Preparation is the key to success in any interview. In this post, we’ll explore crucial Robot Control Systems interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Robot Control Systems Interview

Q 1. Explain the difference between open-loop and closed-loop control systems in robotics.

Imagine you’re teaching a dog a trick. In an open-loop system, you give the command (e.g., ‘sit’) and hope the dog understands and performs the action correctly. There’s no feedback mechanism to check if the dog actually sat. The robot simply executes a pre-programmed sequence of actions without regard to the actual outcome. This is simple to implement but highly susceptible to errors and external disturbances. For example, a robotic arm instructed to move 10 centimeters might not reach the precise point if there is a slight variation in its initial position or external forces acting upon it.

In a closed-loop system, you give the command and then observe the dog’s response. If the dog doesn’t sit, you correct the command or try a different approach. This is analogous to a robot using sensors to monitor its actions and compare them to the desired outcome. A feedback loop adjusts the robot’s behavior to minimize the difference between the desired state and the actual state. Consider the same robotic arm equipped with a position sensor: the sensor constantly monitors the arm’s position, comparing it to the target position, and adjusts the motor accordingly until the desired position is accurately achieved. Closed-loop systems are far more robust and accurate than open-loop systems, able to handle disturbances and achieve greater precision, although they are also more complex to design and implement.

Q 2. Describe different types of robot actuators and their applications.

Robot actuators are the ‘muscles’ of a robot, converting energy into motion. There are several types:

- Electric Motors: These are widely used due to their precision, controllability, and efficiency. Examples include servo motors (precise position control), stepper motors (precise incremental movements), and DC motors (continuous rotation). You’ll find these in industrial robots, collaborative robots (cobots), and even small hobbyist robots.

- Hydraulic Actuators: These use pressurized fluid to generate force, ideal for high-force applications. Think of heavy-duty industrial robots in manufacturing plants or large construction equipment. They offer high power density but can be less precise and more challenging to control than electric motors.

- Pneumatic Actuators: These use compressed air to create motion, known for their speed and simplicity. They are commonly used in simpler robots or in applications where fast, on/off control is sufficient, such as pick-and-place operations in automated systems.

The choice of actuator depends on the specific application requirements, considering factors such as required force/torque, speed, precision, cost, and environmental factors.

Q 3. What are the advantages and disadvantages of using PID controllers in robotics?

PID (Proportional-Integral-Derivative) controllers are ubiquitous in robotics due to their relative simplicity and effectiveness in regulating various aspects of robot behavior, like position, velocity, or temperature. They work by calculating an error signal—the difference between the desired state and the actual state—and adjusting the control signal accordingly.

Advantages:

- Simplicity: PID controllers are relatively easy to understand and implement.

- Wide Applicability: Effective across a range of systems and applications.

- Robustness: Can handle disturbances and uncertainties to some extent.

Disadvantages:

- Tuning Difficulty: Finding optimal PID gains (proportional, integral, and derivative constants) can be challenging and often requires trial and error or more sophisticated tuning methods.

- Limited Performance: PID controllers might struggle with complex, highly nonlinear systems or systems with significant time delays.

- Steady-State Error: A pure PID controller might exhibit a small persistent error in the steady state.

In practice, sophisticated adaptive control techniques or model-based approaches are often preferred for complex robotics scenarios.

Q 4. How do you handle sensor noise and uncertainty in robot control systems?

Sensor noise and uncertainty are inevitable in robotics. Multiple strategies are employed to mitigate their effects:

- Sensor Fusion: Combine data from multiple sensors to get a more accurate and reliable estimate. For example, using both an inertial measurement unit (IMU) and a GPS to estimate a robot’s position, leveraging the strengths of each sensor to compensate for the weaknesses of the other.

- Kalman Filtering (discussed in detail below): A powerful technique for estimating the state of a dynamic system in the presence of noise.

- Data Smoothing: Apply algorithms like moving averages or low-pass filters to reduce high-frequency noise.

- Robust Control Techniques: Design controllers that are less sensitive to uncertainties and disturbances. For instance, using H-infinity control methods can explicitly consider uncertainties during design.

- Sensor Calibration: Regularly calibrate sensors to improve accuracy and reduce systematic errors.

The choice of technique depends on the specific sensors, noise characteristics, and the application’s requirements for accuracy and robustness.

Q 5. Explain the concept of Kalman filtering and its use in robotics.

Kalman filtering is a powerful recursive algorithm that estimates the state of a system from a series of noisy measurements. It’s like a sophisticated form of prediction and correction. Imagine tracking a moving object: the Kalman filter uses previous measurements and a model of the object’s motion to predict its future position. Then, it incorporates new measurements to correct the prediction, resulting in an improved estimate that’s less influenced by noise.

In robotics, Kalman filters are used in:

- State Estimation: Estimating a robot’s position, velocity, and orientation from sensor data like IMUs, GPS, and encoders.

