Are you ready to stand out in your next interview? Understanding and preparing for Forklift and Hoist Operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Forklift and Hoist Operation Interview

Q 1. What are the different types of forklifts and their applications?

Forklifts come in a variety of types, each designed for specific applications. The choice depends heavily on the type of load, the environment, and the required maneuverability.

- Counterbalance Forklifts: These are the most common type, using counterweights to balance the load. They’re versatile and suitable for various applications, from warehousing to construction sites. Think of the classic image of a forklift – that’s usually a counterbalance model.

- Reach Trucks: Designed for narrow aisles, reach trucks extend their forks to pick up and place pallets deep within racking systems. They are crucial for maximizing storage space in warehouses.

- Sit-down Rider Forklifts: The operator sits while operating the forklift, offering better comfort and control for extended use. These are very common in warehousing and distribution centers.

- Stand-up Rider Forklifts: These are compact and maneuverable, ideal for smaller spaces and applications where frequent direction changes are necessary. They’re often used in smaller warehouses or retail environments.

- Order Pickers: These forklifts are designed to quickly and efficiently pick orders from high-level racking. They’re common in distribution centers focusing on order fulfillment.

- Side Loaders: Ideal for handling long or awkwardly shaped loads, side loaders pick up loads from the side, making them perfect for construction or lumberyards.

- Electric Forklifts: These are powered by batteries, making them quieter and cleaner than gas or propane forklifts. They’re increasingly popular in indoor environments due to their reduced emissions.

- Internal Combustion (IC) Forklifts: Powered by either propane or gasoline, these offer greater power and longer operating times but produce emissions.

For example, a lumberyard would benefit from a side loader or a heavy-duty counterbalance forklift, while a grocery warehouse might use a reach truck and electric order pickers.

Q 2. Explain the pre-operational checklist for a forklift.

A thorough pre-operational checklist is paramount for safe forklift operation. Skipping even one step can have serious consequences. My checklist always includes:

- Visual Inspection: Checking tires for wear and tear, ensuring lights and horns are functioning, examining the mast for damage, verifying the forks are aligned and undamaged, and inspecting the hydraulic system for leaks.

- Fluid Levels: Checking engine oil, coolant, hydraulic fluid, and fuel levels (for IC forklifts) to ensure sufficient operation and prevent damage.

- Battery Check (for electric forklifts): Ensuring the battery is sufficiently charged and properly connected.

- Horn Test: Testing the horn to ensure it is audible and functional.

- Safety Devices: Confirming that the seatbelt, brakes, and other safety devices are in working order. This includes checking the emergency stop button.

- Operational Test: Performing a short test run to check steering, lift, tilt, and braking systems before commencing operations.

- Load Capacity Check: Verifying the load capacity of the forklift and ensuring it’s suitable for the task at hand.

For instance, if I notice a hydraulic leak, I immediately report it and take the forklift out of service. It’s better to be safe than sorry.

Q 3. Describe the proper procedure for loading and unloading cargo.

Loading and unloading cargo safely requires careful planning and execution. The procedure involves several key steps:

- Assessment: Assessing the weight and dimensions of the cargo to ensure they’re within the forklift’s capacity. Understanding the center of gravity is crucial.

- Positioning: Positioning the forklift close to the load, ensuring a stable and level surface for both the forklift and the cargo.

- Fork Placement: Carefully inserting the forks underneath the load, ensuring they’re evenly positioned and securely engaged. Never lift a load with the forks only partially underneath.

- Lifting: Slowly lifting the load to a safe height, keeping it level and stable. Avoiding sudden movements is vital.

- Transportation: Carefully and slowly transporting the load to its destination, avoiding sudden turns or jerky movements. Maintaining a safe speed appropriate to conditions is critical.

- Unloading: Lowering the load slowly and carefully to the designated spot. Ensuring clear surroundings is vital before lowering.

For example, when loading a pallet of boxes, I’ll ensure the forks are under the pallet’s strongest points and maintain a slow, steady speed during transport.

Q 4. How do you ensure the stability of loads during transportation?

Maintaining load stability is critical for preventing accidents. This involves:

- Center of Gravity: Distributing the load evenly to keep the center of gravity low and within the forklift’s safe operating parameters. An unevenly distributed load can easily cause tipping.

- Securement: Using appropriate straps, chains, or other securing devices to prevent shifting during transport, especially for unstable loads.

- Load Weight: Never exceeding the forklift’s rated load capacity. This information is always clearly displayed on the forklift’s data plate.

- Smooth Operation: Avoiding sudden acceleration, braking, or turns, which can cause the load to shift or tip. Gentle movements are key.

- Proper Fork Placement: Ensuring the forks are properly positioned under the load’s center of gravity.

Imagine trying to transport a stack of awkwardly placed boxes – securing them prevents damage and maintains stability during travel.

Q 5. What safety measures do you take when operating a forklift in a congested area?

