Unlock your full potential by mastering the most common Operating Dozers interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Operating Dozers Interview

Q 1. Describe your experience operating different types of dozers (e.g., crawler, wheel).

My experience encompasses operating both crawler and wheel dozers, each with its unique strengths. Crawler dozers, with their tracks, excel in challenging terrains like mud, steep slopes, and rough ground, providing superior traction and stability. I’ve extensively used them for tasks such as land clearing, road building, and heavy-duty earthmoving in challenging conditions. For instance, I successfully cleared a heavily wooded area using a D8 crawler dozer, navigating steep inclines and rocky patches with precision. Wheel dozers, on the other hand, are faster and more maneuverable on smoother surfaces like compacted earth or gravel roads. Their speed and agility make them ideal for finish grading and lighter earthmoving applications. I’ve utilized wheel dozers in projects involving road maintenance and site preparation where speed and efficiency were paramount. The difference is analogous to choosing between a four-wheel drive vehicle for off-roading and a sports car for paved roads.

Q 2. Explain the process of pre-operational checks for a dozer.

Pre-operational checks are crucial for safe and efficient dozer operation. My routine involves a systematic approach, starting with a visual inspection of the entire machine. I check for any visible damage, leaks, or loose components. Then, I verify fluid levels – engine oil, hydraulic fluid, coolant, and fuel. Next, I test all controls – steering, blade controls, and throttle – to ensure smooth and responsive operation. I also inspect the tracks or tires for wear and tear, checking for proper inflation in wheel dozers. Testing the brakes is paramount; ensuring they engage and release correctly prevents accidents. Finally, I always check the condition of the blade itself, looking for any cracks or damage that could affect its performance or safety. This thorough check-list prevents unexpected breakdowns and ensures the machine’s readiness for the task at hand. It’s like a pilot’s pre-flight checklist, crucial for a safe and successful operation.

Q 3. How do you ensure safe operation of a dozer in various terrains?

Safe dozer operation across various terrains requires adapting techniques and adhering to safety protocols. On steep slopes, I maintain a low center of gravity, avoid sudden movements, and always work uphill whenever possible. In soft or muddy conditions, I use a lower gear to maintain traction, avoiding spinning tracks or tires. I adjust my speed to match the terrain conditions – slower on uneven ground and faster on stable surfaces. Before operating in any unfamiliar terrain, I conduct a thorough site assessment to identify potential hazards. I also pay attention to weather conditions, adjusting operations accordingly for factors like rain or snow, which can significantly impact traction and visibility. I always prioritize safety by maintaining a safe distance from edges, obstacles, and other equipment or personnel. My approach ensures efficiency while mitigating risks, much like a cautious driver adjusts their speed and driving style based on road conditions.

Q 4. What are the common causes of dozer blade malfunctions and how do you troubleshoot them?

Common dozer blade malfunctions often stem from hydraulic issues, wear and tear, or impact damage. Hydraulic leaks, for instance, can be identified through visible fluid loss or reduced blade responsiveness. Troubleshooting involves checking hydraulic lines, cylinders, and seals for damage or leaks. Wear and tear, particularly on cutting edges, often necessitates replacement or sharpening to maintain optimal performance. I identify this through visual inspection or by noticing reduced cutting efficiency. Impact damage, such as hitting rocks, can bend or break the blade or its supporting structure; requiring careful inspection and often welding or replacement. Diagnosing these problems is methodical; I inspect visually, check hydraulic pressure, and listen for unusual noises to pinpoint the exact cause of the malfunction. It’s like diagnosing a car problem – you need to systematically check various components to identify the root cause.

Q 5. Describe your experience with GPS-guided dozer operation.

I have considerable experience with GPS-guided dozer operation. This technology significantly enhances accuracy and efficiency in grading and earthmoving. GPS systems provide real-time guidance, allowing me to achieve precise grading to pre-determined specifications. I’ve used these systems for large-scale projects involving road construction and land leveling, where maintaining precise elevations and slopes is critical. The system provides visual guidance on a screen, indicating the desired grade and the dozer’s current position. This is particularly useful in large, complex projects that require consistent accuracy, often reducing rework and material waste. It’s like having a very precise and accurate virtual surveyor guiding your every move. This technology drastically improves the efficiency and accuracy compared to traditional methods.

