Unlock your full potential by mastering the most common Mold Changeovers interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Mold Changeovers Interview

Q 1. What are the key steps involved in a typical mold changeover process?

A typical mold changeover involves a series of carefully orchestrated steps to ensure efficiency and safety. Think of it like a well-choreographed dance where each move has a purpose. It’s not just about swapping molds; it’s about minimizing downtime and maximizing productivity.

- Preparation: This includes reviewing the changeover plan, gathering necessary tools and materials, and ensuring the machine is safely shut down and properly isolated (lockout/tagout procedures).

- Mold Removal: Carefully removing the existing mold, often using specialized equipment like cranes or hoists, paying close attention to protecting the mold and surrounding machinery from damage.

- Machine Cleaning: Thoroughly cleaning the injection molding machine’s clamping unit, nozzle, and sprue area, removing any residual plastic or debris from the previous run. This prevents contamination of the new mold and ensures optimal performance.

- Mold Installation: Precisely installing the new mold, ensuring proper alignment and connection of water lines, heaters, and ejector pins. This requires attention to detail and adherence to manufacturer’s specifications.

- Testing and Adjustments: This crucial stage involves running a few test shots to check for proper part ejection, filling, and overall quality. Adjustments to machine parameters (injection pressure, speed, temperature) might be necessary.

- Production Run: Once the test shots are satisfactory, the full production run begins, ensuring consistent quality and productivity.

Q 2. How do you minimize downtime during a mold changeover?

Minimizing downtime during a mold changeover is paramount for maintaining productivity and profitability. It’s about optimizing every second! We achieve this through a multi-pronged approach.

- Pre-planned Changeovers: Thorough planning, including a detailed checklist and pre-staging of tools and materials, reduces on-the-spot decision-making and delays. We utilize a system called ‘Single Minute Exchange of Die’ (SMED) which focuses on separating internal and external setup activities to minimize downtime.

- Ergonomic Design: Workstations and tool layouts are designed for optimal workflow and easy access to parts. Think of a well-organized kitchen; everything is within easy reach.

- Automation: Automating tasks such as mold clamping, ejection systems, and material handling significantly reduces manual labor and time.

- Quick-Change Systems: Utilizing molds and machines designed for rapid changeovers, such as hydraulic systems and automated clamping mechanisms, speeds up the process significantly.

- Training and Skill Development: Highly trained operators are capable of performing changeovers quickly and efficiently. Regular training and simulations maintain efficiency and improve reaction times to unexpected events.

Q 3. Describe your experience with different types of mold changeover systems.

My experience encompasses a variety of mold changeover systems, from simple manual systems to highly automated robotic systems. Each system presents its own set of challenges and benefits.

- Manual Changeovers: These are commonly found in smaller operations with less frequent changeovers. While straightforward, they are time-consuming and reliant on operator skill.

- Semi-Automated Changeovers: These systems incorporate elements of automation, such as automated clamping and ejection, which reduce manual effort and downtime.

- Fully Automated Changeovers: These advanced systems utilize robotics and sophisticated control systems, significantly reducing downtime and human intervention. They often require substantial upfront investment but yield high returns in terms of efficiency and consistency. I’ve worked extensively with such systems in high-volume manufacturing environments.

For instance, I once oversaw the transition of a facility from a manual to a semi-automated system. This required careful planning, employee training, and process optimization. The outcome was a significant reduction in downtime and a boost in overall productivity.

Q 4. How do you ensure the safety of personnel during a mold changeover?

Safety is paramount during any mold changeover. We adhere to strict safety protocols to prevent accidents and injuries.

- Lockout/Tagout Procedures: Before any work begins, we ensure that the injection molding machine is completely shut down and locked out to prevent accidental starts.

- Personal Protective Equipment (PPE): All personnel involved wear appropriate PPE, including safety glasses, gloves, steel-toe boots, and hearing protection.

- Proper Lifting Techniques: To prevent injuries, we utilize proper lifting techniques and equipment, such as cranes or hoists, for handling heavy molds.

- Training and Communication: Regular safety training is provided to all personnel involved, emphasizing safe work practices and emergency procedures. Clear communication is vital to prevent mishaps.

- Risk Assessment: A thorough risk assessment is conducted before each changeover to identify potential hazards and implement preventative measures.

We treat safety not as an afterthought but as an integral part of the entire process. It’s not just about following regulations; it’s about creating a culture of safety where everyone feels responsible for their own well-being and the well-being of their colleagues.

Q 5. What are some common problems encountered during mold changeovers and how do you troubleshoot them?

Common problems during mold changeovers range from simple to complex. Troubleshooting requires systematic approaches.

- Mold Misalignment: This leads to improper part ejection or quality issues. Troubleshooting involves carefully checking alignment and making adjustments.

- Hydraulic or Pneumatic Leaks: These can cause delays and safety concerns. We diagnose the leaks and repair or replace components.

- Ejector Pin Problems: Broken or improperly adjusted ejector pins result in parts sticking or being damaged. We check and replace or repair these pins.

