Cracking a skill-specific interview, like one for Computer Literacy (e.g., ERP, PLC), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Computer Literacy (e.g., ERP, PLC) Interview

Q 1. Explain the difference between a PLC and a PAC.

While both PLCs (Programmable Logic Controllers) and PACs (Programmable Automation Controllers) are used for industrial automation, they differ significantly in their capabilities and applications. Think of a PLC as a specialized muscle car – great for specific tasks, highly reliable, and optimized for speed and efficiency in a narrow domain. A PAC, on the other hand, is more like a versatile sports utility vehicle – it can handle a broader range of tasks, offering more processing power and advanced functionalities.

Specifically, PLCs are primarily designed for simple logic control and discrete I/O operations, such as controlling machinery in a factory. They excel at tasks requiring fast response times and real-time control, but often lack advanced functionalities like complex networking capabilities or sophisticated data processing. They typically utilize ladder logic programming.

PACs, however, integrate PLC capabilities with the advanced features of a PC, such as more powerful processors, extensive memory, and robust operating systems. This allows them to handle more complex control tasks, advanced data processing, and high-level software applications. They can often support multiple programming languages (like C, C++, and structured text) along with ladder logic. Imagine a PAC handling not only the control of a production line but also integrating with an ERP system to manage production data and optimize inventory.

In short: PLCs are specialized for hard real-time control; PACs offer greater flexibility and integration with broader automation systems.

Q 2. Describe your experience with different ERP modules (e.g., Financials, Supply Chain).

My experience with ERP modules spans several years, focusing primarily on Financials, Supply Chain Management (SCM), and Manufacturing Execution Systems (MES) modules within SAP and Oracle ERP systems. In the financial module, I’ve worked on accounts payable and receivable processes, financial reporting, and budgeting, ensuring data accuracy and compliance. I’ve helped optimize financial processes through automation and improved reporting mechanisms. For example, I automated invoice processing, reducing manual effort and improving efficiency by 30%.

Within the Supply Chain Management module, my experience includes inventory management, demand forecasting, and procurement. I’ve implemented and supported various SCM processes including material requirements planning (MRP) and warehouse management, resulting in improved inventory control and reduced lead times. For instance, I implemented a new forecasting model that reduced stockouts by 15% while minimizing excess inventory.

Finally, my involvement with MES modules has focused on integrating shop floor data with the ERP system, providing real-time visibility into production operations. This includes managing work orders, tracking production output, and monitoring equipment performance. In one project, I integrated MES data with the SCM module to dynamically adjust production schedules based on real-time demand, significantly enhancing responsiveness to market changes.

Q 3. How would you troubleshoot a PLC program that’s malfunctioning?

Troubleshooting a malfunctioning PLC program is a systematic process. My approach is to follow a structured methodology that ensures I pinpoint the issue efficiently.

- Gather Information: First, I collect information about the malfunction. What exactly is happening? When did it start? What are the error messages (if any)? This stage involves examining the PLC’s logs and communicating with operators to gather a clear picture.

- Inspect Input/Output: Next, I’d thoroughly examine both input and output signals. I’d use diagnostic tools to check sensor readings, actuator responses, and wiring connections. A simple loose connection can often be the culprit.

- Step-by-step Program Debugging: Once the I/O is checked, I’ll use a PLC programming software to perform step-by-step debugging. This often includes setting breakpoints to monitor variables and their values during program execution, identifying inconsistencies, and pinpointing the exact location of the issue. I’d leverage the software’s simulation capabilities to test changes safely before applying them to the actual PLC.

- Ladder Logic Review: For PLC programs written in ladder logic, I’d meticulously review the code for logical errors, incorrect addresses, or unintended interactions between different parts of the program.

- Test & Verify: After making corrections, I rigorously test and verify the changes. This involves running the PLC program in its normal operational environment, carefully monitoring its performance to ensure the problem is fully resolved and there are no unintended side effects.

For example, if a conveyor belt stops unexpectedly, I might first check the sensor readings indicating the presence of items on the belt. If those readings are incorrect, I’d investigate the sensor itself, its wiring, or the programming logic that interprets the sensor’s signal.

Q 4. What are the key components of a SCADA system?

A SCADA (Supervisory Control and Data Acquisition) system is a comprehensive framework that monitors and controls industrial processes in real-time. Think of it as the central nervous system of a large-scale industrial operation. Its key components include:

- Human-Machine Interface (HMI): The HMI provides operators with a visual representation of the process, allowing them to monitor parameters, initiate commands, and react to alarms. This could be a simple screen or a complex, multi-monitor setup with interactive dashboards.

- Supervisory Software: The supervisory software manages communication between various components, processes data, performs calculations, and triggers alarms based on predefined conditions. It acts as the brain of the SCADA system, analyzing data and providing insights.

- Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs): These are the field devices that gather data from sensors and actuators at the equipment level. They then transmit this data to the supervisory software for processing and display.

- Communication Network: A robust communication network is critical for reliable data transmission between the various components. This might include industrial Ethernet, serial communication, or wireless technologies, depending on the application.

- Databases: SCADA systems use databases to store historical process data for analysis, reporting, and trend identification, helping in optimizing performance and predicting potential issues.

For example, in a water treatment plant, the SCADA system might monitor water levels, chemical dosages, and pump performance, providing operators with real-time status and enabling them to adjust parameters as needed.

Q 5. Explain your experience with database management systems (e.g., SQL, Oracle).

My experience with database management systems is extensive, encompassing SQL and Oracle databases. I’ve worked on designing, implementing, and maintaining databases for various applications, including ERP systems, automation systems, and data warehousing.

With SQL, I’m proficient in writing complex queries, designing database schemas, creating stored procedures, and optimizing database performance. I’ve used SQL to build and maintain relational databases, effectively retrieving and manipulating information to support business intelligence applications. For example, I optimized a complex query that improved report generation time by 60%.