- Sensor Fusion: Combining data from multiple sensors to obtain a more accurate and reliable estimate.

- Robot Mapping and Localization (SLAM): Building maps of an environment and simultaneously localizing the robot within the map.

Kalman filtering elegantly combines prior knowledge (the model) with new sensor data, resulting in a robust and accurate state estimate even with noisy measurements.

Q 6. Describe different robot coordinate systems (e.g., Cartesian, joint, world).

Robots need to understand their position and orientation relative to their environment and themselves. Different coordinate systems are used for this purpose:

- Joint Coordinates: Describe the configuration of the robot’s joints, typically expressed as angles or distances. Each joint has its own coordinate system, and the robot’s overall configuration is defined by the set of joint coordinates. This is internal to the robot itself.

- Cartesian Coordinates: A common representation using three linear coordinates (x, y, z) to specify a point in space, plus three angles (roll, pitch, yaw) to define orientation. This system is useful for describing the position and orientation of the robot’s end-effector (tool) in the world.

- World Coordinates: A global reference frame used to describe the position and orientation of objects in the robot’s environment. It acts as a fixed point of reference.

Transformations between these coordinate systems are crucial for robot control, enabling the robot to translate commands given in one coordinate system into actions in another. For example, a user might specify a desired position in Cartesian coordinates, but the robot controller needs to convert this to joint coordinates to send the appropriate signals to the motors.

Q 7. How do you perform robot trajectory planning and path generation?

Robot trajectory planning involves determining the path and motion profile for the robot to follow. It encompasses two main steps:

- Path Planning: Finding a collision-free path from a start point to a goal point. Algorithms like A*, RRT (Rapidly-exploring Random Tree), and potential fields are commonly employed. The result is a sequence of points representing the desired path. Consider a robot arm needing to navigate through obstacles to reach a target location; path planning would find an optimal, obstacle-avoiding route.

- Motion Planning: Determining the velocity and acceleration profiles for the robot to follow along the planned path. This ensures smooth and safe movement, avoiding jerky motions or exceeding the robot’s physical limitations. Techniques like cubic splines or trapezoidal velocity profiles are often used.

The choice of algorithms depends on the robot’s characteristics, environmental constraints, and the specific task. Sophisticated trajectory planning algorithms need to consider factors like dynamic constraints (maximum velocity, acceleration), kinematic constraints (joint limits), and the presence of obstacles. In practice, simulations and testing are crucial to validate and refine the planned trajectory.

Q 8. What are the challenges of implementing real-time control in robotics?

Real-time control in robotics demands immediate responses to sensor data and environmental changes. The main challenge lies in meeting stringent timing constraints. Imagine a robot arm needing to precisely weld a seam – any delay can result in a faulty weld. This necessitates efficient algorithms and hardware capable of processing information and executing actions within milliseconds. Other challenges include:

- Deterministic behavior: Predicting the exact timing of actions is crucial. Unexpected delays (e.g., garbage collection in software) can lead to instability.

- Resource limitations: Robots often operate with limited computational power and memory. Efficient code and optimized algorithms are crucial to avoid exceeding these limits.

- Handling sensor noise and uncertainty: Real-world sensors are not perfect. Effective control systems need to filter noise and handle uncertainty in sensor readings accurately.

- Integration of different systems: Real-time control involves coordinating multiple subsystems (sensors, actuators, controllers). Synchronization and communication protocols must be carefully designed.

Overcoming these challenges often involves using real-time operating systems (RTOS), specialized hardware, and carefully designed control algorithms. For example, a robotic surgery system demands extremely low latency, relying on sophisticated RTOS and highly optimized code.

Q 9. Explain different robot programming languages and their applications.

Robot programming languages vary widely, each with its strengths and weaknesses. Some popular options include:

- ROS (Robot Operating System): A widely used framework rather than a single language. It provides tools and libraries for building complex robotic systems, often using Python or C++ for application-specific code. ROS is excellent for modularity and large-scale projects. Think of building a modular house – ROS provides the structural elements, allowing programmers to add features.

- C++: Offers speed and control, making it ideal for real-time applications and low-level control. It’s commonly used for implementing control algorithms directly on the robot controller.

- Python: Easy to use and versatile, often used for higher-level tasks like path planning, computer vision integration, and data analysis. Its flexibility makes it great for rapid prototyping and experimentation. Imagine building a quick wooden structure in your garage. Python offers this level of quick assembly.

- MATLAB/Simulink: Powerful tools for modeling, simulation, and algorithm development. Simulink’s graphical interface makes it easier to design and test control systems. This is like having a sophisticated architectural model, enabling easier testing before full-scale construction.

- RAPID (ABB robots): A proprietary language used for programming ABB robots. It focuses on ease of use and industry-specific functions for their robot controllers. This is like a specialized toolkit that contains the perfect tools for a specific robot model.