- Temperature Control Issues: Incorrect temperatures can affect part quality. We adjust temperature controllers and check for heating element problems.

- Material Related Issues: Issues with material flow and quality can impact the molding process. This requires investigation of material properties and feeding system.

My troubleshooting approach is systematic. I start with a thorough visual inspection and then use diagnostic tools to pinpoint the issue. I follow a structured process, documenting every step, and involve other team members when necessary. A methodical approach is key.

Q 6. Explain your experience with preventative maintenance to reduce mold changeover issues.

Preventative maintenance is key to reducing mold changeover issues and maximizing uptime. We treat it as an investment, not an expense.

- Regular Mold Inspections: We regularly inspect molds for wear and tear, identifying potential problems before they become major issues. This includes checking for cracks, corrosion, and damage to ejector pins.

- Scheduled Maintenance on Machines: Injection molding machines require routine maintenance, including lubrication, cleaning, and part replacements. This prevents breakdowns and prolongs machine life.

- Calibration of Sensors and Controllers: Ensuring that sensors and controllers are accurately calibrated prevents quality issues and malfunctions. Regular calibration reduces the need for adjustments during mold changeovers.

- Cleaning and Lubrication of Mold Components: Regular cleaning and lubrication of the mold components reduces friction, prevents wear and tear, and ensures smooth operation.

- Spare Parts Inventory: Maintaining an inventory of common spare parts minimizes downtime when replacements are needed during changeovers.

For example, by implementing a preventative maintenance program, we reduced mold changeover downtime by 15% in one of our facilities. This led to a significant increase in production and a positive impact on our bottom line. Preventative maintenance is a proactive approach that pays for itself over time.

Q 7. How do you document and track mold changeover procedures?

Documentation and tracking of mold changeover procedures are critical for maintaining consistency, improving efficiency, and troubleshooting problems. We use a combination of methods.

- Detailed Changeover Plans: These include step-by-step instructions, diagrams, and checklists for each mold. These plans are easily accessible to operators.

- Digital Records: We store all changeover documentation electronically. This makes it easy to access and share information, track performance metrics, and identify areas for improvement. We use a computerized maintenance management system (CMMS).

- Data Logging: We collect data on changeover times, downtime, and reasons for delays. This data is used to identify bottlenecks and opportunities for improvement.

- Operator Feedback: We encourage operators to provide feedback on the changeover process, identify challenges, and suggest improvements.

- Regular Audits: We conduct regular audits to ensure that changeover procedures are followed and that the documentation is accurate and up-to-date.

Our systematic approach ensures that every changeover is documented meticulously, providing a valuable resource for continuous improvement and training.

Q 8. How do you ensure the quality of parts produced after a mold changeover?

Ensuring part quality after a mold changeover is paramount. It’s a multi-step process that begins even before the changeover itself. We start by meticulously inspecting the new mold for any damage or defects. This includes checking for proper gate placement, ensuring consistent cavity dimensions, and verifying the ejection system’s functionality. Next, we perform a trial run, producing a small sample batch of parts. These parts are then subjected to rigorous quality control checks, including dimensional measurements, visual inspections for imperfections (like flash or sink marks), and sometimes even destructive testing depending on the part’s criticality. We use statistical process control (SPC) charts to monitor key characteristics throughout the production run, ensuring they remain within acceptable limits. Any deviations trigger an immediate investigation and corrective actions, preventing the production of non-conforming parts.

For example, if we’re changing molds for a plastic bottle cap, we’d closely examine the cap’s height, diameter, thread pitch, and sealing surface for any inconsistencies. Failure to meet these specifications could compromise the cap’s functionality, leading to significant quality issues. We document all inspection and testing results for traceability and continuous improvement.

Q 9. What are the key performance indicators (KPIs) you monitor for mold changeover efficiency?

Key Performance Indicators (KPIs) for mold changeover efficiency are critical for optimizing our processes. We focus on several key metrics:

- Changeover Time: This measures the total time taken from the moment the old mold is removed to when the new mold is producing acceptable parts. Reducing this time is a primary goal. We track this down to the minute.

- Downtime: The time the injection molding machine is idle during the changeover. Minimizing downtime directly impacts production output and profitability.

- Number of Defective Parts: After the changeover, a high number of defective parts indicates a problem with the setup, mold condition, or process parameters. We aim for zero defects.

- Scrap Rate: The percentage of parts rejected due to defects. This KPI directly impacts cost efficiency.

- Mean Time Between Failures (MTBF): For the new mold, this reflects its reliability and helps predict potential future downtime.

By tracking these KPIs, we can identify bottlenecks, pinpoint areas for improvement, and continuously optimize our changeover procedures.

Q 10. Describe your experience using various tools and equipment during mold changeovers.

My experience with tools and equipment involved in mold changeovers is extensive. This includes:

- Overhead Cranes and Hoists: Essential for safely moving heavy molds.

