas, while a roller provides more control and is better for intricate designs. Dipping is suitable for smaller projects but may result in inconsistencies.

- Drying Process: Proper drying is essential to ensure optimal adhesion. Environmental conditions such as temperature and humidity significantly impact the drying time and the quality of the bond. We always utilize controlled environments to avoid any issues arising from improper drying.

In my experience, achieving a consistent, even application of latex is crucial for preventing issues such as uneven backing, shedding, or weak adhesion. We continually monitor the process, making adjustments as needed to ensure every rug meets our high standards. For instance, on a large project, we might use a specialized sprayer to apply latex evenly, followed by controlled air circulation to optimize drying time and adhesion.

Q 22. Explain your knowledge of different finishing techniques for tufted rugs.

Finishing techniques for tufted rugs are crucial for achieving the desired aesthetic and durability. They range from simple to complex processes, impacting the rug’s final look and feel. These techniques often build upon each other.

Shearing and Trimming: This is the most basic finishing step, involving carefully trimming the loops of yarn to create a consistent pile height. Different shearing techniques, using specialized tools like electric shears or hand shears, create varied textures—from a plush, high pile to a low, densely packed surface.

Serging/Overlocking: The edges of the rug are stitched using a serger to prevent fraying and add a professional finish. The choice of thread color can be used to complement or contrast with the rug’s main design. This also enhances the rug’s durability.

Binding: This involves adding a fabric border to the edges, usually cotton or a similar durable material. Binding provides additional protection and enhances the overall appearance, particularly for rugs with intricate designs that might be vulnerable at the edges.

Latex Backing: Applying a latex backing adds stability and prevents the rug from shifting or bunching. It’s especially useful for larger rugs and areas with high foot traffic. Different types of latex provide varying levels of durability and flexibility.

Washing and Cleaning: A final washing step can remove any loose fibers or excess adhesive from the backing. This step is essential for maintaining the rug’s quality and cleanliness before delivery. The specific cleaning method depends on the rug’s material and construction.

Choosing the right finishing technique is crucial. For a high-end rug, a combination of shearing, serging, binding, and latex backing might be employed, while a simpler rug might only need shearing and serging.

Q 23. How do you maintain the quality and consistency of your work over long periods?

Maintaining quality and consistency in tufting requires a meticulous approach, combining skilled craftsmanship with efficient processes. I achieve this through several key strategies:

Consistent Materials: Sourcing my materials from reputable suppliers ensures consistent yarn quality, color, and texture. This minimizes variations in the final product. I maintain detailed records of my suppliers and material batches.

Calibrated Equipment: Regular maintenance and calibration of my tufting gun and other tools are essential. A well-maintained tufting gun ensures consistent knot density and evenness of the pile. I keep a detailed maintenance log for all my equipment.

Standard Operating Procedures (SOPs): I have established clear SOPs for each stage of the tufting process, from design transfer to finishing. This ensures every project follows the same high standards. These SOPs are reviewed and updated regularly.

Quality Checks: At each stage of production, I perform rigorous quality checks. This includes examining the yarn tension, knot density, and overall evenness of the tufting. Identifying and rectifying any issues early in the process prevents major problems later.

Continuous Learning: The tufting field is constantly evolving. I stay updated through workshops, online courses, and industry publications to learn new techniques and best practices. I actively seek feedback on my work to identify areas for improvement.

This multi-pronged approach ensures that the rugs I produce maintain a high standard of quality and consistency, even over extended periods.

Q 24. What are the key differences between hand tufting and machine tufting?

Hand tufting and machine tufting are both methods of creating tufted rugs, but they differ significantly in their process, scale, and the resulting product.

Hand Tufting: This is a labor-intensive process where individual knots are inserted into the backing fabric using a tufting gun operated by hand. This allows for intricate designs and fine details. The outcome is a unique, handcrafted rug with subtle variations in texture and pile height. It’s ideal for one-of-a-kind pieces and smaller rugs.