The choice of language depends on the specific application and the programmer’s expertise. A small, simple task might use Python, while a high-speed industrial robot would benefit from the speed and efficiency of C++ combined with the structure of ROS.

Q 10. Discuss the role of inverse kinematics in robot control.

Inverse kinematics solves the problem of finding the joint angles of a robot given the desired position and orientation of its end-effector. Imagine you want your robot arm to reach a specific point in space; inverse kinematics calculates the angles each joint needs to achieve this. It’s like figuring out the sequence of steps you need to take to reach a destination on a map.

It’s a crucial component of robot control because it translates high-level tasks (e.g., move to this point) into low-level commands (e.g., set joint angles). Several methods exist to solve inverse kinematics:

- Geometric methods: Solve inverse kinematics using geometric relationships between robot links and joints. These are often suitable for simple robots with a small number of degrees of freedom.

- Iterative numerical methods (e.g., Newton-Raphson): These methods iteratively refine an initial guess for joint angles until they satisfy the desired end-effector position and orientation. They are more general and can handle complex robots.

- Closed-form solutions: Analytical solutions exist for specific robot configurations that directly compute joint angles from the desired pose. They are computationally efficient but can only be found for some specific robot geometries.

Choosing the best method depends on the robot’s geometry and complexity. For a simple robotic arm, a geometric approach might suffice. Complex robots or those requiring real-time performance might benefit from numerical techniques that are pre-computed and stored.

Q 11. Describe different methods for robot calibration and their importance.

Robot calibration involves accurately determining the robot’s kinematic and dynamic parameters. This means precisely measuring the lengths of robot links, the locations of joints, and other physical properties. Think of it like getting your car’s wheel alignment checked – you need accurate measurements to ensure it runs smoothly.

Accurate calibration is crucial because errors in these parameters can lead to significant positioning errors and affect the robot’s overall performance. Methods for calibration include:

- Geometric calibration: Measures the link lengths and joint offsets using tools like laser trackers or theodolite. This involves precisely measuring the physical dimensions of the robot.

- Kinematic calibration: Identifies errors in the robot’s kinematic model by measuring the robot’s pose at multiple points in its workspace. This involves observing the robot’s movement and using sophisticated software to identify discrepancies.

- Dynamic calibration: Determines the robot’s inertia parameters and friction coefficients. This is important for precise motion control, especially at high speeds and accelerations. This involves observing the robot’s response to known forces and torques.

The choice of method depends on the robot’s complexity and the required accuracy. For high-precision applications, like those in manufacturing or surgery, more advanced and meticulous calibration is essential.

Q 12. How do you address robot singularities and avoid them?

Robot singularities are configurations where the robot loses one or more degrees of freedom. Imagine trying to bend your elbow fully while your arm is extended straight out to the side. There is a point where movement in one direction is impossible. In robot terms, it means the robot’s Jacobian matrix (which maps joint velocities to end-effector velocities) becomes singular, resulting in infinite joint velocities for small end-effector velocities.

Singularities cause problems because they can lead to unpredictable robot behavior, high joint velocities, and even physical damage. Addressing singularities is crucial for safe and stable robot operation.

Strategies for avoiding singularities include:

- Path planning: Plan robot trajectories that avoid regions near singularities. Advanced path planners incorporate singularity avoidance algorithms to keep the robot away from these problematic configurations.

- Redundant robots: Employ robots with more degrees of freedom than necessary. This allows the robot to reach the same end-effector pose through multiple joint configurations, making it possible to avoid singularities.

- Singularity robust control: Design control algorithms that are not significantly affected by the presence of singularities. These methods typically involve modifying the control law to avoid problematic configurations.

- Joint limit avoidance: Prevent the robot from reaching joint limits that may lead to singularities. This can be done via careful trajectory planning or by setting software limits on the joint angles.

These strategies work in tandem. For example, path planning may avoid the vicinity of singularities, but if a disturbance is present, a singularity robust control strategy will help mitigate the issue. A well-designed control system will often incorporate all these.

Q 13. Explain the concept of robot dynamics and its influence on control design.

Robot dynamics describes the relationship between the forces and torques acting on a robot and its resulting motion. It considers the robot’s inertia, friction, gravity, and other forces that influence its movement. Understanding robot dynamics is essential for designing effective control systems because these forces impact the robot’s behavior.

Imagine pushing a shopping cart – a heavier cart (higher inertia) requires more force to accelerate. Similarly, the weight and shape of a robot arm significantly impact the forces and torques required for precise movement. Ignoring dynamics can lead to inaccurate robot movements or even instability.

The influence on control design is significant because accurate models of robot dynamics are needed for:

- Feedforward control: Predicting the required torques to achieve desired motions and compensating for known dynamic effects.

- Feedback control: Using sensor measurements to correct for unexpected disturbances or errors in the robot’s motion.