Operating in congested areas demands extra vigilance and caution. My approach involves:

- Slow Speed: Maintaining a very slow speed, allowing ample time to react to unexpected obstacles or pedestrian movements.

- Horn Usage: Using the horn frequently to warn pedestrians and other equipment operators of my presence and intentions.

- Awareness: Maintaining constant awareness of my surroundings, including pedestrians, other equipment, and obstacles.

- Clear Path: Ensuring a clear path before moving, and avoiding sharp turns or sudden stops.

- Communication: Communicating with pedestrians and other equipment operators to coordinate movements and prevent collisions.

- Backup Assistance: Using a spotter when visibility is limited, especially when backing up.

For example, in a busy warehouse, I would proceed slowly, use my horn frequently, and constantly scan my surroundings for hazards. A spotter can be invaluable in tight spaces.

Q 6. What are the load capacity limitations of a forklift?

A forklift’s load capacity is determined by its design and is clearly indicated on a data plate affixed to the machine. This plate specifies the maximum weight the forklift can safely lift at various mast heights. Exceeding this capacity is incredibly dangerous and can lead to catastrophic accidents. Factors that influence load capacity include:

- Forklift Model: Different models have different load capacities.

- Mast Height: The higher the mast, the lower the weight capacity.

- Load Center: The distance of the load’s center of gravity from the forklift’s mast significantly impacts stability and safe load capacity.

It’s crucial to always refer to the data plate before lifting any load. Never guess or estimate the load capacity; always check the specifications.

Q 7. How do you identify and report forklift malfunctions?

Identifying and reporting malfunctions is crucial for maintaining safe operations. My approach involves:

- Regular Inspections: Conducting thorough pre-operational inspections and paying close attention to any unusual sounds, vibrations, or leaks.

- Monitoring Performance: Observing the forklift’s performance during operation and noting any deviations from normal behavior. This includes things like unusual hydraulic actions or engine performance.

- Immediate Reporting: Reporting any suspected malfunction immediately to my supervisor or maintenance personnel. Never attempt to operate a forklift with known issues.

- Documentation: Properly documenting all reported malfunctions, including the date, time, nature of the problem, and any relevant observations.

- Tagging: Tagging the forklift out of service to prevent further use until repairs are made.

For example, if I hear a grinding noise from the hydraulics, I’ll immediately stop the forklift, report the issue, and tag it out of service, preventing potential damage or accidents.

Q 8. Explain the different types of hoisting mechanisms.

Hoisting mechanisms are the heart of lifting operations, and several types exist, each suited to different applications and load capacities. They are broadly categorized based on their power source and lifting method.

- Electric Hoists: These are powered by electricity and offer precise control and high lifting speeds. They are common in factories and warehouses. Variations include chain hoists (using a chain as the lifting element) and wire rope hoists (using a steel wire rope).

- Pneumatic Hoists: Using compressed air as their power source, these hoists are ideal for environments where electrical power is limited or risky, like some construction sites or areas with flammable materials. They generally offer ruggedness and reliability.

- Hydraulic Hoists: These use hydraulic fluid under pressure to generate lifting force. Hydraulic hoists are known for their ability to lift extremely heavy loads and are often found in industrial settings or for heavy construction equipment.

- Manual Hoists: These require human power, typically through a hand crank or lever system. They are used for lighter loads where electricity or compressed air isn’t available. Examples include chain blocks and come-alongs.

The choice of hoisting mechanism depends heavily on the load’s weight, the environment, and the required speed and precision of the lift.

Q 9. Describe the safety precautions associated with hoist operation.

Safety is paramount in hoist operation. A comprehensive safety program should be in place, including regular inspections and operator training. Key safety precautions include:

- Proper Training: Operators must receive thorough training on the specific type of hoist they will operate, covering pre-operational checks, safe operating procedures, and emergency responses.

- Pre-Operational Inspection: A meticulous inspection must be conducted before each use, checking for wear and tear, damage to the hoist components, and proper functionality of safety mechanisms.

- Load Capacity: Never exceed the hoist’s rated load capacity. Overloading can lead to catastrophic failure.

- Proper Rigging: Use appropriate lifting slings, chains, or ropes that are in good condition and rated for the load’s weight. Ensure the load is securely attached and balanced.

- Clear Communication: Maintain clear communication between the hoist operator and anyone working near the hoist or load.

- Personal Protective Equipment (PPE): Always use appropriate PPE, including safety helmets, gloves, and safety shoes.

- Emergency Procedures: All personnel should know the emergency procedures in case of a malfunction or accident.

Following these precautions significantly reduces the risk of accidents and ensures the safe operation of hoisting equipment.

Q 10. What are the weight limits and load-bearing capacities for different types of hoists?

Weight limits and load-bearing capacities vary significantly depending on the hoist type, manufacturer, and model. These ratings are clearly specified on the hoist itself and in the manufacturer’s documentation. For example:

- Small Electric Chain Hoists: Might have capacities ranging from a few hundred pounds to several tons.

