Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Airless Spray Painting interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Airless Spray Painting Interview

Q 1. What are the different types of airless spray guns and their applications?

Airless spray guns come in various types, each suited for specific applications. The key differences lie in the nozzle size, fluid tip design, and overall power.

- Standard Airless Spray Guns: These are versatile and widely used for a broad range of projects, from painting fences to applying primers on walls. They offer a good balance of atomization and paint transfer efficiency. Think of these as the ‘all-arounders’ of the airless world.

- HVLP (High Volume Low Pressure) Airless Spray Guns: While technically not strictly ‘airless,’ some manufacturers offer guns that combine airless technology with a low-pressure air assist for finer atomization and reduced overspray. These are ideal for projects requiring a smoother, more refined finish, like automotive painting or furniture refinishing. They produce a much softer spray pattern.

- Heavy-Duty Airless Spray Guns: Designed for high-volume, industrial applications, these guns can handle thicker materials and higher pressures. Imagine using these for applying heavy-bodied texture coatings or protective coatings on large structures.

- Airless Spray Guns with RAC (Reverse Airless Coating) systems: These specialized guns are designed for applying high-viscosity coatings such as epoxy or polyurethane. They combine the power of airless with a specialized piston to handle the thicker materials.

The choice of spray gun depends heavily on the project’s scope and the properties of the paint being used. A small project might only need a standard gun, while a large industrial job might require a heavy-duty unit.

Q 2. Explain the principle of airless spray painting.

Airless spray painting relies on forcing paint through a small nozzle at extremely high pressure. Unlike air spray systems that use compressed air to atomize the paint, airless systems use a powerful pump to create the necessary pressure. This high pressure forces the paint through a tiny nozzle, breaking it up into a fine mist that is then projected onto the surface. This process eliminates the need for compressed air, resulting in higher transfer efficiency (less paint waste).

Think of it like this: a garden hose with a narrow nozzle. The higher the water pressure, the finer the spray. Airless sprayers operate on the same principle, but with significantly higher pressure and specialized fluid nozzles to achieve the desired atomization.

Q 3. Describe the process of setting up an airless spray painting system.

Setting up an airless spray painting system is a multi-step process that requires attention to detail. Safety is paramount, so always refer to the manufacturer’s instructions. The typical steps include:

- Gather Supplies: This includes your airless sprayer, paint strainers, hoses, spray gun, appropriate safety gear (mask, goggles, protective clothing), and cleaning solvents.

- Prepare the Paint: Strain the paint through a fine-mesh filter to remove any impurities that could clog the nozzle. This step is crucial for preventing costly downtime.

- Connect the System: Securely attach the hose to the pump and the spray gun. Ensure all connections are tight to prevent leaks.

- Prime the Pump: Most airless systems require priming before operation to remove air from the lines. This is usually done by opening the fluid valve and allowing the paint to flow until it’s free of air bubbles.

- Adjust the Pressure: Set the pressure according to the paint manufacturer’s recommendations and the type of nozzle being used. This usually involves adjusting a dial or knob on the airless pump.

- Test Spray: Before starting the main project, perform a test spray on a piece of scrap material to check the spray pattern, viscosity, and overall performance. Adjust the pressure or nozzle tip as needed.

Proper setup is critical for a smooth and efficient painting process. A poorly set up system can lead to poor finish quality, equipment damage, and safety hazards.

Q 4. How do you determine the correct paint viscosity for airless spraying?

Correct paint viscosity is vital for achieving a quality finish with airless spraying. Too thick, and you’ll get a heavy, uneven finish with runs and sags. Too thin, and the coverage will be poor and you’ll risk excessive overspray. Determining the correct viscosity often involves using a Zahn cup or similar viscosity measuring tool. The manufacturer’s instructions for the paint usually specify the ideal viscosity range.

Many paints require thinning with water or a specified thinner to reach the optimal viscosity. Always test a small area before applying to the entire surface to verify the consistency is correct. It’s always best to err on the side of slightly thinner rather than too thick as a thicker paint can easily clog your equipment. Consider using a viscosity reducer such as Floetrel.

Q 5. What are the safety precautions you take while using an airless spray system?

Safety is paramount when using an airless spray system. The high pressure involved poses significant risks if proper precautions aren’t followed. Crucial safety measures include:

- Eye Protection: Always wear safety goggles or a face shield to protect your eyes from paint splatters and overspray.

- Respiratory Protection: Use an appropriate respirator designed for paint overspray to prevent inhalation of paint particles and fumes. This is especially important with solvents or other potentially harmful materials.

- Protective Clothing: Wear long sleeves, pants, and closed-toe shoes to protect your skin from paint.

- Proper Ventilation: Ensure adequate ventilation in the work area to prevent the buildup of hazardous fumes. Consider working outdoors or using ventilation equipment.

- Training and Instruction: It’s crucial to thoroughly understand the operation and safety procedures before using an airless spray system. Professional training is highly recommended.