- Trajectory planning: Generating smooth and physically feasible trajectories that account for dynamic constraints.

For high-performance robot control, accurate dynamic models are crucial. These models are often derived using Lagrangian or Newton-Euler methods, and their complexity increases with the number of links and degrees of freedom in the robot. Model-based control methods leverage these models to achieve better performance and robustness.

Q 14. What are the common methods for robot safety and emergency stop mechanisms?

Robot safety is paramount, and robust emergency stop mechanisms are essential. These systems should be designed to quickly and reliably halt robot motion in hazardous situations. Think of an emergency brake in a car – it’s a crucial safety feature.

Common methods for robot safety include:

- Emergency stop buttons (EStop): Physically accessible buttons that immediately halt all robot motion and power. These must be easily accessible and clearly marked.

- Safety light curtains: Infrared or laser beams that create a protective zone around the robot. If the beams are interrupted, the robot stops immediately.

- Safety mats and sensors: Pressure-sensitive mats or proximity sensors that detect the presence of humans or obstacles in the robot’s workspace. These trigger a halt to avoid collisions.

- Speed and separation monitoring: Systems that monitor the robot’s speed and distance from obstacles, triggering a reduction in speed or complete stop when limits are exceeded.

- Software-based safety systems: Programs that monitor robot movements and conditions (like joint angles, velocities, and external forces) and stop the robot if unsafe conditions are detected.

- Redundant safety systems: Multiple independent safety mechanisms that provide backup redundancy to prevent a single point of failure.

These systems should be designed according to relevant safety standards (e.g., ISO 13849, ISO 10218) to ensure they are effective and reliable. A layered approach, with multiple safety features working in conjunction, is usually preferred.

Q 15. Describe your experience with different robot communication protocols (e.g., CAN, ROS).

Robot communication protocols are crucial for coordinating actions between different components of a robotic system. My experience encompasses both low-level protocols like CAN and higher-level frameworks like ROS (Robot Operating System).

CAN (Controller Area Network) is a robust, real-time protocol commonly used for low-level control of actuators and sensors in industrial robots. I’ve used CAN extensively in projects involving precise motor control and sensor data acquisition, ensuring synchronization and reliable data transfer in harsh environments. For example, I integrated CAN communication to control multiple motors on a six-axis robotic arm, synchronizing their movement for complex tasks.

ROS (Robot Operating System), on the other hand, provides a sophisticated framework for building complex robotic systems. It handles higher-level functionalities like task planning, sensor fusion, and navigation. I’ve utilized ROS in several projects, including autonomous mobile robot navigation and collaborative robot control. A notable project involved using ROS to orchestrate communication between a vision system, a robotic arm, and a mobile base for a pick-and-place application. ROS’s flexibility and modular design simplifies the development and maintenance of large-scale robotic systems.

In essence, I’m comfortable working with both low-level protocols demanding real-time performance and high-level frameworks offering a modular and flexible architecture for complex robot control.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of force/torque sensing and its application in robot control.

Force/torque sensing involves measuring the forces and torques applied to a robot’s end-effector. This provides crucial feedback for tasks requiring interaction with the environment, such as assembly, polishing, or human-robot collaboration. Imagine a robot trying to assemble a delicate piece; without force/torque sensing, it could easily damage the part.

These sensors are typically 6-axis sensors measuring forces along three orthogonal axes and torques around those same axes. The data from these sensors is fed into the robot’s control system, allowing for adaptive control strategies. For instance, if the robot encounters unexpected resistance during an assembly task, the force/torque data can be used to adjust the applied force, preventing damage and ensuring successful completion.

Applications include:

- Compliance Control: Allowing the robot to yield to external forces, crucial for human-robot interaction.

- Force Regulation: Maintaining a constant force during tasks like polishing or grinding.

- Impedance Control: Controlling the robot’s mechanical impedance (stiffness and damping) to adapt to the environment.

In practice, I’ve integrated force/torque sensors into robotic systems using various interfaces like analog-to-digital converters and digital communication protocols. The data is processed and used in control algorithms implemented in software, allowing the robot to react intelligently to external forces and torques.

Q 17. How do you implement and tune a feedback control system for a robotic manipulator?

Implementing and tuning a feedback control system for a robotic manipulator involves several steps. It’s analogous to teaching a robot to balance on a ball—it needs continuous feedback and adjustments to stay upright.

1. Model the System: Develop a mathematical model of the manipulator’s dynamics, including inertia, friction, and gravity effects. This model will form the basis of your control design.

2. Choose a Control Algorithm: Common algorithms include PID (Proportional-Integral-Derivative), computed torque control, and model predictive control. The choice depends on factors such as the desired performance, system complexity, and computational resources.

3. Implement the Controller: Translate the chosen algorithm into code, typically using a real-time operating system (RTOS) for precise control. You’ll need to interface with sensors to obtain feedback and actuators to send control commands.

