Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Pneumatic Hydraulic Riveting interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Pneumatic Hydraulic Riveting Interview

Q 1. Explain the principle of operation of a pneumatic-hydraulic riveting system.

Pneumatic-hydraulic riveting systems cleverly combine the power of compressed air with the precise force control of hydraulics to set rivets. The system works by using a pneumatic cylinder to drive a hydraulic pump. Compressed air pushes a piston in the pneumatic cylinder, which in turn drives a hydraulic pump. This pump increases the pressure of the hydraulic fluid, which is then directed to a hydraulic cylinder. This hydraulic cylinder then provides the controlled force required to set the rivet, delivering a consistent and powerful squeeze without the risk of damage to the workpiece. Think of it like this: compressed air provides the initial power, and the hydraulic system acts like a smooth, controlled transmission, carefully delivering that power to the rivet. This controlled force is crucial for achieving strong, reliable joints.

Q 2. Describe the different types of rivets used in pneumatic-hydraulic riveting.

Several rivet types are compatible with pneumatic-hydraulic riveting systems, each suited for different applications and material thicknesses. Common types include:

- Solid rivets: These are simple, cylindrical rivets made from a single piece of metal. They’re inexpensive and widely used for general applications.

- Blind rivets: Designed to be set from one side of the material only, ideal where access to the rear is impossible. These often use a mandrel that is pulled back into the rivet body after setting, leaving a flush surface.

- Countersunk rivets: These have a countersunk head that sits flush or slightly below the surface of the material, providing a smooth finish.

- Semi-tubular rivets: These hollow rivets are strong and commonly used for joining thicker materials.

- Specialty rivets: Materials such as stainless steel, aluminum, or even more specialized alloys can be used for various industrial applications, offering different corrosion resistance or strength properties.

The choice depends heavily on the job at hand. For example, blind rivets are essential when riveting sheet metal panels in a car body, where reaching the back side is impractical.

Q 3. How do you select the appropriate rivet size and type for a specific application?

Selecting the correct rivet size and type is paramount for a strong and reliable joint. Several factors guide this selection:

- Material thickness: Thicker materials require larger rivets with greater shank length to ensure sufficient grip.

- Material type: Different materials require rivets with appropriate shear strength and material compatibility to avoid corrosion or failure.

- Joint strength requirements: The intended application dictates the necessary rivet strength. A structural component would necessitate a higher strength rivet than a cosmetic panel.

- Aesthetics: For visible applications, the rivet head style and finish may be a key consideration.

- Accessibility: Blind rivets are essential where rear access to the joint is limited.

Manufacturers provide charts and guidelines relating rivet sizes to material thicknesses. Consult these guidelines diligently. Improper rivet selection can lead to joint failure and potential safety hazards.

Q 4. What safety precautions are crucial when operating pneumatic-hydraulic riveting equipment?

Safety is paramount when operating pneumatic-hydraulic riveting equipment. Here are some crucial precautions:

- Eye protection: Always wear safety glasses or goggles to protect against flying debris or rivet fragments.

- Hearing protection: The equipment can be quite noisy; earplugs or muffs are essential.

- Hand protection: Use gloves to prevent injuries from sharp rivet edges or the machine itself.

- Proper machine maintenance: Regular inspection of the equipment for leaks, wear, and tear is critical for safe operation. Never operate malfunctioning equipment.

- Training and authorization: Only trained and authorized personnel should operate the equipment.

- Work area safety: Keep the work area clear of obstructions and ensure adequate lighting.

- Emergency shutoff: Be familiar with the location and operation of the emergency stop button.

Ignoring these precautions can lead to serious injuries. Prioritize safety at all times.

Q 5. Explain the process of setting up a pneumatic-hydraulic riveting machine for a given job.

Setting up a pneumatic-hydraulic riveting machine involves a few key steps:

- Select the correct rivet: Choose the appropriate rivet size, type, and material based on the application and materials being joined (as discussed previously).

- Prepare the workpieces: Ensure the workpieces are accurately aligned and clamped securely in place to prevent movement during riveting.

- Adjust the riveting head: Set the riveting head to accommodate the correct rivet type and size.

- Adjust the pressure: The hydraulic pressure should be adjusted according to the rivet specifications and material thickness. Too low, and the rivet won’t set properly; too high, and you risk damaging the workpieces.

