Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Hydraulic Equipment Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Hydraulic Equipment Operation Interview

Q 1. Describe the principles of Pascal’s Law and its application in hydraulic systems.

Pascal’s Law is fundamental to hydraulics: it states that pressure applied to a confined, incompressible fluid is transmitted equally and undiminished in all directions throughout the fluid. Imagine squeezing a balloon filled with water – the pressure you apply isn’t just felt at the point of your squeeze, but spreads evenly across the entire balloon’s surface. This is Pascal’s Law in action.

In hydraulic systems, this principle allows us to multiply force. A small force applied to a small area generates a large force over a larger area. This is the basis of hydraulic jacks, presses, and braking systems. For example, in a hydraulic jack, a small piston with a smaller surface area receives input force. This force is then transmitted through the hydraulic fluid to a larger piston with a greater surface area, resulting in a significantly amplified output force. The pressure remains consistent.

The equation illustrating this is: F1/A1 = F2/A2, where F1 and A1 are the force and area on the input side, and F2 and A2 are the force and area on the output side. The ratio of areas directly influences the force amplification.

Q 2. Explain the difference between open-center and closed-center hydraulic systems.

The key difference between open-center and closed-center hydraulic systems lies in how the fluid is routed when actuators (like hydraulic cylinders) are not actively working.

- Open-center systems: When a valve is not directing fluid to an actuator, the fluid flows freely back to the reservoir through the valve’s open center. This means the pump continuously runs, even during periods of inactivity, with the excess flow going back to the tank. Think of it like a constantly flowing river with some water diverted by channels (actuators) when needed.

- Closed-center systems: In closed-center systems, there is no direct path back to the reservoir when actuators aren’t working. The pump continues running but supplies fluid only when needed, with the flow being blocked until an actuator is activated and the valve opens the path. This is more efficient, conserving energy and reducing heat generation.

Open-center systems are simpler and less expensive, often found in less demanding applications. Closed-center systems, being more complex, offer better precision, responsiveness, and control, making them suitable for sophisticated machinery such as CNC machines or robotics.

Q 3. What are the common types of hydraulic pumps and their applications?

Several types of hydraulic pumps exist, each suited to different applications:

- Gear pumps: These are relatively simple and inexpensive, using meshing gears to move fluid. They’re suitable for lower-pressure applications with moderate flow rates, like power steering systems.

- Vane pumps: These pumps use vanes sliding within a rotor, providing a smooth and quieter operation than gear pumps. They’re commonly used in applications requiring higher flow rates, such as mobile equipment.

- Piston pumps: Piston pumps offer high pressure and high efficiency and are the workhorse of high-pressure hydraulic systems. They’re categorized into radial piston, axial piston (with swashplate or bent-axis), and others. These pumps are commonly found in heavy machinery and industrial applications requiring high accuracy and force.

The choice of pump depends on factors such as required pressure, flow rate, efficiency needs, and cost considerations. For instance, a gear pump might be sufficient for a small agricultural machine, whereas a high-pressure axial piston pump would be necessary for a large excavator.

Q 4. How do hydraulic valves control fluid flow and pressure?

Hydraulic valves are the control elements of hydraulic systems, managing the flow and pressure of the hydraulic fluid. They act like sophisticated plumbing valves, but with precise control.

Different types of valves perform specific functions:

- Directional control valves: These valves direct the flow of hydraulic fluid, starting, stopping, or changing the direction of fluid flow to actuators. Think of them as switches controlling the movement of hydraulic cylinders.

- Pressure control valves: These maintain a specific pressure within the system, preventing overpressure or regulating the pressure supplied to actuators. They act as safety devices and flow regulators.

- Flow control valves: These regulate the flow rate of hydraulic fluid, controlling the speed of actuators. Think of them as speed controllers for hydraulic cylinders or motors.

These valves work by using spools (sliding components) or other mechanisms to alter the pathways of the fluid, precisely adjusting pressure and flow in accordance with the system’s commands.

Q 5. Describe the function of a hydraulic accumulator.

A hydraulic accumulator is like a pressure reservoir in a hydraulic system. It stores energy under pressure, either as compressed gas or a pre-charged spring. Its primary functions are:

- Shock absorption: It acts as a cushion, absorbing pressure surges and shocks to protect other components from damage. Imagine a shock absorber on a vehicle—that’s a similar principle.

- Emergency power source: In the event of pump failure, the accumulator can provide temporary power, allowing safe shutdown or continued operation for a short period.

- Pressure compensation: It helps to maintain a consistent pressure in the system, compensating for flow fluctuations and reducing pressure drops.