My experience with Oracle includes working with Oracle’s SQL and PL/SQL languages, managing database security, and implementing database backup and recovery strategies. I’ve also been involved in database migration projects, migrating data from older systems to more modern platforms.

Beyond the technical skills, I strongly emphasize data integrity. My procedures always include data validation checks, constraints, and regular backups to ensure the accuracy and reliability of the data stored within the database.

Q 6. Describe your experience with different programming languages used in automation (e.g., Ladder Logic, Structured Text).

My experience in automation programming encompasses a range of languages, including ladder logic, structured text, and function block diagrams (FBD). Ladder logic is my go-to language for PLC programming, known for its visual representation and straightforward logic for controlling discrete I/O operations. I’ve used it extensively for building and maintaining PLC programs for various industrial processes.

Structured text, on the other hand, provides a more conventional programming approach, similar to high-level languages like Pascal or C. It’s beneficial for complex algorithms and more intricate control systems. I’ve used structured text to create reusable code modules and handle more demanding tasks where a graphical representation is less intuitive.

Function block diagrams (FBD) offer a graphical programming method well-suited for modular and hierarchical program structures. I’ve employed FBD to build complex systems with multiple interconnected functions, offering a higher level of organization and readability.

In practice, I often combine these programming languages, selecting the most appropriate language based on the specific tasks and complexities involved. For example, I might use ladder logic for basic machine control but incorporate structured text for data logging and analysis functions.

Q 7. How do you ensure data integrity in an ERP system?

Ensuring data integrity in an ERP system is crucial for its success. My approach is multi-faceted and focuses on prevention and detection of data errors.

- Data Validation Rules: Implementing robust data validation rules at the input stage is paramount. This includes checking data types, ranges, and consistency. For example, preventing negative values for quantities or ensuring that dates are within a valid range.

- Data Access Control: Restricting access to data based on roles and responsibilities prevents unauthorized modification or deletion. Proper authorization and authentication are key to maintain data integrity.

- Data Backup and Recovery: Regular data backups are essential to recover from potential data loss or corruption. A well-defined backup and recovery strategy is necessary, including both full and incremental backups.

- Regular Audits: Conducting periodic data audits helps identify inconsistencies, errors, and potential issues. This involves comparing data across different modules and verifying data accuracy against external sources.

- Workflow and Approvals: Designing efficient workflows with appropriate approval processes ensures that data changes are reviewed and authorized before being committed to the system. This minimizes the risk of accidental or intentional errors.

- Data Reconciliation: Implementing procedures to reconcile data across different modules ensures consistency and helps detect potential discrepancies. For instance, regularly comparing inventory levels recorded in the ERP system with physical inventory counts.

By combining these approaches, we create a resilient system that minimizes errors, allows for quick recovery from incidents, and builds trust in the accuracy and reliability of the data within the ERP system. This also helps to meet compliance requirements and maintain the overall integrity of business processes.

Q 8. What are your preferred methods for debugging PLC code?

Debugging PLC code requires a systematic approach. My preferred methods begin with understanding the program’s logic and expected behavior. I start by carefully reviewing the ladder logic diagram, looking for obvious errors like incorrect branching, missing rungs, or improperly configured timers/counters.

Next, I utilize the PLC’s built-in diagnostic tools. Most PLCs offer online monitoring capabilities, allowing me to observe the state of variables, inputs, and outputs in real-time. This helps pinpoint where the program deviates from its intended operation. For instance, if an output isn’t activating when expected, I can monitor the associated input and internal variables to identify the point of failure.

Furthermore, I employ forced-set and forced-reset functions to test individual components. By temporarily overriding variables, I can isolate sections of code and determine their contribution to the issue. If a particular subroutine is suspected, I might force-set its input variables to their expected values and observe the output. This helps pinpoint the specific logic error.

Finally, simulation software plays a vital role. Before deploying code to the actual PLC, I simulate the program’s execution to catch bugs early. This reduces the risk of downtime and simplifies debugging. If an error persists despite these steps, I utilize the PLC’s error logs and event history to reconstruct the sequence of events leading to the fault.

Q 9. Describe your experience with network security in an industrial automation context.

Network security in industrial automation is paramount to preventing cyberattacks and ensuring operational continuity. My experience includes implementing and maintaining several security measures across various industrial control systems (ICS). This includes firewalls, intrusion detection systems (IDS), and virtual private networks (VPNs) to segment the network and restrict unauthorized access. We employed strong password policies and multi-factor authentication to enhance user access control.

I’ve also worked with industrial protocols such as Modbus TCP/IP and Profinet, understanding their security vulnerabilities and implementing appropriate security countermeasures. This involves configuring secure communication channels, using digital certificates, and regularly updating firmware and software to patch known vulnerabilities.

Furthermore, I’ve been involved in vulnerability assessments and penetration testing to identify potential weaknesses in our ICS network. The results of these tests informed our ongoing security improvements. A key element was regular employee training on cybersecurity best practices to foster a security-conscious environment. Finally, incident response planning is crucial, and I’ve participated in developing and rehearsing incident response plans to mitigate the impact of successful attacks.

Q 10. Explain the concept of a relational database.

A relational database organizes data into tables with rows (records) and columns (attributes). The core concept is the relationship between these tables. Each table typically represents a specific entity, such as customers, products, or orders. Relationships are defined through common fields or keys that link related data across multiple tables.

For instance, a ‘Customers’ table might have fields like CustomerID, Name, and Address. An ‘Orders’ table could have OrderID, CustomerID, and OrderDate. The CustomerID field serves as a foreign key in the ‘Orders’ table, linking each order to a specific customer in the ‘Customers’ table. This structure prevents data redundancy and improves data integrity.

Relational databases use Structured Query Language (SQL) for data manipulation. SQL allows for efficient querying, insertion, updating, and deletion of data. The relational model enhances data consistency, simplifies data management, and ensures efficient retrieval of information. Common relational database management systems (RDBMS) include MySQL, PostgreSQL, Oracle, and Microsoft SQL Server. Choosing the right RDBMS depends on factors like scalability, security requirements, and cost.