- Test rivet: Perform a test rivet on a scrap piece of the same material to confirm the settings before proceeding with the actual workpiece.

- Operate the machine: Carefully place the rivet in the riveting head and operate the machine following the manufacturer’s instructions.

Always refer to the machine’s operating manual for specific instructions. Each machine is slightly different.

Q 6. How do you troubleshoot common malfunctions in a pneumatic-hydraulic riveting system?

Troubleshooting pneumatic-hydraulic riveting systems often involves systematic checks:

- No riveting action: Check air pressure, hydraulic fluid levels, and the condition of hoses and connections for leaks. Examine the pneumatic and hydraulic cylinders for proper operation.

- Inconsistent rivet setting: Verify pressure settings are correct. Check for worn or damaged riveting dies, and ensure the rivets being used are of the correct size and type.

- Rivet failure: This indicates that the rivet type, size, or pressure settings are incorrect for the materials involved. Also check for defects in the rivets themselves.

- Hydraulic leaks: Inspect all hydraulic lines and connections for leaks. Repair or replace damaged components as necessary.

- Air leaks: Similar to hydraulic leaks, check pneumatic lines and connections.

A methodical approach to troubleshooting will help isolate the problem quickly. If problems persist, consult a qualified technician.

Q 7. Describe the process for inspecting rivets after installation.

Post-installation rivet inspection ensures the integrity of the joint. Several inspection methods can be used:

- Visual inspection: Examine the rivet head for proper formation and flushness. Look for any signs of damage or deformation.

- Shear testing (destructive): For critical applications, a shear test can be performed to verify the joint strength. This involves applying a force to the joint until failure to determine the shear strength.

- Pull testing (destructive): Measure the force required to pull the rivet out of the material, this verifies the clamping force achieved by the rivet.

- Non-destructive testing (NDT): Methods like ultrasonic testing or radiographic inspection can be employed to detect internal flaws in the rivet or the joint without causing damage. These are often used in highly critical applications.

The chosen inspection method depends on the application’s criticality and the desired level of assurance. Visual inspection is a good first step, and destructive testing might be necessary for crucial structural components.

Q 8. What are the advantages and disadvantages of pneumatic-hydraulic riveting compared to other fastening methods?

Pneumatic-hydraulic riveting offers a powerful and efficient method for joining materials, particularly in situations requiring high clamping force. Let’s compare it to other fastening methods:

Advantages:

- High clamping force: Pneumatic-hydraulic systems generate significantly higher forces than purely pneumatic or manual riveting, ideal for thick materials or high-strength joints. Imagine trying to rivet thick steel plates – manual riveting would be incredibly difficult, while pneumatic-hydraulic easily handles it.

- Consistent rivet quality: The controlled hydraulic pressure ensures consistent squeeze on the rivet, leading to uniform deformation and strong, reliable joints. This repeatability is crucial for manufacturing processes.

- Versatility: These systems can be adapted for various rivet types and materials, offering flexibility in production.

- Relatively easy operation: While requiring understanding, the basic operation is generally straightforward, increasing efficiency.

Disadvantages:

- Higher initial cost: Pneumatic-hydraulic riveting equipment is more expensive than simple hand tools or some pneumatic riveters.

- Complexity: The system is more complex than simpler methods, meaning more potential points of failure and requiring more maintenance.

- Space requirements: The equipment can be bulky, requiring adequate workspace.

- Compressed air requirement: The pneumatic component needs a reliable compressed air supply.

In summary, pneumatic-hydraulic riveting excels when high strength and consistency are paramount, justifying the higher initial cost and complexity over simpler methods.

Q 9. How do you maintain and lubricate pneumatic-hydraulic riveting equipment?

Maintaining and lubricating pneumatic-hydraulic riveting equipment is critical for ensuring its longevity and safe operation. This involves a multi-step process:

- Regular inspection: Inspect all hoses, fittings, and cylinders for leaks, wear, and damage. Check the air lines for leaks and ensure proper pressure regulation.

- Lubrication: Use the recommended hydraulic fluid, regularly checking and topping up the reservoir as needed. Follow manufacturer’s instructions regarding the type and frequency of lubrication for pneumatic components, typically including air filters and moving parts.

- Cleaning: Keep the equipment clean and free from debris. This prevents contamination of the hydraulic fluid and ensures smooth operation of pneumatic components.