Machine Tufting: This utilizes an automated machine that inserts thousands of knots per minute. It is much faster and more efficient, suitable for mass production and large rugs. Machine tufting typically produces a more uniform pile height and texture, although advancements in technology are blurring the lines, allowing for more complex designs. Machine-tufted rugs can be very affordable depending on the quality of materials used.

The key difference lies in the level of control and customization. Hand tufting offers unmatched artistic freedom, while machine tufting excels in efficiency and scalability. The choice depends on the desired level of detail, production volume, and budget.

Q 25. Describe your experience with shearing and trimming tufted fabrics.

Shearing and trimming are critical steps in finishing tufted rugs, directly impacting their appearance and texture. My experience involves using both electric and hand shears, selecting the appropriate tool based on the design and desired effect.

Electric Shears: These are ideal for achieving consistent pile height across large areas, particularly in machine-tufted rugs. The adjustable height settings allow for precise control, ensuring a uniform finish.

Hand Shears: I use hand shears for intricate designs and detailed work, requiring more precision and control. They are particularly useful for creating textured effects or shaping the edges of a rug with complex contours. Maintaining sharp blades is crucial for a clean cut.

The process requires a keen eye for detail and a steady hand. I often use templates or guidelines to ensure evenness, particularly in large-scale projects. I also understand the importance of adjusting the shearing height to account for variations in yarn thickness and tufting density. A poorly executed shearing job can ruin the rug’s aesthetics and value, so practice and skill are paramount.

Q 26. Explain the importance of maintaining a clean and organized workspace.

Maintaining a clean and organized workspace is paramount for efficiency, safety, and quality control in tufting. A cluttered workspace leads to wasted time searching for tools, increased risk of accidents, and potential damage to materials. My approach involves:

Dedicated Storage: I use clearly labeled storage containers for yarns, tools, and backing fabrics, keeping frequently used items within easy reach.

Regular Cleaning: I regularly sweep and vacuum the floor to remove loose fibers and debris. I also clean my tools after each use, keeping them organized and ready for the next project.

Designated Areas: My workspace is divided into zones for different tasks (e.g., yarn preparation, tufting, shearing). This ensures smooth workflow and prevents cross-contamination of materials.

Waste Management: I use separate bins for different types of waste (e.g., yarn scraps, packaging) to ensure proper disposal and recycling.

A well-organized workspace is more than just tidy; it reflects professionalism, fosters creativity, and reduces stress, leading to improved quality of work and overall productivity.

Q 27. How do you adapt to changing project requirements and deadlines?

Adaptability is crucial in the tufting industry. Project requirements and deadlines can change unexpectedly, so I’ve developed strategies to handle these situations effectively. These include:

Clear Communication: I maintain open and transparent communication with clients to understand their expectations and any potential changes. This helps prevent misunderstandings and allows for timely adjustments.

Prioritization and Planning: I use project management tools to prioritize tasks and allocate resources efficiently. If deadlines shift, I reassess the project plan and identify potential bottlenecks.

Flexibility and Problem-Solving: I’m adept at adjusting my workflow and problem-solving skills to accommodate unexpected changes. This might involve adjusting the production schedule, modifying the design, or sourcing alternative materials.

Contingency Planning: I anticipate potential challenges and develop contingency plans to mitigate their impact. This might include having backup materials or scheduling extra time for unforeseen delays.

My proactive approach, coupled with clear communication and problem-solving skills, enables me to manage changing project needs seamlessly and meet deadlines effectively, while maintaining a high standard of workmanship.

Q 28. Describe a time you had to solve a complex problem during a tufting project.

During a recent project involving a complex, multi-colored geometric design, I encountered a challenge with the yarn color transitions. The original design called for very fine gradations between colors, and achieving these smooth transitions using standard tufting techniques proved difficult. The resulting color bands were too noticeable.

To solve this, I experimented with different tufting techniques. I explored using multiple tufting guns simultaneously with different shades of yarn, creating a more blended effect. I also adjusted the placement and density of the tufts to soften the transitions between the color blocks. I tested different yarn types to find those which blended better. Finally, I developed a new workflow where I pre-mixed small batches of yarns with subtly varying shades to create more natural transitions.