Q 6. How do you maintain accurate grading and leveling using a dozer?

Maintaining accurate grading and leveling involves careful blade control, understanding the soil conditions, and using the appropriate techniques. I begin by establishing a benchmark or reference point, often using survey markers or existing grades. I use the dozer’s blade to progressively move and shape the earth, constantly checking against the desired grade using either visual cues or electronic grade control systems. Smooth and precise blade movements are crucial; avoiding abrupt actions that could lead to uneven grading. I adjust the blade angle and tilt to achieve the desired slope or level. Soil type plays a significant role – compacted soil needs more passes than loose soil. Experience helps in anticipating how the soil will react to the blade, enabling efficient and precise work. This process is akin to sculpting; carefully shaping and refining the earth until the desired result is achieved.

Q 7. What safety procedures do you follow when working near other equipment or personnel?

Safety is paramount when working near other equipment or personnel. I always maintain a safe distance – typically, at least 50 feet, and more depending on the operation – from other equipment and ensure clear communication with other operators. Before commencing any task, I conduct a thorough site assessment, identifying potential hazards and establishing clear communication protocols with colleagues. I use visual signals and hand signals to communicate with colleagues and operators of other equipment, and only operate the dozer when visibility is adequate. I also ensure that the area is free of any personnel before beginning work, and only allow authorized personnel into the working area. This approach, prioritizing communication and maintaining a safe distance, prevents accidents and ensures a safe work environment for everyone on the site.

Q 8. Explain the difference between different types of dozer blades (e.g., straight, U-blade).

Dozer blades come in various shapes, each optimized for specific tasks. The most common types are straight blades, U-blades, and S-blades. A straight blade is best for precise grading and pushing large amounts of material over short distances. Think of it like a flat shovel – efficient for moving a lot in one go. A U-blade, shaped like a U, is excellent for material spreading and fine grading, as the curved shape helps to distribute material more evenly. Imagine it as a wide, shallow scoop, ideal for leveling. Finally, an S-blade combines features of both; its angled design helps with both pushing and spreading, offering a balance between precision and volume.

The choice of blade depends entirely on the job. For example, on a large-scale earthmoving project requiring significant material relocation, a straight blade would be the go-to. However, for landscaping work that demands finer control over grading, a U-blade would be preferred. An S-blade becomes useful when you need a balance of both capabilities on a single project.

Q 9. How do you adjust the dozer blade for different tasks (e.g., pushing, spreading)?

Adjusting the dozer blade involves manipulating its tilt and pitch. Tilt refers to the sideways angle of the blade, and pitch refers to its angle from the ground. These adjustments are controlled from the operator’s cab using hydraulic levers. For pushing, you’d usually use a relatively flat blade position with minimal tilt to maximize pushing force. For spreading, you’d tilt the blade slightly to one side to begin moving the material, then gradually adjust the pitch to raise and lower the blade for even distribution. It’s like using a giant, controlled snowplow – a small adjustment in angle makes a big difference in the result.

Think of it like baking a cake: The recipe (the task) dictates your ingredients (blade settings). If you’re pushing a large pile of dirt (a large, heavy ingredient), you’d use a low, flat blade (gentle stirring). If you’re spreading topsoil (a delicate ingredient), you’d use a tilted, slightly raised blade (gentle folding).

Q 10. How do you handle challenging terrain conditions (e.g., rocky, muddy)?

Challenging terrain requires careful and adaptable operation. On rocky terrain, you’d operate at a slower speed and carefully select your path to avoid damaging the blade or tracks. It’s crucial to maintain momentum and avoid sudden stops or starts to prevent getting stuck. I might choose to use a ripper attachment (if equipped) to break up the larger rocks before pushing. Muddy terrain is a different challenge – traction is key. Reducing speed and using the blade strategically can help maintain stability and avoid getting bogged down. Understanding the dozer’s limitations is paramount, and adjusting the working methods according to the situation prevents costly delays and accidents.

Imagine navigating a muddy field in a car versus a tank. In a car, you must be careful; one wrong move, and you get stuck. The dozer, like a tank, offers more power, but still requires awareness. The key is adjusting your driving strategy to match the current terrain.

Q 11. What is your experience with different types of dozer tracks or tires?

