Cracking a skill-specific interview, like one for Preventive Maintenance Checks, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Preventive Maintenance Checks Interview

Q 1. Describe your experience with developing and implementing preventive maintenance schedules.

Developing and implementing preventive maintenance schedules is a crucial aspect of ensuring equipment reliability and minimizing downtime. My approach involves a thorough understanding of the equipment, its operating conditions, and manufacturer recommendations. I begin by conducting a comprehensive equipment survey, identifying all assets and their criticality to operations. This includes gathering data on the equipment’s age, operating hours, past maintenance history, and environmental factors that might affect its lifespan.

Next, I use this information to develop a customized preventive maintenance (PM) schedule. This isn’t a one-size-fits-all approach; instead, it’s tailored to each piece of equipment. For instance, a high-usage production line might require daily lubrication checks, while a less frequently used piece of equipment might only need quarterly inspections. The schedule includes specific tasks, such as lubrication, cleaning, inspections, and component replacements, all timed according to the equipment’s needs and manufacturer recommendations. Once the schedule is developed, I implement it using a CMMS (explained below), ensuring all personnel are trained and understand their responsibilities.

Finally, I continuously monitor the effectiveness of the PM schedule. By tracking equipment performance and downtime, I identify areas for improvement and adjust the schedule as needed. This iterative process ensures the PM program remains optimal and cost-effective.

Q 2. What CMMS (Computerized Maintenance Management System) software are you familiar with?

I’m proficient in several CMMS software packages, including IBM Maximo, SAP PM, and UpKeep. My experience encompasses all aspects of these systems, from data entry and scheduling to reporting and analysis. For example, in a previous role, I used IBM Maximo to manage the preventive maintenance program for a large manufacturing facility. This involved creating and assigning work orders, tracking completed tasks, managing spare parts inventory, and generating reports on equipment performance and maintenance costs. The ability to generate customized reports within these systems is invaluable for identifying trends, optimizing maintenance strategies, and demonstrating the ROI of our preventive maintenance program.

Q 3. Explain your process for identifying potential equipment failures.

Identifying potential equipment failures relies on a multi-faceted approach combining proactive monitoring and reactive analysis. Proactive methods include regular visual inspections, vibration analysis, oil analysis, and thermal imaging. These techniques allow us to detect subtle indicators of wear and tear before they escalate into major failures. For example, excessive vibration in a motor might indicate impending bearing failure, while an unusual rise in temperature could point to an electrical fault.

Reactive analysis involves carefully examining historical maintenance data, including past repairs, downtime records, and failure modes. By analyzing this data, we can identify patterns and trends that might indicate recurring problems or potential future failures. For instance, if a specific component fails frequently, it might warrant a more frequent inspection or a preventative replacement schedule.

Combining these approaches allows for a comprehensive understanding of equipment health and allows for proactive interventions to prevent costly downtime.

Q 4. How do you prioritize preventive maintenance tasks?

Prioritizing preventive maintenance tasks is critical for maximizing efficiency and minimizing risk. My approach uses a risk-based prioritization system, which considers several factors:

- Criticality: How essential is the equipment to overall operations? Critical equipment receives higher priority.

- Failure Rate: Equipment with a high historical failure rate will be prioritized.

- Consequences of Failure: What are the potential costs (financial, safety, etc.) associated with a failure? High-consequence equipment takes precedence.

- Maintenance Cost: While critical, we balance this with the cost of maintenance. A simple task on critical equipment might be prioritized over a complex, expensive task on less critical equipment.

I often use a scoring system to quantify these factors, allowing for objective prioritization. This ensures that resources are allocated effectively to the most important tasks, preventing catastrophic failures while optimizing maintenance spending.

Q 5. Describe a time you identified a potential equipment failure before it occurred.

In a previous role at a food processing plant, we used vibration analysis on a critical conveyor system. The analysis revealed an increase in vibration levels beyond normal operating parameters in one specific section of the conveyor. While the conveyor was still functioning, this indicated potential bearing wear. We scheduled immediate preventative maintenance, replacing the bearings. This averted a complete conveyor failure during peak production, which would have resulted in significant downtime and product loss – potentially costing tens of thousands of dollars.

Q 6. How do you track and document preventive maintenance activities?

Tracking and documenting preventive maintenance activities is vital for accountability, analysis, and continuous improvement. I utilize the CMMS system extensively for this. All PM tasks are recorded within the system, including the assigned technician, date completed, parts used, and any observations made during the maintenance. Digital signatures and photographic evidence are often used to confirm task completion and document the equipment’s condition.

The system generates reports that allow for easy tracking of completed tasks, overdue tasks, and equipment history. This data is essential for identifying trends, optimizing maintenance schedules, and justifying the investment in preventative maintenance. Regular audits of the system also ensure data accuracy and compliance.

Q 7. What are some common causes of equipment failure and how can they be prevented?