- Fire Safety: Be aware of fire hazards associated with solvents and paint. Have a fire extinguisher readily available.

Never compromise on safety. A moment of carelessness can lead to serious injury or health problems.

Q 6. How do you clean and maintain an airless spray gun?

Cleaning and maintaining your airless spray gun is crucial for its longevity and performance. Proper cleaning prevents clogging, ensures even paint application, and extends the life of the equipment. The process generally involves:

- Immediate Cleaning: As soon as you finish spraying, immediately flush the gun and hoses with the appropriate thinner or cleaner recommended by the paint manufacturer. This prevents paint from drying and solidifying inside.

- Disassembly: Disassemble the spray gun according to the manufacturer’s instructions. This usually involves separating the nozzle, tip, and other components.

- Thorough Cleaning: Clean all components with the recommended solvent using brushes, rags, and appropriate cleaning tools. Pay special attention to the nozzle and filter to ensure they are completely free of paint residue.

- Reassembly: Carefully reassemble the spray gun, making sure all parts are correctly seated and tightened.

- Storage: Store the clean gun in a safe, dry place, protecting it from dust and damage.

Regular maintenance, including occasional lubrication of moving parts, will keep your airless spray gun operating at peak efficiency.

Q 7. What are the common problems encountered in airless spraying, and how do you troubleshoot them?

Several common problems can occur during airless spraying. Knowing how to troubleshoot these issues is essential for maintaining productivity and achieving a professional finish.

- Clogged Nozzle: This is a frequent problem, often caused by using unfiltered paint or improper cleaning. Solution: Clean the nozzle thoroughly using a cleaning needle and solvent. Replace the nozzle if necessary.

- Uneven Spray Pattern: This could be due to incorrect pressure settings, a worn-out nozzle tip, or a partially clogged nozzle. Solution: Check pressure settings, inspect the nozzle for wear or clogging, and replace or clean the nozzle as needed.

- Runs and Sags: These are typically caused by using paint that’s too thick or applying it too heavily. Solution: Thin the paint to the correct viscosity, adjust the spray pattern, and reduce the application rate.

- Overspray: Excessive overspray results in paint wastage and an uneven finish. Solution: Check the pressure settings, adjust the spray distance, or use a lower-pressure setting if possible.

- Pump Issues: Problems with the airless pump can range from leaks to motor malfunctions. Solution: Consult the manufacturer’s instructions or contact a service technician for assistance.

Regular maintenance and careful attention to detail can greatly reduce the frequency of these problems.

Q 8. Explain the importance of proper surface preparation before airless spraying.

Proper surface preparation is paramount in airless spraying. Think of it as laying a perfect foundation for a house – a poorly prepared surface will lead to a subpar finish, no matter how good your paint or technique is. It ensures the paint adheres properly, prevents peeling, and leads to a professional, long-lasting finish.

- Cleaning: Remove all dirt, dust, grease, and loose particles. A pressure washer is excellent for exterior surfaces, while a scrub brush and detergent work well for interior projects. Thoroughly rinse and allow to dry completely.

- Repairing: Fill any cracks, holes, or imperfections with appropriate fillers and allow ample drying time before sanding. Sanding ensures a smooth surface for even paint application.

- Priming: A primer enhances paint adhesion, particularly on porous surfaces like wood or drywall. It creates a uniform base coat, improving the final paint finish and minimizing the number of coats needed. Choose a primer compatible with your chosen paint type.

- Sanding: After filling and priming, use progressively finer grit sandpaper to achieve a smooth surface. This ensures an even coating and eliminates any texture that could show through the paint. Remember to remove all sanding dust before painting.

For instance, I once worked on a project where the client skipped priming. The result was blotchy paint, poor adhesion, and ultimately, a costly repaint. Proper preparation saved time and money on another project where we meticulously cleaned and primed the exterior of a weathered home, leading to a stunning and durable finish.

Q 9. What are different types of spray tips and their uses?

Airless spray tips come in various sizes and patterns, each suited to different applications. The key characteristic is the tip size, measured in inches, and the spray pattern (e.g., horizontal, vertical, or fan).

- Tip Size: This determines the paint flow rate. Smaller tips are used for finer details and less material flow, while larger tips handle more volume for larger areas and faster coverage. For instance, a smaller tip might be suitable for trim, while a larger tip is perfect for siding.

- Spray Pattern: The pattern shapes the paint’s distribution. Common patterns include round, fan (horizontal or vertical), and even some specialized patterns for specific finishes. The fan pattern is most common, offering control over the width of the spray.

Examples:

- 517 tip: A commonly used general-purpose tip with a good balance between speed and finish quality.

- 311 tip: A smaller tip ideal for detailed work like trim or cabinetry.

- 519 tip: A larger tip for quick coverage on large surfaces like fences or walls.

Q 10. How do you select the appropriate spray tip for a given application?

Selecting the right spray tip is crucial for achieving a quality finish. The ideal tip depends on the material being sprayed, the surface area, and the desired finish.

