Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Hot Work Techniques interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Hot Work Techniques Interview

Q 1. Describe the process for obtaining a hot work permit.

Obtaining a hot work permit is a crucial safety procedure that ensures controlled execution of potentially hazardous tasks. The process usually begins with a formal application submitted to a designated safety officer or supervisor. This application details the type of hot work, location, duration, involved personnel, and necessary precautions. After review, the safety officer assesses the risks involved and verifies the presence of appropriate safety measures before issuing the permit. This permit often includes specific instructions, limitations, and emergency contact information. Once the work is completed, the permit must be closed out, signifying that the work is finished and the area is deemed safe.

For example, imagine a welder needs to work near a fuel storage tank. Their application would specify the location, type of welding (e.g., gas welding, arc welding), duration, fire watch arrangements, and the methods to prevent ignition of flammable materials. The safety officer would then assess this and add any further requirements before issuing the permit. Failure to obtain a permit before commencing hot work is a serious safety violation.

Q 2. What are the five main hazards associated with hot work?

Five main hazards associated with hot work include:

- Fire Ignition: Hot sparks, flames, and molten metal can easily ignite flammable materials nearby, leading to devastating fires.

- Burns: Direct contact with hot surfaces, sparks, or flames can cause severe burns to workers.

- Explosions: Hot work near volatile substances can trigger explosions due to ignition of flammable vapors or gases.

- Toxic Fumes: Certain welding processes release toxic fumes that pose a respiratory hazard to workers.

- Falling Objects: Working at heights during hot work operations introduces the risk of tools, equipment, or materials falling and causing injuries.

Consider a scenario where welding is performed near a solvent storage area. Ignoring the fire hazard could lead to a significant fire. Lack of respiratory protection could expose welders to toxic fumes. The combination of these risks underscores the importance of rigorous safety procedures.

Q 3. Explain the role of a fire watch during hot work activities.

A fire watch is a crucial safety role during hot work operations. The fire watch person is responsible for monitoring the hot work area for any signs of fire or other hazards. Their responsibilities include early fire detection, immediate response to fire incidents (using available fire extinguishers), preventing the spread of fire and ensuring the safety of workers. They also ensure that the area remains clear of combustibles and that safety procedures are followed. They maintain constant vigilance and communication with the workers and the site safety personnel throughout the duration of the hot work.

Imagine a scenario where a fire starts during welding. A vigilant fire watch can immediately detect the fire, deploy a fire extinguisher, and prevent it from spreading to other areas, potentially saving lives and preventing significant property damage. Their presence and attentiveness are non-negotiable for safe hot work operations.

Q 4. What are the minimum distances required for hot work near flammable materials?

Minimum distances for hot work near flammable materials aren’t standardized globally; they depend heavily on the specific materials and local regulations. However, a common principle is to maintain a sufficient distance to prevent ignition. As a general rule, a minimum of 35 feet (10 meters) is often recommended when working near highly flammable materials, such as solvents or large quantities of combustible materials. This distance allows for a safety margin in case of sparks or flames. For less flammable materials, a smaller distance might be acceptable, but a thorough risk assessment should always guide the decision. This distance can be modified through engineering controls like fire-resistant barriers.

For instance, working near a large tank of gasoline necessitates a much greater distance than working near a wooden structure. The risk assessment should justify any deviation from recommended distances, documenting the mitigation measures taken.

Q 5. How do you ensure proper ventilation during hot work operations?

Proper ventilation during hot work operations is essential to remove toxic fumes and prevent the buildup of flammable gases. This can be achieved through several methods. Mechanical ventilation, such as exhaust fans or ventilation systems, is highly recommended, especially in confined spaces or areas with poor natural ventilation. Natural ventilation, utilizing open windows and doors, can be effective in some situations but is less reliable. Local exhaust ventilation, which captures fumes at their source, is particularly effective for controlling specific sources of toxic fumes.

For example, if welding is taking place inside a confined structure, a powerful exhaust fan should be used to remove fumes, minimizing the risk of exposure to toxic gasses. Without proper ventilation, welders could suffer serious health consequences.

Q 6. What types of fire extinguishers are suitable for hot work fires?

The suitable type of fire extinguisher for hot work fires depends on the type of combustible material involved. For Class A fires (ordinary combustibles like wood and paper), water-based extinguishers are generally suitable. Class B fires (flammable liquids like oil and grease) are best extinguished with carbon dioxide (CO2) or dry chemical extinguishers. Class C fires (electrical fires) require CO2 or dry chemical extinguishers to avoid electrical shock. It’s common practice to have multiple types of extinguishers available for hot work situations, covering different fire classes.