- Hydraulic and Pneumatic Cart Systems: Used for efficiently transporting molds between the machine and storage.

- Mold Mounting Hardware: I’m proficient with various types of mold mounting plates, locking mechanisms, and alignment systems. Precision is key here.

- Precision Measuring Instruments: Such as calipers, micrometers, and height gauges are used for detailed mold inspections and ensuring proper alignment.

- Torque Wrenches: To ensure proper tightening of bolts and screws to prevent leaks or damage during operation.

- Specialized Hand Tools: Including various wrenches, screwdrivers, and specialized tools for specific mold types.

I’m comfortable working with various types of machinery, which makes me quite proficient at the process.

Q 11. How do you manage and coordinate mold changeovers during peak production periods?

Managing mold changeovers during peak production demands meticulous planning and coordination. We use a robust scheduling system that considers machine availability, operator skills, mold availability and part demand. Changeovers are often scheduled during less busy periods, such as overnight shifts or planned downtime. We create detailed changeover plans that outline each step, the required personnel, and the estimated time for each task. This minimizes disruptions and ensures smooth transitions. We also leverage lean manufacturing principles such as Single Minute Exchange of Die (SMED) to reduce changeover time. This involves identifying and eliminating non-value-added steps in the process. For instance, pre-preparing tooling and setting up the new mold in advance off the machine can significantly reduce downtime. During peak periods, we may even employ extra personnel to perform parallel tasks for faster changeovers.

Q 12. What is your experience with different types of molds (e.g., hot runner, cold runner)?

I have significant experience with various mold types, including hot runner and cold runner molds. Hot runner molds have runners that are heated, keeping the plastic molten until it reaches the cavity. This eliminates the need for sprues and runners to be removed, resulting in less waste and faster cycle times. However, they are more complex and expensive. Cold runner molds have runners that cool and solidify with the part, requiring post-processing to remove them. They are typically less expensive initially, but have more waste and slower cycle times. I understand the advantages and disadvantages of each and select appropriately based on the project’s needs and part design. Beyond these two, I’m also familiar with multi-cavity molds, family molds, and molds with specialized features like inserts, sliders or collapsible cores.

For example, for high-volume production of small parts, hot runner molds are usually preferred because of the efficiency gains. For smaller production runs or more complex parts, cold runner molds might be a more cost-effective choice.

Q 13. How do you handle unexpected issues or delays during a mold changeover?

Handling unexpected issues during a mold changeover requires a proactive and problem-solving approach. We have contingency plans in place to address common problems, such as mold damage, tooling malfunctions, or material shortages. First, we assess the severity of the issue. If it’s a minor problem, such as a loose screw, our team can quickly address it. However, for more significant issues, we immediately involve more experienced personnel and may need to request specialized equipment or parts. A strong communication channel between the production floor, maintenance team, and engineering department is vital for efficient problem-solving. We thoroughly document all unexpected issues, including the cause, the actions taken, and the time spent resolving the problem, to learn from them and implement preventative measures for future changeovers. We also use root cause analysis techniques to prevent similar issues from recurring.

For instance, if a hydraulic line bursts during a changeover, we immediately shut down the machine, secure the area, and call maintenance. The downtime is recorded, the root cause is identified (maybe a worn line), and preventative maintenance schedules are reviewed to avoid future failures.

Q 14. Explain your understanding of Standard Operating Procedures (SOPs) for mold changeovers.

Standard Operating Procedures (SOPs) for mold changeovers are crucial for consistency, safety, and efficiency. Our SOPs are detailed, step-by-step instructions that cover every aspect of the process, from mold removal and inspection to cleaning, setup, and final verification. These documents include safety guidelines, equipment usage instructions, and quality control procedures. Our SOPs are regularly reviewed and updated to incorporate lessons learned, new technologies, and best practices. Everyone involved in the changeover process is thoroughly trained on the SOPs, ensuring everyone is on the same page and working according to standardized methods. This reduces errors, minimizes downtime, and improves overall efficiency. The SOPs also serve as a valuable training tool for new employees, allowing them to quickly learn and safely perform mold changeovers.

Having a well-defined SOP is like having a recipe for a perfect mold changeover. Following the steps consistently ensures a standardized process, minimizes potential errors, and improves quality.

Q 15. What safety precautions do you always follow when working with molds and machinery?

Safety is paramount in mold changeovers. My approach is always proactive, not reactive. Before even touching a machine, I ensure all lockout/tagout procedures are meticulously followed. This means de-energizing the machine completely and affixing appropriate safety tags to prevent accidental startup. I also wear the required personal protective equipment (PPE), including safety glasses, gloves, steel-toed boots, and hearing protection. During the changeover process, I remain vigilant about potential hazards, such as pinch points, moving parts, and potential for ejected material. I frequently check the surrounding area for obstructions and ensure a clear workspace. Regularly inspecting the mold itself for cracks, damage, or leaks is critical, as a damaged mold presents a serious safety risk. If I ever encounter any unusual situation or uncertain safety protocol, I immediately halt the procedure and consult with a supervisor or safety officer. A safe work environment is not just a policy, it’s a fundamental responsibility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with different types of molding machines (e.g., hydraulic, electric)?