My experience encompasses various track and tire types commonly used in dozers. Steel tracks offer superior traction and durability in harsh conditions, especially rocky or muddy terrain, but they require more maintenance. Rubber tracks provide a quieter and more comfortable operation, and less ground disturbance, but they are less durable and not suited for all terrains. Tires are typically used on smaller dozers working on more developed surfaces, offering good maneuverability but limited traction in tough conditions. The selection of tracks or tires fundamentally impacts a dozer’s performance. Choosing the right one significantly reduces downtime and increases operational efficiency.

It’s like choosing the right shoes for a marathon – steel tracks are like durable hiking boots, ideal for rough terrain, while rubber tracks are like running shoes, better for smoother paths. Tires are more like dress shoes – fine for paved surfaces but not for trails.

Q 12. How do you calculate the amount of material required for a grading project?

Calculating material requirements for grading involves several steps. First, you need accurate measurements of the area to be graded – this often involves surveying and using software or formulas to calculate volumes. Next, you need to determine the depth of cut or fill required. Finally, you need to account for material compaction – soil compresses after being moved, so you must factor in a compaction factor to compensate for the volume reduction. You’ll use these values in simple volume calculations, like Volume = Length * Width * Depth, but remember to always consider the compaction factor, which can be different for different types of soil.

It’s similar to baking a lasagna; you need to know the size of the baking pan (area), the amount of each layer you want (depth of cut/fill), and account for how much each ingredient shrinks during baking (compaction). Get any one of these wrong, and the final result is off.

Q 13. Describe your experience with dozer maintenance and repairs.

Dozer maintenance is crucial for optimal performance and safety. My experience includes regular checks of fluid levels (engine oil, hydraulic fluid, coolant), track tension, and blade condition. I am proficient in identifying and resolving minor issues like worn track pads or hydraulic leaks, and I understand the importance of preventative maintenance – things like greasing pivot points and checking for wear on the undercarriage. For more serious repairs, I work collaboratively with mechanics, ensuring that the repairs are carried out correctly and efficiently.

It’s like regular car maintenance – ignoring it leads to bigger issues later. Regular checks save money and downtime in the long run and ensure the safety of the operator and the machine.

Q 14. What are your skills in operating dozer attachments (e.g., rippers, winches)?

I’m experienced in operating various dozer attachments, including rippers and winches. Rippers are used to loosen hard or rocky ground, significantly improving the efficiency of earthmoving. I know how to adjust the ripper’s depth and angle to optimize its effectiveness, based on the type and firmness of the ground. Winches are invaluable for pulling heavy loads or extracting the machine if it gets stuck. I understand proper winching techniques, including anchoring points and safe operation procedures. The ability to handle these attachments proficiently greatly expands the machine’s capabilities and reduces reliance on additional equipment.

Think of it as upgrading your toolbox. The ripper is a power drill, essential for tougher tasks, while the winch is a heavy-duty tow strap, indispensable when things get tricky.

Q 15. How do you determine the appropriate speed and power for different tasks?

Selecting the right speed and power for a dozer task is crucial for efficiency and safety. It’s like choosing the right gear in a car – too low and you’ll strain the engine; too high and you’ll lose control. I assess the task, considering factors like the soil type, the blade’s load, and the desired grade.

- Soil Type: Hardpan requires more power and a lower gear than loose sand. I’ll adjust the engine throttle and transmission accordingly, ensuring sufficient power without overworking the machine.

- Blade Load: A full blade necessitates a lower gear and slower speed for controlled movement. Conversely, a lighter load allows for higher speeds and potentially a higher gear.

- Desired Grade: Steeper grades demand lower speeds and careful maneuvering to prevent slippage or rollover. I’ll use the blade to maintain control and stability.

For example, when pushing a large volume of compacted clay, I’ll use a lower gear and a moderate speed to ensure the blade maintains a good bite and avoids overloading the engine. In contrast, when lightly spreading topsoil, a higher speed and a lighter touch on the controls are suitable.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with various dozer controls and their functions?

I’m proficient with various dozer controls, including the blade controls (lift, tilt, and angle), the steering levers, the transmission (forward/reverse and gear selection), the throttle, and the differential lock. Understanding their interplay is essential.

- Blade Controls: These allow precise manipulation of the blade for tasks like cutting, pushing, and spreading. Smooth, controlled movements are key here.