- Peak power boosting: It can provide extra power during short-duration, high-demand operations.

Accumulators are essential in applications where smooth operation, protection from surges, or backup power is required, such as in lift systems, presses, and some types of heavy machinery.

Q 6. Explain the purpose of hydraulic filters and their maintenance.

Hydraulic filters remove contaminants like dirt, metal particles, and water from the hydraulic fluid. Clean fluid is crucial for the system’s smooth operation and longevity. Contamination can lead to increased wear, reduced efficiency, and eventual failure of hydraulic components.

Maintaining hydraulic filters involves:

- Regular inspection: Check for pressure drop across the filter. A significant pressure drop indicates filter clogging.

- Periodic replacement: Replace filters according to the manufacturer’s recommendations or based on the condition of the filter element, indicated by pressure drop readings.

- Proper disposal: Dispose of used filters according to environmental regulations.

Ignoring filter maintenance can result in costly repairs or total system failure. Regular checks and timely replacements are essential for preventing contamination-related problems.

Q 7. What are the common causes of hydraulic leaks and how are they diagnosed?

Hydraulic leaks are a common problem stemming from various causes:

- Damaged seals and gaskets: These are common points of failure, often due to wear and tear, improper installation, or age.

- Loose fittings and connections: Loose connections allow fluid to escape.

- Cracked or damaged hoses: Hoses can wear out, get cut, or become brittle over time.

- Failed hydraulic components: Internal leaks within pumps, valves, or cylinders can occur due to wear or malfunction.

Diagnosing hydraulic leaks involves visually inspecting all components, checking connections, and sometimes using leak detection dye or electronic sensors. The location of the leak provides clues to its cause. For example, a leak at a fitting suggests a loose or damaged fitting. A leak near a hose indicates hose damage. Careful investigation is crucial to effectively pinpoint the source of the leak and implement the correct repair strategy. Always use safety precautions when dealing with high-pressure systems.

Q 8. How do you troubleshoot a hydraulic system with low pressure?

Troubleshooting low pressure in a hydraulic system requires a systematic approach. Think of it like a detective investigating a crime scene – you need to gather clues and eliminate possibilities one by one. Low pressure usually indicates a restriction in the flow of hydraulic fluid or a problem with the pump itself.

- Check the fluid level: A simple, yet often overlooked, cause is low fluid level in the reservoir. This is like having low fuel in a car – the engine (pump) can’t do its job properly.

- Inspect the filter: A clogged filter restricts fluid flow, similar to a blocked artery reducing blood flow. Replace or clean the filter as needed.

- Examine the pump: A failing pump is a major culprit. Listen for unusual noises like whining or grinding. Check for leaks around the pump seals. Low oil pressure will quickly damage a pump.

- Check for leaks: Leaks in hoses, fittings, or cylinders can drastically reduce system pressure, think of it as a hole in a water pipe. Visually inspect all components carefully.

- Inspect the valves: Sticking or malfunctioning valves can restrict flow. Check for proper operation of directional control valves, relief valves and check valves.

- Check the hydraulic lines: Kinks or crushing in the hydraulic lines will restrict flow, similar to a kinked garden hose.

- Consider the load: The system might be working correctly but under too heavy a load, like trying to lift a weight far beyond its capacity.

By systematically checking these areas, you’ll quickly narrow down the source of the low pressure and resolve the issue. Remember to always consult the system’s schematic diagram for proper component identification and troubleshooting.

Q 9. Explain the process of bleeding air from a hydraulic system.

Bleeding air from a hydraulic system is crucial for proper operation; trapped air can severely impair performance and even damage components. Think of it like trying to push water through a pipe with air bubbles in it – the flow is severely restricted.

The process typically involves:

- Lowering the system: In many systems it is advantageous to make sure that the reservoir is the lowest point of the system before beginning.

- Locating bleed valves: These valves are strategically placed throughout the system to allow air to escape. Consult the system’s schematic diagram to identify their locations.

- Opening bleed valves: Open each valve slowly, allowing air to escape. This is usually done while the pump is running at a low speed. You’ll often see and hear the air escaping, sometimes with a hissing sound.

- Cycling actuators: Operate hydraulic cylinders or other actuators repeatedly to help purge the air from the system and through the bleed valves.

- Checking for leaks: Once air is removed, carefully check all connections and hoses for leaks.

- Monitoring pressure: Observe the hydraulic pressure gauge to ensure it reaches the specified operating pressure.

This process ensures the system is completely free of air, allowing for smooth, efficient operation. Remember to always refer to the manufacturer’s instructions for the specific procedure on your hydraulic system.