I’m highly proficient with various molding machine types, including hydraulic, electric, and even some hybrid systems. Hydraulic machines, with their powerful, oil-driven systems, demand a thorough understanding of pressure regulation and safety interlocks. I’ve worked extensively with presses ranging from small, benchtop models to large, industrial-scale machines. Electric machines, while often more precise and energy-efficient, require a strong understanding of servo-motor controls and automated sequences. I have experience troubleshooting issues with both hydraulic and electric systems, identifying the source of failures like leaks, sensor malfunctions, or programming errors. Understanding the nuances of each type of machine allows me to adapt quickly to different shop environments and projects. For example, I once resolved a production bottleneck by quickly identifying a faulty hydraulic valve on a machine, saving significant downtime. My expertise spans across various brands and models, allowing for efficient work across diverse settings.

Q 17. Describe your experience with automated mold changeover systems.

My experience with automated mold changeover systems is extensive. I’ve worked with various systems, from simple robotic arms handling molds to fully integrated, automated systems that manage the entire process with minimal human intervention. I’m familiar with the programming aspects of many such systems, including PLC (Programmable Logic Controller) programming, which allows me to troubleshoot and optimize automated sequences. This includes adjusting cycle times, refining robotic movements, and integrating various sensors for enhanced quality control. For example, I was instrumental in implementing a new automated system that reduced our mold changeover time by 60%, significantly improving our overall productivity. Beyond the technical aspects, I recognize the importance of ensuring the system’s safe operation and incorporating proper safety protocols within the automated sequences. It’s not just about speed; it’s about integrating safety and efficiency seamlessly.

Q 18. How do you contribute to a team environment during mold changeover activities?

Effective teamwork is essential during mold changeovers. I believe in open communication and collaboration. I actively participate in pre-changeover planning meetings to ensure everyone understands the process, timelines, and potential challenges. I’m always willing to share my expertise and assist team members, regardless of their experience level. I make sure to keep my team members updated on the progress and highlight any potential issues that could impact the timeline or safety. I also believe in a proactive approach to problem-solving, contributing to brainstorming sessions and offering solutions to potential bottlenecks. A shared understanding fosters efficiency and reduces errors. One instance where this proved invaluable was during a complex mold change where a collaborative effort allowed us to resolve a misalignment issue rapidly, minimizing downtime. My focus is always on supporting the team’s collective success.

Q 19. How do you identify and resolve potential mold damage during changeover?

Identifying and resolving mold damage is crucial for preventing costly downtime and ensuring product quality. My process starts with a thorough visual inspection of the mold before, during, and after the changeover. I look for cracks, chips, scratches, or any signs of wear and tear. I also check for proper function of ejector pins, cooling lines, and other critical components. If I detect any damage, I meticulously document it with photos and written notes. The severity of the damage dictates the next step. Minor scratches might require just cleaning and lubrication; more serious damage may necessitate repairs or replacement of components. I always follow established protocols for mold maintenance and repair, ensuring that any repairs are conducted by qualified personnel. A well-maintained mold is a critical asset, and proactive damage identification is key to minimizing disruptions and ensuring consistently high-quality products. For instance, I once spotted a hairline crack in a mold during a routine inspection, preventing a catastrophic failure during production that would have resulted in significant losses.

Q 20. What are your strategies for improving mold changeover times?

Improving mold changeover times involves a multi-faceted approach. First, I focus on optimizing the process itself. This might involve streamlining the sequence of steps, improving the organization of tools and materials, and eliminating unnecessary movements. Second, I invest in continuous improvement by identifying bottlenecks and addressing inefficiencies. Data analysis, like tracking changeover times, helps pinpoint areas for improvement. Third, I advocate for the use of advanced technologies like automated systems and quick-change tooling to reduce manual labor and improve speed. Fourth, regular training for the team and maintaining well-maintained equipment are essential. For example, I implemented a system of color-coded tool organization, reducing the time spent searching for the right tools during changeovers by 20%. The constant pursuit of improvement, leveraging technology and teamwork, is key to minimizing downtime and maximizing output.

Q 21. How do you ensure the proper alignment and clamping of molds?

Precise alignment and clamping are critical for successful mold changeovers and product quality. I typically use a combination of visual inspection and precision measuring tools to verify accurate alignment. This includes checking for parallelism and squareness of the mold halves. I use alignment pins and bushings to ensure consistent and repeatable alignment. Secure clamping is achieved through proper torque settings on the clamping mechanisms, always referring to the machine’s specifications and using calibrated torque wrenches. I perform regular checks to ensure consistent pressure across the clamping surface, preventing leaks or misalignment during operation. For example, I’ve successfully used laser alignment tools to ensure perfect mold alignment, eliminating the guesswork and reducing the risk of product defects. Accurate alignment and clamping are not merely best practices; they are fundamental to producing high-quality parts consistently.