- Large Hydraulic Hoists: Can lift hundreds of tons.

- Manual Chain Blocks: Typically have capacities from a few hundred pounds to a few tons.

It’s crucial to always consult the hoist’s data plate for the exact weight limit before attempting any lift. Operating a hoist beyond its rated capacity is extremely dangerous and can result in serious injury or death.

Q 11. How do you conduct a pre-operational inspection of a hoist?

A thorough pre-operational inspection is a non-negotiable step before every hoist operation. The inspection should cover these key points:

- Visual Inspection: Check for any visible damage to the hoist structure, cables, chains, hooks, and other components. Look for signs of wear, corrosion, cracks, or deformation.

- Functional Test: Manually operate the hoist through its full range of motion, observing its smooth operation and the absence of unusual noises or vibrations.

- Brake Test: Test the brake mechanism to ensure it functions correctly and holds the load securely.

- Limit Switches: Verify that the upper and lower limit switches are properly adjusted and functioning to prevent over-travel.

- Safety Devices: Inspect safety devices such as overload protection and emergency stops to ensure they are in working order.

- Power Supply: Check the power supply (electrical or pneumatic) to ensure it’s adequate and safe.

- Documentation: Check for any relevant documentation such as inspection records or maintenance logs.

Documenting the inspection findings is essential for maintaining a record of the hoist’s condition and fulfilling safety regulations.

Q 12. How do you handle a load imbalance during hoist operation?

Load imbalance during hoist operation is a significant hazard. If you detect an imbalance, immediately stop the lift. Never attempt to correct an imbalance while the load is in motion. The steps to handle this are:

- Assess the Imbalance: Carefully determine the cause of the imbalance. Is the load improperly secured? Is the weight distribution uneven?

- Lower the Load: Gently lower the load to the ground.

- Correct the Imbalance: Secure the load properly, ensuring even weight distribution. This might involve readjusting the slings or chains.

- Re-evaluate: Before attempting another lift, re-evaluate the situation and ensure the load is balanced and securely attached.

Preventing load imbalances in the first place is key. Carefully plan the lift, ensure proper rigging techniques are used, and double-check everything before starting the hoist.

Q 13. What are the emergency procedures for a hoist malfunction?

Emergency procedures for hoist malfunctions vary depending on the specific issue, but some common steps apply to most situations:

- Stop the Hoist: Immediately stop the hoist using the emergency stop button or other available means.

- Assess the Situation: Determine the nature of the malfunction. Is there a mechanical issue? Electrical problem?

- Evacuate the Area: Clear the immediate area around the hoist to prevent injury. Warn others in the vicinity.

- Report the Malfunction: Report the incident to the appropriate personnel, such as a supervisor or maintenance crew.

- Do Not Attempt Repairs: Do not attempt to repair the hoist yourself unless you are specifically trained to do so. Only qualified personnel should perform repairs.

- Follow Company Protocol: Follow established company emergency procedures and protocols.

Regular maintenance, thorough inspections, and comprehensive operator training can help prevent malfunctions and ensure a safe response in case of an emergency.

Q 14. What are the different types of forklift attachments and their uses?

Forklift attachments significantly broaden the versatility of forklifts, enabling them to handle a wider range of materials and tasks. Some common attachments include:

- Side Shifters: Allow the operator to laterally shift the forks, facilitating precise placement of loads in confined spaces.

- Rotators: Rotate the forks, enabling easier handling of long or awkward objects.

- Clamps: Used for handling various materials such as paper rolls, barrels, and other cylindrical objects.

- Bale Clamps: Specifically designed for handling bales of materials like hay, cotton, or waste paper.

- Carriage Movers: Used to move materials from one position to another without having to move the forklift.

- Fork Extensions: Increase the fork length to handle longer loads.

- Positioners: Allow the operator to adjust the fork position, improving handling of uneven or unstable loads.

- Push-Pull Attachments: Aid in pushing and pulling heavy objects.

The selection of the appropriate attachment depends on the specific material being handled and the operational requirements. Using the wrong attachment can lead to accidents and damage. Always ensure the attachment is compatible with your forklift and rated for the load’s weight.

Q 15. Explain the proper techniques for using forklift attachments.

Using forklift attachments safely and effectively requires understanding their specific capabilities and limitations. Before attaching any implement, ensure it’s compatible with your forklift model and that you’ve received proper training on its use. Always inspect the attachment for any damage before use.

- Proper Attachment: Securely connect the attachment, following the manufacturer’s instructions precisely. Double-check all pins, clamps, and hydraulic connections. A poorly secured attachment can lead to accidents.

- Load Center Considerations: Understand how the attachment alters the forklift’s load center. This impacts stability, especially when carrying heavy or unusually shaped loads. Improper load distribution increases the risk of tipping.

