Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Kiln Lining Inspection interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Kiln Lining Inspection Interview

Q 1. Describe your experience with different kiln lining materials (e.g., firebricks, castables).

My experience encompasses a wide range of kiln lining materials, each with its own strengths and weaknesses. I’ve worked extensively with firebricks, which are known for their excellent refractory properties and relatively long lifespan, but are also more expensive and susceptible to thermal shock. I’ve also had significant experience with castables, particularly monolithic refractories. These offer advantages in terms of installation speed and the ability to conform to complex shapes, reducing the need for numerous individual bricks. However, castables require careful placement and curing to achieve optimal performance. I’ve also worked with insulating firebricks, which are crucial for energy efficiency. The choice of material depends heavily on the type of kiln, the operating temperature, the chemical environment, and the budget.

For instance, in a cement kiln operating at very high temperatures, high-alumina firebricks might be preferred for their superior resistance to slag attack. In a smaller, less demanding application, a well-designed castable might be a more cost-effective solution. Understanding the trade-offs between these materials is essential for designing a robust and efficient kiln lining.

Q 2. Explain the various methods used for kiln lining inspection.

Kiln lining inspection employs various methods, each offering unique insights into the lining’s condition. Visual inspection is the most basic, involving a thorough examination of the lining’s surface for cracks, spalling, erosion, or other signs of damage. This often requires specialized equipment like borescopes or endoscopes to access hard-to-reach areas. Thermal imaging can reveal temperature variations indicating potential hot spots or areas of compromised insulation. Acoustic emission monitoring detects micro-cracks and other structural changes within the lining, providing early warnings of impending failure. Finally, advanced techniques like ground-penetrating radar or ultrasonic testing can assess the lining’s thickness and detect internal flaws that aren’t visible on the surface.

Think of it like a medical checkup: a visual exam is like looking at the skin, while thermal imaging is like taking a temperature reading, and acoustic emission is like listening to the heart for irregularities. Combining these methods gives the most comprehensive assessment.

Q 3. How do you identify and assess different types of kiln lining damage?

Identifying and assessing kiln lining damage requires careful observation and understanding of the different failure modes. Common types of damage include spalling (the chipping or flaking of the refractory material), erosion (the gradual wearing away of the lining), cracking (fractures within the lining), and penetration (damage caused by the penetration of molten materials). The severity of the damage is assessed based on its extent, location, and impact on the kiln’s overall integrity. For example, a small crack might be relatively minor, while extensive spalling in a critical area could indicate imminent failure.

A systematic approach is key. We document the type, location, size, and severity of each instance of damage, often with detailed photographic and video records. This meticulous documentation allows for precise analysis and informed decision-making concerning repairs or replacement.

Q 4. What are the key indicators of impending kiln lining failure?

Several key indicators suggest impending kiln lining failure. These include increased energy consumption (due to heat loss through damaged insulation), changes in kiln operating parameters (such as temperature fluctuations), increased refractory dust in the kiln exhaust, and the appearance of unusual sounds or vibrations. Also, significant changes in the chemical composition of the product may indicate that the lining is interacting negatively with the processed materials. Regular monitoring of these indicators, combined with visual inspections, allows for proactive maintenance and minimizes the risk of catastrophic failure.

Think of it like a car engine – unusual noises, increased fuel consumption, and reduced performance are all indicators that something is wrong. Ignoring these warnings can lead to major problems.

Q 5. What safety precautions are crucial during kiln lining inspections?

Safety is paramount during kiln lining inspections. The extreme temperatures, confined spaces, and potential for falling debris pose significant risks. Before any inspection, a detailed risk assessment must be conducted, and appropriate personal protective equipment (PPE) must be worn. This includes heat-resistant suits, safety helmets, respiratory protection, and safety footwear. Proper lockout/tagout procedures are crucial to prevent accidental activation of the kiln during the inspection. Confined space entry procedures must be followed, including atmospheric monitoring to ensure safe breathing conditions. Finally, a well-defined communication plan should be in place to ensure effective coordination among the inspection team.

Safety is not just a procedure, it’s a mindset. A thorough and proactive approach to safety can prevent accidents and ensure the well-being of all personnel.

Q 6. Explain the process of documenting inspection findings.

