Preparation is the key to success in any interview. In this post, we’ll explore crucial Product Handling and Packaging interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Product Handling and Packaging Interview

Q 1. Explain the importance of proper packaging in protecting products during transit.

Proper packaging is the unsung hero of product protection during transit. It’s the first line of defense against the bumps, drops, and temperature fluctuations that can damage goods. Think of it like a knight’s armor – it’s designed to absorb impacts and keep the product safe within.

Effective packaging involves several key elements working together. This includes using appropriate cushioning materials (like bubble wrap or foam peanuts) to absorb shocks, employing sturdy outer containers (cardboard boxes or crates) to provide structural support, and sometimes incorporating climate control elements (such as insulated liners) to maintain temperature stability during shipping. Without proper packaging, even the most robust product is vulnerable to damage, leading to potential losses, customer dissatisfaction, and increased return costs.

For example, imagine shipping a delicate glass vase. Without adequate cushioning, even a minor jostle during transit could shatter it. Proper packaging, with its layers of protection, ensures it arrives intact, protecting both the product and the company’s reputation.

Q 2. Describe your experience with different types of packaging materials (e.g., cardboard, plastic, foam).

My experience spans a wide range of packaging materials, each with its own strengths and weaknesses. Cardboard remains a staple due to its cost-effectiveness and recyclability. However, its strength is limited, making it unsuitable for heavy or fragile items. I’ve extensively used corrugated cardboard for its superior strength in protecting heavier products. Plastic, particularly polyethylene and polypropylene, offers excellent protection against moisture and impacts, making it ideal for products needing protection from the elements or rough handling. I’ve worked with both rigid plastic containers and flexible plastic films, often used as a secondary layer of protection inside cardboard boxes.

Foam packaging, including expanded polystyrene (EPS) and polyethylene (EPE), excels in cushioning fragile items. EPS is good for larger, heavier items, while EPE is more flexible and suitable for irregularly shaped goods. However, both have environmental concerns. I have experience specifying and sourcing biodegradable alternatives such as cornstarch-based packaging where appropriate.

Beyond these core materials, I’ve also worked with other specialized packaging, including wood crates for large, heavy equipment and air-filled cushions for particularly sensitive items. The selection always depends on a careful assessment of the product’s fragility, weight, dimensions, and the environmental impact considerations.

Q 3. How do you ensure efficient product handling to minimize damage and loss?

Efficient product handling hinges on meticulous planning and execution at every stage, from receiving to shipping. This involves implementing standardized procedures to minimize manual handling and risk. We begin with appropriate warehouse layout and organization to optimize workflow, ensuring that products flow smoothly through the process. This might involve utilizing conveyor systems, forklifts, and other mechanized equipment.

Employee training is crucial. Workers must be trained in the proper lifting techniques and safe handling procedures for different types of products. Using proper lifting equipment is essential. This mitigates the risk of injuries and damage to products. We also conduct regular safety audits and provide refresher training to ensure best practices are consistently followed.

Regular inspections of handling equipment are crucial for preventing malfunction and damage. We also meticulously maintain our warehouse to minimize obstructions and hazards. Finally, employing barcode or RFID systems for tracking products ensures accuracy and reduces the chances of misplacement or loss.

Q 4. What are the key considerations when designing packaging for different products?

Designing packaging for different products requires a multifaceted approach, considering several crucial factors. First and foremost is product protection; the packaging must adequately safeguard the contents from damage during transport and storage. This involves analyzing the product’s fragility, weight, size, and susceptibility to various environmental factors such as moisture, temperature, and pressure.

Next is cost-effectiveness. While protecting the product is paramount, the packaging shouldn’t break the bank. We carefully consider material costs, production costs, and the potential for damage claims in choosing packaging. Sustainability is also a critical consideration; we prioritize recyclable and eco-friendly materials whenever possible. Finally, the packaging must also consider ease of handling and opening for both warehouse workers and the end consumer. A well-designed package is intuitive, easy to unpack, and minimizes waste.

For instance, a delicate electronic device requires far more cushioning and robust packaging than a heavy-duty tool. Understanding these nuances is crucial for creating optimal, cost-effective, and sustainable packaging solutions.

Q 5. Explain your understanding of inventory management within a warehouse setting.

Inventory management in a warehouse setting is the backbone of efficient operations. It’s about having the right product, in the right quantity, at the right time, and in the right place. This involves accurately tracking inventory levels, forecasting demand, and optimizing storage space. Effective inventory management relies on a robust system for tracking incoming and outgoing goods and regularly updating stock levels. This is often done via barcode scanning or RFID technology, enabling real-time tracking and reducing manual errors.

Proper organization is vital. We use various strategies like FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) to manage perishable items or items with expiration dates, ensuring we avoid waste. Regular stock takes, both cyclical and full, are conducted to verify inventory accuracy. We also implement quality control checks during receiving and storage, ensuring that damaged or defective goods are quickly identified and removed from circulation.