- Capacity Limits: Never exceed the combined weight capacity of the forklift and the attachment. Always consult the forklift’s capacity chart and the attachment’s specifications.

- Safe Operation: Operate the forklift smoothly, avoiding sudden stops or jerky movements, particularly when using attachments. These movements can destabilize the load and cause accidents.

- Example: When using a side-shift attachment, remember to distribute the load evenly. Shifting the load too far to one side can cause the forklift to tip.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain a safe working distance from other equipment and personnel?

Maintaining a safe working distance from other equipment and personnel is paramount for preventing collisions and injuries. Think of it like driving a car – you need a safe following distance and awareness of your surroundings.

- Visual Awareness: Constantly scan your surroundings. Use your mirrors and look around before making any movements. Never assume others see you.

- Horn and Signals: Use your forklift’s horn and lights to alert others of your presence and intended movements, especially in blind corners or congested areas.

- Speed Control: Maintain a safe speed, especially in areas with high pedestrian or equipment traffic. Reduce your speed when navigating tight spaces or near people.

- Communication: Communicate with other operators and workers. Use hand signals or radios to coordinate movements and avoid potential conflicts. If unsure about someone’s actions, stop and clarify.

- Safety Zones: Respect established safety zones and designated walkways. Avoid operating your forklift in areas where pedestrians are present, unless absolutely necessary.

Example: If working near a loading dock, maintain a sufficient distance from the edge to prevent falling off. Always be aware of pedestrians and other vehicles approaching the dock.

Q 17. What are the rules for operating a forklift on ramps and inclines?

Operating a forklift on ramps and inclines demands extra caution. The increased risk of tipping necessitates specific procedures.

- Angle of Inclination: Never exceed the manufacturer’s recommended grade or incline. This information is typically found in the forklift’s operator’s manual.

- Load Placement: Keep the load as low as possible to lower the center of gravity, improving stability.

- Slow and Steady: Travel slowly and smoothly, avoiding sudden acceleration or braking. Maintain a consistent speed and try to avoid stopping mid-slope, if possible.

- Facing Uphill: When ascending, face uphill. When descending, also face downhill (if allowed). This provides better control and braking.

- Emergency Brakes: Be prepared to use your emergency brake if needed. Practice using your emergency brake to react quickly.

Example: Before ascending a ramp, assess its steepness and ensure it’s within your forklift’s capabilities. If uncertain, it’s better to request assistance or find an alternative route.

Q 18. How do you manage blind spots when operating a forklift?

Forklifts have significant blind spots, making awareness and prevention crucial. Addressing blind spots effectively is key to safe operation.

- Mirror Usage: Regularly check your mirrors. They are not a replacement for looking around but are important for situational awareness.

- Head Turns and Checks: Before moving, make frequent checks by physically turning your head to ensure visibility of all areas around your forklift.

- Spotter: In congested areas or when navigating tight corners, utilizing a spotter is extremely helpful. A spotter can help you avoid unseen obstacles or pedestrians.

- Slow and Cautious Movements: Always move slowly in areas with reduced visibility. This gives you more time to react to unexpected situations.

- Awareness Training: Regular training emphasizes the identification and mitigation of blind spots and encourages careful operation.

Example: Before backing up, completely stop, sound your horn, and carefully check your mirrors and look over your shoulder to ensure there are no obstacles or personnel behind you. This simple process significantly reduces the risk of an accident.

Q 19. How do you react to a near-miss incident while operating a forklift or hoist?

A near-miss incident, while not resulting in an accident, highlights potential dangers needing immediate attention.

- Immediate Stop: Stop immediately to assess the situation and ensure everyone is safe.

- Incident Reporting: Report the incident through the appropriate channels. Detailed accounts help prevent future occurrences.

- Root Cause Analysis: Analyze what caused the near miss. Was it a blind spot, unsafe speed, or equipment malfunction?

- Corrective Actions: Implement corrective actions to prevent similar incidents. This might involve additional training, equipment modifications, or procedural changes.

- Follow-up: Follow up on corrective actions to ensure their effectiveness.

Example: If you nearly hit a rack while turning, consider if better mirror usage, slower speeds, or improved aisle markings could prevent a similar incident in the future.

Q 20. What is your experience with different types of warehouse layouts?

My experience encompasses various warehouse layouts, from traditional aisle-based systems to more modern designs.

- Aisle-Based Warehouses: These are the most common, with designated aisles for forklifts. Efficient navigation and load management are key here.

- High-Bay Warehouses: These utilize vertical space with high racking systems. This necessitates specialized equipment and safety protocols for height and weight considerations.

- Narrow Aisle Warehouses: This design uses very narrow aisles, often requiring reach trucks or very maneuverable forklifts.

- Automated Warehouses: These utilize automated guided vehicles (AGVs) and other automated systems, requiring a different skill set in terms of coordination and system understanding.

- Combination Layouts: Many warehouses incorporate elements from multiple layouts, demanding flexibility and adaptability.