Inspection findings are meticulously documented using a combination of methods. Detailed written reports provide a comprehensive overview of the inspection, including the date, time, personnel involved, and the specific areas inspected. High-resolution photographs and videos capture the extent and nature of any damage, providing visual evidence for future reference. Schematic drawings and diagrams pinpoint the exact location of observed defects. Data from thermal imaging, acoustic emission monitoring, and other advanced techniques are also included, providing objective measurements of the lining’s condition. This comprehensive documentation ensures accuracy, clarity, and efficient communication of the inspection findings.

Imagine a detective documenting a crime scene – every detail matters, and a clear, comprehensive report helps to determine the root cause and inform next steps.

Q 7. How do you interpret and report inspection data to improve kiln performance?

Interpreting and reporting inspection data focuses on identifying the root cause of any observed damage and recommending actions to improve kiln performance and extend lining life. The data are analyzed to identify patterns and trends, helping predict potential future problems. For example, consistent erosion in a specific area may indicate a problem with the kiln’s airflow or the material being processed. The findings are then translated into clear and actionable recommendations, which may include localized repairs, scheduled maintenance, operational adjustments, or even complete lining replacement. This proactive approach ensures the kiln operates efficiently, safely, and with minimal downtime.

Think of it like a doctor interpreting test results – the data provide clues to diagnose the problem and recommend a treatment plan. Effective communication of these findings is crucial for successful treatment.

Q 8. What software or tools do you use for kiln lining inspection and reporting?

For kiln lining inspections and reporting, I utilize a suite of software and tools tailored to the specific needs of the project and kiln type. This often includes 3D modeling software like AutoCAD or Revit to create detailed as-built models of the kiln lining, allowing for precise measurements and the easy identification of problem areas. We then use specialized inspection software to overlay inspection data, such as from thermal imaging or ultrasonic testing, onto these 3D models. This allows for a comprehensive, visual representation of the lining’s condition. Furthermore, I employ data management systems to store, organize, and readily access inspection reports, images, and other relevant documentation, improving efficiency and collaboration within the team. For generating reports, I often use Microsoft Word or dedicated reporting software that can generate professional-looking documents incorporating images and data from the inspection process. Finally, we utilize mobile data collection apps that allow on-site data capture and integration with the larger reporting system, streamlining the entire workflow.

Q 9. Describe your experience with thermal imaging in kiln lining inspections.

Thermal imaging plays a crucial role in kiln lining inspections, allowing for the non-destructive detection of hot spots indicating areas of compromised insulation or potential lining failure. My experience encompasses various thermal cameras with different spectral ranges and resolutions, ensuring I can select the most appropriate tool for the specific kiln and its operating conditions. For example, a high-resolution camera might be necessary for a large rotary kiln to ensure accurate detection of smaller defects. I’m proficient in interpreting thermal images, understanding how factors like emissivity and ambient temperature can affect readings, and correlating these findings with visual inspections. For instance, a consistent hot spot along a vertical seam in a rotary kiln lining often indicates a crack or gap allowing heat to escape. This data is then meticulously documented and integrated into the overall assessment of the lining’s condition. I then use the thermal imaging data to create detailed heat maps, visualizing temperature distributions and pinpointing problematic zones requiring attention.

Q 10. How do you determine the extent of required repairs or replacements?

Determining the extent of required repairs or replacements involves a multi-step process combining visual inspection, thermal imaging analysis, and sometimes ultrasonic testing to assess the depth and severity of any damage. First, I meticulously document all observed defects, including their location, size, and type (e.g., cracks, erosion, spalling). Next, I analyze thermal images to identify areas of heat loss, correlating them with the visual inspection findings. If required, we perform non-destructive testing such as ultrasonic thickness gauging to measure the remaining thickness of the refractory lining at critical locations. This data provides quantitative information on the extent of wear and tear, informing decisions about repairs versus complete replacement. The decision-making process considers factors such as the severity of the damage, the remaining lifespan of the lining, and the overall cost-effectiveness of different repair strategies. We also consider the kiln’s operating schedule and potential downtime to ensure the most efficient and least disruptive course of action. We often use a risk assessment matrix to prioritize repairs based on the potential impact on kiln operation and safety.

Q 11. What are the common causes of kiln lining wear and tear?