4. Tune the Controller: This iterative process involves adjusting the control gains (e.g., Kp, Ki, Kd for a PID controller) to achieve desired performance. Techniques such as Ziegler-Nichols method or auto-tuning algorithms can be employed. This stage often involves experimentation and fine-tuning using real-world data and observations.

5. Evaluate and Refine: Assess the performance of the tuned controller using metrics like settling time, overshoot, and steady-state error. Further refinement might be needed to optimize performance.

Example (PID Control): A simple PID controller for joint angle control might look like this (pseudo-code):

error = desired_angle - actual_angle;integral += error;derivative = (error - previous_error);control_signal = Kp * error + Ki * integral + Kd * derivative;previous_error = error;Tuning the Kp, Ki, and Kd values is crucial to achieving stable and accurate control.

Q 18. Discuss the challenges of integrating different sensors into a robot control system.

Integrating different sensors into a robot control system presents several challenges. Imagine trying to assemble a jigsaw puzzle using only one eye—it’s much harder than using two!

1. Sensor Fusion: Combining data from multiple sensors is critical. Different sensors might have different sampling rates, noise levels, and coordinate systems, requiring careful calibration and data fusion techniques like Kalman filtering to obtain a consistent and accurate representation of the robot’s environment and state.

2. Communication and Synchronization: Sensors need to communicate with the control system reliably and in a synchronized manner. This involves selecting appropriate communication protocols and ensuring real-time data transfer.

3. Data Processing: Raw sensor data often needs preprocessing before use in control algorithms. This might involve filtering, noise reduction, or feature extraction.

4. Calibration and Error Handling: Calibration is crucial to ensure accurate measurements. Robust error handling is necessary to manage sensor failures or unexpected input.

5. Computational Constraints: Processing data from numerous sensors can be computationally intensive, particularly on resource-constrained embedded systems.

To address these challenges, I use a structured approach, starting with a careful selection of sensors based on application requirements. Then I focus on data synchronization, using techniques like timestamping and data buffers, followed by robust data fusion algorithms to combine data effectively and error handling routines to maintain system stability.

Q 19. Explain the role of computer vision in robot control and navigation.

Computer vision plays a pivotal role in enabling robots to perceive and interact with their environment, similar to how our eyes guide our actions. It provides robots with the ability to ‘see’ and understand their surroundings.

In Robot Control: Computer vision allows robots to:

- Object Recognition and Manipulation: Identify and manipulate objects based on visual input, crucial for tasks like pick-and-place or assembly.

- Navigation and Localization: Use visual features to navigate and locate themselves within an environment, for example, using SLAM (Simultaneous Localization and Mapping).

- Obstacle Avoidance: Detect and avoid obstacles in real-time, crucial for safe operation.

- Human-Robot Interaction: Understand human gestures and expressions for improved collaboration.

In Robot Navigation: Computer vision aids in:

- Path Planning: Generate optimal paths based on visual information about the environment.

- Visual Odometry: Estimate the robot’s movement by analyzing changes in the visual input.

- Map Building: Create maps of the environment using visual information.

I’ve employed computer vision techniques extensively in projects such as autonomous navigation of mobile robots using visual SLAM, object recognition for robotic manipulation, and gesture-based control of robotic arms.

Q 20. How do you design and implement a robust control system for a mobile robot?

Designing a robust control system for a mobile robot requires a multi-faceted approach. It’s like planning a road trip—you need a map, navigation system, and a robust vehicle.

1. Locomotion Control: Design algorithms to control the robot’s movement. This involves choosing appropriate control strategies (e.g., PID, model predictive control) to manage wheel velocities or joint angles, depending on the robot’s design.

2. Sensor Integration: Integrate sensors like encoders, IMUs (Inertial Measurement Units), GPS, and potentially lidar or cameras to provide feedback on the robot’s pose (position and orientation) and environment.

3. Navigation: Implement algorithms for path planning and obstacle avoidance. Common algorithms include A*, Dijkstra’s algorithm, and potential field methods. The choice depends on the complexity of the environment and the robot’s capabilities.

4. Localization: Employ techniques like Kalman filtering or particle filtering to estimate the robot’s location and orientation based on sensor data. This is crucial for accurate navigation.

5. Robustness: Ensure the control system is robust to sensor noise, unexpected obstacles, and environmental variations. This often involves incorporating error handling, fault detection, and recovery mechanisms.

Example: I developed a control system for an autonomous cleaning robot using a combination of PID control for wheel velocity, Kalman filtering for localization, and a potential field method for obstacle avoidance. The system successfully navigated cluttered environments while avoiding collisions and maintaining consistent cleaning performance.

Q 21. Describe your experience with different robot control architectures (e.g., hierarchical, hybrid).

Robot control architectures dictate how different control tasks are organized and coordinated. My experience includes both hierarchical and hybrid architectures.

