Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Proficiency in Hand Tools and Power Equipment interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Proficiency in Hand Tools and Power Equipment Interview

Q 1. What safety precautions do you take when using power tools?

Safety is paramount when using power tools. My approach is based on a layered safety system, encompassing preparation, execution, and post-use procedures. Before starting any project, I always inspect the tool for damage, ensure all guards are in place and functioning correctly, and check the power cord for any fraying or damage. I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection (especially with loud tools like circular saws), and work gloves. When operating the tool, I maintain a firm grip, avoid loose clothing that could get caught in moving parts, and ensure proper ventilation in the workspace to prevent inhaling dust or fumes. After use, I unplug the tool, clean it thoroughly, and store it safely, away from children and moisture.

- Example: Before using a circular saw, I always check the blade is sharp and securely fastened, the riving knife is properly aligned, and the safety guard is operational. I also ensure the work area is clear of obstacles and that I have a stable base to work from.

- Example: When using a router, I always use a router table or jig to ensure consistent depth and safety.

Q 2. Describe your experience with various hand saws (e.g., hacksaw, hand saw, coping saw).

I’m proficient with a variety of hand saws, each suited for specific tasks. The hacksaw, with its fine-toothed blade, excels at cutting metal. Its reciprocating motion allows precise cuts. The standard hand saw, with its coarser teeth, is ideal for woodworking, offering a quicker cut through lumber. I use a coping saw, with its narrow blade and adjustable frame, for intricate curves in wood or other softer materials. Selecting the right saw significantly impacts the efficiency and quality of the cut.

- Example: When cutting through a steel pipe, I’d choose a hacksaw with a blade appropriate for the pipe’s diameter and material. Using a hand saw would be inefficient and potentially damage the blade.

- Example: For a clean cut on a 2×4, the hand saw offers speed and efficiency, while the coping saw would be impractical.

Q 3. How do you maintain and care for your hand tools?

Maintaining hand tools is crucial for their longevity and safe operation. After each use, I clean them thoroughly, removing debris and sawdust. I lubricate moving parts with appropriate lubricants, like mineral oil for wood-handled tools. For tools like chisels and plane blades, I hone the edges regularly to maintain sharpness, extending their lifespan and ensuring clean cuts. I store my tools in a dry, organized manner to prevent rust and damage.

- Example: I use a honing steel to sharpen my chisels, maintaining a keen edge for precise work.

- Example: I store my wood-handled tools in a climate-controlled area to prevent cracking and warping.

Q 4. Explain the difference between a drill press and a handheld drill.

The key difference between a drill press and a handheld drill lies in stability and precision. A drill press is a stationary machine offering far greater accuracy and control, ideal for precise holes at consistent depths. The workpiece is clamped securely, minimizing movement and ensuring perpendicular drilling. In contrast, a handheld drill is portable and versatile, suitable for a wider range of tasks and locations, but less precise for critical applications. The handheld drill’s flexibility is traded for a potential sacrifice in accuracy and hole consistency.

- Example: I would use a drill press for creating precisely spaced pilot holes for assembling cabinets, as accuracy and perpendicularity are essential.

- Example: A handheld drill would be more suitable for quickly drilling holes in various locations during a repair job, such as when installing drywall.

Q 5. What are the different types of screwdrivers and when would you use each?

Screwdrivers come in various types, each designed for specific screw heads. Phillips head screwdrivers have a cross-shaped tip, while slotted screwdrivers have a flat blade. Torx screwdrivers have a star-shaped tip, often used in high-torque applications. Hex (Allen) keys are used with hexagonal sockets. The choice depends on the screw head: a wrong type will either damage the screw or the screwdriver.

- Example: I’d use a Phillips head screwdriver for assembling furniture, where it’s common to find Phillips head screws.

- Example: A Torx screwdriver might be needed for working on electronic devices or some high-end automotive parts, where these screws are more likely to be found.

Q 6. How do you troubleshoot a malfunctioning power tool?

Troubleshooting a malfunctioning power tool begins with safety: always unplug the tool before any inspection or repair. A common issue is a faulty power cord; check for cuts or fraying. If the tool doesn’t turn on, the power switch may be faulty. If it runs erratically, the motor might need servicing. For drills, a clogged chuck or worn-out bits are possibilities. For saws, blade problems are frequent. Always consult the tool’s manual for specific troubleshooting guidelines.

- Example: If a circular saw won’t start, I would first check the power cord and outlet. If these are fine, I’d examine the power switch. If the issue persists, it could point to a motor problem requiring professional repair.

- Example: If a drill isn’t clamping the bit, I’d check the chuck to see if it’s properly tightened or damaged.

Q 7. Describe your experience with different types of hammers and their applications.

My experience encompasses various hammers, each with specific applications. Claw hammers, with their claw for removing nails, are essential for general carpentry. Ball-peen hammers, with their rounded peen (end), are useful for shaping metal. Sledgehammers are hefty tools for demolition and heavy-duty work. Mallet-style hammers protect the workpiece from damage, suitable for delicate projects like shaping wood.

- Example: I’d use a claw hammer for framing a wall, driving nails and removing any missed ones.

- Example: A ball-peen hammer is used for fine metalwork and shaping, where its precision is needed.

- Example: I would only use a sledgehammer for tasks requiring significant force, such as breaking up concrete or driving large stakes.

Q 8. How do you measure and cut materials accurately using hand tools?

Accurate measurement and cutting with hand tools relies on a combination of precision instruments and careful technique. For example, when cutting wood, I’d first use a measuring tape to precisely mark the desired length on the material. I ensure the tape measure is taut and aligned with the cutting line to avoid errors. Then, I’d use a square to create a perfectly perpendicular line at the marked point. This prevents angled cuts. For precise cuts, a fine-toothed saw is crucial, allowing for clean, straight lines. The saw should be moved smoothly and consistently, avoiding jerky motions that could cause inaccuracies or damage the material.

For metal, a hacksaw with the correct blade for the metal type is essential. Marking the cut line with a scriber or marking gauge ensures accuracy. A vice or clamps are invaluable for holding the metal securely during the cutting process. Regular blade changes are crucial to maintaining a clean cut and preventing damage to the saw. Always remember to protect your eyes with appropriate safety glasses.

Imagine building a bookshelf: Inaccurate cuts on the shelves would make the whole structure unstable. Precision in measurement and cutting is paramount for both aesthetics and functionality.