Kiln lining wear and tear stems from several factors:

- Abrasion: The constant movement of materials within the kiln, particularly in rotary kilns, leads to abrasive wear on the lining.

- Chemical attack: The chemical composition of the materials being processed can react with the lining material, causing chemical erosion and degradation.

- Thermal shock: Rapid temperature fluctuations during kiln startup, shutdown, or process upsets can cause thermal stress, leading to cracking and spalling.

- Spalling: The sudden detachment of pieces of the refractory lining due to thermal stress or chemical attack.

- Erosion: The gradual wearing away of the lining material by the flow of materials or gases within the kiln.

- Improper installation: Faulty installation techniques can create weaknesses in the lining, accelerating wear and tear.

Q 12. How do you prioritize repair work based on inspection findings?

Prioritizing repair work is crucial for minimizing downtime and maintaining operational efficiency. I employ a risk-based approach, prioritizing repairs based on the severity and potential impact of the identified defects. This often involves a combination of factors:

- Safety concerns: Any defects posing an immediate safety risk, such as significant cracks or areas of potential collapse, are addressed first.

- Operational impact: Defects impacting kiln efficiency, such as significant heat loss or material leakage, are high priority.

- Cost-benefit analysis: The cost of repair versus the potential cost of delayed repairs or kiln failure is considered.

- Urgency: Repairs necessary to prevent catastrophic failure are prioritized over less critical repairs.

Q 13. What is your experience with different types of kiln (rotary, shaft, etc.)?

My experience spans a wide range of kiln types, including rotary kilns (which are most common in cement, lime, and mineral processing industries), shaft kilns (used in various applications like ceramic firing), and also tunnel kilns. I understand the unique design features, operating parameters, and typical wear patterns associated with each type. For example, rotary kilns typically experience significant abrasion and thermal shock, whereas shaft kilns often suffer from localized wear in specific zones due to material flow patterns. This understanding allows me to tailor my inspection techniques and repair recommendations to the specific kiln type, ensuring optimal results and maximizing the lining’s service life.

Q 14. Describe your experience with different kiln operating conditions and their impact on lining life.

Different kiln operating conditions significantly impact lining life. Factors such as temperature fluctuations, material throughput, and the chemical composition of the processed materials all play a role. For example, frequent startups and shutdowns exacerbate thermal shock, leading to accelerated wear. Similarly, high material throughput can increase abrasive wear, while aggressive chemical environments can corrode the lining. I have extensive experience analyzing the relationship between operating conditions and lining degradation. For example, in a cement kiln, higher clinker production rates lead to increased wear on the lining in the burning zone. I often work with kiln operators to optimize operational parameters to extend lining life. This includes analyzing kiln logs, identifying trends in temperature and production rates, and working to minimize abrupt changes that could damage the lining. The goal is to achieve a balance between maximizing production and mitigating unnecessary wear and tear to extend the life of the refractory lining.

Q 15. How do you ensure accurate and consistent data collection during inspections?

Accurate and consistent data collection during kiln lining inspections is paramount for effective maintenance planning and preventing costly downtime. We achieve this through a multi-pronged approach.

- Standardized Inspection Forms: We utilize meticulously designed forms that dictate specific data points to be recorded for each section of the kiln lining. This ensures uniformity across inspections, regardless of the inspector.

- Digital Data Capture: Instead of relying solely on handwritten notes, we leverage tablets or other mobile devices with specialized software. This allows for immediate data entry, reducing transcription errors and enabling real-time analysis.

- High-Resolution Imaging: We incorporate high-resolution photography and videography to document the condition of the lining, providing visual evidence to support quantitative data. This is particularly useful for tracking wear patterns over time.

- Calibration and Verification: Any measuring instruments used (e.g., thickness gauges, thermocouples) are regularly calibrated to ensure accuracy. We also employ cross-checking methods, where multiple inspectors independently assess the same area to identify discrepancies and refine our process.

- Data Management System: All collected data is entered into a centralized database, facilitating trend analysis, predictive maintenance scheduling, and easy retrieval of historical inspection reports.

For example, if we find consistently high wear in a specific zone of the kiln, the data will highlight this trend, allowing us to proactively address the issue before it leads to a major failure.