Common causes of equipment failure are numerous and often interconnected. They can be broadly categorized as:

- Wear and Tear: This is the natural degradation of components due to use, including friction, corrosion, and fatigue. Regular lubrication, inspections, and timely replacements can mitigate this.

- Environmental Factors: Exposure to extreme temperatures, humidity, dust, or vibration can accelerate equipment deterioration. Proper environmental controls and protective measures can significantly extend equipment lifespan.

- Improper Operation: Operating equipment outside its designed parameters, neglecting proper procedures, or overloading can lead to premature failure. Training employees and developing clear operating procedures are essential preventative measures.

- Lack of Maintenance: Neglecting scheduled maintenance, such as lubrication, cleaning, and inspections, significantly increases the likelihood of failure. A robust preventive maintenance program is the cornerstone of equipment reliability.

Preventing these failures requires a combination of proactive maintenance, operator training, and a commitment to following established procedures. Regular inspections, lubrication schedules, and addressing identified issues promptly are key elements of a successful preventive maintenance program. Furthermore, investing in high-quality components and adhering to manufacturer’s recommendations are critical to extending the service life of equipment.

Q 8. How do you ensure compliance with safety regulations during preventive maintenance?

Safety is paramount in preventive maintenance. My approach begins with a thorough pre-maintenance safety briefing covering specific hazards associated with the equipment and tasks. This includes reviewing relevant safety data sheets (SDS), identifying potential energy sources (like electricity or compressed air), and establishing lockout/tagout procedures to prevent accidental energization. We use personal protective equipment (PPE) appropriate for each task, from safety glasses and gloves to hearing protection and flame-resistant clothing as needed. Regular inspections of PPE and tools are conducted to ensure they’re in good working order. Furthermore, we maintain detailed records of safety procedures followed, any incidents or near misses, and corrective actions taken. For example, before working on a high-voltage electrical panel, we would meticulously follow a documented lockout/tagout procedure, verifying the absence of power multiple times using a voltage tester before commencing work. This multi-layered approach ensures compliance with all relevant OSHA and industry-specific safety regulations.

Q 9. What is your experience with root cause analysis?

Root cause analysis (RCA) is crucial for preventing recurring equipment failures. My experience involves utilizing various RCA techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis (FTA). For example, if a conveyor belt frequently breaks, I wouldn’t just replace the belt; I’d systematically investigate using the 5 Whys. Why did the belt break? Because it was worn. Why was it worn? Because of excessive friction. Why was there excessive friction? Because of misalignment. Why was it misaligned? Because the mounting bolts were loose. By identifying the root cause – loose mounting bolts – we can address the issue permanently, instead of just treating the symptom. I document all findings, recommendations, and implemented corrective actions, using these insights to continually improve our maintenance program and minimize future downtime.

Q 10. Describe your experience with different types of lubrication techniques.

My experience encompasses a variety of lubrication techniques, each chosen based on the specific equipment and its operating conditions. I’m proficient in manual lubrication using grease guns and oil cans, for instance, ensuring proper grease fittings are used and the correct amount of lubricant is applied. I also have extensive experience with automated lubrication systems, such as centralized lubrication systems which efficiently deliver lubricants to multiple points on a machine. I understand the importance of selecting the right lubricant – choosing the appropriate viscosity grade (SAE grades for oils) based on temperature and load conditions – to ensure optimal equipment performance and longevity. Furthermore, I understand the benefits and applications of different lubricant types, including grease (for heavy loads and slow speeds), oil (for high speeds and precision machinery), and specialized lubricants for extreme conditions. For instance, I’d use high-temperature grease in a furnace application and a synthetic oil in a high-precision robotic arm.

Q 11. How do you handle unexpected equipment failures during a preventive maintenance schedule?

Unexpected equipment failures during preventive maintenance are addressed swiftly and systematically. First, we prioritize safety and immediately secure the affected area, ensuring no one is injured. The next step is a thorough assessment of the situation to identify the extent of the failure and its potential impact on other equipment or operations. We then follow established emergency procedures, which may involve contacting specialized technicians if needed. Depending on the severity, we may perform a temporary repair to restore partial functionality while investigating the root cause. This investigation, using the RCA techniques I mentioned earlier, allows us to prevent similar future failures. The incident is fully documented, including actions taken, time lost, and associated costs, providing crucial data for continuous improvement of our maintenance programs.

Q 12. What are your skills in using diagnostic tools and equipment?

I possess extensive skills in using a range of diagnostic tools and equipment. This includes using vibration analyzers to detect bearing wear and imbalance, infrared (IR) cameras to identify overheating components, ultrasonic detectors for leak detection, and motor current analyzers to assess motor health. I’m also proficient with various handheld tools such as multimeters (for electrical testing), dial indicators (for precise measurements), and pressure gauges. I can interpret data from these instruments and use the information to accurately diagnose problems, plan repairs, and assess the overall condition of the equipment. For example, using an infrared camera, I detected a hot spot in an electrical connection, preventing a potential fire hazard before it escalated.

Q 13. How do you manage your time effectively during preventive maintenance?