Q 9. What are the safety measures you take when working with electrical power tools?

Safety is my top priority when working with power tools. Before starting any project, I always inspect the tool for any damage, ensuring cords are undamaged, and plugs are securely in place. I always wear appropriate personal protective equipment (PPE), including safety glasses or a face shield to protect my eyes from flying debris, hearing protection to mitigate the loud noise of many power tools, and work gloves to protect my hands.

I ensure the work area is well-lit and free of clutter to prevent tripping hazards. I make sure that the tool is securely grounded or uses a GFCI outlet, especially when dealing with electrical power tools near water. I always disconnect the power tool before making any adjustments or changing blades.

Furthermore, I never force a tool beyond its capabilities. If a tool binds or stalls, I stop immediately, investigate the cause, and only resume after resolving the issue. I regularly maintain my tools, keeping them sharp and properly lubricated to ensure safe and efficient operation. Imagine operating a router without safety glasses—the risk of eye injury is significant. Safety is not just a guideline; it’s a non-negotiable practice.

Q 10. How do you select the appropriate drill bit for a specific material?

Selecting the right drill bit is crucial for effective and safe drilling. The material dictates the bit’s type and size. For wood, I’d use a twist drill bit. The size is determined by the screw or fastener being used, ensuring a slightly smaller diameter for a snug fit. For metal, I would use a high-speed steel (HSS) drill bit, possibly with a cobalt additive for harder materials. The point angle and material of the bit are critical for preventing slippage and ensuring a clean hole. For masonry, a masonry bit with a carbide tip is necessary, designed to withstand the abrasive nature of brick, concrete, or stone.

The size of the hole, of course, dictates the size of the bit. Pilot holes are sometimes needed for larger bits or for preventing wood from splitting when drilling larger holes. I always check the bit’s condition before drilling—a dull or damaged bit can lead to broken bits or uneven holes.

For instance, attempting to drill metal with a wood bit would be ineffective and damage the bit. Choosing the right bit ensures a clean, efficient, and safe drilling process.

Q 11. Explain the proper techniques for using a level and measuring tape.

Using a level and measuring tape accurately is fundamental to any construction or carpentry project. A level is used to ensure surfaces are perfectly horizontal or vertical. I start by placing the level on the surface being checked, ensuring good contact along its entire length. I then observe the air bubble within the level’s vial; if the bubble is centered between the markings, the surface is level. If not, adjustments need to be made.

A measuring tape is used to take accurate linear measurements. It’s important to ensure the tape is taut and pulled straight to avoid errors. When measuring long distances, an assistant can be helpful to hold the end of the tape in place. Reading the tape correctly is key; it’s important to pay close attention to the graduations, especially on the hook at the end which is generally used to be outside of the measurement.

Consider hanging a picture frame: Using a level ensures the frame hangs straight, while the measuring tape guarantees it is properly centered. Accurate use of these tools is fundamental for a professional and aesthetically pleasing result.

Q 12. What is your experience with various types of wrenches?

My experience encompasses a wide range of wrenches, including open-ended, box-end, combination, adjustable, and socket wrenches. Open-ended wrenches are useful for quick work, but they can slip more easily. Box-end wrenches provide better grip and torque, preventing slippage. Combination wrenches offer the best of both worlds. Adjustable wrenches are versatile but generally provide less torque than other types. Socket wrenches, with their various sizes and drive types, offer precision and high torque for many applications, especially with ratchet handles and extensions.

I’m adept at selecting the right wrench for each job, considering factors like the size and shape of the fastener, the available space, and the required torque. I am familiar with torque wrenches which allow for precise control over fastening force and are vital in applications where proper torque is critical, such as automotive work. This ensures bolts and nuts are tightened to the manufacturer’s specifications, preventing damage to components.

For example, when working on an engine, the correct socket wrench is crucial to avoid stripping the bolt head or causing damage to the engine components. This experience is important to ensure both the safety of the individual and the efficient completion of the job.

Q 13. Describe your experience with using pneumatic tools.

I have extensive experience using various pneumatic tools, including impact wrenches, air drills, and air hammers. Pneumatic tools are powerful and efficient, but require careful handling. Before using any pneumatic tool, I inspect the air hose for damage and ensure the air compressor is functioning correctly and at the proper pressure. I also check the tool itself for any signs of wear or damage.

Impact wrenches are invaluable for quickly loosening or tightening fasteners, especially in situations where manual tools struggle. Air drills provide high speed and torque for drilling, particularly in heavy-duty applications. Air hammers are powerful tools used for demolition or chipping, requiring even more caution due to their high impact.

Safety is paramount when using these tools. The high speed and force these tools exert necessitates appropriate PPE, including eye protection, hearing protection, and possibly a respirator, depending on the application. Secure footing is also essential due to the recoil and vibration of these tools.

Q 14. How do you identify and address potential hazards when using power equipment?

Identifying and addressing potential hazards is an integral part of safely operating power equipment. This process begins with a thorough pre-use inspection of the equipment. I look for any damage to cords, plugs, housings, or blades. I also check for proper grounding and any loose parts.

The work area is a critical factor; ensuring adequate lighting, a clear and organized workspace, and proper ventilation are essential. I need to identify any tripping hazards, overhead obstacles, and potential contact with other objects or people. I assess the material I’m working with—are there any sharp edges or hazardous substances involved? The task itself needs to be analyzed for potential dangers, such as kickback from saws or the release of dangerous substances such as dust or fumes.

If a hazard is identified, I take appropriate mitigating measures before starting the work. This could involve using additional PPE, adjusting the work area, employing additional safety equipment (such as a safety harness during overhead work), or modifying my work procedures. Ignoring a potential hazard could lead to serious injury or equipment damage.

Q 15. What is your experience with different types of pliers and their applications?

Pliers are indispensable hand tools used for gripping, bending, cutting, and twisting various materials. My experience encompasses a wide range, from basic slip-joint pliers to specialized types like needle-nose, linesman’s, and locking pliers.

- Slip-joint pliers: These are versatile and adjustable, ideal for general-purpose gripping and light-duty work, like holding small parts or bending wires. I’ve used these extensively in electrical work and plumbing repairs.

- Needle-nose pliers: Their long, slender jaws are perfect for reaching into tight spaces and manipulating small components. I frequently use them in electronics repair and jewelry making.