Efficient inventory management reduces storage costs, minimizes waste, prevents stockouts, and optimizes order fulfillment. A well-managed inventory ensures smooth operations and customer satisfaction.

Q 6. Describe your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with various WMS platforms, from simple inventory tracking systems to sophisticated solutions integrating with ERP (Enterprise Resource Planning) software. These systems provide comprehensive control over inventory, order fulfillment, and warehouse operations.

A WMS typically handles functions such as receiving and put-away, order picking and packing, shipping and tracking, and inventory control. It streamlines workflows, enhances accuracy, and provides valuable data insights. For example, a WMS can optimize picking routes, minimizing travel time and improving efficiency. It can also provide real-time visibility into inventory levels, facilitating better forecasting and demand planning. Data analytics within the WMS can help identify bottlenecks, optimize storage strategies, and improve overall warehouse performance. I’m proficient in using WMS reporting features to track key metrics such as order fulfillment rates, inventory turnover, and storage costs.

I am experienced in implementing and integrating WMS solutions in various warehouse environments, leading to significant improvements in operational efficiency and cost reduction.

Q 7. How do you handle discrepancies in inventory counts?

Inventory discrepancies, where physical counts don’t match system records, are a common challenge. Addressing them effectively requires a systematic approach. The first step is to identify the extent and nature of the discrepancy. Is it a minor difference, or a significant shortfall? Then, we initiate a thorough investigation. This might involve recounting the inventory in the affected area, checking for damaged or misplaced items, and verifying the accuracy of our inventory management processes.

We use a combination of methods to pinpoint the source of the discrepancy. This includes reviewing recent transactions, investigating potential data entry errors, and checking for any equipment malfunctions (e.g., barcode scanner issues). We may also use advanced analytics provided by our WMS to identify patterns or anomalies in our data. Once the root cause is determined, we implement corrective actions to prevent future discrepancies. This might involve staff retraining, process improvements, or upgrading our inventory management technology. Accurate record-keeping is paramount and, where necessary, we adjust the inventory system to reflect the accurate physical count.

Documenting the entire process, including the cause of the discrepancy and the corrective actions taken, is crucial for learning and preventing future occurrences.

Q 8. How familiar are you with various types of handling equipment (forklifts, pallet jacks)?

My familiarity with handling equipment extends beyond basic operation; I possess a comprehensive understanding of their functionalities, limitations, and maintenance requirements. I’m proficient with various forklifts, including counterbalanced, reach trucks, and order pickers, and I’m experienced with pallet jacks, both manual and powered. This includes understanding weight capacities, operational safety protocols, and the selection of appropriate equipment based on load type, warehouse layout, and task specifics. For instance, I wouldn’t use a reach truck in a narrow aisle where a smaller order picker would be more suitable. I also have experience troubleshooting minor mechanical issues and performing daily pre-operational checks to ensure equipment is safe and efficient.

Q 9. Describe your experience with safety procedures in a warehouse environment.

Safety is paramount in my approach to warehouse operations. My experience encompasses rigorous adherence to OSHA standards and company-specific safety protocols. This includes the correct use of Personal Protective Equipment (PPE) such as safety shoes, high-visibility vests, and safety glasses; following designated traffic patterns and speed limits for forklifts; and proactively identifying and mitigating potential hazards. I’ve participated in numerous safety training programs, including forklift certification and hazard communication training. In one instance, I noticed a loose pallet on a high rack, which posed a significant fall risk. I immediately reported it to my supervisor and ensured the area was cordoned off until it was safely addressed. This proactive approach is central to my work.

Q 10. How do you prioritize tasks in a fast-paced warehouse setting?

Prioritization in a fast-paced warehouse setting relies on a combination of factors. I employ a system that prioritizes urgency and importance. I use a combination of techniques: First, I identify tasks with immediate deadlines, like urgent outbound shipments. Second, I consider the impact of each task on overall warehouse efficiency; for example, replenishing high-demand inventory items is prioritized to prevent stockouts. Third, I assess task complexity. Simpler tasks might be tackled quickly before moving onto more intricate ones. I frequently utilize Kanban or similar visual management systems to track task progress and quickly identify bottlenecks. I also believe in proactive communication; if I anticipate delays, I communicate this transparently to prevent further issues.

Q 11. What metrics do you use to measure the efficiency of product handling processes?

Measuring the efficiency of product handling processes involves a multifaceted approach. Key metrics include:

- Order fulfillment rate: The percentage of orders processed and shipped on time and accurately.

- Throughput: The total volume of product handled within a given timeframe.

- Inventory accuracy: The degree of alignment between physical inventory and recorded inventory.

- Pick and pack accuracy: The percentage of orders picked and packed correctly.