For example, at a construction site where both wood and solvents are present, both a water-based extinguisher and a dry chemical or CO2 extinguisher should be available and readily accessible to the fire watch.

Q 7. Describe the pre-hot work inspection procedures.

Pre-hot work inspection procedures are crucial for identifying and mitigating potential hazards before commencing hot work. These procedures typically involve a thorough visual inspection of the area, checking for the presence of flammable materials, ensuring adequate fire protection measures (extinguishers, fire blankets), verifying ventilation, and checking electrical equipment for safety. All potentially flammable materials in the surrounding area should be removed or protected. The area should be cleared of debris to prevent accidental fires. Any equipment being used should be inspected to ensure it is in safe working order.

For instance, before welding on a steel structure, the area should be inspected for the presence of flammable materials such as oil, paint, or nearby combustible items. The welder should ensure that fire extinguishers are functioning and readily accessible, and that the area has proper ventilation.

Q 8. What are the post-hot work procedures?

Post-hot work procedures are crucial for ensuring the safety and preventing incidents after a hot work operation. They focus on verifying the complete extinguishment of all ignition sources and confirming the area’s safe condition for general activity.

- Inspection: A thorough inspection of the hot work area is paramount. This involves checking for embers, sparks, or any residual heat using appropriate thermal detection tools. For example, a thermal imaging camera can be used to scan the area for heat signatures that might not be immediately visible.

- Cooling: Sufficient cooling of the affected area must be done, using water or other suitable methods, to ensure that all materials have cooled down below their ignition temperature. The duration of cooling depends on the materials involved and the intensity of the hot work.

- Clean-up: Removal of all debris, slag, and other byproducts of the hot work process is essential. This prevents accidental ignition from hidden embers and maintains workplace cleanliness.

- Documentation: Detailed documentation of the post-hot work inspection, including any findings and corrective actions taken, must be recorded. This forms part of the audit trail for compliance and incident investigation.

- Notification: Once the area is deemed safe, the relevant personnel must be notified that the hot work area is clear and ready for normal operations. This might involve updating work permits or notifying those whose tasks might have been affected by the hot work.

Imagine a welding operation in a confined space. After the welding is complete, a thorough inspection with a thermal camera is needed to ensure no hidden heat remains within the structure. Then, the area is cooled down and cleaned, before finally receiving clearance for continued work.

Q 9. How do you manage hot work in confined spaces?

Managing hot work in confined spaces presents unique challenges due to limited ventilation and increased risks of fire and asphyxiation. Stringent safety measures are critical.

- Ventilation: Adequate ventilation is vital to prevent the buildup of flammable gases and fumes produced during the hot work. Mechanical ventilation systems, such as exhaust fans, should be used to ensure a continuous flow of fresh air into the confined space. Regular monitoring of oxygen levels is also necessary.

- Fire Protection: Fire extinguishers suitable for the specific fire hazards must be readily available and accessible within the confined space. Ideally, a fire watch should be maintained during and after the hot work operation.

- Personal Protective Equipment (PPE): Workers should wear appropriate PPE, including respiratory protection to avoid inhaling harmful fumes, and flame-retardant clothing to protect against burns. A safety harness with a lifeline might be necessary if working at height within the confined space.

- Permit-to-Work System: A robust permit-to-work system is essential, clearly specifying the hot work tasks, safety precautions, and emergency procedures. The permit should be approved by a competent authority before work commences.

- Emergency Procedures: Clear emergency procedures, including escape routes and communication protocols, must be established and understood by all personnel involved. Regular emergency drills might also be required.

Consider a scenario involving welding inside a storage tank. Before starting, the tank would need thorough purging and ventilation to remove any flammable vapors. A comprehensive respiratory protection system would be essential for workers, and the tank would need a dedicated fire watch and appropriate fire suppression system.

Q 10. What are the responsibilities of a hot work permit issuer?

The hot work permit issuer holds a significant responsibility for ensuring the safety of hot work operations. They must possess the necessary knowledge, skills, and experience to assess risks and authorize the work only when safe conditions are met.

- Risk Assessment: The issuer must conduct a thorough risk assessment, identifying potential hazards associated with the hot work and implementing appropriate control measures. This includes assessing the flammability of materials, the proximity to ignition sources, and the adequacy of ventilation.

- Permit Review: The issuer reviews and approves the hot work permit, ensuring that all necessary information and safety precautions are detailed. This includes confirming the competence of the personnel involved and the availability of necessary equipment and fire protection systems.