Example: In a high-bay warehouse, I’ve become proficient in using lift trucks equipped with safety features such as load height indicators to reduce the risk of overhead collisions.

Q 21. How do you prioritize tasks and manage your time effectively in a warehouse environment?

Effective task prioritization and time management are crucial in a warehouse setting. Efficient work practices and clear communication greatly help.

- Prioritization: Prioritize tasks based on urgency and importance, focusing on time-sensitive orders or high-value items first.

- Route Planning: Plan efficient routes to minimize travel time and reduce unnecessary movement.

- Batching Similar Tasks: Group similar tasks together to streamline workflows. For example, completing all inbound deliveries before outbound shipments.

- Time Tracking: Monitor my progress and adjust my schedule as needed. Tracking completion times helps to identify areas for improvement.

- Communication: Maintain open communication with supervisors and colleagues to ensure tasks are completed accurately and efficiently, and to address unforeseen obstacles promptly.

Example: Instead of randomly picking orders, I prioritize those with impending deadlines to ensure timely delivery. This approach ensures customer satisfaction and avoids unnecessary delays.

Q 22. Explain your experience with different types of warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) spans several leading platforms. I’ve worked extensively with both cloud-based and on-premise systems, including Manhattan Associates, Blue Yonder, and Infor WMS. My experience isn’t limited to simply operating within these systems; I understand their core functionalities like inventory tracking, order fulfillment, and warehouse control. For example, in my previous role at Acme Distribution, we utilized Manhattan Associates WMS to optimize our picking processes. This involved configuring the system to utilize directed putaway strategies, resulting in a 15% reduction in picking time. I am familiar with different modules within these systems, such as labor management, slotting optimization, and reporting and analytics, and how they all integrate to create an efficient warehouse operation. My understanding extends to the integration of WMS with other enterprise resource planning (ERP) systems, ensuring seamless data flow throughout the supply chain. I’m proficient in troubleshooting system errors and performing data analysis to identify areas for improvement.

Q 23. What is your experience with inventory control and management?

Inventory control and management are fundamental to my work. My experience includes cycle counting, physical inventory checks, and reconciliation of discrepancies. I understand the importance of accurate inventory data for effective order fulfillment and minimizing stockouts. At my previous company, I implemented a new cycle counting methodology that reduced inventory discrepancies by 20%. This involved training the team on proper counting techniques and utilizing barcode scanners to ensure data accuracy and efficiency. I’m familiar with various inventory management techniques, such as FIFO (First-In, First-Out) and LIFO (Last-In, First-Out), and know how to apply them based on the specific product and industry requirements. My skills also include managing stock levels, identifying slow-moving items, and proposing strategies to improve inventory turnover. I am adept at using inventory management software to generate reports, identify trends, and make data-driven decisions.

Q 24. Describe your experience with safety training and certifications.

Safety is my top priority. I hold a valid forklift certification, renewed annually, and have completed comprehensive safety training programs covering all aspects of safe forklift and hoist operation, including pre-operational inspections, load stability, and emergency procedures. My certifications also include OSHA 10-hour training and training on specific safety protocols for hazardous materials handling. Beyond formal certifications, I’m actively involved in safety meetings and participate in proactive hazard identification and risk assessment exercises. I am comfortable providing safety training to other team members and ensuring adherence to company safety policies. I believe that a strong safety culture is paramount to prevent accidents and maintain a productive and injury-free work environment. A personal example of this is when I spotted a potential hazard – a loose floorboard in the warehouse aisle – and immediately reported it to management, preventing a possible accident.

Q 25. How do you handle challenging or stressful situations in a fast-paced warehouse setting?

Fast-paced warehouse environments often present challenges. My approach to stressful situations is systematic and calm. I prioritize tasks based on urgency and importance, utilizing time management techniques to ensure efficiency. For example, if there’s a sudden surge in order volume, I’d first assess the situation, communicate with my team to determine the most critical orders, and then efficiently adjust our workflow to meet the demand. I firmly believe in clear and open communication, so I’ll readily collaborate with colleagues and supervisors to find solutions to unforeseen problems. If I encounter a problem beyond my skillset, I’ll seek assistance from experienced team members or supervisors, rather than attempting to resolve it independently and risk further complications. Maintaining a positive attitude, even under pressure, contributes to overall team morale and productivity. I believe in staying proactive and adaptable, allowing me to remain calm and efficient even amidst the chaos.

Q 26. What are your strengths and weaknesses as a forklift/hoist operator?

My strengths as a forklift and hoist operator include my proficiency in operating various types of equipment, my strong attention to detail, my commitment to safety, and my ability to work efficiently under pressure. I am highly skilled in maneuvering equipment in tight spaces and navigating busy warehouse environments. A specific example is my ability to consistently meet daily targets in a high-volume distribution center. My attention to detail ensures that all loads are secured properly and that pre-operational checks are rigorously performed. My weakness, which I am actively working to improve, is delegation. While I’m highly proficient in many areas, I sometimes find it difficult to delegate tasks, opting to handle everything personally. I’m currently implementing strategies to build my delegation skills, focusing on improving my trust in others and identifying individual strengths within the team.