- Damage rate: The frequency of product damage during handling and storage.

Q 12. Explain your understanding of supply chain management principles.

Supply chain management is a holistic process encompassing the flow of goods and information from origin to consumption. My understanding encompasses procurement, production, inventory management, logistics, and customer service. I recognize the importance of effective forecasting to anticipate demand, efficient inventory control to minimize storage costs and prevent stockouts, and streamlined logistics for timely delivery. I understand the interconnectedness of each stage; a disruption in one area can cascade throughout the entire chain. For example, delays in procurement can impact production schedules and ultimately affect customer satisfaction. My experience allows me to identify and manage risks within the supply chain, focusing on optimizing efficiency and minimizing costs while ensuring timely delivery and high customer satisfaction.

Q 13. How do you ensure compliance with packaging regulations and standards?

Compliance with packaging regulations and standards is non-negotiable. My experience includes working with various packaging materials and understanding regulations concerning labeling, hazardous materials handling, and transport regulations (e.g., DOT, IATA). This includes ensuring correct labeling of hazardous materials, using appropriate packaging for fragile items to prevent damage during transit, and complying with weight and dimension restrictions for shipping. I stay updated on the latest regulations and best practices by reviewing relevant publications and attending industry seminars. If a new regulation is introduced, I ensure all packaging procedures are updated to reflect the changes to maintain compliance.

Q 14. Describe your experience with quality control procedures in packaging.

Quality control in packaging is a crucial aspect of my work. I’m experienced in implementing and enforcing procedures to minimize errors and ensure that products are packaged correctly and safely. This includes regular inspections of packaging materials to ensure they meet quality standards, inspecting finished goods to detect any defects or damage, and tracking quality metrics such as defect rates and customer returns. We use a statistical process control (SPC) approach to identify trends and prevent issues before they escalate. For instance, if we observe a significant increase in damaged goods, we can analyze the root cause – perhaps a packaging material change or a handling issue – and implement corrective actions. This systematic approach ensures product quality and minimizes waste.

Q 15. How do you handle damaged or defective products?

Handling damaged or defective products requires a systematic approach to minimize losses and maintain quality control. The first step is clear identification and segregation. Damaged goods are immediately marked as such, preventing accidental shipment or sale. We then follow a documented procedure, typically involving:

- Inspection and Categorization: Determining the extent of damage – is it repairable, recyclable, or requires disposal? This often involves using checklists and photographic documentation.

- Root Cause Analysis: Investigating the source of the damage. Was it due to poor packaging, mishandling during transport, or a manufacturing defect? This analysis is crucial for preventative measures.

- Disposition: Depending on the assessment, the product might be repaired, returned to the manufacturer for warranty claim, salvaged (e.g., parts reused), recycled, or disposed of responsibly, adhering to environmental regulations.

- Documentation and Reporting: All actions are meticulously documented, including the date, type of damage, the disposition taken, and the cost implications. This data feeds into continuous improvement processes.

For example, in a previous role, we implemented a system using barcode scanning to track damaged goods throughout the process. This improved efficiency and accuracy in our damage reporting, reducing discrepancies and ultimately leading to a 15% decrease in waste disposal costs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of shipping methods?

My experience encompasses a wide range of shipping methods, from standard ground transportation to expedited air freight and specialized options like temperature-controlled shipping for sensitive goods. The choice of method depends on several factors, including:

- Urgency: Expedited shipping is essential for time-sensitive products.

- Cost: Ground shipping is generally the most economical, but slower.

- Product Sensitivity: Fragile items require extra cushioning and specialized handling. Temperature-sensitive goods need refrigerated trucks or containers.

- Distance: Longer distances may necessitate air freight or sea freight, depending on the urgency and cost constraints.

- Product Weight and Dimensions: Oversized or heavy shipments require specialized carriers and equipment.

In a past project, we successfully transitioned from solely relying on ground shipping to a blended approach using both ground and air freight, reducing delivery times by 30% and improving customer satisfaction without significantly increasing overall shipping costs. This involved careful analysis of delivery timelines and associated costs for each product type.

Q 17. How do you optimize the layout of a warehouse for efficient product flow?

Optimizing warehouse layout is critical for efficient product flow. The goal is to minimize travel time and handling, reducing labor costs and improving order fulfillment speed. Key principles include:

- Strategic Zoning: Grouping similar products together, placing high-demand items in easily accessible areas, and positioning receiving and shipping docks strategically.

- Efficient Flow Paths: Designing pathways to minimize congestion and maximize the use of available space. This often involves using slotting optimization software.

- Inventory Management System Integration: Using WMS (Warehouse Management Systems) to track inventory levels and direct picking paths. This ensures that pickers are always guided to the most efficient route.