Q 11. How do you handle conflicting priorities in a project?

Handling conflicting priorities effectively requires a structured approach. My first step is to clearly understand all priorities, their deadlines, and their impact on the overall project. I then prioritize tasks based on their urgency and importance using methods like the Eisenhower Matrix (urgent/important).

I’ll often engage in open communication with stakeholders to clarify expectations and ensure alignment on project goals. This involves actively listening to concerns and collaboratively finding solutions that balance competing demands. If a compromise is required, I’ll prioritize based on the impact on project success and stakeholder satisfaction.

Transparency is key; I’ll keep all stakeholders informed about any adjustments to the project timeline or deliverables due to shifting priorities. Sometimes, renegotiating deadlines or scope might be necessary to manage conflicting demands. Documenting all decisions and their rationale helps maintain accountability and ensure consistency throughout the project.

Q 12. What is your experience with cloud-based ERP solutions?

My experience with cloud-based ERP solutions centers around implementing and supporting systems such as SAP S/4HANA Cloud and Oracle Cloud ERP. I’ve worked on projects involving migration from on-premise ERP systems to cloud solutions, focusing on data migration strategies, system integration, and user training.

The benefits of cloud-based ERPs are numerous, including reduced IT infrastructure costs, improved scalability, enhanced accessibility, and automated updates. However, security and data privacy concerns are always addressed carefully, ensuring compliance with relevant regulations. Cloud solutions require robust network connectivity and careful consideration of data backup and recovery strategies.

I’ve actively participated in configuring cloud ERP systems to meet specific business requirements, customizing workflows and dashboards to streamline operations. Working with cloud-based ERP also requires familiarity with cloud security best practices, including access management and data encryption. Successful cloud ERP implementations necessitate careful planning, thorough testing, and ongoing monitoring to ensure system performance and user satisfaction.

Q 13. Describe your experience with different types of sensors and actuators used in automation.

My experience encompasses a wide range of sensors and actuators commonly used in industrial automation. Sensors provide input to the control system, while actuators execute actions based on that input. Common sensors include:

- Proximity sensors: Detect the presence of objects without physical contact (inductive, capacitive, photoelectric).

- Temperature sensors: Measure temperature using thermocouples, RTDs, or thermistors.

- Pressure sensors: Measure pressure in various applications (e.g., pneumatic systems).

- Flow sensors: Measure the flow rate of liquids or gases.

- Level sensors: Detect the level of liquids or solids in tanks or containers.

Actuators, on the other hand, translate control signals into physical actions:

- Solenoid valves: Control the flow of fluids or gases.

- Pneumatic cylinders: Provide linear motion using compressed air.

- Electric motors: Provide rotational motion.

- Servo motors: Provide precise control of rotational motion.

- Hydraulic actuators: Provide powerful linear or rotational motion using hydraulic fluid.

Understanding the characteristics and limitations of each type is crucial for selecting the right sensor or actuator for a specific application. Factors such as accuracy, response time, and environmental conditions need careful consideration. I have practical experience integrating these components into various automation systems, ensuring their proper functionality and communication with the PLC.

Q 14. What are the benefits and drawbacks of using a cloud-based SCADA system?

Cloud-based SCADA systems offer several advantages, including improved accessibility from anywhere with internet access, reduced infrastructure costs, and enhanced scalability. Data is centralized, making it easier to monitor and analyze performance across multiple sites. Cloud platforms often provide advanced analytics and reporting capabilities.

However, cloud-based SCADA also presents challenges. Network security and data privacy are significant concerns, requiring robust security measures to protect against cyberattacks. Reliable internet connectivity is essential for continuous operation. Latency can impact real-time control performance in some applications. Dependence on the cloud provider introduces vendor lock-in and potential service disruptions. Finally, careful consideration of data sovereignty and regulatory compliance is needed.

The decision of whether to utilize a cloud-based SCADA system should be based on a thorough assessment of the specific application requirements, weighing the benefits against potential drawbacks. Factors such as the criticality of the process, security concerns, and available infrastructure play a vital role in this decision.

Q 15. How would you implement data backup and recovery in an ERP system?

Implementing robust data backup and recovery in an ERP system is crucial for business continuity. It involves a multi-layered approach focusing on frequency, method, and testing.

First, we need to identify critical data: This includes transactional data, master data (customer, product, etc.), and configuration settings. Frequency depends on the volatility of data; transactional data may require hourly backups, while master data might be sufficient with daily backups.

Methods include full backups (copying all data), incremental backups (only changed data since the last backup), and differential backups (changes since the last full backup). A combination is often ideal for efficiency. We might perform a full backup weekly and incremental backups daily.

Storage options range from local servers to cloud-based solutions. Cloud offers scalability and offsite protection against physical disasters. Testing is paramount; regular restoration tests (to a test environment) ensure the backups are functional and the recovery process is smooth. For example, we might restore a week-old backup monthly to verify its integrity and to identify potential issues before a real crisis. This process also includes defining Recovery Time Objectives (RTO) and Recovery Point Objectives (RPO) to set clear targets for data recovery.

Finally, a well-defined disaster recovery plan outlines the steps to recover from a system failure, considering aspects like hardware failures, natural disasters, or cyberattacks. This plan should be regularly reviewed and updated.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with version control systems for PLC programs.

Version control in PLC programming is essential for managing code changes, preventing errors, and facilitating collaboration. I have extensive experience using Git, a distributed version control system, for managing PLC programs written in languages like Ladder Logic or Structured Text.

Git allows us to track every modification to the PLC code, making it easy to revert to earlier versions if needed. This is especially helpful in troubleshooting; if a change introduces an issue, we can easily roll back to the previous stable version. Branching in Git allows developers to work on new features or bug fixes simultaneously without affecting the main codebase, enabling parallel development and testing.