- Material Viscosity: Thicker paints require larger tips to ensure smooth flow. Thin paints, conversely, may need smaller tips to avoid overspray and runs.

- Surface Area: Larger surfaces necessitate larger tips for faster coverage, while smaller areas and detailed work are best suited for smaller tips.

- Desired Finish: A smoother finish typically requires a smaller tip and more passes, while a slightly textured finish might be achieved with a larger tip and fewer passes.

For example, painting a large exterior wall with thick exterior paint might require a 519 or even a larger tip. But when painting intricate trim work, a 311 or similar smaller tip is the way to go. Always refer to the paint manufacturer’s recommendations for the optimal tip size.

Q 11. How do you calculate the amount of paint needed for a project?

Calculating paint needs is vital to avoid running short or buying excess. Accurate calculations save time and money. You’ll need the surface area and the paint coverage per unit.

- Measure the surface area: Break down complex shapes into simpler ones (rectangles, squares, triangles). For irregular surfaces, approximate measurements are acceptable.

- Determine paint coverage: Check the paint can’s label; it typically states coverage in square feet per gallon (or liter). This value varies depending on the paint type and the surface.

- Calculate total paint needed: Divide the total surface area by the paint coverage per gallon to find the number of gallons needed. Add extra for touch-ups and potential waste. For example, if you have 1000 sq ft to paint and the paint covers 350 sq ft per gallon, you’d need roughly 3 gallons (1000/350 ≈ 2.86).

Remember: This is an estimate. It’s always wiser to purchase slightly more paint than you think you need, considering the possibility of spills or needing additional coats.

Q 12. Describe the different types of paint suitable for airless spraying.

Many paints are compatible with airless sprayers, but some are better suited than others. The key factors are viscosity and solids content.

- Latex Paints: Popular choice for interior and exterior use. They are relatively easy to spray, but need to be thinned according to manufacturer instructions.

- Acrylic Paints: Also widely used, offering good durability and color retention. Similar to latex paints, these may need thinning.

- Oil-Based Paints: Offer excellent durability and weather resistance, but require solvents for thinning. They have a slower drying time, and proper ventilation is crucial.

- Specialty Paints: Epoxies, urethanes, and stains are also sprayable, but require specific tips and techniques tailored to their unique properties. Always follow the manufacturer’s instructions regarding thinning and spraying.

It’s important to note that some paints might be too thick or thin for airless sprayers, leading to clogging or poor coverage. Always check the manufacturer’s recommendations for airless sprayability.

Q 13. What is the impact of air pressure on spray pattern and finish?

Air pressure significantly impacts the spray pattern and finish. Too little pressure results in a weak, inconsistent spray, while excessive pressure can lead to overspray, uneven coating, and runs.

- Lower Pressure: Produces a finer spray, ideal for detailed work or achieving a smoother finish. However, it requires more passes and can slow down the painting process.

- Higher Pressure: Results in a wider, heavier spray, ideal for faster coverage of large areas. However, it increases the risk of overspray and unevenness.

Finding the ‘sweet spot’ depends on many factors including the paint viscosity, tip size, and distance from the surface. Practice and experimentation are key to mastering this balance. Begin with a lower pressure and gradually increase it until you find the ideal setting for your specific project and materials.

Q 14. How do you achieve a uniform finish when airless spraying?

A uniform finish requires careful technique and attention to detail. Consistency is key.

- Maintain a consistent distance: Hold the sprayer at a consistent distance from the surface (usually 12-18 inches) to ensure uniform paint distribution. Varying distances lead to uneven coating.

- Overlap each pass: Overlap each spray pass by approximately 50% to prevent streaking and ensure complete coverage. Think of it like shingling a roof – you need to overlap to seal gaps.

- Use smooth, even strokes: Avoid abrupt movements. Move the sprayer smoothly and steadily in a controlled manner. Erratic movements lead to uneven coverage and potentially dripping.

- Adjust the spray pattern: For complex shapes or corners, adjust the spray pattern width to maximize control and minimize overspray.

- Use the appropriate tip size and pressure: As discussed earlier, the right tip and pressure settings contribute significantly to a uniform finish.

- Clean the equipment: Regular cleaning prevents clogging and ensures the sprayer is functioning optimally. This is crucial for maintaining consistent paint flow and an even finish.

Practice on scrap material before starting the project to hone your technique and find the optimal settings for your materials and equipment. Experience and attention to detail are the best ways to achieve a professional-looking, uniform finish.

Q 15. How do you handle different types of surfaces, such as wood, metal, and concrete?

Surface preparation is paramount in airless spray painting, regardless of the material. Different surfaces require different approaches to ensure optimal adhesion and a professional finish.

Wood: Wood surfaces need to be sanded smooth to remove any imperfections or splinters. A quality wood primer is crucial before applying the final coat of paint. This ensures better paint adhesion and prevents the wood grain from showing through. I often use a wood filler to repair any significant damage before sanding.