Q 27. Where do you see yourself in 5 years regarding your career in this field?

In five years, I envision myself as a seasoned and respected member of the warehouse team, possibly in a supervisory or training role. I’m eager to continue enhancing my skills and knowledge, possibly pursuing advanced certifications in warehouse management or logistics. I am interested in contributing to the development of innovative solutions and process improvements within the warehouse. My goal is to become a valuable resource, mentoring and training new operators while maintaining my high standards of safety and efficiency.

Q 28. Do you have any questions for me?

Yes, I have a few questions. First, what opportunities for professional development and advancement are available within the company? Second, what are the company’s specific safety procedures and training protocols? Finally, could you tell me more about the team dynamics and working environment within the warehouse?

Key Topics to Learn for Forklift and Hoist Operation Interview

- Forklift Safety Procedures: Understanding and applying OSHA regulations, pre-operational checks, and safe operating procedures.

- Load Handling Techniques: Proper load securing, weight distribution, and maneuvering techniques for various loads and environments.

- Equipment Maintenance: Basic knowledge of routine maintenance checks, identifying potential issues, and reporting malfunctions.

- Hoist Operation Principles: Understanding different types of hoists, load capacity, safe lifting practices, and emergency procedures.

- Warehouse Layout and Logistics: Efficient navigation within warehouse spaces, understanding traffic flow, and optimizing movement of goods.

- Troubleshooting and Problem-Solving: Identifying and resolving common operational issues, such as load instability or equipment malfunctions.

- Communication and Teamwork: Effective communication with colleagues and supervisors, adhering to team protocols, and reporting concerns promptly.

- Applicable Regulations and Compliance: Knowledge of relevant safety standards and regulations related to forklift and hoist operations.