Q 22. Explain your experience with different types of resins and their impact on changeovers.

My experience encompasses a wide range of resins, from the common polypropylene (PP) and polyethylene (PE) to more specialized engineering plastics like ABS, polycarbonate (PC), and liquid silicone rubber (LSR). Each resin presents unique challenges during mold changeovers. For instance, PP and PE, being thermoplastic, require careful temperature control to avoid warping or sticking. LSR, on the other hand, necessitates strict cleanliness protocols to prevent contamination, impacting the changeover process significantly. The viscosity of the resin also plays a crucial role; higher viscosity resins require more thorough cleaning and potentially specialized tooling. I’ve learned to tailor my approach to each resin type, optimizing procedures for efficiency and minimizing downtime. For example, with LSR, pre-preparing degassing units and implementing a rigorous purging process is vital, whereas with PP we might prioritize faster cooling techniques.

In one project involving a changeover from a high-flow PP to a more viscous PC, I implemented a multi-stage purging process with different solvents, significantly reducing the changeover time by 20% compared to previous methods.

Q 23. How do you perform a complete inspection of the mold before and after a changeover?

A thorough mold inspection is crucial before and after each changeover to ensure quality and prevent costly mistakes. Before the changeover, I meticulously inspect the mold for any signs of damage, wear, or contamination from the previous run. This involves visually checking for scratches, cracks, or burrs; carefully examining the parting line for inconsistencies; and checking the cooling channels for any blockages. I also meticulously check for any leftover resin or release agents. After the changeover, I repeat the inspection process, verifying the new mold is correctly installed, all components are securely fastened, and no damage occurred during the process. I pay special attention to the ejection system, ensuring smooth operation and complete part removal. Thorough documentation of these findings, including photographic evidence, is a critical part of the process, facilitating root-cause analysis in case of future issues.

Think of it like a pre-flight check for an airplane – a rigorous process ensuring every system is in perfect order before takeoff, minimizing potential risks.

Q 24. How do you maintain accurate records of mold changeover times and associated costs?

Maintaining accurate records is vital for tracking efficiency, identifying areas for improvement, and justifying investments. I use a combination of digital and physical methods. A dedicated spreadsheet, often linked to our manufacturing execution system (MES), captures changeover start and end times, along with a breakdown of labor costs, material costs (e.g., cleaning solvents), and any unexpected downtime. Photographs and videos documenting the process are attached as needed. The MES helps in capturing real-time data on production parameters. This comprehensive data allows us to analyze trends, identify bottlenecks, and make data-driven decisions to optimize the process. For example, analyzing data over several months revealed that a specific cleaning solvent was significantly slowing the process; switching to a more efficient alternative saved us nearly 1 hour per changeover.

Q 25. Describe your experience with using changeover checklists and documentation.

Changeover checklists and documentation are indispensable for consistency and efficiency. I utilize a highly detailed checklist tailored to each mold and resin type, outlining each step precisely. This checklist ensures nothing is missed, reducing the risk of errors and delays. The documentation includes: pre-changeover inspection reports, changeover procedures followed, post-changeover inspection reports, any deviations from the standard procedure, and time taken for each step. This information is vital for training new personnel and identifying areas for process optimization. We utilize a digital document management system to store and access this information readily. The system uses barcodes to track mold status, automating part of the data entry process.

Imagine building a complex Lego structure – a comprehensive instruction manual (checklist) guides you through each step, minimizing errors and leading to a flawless outcome.

Q 26. How do you handle conflicts or discrepancies in production schedules affecting changeovers?

Conflicts in production schedules often necessitate flexible and proactive solutions. When discrepancies arise, I collaborate closely with production planning and scheduling teams to find the best compromise. This often involves prioritizing urgent orders, adjusting changeover schedules, and potentially leveraging overtime or additional resources. Open communication is crucial – transparently explaining the implications of any schedule changes to all stakeholders. We employ a system of escalation, where unresolved conflicts are reported to a supervisor for resolution. In one instance, a conflict arose due to an unexpected urgent order. By collaborating with the planning team, we re-sequenced the changeovers, sacrificing some minor efficiency to meet the critical deadline. This averted significant financial penalties.

Q 27. What is your experience with implementing lean manufacturing principles in mold changeovers?

Implementing lean manufacturing principles significantly improved our mold changeover efficiency. We focused on reducing waste – specifically, wasted time and resources. This involved streamlining processes (eliminating unnecessary steps), standardizing procedures (ensuring consistency), reducing setup times (using quick-change tooling and pre-prepared parts), and improving workspace organization (implementing 5S methodology). Kaizen events, where teams brainstorm process improvements, proved invaluable. For instance, by implementing quick-change tooling for our most frequently used molds, we reduced changeover times by approximately 30%. We also use value stream mapping to visually analyze the entire changeover process, identifying and eliminating bottlenecks.

Q 28. How do you ensure that all necessary tools, parts, and materials are available before starting a mold changeover?