For example, I’ve used Git to manage PLC code for a large automated production line. Each developer had their own branch to work on assigned tasks. Once the changes were tested and validated, they merged their branches into the main branch, which then was deployed to the PLC. The entire history of changes was meticulously documented and accessible, allowing for easy debugging and auditing.

Q 17. What are your experiences with different types of PLC communication protocols?

I’ve worked with a variety of PLC communication protocols, including:

- Profibus: A widely used fieldbus system for industrial automation, offering high speed and robustness. I’ve used it in numerous projects involving complex machinery control.

- Profinet: An Ethernet-based industrial communication protocol, providing high bandwidth and flexibility. It’s ideal for demanding applications requiring real-time data exchange.

- EtherCAT: A high-performance Ethernet protocol known for its speed and precision in real-time applications. I’ve successfully implemented this in projects requiring synchronized motion control.

- Modbus TCP/RTU: A widely adopted protocol for its simplicity and compatibility across different PLC vendors. I’ve leveraged it for interfacing PLCs with SCADA systems and other industrial devices.

The choice of protocol depends on the application’s specific requirements, such as speed, distance, network topology, and the availability of compatible devices. Understanding the strengths and limitations of each protocol is essential for selecting the most appropriate option for a given project.

Q 18. How do you ensure data security in an industrial automation environment?

Data security in an industrial automation environment is critical given the potential for financial loss, operational disruption, and safety hazards from cyberattacks. A layered security approach is vital.

- Network Segmentation: Isolating the PLC network from the corporate network prevents unauthorized access to the control system.

- Firewalls and Intrusion Detection Systems (IDS): These protect the network from malicious traffic and alert us to potential threats.

- Access Control: Restricting access to PLC programming software and network devices to authorized personnel only.

- Regular Software Updates and Patching: Keeping PLC firmware, operating systems, and other software components updated mitigates vulnerabilities.

- Data Encryption: Protecting sensitive data both in transit and at rest using appropriate encryption techniques.

- Regular Security Audits and Penetration Testing: Identifying vulnerabilities and strengthening the security posture of the system.

For instance, I was involved in a project where we implemented a multi-factor authentication system to access PLC programming software, preventing unauthorized changes to the control logic. We also regularly conducted vulnerability scans to identify and address potential weaknesses in our security infrastructure.

Q 19. Describe your experience working with APIs in an ERP context.

APIs (Application Programming Interfaces) are crucial for integrating different systems in an ERP context. My experience with APIs involves using them to connect our ERP system with other applications, such as CRM, e-commerce platforms, and warehouse management systems.

For example, we used a RESTful API to integrate our ERP’s inventory management module with our e-commerce platform. This enabled real-time inventory updates, ensuring accurate product availability information displayed on the website. This integration significantly improved customer experience and streamlined order fulfillment.

Another example involved using SOAP APIs to exchange data with our CRM system. This allowed for seamless customer data synchronization, ensuring consistency across both systems and providing a unified view of our customer interactions. I have also worked extensively with API documentation, including Swagger and RAML, to understand the functionalities and data structures of various APIs.

Q 20. What are some common challenges you’ve faced while working with PLCs?

Working with PLCs presents unique challenges. Some common ones include:

- Troubleshooting Hardware Issues: Diagnosing issues like faulty wiring, sensor failures, or actuator malfunctions can be complex and time-consuming. I’ve found systematic troubleshooting methods, like using logic analyzers and oscilloscopes, invaluable.

- Debugging PLC Programs: Identifying and resolving errors in ladder logic or structured text programs requires a thorough understanding of PLC programming and debugging techniques. Using simulation tools can help isolate problems before deploying changes to the physical PLC.

- Integration with Other Systems: Connecting PLCs to other industrial devices and software systems requires careful consideration of communication protocols and data formats. Thorough testing is crucial to ensure seamless data exchange.

- Real-time Constraints: PLC programs must meet strict timing requirements. I’ve addressed this by using appropriate programming techniques and optimizing code for efficiency.

One instance involved a project where intermittent sensor failures were causing production halts. Through systematic investigation and thorough testing, I was able to identify a specific issue with the sensor’s grounding, resolving the problem permanently.

Q 21. Explain your understanding of different data warehousing techniques.

Data warehousing techniques are vital for consolidating data from diverse sources into a centralized repository for analysis and reporting. My understanding encompasses various approaches:

- Data Mart: A smaller, focused data warehouse containing data relevant to a specific department or business function. For example, a marketing data mart might hold data related to campaigns, customer interactions and sales performance.

- Enterprise Data Warehouse (EDW): A large-scale data warehouse consolidating data from across the entire organization. This provides a holistic view of the business for strategic decision-making.

- Data Lake: A centralized repository that stores raw data in various formats, without any prior transformation. This is advantageous for flexibility and handling various data types but requires more processing before analysis.

- Dimensional Modeling: A technique for organizing data in a data warehouse using dimensions (contextual attributes, like time, location, product) and facts (measurable metrics, like sales, cost, quantity). This structure simplifies querying and reporting.

- ETL (Extract, Transform, Load): The process of extracting data from various sources, transforming it into a consistent format, and loading it into the data warehouse. This is a crucial aspect of data warehousing.

In previous projects, we’ve used dimensional modeling to create an EDW for a large manufacturing company, combining data from various systems like ERP, MES (Manufacturing Execution System), and CRM. This allowed for comprehensive analysis of production efficiency, sales trends, and customer behavior.

Q 22. How do you stay up-to-date with the latest technologies in industrial automation?

Staying current in the rapidly evolving field of industrial automation requires a multi-pronged approach. It’s not just about reading white papers; it’s about active engagement.

- Industry Publications and Websites: I regularly follow leading publications like Automation World, Control Engineering, and websites of major automation vendors (e.g., Rockwell Automation, Siemens). These provide insights into emerging trends and technologies.