- Air filter maintenance: Regularly change or clean the air filters to prevent contaminants from entering the pneumatic system. Dirty filters can dramatically reduce the life of pneumatic components.

- Hydraulic fluid change: Periodically change the hydraulic fluid following manufacturer recommendations, removing contaminants and ensuring optimal performance.

- Safety checks: Regularly check all safety mechanisms, including pressure relief valves, to ensure they are functioning correctly. Safety is paramount!

Think of it like maintaining a car – regular checks and servicing prevent major issues down the road. Neglecting maintenance can lead to costly repairs and downtime.

Q 10. Explain the importance of proper rivet squeeze and its impact on joint strength.

Proper rivet squeeze is absolutely vital for achieving a strong and reliable joint. It’s the amount of deformation the rivet undergoes during the riveting process.

Importance:

- Full fill: Adequate squeeze ensures the rivet completely fills the rivet hole, creating a solid mechanical lock between the joined parts. Insufficient squeeze results in a loose rivet, compromising joint strength.

- Head formation: Proper squeeze forms the rivet head correctly, distributing the clamping force evenly across the joint. A poorly formed head leads to stress concentration and potential failure.

- Joint strength: The strength of the riveted joint is directly related to the quality of the rivet squeeze. Consistent, proper squeeze translates to consistently strong joints.

Impact on Joint Strength:

Insufficient squeeze leads to weaker joints prone to failure under load. Conversely, excessive squeeze can cause material damage or rivet fracture. Finding the optimal squeeze for the specific rivet, material, and joint design is crucial for ensuring consistent and reliable performance. Imagine it as creating the perfect handshake – too weak, and it’s ineffective. Too strong, and it’s painful.

Q 11. What are the signs of a faulty rivet?

Recognizing a faulty rivet is crucial for ensuring structural integrity. Look for these signs:

- Loose rivet: The rivet head feels loose or can be moved easily.

- Uneven head formation: The rivet head is misshapen or not uniformly formed, indicating improper squeeze.

- Cracks or breaks: Cracks are visible in the rivet head or shank.

- Excessive protrusion: The rivet shank protrudes excessively, suggesting insufficient squeeze.

- Gaps at the joint: There is a visible gap between the joined materials after riveting.

- Rivet shank damage: The rivet shank appears damaged or deformed.

If any of these signs are present, the rivet should be replaced to guarantee the joint’s integrity. Think of it like a loose screw – it may appear minor, but could have major consequences.

Q 12. How do you handle different material thicknesses when riveting?

Handling different material thicknesses requires adjusting the riveting process to ensure proper squeeze and prevent damage. This primarily involves:

- Rivet selection: Choosing the correct rivet diameter and length for the material thickness is essential. Too short, and the rivet won’t properly fill the hole. Too long, and it might damage the material.

- Pressure adjustment: The hydraulic pressure needs to be adjusted to accommodate varying material thicknesses. Thicker materials require higher pressures for adequate squeeze.

- Rivet setting tool selection: Some riveting tools are designed for specific material thickness ranges.

- Trial runs: Perform test rivets on scrap material to determine the optimal settings before riveting on the final product.

Imagine trying to drive a small nail into a thick piece of wood using a light hammer – it won’t work. Adjusting pressure and selecting the correct rivet is analogous to choosing the right tool for the job.

Q 13. Describe the role of the hydraulic intensifier in the system.

The hydraulic intensifier is a crucial component in a pneumatic-hydraulic riveting system. It boosts the relatively low pressure of the pneumatic system to the much higher pressure needed for the hydraulic riveting process.

Function:

The intensifier acts as a pressure multiplier. It receives compressed air from the pneumatic system, which drives a piston to compress hydraulic fluid. This multiplication of force enables the generation of the significantly higher pressure necessary to create the powerful clamping force needed for riveting, especially with thicker materials. Think of it as a hydraulic gearbox, increasing the force but slowing down the speed.

Q 14. What are the different types of pneumatic valves used in the system and their function?

Several types of pneumatic valves play critical roles in controlling the pneumatic-hydraulic riveting process. Here are a few common examples:

- Air control valve: This valve regulates the flow of compressed air to the intensifier, controlling the hydraulic pressure generated. It is often a simple on/off valve or a pressure-regulated valve for more precise control.

- Directional control valve: This valve directs the flow of compressed air and/or hydraulic fluid to specific actuators within the system. This allows for sequential operation of components, like initiating the clamping process and then the riveting process.