- Inspection: Before, during, and after the hot work operation, the issuer or a designated representative will inspect the area to verify that safety procedures are followed and no hazards are present. This helps to prevent accidents or incidents.

- Competency: The issuer must possess the necessary expertise and training to assess the risks associated with hot work, particularly those specific to the work being performed.

- Emergency Response: The issuer should have a clear understanding of emergency procedures and be able to provide assistance in the event of an incident.

A competent issuer won’t simply sign a permit; they’ll actively participate in the safety process, ensuring adequate ventilation is in place, fire watch is assigned, and all involved understand the potential risks and mitigation strategies.

Q 11. Explain the importance of pre-job planning for hot work.

Pre-job planning for hot work is paramount in preventing accidents and injuries. It’s about proactively identifying and mitigating risks before hot work even begins.

- Hazard Identification: A detailed identification of all potential hazards in the work area is crucial. This includes flammable materials, nearby equipment, and the environment itself.

- Risk Assessment: A thorough risk assessment should be conducted to evaluate the likelihood and severity of each identified hazard. This helps prioritize control measures.

- Control Measures: Specific control measures should be implemented to eliminate or mitigate the identified risks. This could include using fire-resistant materials, providing adequate ventilation, or implementing a fire watch.

- Resource Allocation: Ensuring sufficient resources, such as appropriate PPE, fire extinguishers, and trained personnel, are available is essential.

- Communication: Clear communication among all personnel involved, including the hot work team, supervisors, and other workers in the area, is crucial.

Think of constructing a skyscraper. Welding on a high floor requires meticulous planning. This would involve fire safety protocols, emergency escape routes, detailed risk assessments concerning wind and material handling, and pre-planned communication channels to alert those below in case of any incident.

Q 12. How do you identify and control ignition sources during hot work?

Identifying and controlling ignition sources is fundamental to safe hot work practices. This requires a multi-faceted approach.

- Elimination: The most effective method is to eliminate ignition sources entirely from the hot work area. This means removing any flammable materials, electrical equipment, and other potential sources of ignition.

- Isolation: Where elimination is not possible, ignition sources should be isolated from the hot work area using barriers, enclosures, or other means to prevent accidental contact.

- Control: Implementing engineering controls, such as grounding and bonding of electrical equipment, can significantly reduce the risk of ignition. Using intrinsically safe tools is also highly recommended.

- Fire Watch: A trained fire watch is essential to continuously monitor the hot work area for any signs of fire or sparks, and to take immediate action in case of an incident. The duration of the fire watch depends on the duration and nature of the hot work.

- Supervision: Experienced personnel should supervise the hot work operation to ensure that all safety procedures are being followed.

For instance, when welding near a gas pipeline, the pipeline needs to be isolated and depressurized, and a fire watch should be deployed to monitor for any sparks or leaks. The surrounding area should be cleared of flammable materials.

Q 13. What are the legal requirements for hot work in your region?

Legal requirements for hot work vary significantly by region. It’s crucial to consult the specific regulations applicable to your location. Generally, these requirements align with internationally recognized best practices and often involve compliance with national or regional occupational safety and health (OSH) standards and regulations. These often include specific guidelines on hot work permits, risk assessments, fire prevention, and emergency response procedures.

Note: This answer cannot provide specific legal requirements for a particular region as these vary greatly and are subject to change. It is essential to consult the relevant national, regional, and potentially even local regulations applicable to the specific location where the hot work will take place. OSHA (in the USA), HSE (in the UK) and equivalent organizations in other countries provide detailed guidelines and regulations on hot work safety.

Q 14. What is the difference between a hot work permit and a cold work permit?

The key difference lies in the potential for ignition sources and the associated risks. A hot work permit authorizes activities that involve processes capable of generating heat or sparks, such as welding, cutting, or brazing. These carry a high risk of fire or explosion. A cold work permit, on the other hand, covers activities with a lower risk of ignition, involving no significant heat sources, like routine maintenance, cleaning, or inspection. It’s still a permit to work in potentially hazardous environments, focusing on other potential hazards like confined spaces or elevated work.

Essentially, a hot work permit is a subset of a wider permit-to-work system, and involves significantly more stringent requirements concerning fire prevention and control. The documentation required and the approval process are more complex for hot work permits compared to cold work permits, which generally require less oversight.

Q 15. How do you manage hot work near energized electrical equipment?