- Steering Levers: These steer the dozer, offering both precise maneuvering and rapid response. I’m adept at using differential steering to achieve tight turns and accurate placement of the blade.

- Transmission: Correct gear selection is vital for efficiency and power. I’ll match the gear to the load and terrain conditions.

- Throttle: Precise throttle control is paramount for maintaining a balance between power and fuel efficiency. I know how to modulate the throttle to match the task demands.

- Differential Lock: This feature provides added traction in difficult conditions, like mud or snow. I know when to engage it and when it’s not necessary.

For instance, I use differential steering to make accurate cuts while maintaining a consistent depth. The ability to smoothly transition between gears, coupled with precise throttle control, contributes to both productivity and safety.

Q 17. Describe your experience with site planning and surveying for dozer operations.

Site planning and surveying are crucial for efficient dozer operation. Before starting any job, I review the site plan, identifying key areas like cut lines, fill areas, and potential obstacles. I often use surveying equipment (or the site survey data) to understand the existing grades and plan the most efficient cutting and filling strategy.

- Understanding the Site Plan: I’ll study the plan to identify the optimal route for the dozer, minimizing the number of turns and maximizing efficiency.

- Grade Considerations: Slope stability, sightlines, and potential drainage issues are considered. This prevents errors and safety hazards.

- Obstacle Identification: Identifying buried utilities, rocks, or other obstacles is critical to prevent damage to the dozer or the site. This often involves coordinating with surveyors or other personnel.

For example, on a recent project involving road construction, I used survey data to determine the precise cut and fill required to achieve the desired grade. This approach ensured accurate leveling and minimized wasted effort and material.

Q 18. How do you communicate effectively with other crew members during dozer operations?

Clear and effective communication is vital for safety and efficiency. On the job site, I use a combination of hand signals, radio communication, and direct verbal communication.

- Hand Signals: Standard hand signals are used to communicate intentions and potential hazards, especially in noisy environments where radio communication may be ineffective.

- Radio Communication: I use the radio to coordinate with other equipment operators, ensuring safe distances are maintained and work flows smoothly. Clear, concise messages are key.

- Direct Verbal Communication: When close enough, direct verbal communication is used for quick adjustments or clarifications.

For instance, before starting a pass, I’ll use the radio to let others know my planned route and to confirm that the area is clear. If I encounter an unexpected obstacle, I’ll immediately inform the team using the most appropriate communication method.

Q 19. What are your methods for optimizing fuel efficiency while operating a dozer?

Optimizing fuel efficiency is both environmentally responsible and cost-effective. My methods include:

- Smooth Operation: Avoiding sudden accelerations and decelerations saves fuel and reduces wear and tear on the machine. Gentle control inputs are essential.

- Proper Gear Selection: Using the correct gear for the task prevents engine lugging (which wastes fuel) and allows the engine to operate in its most efficient range.

- Load Management: Avoiding overloading the blade reduces the strain on the engine and improves fuel efficiency. It’s better to make multiple passes with a lighter load than one pass with an overloaded blade.

- Regular Maintenance: Regular maintenance, including air filter changes and engine tune-ups, ensures the engine operates at peak efficiency.

For example, on a long haul, I’ll plan my route to minimize unnecessary maneuvers. This involves choosing the most efficient path, even if it means a slightly longer distance.

Q 20. How do you prevent dozer damage and ensure its longevity?

Preventing dozer damage and ensuring its longevity involves proactive measures and responsible operation.

- Pre-Operational Checks: Thorough pre-operational checks are essential. This includes inspecting fluid levels, checking tire pressure, ensuring the blade is properly attached, and assessing for any damage.

- Careful Operation: Operating the dozer within its capabilities, avoiding overloading, and being mindful of the terrain are crucial for minimizing wear and tear.

- Regular Maintenance: Scheduled maintenance is key, this includes replacing fluids, inspecting wear parts, and addressing any issues promptly.

- Proper Storage: Storing the dozer properly, out of harsh weather elements, contributes to longer life. Regular cleaning also helps.

For example, I always check the blade’s condition before starting work and report any cracks or damage to my supervisor immediately. This prevents a small problem from becoming a major repair.

Q 21. What is your approach to problem-solving when operating a dozer faces issues?

My problem-solving approach involves a systematic process:

- Identify the Problem: First, I accurately identify the issue. Is it a mechanical problem, an operational issue, or something else?