- Solenoid valves: These are electrically controlled valves that switch the flow of compressed air on and off, often used for automated systems to initiate the riveting cycle.

- Pressure relief valve: This valve acts as a safety device, automatically relieving pressure if it exceeds a predetermined limit, protecting the system and personnel from damage.

These valves work in coordination to sequence the process precisely, creating a controlled and reliable riveting action.

Q 15. Explain the importance of air pressure regulation in pneumatic-hydraulic riveting.

Air pressure regulation is paramount in pneumatic-hydraulic riveting because it directly controls the force applied to the rivet during the setting process. Too little pressure results in insufficiently formed rivets, leading to potential failure. Too much pressure can cause rivet buckling, material damage to the joined parts, or even tool damage. Think of it like baking a cake – you need the right amount of heat (pressure) to achieve the perfect outcome. The ideal pressure is determined by the rivet material, diameter, and the thickness of the materials being joined. A pressure regulator allows for precise control, ensuring consistent and reliable riveting across all parts.

In a practical setting, imagine a production line riveting thin aluminum sheets. If the pressure isn’t precisely regulated, some rivets may be loose (under-pressure) and others could be damaged (over-pressure), creating inconsistencies and requiring rework. A properly calibrated regulator ensures each rivet is set with the appropriate force, improving efficiency and product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent rivet quality throughout a production run?

Consistent rivet quality across a production run hinges on several factors. First, and most importantly, consistent air pressure is crucial, as previously discussed. Second, using appropriately sized rivets and maintaining a properly calibrated riveting tool is essential. Regular inspection and maintenance of the tool, including checking for wear and tear on the anvils and the ram, helps to maintain consistent force application. Third, proper material selection and preparation are critical. Ensuring that the workpieces are clean, free from defects, and properly aligned minimizes inconsistencies. Finally, operator training is vital. A well-trained operator understands the nuances of the tool and the process, ensuring correct operation and consistent results.

For example, during a large-scale aircraft assembly, consistency in rivet quality is non-negotiable for safety and structural integrity. Regular checks, using sampling techniques, along with meticulous tool maintenance ensure that every rivet meets the high standards required.

Q 17. How do you deal with rivet buckling or deformation during installation?

Rivet buckling or deformation is usually a sign of excessive pressure or improper alignment of the workpieces. To address this, first, reduce the air pressure and check the pressure regulator for proper calibration. Second, ensure the workpieces are correctly positioned and clamped securely to prevent movement during the riveting process. Third, verify that the correct rivet size and material are being used for the specific application. An improperly sized rivet or one not suitable for the material thickness can easily lead to deformation. Using a larger diameter rivet than required can also cause this problem.

For instance, if you are riveting thick steel plates, using too much pressure will certainly cause buckling. In such cases, you might need to reduce the pressure significantly or consider using a different technique such as multiple smaller rivets to distribute the load.

Q 18. What are the common causes of rivet failures?

Rivet failures can stem from several causes. Incorrect rivet size or material is a common culprit, as is insufficient pressure resulting in a poorly formed rivet head. Excessive pressure, as mentioned, can cause buckling or material damage around the rivet. Poor material preparation, such as dirty or oily surfaces, can prevent proper adhesion and lead to failure. Finally, operator error, such as misalignment or incorrect application of the tool, can also result in defective rivets. Also consider the potential for material defects in the workpieces themselves.

Think of it like building a house – if the foundation (material preparation) or the nails (rivets) aren’t right, the whole structure (assembly) could fail. Regular quality checks and well-maintained tools are essential to prevent such occurrences.

Q 19. How do you interpret riveting machine gauges and indicators?

Riveting machine gauges and indicators typically display air pressure, sometimes in PSI (pounds per square inch), and may include indicators showing the power stroke or the setting force. Understanding these gauges is crucial for proper operation. The pressure gauge tells you if the air pressure is within the acceptable range for the specific job. Deviation from this range should prompt investigation and adjustment of the pressure regulator. Other indicators might show the tool’s operational status, such as whether it’s ready for operation or requires maintenance.

For example, a gauge reading consistently below the specified pressure might indicate a leak in the pneumatic system requiring immediate attention. On the other hand, if it consistently reads high, one should lower the air pressure or review the rivet sizing parameters.

Q 20. Describe the process of calibrating and maintaining riveting tools.