Managing hot work near energized electrical equipment requires meticulous planning and adherence to strict safety protocols. The fundamental principle is to ensure complete electrical isolation before commencing any hot work. This means de-energizing the equipment, locking out and tagging out (LOTO) the power source to prevent accidental re-energization. Think of it like this: you wouldn’t perform surgery without sterilizing the instruments; similarly, you wouldn’t perform hot work near live electricity without ensuring it’s completely dead.

Before starting, a thorough risk assessment is crucial, identifying all potential hazards and outlining control measures. This includes verifying the absence of voltage using appropriate testing equipment and potentially grounding the equipment to prevent stray electrical currents. A competent person, who understands electrical safety, should always oversee the process, and a permit-to-work system should be in place, documenting all steps and approvals.

If complete de-energization isn’t feasible due to operational constraints, then specialized techniques like employing insulated barriers, fire-resistant blankets, or working behind a suitable non-conductive screen might be considered. However, these are secondary measures, and complete de-energization remains the safest approach. This process is documented thoroughly for audit trails.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different types of hot work and their associated risks.

Hot work encompasses various processes involving the production of a heat or spark, potentially igniting flammable materials. The risks associated significantly vary depending on the specific activity and environment.

- Welding: This involves joining metals using intense heat. Risks include arc flash (intense light and heat), burns, fire, and exposure to harmful fumes.

- Cutting (e.g., torch cutting, plasma cutting): Similar to welding, these methods generate extreme heat and sparks, posing fire and burn risks, along with the danger of flying sparks.

- Brazing and Soldering: These methods use lower temperatures than welding but can still ignite flammable materials if not properly controlled.

- Grinding and Abrasive Blasting: These generate sparks and heat, with risks of fires, eye injuries, and respiratory issues from dust.

The associated risks depend on factors such as the type of material being worked on, the presence of flammable materials, the surrounding environment, and the competence of the workers involved. Each type of hot work necessitates specific safety precautions and PPE to mitigate these risks effectively.

Q 17. How do you communicate hot work activities to others on site?

Effective communication is paramount to hot work safety. Before any hot work begins, the planned activity must be clearly communicated to everyone on-site who might be affected. This isn’t simply a verbal announcement; it requires a formal process.

Typically, this involves:

- Hot Work Permits: A formal permit system allows for documented authorization, outlining the location, duration, and specific precautions. This serves as a central communication tool.

- Site Notices/Signage: Clear signage in the designated hot work area warns others of ongoing activity. This helps prevent accidental entry into the hazardous zone.

- Verbal Warnings: A direct verbal warning to nearby workers before commencing the hot work is also necessary to ensure everyone is aware. Think of it as a pre-flight checklist before starting a risky maneuver.

- Emergency Contact Information: Easily accessible emergency contact numbers for immediate response in case of incident.

The communication method used depends on the site’s size and complexity but should always aim for clarity, visibility, and verification of understanding.

Q 18. What is the role of PPE in hot work safety?

Personal Protective Equipment (PPE) is the frontline defense against hot work hazards. It acts as a barrier between the worker and potential dangers. The specific PPE required will vary depending on the hot work activity, but generally includes:

- Flame-resistant clothing: Protects against burns from flames or sparks. This often includes jackets, trousers, gloves, and footwear made of materials like Nomex or other fire-resistant fabrics.

- Welding helmet/face shield: Protects the eyes and face from intense UV radiation, sparks, and molten metal splatter.

- Safety glasses/goggles: Provide eye protection against flying particles, especially during grinding or cutting.

- Gloves: Protect hands from burns, cuts, and chemical exposure. Different types of gloves are used for different applications.

- Hearing protection: Reduces noise exposure from machinery.

- Respiratory protection: Protects against harmful fumes and dust produced during certain processes. This could range from simple dust masks to specialized respirators.

PPE is crucial, but it should be viewed as a last line of defense. Engineering controls (like proper ventilation) and administrative controls (like training and permit systems) are always prioritized to eliminate or reduce hazards before relying solely on PPE.

Q 19. Explain the different classes of fire and the appropriate extinguishers.

Fires are classified to help determine the appropriate extinguishing agent. The most common classes are:

- Class A: Ordinary combustible materials, like wood, paper, cloth. Water is typically effective.

- Class B: Flammable liquids like petrol, oil, and grease. CO2, foam, or dry chemical extinguishers are used.

- Class C: Energized electrical equipment. CO2 or dry chemical extinguishers are preferred as water conducts electricity.

- Class D: Combustible metals like magnesium, titanium, and sodium. These require special extinguishing agents designed for metal fires.

- Class F: Cooking oils and fats. Wet chemical extinguishers are specifically designed for this class.