Q 10. How do you interpret hydraulic system schematics and diagrams?

Hydraulic schematics and diagrams are the roadmaps for understanding how a hydraulic system functions. They’re like blueprints for a house, showing the arrangement of all components and their interconnections.

Interpreting them involves:

- Identifying components: Learn to recognize standard symbols for pumps, valves, actuators, and other elements. Each symbol represents a specific part of the system.

- Tracing fluid flow: Follow the lines to see the path of the fluid through the system. This helps understand the sequence of operations.

- Understanding valve functions: Grasp how different valves (directional control valves, check valves, relief valves) direct and control fluid flow.

- Analyzing pressure and flow: Look for pressure indicators and flow indicators to understand how the fluid moves through the system and the forces exerted on components.

- Referencing the legend: The legend helps connect the graphical symbols to the real-world components.

Practice is key. The more you work with schematics, the more comfortable you’ll become at interpreting them, allowing you to quickly diagnose problems and understand a system’s functionality.

Q 11. What safety precautions should be taken when working with hydraulic equipment?

Safety is paramount when working with hydraulic equipment. High-pressure hydraulic systems are powerful and pose significant hazards if not handled correctly. Think of it like working with electricity – proper precautions are essential to prevent accidents.

- Lockout/Tagout procedures: Always use lockout/tagout procedures before performing any maintenance or repair work. This ensures that the system is completely de-energized and safe to work on.

- Eye protection: Wear safety glasses or goggles to protect your eyes from potential high-pressure fluid jets or flying debris.

- Hearing protection: Hydraulic systems can be noisy, so ear protection is recommended.

- Gloves: Wear heavy-duty gloves to protect your hands from cuts, abrasions, and fluid exposure.

- Protective clothing: Wear appropriate clothing that will not get caught in moving parts and offer protection from potential fluid leaks.

- Awareness of pressure: Never work near a hydraulic system that is under pressure without appropriate safety precautions.

- Proper lifting techniques: Hydraulic components can be heavy; use proper lifting techniques and equipment.

- Fire prevention: Hydraulic fluid can be flammable; take appropriate steps to prevent fires, especially in the presence of sparks or open flames.

- Trained personnel: Only trained and authorized personnel should work on hydraulic systems.

Always prioritize safety; it’s not just a set of rules, it’s a way of life when working with hydraulic equipment.

Q 12. Describe the different types of hydraulic fluids and their properties.

Hydraulic fluids are the lifeblood of hydraulic systems, each type tailored to specific applications. They’re carefully chosen to ensure optimal system performance and longevity. Think of them as specialized oils, each designed for a specific task.

- Mineral oils: These are the most common type, offering a good balance of performance and cost. However, they can be susceptible to oxidation and degradation over time.

- Synthetic oils: These offer superior performance in extreme temperature ranges and have better resistance to oxidation and degradation than mineral oils. They’re typically more expensive.

- Water-glycol fluids: Used in some applications where fire resistance is critical, they have lower viscosity than oil but are less suitable for high-pressure systems.

- Phosphate ester fluids: Used where fire resistance is essential, offer superior fire resistance compared to other types but may be less compatible with certain seal materials.

The choice of fluid depends on factors such as operating temperature, pressure, system components, and environmental considerations. The fluid’s properties, such as viscosity, lubricity, and resistance to degradation, are crucial for efficient and reliable system operation. Always refer to the manufacturer’s recommendations for the appropriate fluid type.

Q 13. Explain the concept of hydraulic horsepower.

Hydraulic horsepower represents the rate at which a hydraulic system can do work. It’s a measure of the system’s power, expressed in horsepower (hp). Think of it as the engine’s power for a hydraulic system.

It’s calculated using the formula:

Hydraulic Horsepower (hp) = (Pressure (psi) × Flow Rate (gpm)) / 1714Where:

- Pressure (psi) is the hydraulic pressure in pounds per square inch.

- Flow Rate (gpm) is the flow rate of the hydraulic fluid in gallons per minute.

For example, a system with a pressure of 3000 psi and a flow rate of 10 gpm would have a hydraulic horsepower of approximately 17.5 hp (3000 x 10 / 1714 ≈ 17.5).

Understanding hydraulic horsepower is vital for sizing systems correctly and ensuring they can handle the required workload. A system with insufficient hydraulic horsepower will struggle to perform its intended function. It’s a critical factor in the selection and design of hydraulic equipment.

Q 14. What is hydraulic shock and how can it be prevented?

Hydraulic shock, also known as water hammer, is a sudden pressure surge in a hydraulic system caused by the rapid deceleration or stoppage of fluid flow. Think of it like slamming on the brakes in a car – the sudden stop creates a jolt.