Metal: Metal surfaces, especially if they’re rusty or have old paint, require thorough cleaning. I often use a wire brush or sandblaster to remove rust and old paint, followed by a metal primer designed for corrosion resistance. This prevents future rust and ensures the new paint adheres properly. For galvanized metal, a special etching primer is necessary for adhesion.

Concrete: Concrete demands a different approach. It usually needs to be cleaned thoroughly to remove dust, dirt, and any efflorescence (salt deposits). A concrete bonding primer is vital for optimal paint adhesion. This specialized primer helps the paint stick to the porous concrete surface and prevents peeling or cracking.

In essence, the key is proper surface preparation tailored to the specific material. Ignoring this step often leads to premature paint failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental considerations when using airless spray painting?

Environmental responsibility is a significant concern in airless spray painting. Overspray and VOC (Volatile Organic Compound) emissions are the major environmental impacts. To minimize these, I always prioritize:

Using low-VOC paints: These paints have lower environmental impact and improve indoor air quality. The reduced VOC content means less harmful fumes are released into the atmosphere.

Proper containment: This involves using drop cloths, plastic sheeting, and masking tape to contain overspray. It’s not just about protecting the surrounding area, it’s also about preventing paint waste and environmental pollution. I invest in high-quality containment materials to ensure effectiveness.

Responsible disposal: Proper disposal of used paint and cleaning materials is essential. I follow local regulations to ensure hazardous waste is handled correctly, preventing environmental contamination.

Spraying technique: Maintaining an appropriate distance from the surface and controlling the spray pattern minimizes overspray.

By combining the right materials and practices, I can significantly minimize the environmental impact of airless spray painting. It’s a commitment that benefits both the environment and my clients.

Q 17. Describe your experience with different types of airless spray equipment.

My experience spans various airless spray equipment, from smaller, hand-held units ideal for smaller jobs to larger, professional-grade machines for large-scale projects. I’m proficient with both electric and gas-powered systems.

Smaller units: These are perfect for touch-ups, smaller fences, or interior projects. They are easy to maneuver and require less maintenance but have limited capacity.

Larger, professional-grade units: These are more powerful and have larger tanks, enabling continuous spraying over extended periods. They’re crucial for large projects like house exteriors or commercial buildings, and I’m experienced with adjusting their settings for optimal paint transfer. I’m familiar with Graco, Titan, and Wagner brands, and I know how to maintain and troubleshoot their various components.

Beyond the machine itself, my experience extends to understanding the importance of proper tip selection to match the paint viscosity and desired finish. I regularly perform preventative maintenance to ensure optimal performance and longevity of the equipment.

Q 18. Explain your knowledge of various paint application techniques.

Airless spray painting offers a range of application techniques to achieve different results. My expertise includes:

Wet-on-wet application: This involves applying subsequent coats before the previous coat is completely dry, which can lead to a smoother, more uniform finish. It’s particularly useful with paints that tend to show lap marks.

Back-and-forth technique: This is a fundamental technique that involves overlapping passes in a systematic pattern to ensure even coverage. I adjust my technique depending on whether I’m working with a horizontal, vertical, or other surface.

Pattern control: I master fan width control and spray distance to manage paint flow, ensuring consistent coverage without runs or sags. The ability to accurately adjust these parameters is critical for achieving a professional finish.

Layering: For certain projects, building up several thin coats provides a superior finish compared to applying one thick coat. This allows for better penetration and leveling of the paint.

I adapt my technique based on the paint type, surface, and desired finish. Experience has taught me that a consistent and controlled approach is essential for a high-quality result.

Q 19. How do you handle overspray and minimize paint waste?

Minimizing overspray and paint waste is crucial for both cost-effectiveness and environmental responsibility. My strategies include:

Proper preparation: Thorough masking and drop cloths significantly reduce overspray. I meticulously cover areas not being painted.

Controlled spraying technique: Maintaining the correct distance from the surface and using a consistent, overlapping pattern reduces waste.

Tip selection: The correct tip size ensures appropriate paint flow and minimizes overspray. I choose the best tip size for the job and the paint’s viscosity.

Airless spray gun maintenance: Regular cleaning prevents clogging, ensuring consistent spray and reducing wasted paint from uneven application.

Recycling: I ensure leftover paint is disposed of properly according to local regulations, minimizing environmental impact.

By implementing these strategies, I can significantly reduce overspray, paint waste, and the overall project cost. It’s a critical aspect of responsible and professional airless spray painting.

Q 20. What is your experience with different types of spray patterns?

Different spray patterns are achievable by adjusting the airless spray gun’s nozzle and pressure settings. My experience encompasses:

Horizontal pattern: Ideal for large, flat surfaces such as walls or fences. I achieve this by aligning the gun correctly and maintaining a consistent distance.

Vertical pattern: Best for surfaces like doors or trim where vertical strokes are needed for even coverage.

Fan width adjustment: I can adjust the fan width to match the surface area, optimizing coverage and minimizing overspray. A wider fan is better for large areas, while a narrower fan is useful for intricate details.