Hierarchical Architectures: These organize control into levels, with higher levels providing goals and lower levels executing them. Imagine a military command structure—higher-level commands dictate strategic goals, while lower levels handle tactical execution. This is efficient for complex tasks, but can be rigid and inflexible if lower levels fail.

Hybrid Architectures: These combine different control approaches, leveraging the strengths of each. For example, a hybrid architecture might use a hierarchical structure for high-level planning, while integrating reactive control at lower levels to handle unexpected events. This provides flexibility and adaptability.

In practice, I’ve designed and implemented both types of architectures. For example, I implemented a hierarchical architecture for a robotic arm assembly task, with high-level planning modules determining the sequence of actions and low-level controllers managing individual joint movements. For a mobile robot navigation application, I used a hybrid approach combining a high-level path planning module with reactive obstacle avoidance using a potential field method.

The choice of architecture depends on factors like task complexity, real-time constraints, and the need for adaptability. I select the architecture that best suits the specific application requirements.

Q 22. Explain the concept of model predictive control (MPC) and its advantages in robotics.

Model Predictive Control (MPC) is an advanced control algorithm that optimizes a robot’s actions over a predicted future time horizon. Instead of reacting solely to the current state, MPC predicts the robot’s future behavior based on a model of its dynamics and its environment, and then computes a control sequence that minimizes a cost function over that horizon. This cost function typically considers factors such as minimizing error, energy consumption, and collision avoidance.

Advantages in Robotics:

- Handles Constraints Effectively: MPC excels at handling constraints such as joint limits, actuator saturation, and workspace obstacles. The optimization process inherently accounts for these limitations, leading to safer and more feasible trajectories.

- Improved Trajectory Tracking: By considering future states, MPC can anticipate disturbances and adjust the control actions proactively, resulting in more accurate trajectory tracking than simpler control methods.

- Optimal Control: MPC aims to find the optimal control sequence based on a defined cost function, allowing for the balancing of multiple objectives.

- Adaptability: MPC can adapt to changes in the environment or robot dynamics by updating its predictions and recalculating the control sequence. This is crucial for tasks in unpredictable environments.

Example: Imagine a robotic arm tasked with picking up an object. An MPC controller would predict the arm’s motion, taking into account its inertia and the object’s position. It would then calculate the optimal speed and acceleration profiles, ensuring the arm doesn’t collide with any obstacles and smoothly grasps the object, even if the object’s position slightly changes during the motion.

Q 23. How do you ensure the stability of a robot control system?

Ensuring the stability of a robot control system is paramount. Instability can lead to erratic movements, collisions, and even damage to the robot or its surroundings. Several techniques are employed to ensure stability:

- Lyapunov Stability Analysis: This mathematical framework proves the stability of a system by finding a Lyapunov function, which shows that the system’s energy decreases over time, converging to a stable equilibrium point. This is commonly used for analyzing the stability of linear and nonlinear systems.

- Robust Control Techniques: These methods design controllers that are less sensitive to uncertainties in the robot model or external disturbances. Examples include H-infinity control and sliding mode control.

- Gain Tuning and Controller Design: Properly tuned proportional-integral-derivative (PID) controllers are widely used and their gains must be carefully selected through experimentation and analysis to achieve stable behavior. More advanced controllers like MPC require careful parameter selection and model validation.

- Feedback Control: Using sensors to measure the robot’s actual state and using that information to correct deviations from the desired trajectory is fundamental to stability. Closed-loop control systems constantly adjust the control actions to maintain stability.

- Safety Mechanisms: Implementing emergency stops, limit switches, and other safety features adds a layer of protection against instability or unexpected events.

Example: Consider a robotic manipulator. An improperly tuned PID controller might cause oscillations or overshoots during movement. Lyapunov stability analysis can help determine the stability margin and guide the tuning process. Robust control techniques can compensate for uncertainties in the manipulator’s dynamics, ensuring stable performance even if the payload changes.

Q 24. Describe your experience with robot simulation and its use in development.

Robot simulation plays a critical role in robotics development. It allows for the testing and refinement of control algorithms, trajectory planning, and other aspects of robot behavior without the need for physical hardware, saving considerable time and resources. I have extensive experience using various simulation platforms, including Gazebo, ROS, and V-REP.

Use in Development:

- Algorithm Testing: Simulators allow for repeated testing of control algorithms under various conditions and scenarios. This helps identify potential issues early in the development cycle, reducing the risk of failures on the physical robot.

- Trajectory Planning and Optimization: Simulators enable the design and optimization of robot trajectories, taking into account factors such as joint limits, obstacles, and dynamic constraints. This process is significantly faster and safer in simulation than on the real robot.

- Hardware-in-the-Loop (HIL) Simulation: HIL simulations integrate a real-time controller with a simulated robot environment. This setup bridges the gap between simulation and the real world, allowing for testing under realistic conditions.