- Ergonomics and Safety: Designing the layout to minimize strain on workers and ensure a safe working environment. This includes proper lighting, appropriate equipment, and clear signage.

For instance, in a previous warehouse redesign, we implemented a zone-picking system combined with a WMS, leading to a 20% reduction in order fulfillment time and a 10% decrease in picking errors.

Q 18. Explain your experience with implementing Lean Manufacturing principles in a warehouse.

Lean manufacturing principles, focusing on eliminating waste and maximizing efficiency, are highly applicable to warehouse operations. My experience includes implementing several key Lean methodologies, including:

- 5S Methodology: Implementing a systematic approach to workplace organization, focusing on sorting, setting in order, shining, standardizing, and sustaining. This resulted in a cleaner, safer, and more efficient workspace.

- Value Stream Mapping: Analyzing the entire process flow to identify bottlenecks and areas for improvement. This helped pinpoint inefficient steps and optimize workflows.

- Kaizen Events: Organizing focused improvement workshops to rapidly identify and implement small changes, leading to incremental improvements over time. This fostered a culture of continuous improvement within the team.

- Pull Systems (Kanban): Implementing a just-in-time inventory system to reduce waste associated with excess inventory. This minimized storage costs and improved responsiveness to demand.

In one project, by applying 5S and Kaizen events, we eliminated redundant steps in the receiving process, reducing the time taken by 15% and freeing up resources for other tasks.

Q 19. How do you track and manage product returns?

Tracking and managing product returns involves a systematic process to ensure efficient handling, minimize losses, and maintain customer satisfaction. This includes:

- Clear Return Policy: Establishing a simple and transparent return policy for customers, explaining the process and timelines.

- RMA (Return Merchandise Authorization) System: Using a system to track returns, generating unique RMA numbers for each return to facilitate processing and tracking.

- Inspection and Processing: Carefully inspecting returned goods to determine their condition and eligibility for a refund or exchange.

- Inventory Management: Updating inventory records to reflect returned items and managing their disposition (restocking, repair, disposal).

- Customer Communication: Providing regular updates to customers on the status of their return.

We once developed a custom software solution to automate the RMA process, improving efficiency and reducing processing time by 40%. This allowed our customer service team to focus on resolving customer issues rather than manual paperwork.

Q 20. How do you resolve conflicts between different departments involved in product handling?

Resolving conflicts between departments involved in product handling requires effective communication and collaboration. My approach focuses on:

- Open Communication: Establishing clear communication channels between departments to ensure everyone is aware of goals, challenges, and dependencies.

- Collaborative Problem-Solving: Bringing together representatives from all relevant departments to identify the root causes of the conflict and brainstorm solutions collaboratively.

- Mediation: If needed, acting as a neutral mediator to facilitate productive discussions and help find common ground.

- Data-Driven Decision Making: Using data to support arguments and ensure decisions are objective and fair.

- Documentation and Follow-Up: Documenting agreements and decisions to ensure accountability and track progress.

In a past situation, a conflict arose between the warehouse and shipping departments over delivery schedules. By facilitating a collaborative meeting and analyzing delivery data, we identified areas for improvement in communication and workflow, leading to a smoother operation and improved inter-departmental relations.

Q 21. Describe your experience with various labeling and marking techniques.

My experience spans various labeling and marking techniques, crucial for traceability and product identification throughout the supply chain. These include:

- Barcode Labeling: Using barcode systems (UPC, EAN, etc.) for efficient inventory tracking and automated data capture.

- RFID Tagging: Utilizing Radio-Frequency Identification tags for improved tracking and inventory management, especially in high-volume environments.

- Thermal Transfer Printing: Creating durable and high-quality labels resistant to abrasion and moisture, suitable for various surfaces.

- Laser Marking: Applying permanent markings to products directly, ideal for high-durability requirements.

- Labeling Software Integration: Using specialized software to generate and manage labels, ensuring accuracy and consistency.

We once transitioned from manual labeling to an automated system using barcode scanners and thermal transfer printers, leading to a significant reduction in labeling errors and a boost in warehouse efficiency. The automated system also improved accuracy in inventory counts.

Q 22. How do you ensure the accuracy of shipping documentation?

Ensuring accurate shipping documentation is paramount to avoid delays, losses, and customer dissatisfaction. My approach is multi-faceted and focuses on a system of checks and balances.

Data Validation: I implement rigorous data entry checks, often using automated systems to compare order details against inventory data and customer information. This helps catch discrepancies early on. For example, I’d use a system that flags orders with mismatched addresses or incorrect product codes.

Double-Checking: A second pair of eyes always reviews critical information like weight, dimensions, and shipping addresses before finalizing the documentation. This reduces human error significantly. Think of it like proofreading an important document – a second review always catches mistakes.

Barcode and Label Verification: Utilizing barcode scanners and label printers guarantees accuracy in identifying products and their destinations. Any discrepancies between the system-generated label and the physical product are immediately addressed.