Selecting the wrong extinguisher can worsen a fire. Understanding the fire classes and the corresponding extinguishers is crucial for effective fire suppression.

Q 20. How do you handle a hot work emergency?

A hot work emergency requires immediate and decisive action. The priority is always to ensure the safety of personnel. The steps involved would be:

- Evacuate the area: Immediately clear the area of all non-essential personnel.

- Alert emergency services: Call emergency services (fire department, medical services) to report the incident.

- Attempt to contain the fire (if safe): If it is safe to do so and you have the appropriate training, attempt to use a suitable fire extinguisher to contain the fire, but only if you can do so without putting yourself or others in danger. Never attempt to fight a fire that is out of control.

- Provide first aid: Administer first aid to any injured individuals.

- Assist emergency responders: Cooperate fully with emergency services and provide them with any necessary information.

- Post-incident investigation: After the emergency is under control, a thorough investigation is necessary to determine the cause of the incident, identify contributing factors, and implement corrective actions to prevent recurrence.

Regular training in fire safety procedures, including emergency response protocols, is essential for all hot work personnel.

Q 21. What is the purpose of a hot work risk assessment?

A hot work risk assessment is a systematic process to identify and evaluate potential hazards associated with hot work activities and to determine appropriate control measures to mitigate those risks. It’s like a pre-flight check for a complex operation. It helps avoid incidents by anticipating problems beforehand.

The purpose is to:

- Identify hazards: List all potential hazards related to the specific hot work, including fire, burns, explosions, falls, electrical shocks, and exposure to hazardous substances.

- Assess risks: Evaluate the likelihood and severity of each identified hazard, considering factors like the type of work, location, materials, and environmental conditions.

- Implement controls: Develop and implement control measures to eliminate or reduce the risks. These can include engineering controls (e.g., ventilation), administrative controls (e.g., permit-to-work systems, training), and PPE.

- Document findings: Record all aspects of the risk assessment, including the identified hazards, risk levels, control measures, and responsibilities. This documentation provides a crucial record for auditing purposes and helps improve future hot work safety procedures.

A well-conducted risk assessment is not a one-time event; it should be regularly reviewed and updated as conditions change.

Q 22. How do you ensure the safe storage and handling of flammable materials near hot work areas?

Safe storage and handling of flammable materials near hot work areas is paramount to preventing fires and explosions. Think of it like this: flammable materials are the fuel, and hot work is the ignition source. We need to minimize their interaction.

- Designated Storage Areas: Flammable materials should be stored in clearly marked, designated areas, ideally a significant distance from the hot work location. These areas must be well-ventilated and protected from ignition sources.

- Proper Containment: Flammable liquids should be kept in approved, sealed containers. Solids should be stored in a way that prevents accidental ignition or dispersal (e.g., in closed cabinets or covered containers).

- Material Safety Data Sheets (MSDS): We always consult MSDS for each flammable material to understand its specific hazards and appropriate handling procedures. This ensures we use the correct safety precautions.

- Fire Prevention Measures: This includes implementing things like fire extinguishers specifically suited to the flammable material’s class, fire-resistant barriers, and a readily available water supply. We also frequently inspect these to guarantee they are in perfect working order.

- Pre-Work Inspection: Before any hot work commences, a thorough inspection of the area is critical. This removes all unnecessary flammable materials to minimize risk. Imagine finding a discarded rag soaked in thinner – that’s a disaster waiting to happen.

For example, during a welding job near a paint storage area, we’d move the paints to a designated faraway location, creating a safe distance and using fire-resistant barriers for extra protection.

Q 23. What are the common causes of hot work accidents?

Hot work accidents stem from a combination of factors, often involving human error and inadequate safety precautions. Common causes include:

- Inadequate Pre-Work Inspection: Failing to identify and remove flammable materials from the hot work area is a major contributor. For example, not noticing a hidden gas line or a pile of combustible debris.

- Improper Equipment Usage: Incorrectly using or maintaining hot work equipment (e.g., welding torches, cutting equipment) can cause sparks, flames, or hot metal to ignite nearby materials.

- Lack of Fire Watch/Protection: Not having a properly trained fire watch present during and after hot work can lead to undetected ignition sources. The fire watch’s job is to monitor for any signs of fire or smoldering and take appropriate actions.

- Inadequate Ventilation: Poor ventilation can lead to the buildup of flammable gases or vapours, which can cause explosions or rapid fire spread.

- Ignoring Safety Procedures: Neglecting established safety protocols, like not obtaining permits, not using appropriate PPE (Personal Protective Equipment), or not having a fire suppression plan, significantly increases risk.