- Linesman’s pliers: These feature a wider jaw and a cutting edge, making them suitable for gripping and cutting wires. Their strength comes in handy when working with heavier gauge wires in electrical installations.

- Locking pliers (e.g., Vise-Grips): These pliers offer a powerful grip that remains locked until manually released, ideal for holding parts securely during assembly or disassembly. They’re invaluable when dealing with stubborn nuts or bolts.

The choice of pliers depends entirely on the task. For instance, I wouldn’t use slip-joint pliers to cut a thick wire – linesman’s pliers would be far more appropriate and safer. Understanding the nuances of each type is crucial for efficiency and safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle damaged or malfunctioning tools?

Handling damaged or malfunctioning tools is critical for safety and preventing accidents. My approach is a three-step process:

- Assessment: I carefully inspect the tool for the nature and extent of the damage. Is it a minor dent, a broken handle, or a malfunctioning mechanism? A clear assessment guides the next steps.

- Repair or Replacement: Minor damages, like a loose handle, might be repairable. I’m proficient in basic repairs, such as tightening screws or replacing broken parts. However, for significant damage compromising safety, replacement is mandatory. I always prioritize safety over repair.

- Documentation and Disposal: If a tool is beyond repair, I’ll properly document its disposal according to company safety guidelines. This includes ensuring that sharp edges are safely covered before discarding the tool.

For example, if I noticed a crack in the handle of a hammer, I wouldn’t continue using it. The risk of the handle breaking and causing injury is too high. I would immediately take it out of service and request a replacement.

Q 17. Explain your experience with various types of cutting tools (e.g., chisels, planes).

My experience with cutting tools includes a variety of chisels and planes, each suited for specific applications. Understanding their differences is paramount to achieve clean, precise cuts.

- Chisels: These are used for shaping and cutting wood, metal, or other materials. Different types, such as firmer chisels, mortise chisels, and gouges, are used for varied tasks. For example, a firmer chisel is ideal for paring wood, while a mortise chisel excels at creating precise holes.

- Planes: Planes are used for smoothing and shaping surfaces. Jack planes, smoothing planes, and block planes are examples of planes used for different applications and wood types. I’ve used these to create smooth, even surfaces on wooden furniture projects, requiring a good understanding of blade sharpness and angle adjustment.

Sharpening and maintaining these tools are crucial. A dull chisel or plane will not only produce poor results but also increases the risk of accidents. I’m skilled in sharpening both chisels and planes using both sharpening stones and honing guides.

Q 18. How do you ensure the safety of yourself and others when operating power tools?

Safety is paramount when operating power tools. My approach involves a multi-layered strategy:

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, hearing protection, and work gloves, tailored to the specific tool and task. For example, when using a circular saw, I’d also wear a dust mask and possibly a face shield.

- Tool Inspection: Before each use, I meticulously inspect the tool for any damage or loose parts. A damaged power tool is an accident waiting to happen. I also ensure that all guards and safety mechanisms are correctly installed and functioning.

- Safe Operating Procedures: I strictly adhere to the manufacturer’s instructions and follow safe operating procedures. This includes maintaining a firm grip, using the correct speed and feed rates, and never reaching across the cutting path of a blade.

- Workplace Safety: I maintain a clean and organized workspace, free of obstructions. This minimizes the risk of tripping or accidental contact with the power tool.

Think of it like driving a car; you wouldn’t drive without checking your mirrors and seatbelts. Similarly, treating power tools with respect and following safety protocols is essential.

Q 19. Describe your experience using different types of fasteners (e.g., screws, nails, bolts).

My experience with fasteners covers a broad spectrum, from simple nails to complex bolted assemblies. The selection of the right fastener is critical for the strength and longevity of any project.

- Nails: I’m familiar with different types of nails – common, finishing, brads – and their applications. Nail selection depends on the material being fastened and the required holding strength.

- Screws: I have experience with various screw types, including wood screws, machine screws, sheet metal screws, and self-tapping screws. Selecting the appropriate screw type, size, and length ensures a strong and secure joint.

- Bolts: I’m proficient in using bolts, nuts, and washers to create strong, robust connections, particularly in metalwork and heavier construction projects. Understanding bolt thread types and using appropriate torque is vital.

For example, when building a wooden frame, I would use wood screws for joining the members, while metal brackets might be attached using bolts and nuts. The choice depends on the required strength and aesthetic considerations.

Q 20. What is your experience with using a variety of measuring instruments?

Accurate measurements are fundamental to any construction or repair project. My experience includes using a range of measuring instruments:

- Tape Measures: Essential for linear measurements. I’m proficient in using both standard and metric tape measures, understanding their limitations and ensuring accurate readings.

- Level: Crucial for ensuring surfaces are perfectly horizontal or vertical. I use both spirit levels and laser levels, depending on the application and required accuracy.

- Squares: Used to check for right angles and ensure precise alignment. I use try squares, combination squares, and speed squares for different tasks.

- Calipers: Used for precise internal and external measurements, especially useful in mechanical work and machining.

For instance, when installing cabinetry, a level is crucial to ensure that the cabinets are perfectly aligned, while a tape measure helps determine the precise locations of mounting points. The choice of measuring tool depends on the task’s complexity and required accuracy.

Q 21. How do you interpret technical drawings and blueprints related to tool usage?

Interpreting technical drawings and blueprints is a vital skill. My approach involves a systematic process:

- Overview: I start by examining the overall drawing, noting dimensions, tolerances, and material specifications. This gives me a general understanding of the project.

- Detailed Examination: I then carefully examine each section of the drawing, paying close attention to details such as part numbers, assembly instructions, and any specific tool requirements.

- Identification of Tools: I identify the tools required for the project based on the drawing’s details, ensuring I have the correct tools before starting any work.

- Visualization: I use my spatial reasoning skills to visualize the assembly process from the drawing. This helps anticipate potential challenges and plan my workflow accordingly.

For example, a blueprint might specify the use of a specific type of drill bit and the required hole diameter. Understanding this information helps ensure that the final product meets the required specifications and fits correctly.

Q 22. Describe your troubleshooting skills when dealing with equipment malfunctions.