Ensuring availability of all necessary tools, parts, and materials before initiating a changeover is paramount. We employ a comprehensive parts management system using Kanban principles for frequently used items. A dedicated tool crib houses all the specialized tools required for each mold. Before each changeover, a pre-changeover checklist verifies the availability of all essential components, including molds, inserts, tooling, resins, lubricants, and cleaning agents. Any missing items are immediately flagged and procured. We use barcodes to track the location and availability of tools and parts. This organized and proactive approach significantly minimizes disruptions and delays during the changeover process.

Think of it like preparing for a complex surgery – every instrument, implant, and piece of equipment must be available and sterilized before the procedure starts.

Key Topics to Learn for Mold Changeovers Interview

- Safety Procedures: Understanding and adhering to all safety protocols during changeovers, including lockout/tagout procedures and personal protective equipment (PPE) requirements.

- Changeover Process Optimization: Analyzing and improving the efficiency of the mold changeover process, identifying bottlenecks, and suggesting improvements to reduce downtime.

- Mold Components & Functionality: Detailed knowledge of mold components (cavity, core, runner system, etc.) and their function within the injection molding process.

- Troubleshooting & Problem-Solving: Diagnosing and resolving common issues encountered during mold changeovers, such as misalignment, leaks, or part defects. This includes preventative maintenance knowledge.

- Process Documentation & Record Keeping: Maintaining accurate and detailed records of changeover procedures, including time tracking and any necessary adjustments made.

- Preventive Maintenance: Understanding and performing routine maintenance tasks on molds to extend their lifespan and minimize downtime. This includes identifying wear patterns and necessary replacement parts.

- Automation & Robotics (if applicable): Familiarity with automated mold changeover systems and robotic integration, including programming and troubleshooting.

- Quality Control: Ensuring the quality of parts produced after a mold changeover, implementing inspection procedures and addressing any non-conformances.

- Material Handling: Safe and efficient handling of molds and related components, including proper lifting techniques and storage practices.

- Teamwork & Communication: Effectively collaborating with team members during the changeover process, communicating challenges, and coordinating efforts for a smooth transition.