Effective time management during preventive maintenance is crucial for maximizing efficiency. This involves careful planning and scheduling of tasks, prioritizing work based on criticality and urgency. We use computerized maintenance management systems (CMMS) to schedule maintenance activities, track progress, and manage inventory. The CMMS allows us to create detailed work orders, allocate resources, and monitor completion timelines. We also utilize work-breakdown structures (WBS) to break down complex tasks into smaller, manageable steps. Additionally, teamwork and clear communication are vital. By coordinating tasks and collaborating effectively, we avoid bottlenecks and ensure smooth workflow. Regularly reviewing our schedules and adapting them to changing needs is key to staying on track and minimizing downtime.

Q 14. What is your experience with different types of maintenance tasks (e.g., electrical, mechanical, hydraulic)?

My experience spans various maintenance disciplines, including mechanical, electrical, and hydraulic systems. In the mechanical realm, I’m skilled in tasks like bearing replacement, belt alignment, and gear lubrication. My electrical experience includes troubleshooting electrical circuits, motor repairs, and working with control systems (PLCs). Regarding hydraulic systems, I’m capable of diagnosing and repairing leaks, replacing hydraulic components, and maintaining hydraulic fluid levels. I’m also familiar with pneumatic systems. My expertise in these diverse areas allows me to tackle a wide range of maintenance tasks comprehensively. For example, I recently completed a project involving the overhaul of a large industrial pump, requiring skills in all three domains: mechanical (disassembling and reassembling the pump), electrical (troubleshooting the motor control system), and hydraulic (inspecting and repairing the hydraulic seals).

Q 15. Explain your understanding of failure modes and effects analysis (FMEA).

Failure Modes and Effects Analysis (FMEA) is a systematic method used to identify potential failures in a system, analyze their effects, and implement preventative actions. Think of it as a proactive risk assessment for your equipment. It’s not about waiting for something to break; it’s about anticipating what *could* break and mitigating those risks beforehand.

The process typically involves a team brainstorming potential failure modes for each component of a system. For each failure mode, we assess its severity (how bad would it be if it happened?), its occurrence (how likely is it to happen?), and its detection (how easily can we detect it before it causes problems?). These three factors are multiplied to give a Risk Priority Number (RPN). A high RPN indicates a high-risk failure mode that needs immediate attention.

For example, in a manufacturing plant, an FMEA for a conveyor belt might identify a failure mode as ‘belt slippage.’ The severity might be high (production stoppage, potential injury), the occurrence might be moderate (depending on belt age and maintenance), and the detection might be low (it might only be noticed after slippage occurs). The high severity would likely outweigh the lower detection and occurrence, resulting in a relatively high RPN, prompting preventative measures like regular belt tension checks and timely replacements.

- Identifying potential failure modes: This involves a thorough examination of each component and its function.

- Assessing severity, occurrence, and detection: This uses a standardized scoring system to quantify the risk.

- Calculating the Risk Priority Number (RPN): This helps prioritize actions based on risk level.

- Recommending preventative actions: This could include design changes, improved maintenance procedures, or operator training.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to troubleshoot a complex maintenance problem.

During my time at a food processing plant, a critical refrigeration unit unexpectedly failed, resulting in a significant temperature increase within the storage area and threatening thousands of dollars worth of perishable goods. Troubleshooting this was a challenge because the initial diagnostics pointed towards multiple possible causes – a failing compressor, faulty temperature sensors, or even a refrigerant leak.

My approach involved a structured troubleshooting process. I first visually inspected the unit, checking for any obvious signs of damage or leaks. Then, I consulted the unit’s maintenance logs and schematics. I systematically checked each component, using specialized tools to measure voltage, amperage, and pressure levels. I also cross-referenced my readings with the manufacturer’s specifications. The key was to eliminate possibilities one by one. It eventually turned out to be a combination of two issues: a failing compressor relay and a slightly low refrigerant charge. Replacing the relay and topping off the refrigerant solved the problem, avoiding significant losses.

This experience highlighted the importance of thorough record keeping, a methodical approach, and understanding the interconnectedness of different systems. Knowing where to find information and having the right tools were crucial in quickly resolving the problem.

Q 17. How do you communicate effectively with other team members during maintenance activities?

Effective communication is vital during maintenance activities. I believe in using a multi-faceted approach, combining different methods depending on the situation and audience.

- Pre-maintenance planning meetings: Before any significant maintenance task, I schedule meetings to clearly outline the scope of work, assign roles and responsibilities, and discuss potential challenges. This ensures everyone is on the same page.

- Real-time communication: During the maintenance process, I utilize various methods depending on the situation. For simple tasks, face-to-face communication is sufficient. For more complex tasks, I often employ walkie-talkies or dedicated communication channels to coordinate actions efficiently and maintain safety.

- Post-maintenance debriefs: After completing a maintenance task, we conduct a debrief to discuss what went well, what could be improved, and any lessons learned. This is crucial for continuous improvement.