My troubleshooting approach is systematic and follows a logical progression. I start by visually inspecting the equipment for obvious issues like loose connections, damaged cords, or broken parts. Then, I’ll check the power source – is it properly plugged in? Is there sufficient power? If it’s a pneumatic tool, I’ll verify air pressure and connections. Next, I’ll refer to the equipment’s manual for troubleshooting guides and diagrams. This often provides clear steps and potential causes of malfunctions. If the problem persists, I’ll systematically test individual components, isolating the fault by using a process of elimination. For instance, if a drill isn’t working, I might swap out the battery or check the chuck to see if the bit is securely fastened. Finally, if I’m unable to resolve the issue, I’ll consult with a senior technician or refer the equipment for professional repair.

For example, I once encountered a malfunctioning circular saw that wouldn’t start. After verifying the power, I found a broken wire inside the power cord. A simple repair fixed the problem, illustrating the importance of thorough visual inspection.

Q 23. Explain your experience with preventative maintenance of hand and power tools.

Preventative maintenance is crucial for ensuring the longevity and safety of hand and power tools. My routine includes regular cleaning of all tools after use, removing debris and dust that could affect performance or create hazards. I lubricate moving parts according to the manufacturer’s instructions, using appropriate lubricants. This significantly reduces friction and wear, extending the tool’s lifespan. I check for any signs of damage, including cracks, bends, or loose components, and replace or repair damaged parts promptly. Sharpness is key for hand tools – I regularly sharpen blades and chisels to maintain efficiency and safety. For power tools, I check cords for fraying or damage, and ensure all guards are properly in place and functional. I also keep detailed records of maintenance performed, including dates and specific actions taken, which helps me track usage and anticipate future maintenance needs. Think of it like regularly servicing a car – regular maintenance prevents major breakdowns down the line.

Q 24. What is your understanding of OSHA regulations regarding hand and power tool safety?

My understanding of OSHA regulations regarding hand and power tool safety is comprehensive. I’m familiar with the requirements for personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves, depending on the task and the tools used. I’m also aware of the regulations regarding tool maintenance, proper use, and storage. OSHA emphasizes the importance of using tools only for their intended purpose, ensuring they are in good working condition, and following the manufacturer’s safety instructions. The regulations address lockout/tagout procedures for preventing accidental starts, proper grounding of power tools, and the safe handling of potentially hazardous materials. I understand the importance of regular training and compliance with all relevant safety standards to prevent accidents and maintain a safe work environment. OSHA’s standards are not just guidelines; they are critical for protecting workers from serious injury or death.

Q 25. How do you adapt your techniques when working with different materials?

Adapting techniques to different materials is fundamental to proficient tool use. For example, when cutting wood, I’d use a sharp, fine-toothed blade on a saw, whereas cutting metal requires a coarser blade designed for metal. The speed and pressure also need to be adjusted; cutting through hardwoods requires more force than cutting softer woods. Working with plastics requires a different approach entirely, often involving lower speeds and specialized cutting tools to avoid melting or cracking. Similarly, drilling into various materials necessitates selecting the appropriate drill bit. A masonry bit is needed for brick or concrete, while a wood bit is used for wood, and a metal bit for metal. Understanding the properties of different materials and selecting the right tools and techniques is crucial for efficiency and safety.

Q 26. Describe a time you had to troubleshoot a complex equipment problem.

I once had to troubleshoot a malfunctioning air compressor that was crucial for a large-scale construction project. It kept shutting off intermittently, causing significant delays. My initial inspection revealed nothing obvious. I systematically checked the pressure switch, the thermal overload protector, and the air filter, but found no immediate problems. Then, I examined the pressure gauge and noticed it was reading lower than expected. This led me to check the air tank for leaks, which I discovered by using soapy water. A small leak was found near a valve. After repairing the leak, the compressor worked perfectly. This situation highlighted the importance of a methodical approach, combining visual inspection, testing of individual components, and understanding of the system’s mechanics. A small, seemingly insignificant leak had a massive impact on the system’s functionality. The experience also reinforced the need for regular preventative maintenance to avoid such problems.

Q 27. What are some common problems encountered while using hand and power tools, and how to fix them?

Common hand tool problems include dull blades, stripped screws, and broken handles. Dull blades are easily addressed by sharpening. Stripped screws can sometimes be salvaged with a screw extractor or by using a larger bit. Broken handles require replacement. For power tools, common issues include worn brushes (in electric motors), damaged cords, and malfunctions in the trigger mechanism. Worn brushes often cause reduced power or inconsistent operation and need to be replaced. Damaged cords present a safety hazard and must be repaired or replaced immediately. Trigger mechanism issues can sometimes be fixed by cleaning and lubrication, but may require professional repair if components are damaged.

- Dull blades: Sharpen with a file or sharpening stone.

- Stripped screws: Use a screw extractor or a larger bit size.

- Worn brushes (power tools): Replace with new brushes.

- Damaged cords (power tools): Repair or replace the cord.

Addressing these issues promptly prevents further damage and enhances safety.

Q 28. How do you stay updated on the latest safety regulations and best practices for hand and power tools?

Staying updated on safety regulations and best practices is an ongoing process. I regularly review OSHA publications and attend relevant safety training courses to remain current on the latest standards. I also subscribe to industry trade magazines and journals, which provide insights into new technologies and safety advancements. Networking with other professionals in the field is another valuable resource, allowing for the exchange of information and best practices. Manufacturer websites are also excellent resources for updates on tool-specific safety information. Continuous learning ensures I’m always equipped with the most up-to-date knowledge, which is critical for maintaining a safe and productive work environment. Staying current isn’t just a good idea – it’s a necessity for the safety of myself and others.

Key Topics to Learn for Proficiency in Hand Tools and Power Equipment Interview

- Safe Handling and Operation: Understanding safety protocols for various hand and power tools, including proper PPE usage and emergency procedures. Practical application includes demonstrating knowledge of lockout/tagout procedures and safe tool storage.

- Tool Selection and Maintenance: Identifying the appropriate tool for specific tasks, understanding the limitations of each tool, and performing basic maintenance (e.g., sharpening, cleaning, lubrication). Practical application involves explaining the differences between various types of saws and drills and their suitability for different materials.

- Measurement and Precision: Accurately measuring and marking materials using various tools (e.g., tape measures, rulers, levels). Practical application includes describing techniques for achieving precise cuts and alignments.

- Material Knowledge: Understanding the properties of different materials (wood, metal, plastic) and how to work with them effectively using hand and power tools. Practical application involves explaining the best practices for cutting different materials to avoid damage or injury.

- Troubleshooting and Repair: Identifying common issues with hand and power tools and performing basic troubleshooting and minor repairs. Practical application includes describing how to address a jammed saw blade or a malfunctioning drill.