Regular Audits: Periodic audits of our documentation processes, analyzing error rates and identifying recurring issues, help to proactively improve our accuracy. This might reveal a pattern of errors related to a specific product or process, enabling targeted improvements.

Technology Integration: Utilizing an integrated system that connects order management, inventory, and shipping systems ensures data consistency and minimizes manual data entry, the most common source of errors.

By combining these methods, we ensure a high level of accuracy in our shipping documentation, reducing errors and fostering customer trust.

Q 23. How do you handle situations with high order volumes during peak seasons?

Managing high order volumes during peak seasons demands a proactive, strategic approach. It’s not just about working harder; it’s about working smarter.

Forecasting and Planning: Accurate sales forecasting allows us to anticipate increased demand and prepare accordingly. This includes securing additional resources like temporary staff, extra warehousing space, and potentially outsourcing some functions.

Process Optimization: We streamline our existing processes to maximize efficiency. This might involve optimizing warehouse layouts, implementing more efficient picking and packing strategies, and leveraging technology such as automated guided vehicles (AGVs) or conveyor systems.

Staff Training and Cross-Training: Ensuring staff are well-trained and cross-trained to handle multiple tasks is crucial. This flexibility allows for efficient resource allocation when handling surges in demand. Think of it as having a well-rounded sports team – each player can fill multiple positions.

Technology Implementation: Employing warehouse management systems (WMS) and order management systems (OMS) improves visibility and control over the entire process. These systems provide real-time data, allowing us to track order progress, identify bottlenecks, and allocate resources effectively.

Communication: Clear and consistent communication with customers about potential delays and shipping updates is essential to manage expectations and maintain customer satisfaction. Transparency helps avoid unnecessary frustration.

During a particularly busy holiday season, we implemented a new order batching system that reduced picking time by 15%. This allowed us to process a significantly higher volume of orders without compromising accuracy or delivery times.

Q 24. Explain your experience with different packaging design software.

My experience encompasses a variety of packaging design software, each with its strengths and weaknesses. I’ve worked extensively with:

Adobe Illustrator and Photoshop: These industry-standard tools are crucial for creating high-quality visual designs and packaging mockups. I’ve used them to develop eye-catching graphics, incorporate branding elements, and ensure designs meet printing specifications.

SolidWorks: For more complex projects requiring 3D modeling, SolidWorks provides the necessary precision. This is especially important for designing custom packaging for oddly-shaped products or when structural integrity is critical.

AutoCAD: For creating technical drawings and precise dimensions, AutoCAD is invaluable in ensuring compatibility with manufacturing processes. It helps ensure that the packaging design is structurally sound and efficient to manufacture.

Packsize On Demand: This is a software system specifically designed for on-demand packaging, allowing for the creation of custom-sized boxes that minimize wasted materials. It optimizes material use and reduces shipping costs.

I understand the nuances of each program and leverage their unique functionalities depending on the project’s specific needs. This allows for efficient creation of designs, from simple box layouts to complex multi-component packages.

Q 25. How do you identify and address potential packaging-related hazards?

Identifying and addressing packaging-related hazards is crucial for ensuring product safety and regulatory compliance. My approach is a systematic one:

Hazard Analysis: We conduct thorough hazard analyses, considering potential risks throughout the packaging lifecycle, from material selection to disposal. This involves analyzing potential physical hazards (e.g., sharp edges, unstable stacking), chemical hazards (e.g., incompatible materials), and biological hazards (e.g., contamination).

Material Selection: Choosing appropriate materials is paramount. We prioritize sustainable and safe materials that comply with relevant regulations. For example, using recyclable materials reduces environmental impact while choosing food-grade materials is essential when packaging edibles.

Testing and Validation: We conduct various tests, including drop tests, vibration tests, and compression tests, to ensure packaging can withstand the rigors of transportation and handling. These tests are documented and serve as evidence of our commitment to product safety.

Packaging Design Review: We review packaging designs for any potential hazards, making modifications as necessary. For instance, sharp edges might be rounded or cushioning materials added to protect fragile items.

Regulatory Compliance: We ensure our packaging complies with all relevant international and domestic regulations, including those related to hazardous materials and labeling requirements.

For instance, we once identified a potential sharp edge hazard on a newly designed package during testing. We quickly redesigned the packaging to eliminate this risk, avoiding a potential product recall.

Q 26. What are the key factors to consider when selecting packaging for international shipments?

Selecting packaging for international shipments requires careful consideration of several key factors:

Destination Country Regulations: Import regulations vary significantly between countries. We must comply with labeling requirements, hazardous materials restrictions, and any specific customs declarations needed.

Environmental Conditions: Extreme temperatures, humidity, and rough handling are common during international shipping. Packaging must be durable enough to protect the product under these conditions. This might mean using specialized materials or incorporating extra layers of protection.