Calibration and maintenance of riveting tools are essential to ensure consistent and reliable results. Regularly inspect the riveting tool for wear and tear, paying particular attention to the anvils and the ram. These parts are subject to significant wear and can lead to inconsistent force application if damaged. Calibration involves checking and adjusting the tool’s mechanisms to ensure they deliver the correct force at the specified air pressure. This may involve adjusting internal components, or it might be as simple as replacing worn-out parts.

A frequent mistake is neglecting regular lubrication. Proper lubrication of the moving parts is essential to reduce friction and ensure smooth operation. The calibration process is usually detailed in the tool’s instruction manual and should be performed according to the manufacturer’s specifications.

Q 21. What are the different types of rivet guns used in the industry?

The industry uses various rivet guns, categorized primarily by their power source and operation. Pneumatic rivet guns, the most common type, use compressed air to power the riveting process. Hydraulic rivet guns utilize hydraulic pressure for more powerful applications. Some specialized rivet guns are designed for specific rivet types or materials, such as blind rivets or those requiring high-strength settings. There are also manual rivet guns, although these are less common in high-volume production settings. Each type offers different capabilities and advantages. Selection depends on factors such as the material being riveted, the size and type of rivet, and the production volume.

For instance, in aerospace manufacturing, where high precision and strength are paramount, hydraulic rivet guns are preferred for their consistent force application. In contrast, in less demanding applications, such as assembling sheet metal enclosures, a pneumatic rivet gun would suffice.

Q 22. Explain the impact of rivet material on joint strength and durability.

The rivet material significantly impacts the strength and durability of the joint. Think of it like choosing the right glue for a project – the wrong one will fail. The material’s tensile strength (how much pulling force it can withstand before breaking), shear strength (resistance to sideways force), and fatigue resistance (ability to withstand repeated stress) are crucial.

- Steel rivets offer high strength and durability, ideal for applications demanding high load-bearing capacity, like structural components in aircraft or heavy machinery. However, they can be prone to corrosion in certain environments.

- Aluminum rivets are lighter and offer good corrosion resistance, making them suitable for aerospace and automotive applications where weight is a concern. They possess lower shear strength compared to steel.

- Stainless steel rivets combine high strength with excellent corrosion resistance, making them suitable for outdoor or marine applications. They’re a premium option, often used where longevity is paramount.

Choosing the wrong rivet material can lead to premature joint failure, compromising safety and requiring costly repairs. For instance, using aluminum rivets in a high-stress structural application would be a design flaw.

Q 23. How do you identify and address potential hazards associated with pneumatic-hydraulic riveting?

Pneumatic-hydraulic riveting involves significant hazards if safety isn’t prioritized. The high-pressure system poses risks of:

- High-velocity rivet ejection: A malfunctioning rivet gun can eject the rivet at dangerous speeds, potentially causing eye injury or penetrating skin. Safety glasses and face shields are mandatory.

- Hydraulic fluid leaks: Leaks can lead to skin irritation or fire hazards if the fluid is flammable. Regular inspection of hoses and connections is crucial.

- Malfunctioning equipment: Damaged or poorly maintained equipment can malfunction, leading to unexpected movements or energy release. Regular maintenance and operator training are essential.

- Noise exposure: Riveting operations are often noisy. Hearing protection is a must to prevent hearing damage.

Addressing these hazards requires a multi-pronged approach: regular equipment inspection, comprehensive operator training focusing on safe operating procedures, the use of appropriate personal protective equipment (PPE), and implementing robust safety protocols within the workplace. Think of it like a safety net – multiple layers of protection to mitigate any potential risk.

Q 24. What is the significance of proper tooling selection in riveting?

Proper tooling selection is paramount in achieving a strong, reliable rivet joint. The rivet gun must be compatible with the rivet size and material. Using the wrong tool can result in improperly set rivets, leading to joint failure. Consider these factors:

- Rivet size and material: The gun’s capacity needs to match the rivet’s diameter and material. Using a gun too small will damage the rivet or gun. A gun too large will cause inconsistent setting.

- Nose piece/mandrel selection: The nose piece must fit the rivet shank correctly to ensure proper head formation and complete expulsion of the mandrel. Using an incorrect nose piece will result in damaged rivets or an incomplete join.

- Gun’s power and pressure: The gun needs sufficient power to set the rivet properly without damaging the material. Too little pressure results in loose rivets. Excessive pressure can damage the material.