This can damage components like hoses, valves, and cylinders, potentially leading to costly repairs or even system failure. Causes include sudden valve closure, pump starting/stopping, and cavitation.

Preventing hydraulic shock involves:

- Slow valve operation: Operate valves smoothly and avoid abrupt changes in flow direction. Think of gradually applying the brakes instead of slamming them.

- Shock absorbers: Installing accumulators or surge dampeners in the system can absorb the pressure shocks, similar to shock absorbers in a car.

- Proper system design: Ensure the system is designed to minimize sudden changes in flow direction.

- Air removal: Air in the system can contribute to cavitation, which exacerbates hydraulic shock.

- Appropriate pump sizing: Proper pump sizing can help mitigate the effects of sudden changes in the demand for fluid flow.

By taking these preventative measures, you can significantly reduce the risk of hydraulic shock and ensure the longevity of your hydraulic system.

Q 15. Describe the function of a hydraulic cylinder and its components.

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear mechanical motion. Think of it as a muscle powered by pressurized fluid. It’s a fundamental component in many hydraulic systems, from construction equipment to industrial machinery. The main components include:

- Cylinder Body/Barrel: This is the outer casing, typically made of steel, which houses the piston and seals.

- Piston: A cylindrical component that moves back and forth within the barrel, converting hydraulic pressure into linear force.

- Piston Rod: Extends from one end of the piston, transferring the linear motion to the load.

- Rod Seals and Piston Seals: These prevent hydraulic fluid leakage past the piston and rod, maintaining system pressure.

- Cylinder Caps (End Caps): These close off the ends of the cylinder, providing structural support and housing the ports for fluid entry and exit.

- Ports: These openings allow hydraulic fluid to enter and exit the cylinder, controlling piston movement.

For example, in a dump truck, a hydraulic cylinder lifts and lowers the truck bed. The pressurized hydraulic fluid enters the cylinder, pushing the piston and extending the rod, thus raising the bed. Reversing the fluid flow retracts the piston and lowers the bed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the different types of hydraulic actuators.

Hydraulic actuators are components that convert hydraulic energy into mechanical work. While hydraulic cylinders are the most common type, providing linear motion, there are others:

- Hydraulic Cylinders (Linear Actuators): These provide straight-line motion, as described above. They come in various configurations, such as single-acting (only one direction of movement using hydraulic pressure, the return is typically by spring or gravity) and double-acting (movement in both directions using hydraulic pressure).

- Hydraulic Motors (Rotary Actuators): These convert hydraulic energy into rotary motion. They’re commonly used to power rotating equipment, such as pumps, winches, and steering mechanisms. Examples include gear motors, vane motors, and piston motors, each with different characteristics and suitability for specific applications.

The choice between a cylinder and a motor depends on the application’s needs. If linear motion is required, a cylinder is appropriate; for rotary movement, a hydraulic motor is necessary. In complex systems, you might find both working together.

Q 17. How do you perform routine maintenance on hydraulic components?

Routine maintenance is critical for ensuring the longevity and efficiency of hydraulic components. It should include:

- Regular Fluid Level Checks: Maintaining the correct fluid level prevents damage from overheating and cavitation.

- Fluid Condition Monitoring: Regularly check the fluid’s colour, clarity, and for any contaminants. Dirty fluid is a major cause of component failure.

- Filter Inspection and Replacement: Filters should be inspected regularly and replaced according to the manufacturer’s recommendations. Contaminated fluid can quickly clog filters, which restricts flow and impacts the entire system.

- Visual Inspection of Hoses and Fittings: Look for leaks, cracks, or signs of wear and tear on hoses and fittings. Replace any damaged components immediately.

- Leak Detection: Regularly check for leaks in the entire system. Even small leaks can indicate bigger problems down the line.

- Component Temperature Monitoring: Excessive heat indicates potential issues, such as restricted flow or internal friction.

Imagine a construction site where a hydraulic excavator’s arm suddenly stops working mid-operation. Routine maintenance like fluid checks could have prevented the problem, avoiding costly downtime and potential safety hazards.

Q 18. What are the common types of hydraulic seals and their applications?

Hydraulic seals are crucial for preventing fluid leakage in hydraulic systems. Several types exist, each with its own application:

- O-rings: These are simple, versatile, and widely used seals, effective for static and low-pressure dynamic applications. They’re inexpensive and easy to install.

- U-cups (U-seals): Commonly used in hydraulic cylinders, they are more robust than O-rings and handle higher pressures and speeds.