- Assess the Situation: I carefully assess the situation to understand the scope and potential consequences of the problem.

- Attempt Solutions: I try simple solutions first. If a blade is stuck, I might try adjusting the blade angle or backing up slightly.

- Seek Assistance: If simple solutions don’t work, I seek assistance from mechanics or supervisors.

- Document Findings: I always document the problem, the troubleshooting steps, and the solution, so future similar issues can be addressed efficiently.

For example, if the dozer engine overheats, I’ll first check the coolant levels. If that doesn’t resolve the issue, I’ll radio for assistance from a mechanic. I’ll then document everything in the machine’s logbook, including the cause, the actions taken, and the resolution.

Q 22. What safety precautions do you take when working in confined spaces?

Confined space entry in dozer operations is rare, but if ever necessary (e.g., inspecting a component under a machine), a strict protocol must be followed. Safety starts with permit-to-work systems. This means a detailed risk assessment is performed, identifying potential hazards like oxygen deficiency, toxic gases, or entrapment. Then, appropriate personal protective equipment (PPE) is selected, which might include a respirator, harness, and safety lines.

Before entry, atmospheric monitoring is crucial to ensure the air is safe to breathe. We’d use gas detectors to check for potentially hazardous gases. A second person must be present as an attendant, ready to assist or call for emergency services. Communication is key; we use two-way radios to stay in contact. After completing the work, a thorough inspection is conducted before exiting to ensure that nothing has been left behind which could represent a hazard. The whole process is meticulously documented.

Q 23. How do you manage potential risks associated with dozer operation?

Managing risks in dozer operation is paramount. It’s a multifaceted approach. First, pre-operational checks are non-negotiable; I inspect the dozer thoroughly, checking fluids, brakes, lights, and the blade’s condition. This prevents mechanical failures. Second, I carefully assess the worksite. This includes identifying potential obstacles (trees, rocks, underground utilities), unstable ground, and weather conditions. Proper planning is crucial; I’ll adjust my operating speed and technique based on the terrain.

Third, communication is key. I maintain clear communication with spotters or other personnel to avoid collisions. Finally, I am always conscious of the dozer’s limitations. I never push the machine beyond its capabilities and I’m acutely aware of the blind spots around the machine. A near miss is a learning opportunity; I’ll analyze what happened and adjust my approach to prevent similar situations in the future. For instance, if I had a close call with a low-hanging branch, I would modify my route and become more cautious of similar obstacles.

Q 24. What is your understanding of relevant regulations and safety standards?

My understanding of regulations and safety standards is comprehensive. I’m familiar with OSHA (Occupational Safety and Health Administration) guidelines for heavy equipment operation, along with any relevant state or local regulations. These include standards for PPE use, confined space entry, fall protection, and hazard communication. I am also knowledgeable about the manufacturer’s guidelines for specific dozer models. Continuous training and staying updated on best practices are key to safe operations. For example, I’m aware of the importance of regular operator training to update knowledge on machine capabilities, safety procedures and emergency protocols.

Q 25. Describe your experience with completing daily reports or logs for dozer operation.

I have extensive experience completing daily reports and logs. These records are essential for maintaining a safe and efficient operation and providing a valuable audit trail. Typically, I document the hours of operation, the type of work performed, any maintenance conducted, fuel consumption, any incidents (near misses or accidents), and the general condition of the dozer. This information is critical for scheduling maintenance, managing costs, and identifying potential issues before they become major problems. I make sure my reports are accurate, concise, and easy to read, using a standardized format provided by the company.

Q 26. How do you identify and report potential hazards or malfunctions?

Identifying and reporting potential hazards or malfunctions is a critical part of my job. I regularly conduct inspections for wear and tear, fluid leaks, unusual sounds or vibrations, or any other signs of malfunction. If I notice anything amiss, I immediately stop the dozer and report the issue through the proper channels, typically using a formal reporting system. This could involve filling out a maintenance request form or notifying my supervisor immediately depending on the severity of the problem. For example, if I notice a significant fluid leak, I wouldn’t hesitate to stop work and alert my supervisor.

Q 27. What are your strengths and weaknesses as a dozer operator?