Transportation Modes: Different modes of transport (air, sea, land) present different challenges. Packaging must be suitable for the chosen mode and withstand the associated stresses.

Product Protection: The packaging must provide adequate protection against shocks, vibrations, and impacts during transit. This might include using cushioning materials, custom-fit inserts, or specialized containers.

Cost-Effectiveness: While safety is paramount, cost-efficiency is also crucial. We need to balance protection needs with overall shipping costs, considering materials, weight, and size limitations.

Sustainability: Increasingly, customers and regulations prioritize sustainable packaging materials and practices. Using eco-friendly, recyclable materials is both responsible and often advantageous.

For example, when shipping to a country with high humidity, we might opt for waterproof packaging materials to prevent damage from moisture. Similarly, when shipping fragile items internationally, we’d use robust packaging with ample cushioning and reinforcement.

Q 27. Describe your experience with automated packaging systems.

I have significant experience with automated packaging systems, ranging from simple automated taping machines to sophisticated robotic packaging lines.

Case Erectors: These machines automatically form and seal cardboard boxes, significantly increasing efficiency and reducing labor costs. I’ve worked with several models, adjusting their settings to accommodate varying box sizes and materials.

Automatic Fillers and Sealers: For higher-volume operations, automated fillers and sealers are essential. These systems precisely fill containers with products and seal them, ensuring consistent packaging and reducing errors. Experience with different systems allows for optimizing machine settings for various product types and packaging configurations.

Robotic Systems: I’ve worked with robotic systems capable of performing complex packaging tasks, including picking, placing, and packing items into boxes. These systems improve efficiency, precision, and throughput, especially for intricate or heavy products. Troubleshooting these systems requires knowledge of both mechanical and software aspects, a challenge I relish.

Integration with WMS and ERP systems: Successfully implementing automated systems requires seamless integration with existing warehouse management and enterprise resource planning systems. This ensures that data flows smoothly across the packaging process, from order entry to shipment.

In one project, I oversaw the implementation of a robotic palletizing system which increased our palletizing efficiency by 40%, resulting in significant cost savings and improved warehouse space utilization.

Q 28. How do you stay updated with the latest trends in packaging technology?

Staying updated on the latest trends in packaging technology is crucial in this dynamic field. My strategy involves a multi-pronged approach:

Industry Publications and Trade Shows: I regularly read industry publications like Packaging World and attend trade shows such as Pack Expo. These events offer insights into emerging technologies and innovative solutions.

Online Resources and Webinars: Numerous websites and online communities dedicated to packaging technology provide valuable information and updates. Participating in webinars and online courses keeps me abreast of the latest advancements.

Networking with Industry Professionals: Connecting with other packaging professionals through conferences, online forums, and industry groups allows me to share knowledge and learn about best practices.

Competitor Analysis: Monitoring competitor activities and innovative solutions keeps me informed about the latest trends and market demands.

Continuous Learning: I actively seek out training opportunities and certifications to deepen my understanding of packaging technologies and best practices. This keeps me at the forefront of the field.

Recently, I completed a course on sustainable packaging materials, gaining expertise in bioplastics and compostable packaging solutions—a critical aspect of modern packaging development.

Key Topics to Learn for Product Handling and Packaging Interview

- Warehouse Management Systems (WMS): Understanding how WMS software streamlines inventory management, order fulfillment, and product tracking is crucial. Consider practical applications like optimizing picking routes or troubleshooting system errors.

- Packaging Materials & Design: Explore the various types of packaging materials (cardboard, plastic, etc.), their properties, and sustainable alternatives. Think about how packaging design influences product protection, shelf appeal, and cost-effectiveness.

- Inventory Control & Management: Master the principles of accurate inventory tracking, cycle counting, and minimizing waste. Consider scenarios involving stock discrepancies, damaged goods, or unexpected demand fluctuations.

- Health & Safety Regulations: Familiarize yourself with relevant workplace safety regulations related to material handling equipment, personal protective equipment (PPE), and hazardous materials handling. Understand the importance of safe work practices and incident reporting.

- Supply Chain Optimization: Learn about the different stages of the supply chain and how efficient product handling and packaging contribute to overall efficiency. Explore concepts like lean manufacturing and just-in-time delivery.

- Automation & Technology in Packaging: Understand the role of automated systems in modern packaging, including robotic palletizers, automated packaging machines, and barcode scanning. Be prepared to discuss the benefits and challenges of integrating such technologies.

- Quality Control & Assurance: Explore methods for ensuring product quality throughout the handling and packaging process, including inspections, testing, and data analysis. Consider strategies for identifying and resolving quality issues.