Career Expert Tips:

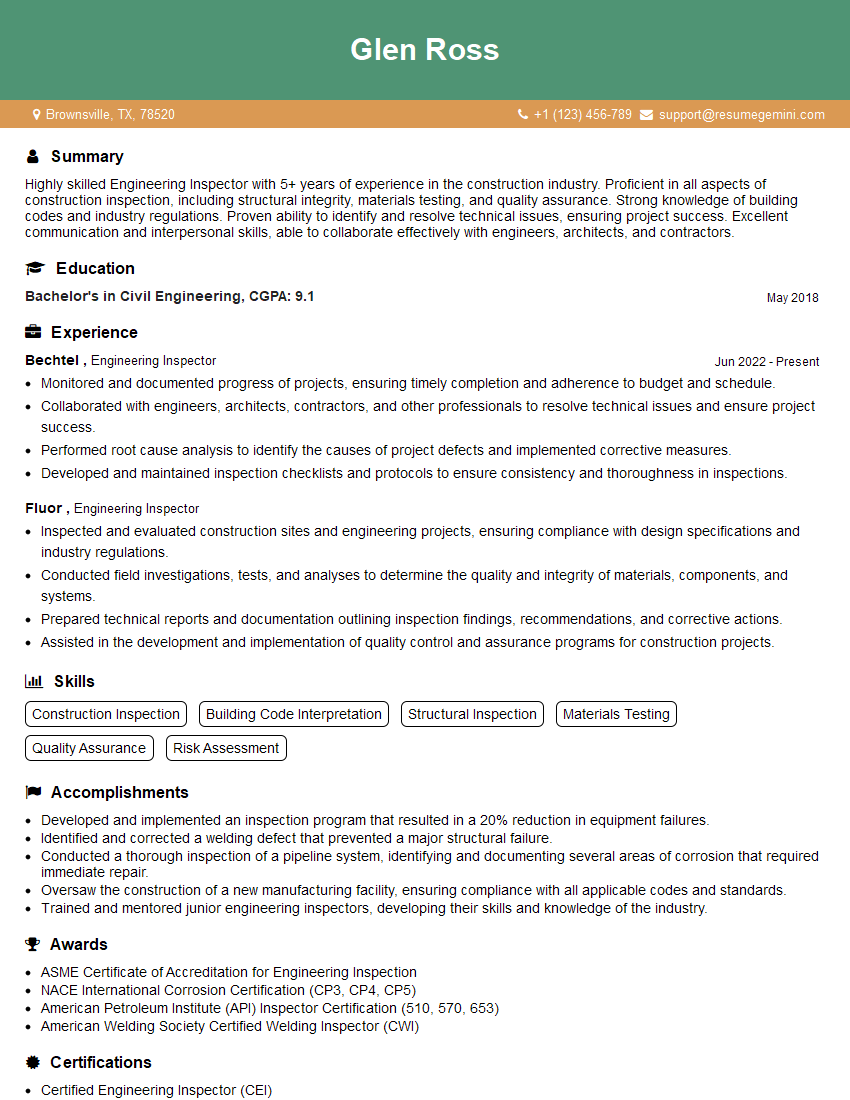

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental considerations during kiln lining inspections and maintenance?

Environmental considerations are crucial during kiln lining inspections and maintenance, focusing primarily on minimizing the impact on air and water quality. Kilns often operate at high temperatures and handle materials that can release harmful substances.

- Dust Control: During inspection and repair, dust from refractory materials can be hazardous. We implement dust suppression techniques, such as using water sprays or vacuum systems, to minimize airborne particulate matter.

- Waste Management: Removed refractory materials are classified as hazardous waste in many jurisdictions and must be handled and disposed of according to relevant regulations. We partner with licensed waste disposal companies to ensure compliance.

- Air Monitoring: We frequently monitor air quality during operations and especially during maintenance, ensuring that hazardous levels of gases or particles are not exceeded. This is often done using portable air quality monitoring equipment.

- Water Management: If water is used for dust suppression or cleaning, we must carefully manage its disposal to prevent contamination of groundwater or surface water. This often involves collecting and treating wastewater before release.

- Personal Protective Equipment (PPE): Inspectors and maintenance crews always wear appropriate PPE, including respirators, safety glasses, and protective clothing, to minimize exposure to hazardous materials and conditions.