My strengths as a dozer operator include a high level of skill and precision, the ability to work efficiently and safely under pressure, and excellent problem-solving skills. I am also a strong team player and capable of adapting to various worksite conditions. I am proactive in maintaining my equipment and adhere strictly to safety regulations. A weakness I’ve recognized is my perfectionism which, at times, can slow my work down. I’m actively working on balancing thoroughness with efficiency by prioritizing tasks and better time management.

Q 28. Why are you interested in this dozer operator position?

I’m interested in this dozer operator position because it aligns perfectly with my skills and experience. I enjoy the challenges and rewards of operating heavy machinery. I’m seeking a role in a company that values safety and professionalism. Your company has a strong reputation in the industry and offers opportunities for career advancement which excites me. I’m confident that my experience, dedication to safety, and strong work ethic would make me a valuable asset to your team.

Key Topics to Learn for Operating Dozers Interview

- Dozer Mechanics and Operation: Understanding the internal workings of a dozer, including the engine, transmission, blade, and undercarriage. This includes preventative maintenance knowledge.

- Safe Operating Procedures: Mastering pre-operational checks, safe operating techniques, and emergency procedures. This includes awareness of site hazards and environmental considerations.

- Grading and Earthmoving Techniques: Developing proficiency in various grading methods, understanding blade angles and their impact on material movement, and efficient techniques for different soil types.

- GPS and Machine Control Systems: Familiarity with utilizing GPS and other machine control technologies to increase accuracy and efficiency in earthmoving operations. Understanding the principles behind these systems is key.

- Troubleshooting and Maintenance: Developing the ability to identify and diagnose common dozer malfunctions, perform basic maintenance tasks, and understand when to seek professional assistance.

- Regulations and Safety Compliance: Understanding relevant safety regulations, environmental protection guidelines, and reporting procedures for operating heavy machinery.

- Production and Efficiency: Knowing how to optimize dozer operations for maximum productivity while maintaining safety standards. This includes understanding factors that influence production rates.