Imagine trying to hammer a nail with a toothpick – it simply won’t work. Similarly, selecting inappropriate tooling compromises the integrity of the joint.

Q 25. Explain the importance of following manufacturer’s specifications and safety guidelines.

Following manufacturer’s specifications and safety guidelines is non-negotiable for several reasons:

- Safety: These guidelines are designed to minimize risks to the operator and others nearby. Neglecting them can lead to serious injury or even death.

- Performance: Specifications ensure the equipment is used correctly to achieve optimal performance. This translates to strong, reliable joints and avoids wasted materials and time.

- Warranty: Failure to follow instructions usually voids the warranty, leaving the user responsible for any equipment failures.

- Legal Compliance: Many jurisdictions have workplace safety regulations that necessitate adherence to manufacturer’s instructions.

Think of it like a recipe: deviating from the instructions can result in a failed dish. Similarly, ignoring specifications in riveting compromises the final result and potential safety.

Q 26. How would you handle a situation where a rivet fails during installation?

If a rivet fails during installation, it’s critical to understand why and take corrective action. The process involves:

- Immediate Stoppage: Immediately cease operation to prevent further damage or injury.

- Investigation: Determine the root cause. This might involve inspecting the rivet, the material being riveted, the rivet gun’s settings, or even the condition of the nose piece.

- Corrective Action: Address the issue. This could involve replacing a damaged rivet gun component, adjusting the pressure settings, or switching to a different rivet material better suited for the application.

- Re-evaluation: Before resuming, double-check that the problem is solved. Ensure that the rivet gun is functioning properly and the chosen rivet material is adequate.

- Documentation: Record the incident, including the cause, corrective actions, and any lessons learned.

Addressing the root cause is crucial to prevent recurrence, making the process efficient and safe. Ignoring a failed rivet can create cascading failures later on.

Q 27. Describe your experience with different types of rivet materials (e.g., aluminum, steel).

My experience spans a wide range of rivet materials. I’ve worked extensively with:

- Aluminum rivets: Primarily in aerospace and automotive applications. Their lightweight nature and corrosion resistance are key advantages. However, their lower shear strength compared to steel needs careful consideration in high-stress applications.

- Steel rivets: Used in heavy-duty applications demanding high strength and durability. I’ve used these in construction, heavy machinery, and bridge construction. Corrosion prevention is vital in certain environments.

- Stainless steel rivets: My experience with stainless steel rivets includes marine and outdoor applications where corrosion resistance is critical. Their strength-to-weight ratio is superior to standard steel.

- Other materials (Monel, Titanium): While less frequent, I’ve had experience with specialty rivet materials like Monel (for corrosion resistance in harsh environments) and titanium (for aerospace applications needing high strength and low weight). The selection heavily depends on the operational context and the material’s characteristics.

Understanding material properties and limitations is essential for successful riveting. The material choice influences design parameters like rivet size and spacing.

Q 28. What are your experiences working with different types of rivet guns?

My experience encompasses several types of rivet guns, each with its own characteristics:

- Hydraulic rivet guns: I have extensive experience operating hydraulic rivet guns. Their controlled power and precision make them suitable for a wide range of applications. I’ve worked with both manual and pneumatic-hydraulic types.

- Pneumatic rivet guns: While less precise than hydraulic models, pneumatic rivet guns are often favored for ease of use and portability. They are a good option when power requirements are less demanding.

- Pull-type rivet guns: These are used for blind rivets – rivets that can be installed from one side only. I’ve found them very useful in situations where access to the opposite side of the material is limited.

Understanding the strengths and limitations of each type is key to selecting the most appropriate tool for a particular job. Factors like rivet size, material type, and accessibility influence the choice.

Key Topics to Learn for Your Pneumatic Hydraulic Riveting Interview

- Pneumatic System Fundamentals: Understanding air compressors, pressure regulators, air cylinders, and pneumatic valves; their roles in the riveting process and troubleshooting common issues.

- Hydraulic System Fundamentals: Knowledge of hydraulic pumps, hydraulic cylinders, hydraulic valves, and pressure control; their interaction with the pneumatic components in a riveting system.

- Riveting Process & Techniques: Mastering the complete riveting cycle, including material preparation, rivet selection, setting parameters (pressure, speed), and quality control checks.

- Safety Procedures and Regulations: Familiarity with relevant safety protocols, lockout/tagout procedures, and personal protective equipment (PPE) required for operating pneumatic hydraulic riveting equipment.