Round pattern: Occasionally useful for spot painting or reaching difficult areas, though generally less efficient for large-scale projects.

Understanding how to manipulate these patterns is critical to achieving a professional, consistent finish. It’s a skill honed through years of practice and a deep understanding of the equipment.

Q 21. Describe your experience with different paint finishes (gloss, matte, satin).

Achieving the desired paint finish – gloss, matte, or satin – is dependent on the paint itself and the application technique. My experience allows me to work with each finish effectively:

Gloss: Gloss paints deliver a high-shine finish that is relatively easy to clean. The application technique needs to be smooth and even to minimize any imperfections that would be highlighted by the shine.

Matte: Matte paints provide a low-shine, flat finish that hides imperfections better than gloss. The application should be consistent to ensure a uniform appearance, as uneven application might lead to a patchy look.

Satin: Satin finishes offer a balance between gloss and matte, providing a soft sheen that’s easier to clean than matte but hides imperfections better than gloss. The application requires a moderate level of precision to avoid any visible inconsistencies.

In each case, proper surface preparation and consistent application are key to achieving the desired finish. The choice of paint and the appropriate airless spray gun settings are also critical factors.

Q 22. How do you ensure consistent paint coverage?

Consistent paint coverage in airless spraying hinges on several key factors. Think of it like baking a cake – you need the right ingredients and technique for a perfect result. First, proper spray gun adjustment is crucial. This involves setting the correct spray tip size and pressure to match the viscosity (thickness) of your paint and the surface texture. Too low a pressure, and you’ll get a patchy, uneven finish. Too high, and you risk overspray and runs.

Secondly, consistent spray technique is vital. Maintain a smooth, even speed and distance from the surface, keeping the gun perpendicular and overlapping each pass by about 50%. Imagine mowing a lawn – you wouldn’t miss patches, would you? This ensures complete coverage without leaving streaks. Finally, the quality of the paint itself matters. Using a paint appropriate for the airless sprayer and properly thinned (following manufacturer’s instructions) is essential. Thick paint can clog the nozzle, while thin paint might result in inconsistent application.

Q 23. What safety equipment should be worn when airless spraying?

Safety is paramount in airless spraying. The high pressure involved and the potential for overspray necessitate comprehensive personal protective equipment (PPE). This includes a full-face respirator with appropriate cartridges to filter out paint mists and volatile organic compounds (VOCs). Think of it as your lifeline, protecting your lungs from harmful particles. A protective suit prevents paint from contacting your skin, and safety glasses or goggles shield your eyes from overspray. Finally, durable gloves protect your hands from chemicals and paint, completing the crucial safety layer.

Q 24. How do you deal with a clogged spray tip?

A clogged spray tip is a common frustration, but manageable. First, turn off the sprayer and relieve the pressure in the system. Safety first! Next, remove the spray tip and carefully inspect it. Common culprits include dried paint and debris. Try using a wire brush or a tip cleaner to remove any obstructions. For stubborn clogs, a suitable solvent, as recommended by the manufacturer, may be necessary. Remember to always follow safety guidelines when handling solvents. After cleaning, reassemble the spray tip, ensuring it’s correctly fitted and check for leaks. If the problem persists after cleaning, you may need to replace the spray tip.

Q 25. How do you maintain the consistency of the paint throughout the project?

Maintaining paint consistency throughout a project requires careful planning and execution. Before starting, thoroughly mix the paint in its container according to manufacturer’s instructions. For larger projects, using a paint shaker or agitator helps to prevent settling and maintain uniformity. During the spraying process, regularly stir the paint in the container to ensure that the pigment and binder remain well-distributed. This is crucial, particularly with paints that have a tendency to settle. Think of it as continuously ensuring the cake batter remains uniformly mixed! Additionally, consider using a paint pump with a built-in filter, which helps to prevent any large debris from clogging the system.

Q 26. Explain your understanding of Health and Safety regulations related to airless spraying.

Health and safety regulations surrounding airless spraying vary by region, but common themes include proper ventilation to mitigate overspray and VOC exposure. Adequate respiratory protection is always mandatory. Proper disposal of paint waste is crucial, adhering to local regulations. Regular equipment maintenance helps prevent accidents, and training and certification might be required in certain jurisdictions. Understanding and adhering to these rules is crucial, not just for personal safety, but to minimize environmental impact. Ignoring these regulations can have serious legal and health consequences.

Q 27. What is your experience working from heights?

I have extensive experience working from heights, always prioritizing safety. This includes using appropriate scaffolding or harnesses, ensuring they are properly secured and inspected before starting work. I am familiar with and comply with all relevant safety regulations and always double-check equipment before use. I prioritize risk assessment and always take precautions to prevent falls. My experience extends to various types of heights and projects, from smaller residential work to larger industrial applications. Safety is never compromised; it’s integral to my work process.

Q 28. How do you manage multiple projects or tasks simultaneously?