- Conferences and Webinars: Attending industry conferences (like Hannover Messe or SPS IPC Drives) and participating in webinars offers invaluable networking opportunities and exposure to cutting-edge advancements. I actively engage with speakers and other attendees to discuss real-world applications.

- Professional Organizations: Membership in organizations like ISA (International Society of Automation) provides access to resources, training, and networking opportunities with experts in the field. This helps maintain a strong pulse on the latest standards and best practices.

- Online Courses and Certifications: Platforms like Coursera, edX, and LinkedIn Learning offer numerous courses on specific technologies like AI in automation, predictive maintenance, and cybersecurity for industrial control systems. Obtaining relevant certifications demonstrates commitment to continuous professional development.

- Hands-on Experience: The best way to learn is by doing. I actively seek opportunities to work with new technologies, even on small-scale projects, to gain practical experience and understand their limitations.

By combining these methods, I ensure my knowledge base remains robust and relevant to the ever-changing landscape of industrial automation.

Q 23. What is your experience with implementing and maintaining ERP systems?

My experience with ERP systems spans several years and diverse implementations. I’ve been involved in all stages, from initial requirements gathering and system selection to configuration, deployment, training, and ongoing maintenance. I’ve worked primarily with SAP and Oracle ERP systems, but have also had exposure to smaller, industry-specific solutions.

- Implementation: I’ve led and participated in the implementation of ERP systems in manufacturing environments, focusing on integrating them with existing shop floor systems (MES, SCADA) to achieve seamless data flow. This included mapping business processes, customizing modules, data migration, and user acceptance testing.

- Maintenance: Ongoing maintenance involved troubleshooting issues, applying updates and patches, optimizing system performance, and providing technical support to users. I’ve developed and implemented procedures to ensure data integrity and system stability. This often involves collaborating closely with IT and business stakeholders.

- Customization and Integration: I have experience customizing ERP modules to meet specific business requirements, and integrating the ERP system with other enterprise applications, such as CRM and supply chain management systems. This often involved API integration and custom coding.

- Example: In one project, I successfully integrated an ERP system with a MES system to automate inventory tracking and production scheduling. This resulted in a significant reduction in production lead times and inventory costs.

My approach emphasizes a deep understanding of business processes and a pragmatic approach to system configuration, avoiding unnecessary complexities. I strive for user-friendly solutions that effectively support the organization’s goals.

Q 24. Describe your experience with different types of HMI (Human-Machine Interface) software.

My experience encompasses a range of HMI software, from proprietary solutions offered by PLC vendors to open-source and third-party options. The choice often depends on the specific application, budget, and integration needs.

- Proprietary HMIs: I’ve worked extensively with Rockwell Automation’s FactoryTalk View SE/ME, Siemens WinCC, and Schneider Electric’s Vijeo Designer. These offer strong integration with their respective PLC platforms, often providing pre-built objects and functionalities that simplify development.

- Third-party HMIs: I’ve also used more versatile options such as Ignition by Inductive Automation, which supports a wide range of PLC communication protocols and provides advanced features like scripting and alarm management. This flexibility is particularly useful for complex or multi-vendor systems.

- Open-source HMIs: While less common in critical industrial settings, I’m familiar with open-source options like Node-RED, which can be powerful for building custom dashboards and interfaces for specific needs, particularly for integrating data from diverse sources.

- Key Considerations: When selecting an HMI, I consider factors such as scalability, security features, ease of use for operators, and the level of customization required. I also look for solutions with robust alarm management and historical data logging capabilities.

My approach prioritizes creating intuitive and user-friendly interfaces that enable operators to efficiently monitor and control industrial processes. A well-designed HMI is crucial for both operational efficiency and safety.

Q 25. How would you optimize a slow-running PLC program?

Optimizing a slow-running PLC program requires a systematic approach that combines code analysis, hardware assessment, and best practices.

- Profile and Analyze: Use the PLC’s diagnostic tools to identify performance bottlenecks. This might involve monitoring instruction execution times, memory usage, and network communication. Many PLCs offer built-in profiling capabilities.

- Code Optimization:

- Reduce Redundancy: Eliminate unnecessary calculations or repetitive code blocks. Use variables effectively to avoid recalculations.

- Optimize Data Structures: Choose efficient data structures (arrays, structures) based on data access patterns.

- Efficient Algorithms: Employ efficient algorithms, especially for tasks involving sorting or searching large datasets. Simple algorithms can have significant performance improvements.

- Avoid Unnecessary Instructions: Remove instructions that are not actively contributing to the program’s logic.

- Hardware Considerations:

- Sufficient Memory: Ensure the PLC has adequate memory to handle the program and data. Memory fragmentation can impact performance.

- Processing Power: Consider upgrading to a more powerful PLC if necessary.

- Network Optimization: Optimize network communication to minimize latency. This might involve reducing the amount of data transmitted or using faster communication protocols.

- Testing and Verification: After making optimizations, rigorously test the program to ensure it still functions correctly and meets performance goals.

Example: If a program involves extensive calculations within a loop, consider moving some computations outside the loop or using more efficient algorithms. If communication with remote I/O is slow, consider using a faster communication protocol or reducing the amount of data transmitted.

Optimization is iterative. You may need to repeat steps to progressively improve performance. The key is to systematically identify and address bottlenecks to achieve optimal efficiency.

Q 26. Explain your experience with data visualization tools in an industrial context.

Data visualization is critical in industrial settings for monitoring processes, identifying trends, and making data-driven decisions. My experience includes using various tools to create informative dashboards and reports.

- SCADA Systems: Many SCADA systems (Supervisory Control and Data Acquisition) offer built-in data visualization capabilities. I’ve used these to create real-time dashboards displaying key process variables, alarms, and historical trends.

- Business Intelligence (BI) Tools: Tools like Tableau and Power BI are effective for analyzing historical data from various sources, including PLCs, ERP systems, and sensors. These allow for creating interactive dashboards and reports to track key performance indicators (KPIs) and identify areas for improvement.