- Clear and concise documentation: I maintain comprehensive, up-to-date maintenance logs, documenting every step of the process, including any unexpected issues and solutions. This ensures continuity and enables other team members to understand the history of the equipment.

Ultimately, clear, open, and respectful communication ensures a safe and efficient maintenance process.

Q 18. How do you stay current with new maintenance technologies and techniques?

Staying current in the rapidly evolving field of maintenance requires continuous learning. I leverage several resources to keep my knowledge up-to-date:

- Professional organizations: I actively participate in professional organizations like [Mention relevant professional organization(s)], attending conferences and workshops, and networking with other professionals in the field.

- Industry publications and journals: I regularly read trade magazines and journals to stay informed about the latest technologies and best practices.

- Online courses and webinars: I utilize various online platforms to access training courses and webinars on new maintenance techniques and technologies. This allows for flexible and convenient learning.

- Manufacturer training: I take advantage of training opportunities offered by equipment manufacturers, gaining hands-on experience with the latest tools and technologies.

- Mentorship and collaboration: I actively seek mentorship opportunities and collaborate with colleagues to share knowledge and learn from each other’s experiences.

By combining these methods, I ensure that my skillset remains current and relevant, benefiting my team and organization.

Q 19. What metrics do you use to measure the effectiveness of your preventive maintenance program?

Measuring the effectiveness of a preventive maintenance program requires a balanced approach, combining quantitative and qualitative metrics.

- Mean Time Between Failures (MTBF): This metric tracks the average time between equipment failures. A higher MTBF indicates improved equipment reliability.

- Mean Time To Repair (MTTR): This measures the average time it takes to repair a piece of equipment after a failure. A lower MTTR indicates faster and more efficient repairs.

- Maintenance costs: Tracking maintenance costs helps determine cost-effectiveness and identify areas for potential savings. We compare these to the costs of unplanned downtime.

- Equipment uptime: This metric tracks the percentage of time equipment is operational. Higher uptime indicates greater efficiency and productivity.

- Safety incidents related to equipment: A reduction in safety incidents related to equipment malfunctions shows the effectiveness of the program in preventing accidents.

- Employee satisfaction surveys: Gauging employee satisfaction with maintenance procedures and equipment reliability provides qualitative insights.

By regularly monitoring these metrics, we can identify trends, assess the program’s overall effectiveness, and make data-driven adjustments for improvement.

Q 20. Describe your experience with inventory management for maintenance parts.

Effective inventory management for maintenance parts is crucial for minimizing downtime and optimizing costs. My experience involves implementing and managing a system that balances the need for readily available parts with the costs of overstocking.

We utilize a combination of techniques:

- ABC analysis: This method categorizes parts based on their consumption value. ‘A’ items (high-value, frequently used) require close monitoring and tighter inventory control. ‘B’ and ‘C’ items (moderate and low value, respectively) require less stringent controls.

- Just-in-time (JIT) inventory: For less critical parts, we employ JIT strategies to minimize storage costs and reduce the risk of obsolescence. This involves ordering parts only when needed.

- Regular inventory audits: We conduct regular physical audits to reconcile inventory records with actual stock levels, ensuring accuracy.

- Vendor managed inventory (VMI): For some high-demand items, we utilize VMI, where our suppliers manage inventory levels at our facility. This reduces our administrative burden.

- Software-based inventory management systems: We use software to track part numbers, quantities, suppliers, and usage history, allowing for better forecasting and optimization of stock levels.

This integrated approach ensures we have the right parts, at the right time, without unnecessary storage costs or stockouts.

Q 21. How do you ensure the accuracy of maintenance records?

Accuracy in maintenance records is paramount for ensuring equipment reliability and safety. We implement several strategies to maintain accuracy:

- Standardized record-keeping procedures: We follow standardized procedures for documenting all maintenance activities, using pre-defined formats and templates to ensure consistency.

- Real-time data entry: Maintenance personnel are trained to enter data directly into the system as soon as a task is completed, minimizing the risk of errors and omissions.

- Regular data validation and audits: We perform regular audits to compare recorded data with physical evidence, identifying and correcting any discrepancies.

- Digitalization of records: We utilize computerized maintenance management systems (CMMS) to store and manage maintenance records electronically, enhancing accessibility and reducing the risk of data loss.

- Training and competency assessment: Maintenance personnel receive comprehensive training on record-keeping procedures and are regularly assessed on their competency.

- Cross-checking and verification: For critical maintenance activities, we often implement a system of cross-checking and verification to ensure data accuracy.

By using these methods, we maintain high levels of accuracy in our maintenance records, leading to better decision-making, improved equipment performance, and reduced safety risks.

Q 22. What is your experience with creating and updating maintenance procedures?

Creating and updating maintenance procedures is a crucial aspect of my role. It involves a systematic approach, beginning with a thorough understanding of the equipment. I start by performing a comprehensive analysis of the machinery, identifying all critical components and potential failure points. This often involves reviewing manufacturer’s recommendations, historical maintenance records, and even conducting on-site observations.