The solution involved a creative combination of technical skills and problem-solving. The final result was a rug that met the client’s expectations, showcasing the smooth color gradations originally envisioned. This experience reinforced the importance of continuous experimentation and adaptation when faced with complex design challenges in tufting.

Key Topics to Learn for Your Tufting Interview

- Tufting Machine Operation: Understanding the mechanics, maintenance, and troubleshooting of various tufting machines (e.g., single needle, multi-needle).

- Yarn Selection and Management: Knowledge of different yarn types, their properties, and how to select the appropriate yarn for desired outcomes. Includes understanding yarn handling, storage, and waste reduction techniques.

- Design and Pattern Creation: Familiarity with creating tufting patterns using design software, translating designs into production-ready formats, and understanding the limitations of the tufting process.

- Tufting Techniques: Mastering various tufting techniques, including pile height control, density control, and creating texture variations.

- Quality Control and Inspection: Identifying and addressing common tufting defects, implementing quality control measures throughout the production process, and ensuring consistent product quality.

- Safety Procedures and Regulations: Adherence to safety protocols in a tufting environment, including machine safety, proper handling of materials, and understanding relevant industry regulations.

- Production Processes and Efficiency: Understanding the entire tufting process from design to finished product, optimizing workflows for efficiency, and contributing to improved production outputs.

- Problem-Solving and Troubleshooting: Diagnosing and resolving common issues encountered during the tufting process, demonstrating problem-solving skills, and implementing preventative maintenance strategies.