Next Steps

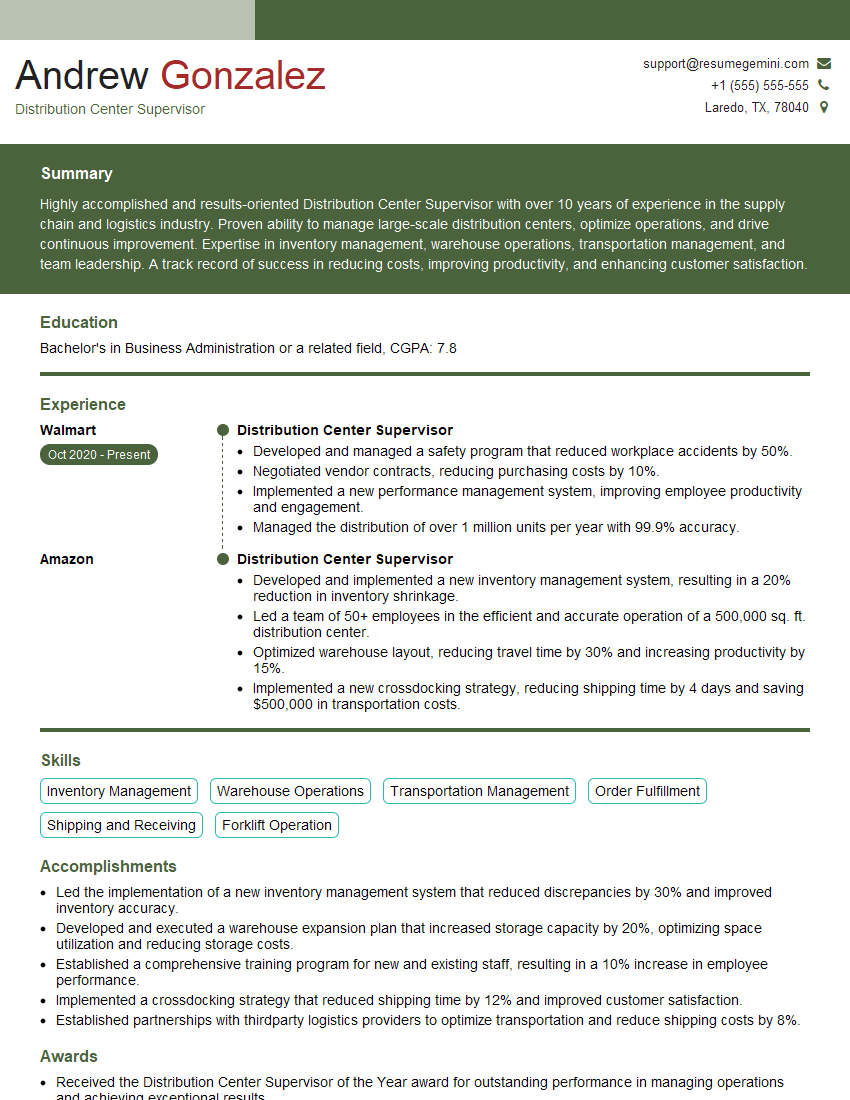

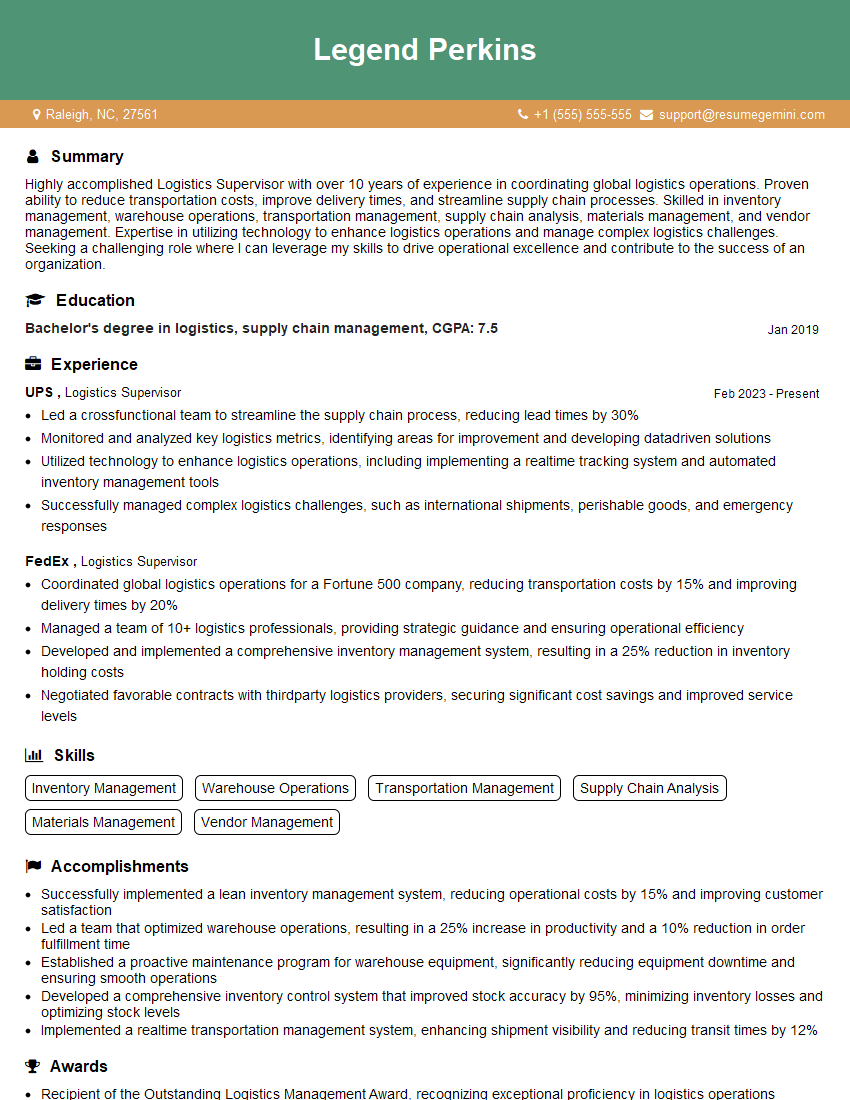

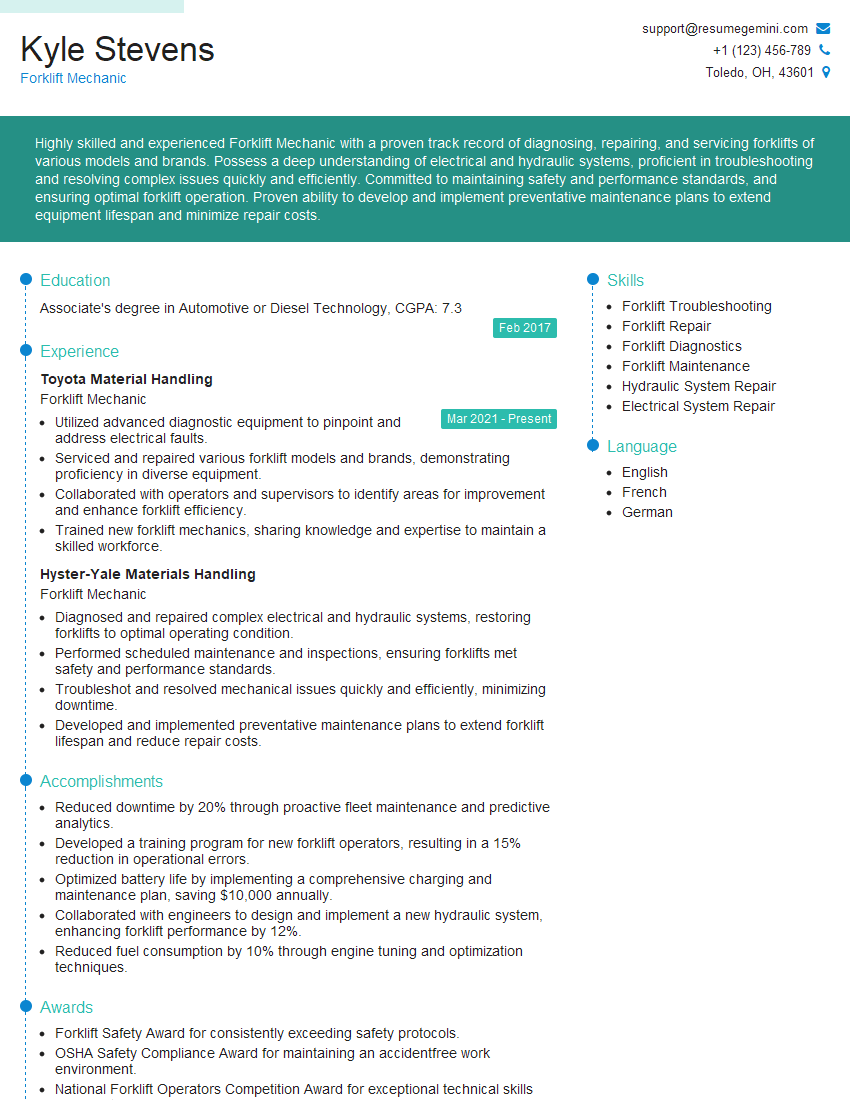

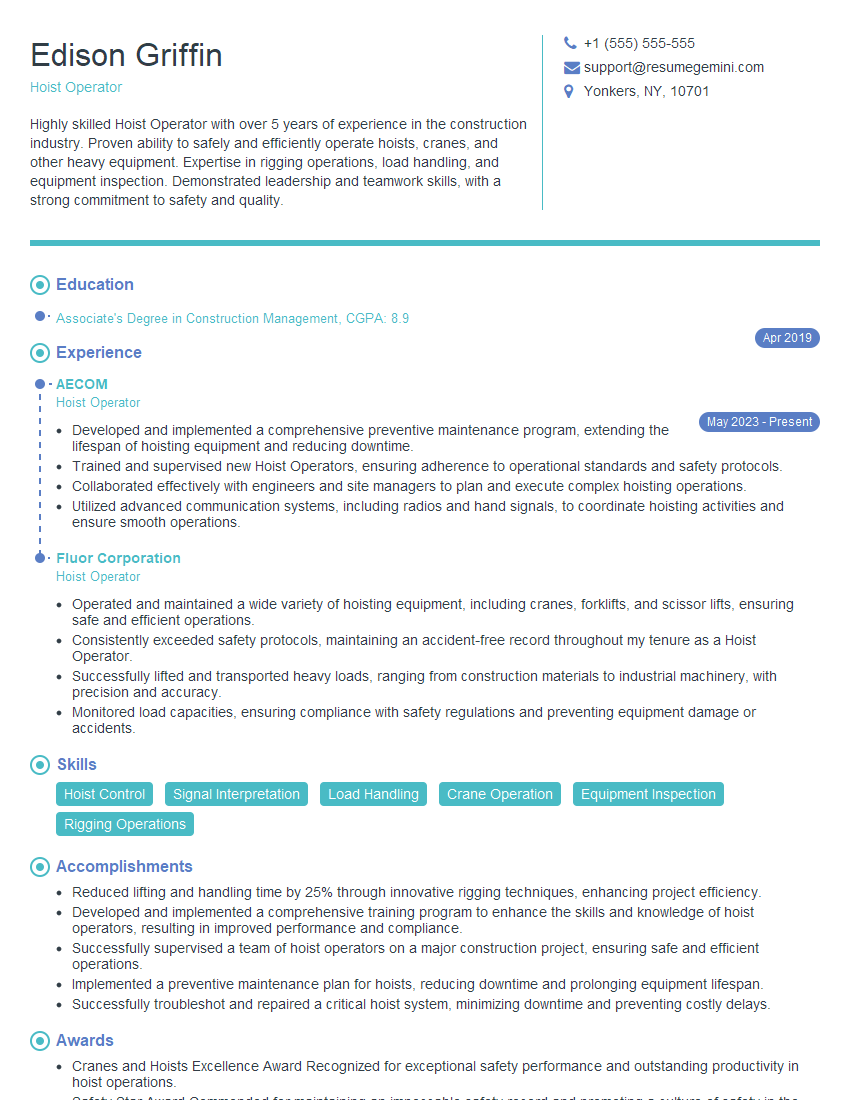

Mastering forklift and hoist operation opens doors to rewarding careers in logistics, warehousing, and manufacturing, offering opportunities for advancement and increased earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is crucial for getting your application noticed. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to forklift and hoist operation roles to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good