- Lip Seals (Radial Shaft Seals): Designed to seal rotating shafts against leakage, they’re vital in pumps and motors. They are commonly used to prevent leakage between a rotating shaft and a stationary housing.

- V-packings: Used in hydraulic cylinders to seal under higher pressures than U-cups. They work by being compressed between a piston and a cylinder wall.

- Backup Rings: These support and protect primary seals, extending their service life and improving seal performance, particularly in high-pressure applications.

Choosing the right seal depends on the specific application’s operating pressure, speed, fluid compatibility, and temperature range. Using the wrong seal can lead to leaks, component damage, and system failure.

Q 19. Explain the importance of hydraulic system cleanliness.

Hydraulic system cleanliness is paramount for optimal performance and longevity. Contaminants like dirt, dust, and metal particles can cause significant damage, including:

- Abrasion: Particles can scratch and wear down internal components, reducing their efficiency and lifespan.

- Blockages: Contaminants can clog valves, filters, and orifices, restricting fluid flow and causing pressure drops.

- Seal Damage: Particles can damage seals, leading to leaks and loss of pressure.

- Corrosion: Contaminated fluid can accelerate corrosion of system components.

Think of it like your car engine. If you consistently use dirty oil, it will quickly wear out the engine parts. Similarly, a hydraulic system with dirty fluid will experience premature component wear and failure, leading to costly repairs and downtime.

Q 20. What are the signs of hydraulic pump failure?

Several signs indicate hydraulic pump failure:

- Reduced Hydraulic Pressure: This is often the first and most noticeable sign. The system may not operate at its full capacity or may fail to perform certain functions.

- Unusual Noises: A whining, groaning, or knocking sound coming from the pump often indicates bearing wear or internal component damage.

- Overheating: Excessive heat generation indicates inefficiencies within the pump, such as internal friction or lack of lubrication.

- Fluid Leakage: Leaks around the pump indicate seal failure or cracks in the pump housing.

- Erratic Fluid Flow: Inconsistent fluid flow rates can point to internal pump component problems.

Ignoring these symptoms can lead to catastrophic pump failure, potentially causing significant damage to other components and resulting in costly repairs and downtime.

Q 21. How do you diagnose and repair a leaking hydraulic hose?

Diagnosing and repairing a leaking hydraulic hose involves several steps:

- Identify the Leak: Pinpoint the exact location of the leak and assess the severity. A small weep might just require tightening a fitting, while a major leak needs hose replacement.

- Isolate the System: To prevent further fluid loss and potential injury, shut down the hydraulic system and isolate the affected section.

- Inspect the Hose: Check for cuts, cracks, abrasions, or kinks along the hose length and around the fittings. Look for signs of chafing against other components.

- Tighten Fittings (If Applicable): If the leak is minor and seems to be coming from a loose fitting, carefully tighten it using the appropriate wrench. Don’t overtighten.

- Hose Replacement (If Necessary): If the hose is damaged beyond repair, measure the length and the fitting types. Order a replacement hose with identical specifications. Properly install the new hose, ensuring fittings are secure and tight.

- System Re-pressurization and Leak Check: Once the repair is complete, restart the system and carefully check for any residual leaks.

Improperly repairing a leaking hose can lead to further fluid loss, equipment damage, and potential safety hazards. It’s crucial to follow safety guidelines and use appropriate tools when working with hydraulic systems.

Q 22. Describe the process of hydraulic system pressure testing.

Hydraulic system pressure testing is crucial for ensuring the system’s integrity and safe operation. It involves systematically pressurizing the system to a predetermined level and observing for leaks, weaknesses, or other anomalies. This process helps identify potential failures before they cause catastrophic damage or downtime.

The process typically involves:

- Isolation: Isolating the section of the system to be tested. This might involve closing valves to prevent pressure from escaping into other parts of the system.

- Pressurization: Using a hydraulic test pump to slowly increase the system pressure to the specified test pressure. This pressure is usually found in the system’s specifications or relevant industry standards.

- Leak Detection: Carefully inspecting all connections, hoses, and components for any signs of leaks, often using soapy water to aid visualization.

- Pressure Holding: Maintaining the test pressure for a specified period (often several minutes) to observe for slow leaks that may not be immediately apparent.

- Documentation: Recording all pressure readings, leak locations (if any), and any other observations. This forms a vital part of the system’s maintenance log.

For instance, I once worked on a large industrial press where pressure testing revealed a tiny pinhole leak in a high-pressure hose that could have easily led to a major failure. Early detection through careful testing prevented significant downtime and potential damage.

Q 23. What are the common types of hydraulic motors?