A classic example: A welder might inadvertently ignite nearby insulation material if they don’t properly clear the area and use fire-retardant covers. Always remember, prevention is key.

Q 24. Describe your experience with hot work in different environments (e.g., indoor, outdoor).

My experience encompasses hot work in diverse settings, and each environment presents unique challenges.

- Indoor Environments: Indoor hot work demands stringent fire safety protocols due to the confined spaces and the potential for rapid fire spread. Ventilation is crucial to avoid the buildup of fumes and gases. We prioritize fire-resistant barriers and have easily accessible fire suppression systems. A recent project involved welding inside a large factory; we had a detailed plan, including fire watch personnel, a dedicated fire extinguisher, and regular ventilation checks.

- Outdoor Environments: While outdoor hot work offers better ventilation, it introduces other risks, such as unpredictable weather conditions and the presence of flammable vegetation. We need to consider wind direction, potential for sparks to ignite dry grass or debris, and sun glare impacting visibility. I once worked on a pipeline repair job where we cleared a large area of vegetation, established a fire watch, and used ground covers to prevent any accidental ignition.

Adaptability is crucial; I’ve successfully completed hot work projects in both scenarios, always adapting my procedures and safety measures to the specific environment.

Q 25. What are the limitations of fire blankets in controlling hot work fires?

Fire blankets are a valuable first response tool for small hot work fires, but they have limitations.

- Limited Size and Coverage: Fire blankets are relatively small, which may not be adequate to cover large fires or rapidly spreading flames.

- Ineffective for certain types of fires: They are not effective against class B (flammable liquid) or class C (electrical) fires. The blanket could even become part of the problem by absorbing and spreading the liquid.

- Difficult to deploy effectively: Deploying a fire blanket quickly and effectively can be challenging during a stressful situation. This can be especially true for inexperienced personnel.

- Potential for re-ignition: Once the fire is extinguished, the heat may reignite the material under the blanket if the heat isn’t properly dissipated. The blanket only smothers the flame; it doesn’t cool the material.

Think of a fire blanket as a temporary measure – it’s better used to contain a small, nascent fire while waiting for more substantial fire suppression methods. It shouldn’t replace proper fire safety training or the availability of more robust equipment, such as fire extinguishers.

Q 26. How do you ensure that hot work is completed in accordance with company safety procedures?

Adherence to company safety procedures is non-negotiable. I ensure compliance through a systematic approach:

- Hot Work Permit System: Always obtaining a hot work permit before commencing any hot work. This permit documents all relevant safety precautions and ensures all necessary approvals are in place.

- Pre-Job Hazard Assessment: Conducting a thorough risk assessment of the hot work area, identifying potential hazards and developing control measures to mitigate risks.

- Equipment Inspection: Ensuring all hot work equipment is in good working order and properly maintained. This includes regular inspections and adherence to maintenance schedules.

- Fire Prevention Measures: Implementing appropriate fire prevention measures, such as providing fire extinguishers, fire-resistant blankets, and clearly marked evacuation routes.

- Post-Job Inspection: Performing a thorough inspection of the hot work area after completion to ensure the area is safe and no smoldering embers remain.

For instance, before commencing welding on a steel structure, I ensure we have a permit, the area is clear of flammables, the fire extinguishers are in place, and we have a fire watch in attendance. Documentation of every step is crucial for accountability and traceability.

Q 27. Describe your experience training others on hot work safety procedures.

I have extensive experience training personnel in hot work safety procedures. My approach is hands-on and focuses on practical application.

- Classroom Instruction: I deliver theory-based training covering relevant safety regulations, procedures, and potential hazards. I use real-life examples of accidents to underscore the importance of safety.

- Practical Demonstrations: I conduct practical demonstrations illustrating the proper use of hot work equipment and safety gear. This helps trainees develop the muscle memory for safe techniques.

- Hands-on Training: I provide supervised hands-on training, allowing trainees to practice their skills in a safe and controlled environment. This builds confidence and competence.

- Quizzes and Assessments: I regularly assess trainees’ understanding and skills through quizzes and practical evaluations to ensure they’ve grasped the concepts fully.

- Ongoing Feedback and Mentorship: I provide ongoing feedback and mentorship to support the continuous improvement of the trainees’ safety practices.

I once trained a group of new welders; starting with classroom instruction, we progressed to hands-on practice, with each trainee closely monitored and given specific feedback on their technique and adherence to safety protocols. Post-training assessments confirmed their competence before they were allowed to work independently.