Next Steps

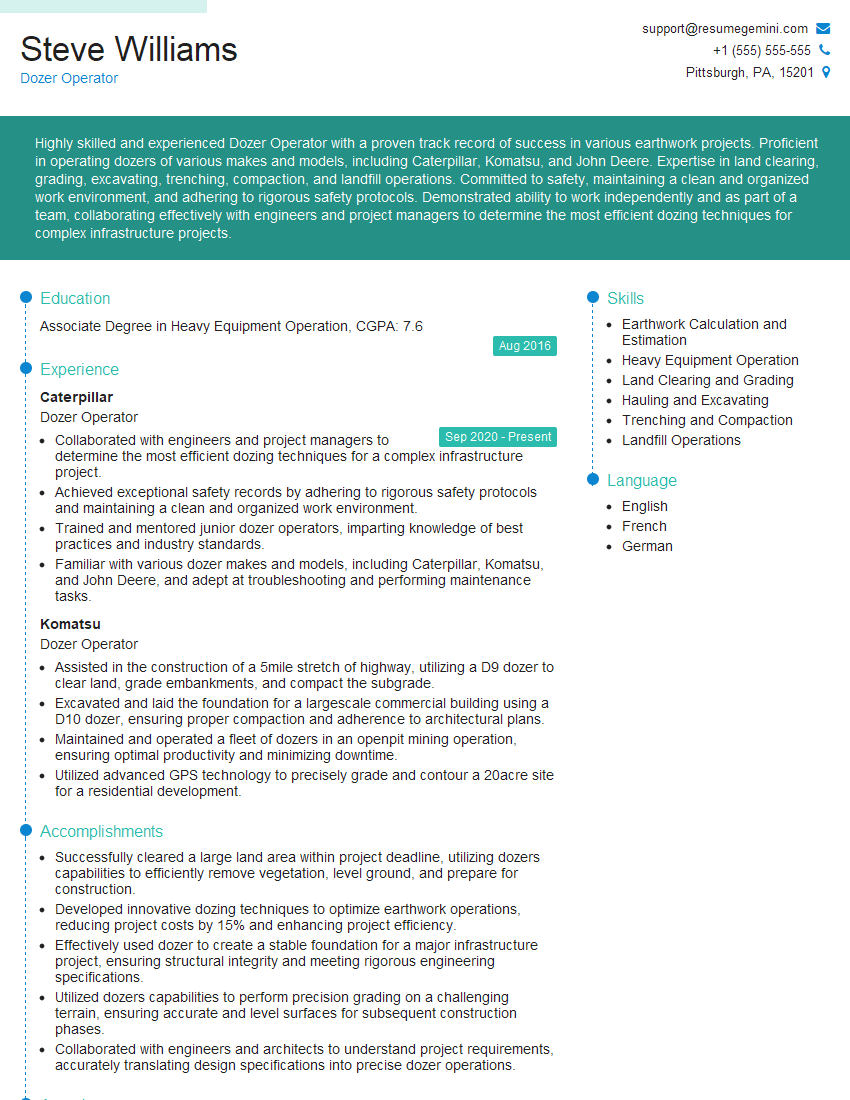

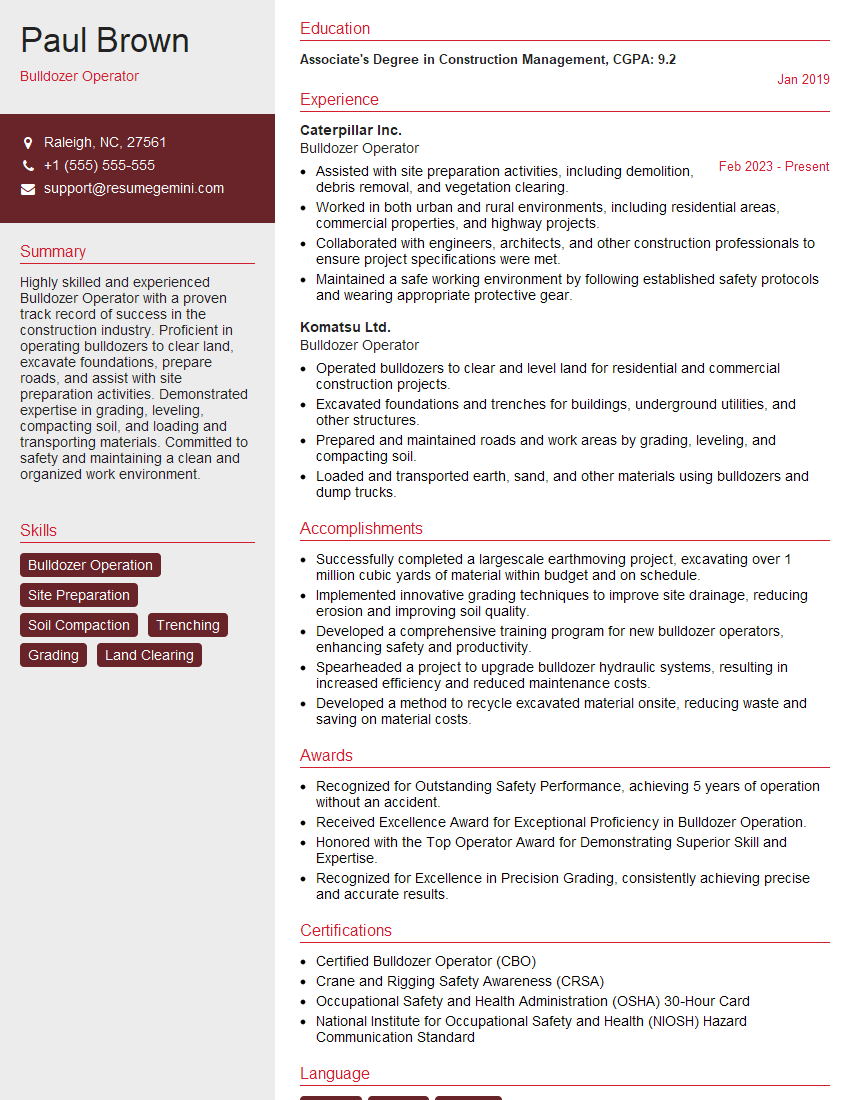

Mastering the operation of dozers opens doors to a rewarding career with excellent earning potential and opportunities for advancement within the construction and earthmoving industries. A strong resume is crucial for showcasing your skills and experience to potential employers. To maximize your chances, create an ATS-friendly resume that highlights your key accomplishments and qualifications. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to the specific demands of the Operating Dozers field. Examples of resumes optimized for Operating Dozers positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).