Hydraulic motors convert hydraulic energy into mechanical energy, providing rotary motion. Several common types exist, each with its own advantages and disadvantages:

- Gear Motors: These motors use meshing gears to displace fluid, creating torque. They’re simple, robust, and relatively inexpensive but can be less efficient at high speeds.

- Vane Motors: These use rotating vanes within a casing to displace fluid. They offer good starting torque and are relatively compact but can be susceptible to wear.

- Piston Motors: These are the most efficient type, using multiple pistons to generate rotation. They can provide high torque and power at high speeds, but they are complex and more expensive.

- Axial Piston Motors: Pistons are arranged parallel to the motor’s axis. They offer high power density, efficiency, and variable displacement.

- Radial Piston Motors: Pistons are arranged radially, offering high torque at low speeds.

The choice of motor depends heavily on the application’s specific requirements regarding speed, torque, efficiency, and cost. For example, a gear motor might be suitable for a low-speed, high-torque application like a conveyor belt, while an axial piston motor would be preferred for a high-speed, high-precision application such as a CNC machine.

Q 24. Explain the concept of hydraulic servo systems.

Hydraulic servo systems are closed-loop control systems that use hydraulics to provide precise and responsive control of a mechanical system. They combine a hydraulic actuator with a feedback mechanism to maintain a desired position or speed. Think of it like a sophisticated, very strong, and highly accurate version of a power steering system in a car.

The system works by comparing a desired position or speed (the setpoint) with the actual position or speed, measured by a feedback device (like a position sensor). The difference between these two values (the error signal) is then used to adjust the hydraulic flow to the actuator, driving the system toward the desired setpoint. A control valve manages this flow precisely.

These systems are essential in applications requiring high accuracy and responsiveness, such as robotics, aircraft control surfaces, and industrial machinery. Their advantage lies in their power density and ability to handle large forces and torques with precision.

Q 25. What are some common hydraulic system troubleshooting techniques?

Troubleshooting hydraulic systems requires a systematic approach. Here’s a framework I often use:

- Safety First: Ensure the system is properly shut down and de-energized before commencing any troubleshooting.

- Visual Inspection: Check for obvious problems, such as leaks, loose connections, or damaged components.

- Pressure Checks: Use pressure gauges to measure pressure at various points in the system to identify pressure drops or blockages.

- Flow Checks: Measure flow rates to detect restrictions or insufficient flow.

- Oil Analysis: Analyze the hydraulic fluid for contamination, degradation, or unusual wear particles which could indicate component failures.

- Component Testing: If necessary, test individual components such as valves, pumps, and motors to pinpoint the faulty element.

For example, a sudden drop in system pressure might indicate a leak, while low flow might point to a clogged filter or a malfunctioning pump. A systematic approach is key to efficient troubleshooting and prevents replacing unnecessary components.

Q 26. How do you safely disconnect and reconnect hydraulic lines?

Disconnecting and reconnecting hydraulic lines requires extreme caution to prevent injury and system damage. High-pressure hydraulic systems contain considerable energy, and sudden releases can cause serious harm.

The steps involved are:

- Isolate the System: Ensure the system is shut down and all pressure is relieved. This often requires opening relief valves or using a pressure relief method specific to the system.

- Use Proper Tools: Employ appropriately sized wrenches or specialized hydraulic line disconnect tools to prevent damage to the fittings.

- Protect Yourself: Wear appropriate safety glasses, gloves, and potentially other personal protective equipment to protect against potential fluid sprays or injuries.

- Proper Connection: Before reconnecting, ensure that the connections are clean, free from debris, and properly aligned. Torque connections to the manufacturer’s specifications.

- Leak Test: After reconnecting, carefully inspect all joints for leaks and address any issues promptly.

I’ve seen many instances where improper line handling has led to costly repairs or even injury. Following safe procedures is paramount.

Q 27. Describe your experience with hydraulic system maintenance and repair.

Throughout my career, I’ve been extensively involved in hydraulic system maintenance and repair. This includes preventative maintenance tasks such as regularly changing hydraulic fluid, inspecting filters and seals, and checking component functionality. I’ve also tackled complex repairs, such as replacing pumps, motors, valves, and hoses. My experience extends to diagnosing and resolving a variety of hydraulic system issues, including leaks, pressure drops, and malfunctions, utilizing the techniques I described previously.

One memorable project involved a large-scale industrial excavator where a critical hydraulic valve failed. By meticulously analyzing the system’s pressure and flow characteristics, I pinpointed the faulty valve and efficiently coordinated its replacement, minimizing costly downtime for the operation. My expertise allows me to quickly troubleshoot and resolve issues, minimizing disruption to operations.