- Project Planning and Execution: Planning and executing small-scale projects using hand and power tools, including material estimation and workflow optimization. Practical application includes outlining the steps involved in a simple woodworking project.

Next Steps

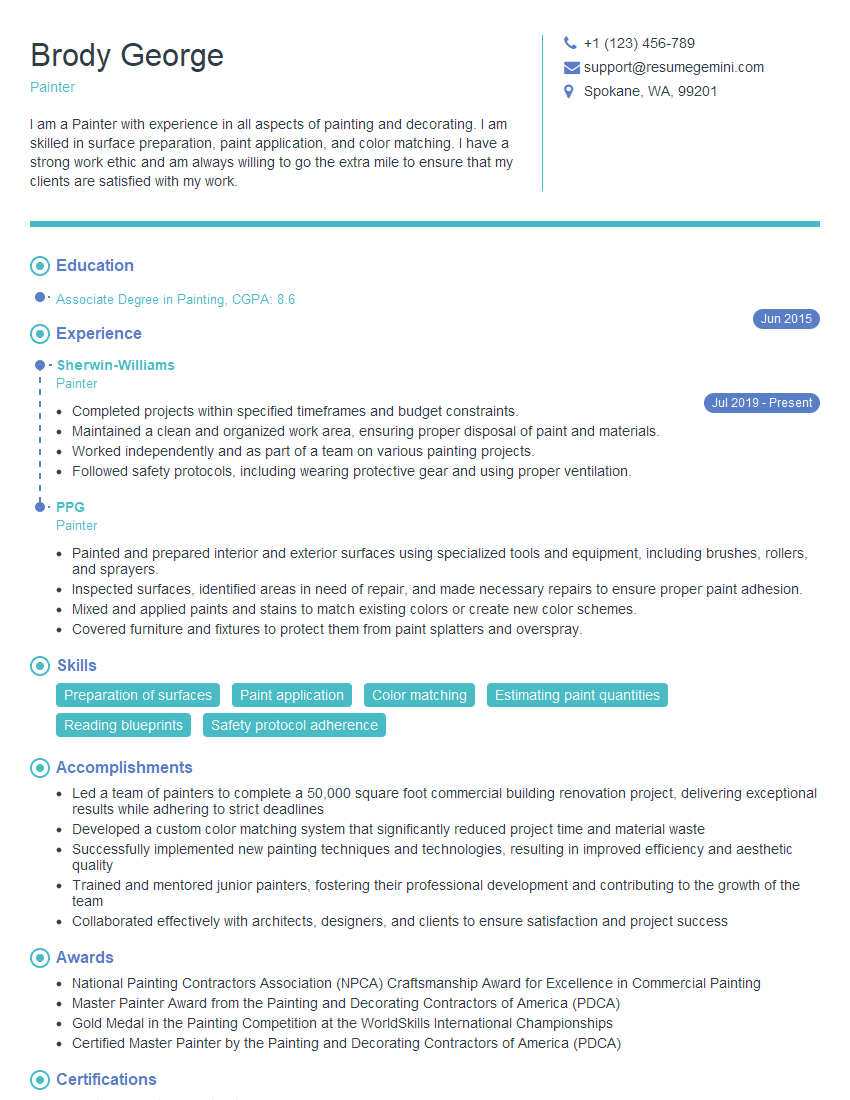