Q 28. How do you keep up-to-date with changes in hot work safety regulations?

Staying current with changes in hot work safety regulations is essential. My methods include:

- Regulatory Updates: I regularly review updates to relevant safety standards, codes, and regulations from organizations like OSHA (Occupational Safety and Health Administration) and other industry-specific bodies.

- Professional Development: I actively participate in professional development courses and workshops to stay informed on best practices and emerging safety technologies.

- Industry Publications: I subscribe to industry publications and journals that cover hot work safety, keeping me abreast of current research and advancements.

- Networking: I network with other professionals in the field to exchange knowledge and best practices. Industry conferences are particularly helpful for this.

- Company Training Programs: I participate in any company-sponsored training programs on updated safety procedures or regulations.

For example, I recently attended a seminar on new fire suppression technologies. This knowledge allowed me to immediately incorporate those technologies into our risk assessments and safety procedures, thereby enhancing safety across our operations. Keeping abreast of the latest developments ensures we’re always operating with the best available safety standards.

Key Topics to Learn for Hot Work Techniques Interview

- Permitting and Authorization: Understanding the legal and regulatory frameworks surrounding hot work, including permit applications, hazard identification, and risk assessment procedures.

- Fire Prevention and Control: Practical application of fire prevention methods, including the use of fire extinguishers, fire blankets, and understanding fire spread dynamics in various environments.

- Hot Work Equipment and Safety: Safe operation and maintenance of welding equipment, cutting torches, and other hot work tools; familiarity with PPE requirements and their correct usage.

- Confined Space Hot Work: Specific safety considerations and procedures when performing hot work in confined spaces, including ventilation, gas detection, and emergency procedures.

- Pre-work Inspection and Planning: Thorough inspection of the work area to identify potential hazards, developing a detailed safety plan, and communicating effectively with other workers.

- Post-work Inspection and Cleanup: Ensuring the complete extinguishment of all ignition sources, proper disposal of waste materials, and documenting the completion of hot work activities.

- Emergency Response Procedures: Understanding emergency protocols for fire incidents, injuries, or equipment malfunctions, and knowing how to properly report and document such events.

- Hazard Communication and Training: Effective communication of hazards to co-workers, understanding the importance of ongoing training and competency assessments.

- Hot Work in Hazardous Environments: Adapting hot work techniques to different environments such as those with flammable materials, potentially explosive atmospheres, or high-risk areas.