Q 28. What are some best practices for maintaining hydraulic system efficiency?

Maintaining hydraulic system efficiency is crucial for optimal performance and longevity. Best practices include:

- Regular Fluid Changes: Following the manufacturer’s recommendations for fluid change intervals, ensuring the quality of the replacement fluid.

- Filter Maintenance: Regularly inspecting and replacing filters according to the schedule. Clogged filters restrict flow and reduce efficiency.

- Leak Detection and Repair: Addressing leaks promptly as they can lead to fluid loss, contamination, and reduced system pressure.

- Proper Lubrication: Ensuring all components receive adequate lubrication to reduce wear and tear.

- Temperature Control: Maintaining proper operating temperature to prevent fluid degradation and component damage.

- Component Condition Monitoring: Regular inspection of components for wear and tear. This could include vibration analysis or other predictive maintenance techniques.

By implementing these practices, you significantly extend the lifespan of your hydraulic system, reduce maintenance costs, and ensure safe and efficient operation. In my experience, proactive maintenance significantly outpaces reactive repairs in terms of cost-effectiveness and reduced downtime.

Key Topics to Learn for Hydraulic Equipment Operation Interview

- Hydraulic System Fundamentals: Understanding Pascal’s Law, pressure, flow, and force relationships within hydraulic systems. This includes the differences between open-center and closed-center systems.

- Hydraulic Components: Familiarize yourself with pumps (gear, vane, piston), valves (directional control, pressure control, flow control), actuators (cylinders, motors), and reservoirs. Know their functions and common maintenance procedures.

- Troubleshooting Hydraulic Systems: Learn to identify common problems like leaks, low pressure, overheating, and component failure. Practice diagnosing issues using systematic approaches, such as checking pressure readings and visually inspecting components.

- Safety Procedures: Mastering safe operating procedures is crucial. This includes understanding lockout/tagout procedures, proper personal protective equipment (PPE) usage, and hazard identification within hydraulic system operation.

- Practical Applications: Be prepared to discuss your experience operating specific types of hydraulic equipment (e.g., excavators, loaders, cranes). Highlight your experience with different control systems and attachments.

- Hydraulic Schematics and Diagrams: Understanding and interpreting hydraulic schematics is vital. Practice reading and interpreting different symbols and understanding the flow of fluid within a system.

- Maintenance and Repair: Demonstrate knowledge of routine maintenance tasks, such as fluid changes, filter replacements, and leak detection/repair. Understand preventative maintenance schedules and their importance.