Next Steps

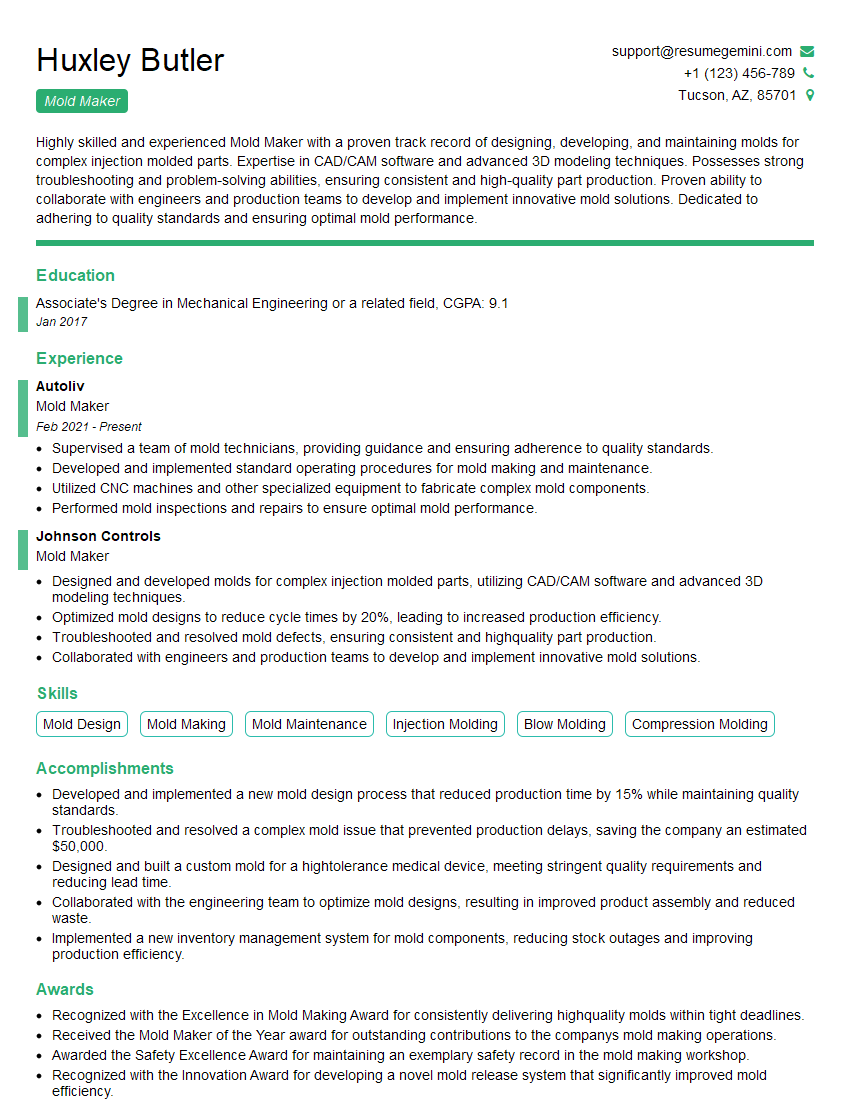

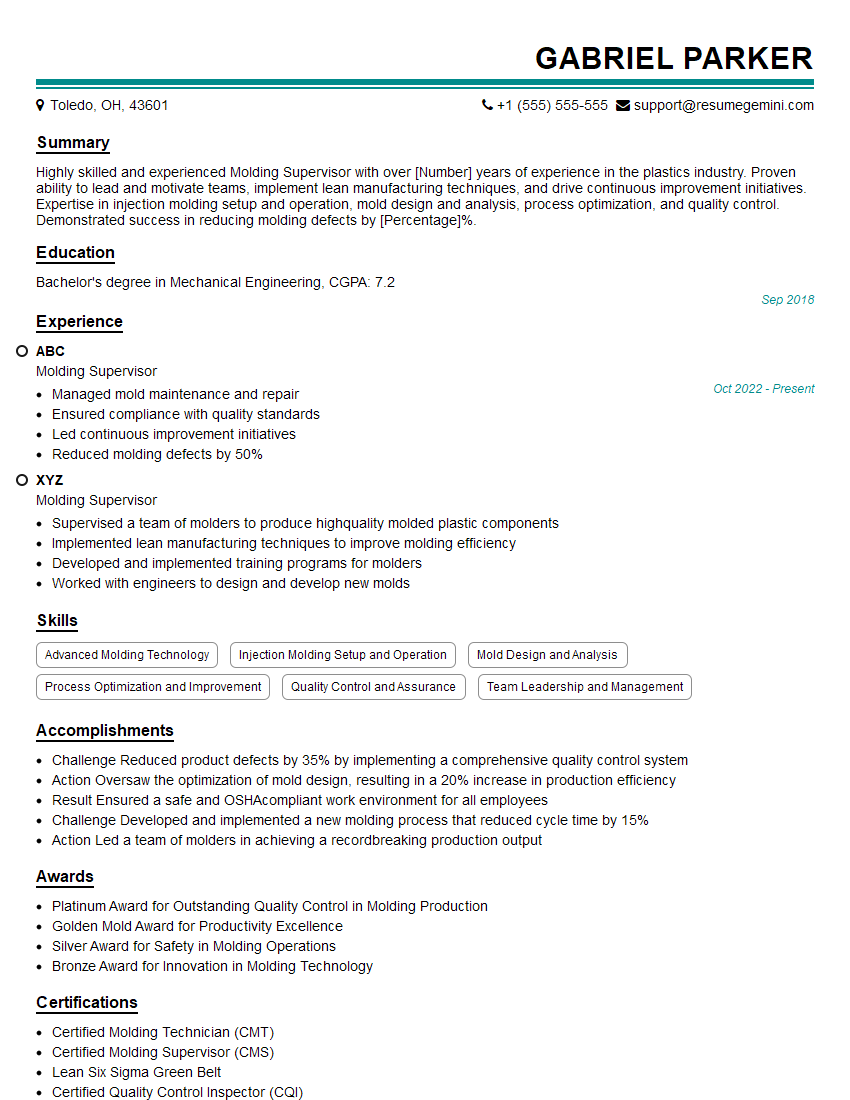

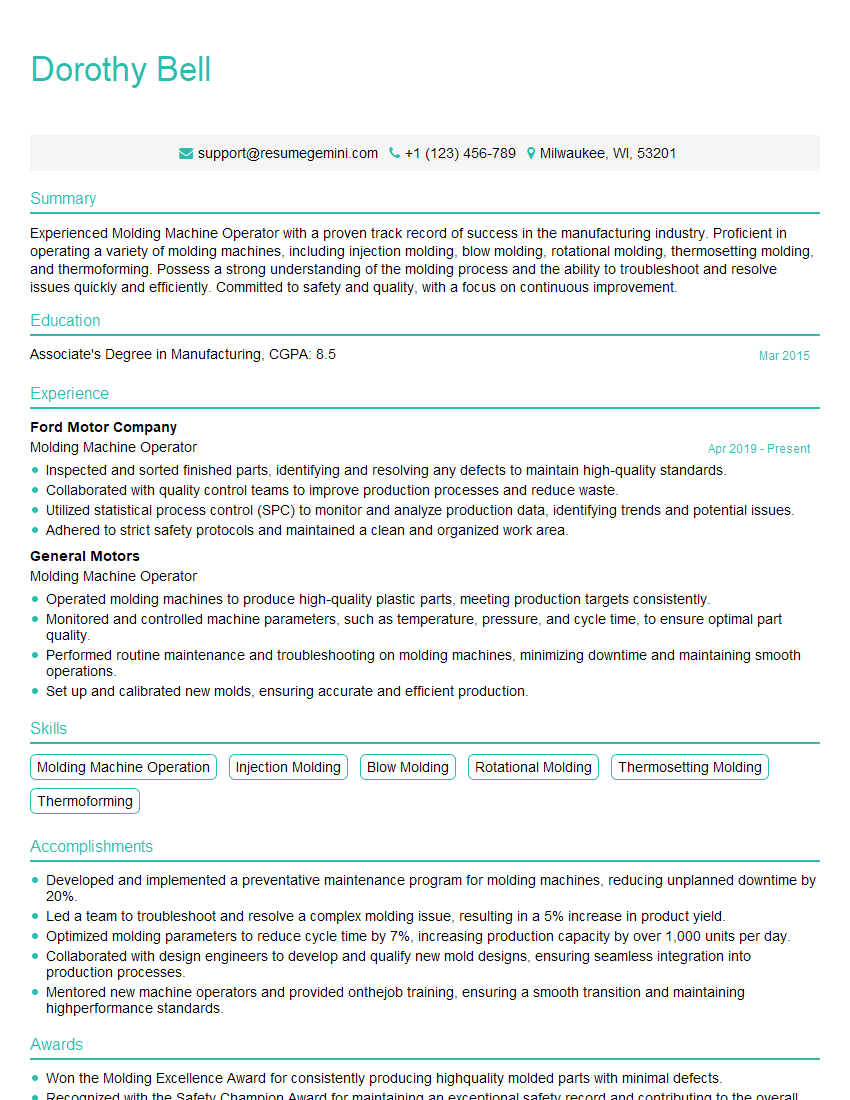

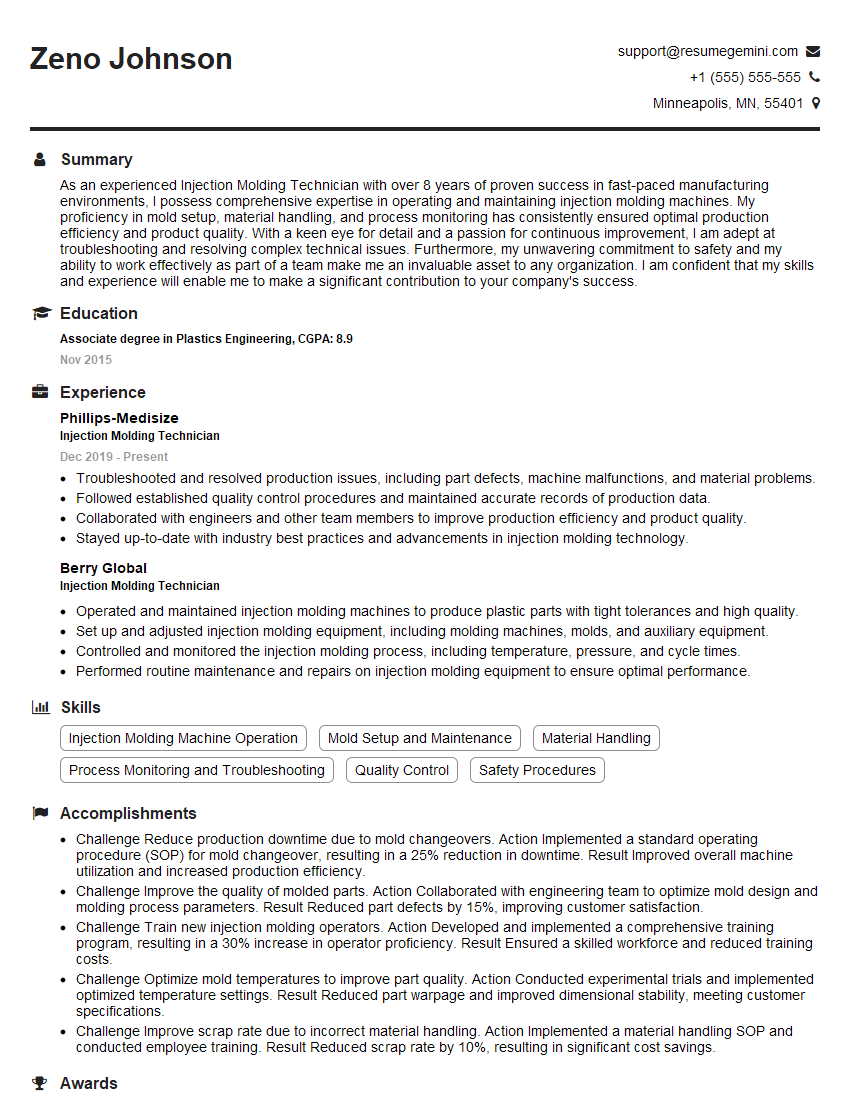

Mastering mold changeovers is crucial for advancement in manufacturing and provides opportunities for increased responsibility and higher earning potential. A well-crafted resume is your first impression on potential employers. Building an ATS-friendly resume is key to maximizing your job search effectiveness. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience in mold changeovers. Examples of resumes tailored to the Mold Changeovers field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good