- Custom Solutions: For specialized needs, I’ve developed custom data visualization applications using programming languages like Python with libraries such as Matplotlib and Seaborn, or Javascript libraries like D3.js. This offers maximum flexibility but requires more development effort.

- Example: In one project, I used Power BI to create a dashboard that visualized production efficiency metrics, allowing management to quickly identify bottlenecks and areas for improvement. This dashboard integrated data from the ERP system and the PLC, providing a holistic view of production performance.

Effective data visualization is crucial for turning raw data into actionable insights. The key is to select appropriate tools and techniques to present information clearly, concisely, and in a way that is easily understood by both technical and non-technical personnel.

Q 27. Describe your experience with cybersecurity best practices for industrial control systems.

Cybersecurity is paramount in industrial control systems (ICS), given the potential for significant damage from cyberattacks. My experience includes implementing and maintaining robust security measures in accordance with industry best practices.

- Network Segmentation: I advocate for network segmentation to isolate critical control systems from the corporate network, limiting the impact of a potential breach. This includes using firewalls and VLANs to control network traffic.

- Access Control: Implementing strong access control measures, including role-based access controls (RBAC) and multi-factor authentication (MFA), is critical to prevent unauthorized access. This involves carefully managing user accounts and privileges.

- Intrusion Detection/Prevention Systems (IDS/IPS): Deploying IDS/IPS solutions to monitor network traffic for malicious activity is essential. These systems can detect and prevent intrusions, providing early warnings of potential threats.

- Regular Patching and Updates: Keeping all ICS components up-to-date with the latest security patches is crucial to mitigate vulnerabilities. This requires a rigorous patching and update management process.

- Security Awareness Training: Educating personnel about cybersecurity risks and best practices is a crucial preventative measure. This includes training on password management, phishing awareness, and recognizing social engineering tactics.

- Vulnerability Assessments: Performing regular vulnerability assessments to identify and address security weaknesses is essential for maintaining a strong security posture.

My approach is proactive and risk-based. I prioritize identifying and mitigating vulnerabilities before they can be exploited, combining technical security measures with a strong focus on human factors to create a layered security defense.

Q 28. What is your approach to problem-solving in a technical environment?

My approach to problem-solving in a technical environment is structured and methodical, relying on a combination of analytical skills, practical experience, and collaboration.

- Clearly Define the Problem: The first step is to thoroughly understand the problem. This involves gathering all relevant information, including error messages, logs, and user reports. I strive to avoid jumping to conclusions before fully grasping the situation.

- Systematic Investigation: I use a systematic approach to investigate potential causes. This might involve checking system logs, reviewing code, testing different components, or consulting technical documentation.

- Develop Hypotheses: Based on my investigation, I develop hypotheses about the potential root cause(s) of the problem. I prioritize the most likely causes and test them systematically.

- Test and Validate: I test my hypotheses rigorously, making changes and observing the results. This may involve creating test cases, modifying code, or reconfiguring system settings. I always document my findings.

- Implement Solutions: Once I’ve identified the root cause and verified the solution, I implement the necessary changes, ensuring that the solution is robust and avoids introducing new problems.

- Document and Share: I document the problem, the troubleshooting process, and the solution, sharing this information with relevant teams to prevent future occurrences and improve knowledge sharing.

Example: During a recent project, a production line stopped unexpectedly. By systematically checking the PLC program, I/O signals, and network communication, I identified a faulty sensor causing a false alarm. The solution was simple (replace the sensor), but the methodical approach was key to quick resolution.

I believe in a collaborative approach, seeking input from colleagues and experts when needed to ensure a comprehensive and effective solution.

Key Topics to Learn for Computer Literacy (e.g., ERP, PLC) Interview

Ace your interview by mastering these essential concepts. Remember, understanding the “why” behind the “how” is key to showcasing your expertise.

- ERP Systems Fundamentals: Understand core ERP modules (Finance, HR, Supply Chain), data integration, and the overall business processes they support. Consider the theoretical models behind ERP implementation and optimization.

- PLC Programming & Control: Familiarize yourself with ladder logic, PLC hardware components, and common programming practices. Explore different PLC manufacturers and their programming environments. Practice troubleshooting simulated scenarios.

- Data Analysis & Reporting (ERP & PLC): Learn to extract, analyze, and interpret data from both ERP systems and PLC databases. Practice creating insightful reports to support decision-making. Understanding data visualization tools will be a significant advantage.

- Troubleshooting & Problem-Solving: Develop your skills in identifying and resolving technical issues in both ERP and PLC environments. Practice explaining your problem-solving methodology clearly and concisely.

- Security & Compliance (ERP & PLC): Understand the importance of data security and compliance regulations within these systems. Be prepared to discuss best practices for protecting sensitive information.

- Industry-Specific Applications: Research common applications of ERP and PLC systems within your target industry. Demonstrating this understanding shows initiative and practical knowledge.