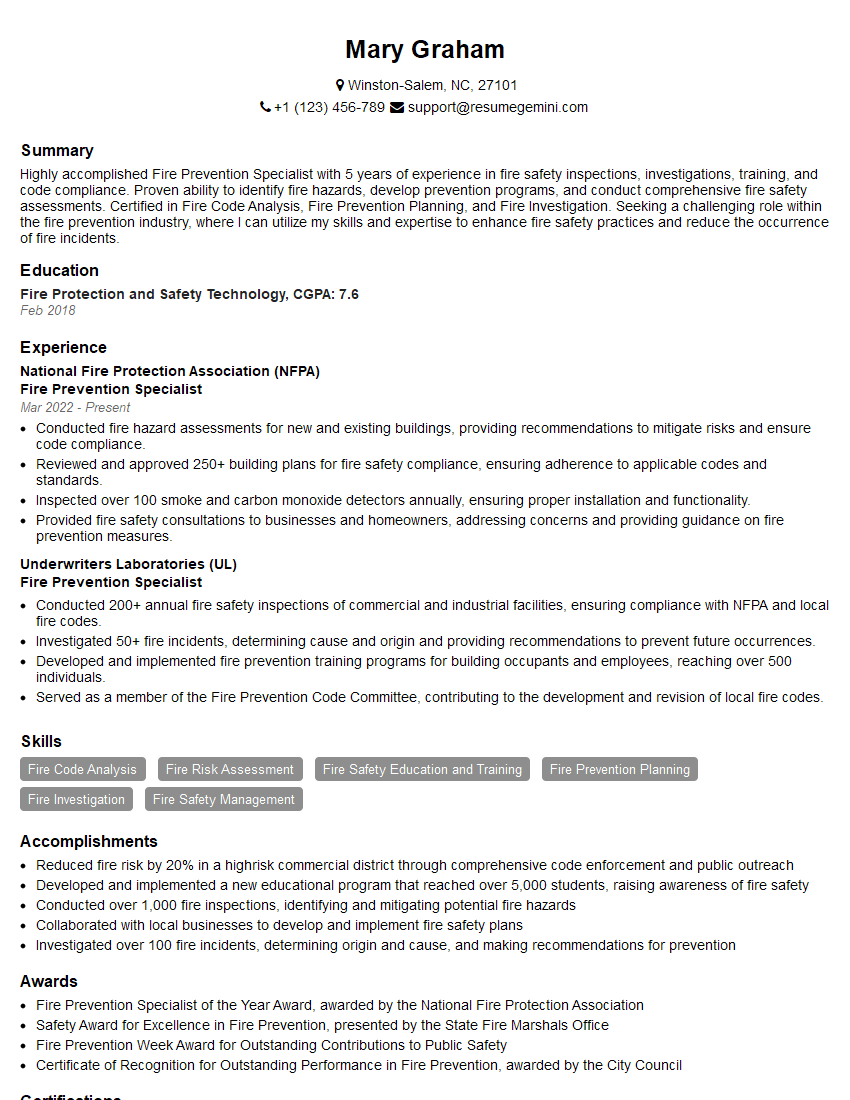

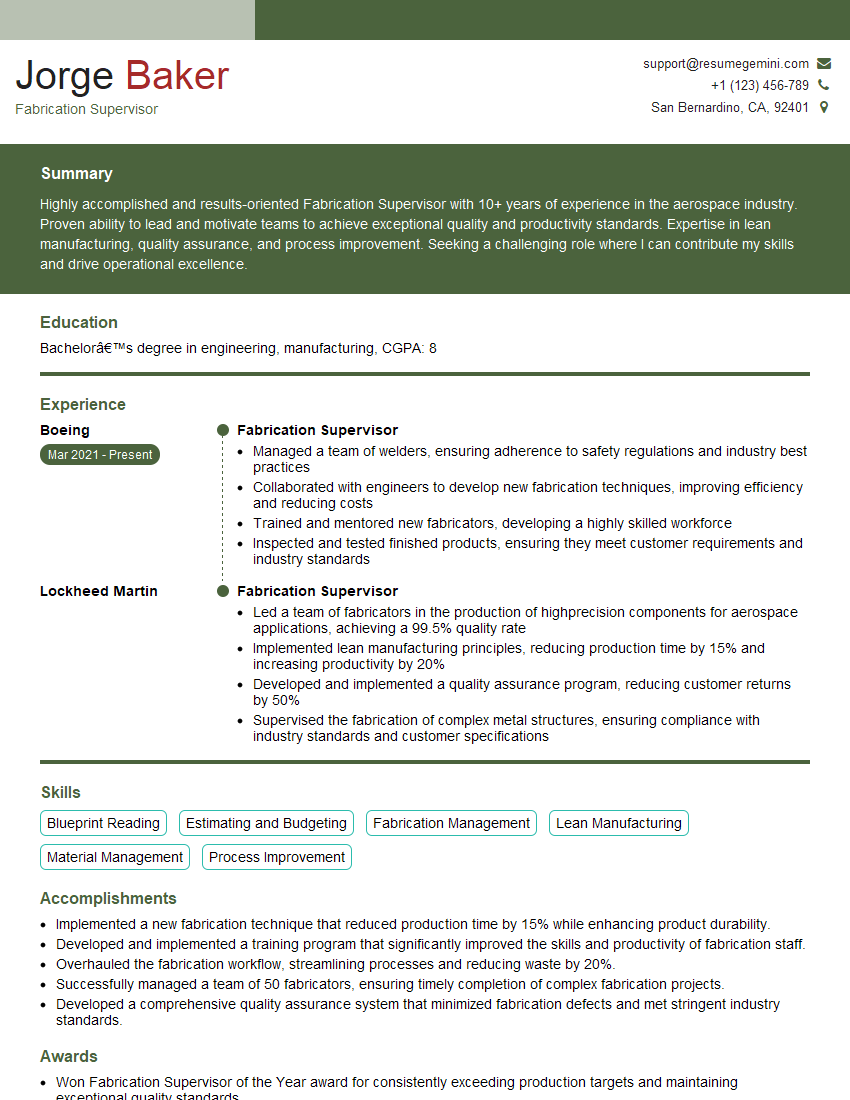

Next Steps

Mastering Hot Work Techniques demonstrates a commitment to safety and professionalism, significantly enhancing your career prospects in industries demanding rigorous safety standards. A strong resume is crucial for showcasing your skills and experience. Create an ATS-friendly resume that highlights your expertise in hot work safety and procedures to maximize your chances of landing your dream job. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Hot Work Techniques are available to guide you, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good