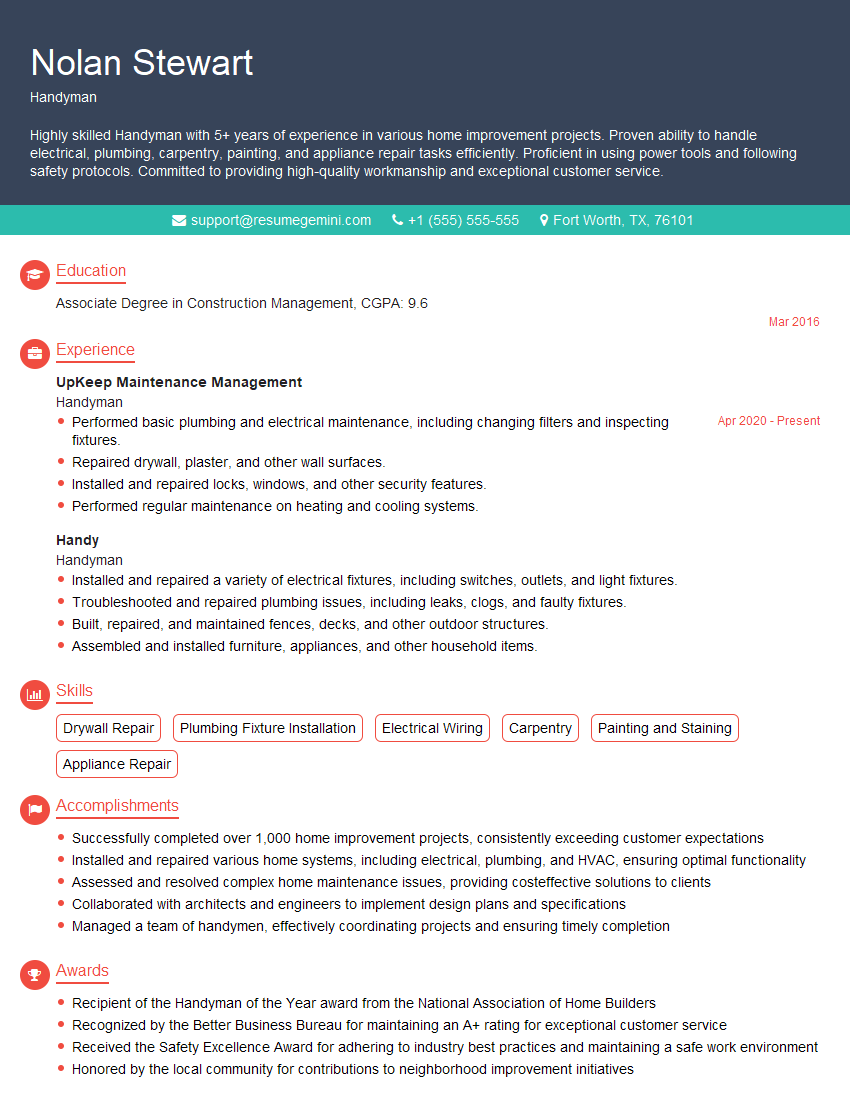

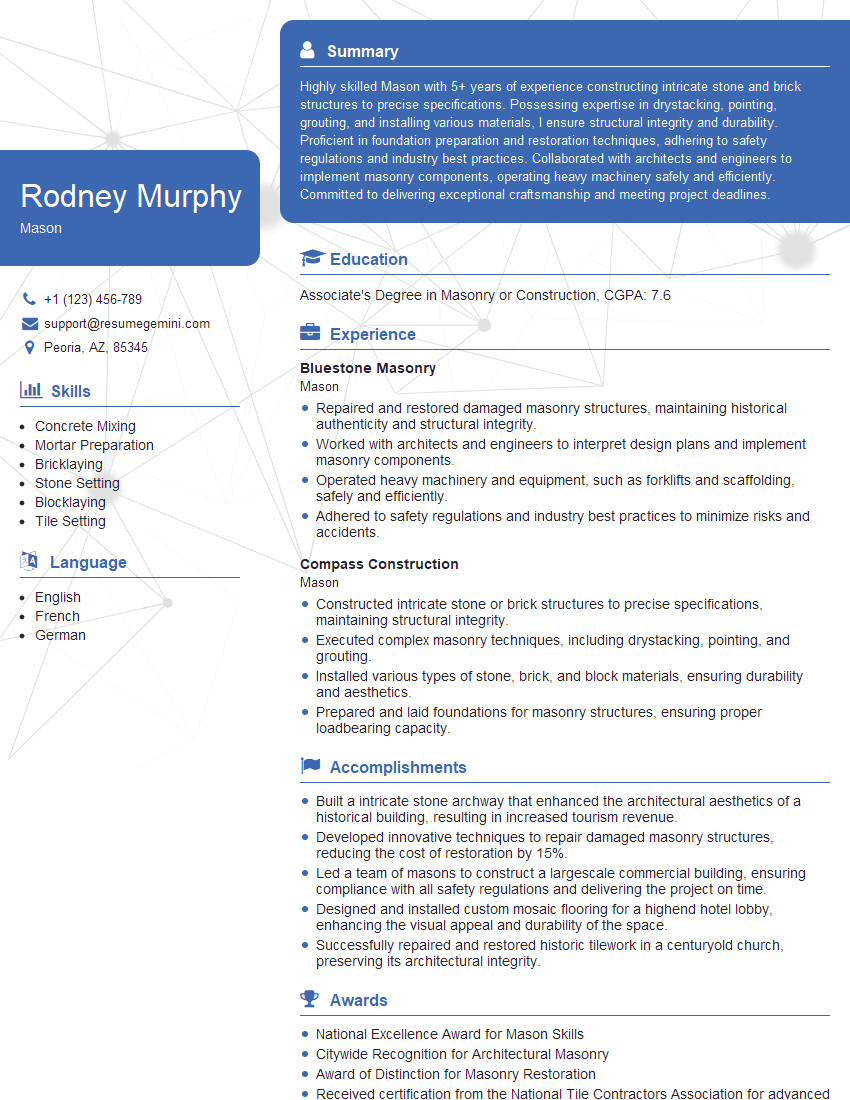

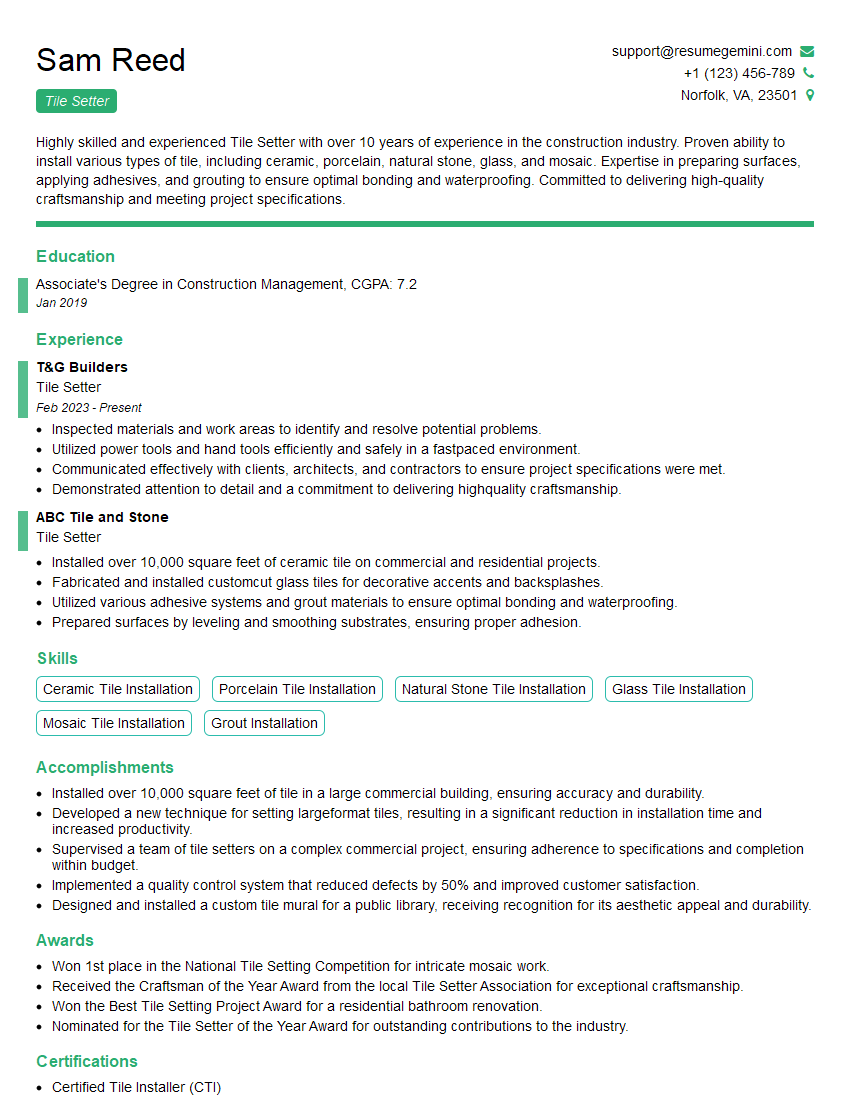

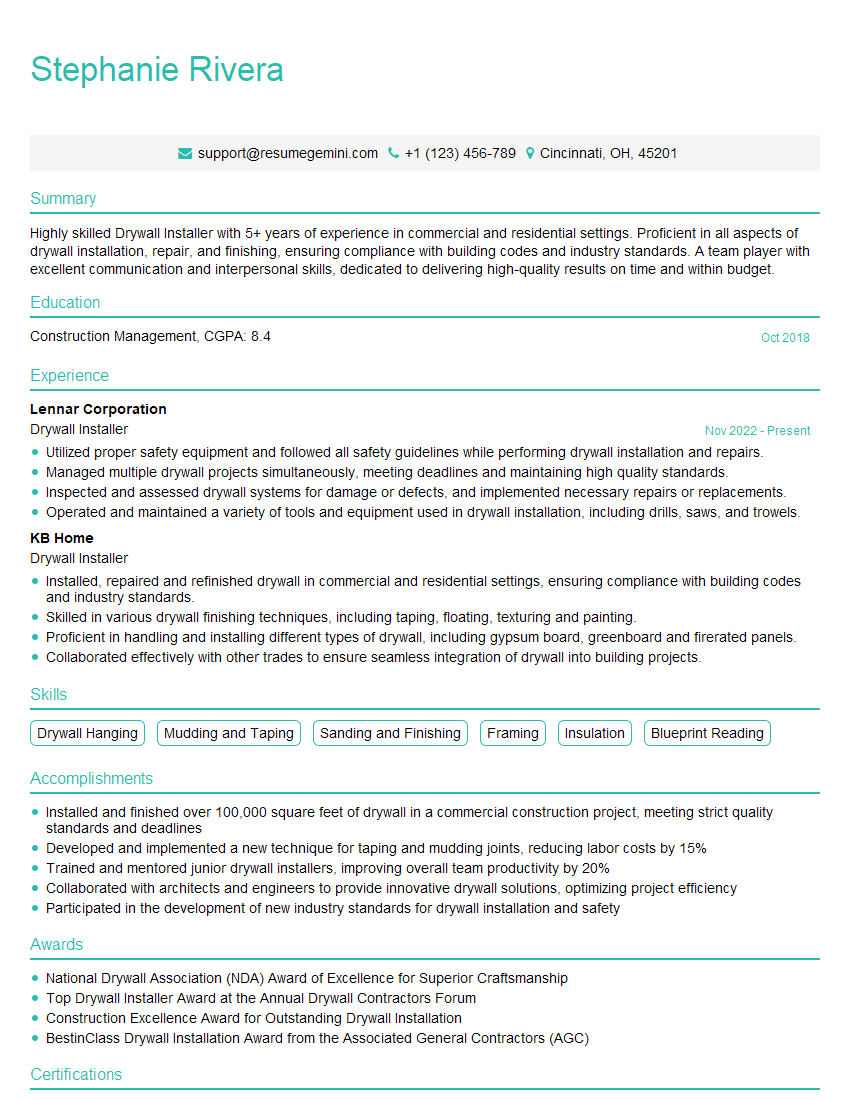

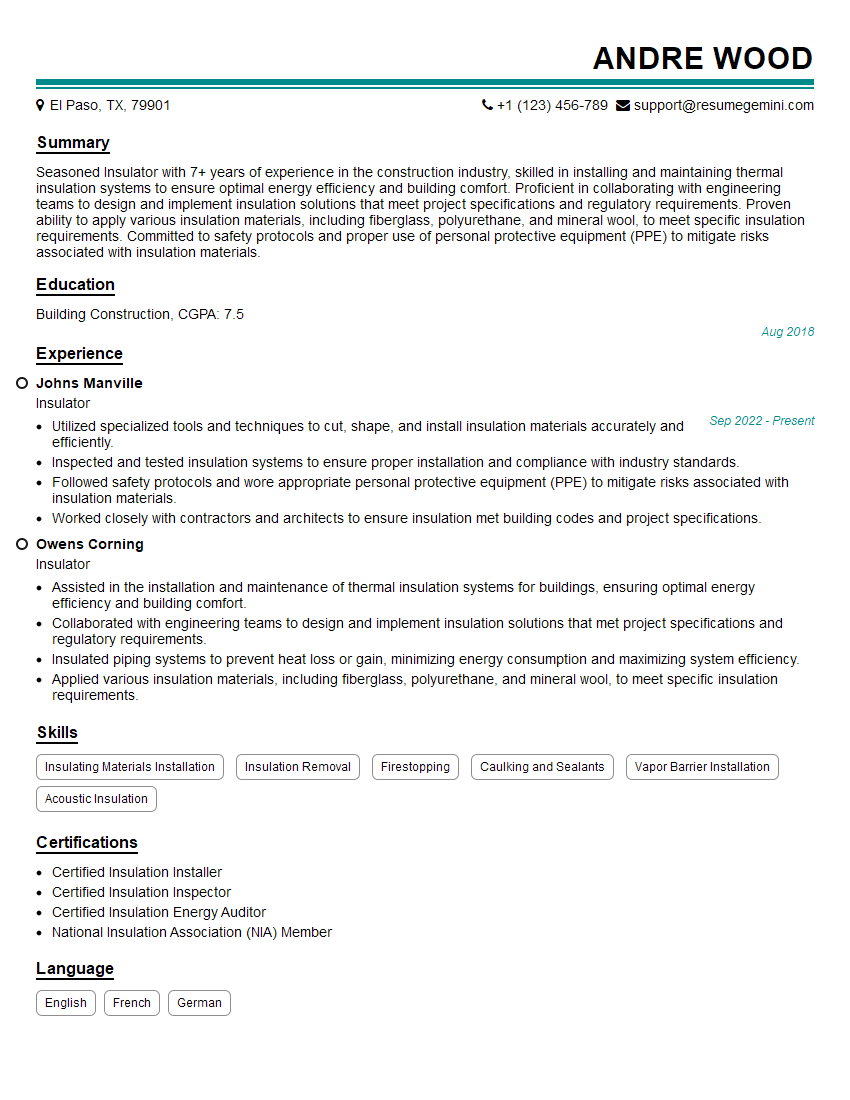

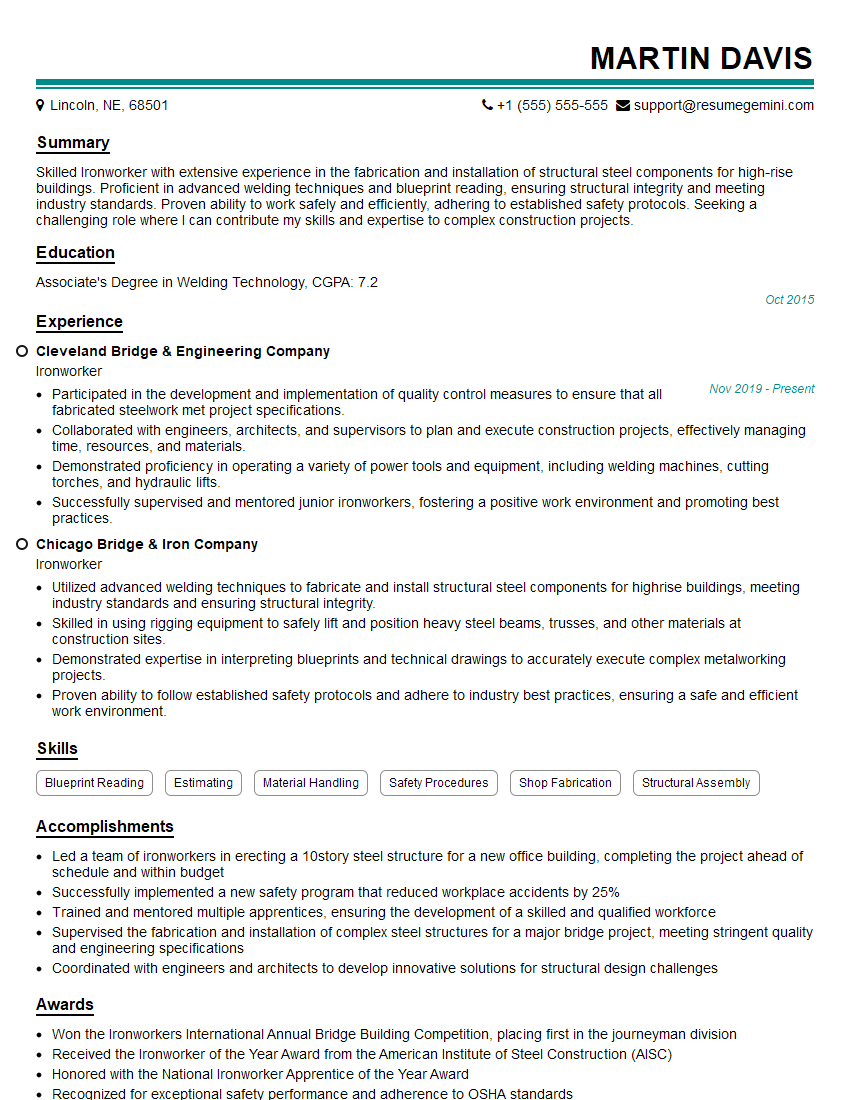

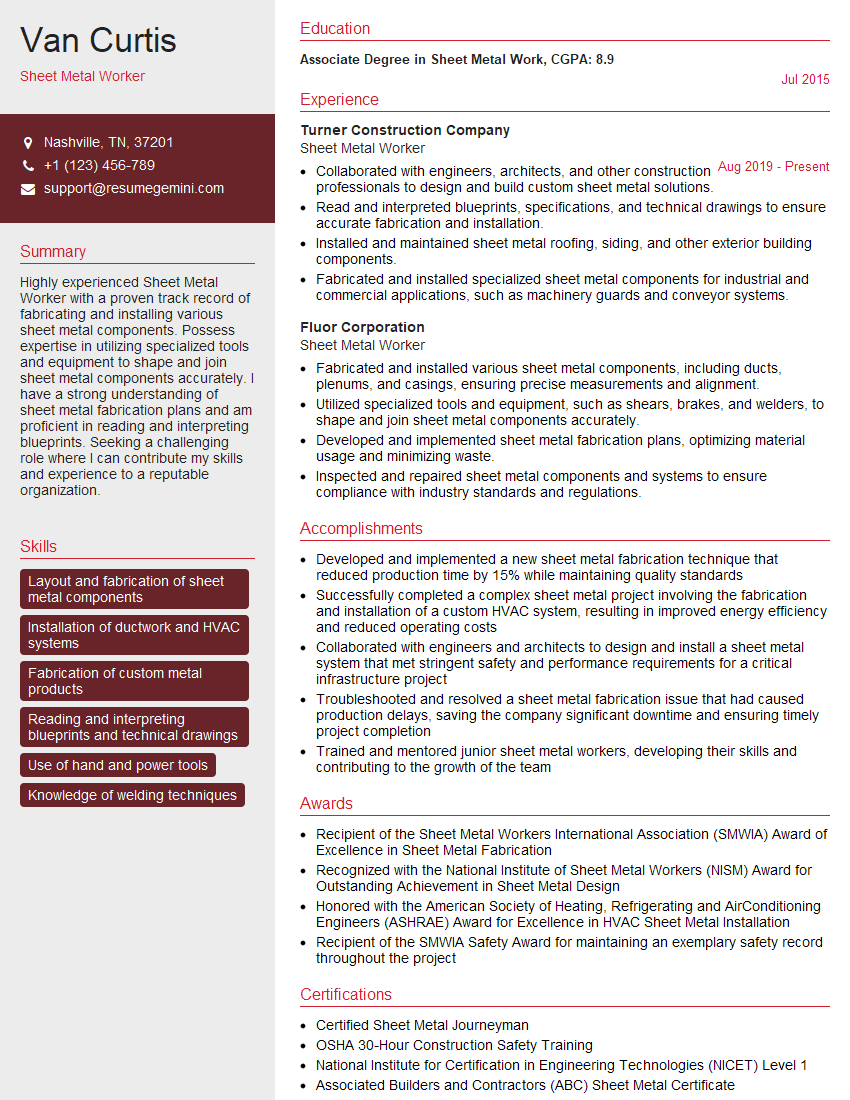

Mastering proficiency in hand tools and power equipment is crucial for career advancement in numerous skilled trades and technical fields. A strong understanding of these skills demonstrates your practical abilities and commitment to safety, significantly enhancing your job prospects. To maximize your chances of securing your ideal role, crafting an ATS-friendly resume is paramount. ResumeGemini can be a valuable tool in this process, helping you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Proficiency in Hand Tools and Power Equipment are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good