Managing multiple projects demands strong organizational skills and a structured approach. I use project management tools to schedule tasks, assign resources, and track progress. Effective communication with clients and team members keeps everyone informed. I prioritize tasks based on deadlines and urgency, focusing on high-priority items first. Regular review and adaptation of my schedule ensure flexibility and efficiency. Think of it like conducting an orchestra – each instrument (project) plays its part, but the conductor ensures the harmonious execution of the entire piece.

Key Topics to Learn for Your Airless Spray Painting Interview

- Equipment Knowledge: Understanding different airless spray painting machines, their components (pump, hose, spray gun), and their maintenance requirements. Practical application includes troubleshooting common malfunctions like tip clogging or low pressure.

- Material Selection & Application: Knowing the properties of various paints, stains, and coatings suitable for airless spray application. Practical application includes choosing the right material for different surfaces (wood, metal, drywall) and adjusting spray settings for optimal results. Consider exploring different types of finishes and their application techniques.

- Safety Procedures: Mastering safety protocols related to handling paint materials (SDS sheets, PPE), operating airless spray equipment, and ensuring a safe work environment. Practical application includes demonstrating knowledge of respiratory protection, proper disposal procedures, and fire safety measures.

- Surface Preparation: Understanding the importance of proper surface preparation techniques such as cleaning, sanding, and priming. Practical application includes explaining how different surface types require different preparation methods for optimal paint adhesion and finish.

- Spray Techniques & Patterns: Mastering various spray techniques (wet-on-wet, overlapping passes) to achieve a smooth, even finish. Practical application includes describing how to control fan width, spray distance, and material flow to avoid runs, sags, and uneven coverage. Explore different spray patterns for various applications.

- Troubleshooting & Problem-Solving: Ability to identify and resolve common issues such as uneven spray patterns, orange peel, and other defects. Practical application includes explaining the causes of these defects and how to correct them through adjustments to equipment settings or application techniques.

- Clean-up and Maintenance: Understanding proper procedures for cleaning spray equipment, disposing of waste materials, and performing routine maintenance to extend the life of the equipment. This includes knowledge of different cleaning solvents and their safe usage.