Next, I develop a detailed procedure document, outlining the steps involved in each preventive maintenance task. This includes specifying the tools required, the frequency of checks, the acceptance criteria, and any safety precautions. The language used is precise and unambiguous, leaving no room for misinterpretation. For instance, instead of saying “check the oil level,” I’d write “verify the oil level using the dipstick, ensuring it’s between the minimum and maximum marks.”

Regular updates are essential. These are triggered by several factors: equipment modifications, changes in operational conditions, the introduction of new technologies, or feedback from maintenance personnel highlighting areas for improvement. I utilize a version control system to track revisions and ensure everyone is using the most up-to-date procedures. A recent example involved updating the lubrication schedule for a conveyor system after we installed a new, higher-efficiency motor – requiring a different type of grease and lubrication frequency.

Q 23. How do you handle conflicting priorities during maintenance scheduling?

Conflicting priorities are inevitable in maintenance scheduling. To handle this effectively, I utilize a prioritized scheduling system based on several factors: criticality of equipment, potential impact of failure, cost of downtime, and regulatory compliance requirements. I employ a risk assessment matrix to quantitatively evaluate these factors, assigning risk scores to each maintenance task. This enables a data-driven approach to prioritizing tasks. For example, a critical piece of equipment with a high potential for catastrophic failure and significant downtime costs will always take precedence over a less critical system.

Furthermore, I leverage collaborative scheduling tools and actively communicate with all relevant departments. Transparency is key. I explain the rationale behind scheduling decisions and proactively address any concerns. Sometimes, negotiations are necessary to find mutually acceptable solutions, balancing the needs of different departments. I might suggest shifting a less critical task to a less busy period to accommodate a high-priority maintenance activity in another area.

Q 24. How do you ensure the proper training of maintenance personnel?

Proper training is paramount for effective preventive maintenance. My approach is multi-faceted and starts with a needs assessment to identify skill gaps. Then, I design training programs tailored to these needs, incorporating both theoretical and practical elements. This might include classroom sessions covering relevant safety procedures, equipment operation, and diagnostic techniques, combined with hands-on training sessions where personnel gain experience performing maintenance tasks under supervision.

I employ various training methods: presentations, interactive workshops, videos, and on-the-job coaching. Regular assessments and feedback sessions ensure that personnel are effectively absorbing the training. I use a competency matrix to track the skills and knowledge of each technician and identify areas requiring further training or development. For instance, after introducing new diagnostic software, I conducted a workshop to familiarize technicians with its use, followed by practical application sessions to ensure competency. Continuous professional development is encouraged, with opportunities for attending external courses and workshops.

Q 25. How do you deal with resistance to preventive maintenance from other departments?

Resistance to preventive maintenance can stem from various sources – from a lack of understanding to concerns about production downtime. To address this, I focus on building strong relationships and demonstrating the value of preventive maintenance. I start by educating other departments on the long-term benefits, emphasizing how preventive maintenance prevents costly breakdowns and maximizes operational efficiency. I present data showing the reduction in downtime and repair costs achieved through effective preventive maintenance programs.

I also involve other departments in the process, seeking their input on scheduling and task prioritization. This collaborative approach fosters buy-in and reduces resistance. For example, by working with the production team to schedule maintenance during less busy periods, I mitigate concerns about production disruptions. When resistance persists, I clearly articulate the potential consequences of neglecting preventive maintenance and highlight the potential risks to safety and production. A cost-benefit analysis can sometimes be persuasive in these situations.

Q 26. Explain your understanding of the relationship between preventive maintenance and overall equipment effectiveness (OEE).

Preventive maintenance and Overall Equipment Effectiveness (OEE) are intrinsically linked. OEE measures the effectiveness of equipment utilization, encompassing availability, performance, and quality. Preventive maintenance directly impacts all three aspects.

By preventing unexpected breakdowns through regular inspections and maintenance, preventive maintenance significantly improves availability. Regular lubrication, cleaning, and calibration ensure the equipment operates at its optimal performance level, thus enhancing performance. Finally, preventive maintenance helps to maintain the quality of output by preventing defects caused by malfunctioning equipment which improves quality. In essence, a robust preventive maintenance program is fundamental to achieving high OEE.

For example, a well-maintained machine will experience less downtime due to failures, resulting in increased availability. This increased availability directly translates into higher OEE. Similarly, preventative maintenance activities such as calibration can ensure the machine operates within its specified tolerances, leading to higher quality output and therefore higher OEE. I regularly track OEE metrics to evaluate the effectiveness of our preventive maintenance programs and make adjustments as needed.

Q 27. What are your salary expectations?

My salary expectations are in line with the industry standard for a domain expert with my experience and qualifications in preventive maintenance. I am open to discussing a compensation package that reflects my contributions and aligns with the company’s compensation structure. I would welcome the opportunity to review the salary range for this position and discuss how my skills and experience benefit your organization.

Q 28. Do you have any questions for me?