Next Steps

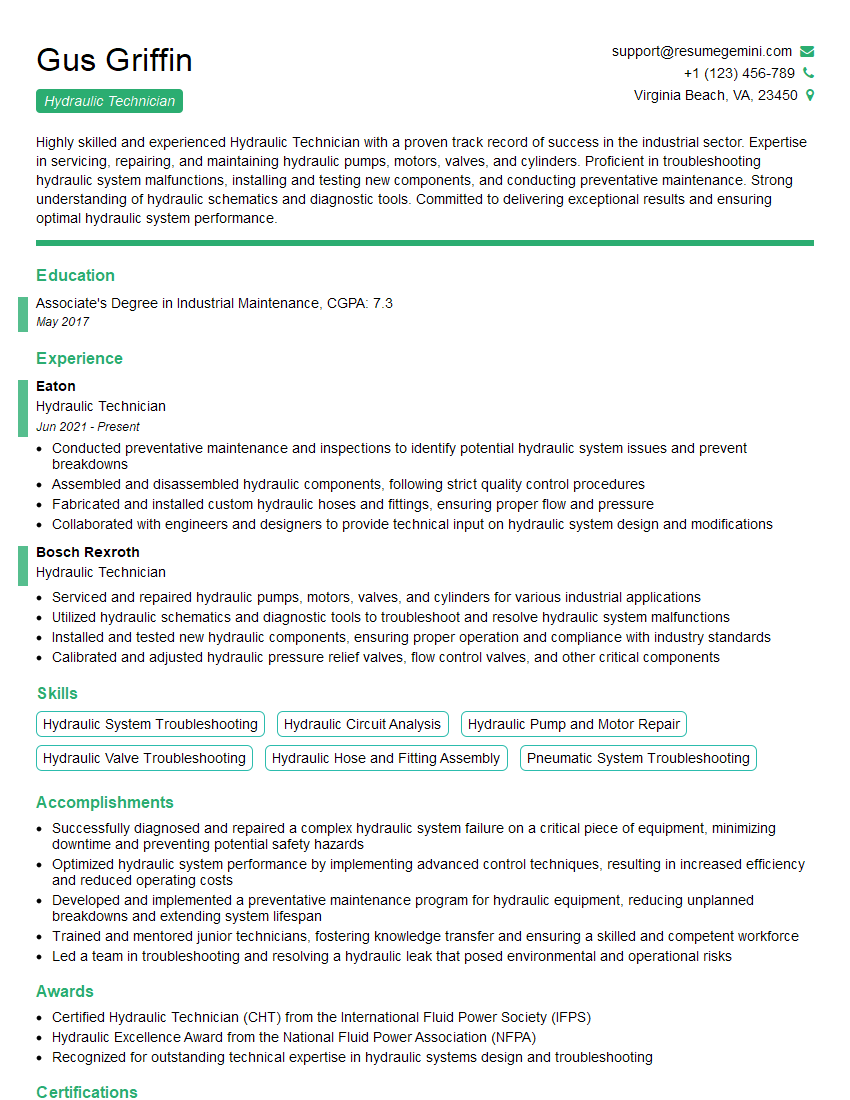

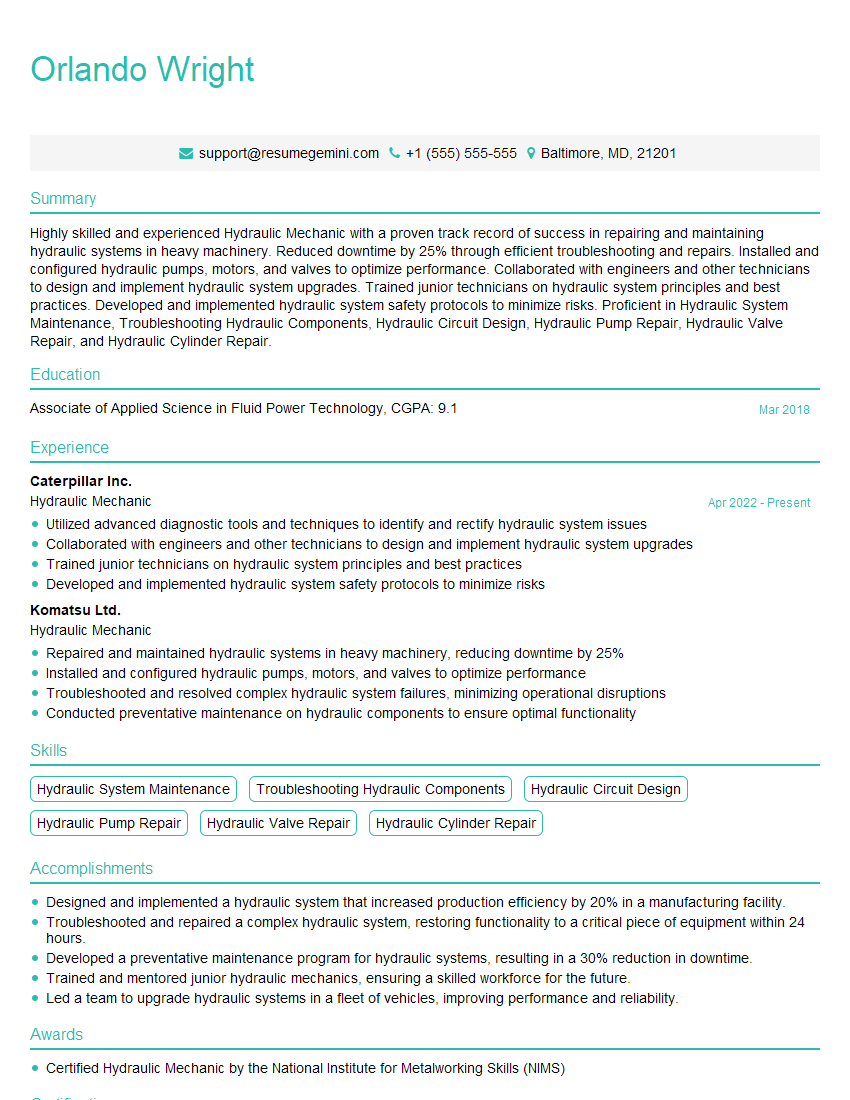

Mastering hydraulic equipment operation opens doors to rewarding and high-demand careers in various industries. A strong foundation in this area significantly enhances your employability and potential for career advancement. To maximize your job prospects, creating a well-structured, ATS-friendly resume is critical. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of your target jobs. We provide examples of resumes specifically crafted for Hydraulic Equipment Operation roles to help guide you. Invest time in crafting a compelling resume to showcase your skills and experience effectively. This will significantly increase your chances of securing interviews and landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good