For instance, a recent project required us to implement a specialized dust collection system to meet stricter environmental standards imposed by the local authorities, resulting in a cleaner and safer work environment.

Q 17. Explain your experience with non-destructive testing (NDT) methods in kiln lining inspection.

Non-destructive testing (NDT) methods are essential for assessing the condition of kiln linings without causing damage. My experience encompasses several techniques:

- Ultrasonic Testing (UT): UT uses high-frequency sound waves to measure the thickness of the lining and detect internal flaws like cracks or delamination. This is invaluable for identifying areas of thinning that might indicate impending failure.

- Infrared Thermography (IRT): IRT measures surface temperature variations to detect areas of heat loss, which often indicate damage or insulation degradation within the lining. Hot spots can signal potential problems.

- Ground Penetrating Radar (GPR): GPR uses electromagnetic waves to create images of the subsurface structure, enabling us to detect subsurface voids or other anomalies within the lining that are not visible on the surface.

- Acoustic Emission Testing (AET): AET monitors the release of acoustic energy to detect active cracking or other damage mechanisms within the lining. This is particularly useful for monitoring the lining during operation to detect any sudden changes.

For example, in one project, I used a combination of UT and IRT to identify a critical area of thinning and a corresponding area of heat loss. This allowed for timely repair, avoiding a major production disruption.

Q 18. How do you manage conflicts between production schedules and necessary maintenance?

Balancing production schedules and necessary maintenance is a constant challenge. We address this through careful planning and collaboration:

- Predictive Maintenance: By analyzing data from inspections and leveraging NDT, we can predict potential failures and schedule maintenance proactively, minimizing downtime. This is far more efficient than reactive maintenance.

- Scheduled Downtime: We work closely with production teams to schedule maintenance during planned shutdowns or periods of lower production. This minimizes disruption to the overall production schedule.

- Phased Maintenance: For extensive repairs, we may adopt a phased approach, carrying out maintenance in sections to reduce the overall downtime. This involves careful planning and sequencing of tasks.

- Risk Assessment: A thorough risk assessment helps prioritize maintenance tasks based on their potential impact on production and safety. This enables us to focus resources where they are most needed.

- Communication: Open and constant communication with production management is essential to coordinate schedules, manage expectations, and ensure everyone is aware of the maintenance plan.

In one case, by implementing predictive maintenance based on early detection of lining wear, we were able to schedule a repair during a planned outage, avoiding an unplanned shutdown that would have cost the company significantly.

Q 19. Describe your experience with kiln lining repair procedures and techniques.

Kiln lining repair procedures depend on the nature and extent of the damage. My experience includes various techniques:

- Patching: Minor damage like small cracks or superficial erosion can be repaired using patching materials similar to the original lining. This is often a quick and cost-effective solution.

- Gunite Application: For more extensive damage, gunite (a mixture of cement and aggregates sprayed onto the surface) can be used to rebuild the lining profile. This is suitable for larger areas of erosion or spalling.

- Brick Replacement: Severe damage may necessitate the replacement of individual bricks or sections of the lining. This is a more labor-intensive process but ensures a durable repair.

- Refractory Castables: These are pre-mixed materials poured and vibrated into place to fill gaps and restore the lining integrity. They provide a seamless repair.

- Thermal Shock Mitigation: During repairs, it’s critical to prevent thermal shock to the surrounding lining by carefully controlling the heating and cooling process. This involves procedures that avoid rapid temperature changes.

For example, I once managed the repair of a significant section of a cement kiln lining using a combination of brick replacement and gunite application. Careful planning and execution minimized downtime and ensured a successful long-term repair.

Q 20. How do you ensure compliance with relevant safety regulations during inspections?

Safety is paramount during kiln lining inspections. Compliance with regulations is ensured through a structured safety program:

- Lockout/Tagout Procedures: Strict lockout/tagout (LOTO) procedures are followed before any work is performed on or near the kiln to prevent accidental startup and injuries.

- Confined Space Entry Protocols: If inspections require entry into confined spaces (like inside the kiln shell), we adhere to rigorous confined space entry protocols, including atmospheric monitoring, rescue plans, and trained personnel.

- Personal Protective Equipment (PPE): All inspectors and maintenance personnel utilize appropriate PPE, including respirators, safety glasses, hearing protection, and heat-resistant clothing.