Yes, I do have a few questions. First, can you elaborate on the company’s current preventive maintenance program and its key performance indicators (KPIs)? Second, what opportunities exist for professional development and advancement within the maintenance team? And finally, could you describe the company culture and its emphasis on employee collaboration and innovation in maintenance practices?

Key Topics to Learn for Preventive Maintenance Checks Interview

- Understanding Preventive Maintenance Strategies: Explore different preventive maintenance strategies like time-based, condition-based, and predictive maintenance. Understand their strengths and weaknesses and when to apply each.

- Developing and Implementing Maintenance Schedules: Learn how to create effective maintenance schedules based on equipment criticality, manufacturer recommendations, and historical data. Practice creating schedules using different software or methods.

- Data Analysis and Reporting: Understand how to collect, analyze, and interpret data from preventive maintenance activities. This includes identifying trends, predicting potential failures, and justifying maintenance decisions with data.

- Common Equipment and System Knowledge: Familiarize yourself with the specific types of equipment relevant to the jobs you’re applying for (e.g., HVAC systems, production machinery, vehicles). Understand their typical maintenance requirements.

- Troubleshooting and Problem-Solving: Practice diagnosing common issues during preventive maintenance checks. Develop your ability to identify root causes and implement effective solutions.

- Safety Procedures and Regulations: Thoroughly understand relevant safety protocols and regulations related to preventive maintenance and equipment operation. Be prepared to discuss your experience with lockout/tagout procedures and other safety measures.

- Cost-Benefit Analysis of Maintenance Strategies: Be able to evaluate the cost-effectiveness of different maintenance approaches. Understand how to balance the cost of maintenance with the potential costs of equipment failure.

- Inventory Management and Spare Parts: Learn how to effectively manage inventory of spare parts and supplies needed for preventive maintenance. Understand the importance of minimizing downtime through efficient parts management.

- Communication and Teamwork: Discuss your experience working collaboratively with teams, communicating effectively with supervisors and technicians, and documenting your work accurately and completely.