Next Steps

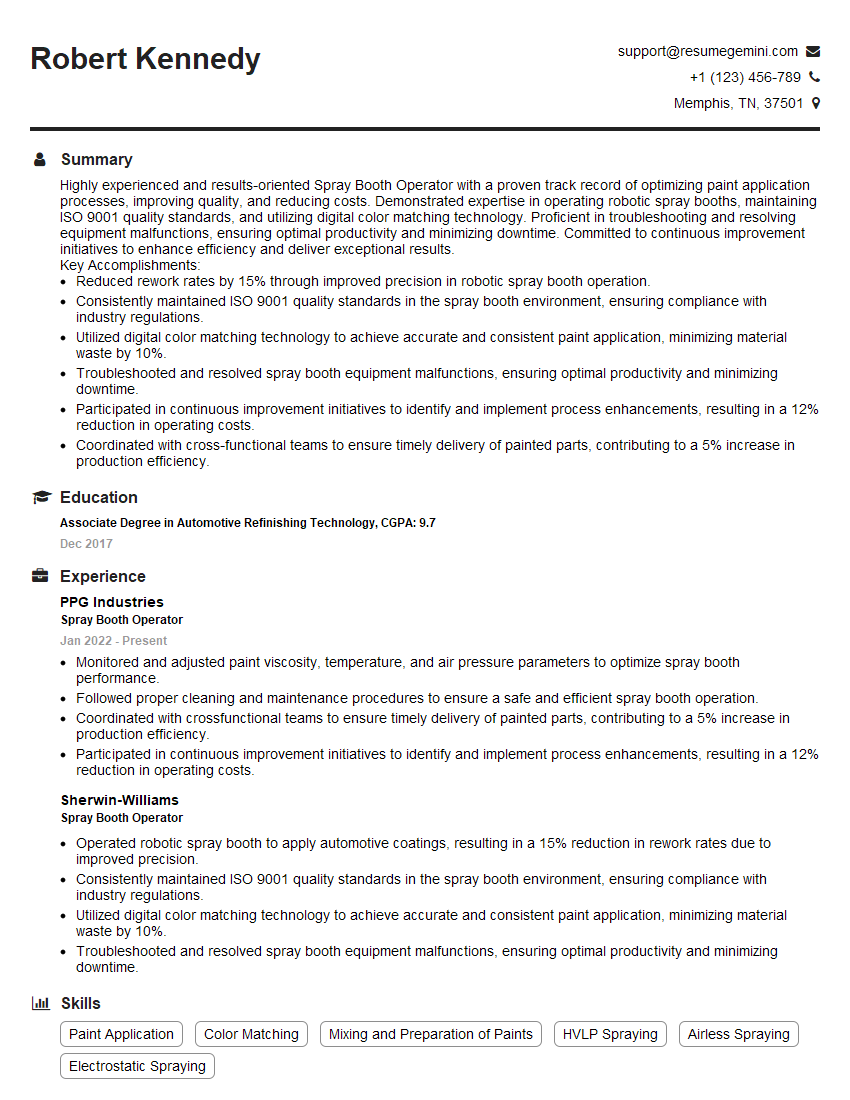

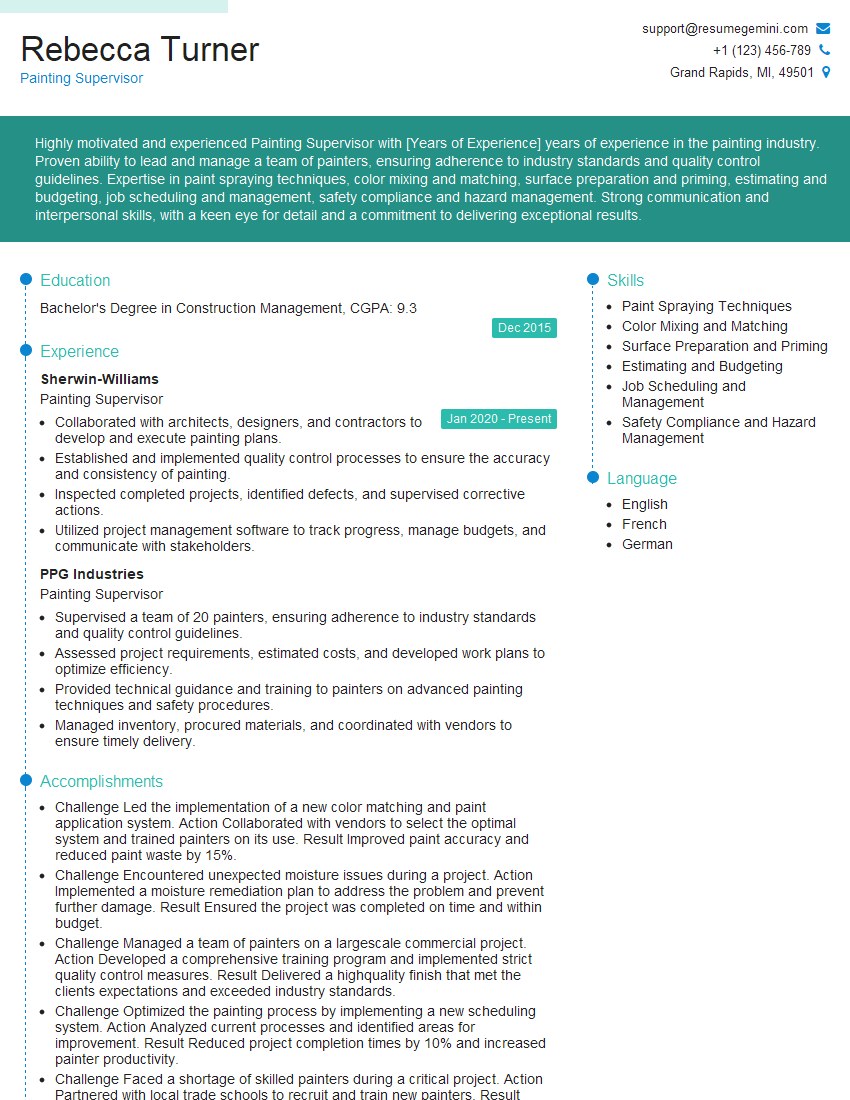

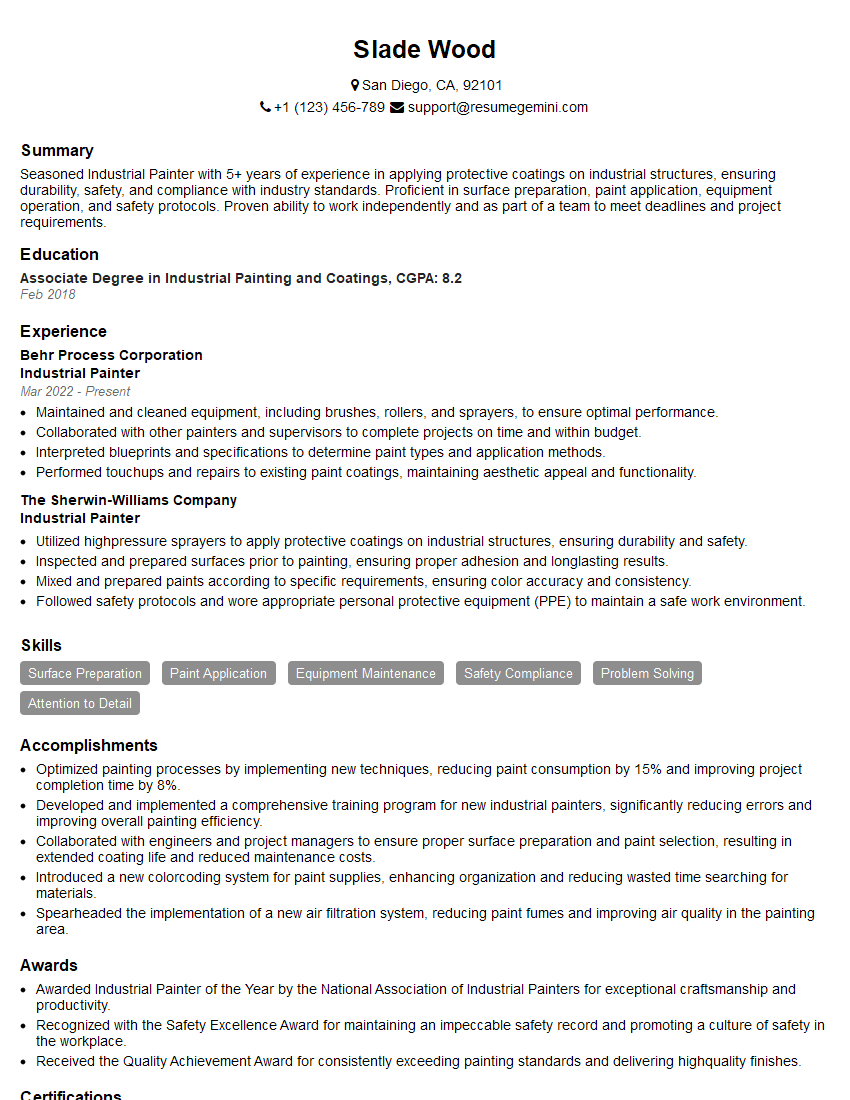

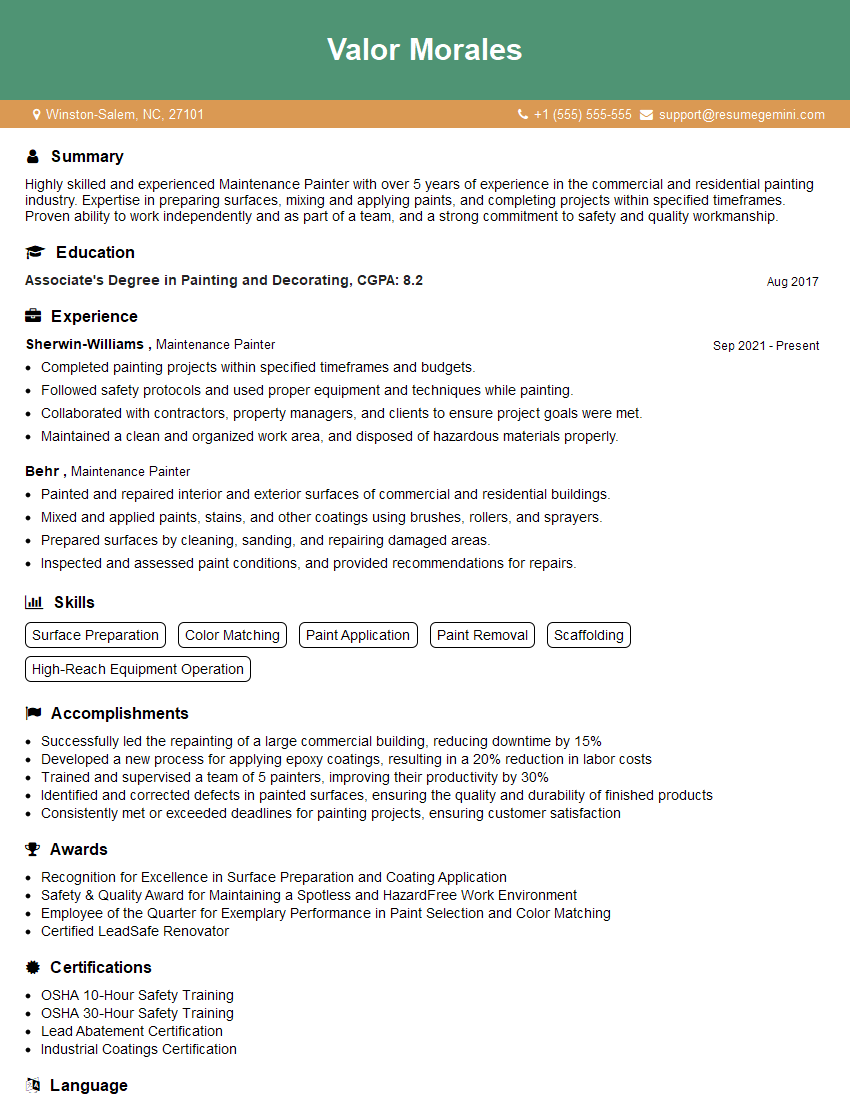

Mastering airless spray painting opens doors to rewarding careers in construction, industrial maintenance, and various other fields. To stand out, a strong resume is crucial. Building an ATS-friendly resume significantly increases your chances of landing an interview. We recommend using ResumeGemini to craft a professional and impactful resume tailored to your skills and experience. ResumeGemini provides examples of resumes specifically designed for airless spray painting professionals to help you get started. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good