Next Steps

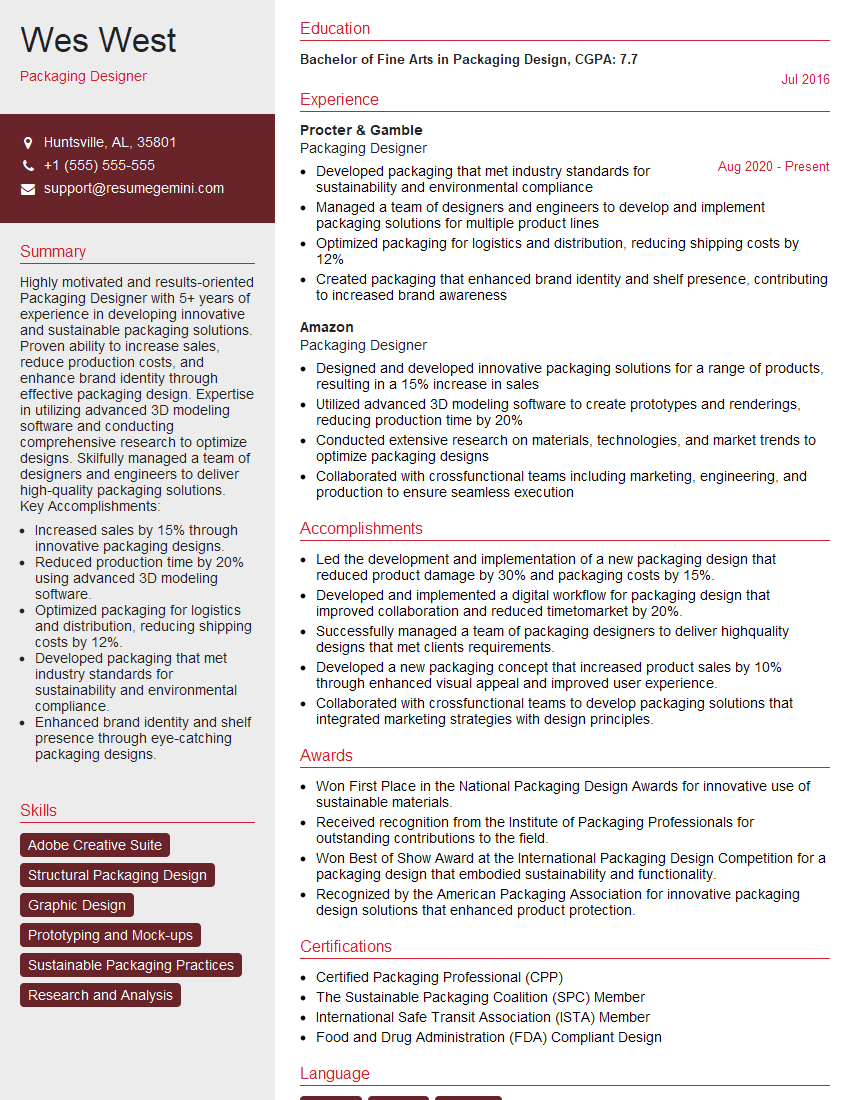

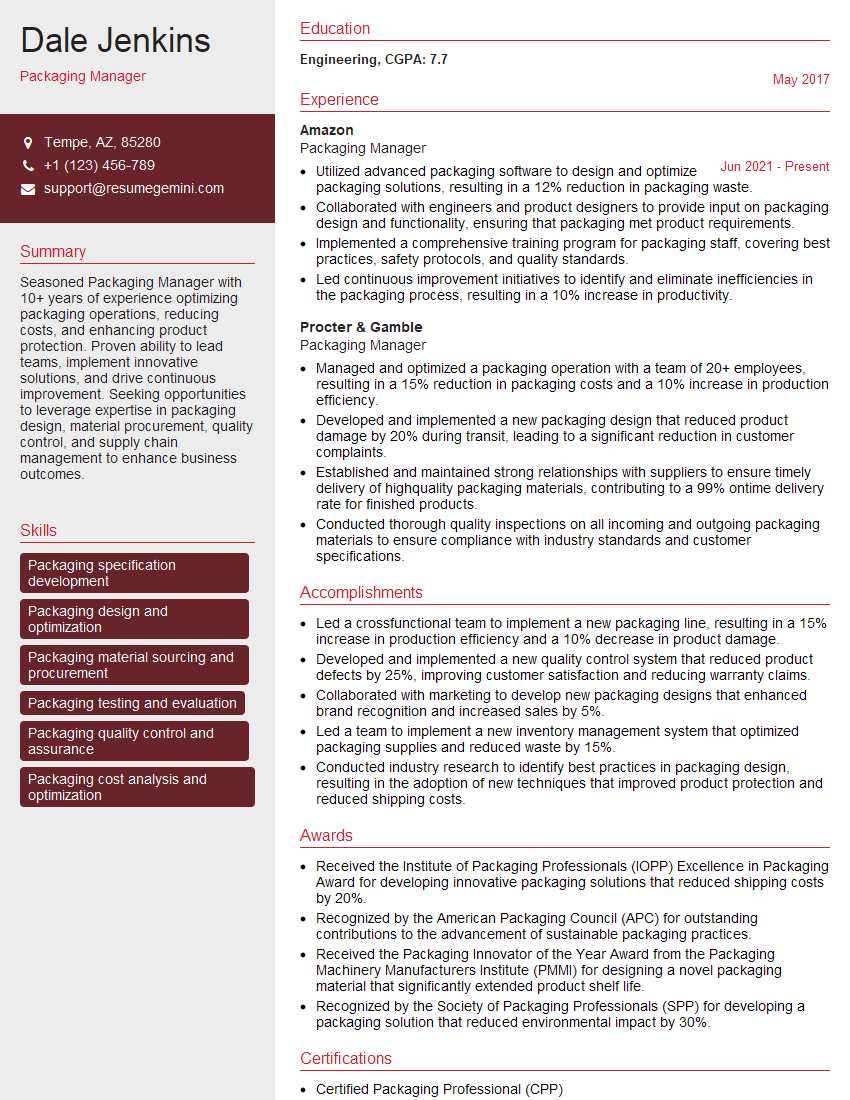

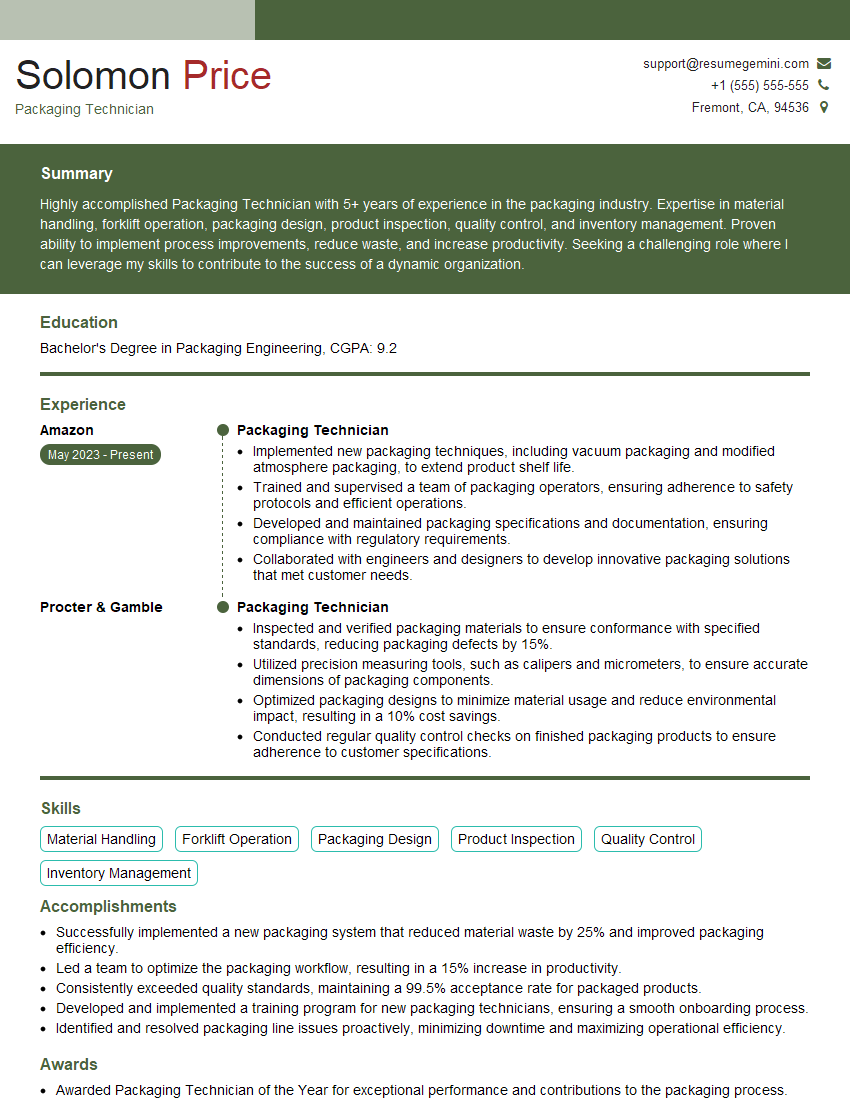

Mastering Product Handling and Packaging principles significantly enhances your career prospects within logistics, manufacturing, and supply chain management. These skills are highly sought after, opening doors to diverse roles and opportunities for professional growth. To maximize your chances of landing your dream job, crafting an ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Product Handling and Packaging are available through ResumeGemini, allowing you to see best practices in action and create a compelling application that stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good