Next Steps

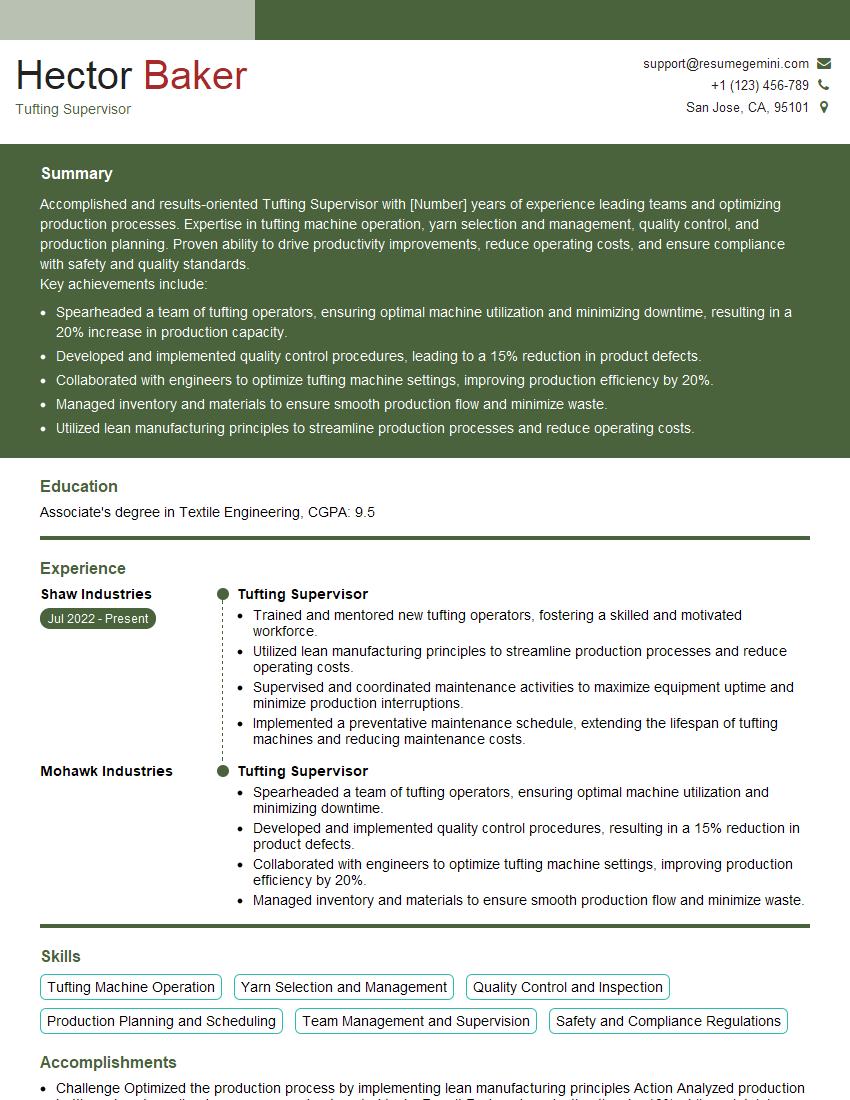

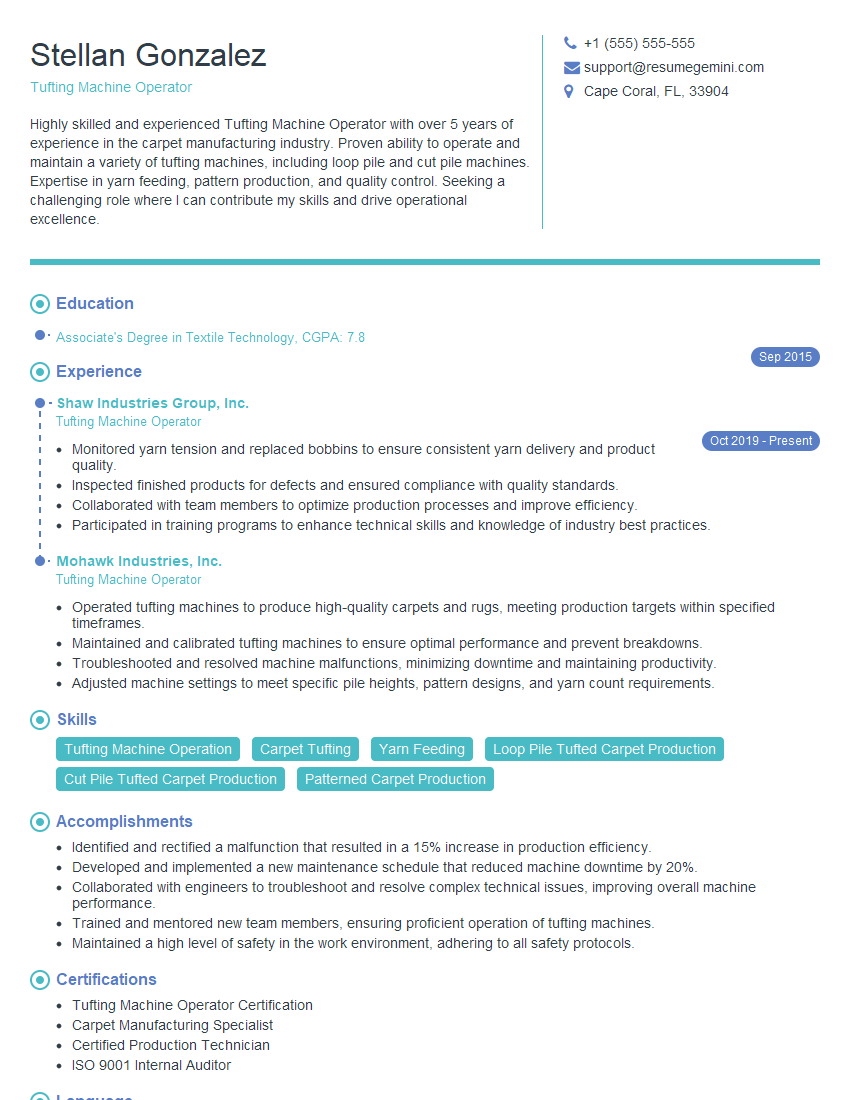

Mastering tufting skills opens doors to exciting career opportunities in a growing industry, offering potential for advancement and specialization. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your tufting expertise. Examples of resumes tailored to the tufting industry are available to help guide you. Take the next step in your career journey – invest in your resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good