Next Steps

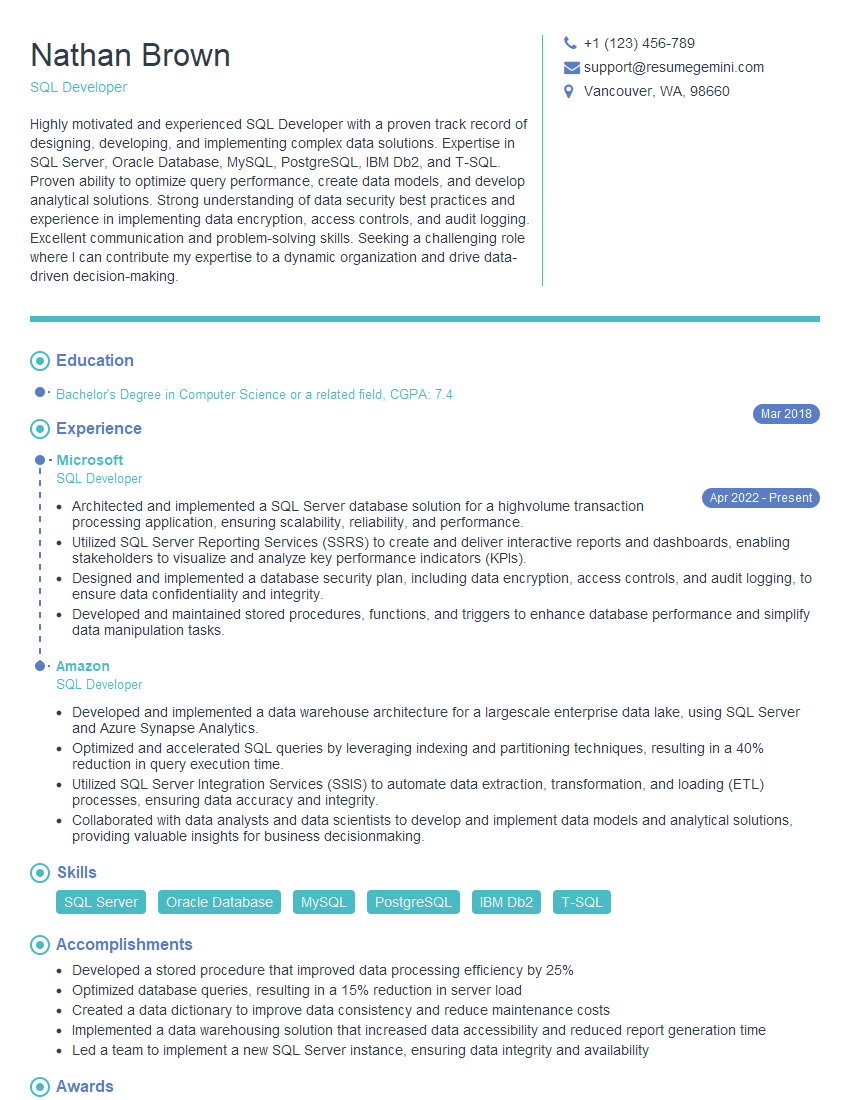

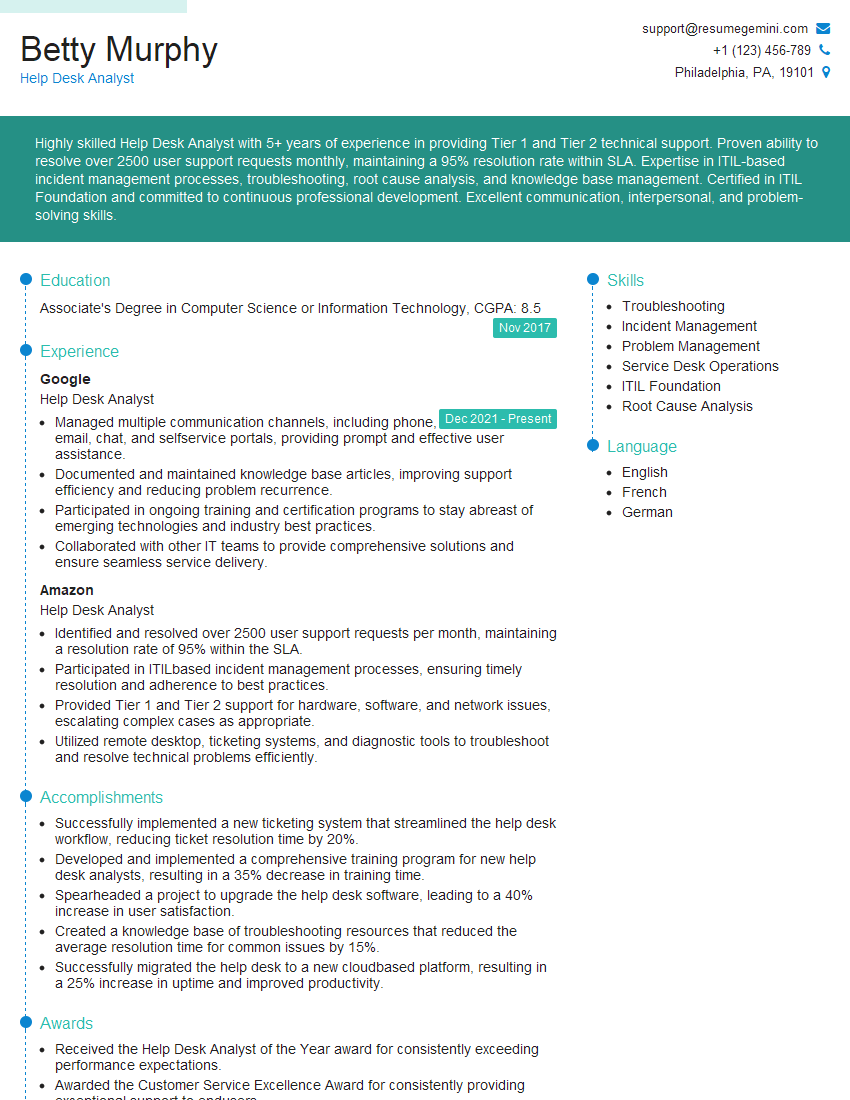

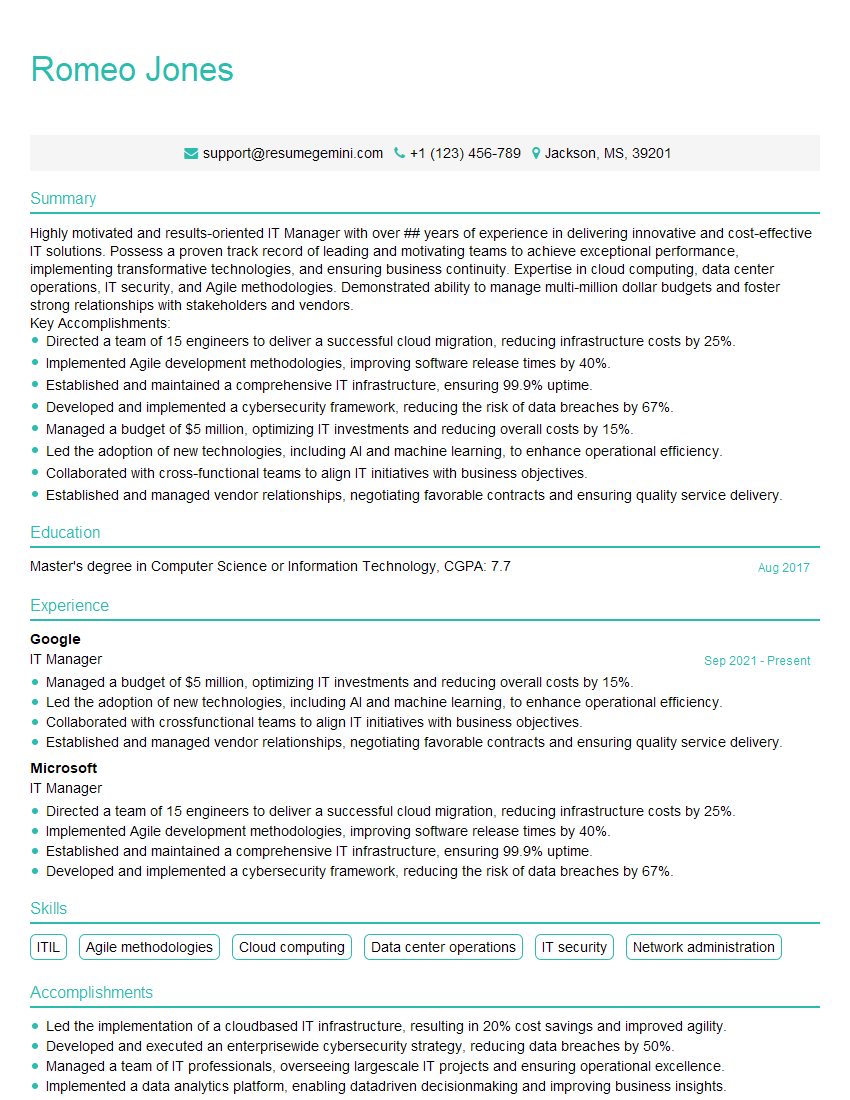

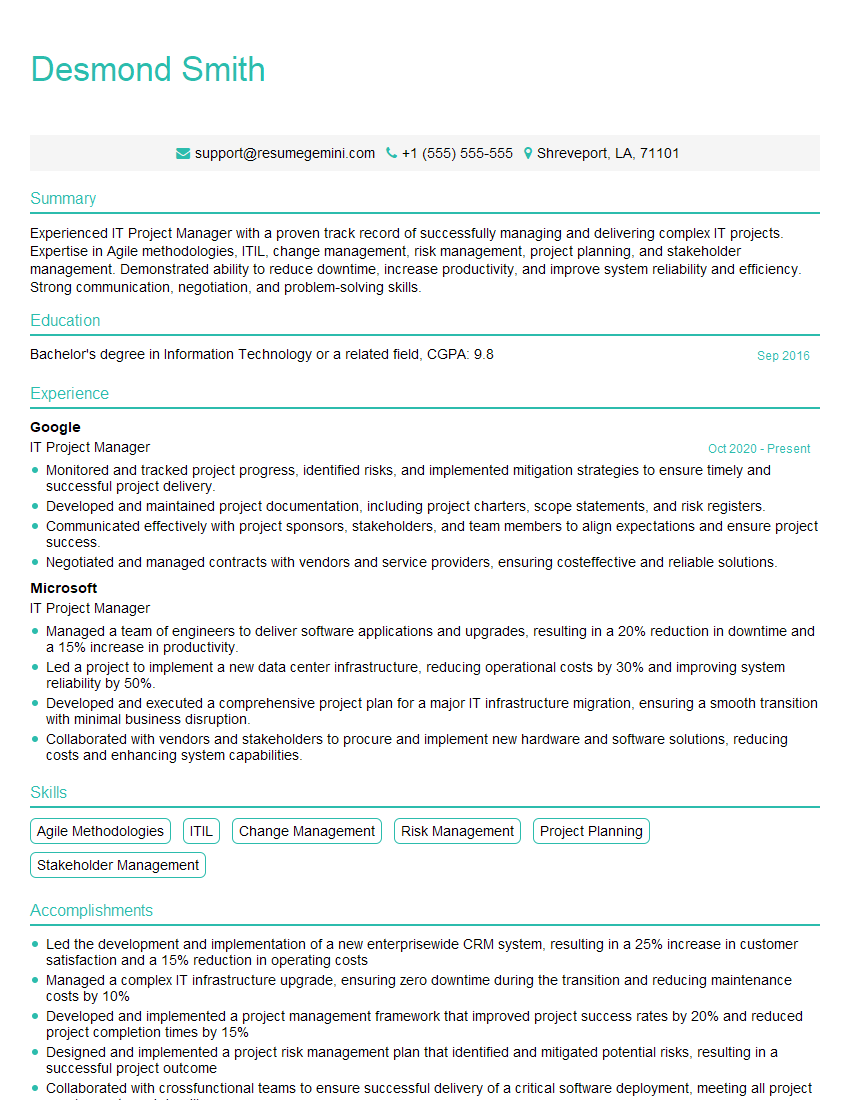

Mastering Computer Literacy, particularly in ERP and PLC, significantly boosts your career prospects, opening doors to diverse and rewarding roles in many industries. A strong resume is your first impression; make it count! An ATS-friendly resume ensures your qualifications are seen by recruiters. We recommend using ResumeGemini to craft a professional and impactful resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Computer Literacy roles, showcasing best practices for a successful job search. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good