- Hazard Identification and Risk Assessment: Prior to each inspection, a thorough hazard identification and risk assessment is conducted to identify potential hazards and implement control measures.

- Training and Competency: All personnel involved in inspections are adequately trained on safety procedures, emergency response, and the use of PPE. Regular refresher training is also provided.

- Documentation: All safety procedures and incidents are meticulously documented to maintain compliance and continually improve safety practices.

We conduct regular safety audits to ensure compliance and identify areas for improvement. Safety is not just a policy; it’s a culture ingrained in our practices.

Q 21. What are the key performance indicators (KPIs) you use to assess kiln lining health?

Key Performance Indicators (KPIs) for assessing kiln lining health are crucial for optimizing maintenance and maximizing kiln efficiency.

- Lining Thickness: Regular measurements using NDT methods (like ultrasonic testing) help track lining wear and predict when repairs might be needed.

- Heat Loss: Monitoring heat loss through infrared thermography identifies areas of damage or insulation degradation, impacting energy efficiency and kiln operation.

- Production Output: Any significant reduction in production output can be a symptom of lining issues, indirectly impacting the KPIs.

- Fuel Consumption: Increased fuel consumption can indicate heat loss due to lining damage, impacting both operational costs and efficiency.

- Downtime: Tracking unplanned downtime due to lining failures helps highlight the effectiveness of our inspection and maintenance program.

- Repair Costs: Monitoring repair costs over time assists in identifying trends and evaluating the effectiveness of different repair strategies.

By tracking these KPIs, we can create a comprehensive picture of kiln lining health, allowing for proactive maintenance planning, maximizing production uptime, and minimizing operational costs.

Q 22. How do you communicate effectively with maintenance crews and management?

Effective communication with maintenance crews and management is crucial for successful kiln lining inspection and maintenance. I utilize a multi-faceted approach. For maintenance crews, I ensure clear, concise instructions, using both verbal and visual aids like detailed diagrams and photographs. I emphasize safety protocols and explain the rationale behind inspection procedures. With management, I use data-driven reports to highlight the kiln’s condition, projected lifespan of the lining, and the cost-benefit analysis of various maintenance strategies. Regular meetings and open communication channels are key to ensuring everyone is informed and on the same page.

- Clear and concise language: Avoiding jargon and technical terms unless absolutely necessary.

- Visual aids: Utilizing diagrams, photos, and videos to illustrate points.

- Data-driven reporting: Presenting findings and recommendations supported by concrete data.

- Regular communication: Establishing consistent channels for updates and feedback.

Q 23. What is your understanding of refractory material properties and their influence on kiln efficiency?

Refractory material properties are paramount to kiln efficiency. Factors like thermal shock resistance, compressive strength, chemical stability, and permeability directly impact the kiln’s performance and lifespan. For instance, high thermal shock resistance prevents cracking and spalling due to rapid temperature changes, minimizing downtime and energy loss. High compressive strength ensures the lining can withstand the weight and pressure of the kiln contents. Chemical stability prevents degradation from the process materials, while low permeability reduces heat loss through the lining. Choosing the right refractory material, based on the specific process conditions and materials being processed, is critical for optimizing energy efficiency and extending the operational life of the kiln.

- Thermal shock resistance: Ability to withstand rapid temperature changes.

- Compressive strength: Ability to withstand pressure and weight.

- Chemical stability: Resistance to degradation from chemical reactions.

- Permeability: Rate at which gases and heat can pass through the material.

Q 24. Explain your experience in developing and implementing kiln lining inspection plans.

My experience in developing and implementing kiln lining inspection plans involves a structured, risk-based approach. I begin by thoroughly assessing the kiln’s operational parameters, the type of refractory materials used, and the history of previous inspections and repairs. This assessment informs the frequency and scope of inspections. The plan includes detailed procedures for visual inspection, using techniques like thermal imaging and ultrasonic testing to detect hidden defects. Crucially, I incorporate documentation protocols – clear reporting formats to record findings, recommended actions, and the associated costs and risks. I’ve successfully implemented plans that reduced downtime by 15% in one facility by proactively addressing potential issues before they became major problems.

- Risk assessment: Identifying potential failure points based on operational data.

- Inspection methods: Combining visual inspection with non-destructive testing techniques.