- Troubleshooting and Maintenance: Developing skills in identifying and resolving common malfunctions, performing preventative maintenance, and understanding the importance of regular inspections.

- Different Types of Rivets & Applications: Understanding the various types of rivets (solid, blind, etc.) and their suitability for different materials and applications. Knowing the strengths and weaknesses of each rivet type.

- Material Science Basics: A foundational understanding of the materials typically riveted (metals, composites) and how their properties affect the riveting process.

- Automation and Control Systems: Familiarity with programmable logic controllers (PLCs) or other automated control systems used in industrial riveting applications.

Next Steps: Elevate Your Career with Pneumatic Hydraulic Riveting Expertise

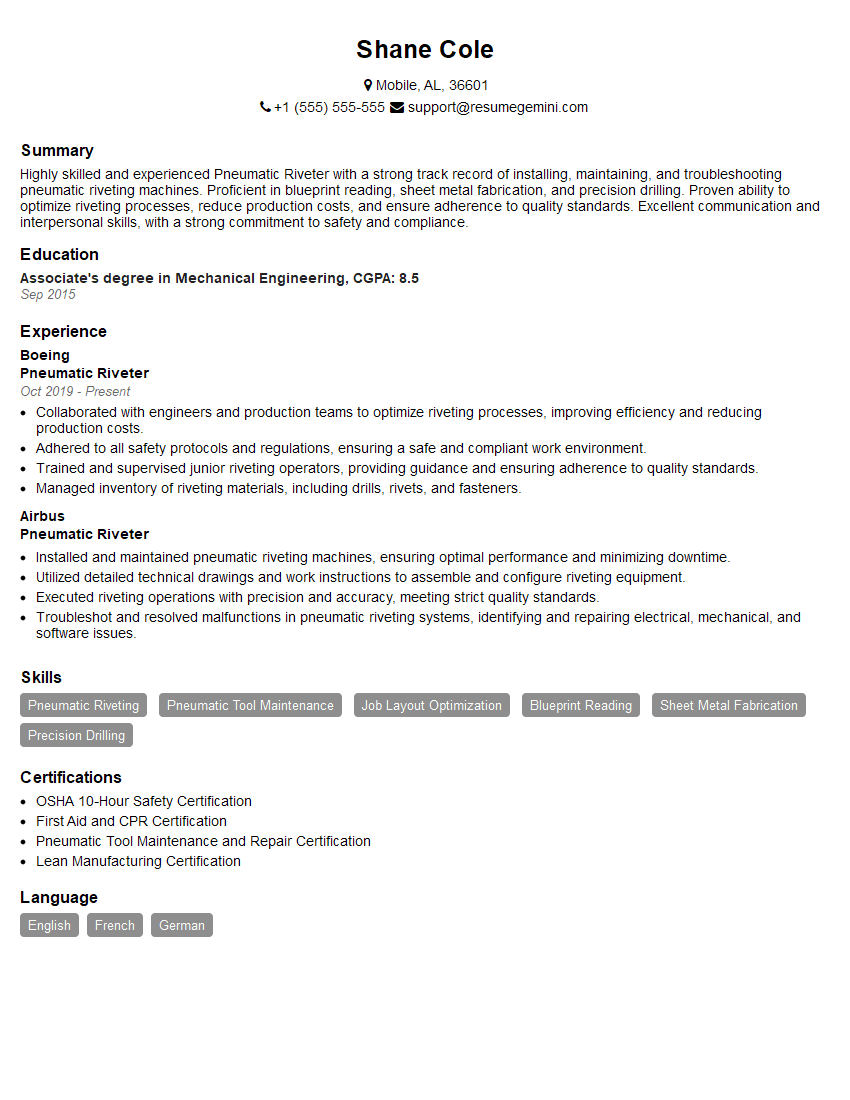

Mastering pneumatic hydraulic riveting opens doors to exciting career opportunities in manufacturing, aerospace, and automotive industries. To maximize your job prospects, a strong, ATS-friendly resume is crucial. This is where ResumeGemini can help. ResumeGemini provides a powerful platform for creating professional, impactful resumes that get noticed by recruiters. We offer examples of resumes specifically tailored to the Pneumatic Hydraulic Riveting field to guide you in showcasing your skills and experience effectively. Take the next step toward your dream career – build a winning resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good