Next Steps

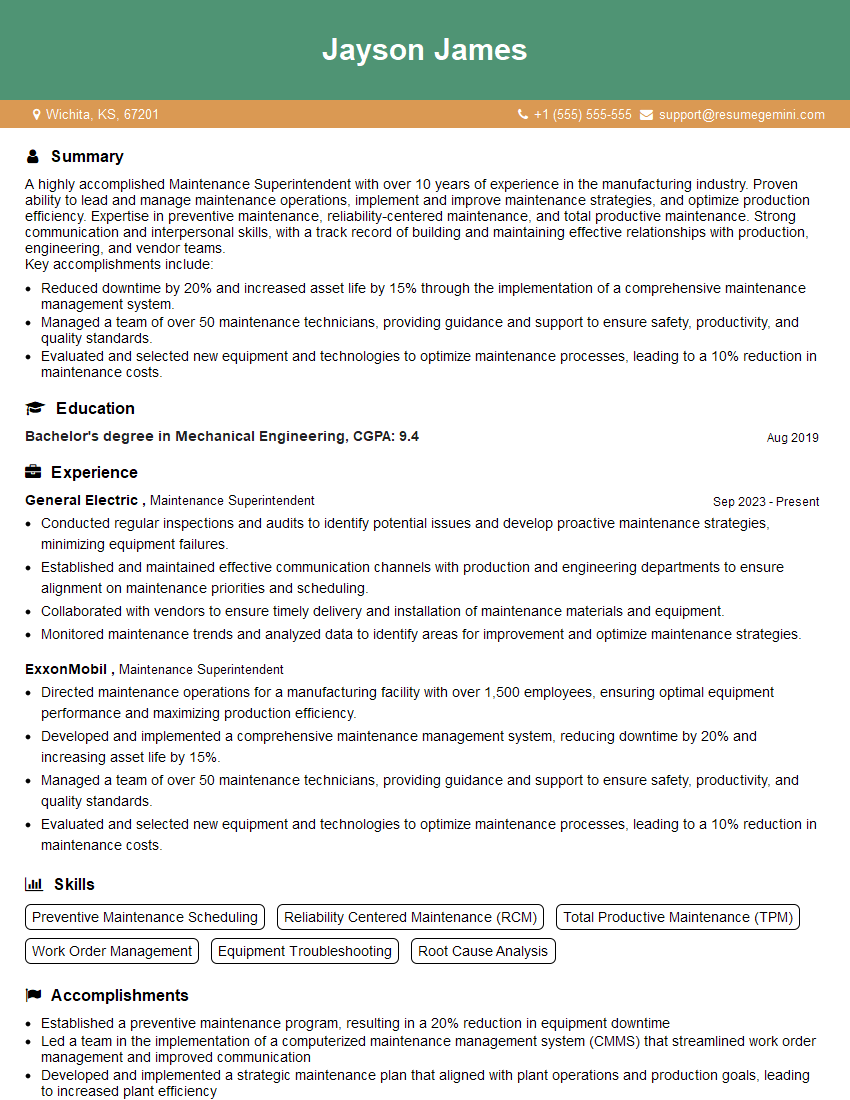

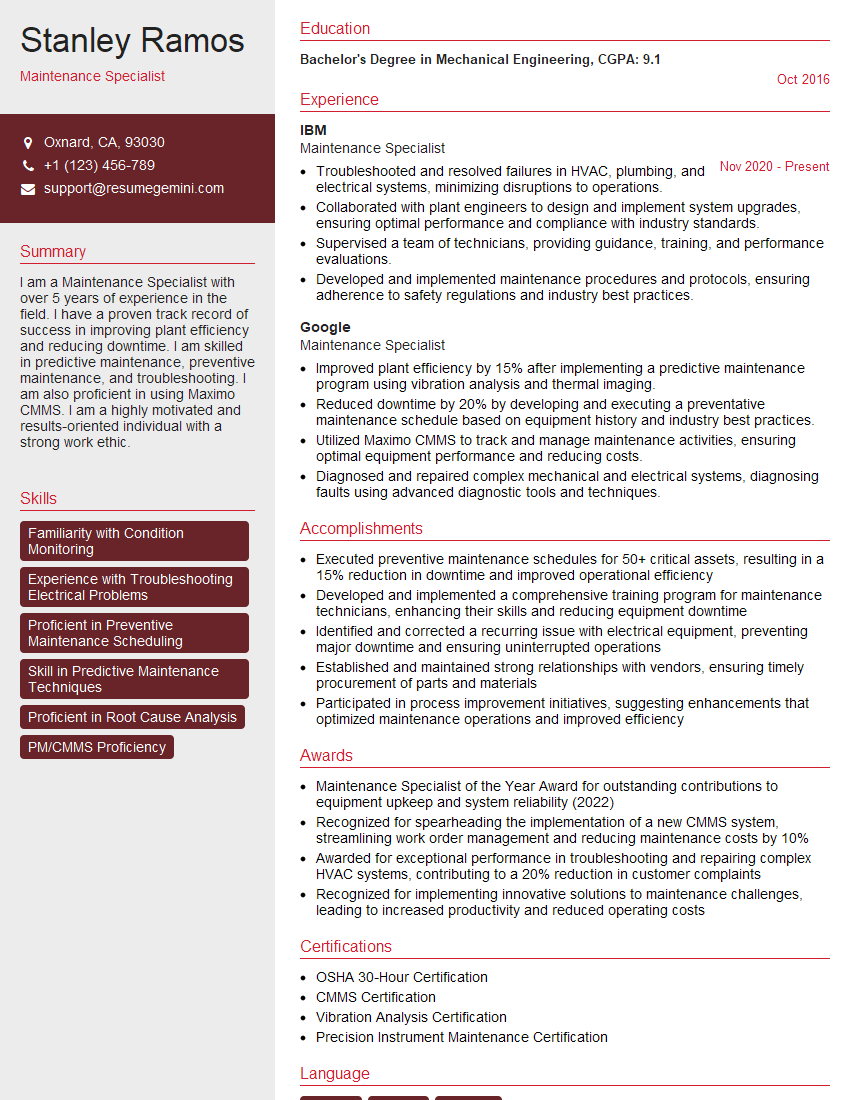

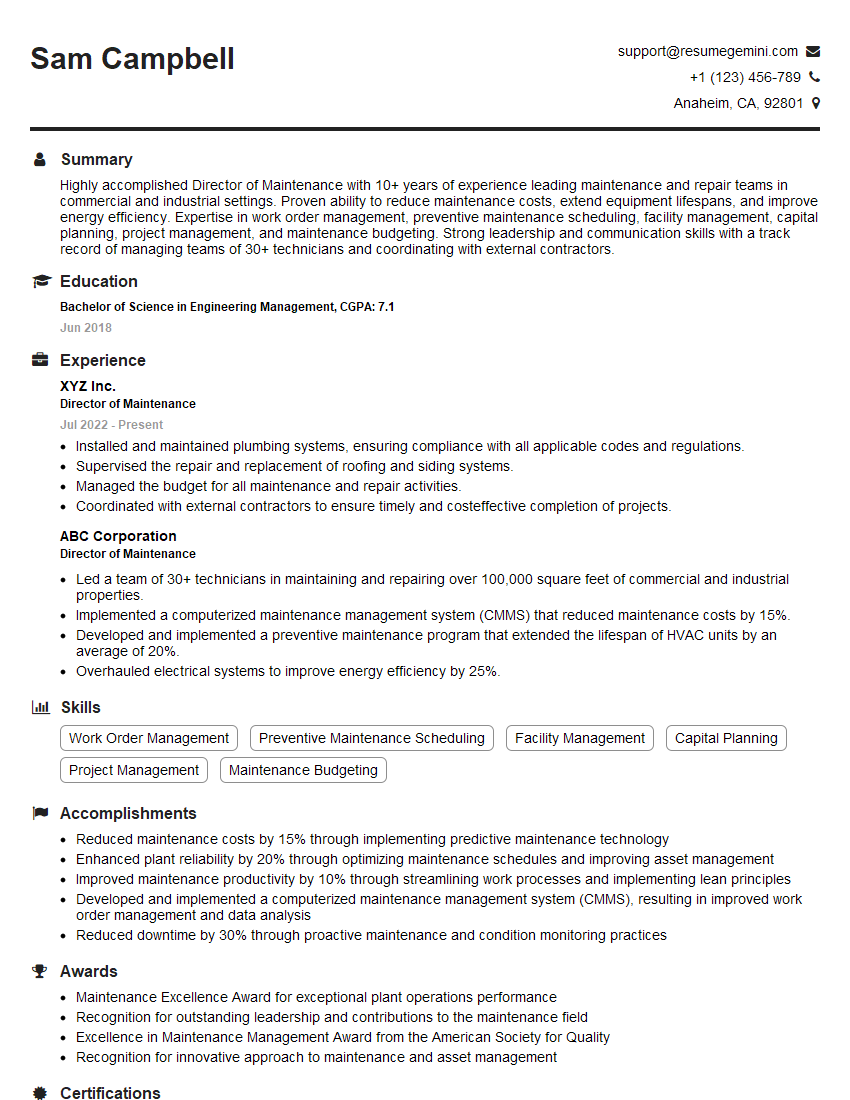

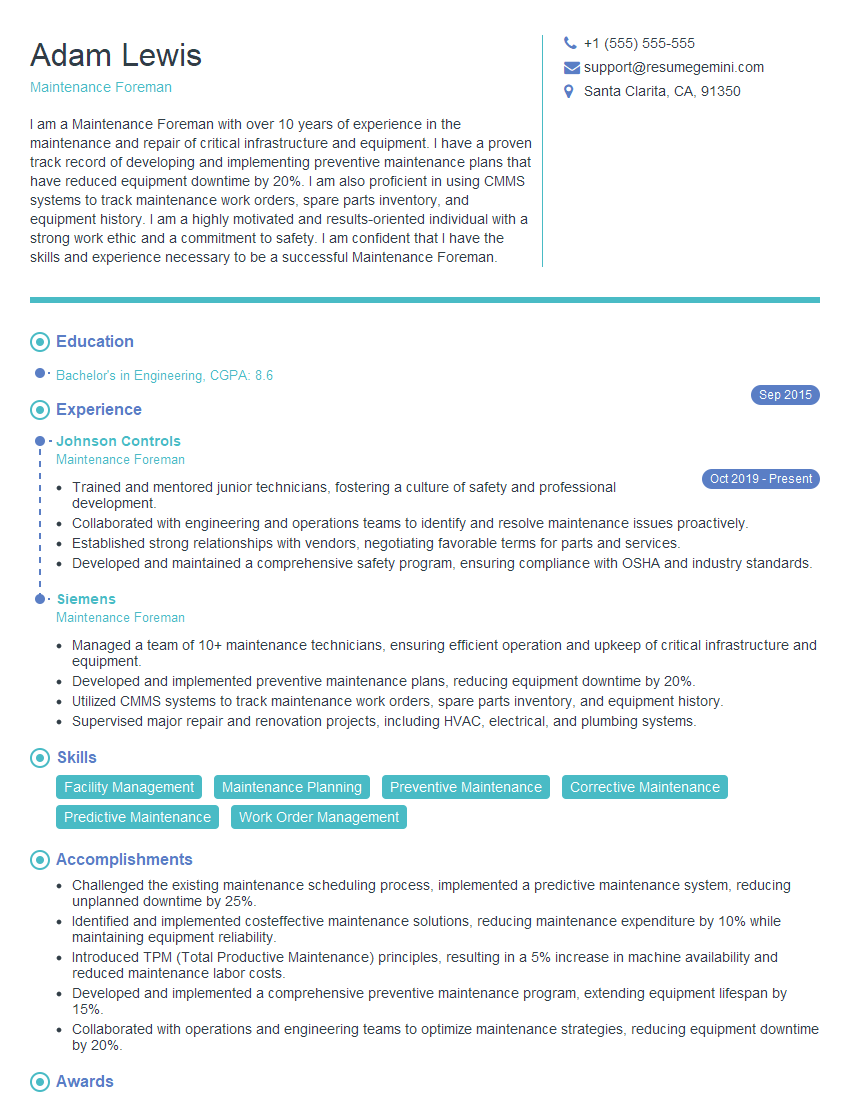

Mastering preventive maintenance checks is crucial for career advancement in many industries. Proficiency in this area demonstrates your commitment to efficiency, safety, and cost-effectiveness. To significantly improve your job prospects, it’s vital to craft an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can help you build a compelling resume that gets noticed. We provide examples of resumes tailored specifically to Preventive Maintenance Checks roles to help you get started. Let ResumeGemini be your partner in achieving your career goals.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good