- Documentation: Detailed reports including photos, thermal images, and repair recommendations.

- Cost-benefit analysis: Evaluating the economic impact of different maintenance strategies.

Q 25. How do you stay updated on the latest advancements in kiln lining technology and materials?

Staying updated on advancements in kiln lining technology is an ongoing process. I actively participate in industry conferences and workshops, subscribe to relevant trade publications, and engage with online communities of kiln technology professionals. I regularly review manufacturers’ literature on new materials and technologies. Furthermore, I maintain a network of contacts within the industry, including refractory specialists and engineers, to exchange knowledge and best practices. This continuous learning ensures I am equipped with the latest techniques and knowledge to optimize kiln lining performance and longevity.

Q 26. Describe a time when you had to troubleshoot a complex kiln lining issue.

In one instance, we experienced unexplained, localized wear on a specific section of the kiln lining. Initial visual inspection didn’t reveal the cause. We then employed thermal imaging, revealing a significant temperature spike in the affected area. This led us to investigate the kiln’s burner configuration. We discovered a slight misalignment causing uneven heat distribution, leading to accelerated wear. The solution involved adjusting the burner, which quickly resolved the issue. This highlighted the importance of using advanced diagnostics beyond visual inspection for accurate problem identification.

Q 27. How would you handle a situation where an unexpected kiln lining problem is discovered?

Discovering an unexpected kiln lining problem requires a swift, methodical response. First, I’d prioritize safety, ensuring the area is secured and personnel are protected. Then, I’d conduct a thorough assessment of the problem’s extent and severity using visual inspection and appropriate non-destructive testing. Based on the assessment, I’d collaborate with maintenance and management to develop a temporary solution to mitigate further damage. This might involve patching, applying a protective coating, or adjusting the kiln’s operational parameters. Concurrently, I’d develop a detailed plan for a permanent repair, considering factors like cost, downtime, and the availability of materials. Open communication with all stakeholders is critical throughout this process.

Q 28. What is your approach to continuous improvement in kiln lining maintenance and inspection?

Continuous improvement in kiln lining maintenance and inspection hinges on data analysis and feedback loops. I regularly analyze inspection data to identify trends and patterns in wear and damage. This information is used to refine inspection schedules, improve maintenance procedures, and inform the selection of refractory materials. We also actively solicit feedback from maintenance crews and operators, incorporating their insights into our continuous improvement efforts. Regularly reviewing industry best practices and incorporating new technologies further enhances our approach, creating a proactive and optimized kiln maintenance program.

Key Topics to Learn for Kiln Lining Inspection Interview

- Kiln Lining Materials: Understanding the properties and limitations of various refractory materials used in kiln linings (e.g., fireclay, high-alumina brick, castables). This includes knowledge of material degradation mechanisms.

- Inspection Methods: Familiarity with different inspection techniques, including visual inspection, thermal imaging, ultrasonic testing, and other non-destructive testing methods. Consider the advantages and limitations of each method.

- Defect Identification and Analysis: Ability to identify common kiln lining defects (e.g., spalling, erosion, cracking, hot spots) and understand their causes and consequences. This includes analyzing inspection data to determine the severity and extent of damage.

- Safety Procedures: Knowledge of relevant safety protocols and regulations for working in high-temperature environments and performing inspections in industrial kilns. Understanding personal protective equipment (PPE) requirements is crucial.

- Repair and Maintenance Strategies: Familiarity with different repair techniques and the selection criteria for choosing appropriate repair methods based on the type and severity of damage. Understanding preventative maintenance scheduling is key.

- Data Interpretation and Reporting: Ability to accurately document inspection findings, interpret data, and generate clear and concise reports for management. Understanding how to present data effectively is essential.

- Understanding Kiln Operation: A basic understanding of how different types of kilns operate (rotary, shaft, etc.) and how lining wear relates to kiln operation parameters is beneficial.

Next Steps

Mastering Kiln Lining Inspection opens doors to exciting career opportunities in the manufacturing and industrial sectors, offering excellent potential for growth and specialization. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume that highlights your skills and experience is crucial for getting noticed by potential employers. To enhance your resume-building experience and significantly improve your job prospects, we recommend using ResumeGemini. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to Kiln Lining Inspection, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good