- Training and Education: Simulators provide a risk-free environment for training personnel on robot operation and programming.

Example: In a project involving a mobile robot navigating a warehouse, I utilized Gazebo to create a realistic simulation of the environment, including obstacles and dynamic objects. I then tested various path planning and control algorithms in the simulator before deploying them on the physical robot, significantly reducing the risk of collisions or failures.

Q 25. What are common troubleshooting techniques for robot control issues?

Troubleshooting robot control issues requires a systematic approach. Here’s a breakdown of common techniques:

- Systematic Diagnosis: Start by carefully examining the error messages and logs generated by the robot control system. This often provides valuable clues about the source of the problem.

- Sensor Data Analysis: Inspect the data from the robot’s sensors, such as encoders, IMUs, and cameras. Inconsistencies or unusual values can indicate sensor faults or environmental disturbances.

- Actuator Checks: Verify the proper functioning of actuators (motors, hydraulics, etc.). Check for mechanical issues, such as jams or binding, and assess their power consumption.

- Software Debugging: Employ debugging tools to step through the control code and identify errors or unexpected behavior. Using breakpoints and logging statements can pinpoint problematic sections of the code.

- Calibration and Adjustment: Ensure that the robot’s sensors and actuators are properly calibrated. Inaccurate calibration can lead to significant control errors.

- Communication Verification: Check the communication links between the robot’s components and the control system. Problems with network connectivity or data transmission can cause malfunctions.

- Model Verification: If using model-based control, verify the accuracy of the robot’s dynamic model. An inaccurate model can lead to poor control performance or instability.

Example: If a robotic arm exhibits jerky movements, one would investigate sensor data (encoders) to rule out sensor noise or malfunction. Then, one would check the motor drivers for proper operation and finally verify the control algorithm’s parameters (e.g., PID gains) for stability and appropriate response.

Q 26. Explain how you would approach designing a control system for a specific robotic application (e.g., pick-and-place).

Designing a control system for a pick-and-place application involves several steps:

- Requirements Gathering and Analysis: Define the task specifications, including the type of objects to be handled, the workspace geometry, the desired speed and accuracy, and any environmental constraints.

- Robot Selection and Kinematics Modeling: Choose an appropriate robot manipulator based on its reach, payload capacity, and degrees of freedom. Develop a kinematic model to relate the robot’s joint angles to its end-effector position and orientation.

- Control Algorithm Selection: Select a suitable control algorithm, such as PID, MPC, or a force/torque controller, based on the requirements. For a simple pick-and-place, PID might suffice, but for more demanding tasks, MPC offers better performance.

- Path Planning: Develop a path planning algorithm to generate a collision-free trajectory for the robot arm to move from the pick location to the place location. This might involve algorithms such as A*, RRT, or cubic splines.

- Control System Implementation: Implement the chosen control algorithm on a suitable platform (e.g., a real-time operating system). This typically involves programming in languages like C++ or Python, using robotics libraries and middleware (e.g., ROS).

- Testing and Validation: Thoroughly test the system using simulation and real-world experiments. Refine the control parameters and algorithm based on the results. Include safety mechanisms to prevent accidents.

Example: For a simple pick-and-place task involving a SCARA robot, I might use a PID controller for each joint to track the desired trajectory generated by a simple linear path planner. The system would be tested in simulation, with virtual sensors providing feedback, before transitioning to real-world testing, incorporating appropriate safety protocols.

Q 27. Discuss the ethical considerations of deploying robots in various environments.

Deploying robots raises several ethical considerations:

- Job Displacement: Automation through robots can lead to job displacement in various sectors. Careful planning and retraining programs are crucial to mitigate this impact.

- Safety and Security: Ensuring robot safety is paramount to prevent accidents and harm to humans or the environment. Robust safety mechanisms and fail-safes should be incorporated into the robot’s design and control system. Security is also vital to prevent malicious attacks.

- Bias and Discrimination: Algorithms used in robotics can inherit biases from the data they are trained on, leading to unfair or discriminatory outcomes. It’s crucial to address these biases during development and deployment.

- Privacy Concerns: Robots deployed in public spaces or homes might collect sensitive data. Appropriate privacy measures are essential to protect individuals’ information.

- Accountability and Responsibility: Determining accountability in case of robot malfunctions or accidents is a complex issue. Clear guidelines and legal frameworks are necessary to address this.

- Environmental Impact: The production and disposal of robots have environmental consequences. Sustainable practices should be adopted throughout their lifecycle.

Example: The deployment of autonomous vehicles raises questions about liability in case of an accident—is it the manufacturer, the software developer, or the owner who is responsible? Addressing such ethical concerns through rigorous testing, transparent design practices, and clear legal frameworks is essential before widespread adoption.

Key Topics to Learn for Robot Control Systems Interview

- Kinematics and Dynamics: Understanding robot arm configurations, forward/inverse kinematics, Jacobian matrices, and dynamic modeling for precise motion control. Practical application: Optimizing robot trajectories for speed and accuracy in assembly tasks.

- Control Algorithms: Mastering PID control, adaptive control, and advanced techniques like model predictive control (MPC). Practical application: Developing robust controllers to handle uncertainties and disturbances in real-world environments.

- Sensors and Actuators: Familiarize yourself with various sensor types (encoders, IMUs, force/torque sensors, cameras) and actuator technologies (electric motors, hydraulics, pneumatics). Practical application: Integrating sensors for feedback control and choosing appropriate actuators for specific robot applications.

- Programming and Software: Proficiency in robot programming languages (e.g., ROS, RAPID) and software tools for simulation and control system design. Practical application: Developing and deploying control algorithms on real robots.

- Robotics Architectures: Understanding different robot control architectures (e.g., centralized vs. decentralized, hierarchical control) and their trade-offs. Practical application: Designing a scalable and robust control system for complex robotic systems.

- Path Planning and Navigation: Explore algorithms for path planning (e.g., A*, RRT) and navigation in both structured and unstructured environments. Practical application: Enabling robots to autonomously navigate complex workspaces.

- Safety and Reliability: Understanding safety standards and best practices for robot control systems to ensure safe and reliable operation. Practical application: Designing fail-safe mechanisms to prevent accidents.

Next Steps

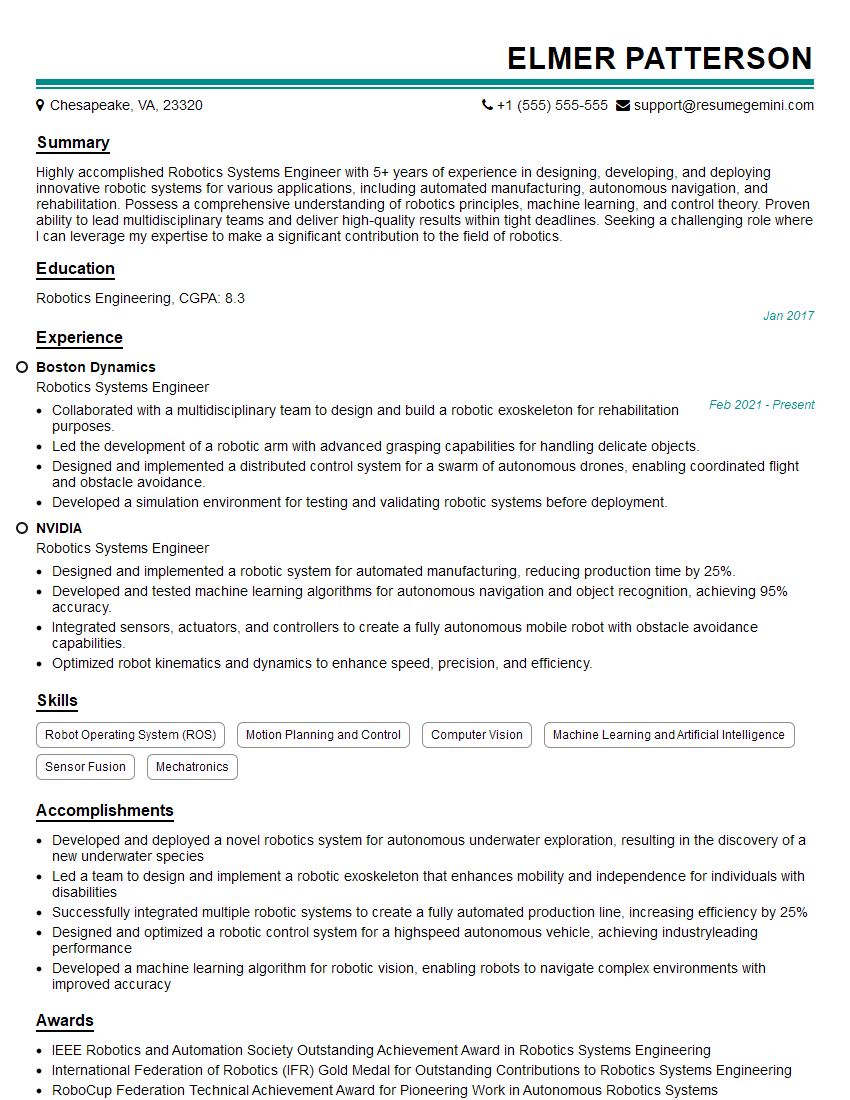

Mastering Robot Control Systems opens doors to exciting and rewarding careers in automation, manufacturing, and robotics research. A strong understanding of these core concepts will significantly enhance your interview performance and increase your job prospects. To further strengthen your candidacy, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications stand out. Examples of resumes tailored to Robot Control Systems are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good